Abstract

Clay materials were prepared with clay and sapropel (SP) or clay and modified (frozen) sapropel (FSP) as the main raw materials. Clay-based materials were formed by mixing clay with a different dosage of SP or FSP (5–30 wt.%). The effect of SP or FSP on the properties and biological resistance of clay-based materials was studied. The results show that the bulk density of clay-based materials decreased, and the compressive strength and initial rate of water absorption increased with the increase in the SP or FSP amount in the clay mixture. Research has shown that SP or FSP can be added as a natural additive containing microfibers to improve the mechanical properties of clay materials. When clay bricks had less than 15% sapropel, dry or frozen, we tested the resistance impact of the fungi Rhodotorula mucilaginosa, Stachybotrys chartarum, Cladosporium cladosporioides, and Aureobasidium pullulans under normal conditions.

1. Introduction

Due to current global concerns about sustainable development, interest in natural building materials such as unfired clay materials has developed. Unfired clay materials have a record of accomplishment as being sustainable as they are a natural material with less embodied energy with minimal emission of CO2 [1,2,3,4,5,6,7]. Using unfired clay materials has several sustainability advantages: (1) unfired clay materials are made from abundant and locally available raw materials, reducing the need for transportation and minimizing the environmental impact associated with extracting and transporting building materials; (2) the production of unfired clay materials generally requires less energy compared to other building materials [1,8]; (3) such materials have good thermal/hygroscopic properties, helping to regulate indoor humidity and temperatures, and this can contribute to energy efficiency [9,10,11,12,13]; and (4) unfired clay materials are biodegradable, meaning that at the end of their life cycle, they can return to the environment without causing long-term harm [14,15,16]. To meet increasingly rigorous requirements, the demand for natural building materials is growing rapidly, and the building materials industry must adapt to the use of materials of lower environmental impact.

Clay raw materials play an important role in the development of environmentally/eco-friendly building materials. In many regions of Europe, there are significant reserves of clay and sapropel (SP). SP is an organic material with a colloidal structure formed over thousands of years at the bottom of lakes from the remains of aquatic animals and plants. There are about 10 billion m3 of sapropel in the lakes and swamps of Lithuania. According to data from the Lithuanian Geological Service, the forecasted resources of sapropel amount to 152,886 thousand m3. New technologies allow for the acquisition of SP in various forms: dry, frozen, or granulated. From this point of view, SP is a promising material for use in the building and construction industries.

Latvian researchers investigated the properties and sound absorption characteristics of composite materials made from sphagnum moss, flax fiber, vermiculite, and SP as a binder [17]. They demonstrated that the compressive strength of such composite materials was 0.1–0.29 MPa, whereas their bending resistance ranged between 0.2 and 0.42 MPa. According to their data, composite materials created with an SP binder had good sound absorption results.

Also, it was demonstrated that composite materials that were made using hemp shives and SP had exceptional thermal and acoustic properties [18,19,20]. The compressive strength of such composites was 0.61–0.28 MPa, whereas their density was 210–410 kg/m3. The lower-density composites best absorb the waves of 300–600 Hz frequency because sound absorption exceeds 0.5 for this frequency range [18]. Vėjelis et al. [21] developed a thermal insulation biocomposite from sapropel and wood processing waste with lower thermal conductivity (0.0612 to 0.0659 W/(mK), and its compressive stress values varied from 0.414 to 1.051 MPa. The bulk density of such a biocomposite was 300 kg/m3.

SP can be used in the production of cement–concrete mixtures for road construction. The results showed that the compressive strength of mixtures containing 5% SP was 28% higher. The increased compressive strength can be explained by the accelerated hydration of the three-calcium silicate of the cement when SP is added [22]. Also, modified SP (SP + zeolite) accelerates the hydration of Portland cement [23]. The effect of SP on the thermal properties of clay soil was examined by Navickas et al. [24]. The authors found that adding about 1–2% (w/w) SP decreases the thermal conductivity of clay soil samples by 18–30%. The effect of SP on expanded clay properties was examined by Vaickelionis et al. [25]. The bloating coefficient of expanded clay was improved when the SP proportions were limited (not more than 5%). Expanded clay samples with 5% (w/w) SP had water absorption of no more than 20%.

Sapropels are rich multicomponent biogenic systems of organic elements that are made by microorganisms during the eutrophication process in lakes. Such processes play an important role in organic decomposition, the nutrient cycle, and intestinal food networks and generally affect several processes of the overall water system [26,27]. Therefore, it can be expected that the wet sapropel, which may contain living microorganisms, could influence the tested materials. Because the samples were made of two components—sapropel and clay—it is important to emphasize that the pH of clay is usually between 8 and 10 [28]. This pH range does not support microorganism growth [29,30]. Therefore, in this work, we produced clay bricks with two types of sapropels, wet and frozen ones.

There are few studies that use SP in the production of building materials. We believe that it is worth paying attention to this natural material and its use in industry. Therefore, this study assesses the potential of sapropel (SP) and its modified form—frozen sapropel (FSP)—as a clay material component. We also tested the structure, physical properties, and biological resistance of such materials. SP and FSP are easy to incorporate into mixtures to achieve the desired properties. The incorporation of a higher amount of SP or FSP in manufacturing lightweight clay bricks yielded higher compressive strength compared with clay samples without the addition of SP and FSP.

2. Materials and Methods

2.1. Materials

Clay was collected from a brick manufacturer located in Lithuania (Figure 1). The clay was dried at 65 °C and 105 °C for 12 h and passed through a 1.25 mm sieve. The chemical and granulometric compositions and Atterberg limits of the clay are shown in Table 1. The bulk density of the clay is 1.14 g/cm3.

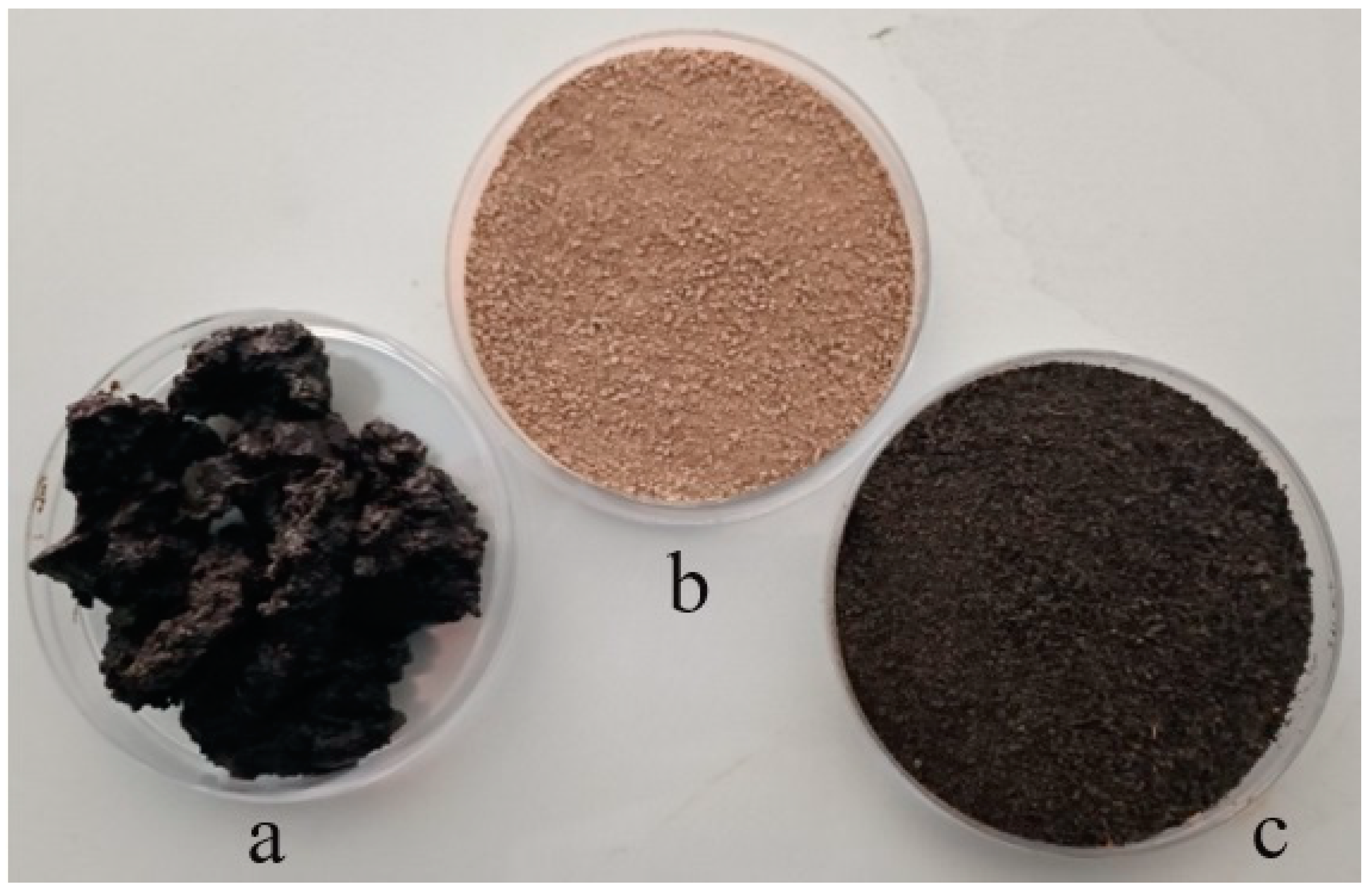

Figure 1.

Images of the materials: (a) SP, (b) clay, and (c) FSP.

Table 1.

Chemical and granulometric compositions and Atterberg limits of the clay.

The organic lake sediment used, sapropel (SP), was obtained from Gervinio Lake in the Druskininkai region, Lithuania (Figure 1). The color of SP is black–brown, and it has a very weak odor (of wet soil). The characteristics of SP are presented in Table 2. SP contains more than 80% organic matter and less than 20% ash [31,32]. The bulk density of SP is 0.68 g/cm3, whereas that of the skeleton is 0.47 g/cm3. The electrical conductivity of SP is estimated to be 6.18 mS/m.

Table 2.

Characteristics of SP.

Modified (frozen) sapropel (FSP) was also used in this study. The method used comprises the filtering of SP, freezing the filtered SP droplets, assembling the frozen SP droplet mass, defrosting them, removing the formed water, and drying the SP. The biocolloidal internal links of water and other material complexes are destroyed via the formation of sapropel droplets into snowflake crystals. After melting said crystals, the biocolloidal links do not recover [33]. The dynamics of the freezing of SP allows one to recognize the following stages of physicochemical and texture-forming processes: free water crystallization laws govern texture formation; the forming of an ice skeleton causes the directed growth of ice crystals; thicker ice crystals force units of the organo-mineral skeleton apart, thus deforming and compressing it; the compression of the SP skeleton is accompanied by dehydration; the desiccation of the SP skeleton activates the aggregation and coagulation of the organo-mineral component; and the high content of the organic component showing high adhesive characteristics in SP causes mineral particle binding in organo-mineral aggregates [34].

The dry matter content in the FSP is 22.27%, and the pH is 8.8. The FSP was passed through a 1.25 mm sieve. The bulk density of the FSP obtained was 0.25 g/cm3, whereas the skeleton density of the FSP was 0.42 g/cm3.

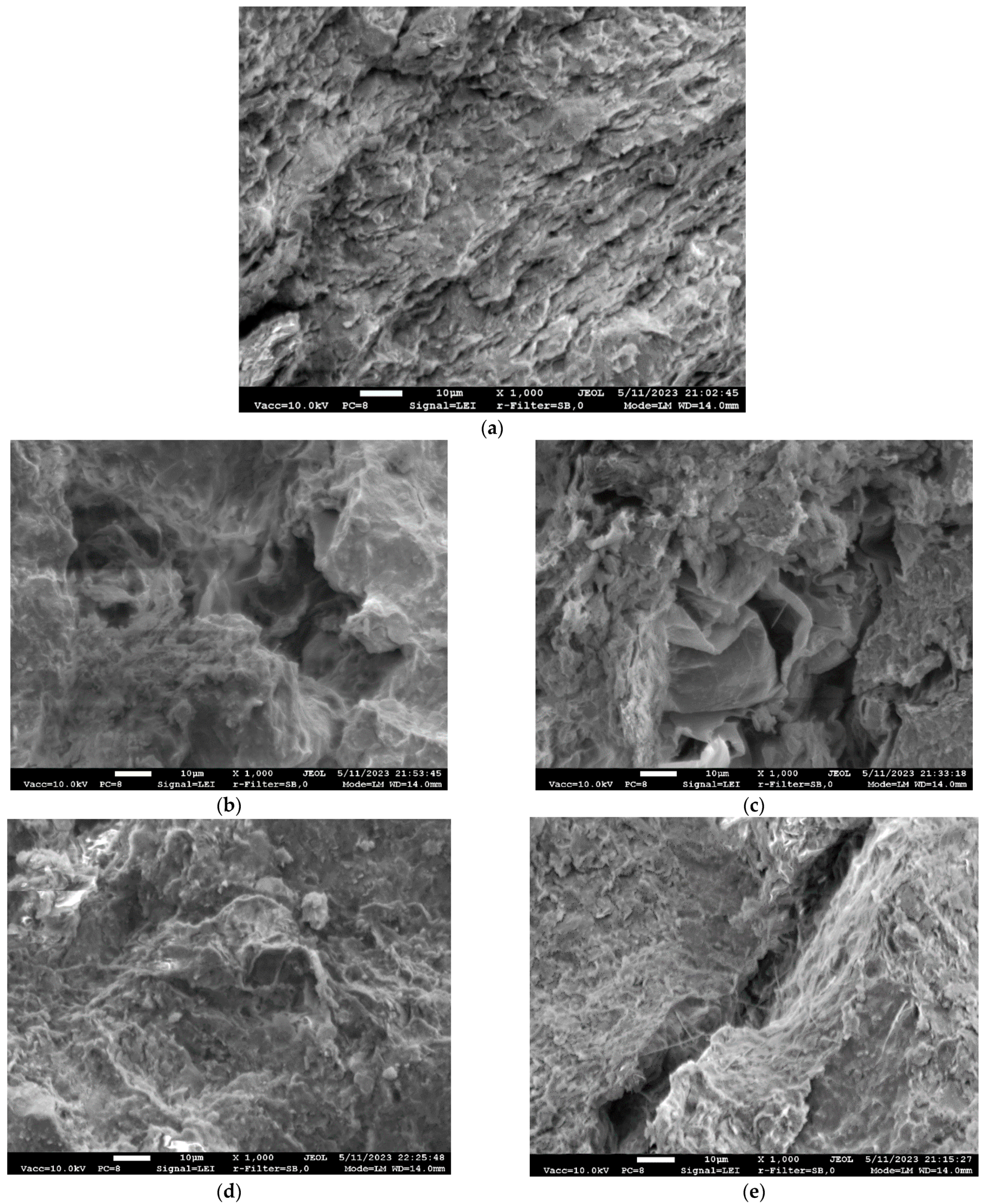

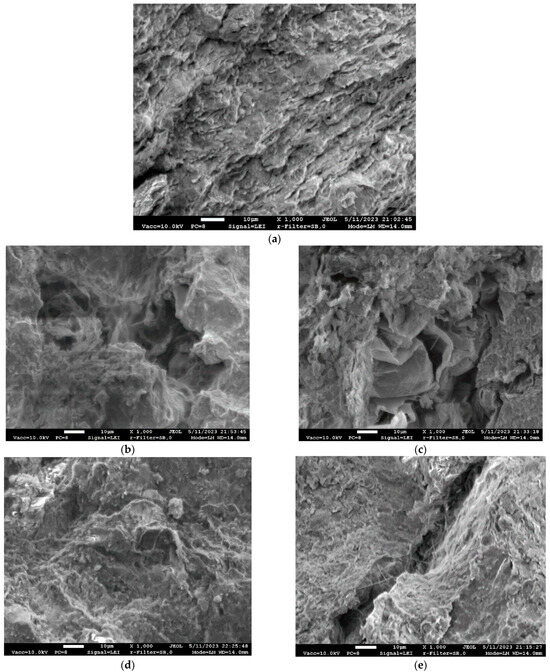

The clay, SP, and FSP surface morphology are shown in Figure 1. Clay has been found to have a diverse composition of particle sizes. The mica grains flanked particles of the fine clay fraction. The 0.5–1.5 μm mica particles exhibit irregular edges and pointed extremities. The shape of the other particles is round or elongated. The size of the particles is from 1 μm to 5 μm. Also, the SEM picture (Figure 2a) reveals voids with a width down to about 3 μm.

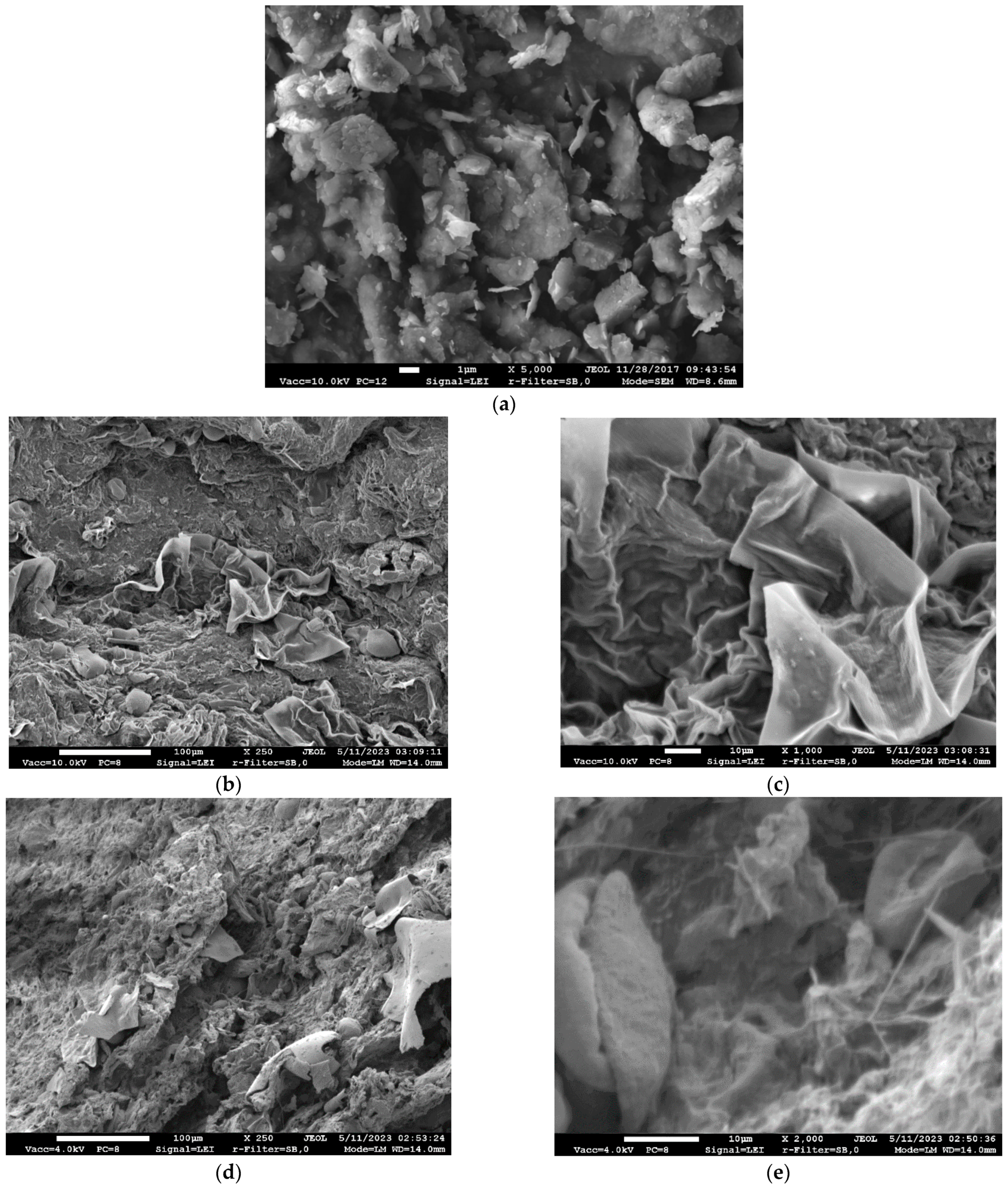

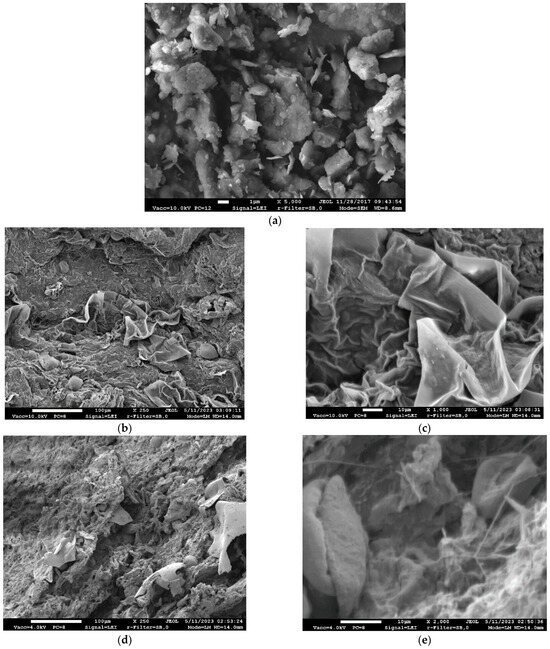

Figure 2.

The structure of clay (a), SP (b) and (c), and FSP (d) and (e).

SP consists of different particles; the structure is heterogeneous. Some SP particles are discrete, about 20 µm round, dense particles. There are also some in the form of 2–5 µm thick strips and 100–150 µm in length (Figure 2b,c). The FSP particles are discrete, about 20–30 µm round, with some being dense and some being rough. Also, some are in the form of stringy, filamentous particles, with them being 0.3–0.5 µm thick and about 10–20 µm long. Such a stringy feature is observed between coarse particles (Figure 2e). Also, there are 20–100 µm long strips (Figure 2d).

2.2. Methods

Firstly, a dry mixture was prepared after mixing clay and sapropel (clay and SP) and clay and frozen-thawed sapropel (clay and FSP) in different dosages. Five different mixtures (clay + SP and clay + FSP) were generated by adding increasing dosages of SP or FSP (0%, 5%, 10%, 15%, 20%, and 30% of SP or FSP by weight) (Table 3). Later, water (22.0–6.0%) was added, and the mixture was left for 12 h. Additional water was not added to the clay mixtures with 20% SP (mixture code SP20) and 30% SP (mixture code SP30) because the moisture content of the SP was 95% (please see Table 2). Afterward, 60 × 30 × 18 mm clay samples were prepared. The samples were formed under a pressure of 5 MPa. The clay samples were dried in the laboratory (20–22 °C; humidity 50–65%) for 14 days.

Table 3.

The mixtures and plasticity of the clay samples.

Plasticity is a fundamental property in the processing of clay-based materials since it defines the technical parameters to convert a clay mixture into a given shape by the application of different pressures. A plasticity of 16–18 is desirable for the production of clay products [35,36,37].

The evaluation phase of the clay samples entailed the testing of physical–mechanical properties including shrinkage, bulk density, compressive strength, and the initial rate of water absorption. Also, the evaluation phase entailed testing of the structure and biological resistance.

The raw materials and specimens that were used were analyzed by means of scanning electron microscopy (SEM). We used a JSM-7600F device (JEOL, Tokyo, Japan), with 10 kV and 20 kV voltage; at a 7–10 mm distance from the sample surface, the surface of the specimens under testing was covered with gold. The chemical compositions of the materials were determined using X-ray fluorescence (XRF-WD). A ZSX Primus IV spectrometer (Rigaku Corp., Tokyo, Japan) equipped with an Rh tube with an anode voltage of 4 kV was employed. Tablet-shaped samples with a diameter of 37 mm were prepared and compressed at 200 kN for analysis. The water content and organic matter of the SP and FSP were determined according to EN 12570 [38] and EN 13820 [39], respectively. The shrinkage, bulk density, and compressive strength of the specimens were determined according to the ASTM C326-09 (2014) [40], LST EN 772-13:2000 [41], and LST EN 826:2013 [42] standards, respectively. The Atterberg limits of the mixtures were determined according to the ASTM D4318 standard [43]. The initial rate of water absorption was determined according to EN 772-11:2011 (E) [44].

Biological resistance was determined according to LST EN 15457:2022 [45]. The fungi Rhodotorula mucilaginosa DSM 70825, Stachybotrys chartarum DSM 2144, Cladosporium cladosporioides DSM 19653, and Aureobasidium pullulans DSM 3042 were incubated on the PDA (VWR BDH Chemicals, Darmstadt, Germany) media for 10–21 days for sporulation; then, these spores were collected in 20 mL of 0.9% NaCl and diluted to 106 units/mL. The suspensions of microorganisms were mixed in equal parts, and then, 1 mL of this mix was poured onto two of the samples: SP0–SP30, and FSP5–FSP30. These samples with the microorganisms were incubated for 3 weeks in a Memmert thermostat at 22 °C and 65% humidity. Images were taken every week.

3. Results and Discussion

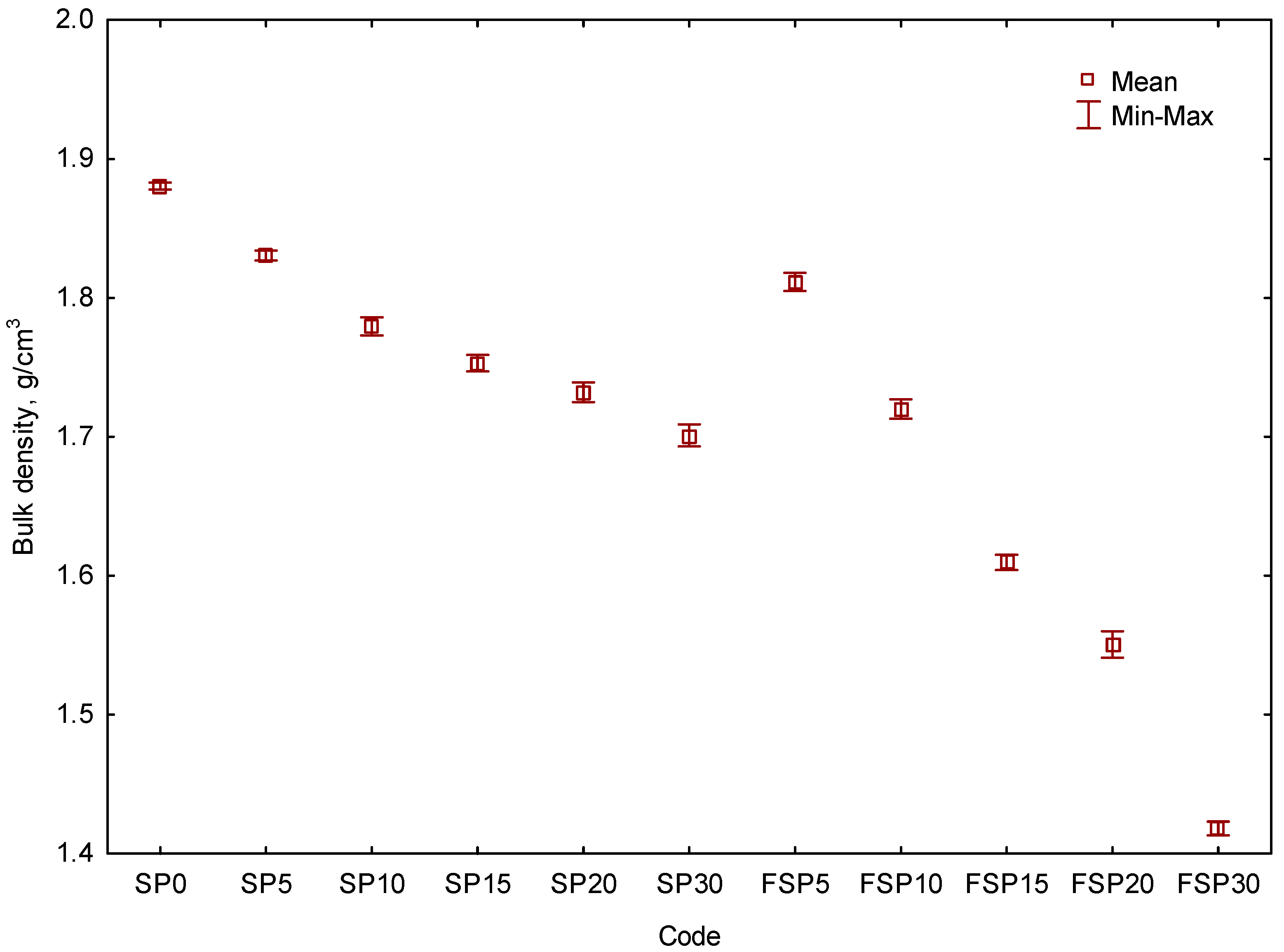

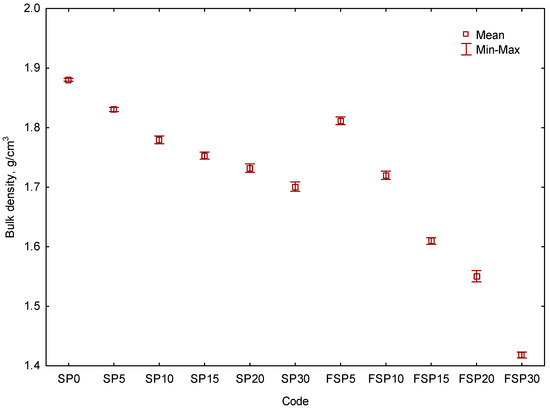

A clear decrease in bulk density was observed with increasing SP or FSP content (Figure 3). The decrease in bulk density with increasing SP or FSP content is a result of the lower density of the SP or FSP compared to the clay density. The additives of organic matter make it possible to obtain clay samples with a lighter, more porous structure [3,46,47,48,49,50,51,52,53]. It should be mentioned that the modification of bulk density during stabilization with natural additives can have a high impact on the material’s mechanical and thermal properties [48,49,53,54,55,56]. Authors [53] reported that corn plant and fescue additives can improve the flexural strength of adobe bricks by 89% and 26%, respectively. Ghavami et al. [57] studied the effect of sisal and coconut fibers on the behavior of soil. The inclusion of 4% sisal or coconut fibers increased the compressive strength from 1.5 MPa to 2.0 MPa. Yetgin et al. [58] addressed the incorporation of straw fibers into adobe bricks. The results showed that as the fiber content increased from 18.8% to 51.5%, the bulk density decreased from 1.83 to 1.43 g/cm3, and the compressive strength decreased in some cases from 3.5 MPa to 1.0 MPa. Millogo et al. [46] investigated the effect of vegetable fiber—Hibiscus cannabinus—on adobe bricks. The results showed that the incorporation of 0.2–0.6 wt.% of 30 mm long Hibiscus cannabinus fibers reduced the thermal conductivity from 1.67 W/(m·K) to 1.30 W/(m·K) of adobe bricks and increased the flexural strength from 0.5 MPa to 1.1 MPa.

Figure 3.

Bulk density of the clay samples.

The bulk density value of the SP5–SP30 samples varied from 1.7 g/cm3 to 1.83 g/cm3 and that of the FSP5–FSP15 samples varied from 1.42 g/cm3 to 1.81 g/cm3. The results showed that adding 5–30% SP (SP5–SP30 samples) decreased the density by 2.7–9.5% compared to the control sample (SP0 sample); also, adding 5–30% FSP (FSP5 and FSP15 samples) decreased the density by 3.7–24.5% compared to the control sample (SP0 sample).

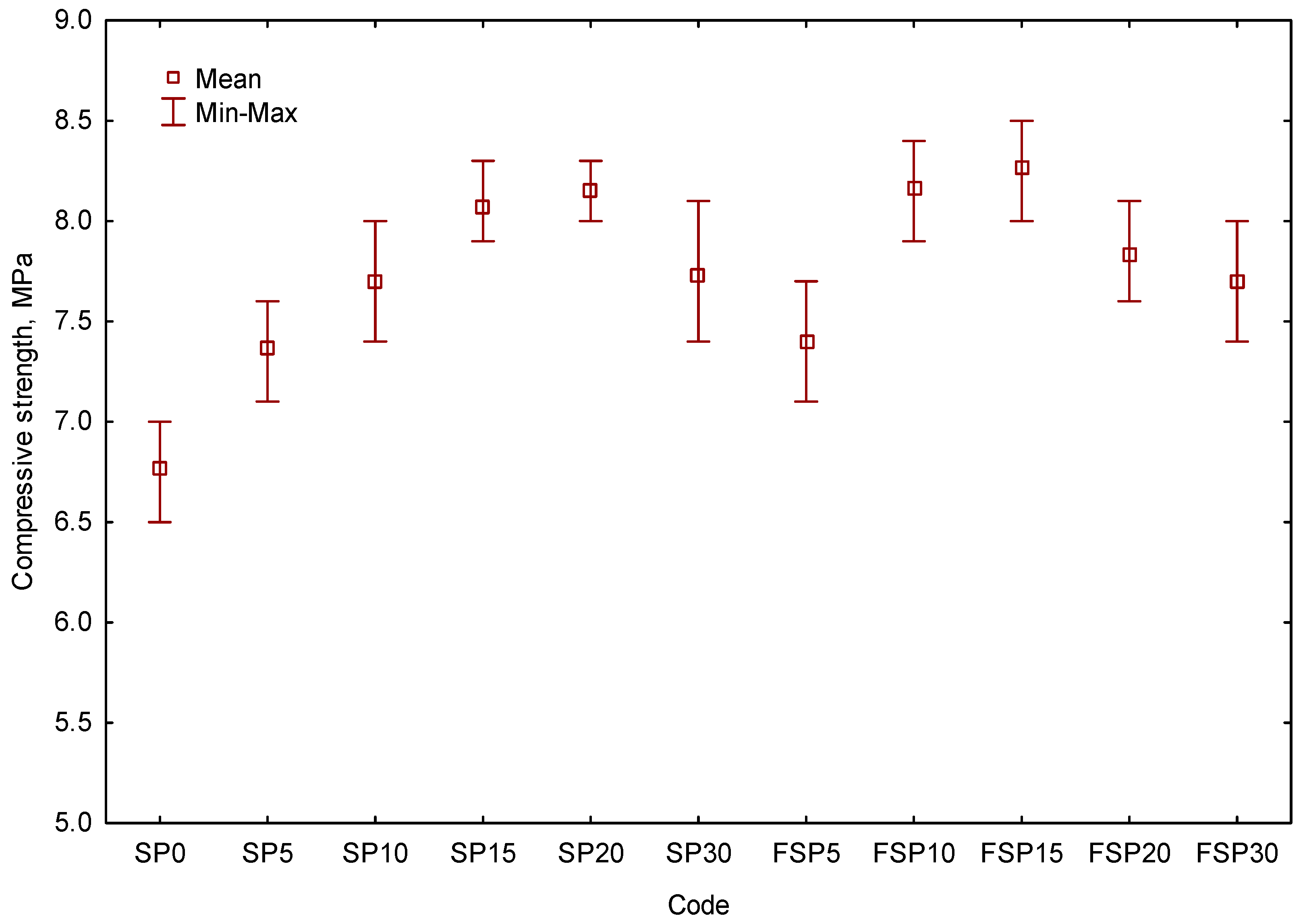

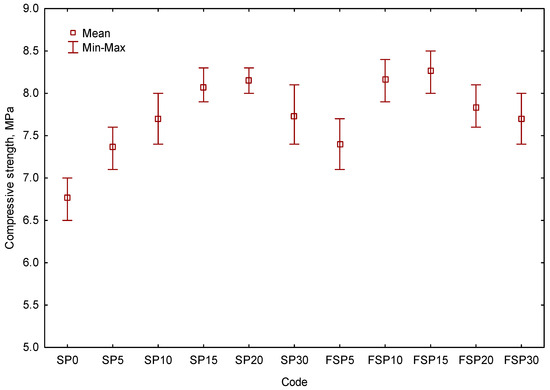

The compressive strength increased when the 5–30% SP or 5–30% FSP content increased (Figure 4). The results showed that adding 5–20% SP (SP5–SP30 samples) increased the compressive strength by 8.8–19.9% compared to the control sample (SP0 sample); also, adding 5–15% FSP (FSP5 and FSP15 samples) increased the compressive strength by 8.7–22.1%. As the SP or FSP content is further increased, the compressive strength decreases somewhat.

Figure 4.

Compressive strength of the clay samples.

Different research studies have shown that the compressive strength of Earth materials can be improved by using natural additives [59,60,61]. Natural additives generally include hemp, sugarcane bagasse, rice husk, straw, wool, coconut fibers, etc. [2,62,63,64,65,66,67,68,69,70,71]. The authors attributed the reason for the increase/decrease in the compressive strength of the clay materials modified with different proportions of natural additives to the better/worse adhesion of the soil matrix with natural additives [55,65].

Our research shows that SP or FSP can also be added as a natural additive containing microfibers (long strips with filamentous particles of SP, Figure 2b,c, and long stringy, filamentous particles of FSP) to improve the mechanical properties of clay materials. The reason may be the redistribution of internal forces from the clay matrix to the “reinforcing natural microfibers”. It should be mentioned that according to the DIN 18945 (2013–08) standard [66], all clay samples with SP and FSP additives belong to the highest Earth bricks class 5 (EB5) because their compressive strength is more than 6.3 MPa.

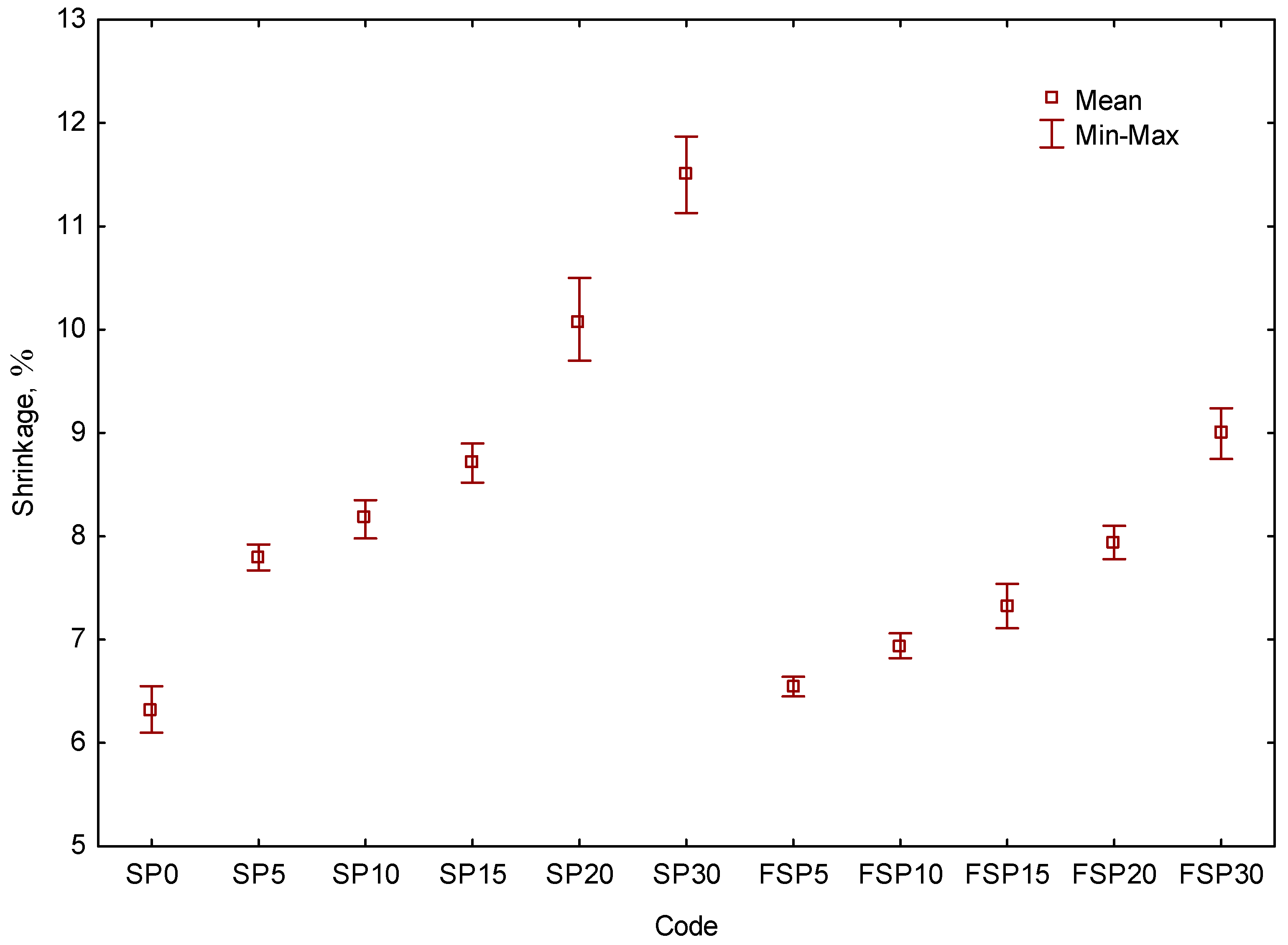

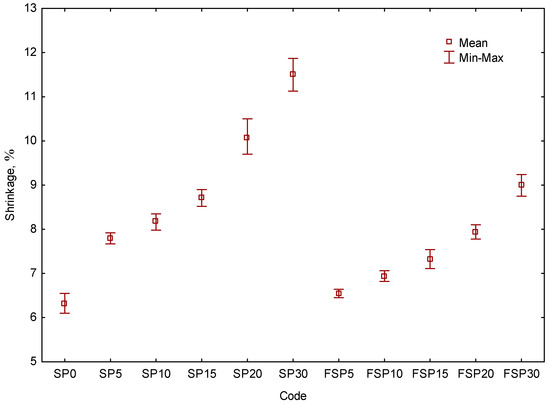

Figure 5 shows the shrinkage for different samples. The shrinkage value varies from 7.8% to 11.5% for the SP5–SP30 samples and from 6.8% to 9.0% for the FSP5–FSP30 samples. The shrinkage of the control sample is 6.3%. The shrinkage increases with the increase in SP or FSP content in clay mixtures, and it is at its maximum at 30% SP (the shrinkage of the SP30 sample is 11.5%) and its minimum at 5% FSP (shrinkage of the FSP5 sample is 6.8%). Samples FSP5–FSP10 (90–95% clay + 5–10% FSP) and the control sample had no significant difference in their shrinkage results. However, samples SP5–SP30 and FSP20–FSP30 had significant differences because the shrinkage of the SP5 and FSP samples was about 6.5% and the shrinkage of the SP30 and FSP samples was 11.5% and 9.0%, respectively. However, sufficiently high shrinkage did not cause the specimens to crack. The authors [67] reported that the shrinkage should not be above 12% for samples in order to obtain dried bricks without cracking.

Figure 5.

Shrinkage of the clay samples.

The highest water content in the SP20 and FSP30 mixtures (Table 3) causes the highest shrinkage. Organic, porous materials absorb water quickly and release water more easily during the drying process [68,69]. Thus, samples with SP or FSP show higher shrinkage than control clay samples after drying.

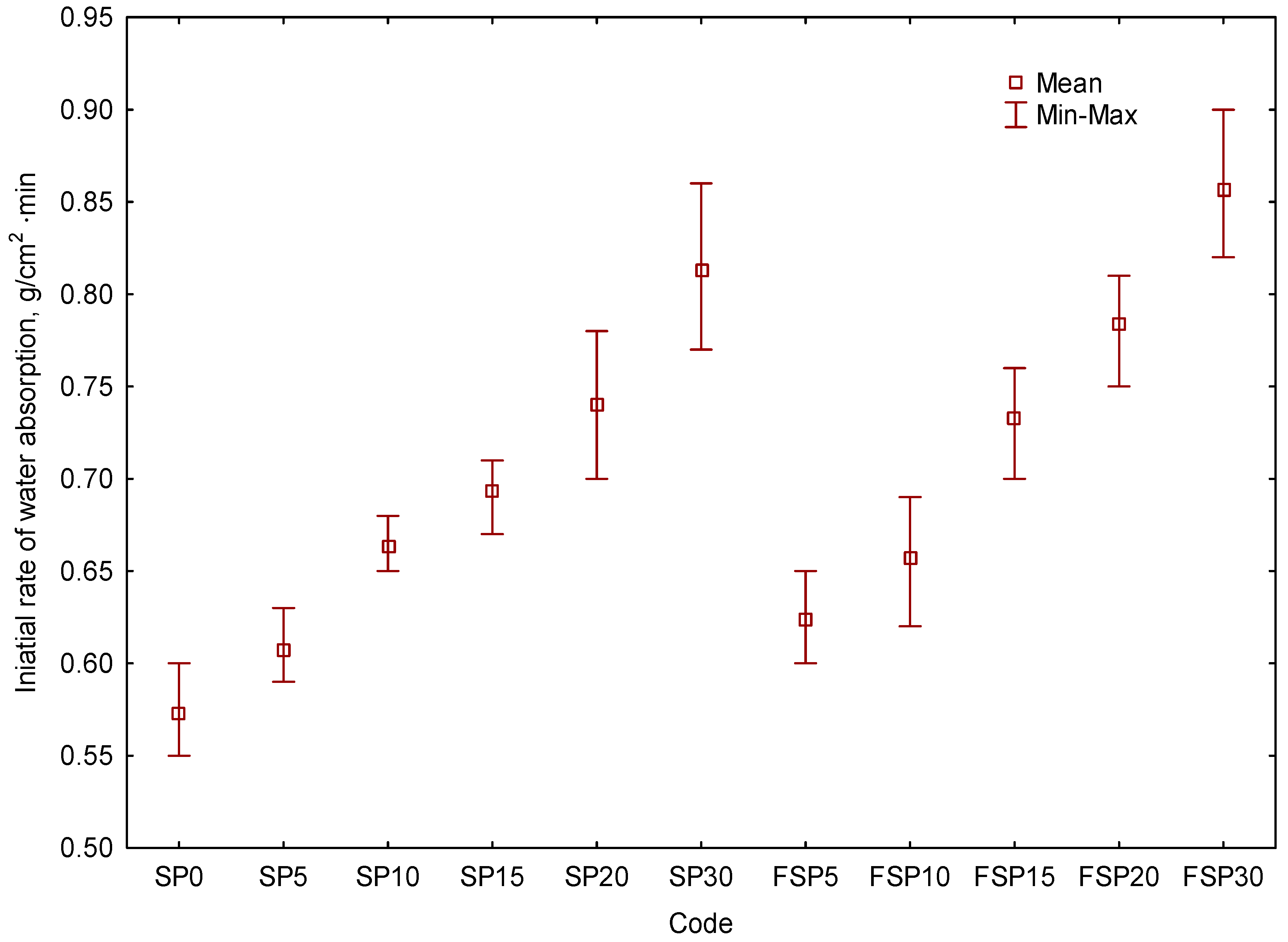

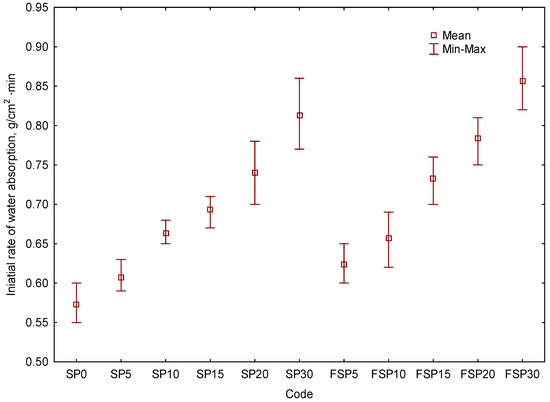

The initial rate of water absorption tests demonstrated that as the SP or FSP percentage in the samples increased, the capillary water absorption was higher compared to the control clay sample (Figure 6). This is because the SP and FSP are organic porous matter and have higher absorption of water than clay. The results showed that adding 5–30% SP increases the initial rate of water absorption by 5.3–40.4% compared to the control sample. Also, adding 5–30% FSP increases the initial rate of water absorption by 8.7–49.1% compared to the control sample.

Figure 6.

Initial rate of water absorption by the clay samples.

In addition, the incorporation of SP or FSP additives prompted changes in the matrix structure, resulting in the creation of interlayer spacing and porous structures in the samples’ matrix. These porous structures inside the clay matrix serve as larger capillary spaces (Figure 7b). In summary, higher SP or FSP content promotes capillary water absorption, due to more pores and void creation. These pores and voids facilitate fluid transfer inside the clay samples’ matrix and increase water absorption rates as a result. Authors [70,71,72,73] highlighted the same relationship between the addition of organic porous materials and the water absorption of clay/Earth materials.

Figure 7.

The structure of the samples: (a) SP0, (b) SP5, (c) SP30, (d) FSP5, and (e) FSP30.

Figure 7 shows the SEM images taken from the brick samples. As shown in Figure 7, increasing the SP or FSP content partially caused an increase in voids in the clay sample structure, thus decreasing the densification (Figure 3) and increasing the initial rate of water absorption (Figure 6) of the clay samples. There is also a noticeable more homogenous matrix between the clay and FSP compared to clay and SP (Figure 7). The structure of the SP30 sample (Figure 2b) reveals voids with a width down to about 20–30 μm. The FSP30 sample structure has pores of 5–10 μm (Figure 2d). Also, increasing the SP or FSP content caused visible microfibers in the clay sample structure. These microfibers seem to reinforce the structure, which increases the compressive strength (Figure 4) of the clay samples.

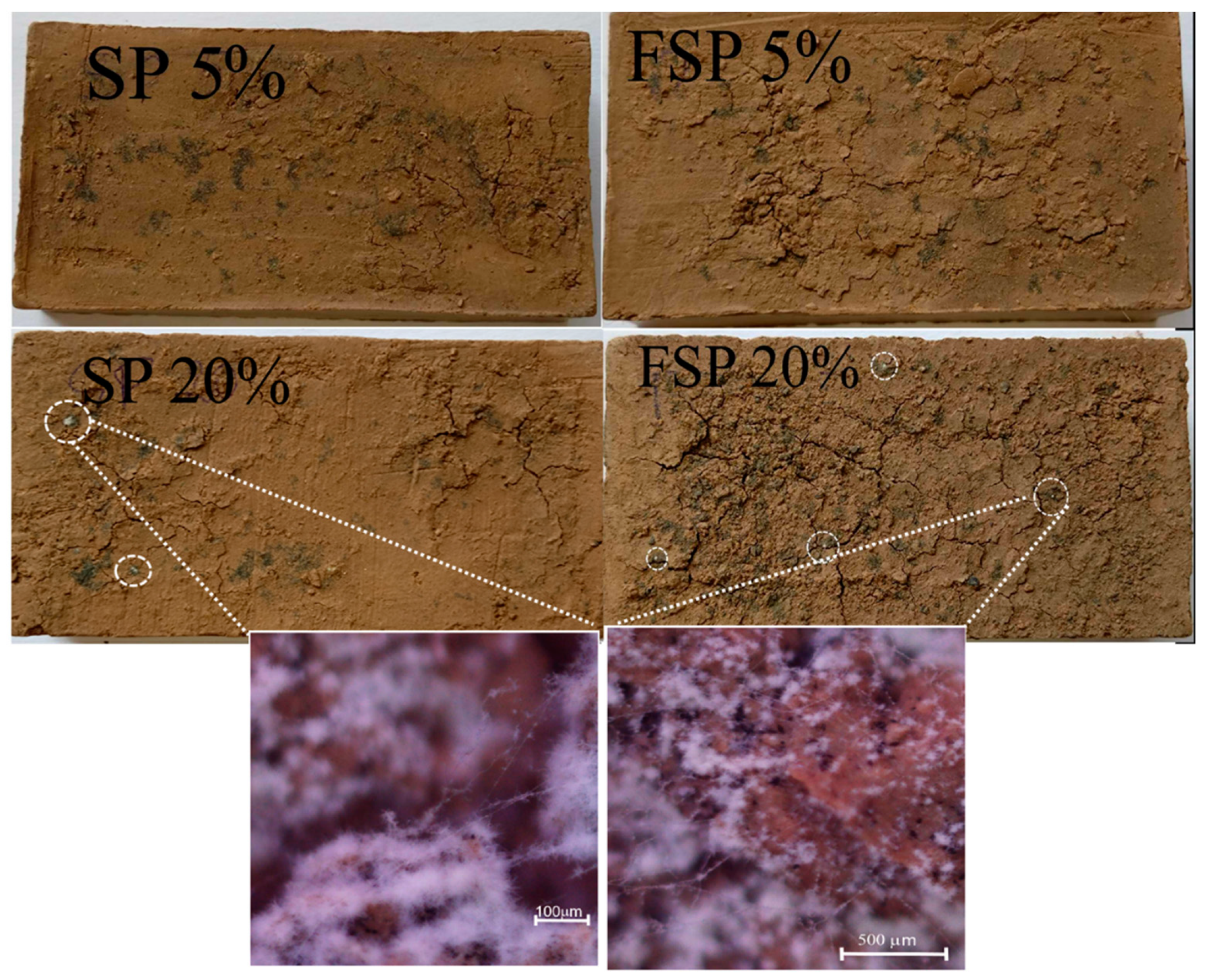

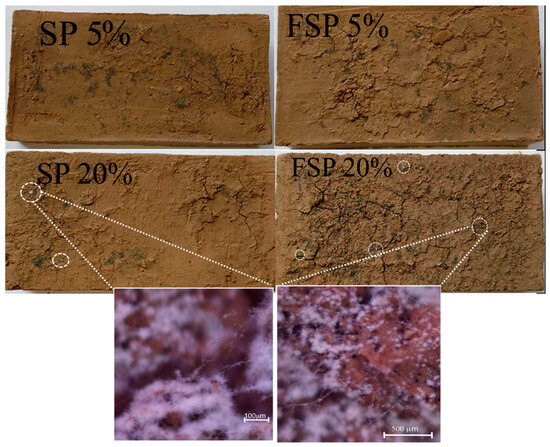

To evaluate the impact of microorganisms on new bricks, the suspensions of fungi mix of four species were inoculated in the clay bricks with wet and frozen–thawed sapropel. The suspension was prepared including the following types of fungi: interior environment Rhodotorula mucilaginosa and Stachybotrys chartarum and exterior environment Cladosporium cladosporioides and Aureobasidium pullulans by LST EN 15457. To identify how the microorganisms in the environment can impact clay bricks, they were incubated under normal conditions at 22 °C with 65% humidity for 3 weeks. The microorganisms did not grow on the bricks with the wet and frozen–thawed sapropel at 0, 5, 10, and 15%, but they grew on the bricks with the 20 and 30% sapropel, which were saturated with the organic matter of 89.5%, total nitrogen of 4.2–6.7%, and carbon of 45–48% (Table 2). The primary constraint on microbial growth in indoor environments is moisture, with fungi displaying greater tolerance for low-moisture conditions compared to bacteria. Moreover, the deliberate or accidental introduction of liquid water and the presence of adsorbed water at certain levels may also facilitate growth [74].

The defects as macro- and micro-cracks, formed on the surface in the first week of the brick samples, were examined. Supposedly, these cracks were formed from excess moisture from the fungi suspensions. Damage that occurs affects the biological resistance of the samples because moisture penetrates into the deeper layers of the samples more easily and the accumulated moisture creates more favorable conditions for the reproduction of microorganisms.

Three weeks after incubation, the defects that appeared on the surface of the samples did not spread to the surface layers of the area, but the microorganisms grew intensively during the second and third weeks of incubation. However, on the bricks with 5, 10, and 15% sapropel, there were visible microorganisms’ spores from the suspension, but the hypha of the fungus was not observed. This indicated that the microorganisms did not grow, but white aerial mycelia of fungi, most likely Aureobasidium pullulans, were growing on clay bricks with 20% and 30% sapropel. After 6 months, the samples were examined repeatedly with light microscopy (Figure 8); these white hyphae colonies indicated that Aureobasidium pullulans could grow when the clay bricks remained in the standard conditions of the room.

Figure 8.

Clay bricks with the 5% and 20% sapropel after the third week of incubation at 22 °C and 65% humidity. The white circle defines a hypha of fungi. After 6 months, these microorganisms were examined with light microscopy magnification at 40×.

White mycelium hyphae indicated that fungi were growing in the cracks of the bricks where there was more humidity. It is possible that the cracks in the bricks were made by excess moisture from the microorganism suspension (the solution of NaCl 0.9%) or that it accumulated from the environment. The microorganisms that grew on the brick with less than 20% of the sapropel, can to inhibited because of lack nutrient or the pH of the samples was greater than approximately 8, as described [29]. No mycelia were observed on the clay bricks with 5%, 10%, and 15% wet or frozen sapropel, which indicated better resistance to biological degradation compared to sapropel concentrations exceeding 20%.

4. Conclusions

Sustainability plays an ever-increasing role in building material manufacturing. Therefore, there is growing interest in unfired clay materials as an eco-material due to their local character and low energy consumption.

To produce eco-materials, an ecological raw material must be used. One such material that is natural and not harmful to environmental and human health is sapropel. In the present study, the properties, structure, and biological resistance of clay materials with SP (sapropel) or FSP (modified (frozen) sapropel) were investigated. The SP or FSP content varied from 5 to 30 wt.%.

Different microfibers are found in SP and FSP structures, which help reinforce the structure and increase the compressive strength of the clay materials. When the SP or FSP content is 5–30 wt.%, clay materials show good compressive strength, with this being 8.7–19.9% and 8.7–22.1% higher than the control clay samples, respectively.

The higher FSP content (20–30 wt.%) of the clay mixtures leads to lighter clay materials (the bulk density is 1.42–1.55 g/cm3), with 15.3–22.4% less bulk density than the control clay samples; however, their compressive strength is still high enough (about 7.7 MPa).

The use of SP or FSP in the production of clay materials increases the compressive strength of these clay materials, which is particularly important for unfired clay/soil/Earth materials.

The biodegradation processes due to microorganisms’ impact play an important role in organic material decomposition, and it is known that sapropel is rich in these organic compounds and could impact the degradation of bricks with sapropel. However, we determined that the biological durability of the clay bricks which have less than 15% sapropel and without excess moisture is good enough, and the wet or frozen sapropel could be used for brick production.

Author Contributions

Conceptualization, V.V. and O.K.; methodology, V.V.; software, D.V.; validation, D.V.; formal analysis, R.A.-P.; investigation, J.U.; resources, R.V.; data curation, R.V.; writ-ing—original draft preparation, O.K.; writing—review and editing, J.U.; visualization, R.A.-P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Center of Excellence project “Civil Engineering Research Centre” (Grant No. S-A-UEI-23-5).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Murmu, A.L.; Patel, A. Towards sustainable bricks production: An overview. Constr. Build. Mater. 2018, 165, 112–125. [Google Scholar] [CrossRef]

- Salim, R.W.; Ndambuki, J.M.; Adedokun, D.A. Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash. Sustainability 2014, 6, 3686–3696. [Google Scholar] [CrossRef]

- Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. Thermal conductivity of unfired earth bricks reinforced by agricultural wastes with cement and gypsum. Energy Build. 2015, 104, 139–146. [Google Scholar] [CrossRef]

- Obonyo, E.; Exelbirt, J.; Baskaran, M. Durability of Compressed Earth Bricks: Assessing Erosion Resistance Using the Modified Spray Testing. Sustainability 2010, 2, 3639–3649. [Google Scholar] [CrossRef]

- Muheise-Araalia, D.; Pavia, S. Properties of unfired, illitic-clay bricks for sustainable construction. Constr. Build. Mater. 2021, 268, 121118. [Google Scholar] [CrossRef]

- Ashour, T.; Azra Korjenic, A.; Abdelfattah, A.; Sesto, E.; Wu, W. Shrinkage Behavior of Stabilized Earth Bricks Reinforced with Wheat and Barley Straw. Sustainability 2023, 15, 16254. [Google Scholar] [CrossRef]

- Boussaa, N.; Kheloui, F.; Chelouah, N. Mechanical, thermal and durability investigation of compressed earth bricks stabilized with wood biomass ash. Constr. Build. Mater. 2023, 364, 129874. [Google Scholar] [CrossRef]

- Kulshreshtha, Y.; Mota, N.J.A.; Jagadish, K.S.; Bredenoord, J.; Vardon, P.J.; van Loosdrecht, M.C.M.; Jonkers, H.M. The potential and current status of earthen material for low-cost housing in rural India. Constr. Build. Mater. 2020, 247, 118615. [Google Scholar] [CrossRef]

- Limami, H.; Imad Manssouri, I.; Cherkaoui, K.; Saadaoui, M.; Khaldoun, A. Thermal performance of unfired lightweight clay bricks with HDPE & PET waste plastics additives. J. Build. Eng. 2020, 30, 101251. [Google Scholar]

- Saidi, M.; Cherif, A.S.; Zeghmati, B.; Sediki, E. Stabilization effects on the thermal conductivity and sorption behavior of earth bricks. Constr. Build. Mater. 2018, 167, 566–577. [Google Scholar] [CrossRef]

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, S.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, L.; Jelle, B.P.; Wang, Y.; Gustavsen, A. Hygrothermal properties of compressed earthen bricks. Constr. Build. Mater. 2018, 162, 576–583. [Google Scholar] [CrossRef]

- Alassaad, F.; Touati, K.; Levacher, D.; Sebaibi, N. Impact of phase change materials on lightened earth hygroscopic, thermal and mechanical properties. J. Build. Eng. 2021, 41, 102417. [Google Scholar] [CrossRef]

- Fernandes, J.; Peixoto, M.; Mateus, R.; Gervásio, H. Life cycle analysis of environmental impacts of earthen materials in the Portuguese context: Rammed earth and compressed earth blocks. J. Clean. Prod. 2019, 241, 118286. [Google Scholar] [CrossRef]

- Wesonga, R.; Kasedde, H.; Kibwami, N.; Manga, M. A Comparative Analysis of Thermal Performance, Annual Energy Use, and Life Cycle Costs of Low-cost Houses Made with Mud Bricks and Earthbag Wall Systems in Sub-Saharan Africa. Energy Built Environ. 2023, 4, 13–24. [Google Scholar] [CrossRef]

- Dabaieh, M.; Heinonen, J.; El-Mahdy, D.; Hassan, D.M. A comparative study of life cycle carbon emissions and embodied energy between sun-dried bricks and fired clay bricks. J. Clean. Prod. 2020, 275, 122998. [Google Scholar] [CrossRef]

- Sleinus, D.; Sinka, M.; Korjakins, A.; Obuka, V.; Nikolajeva, V.; Brencis, R.; Savicka, E. Properties of Sound Absorption Composite Materials Developed Using Flax Fiber, Sphagnum Moss, Vermiculite, and Sapropel. Materials 2023, 16, 1060. [Google Scholar] [CrossRef] [PubMed]

- Balčiūnas, G.; Žvironaitė, J.; Vėjelis, S.; Jagniatinskis, A.; Gaidučis, S. Ecological, thermal and acoustical insulating composite from hemp shives and sapropel binder. Ind. Crop. Prod. 2016, 91, 286–294. [Google Scholar] [CrossRef]

- Balčiūnas, G.; Žvironaitė, J.; Vėjelis, S. The use of sapropel in development of effective thermal insulating materials. Key Eng. Mater. 2014, 604, 313–316. [Google Scholar] [CrossRef]

- Brencis, R.; Pleiksnis, S.; Skujans, J.; Adamovics, A.; Gross, U. Lightweight composite building materials with hemp (Cannabis sativa L.) additives. Chem. Eng. Trans. 2017, 57, 1375–1380. [Google Scholar]

- Vėjelis, S.; Karimova, M.B.; Kuatbayeva, T.K.; Kairytė, A.; Šeputytė-Jucikė, J. Sapropel as a binding material for wood processing waste in the development of thermal insulation biocomposite. Materials 2023, 16, 2230. [Google Scholar] [CrossRef]

- Dudin, V.M. The effect of sapropel additives on the properties of cement concrete for road construction. Smart Compos. Constr. 2023, 4, 48–56. [Google Scholar]

- Vaičiukynienė, D.; Kantautas, A.; Vaickelionis, G.; Vaičiukynas, V. Effects of the Modified Calcareous Sapropel on Portland Cement Hydration. In Proceedings of the IBAUSIL 19 Internationale Baustofftagung, Weimar, Germany, 16–18 September 2015. [Google Scholar]

- Navickas, J.; Kasperiunaite, D.; Mikuckis, F. Thermo physical properties of samples made of unburnt clayey soil and sapropel mixture. In Proceedings of the 12th International Scientific Conference, Engineering for Rural Development, Jelgava, Latvia, 23–24 May 2013; Volume 12. [Google Scholar]

- Vaickelionis, G.; Kantautas, A.; Vaičiukynienė, D. Production of expanded clay pellets by using non-selfbloating clay, lakes sapropel and glycerol. Mater. Sci. 2011, 17, 314–321. [Google Scholar] [CrossRef]

- Kisand, A.; Baty, F.; Kisand, V. Homogeneous microbial diversity in the upper sediment layers of a shallow lake. Aquat. Microb. Ecol. 2013, 70, 77–85. [Google Scholar]

- Banciu, H.L. The saline organic-rich sediments: A short overview. Air Water Compon. Environ. 2018, 129–135. [Google Scholar]

- Penn, C.J.; Camberato, J.J. A critical review on soil chemical processes that control how soil pH affects phosphorus availability to plants. Agriculture 2019, 9, 120. [Google Scholar] [CrossRef]

- Rousk, J.; Bååth, E.; Brookes, P.C.; Lauber, C.L.; Lozupone, C.; Caporaso, J.G.; Knight, R.; Fierer, N. Soil bacterial and fungal communities across a pH gradient in an arable soil. ISME J. 2010, 4, 1340–1351. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Shi, Y.; Fang, J.; Chu, H.; Adams, J.M. Soil microbial network complexity varies with pH as a continuum, not a threshold, across the North China Plain. Front. Microbiol. 2022, 13, 895687. [Google Scholar] [CrossRef] [PubMed]

- Stankeviča, K.; Kļaviņš, M. Sapropelis un tā izmantošanas iespējas/Sapropel and its application possibilities. Mater. Sci. Appl. Chem. 2013, 29, 109–126. [Google Scholar] [CrossRef]

- Bakšienė, E.; Ciūnys, A. Dredging of lake and application of sapropel for improvement of light soil properties. J. Environ. Eng. Landsc. Manag. 2012, 20, 97–103. [Google Scholar] [CrossRef]

- Utenkova, T.; Kremcheev, E.; Korotkova, O. Existing methods of dehydration of sapropel. E3S Web Conf. 2020, 174, 01004. [Google Scholar] [CrossRef]

- Chuvilin, E.M.; Ershov, E.D.; Murashko, A.A. Transformation of sapropel in the process of freezing. In Premafrost and Action of Natural or Artificial Cooling; International Institute of Refrigeration: Paris, France, 1998; pp. 34–40. [Google Scholar]

- Andrade, F.A.; Al-Qureshi, H.A.; Hotza, D. Measuring the plasticity of clays: A review. Appl. Clay Sci. 2011, 51, 1–7. [Google Scholar] [CrossRef]

- Tiwari, B.; Ajmera, B. A new correlation relating the shear strength of reconstituted soil to the proportions of clay minerals and plasticity characteristics. Appl. Clay Sci. 2011, 53, 48–57. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J.; O’Kelly, B.C. Review and critical examination of fine-grained soil classification systems based on plasticity. Appl. Clay Sci. 2021, 200, 105955. [Google Scholar] [CrossRef]

- EN ISO 12570; Hygrothermal Performance of Building Materials and Products—Determination of Moisture Content by Drying at Elevated Temperature. European Committee for Standardization: Brussels, Belgium, 2000.

- EN 13820; Thermal Insulating Materials for Building Applications—Determination of Organic Content. European Committee for Standardization: Brussels, Belgium, 2003.

- ASTM C326-09; Standard Test Method for Drying and Firing Shrinkages of Ceramic Whiteware Clays. ASTM: Conshohocken, PA, USA, 2018.

- LST EN 772-13; Methods of Test for Masonry Units—Part 13: Determination of Net and Gross Dry Density of Masonry Units (Except for Natural Stone). The British Standards Institution: London, UK, 2000; p. 16.

- LST EN 826; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. The British Standards Institution: London, UK, 2013; p. 13.

- ASTM-D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: Conshohocken, PA, USA, 2017; p. 20.

- EN 772-11; Methods of Test for Masonry Units—Part 11: Determination of Water Absorption of Aggregate Concrete, Autoclaved Aerated Concrete, Manufactured Stone and Natural Stone Masonry Units Due to Capillary Action and the Initial Rate of Water Absorption of Clay Masonry Units. The British Standards Institution: London, UK, 2011; p. 8.

- LST EN 15457; Paints and Varnishes—Laboratory Method for Testing the Efficacy of Film Preservatives in a Coating against Fungi. The British Standards Institution: London, UK, 2022; p. 13.

- Millogo, Y.; Morel, J.C.; Aubert, J.E.; Ghavami, K. Experimental analysis of Pressed Adobe Blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Noureddine, O.; Erba, S.; Sahbi, H.; Khaldoun, A. Effect of reinforced recycled sawdust-fibers additive on the performance of ecological compressed earth bricks. J. Build. Eng. 2023, 68, 106140. [Google Scholar] [CrossRef]

- Lima, J.; Faria, P. Eco-efficient earthen plasters: The influence of the addition of natural fibers. In Natural Fibres: Advances in Science and Technology towards Industrial Applications: From Science to Market; Springer: North Holland, The Netherlands, 2016; pp. 315–327. [Google Scholar]

- Santos, T.; Nunes, L.; Faria, P. Production of eco-efficient earth-based plasters: Influence of composition on physical performance and bio-susceptibility. J. Clean. Prod. 2017, 167, 55–67. [Google Scholar] [CrossRef]

- AlShuhail, K.; Aldawoud, A.; Syarif, J.; Abdoun, I.A. Enhancing the performance of compressed soil bricks with natural additives: Wood chips and date palm fibers. Constr. Build. Mater. 2021, 295, 123611. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B. Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr. Build. Mater. 2015, 101, 797–809. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Recycled wastewater treatment plant sludge as a construction material additive to ecological lightweight earth bricks. Clean. Eng. Technol. 2021, 2, 100050. [Google Scholar] [CrossRef]

- Serrano, S.; Barreneche, C.; Cabeza, L.F. Use of by-products as additives in adobe bricks: Mechanical properties characterisation. Constr. Build. Mater. 2016, 108, 105–111. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Concha-Riedel, J.; Antico, F.C.; Valdés, C.; Cáceres, G. Influence of natural fiber dosage and length on adobe mixes damage-mechanical behavior. Constr. Build. Mater. 2018, 174, 645–655. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Randazzo, L.; Montana, G.; Hein, A.; Castiglia, A.; Rodonò, G.; Donato, D.I. Moisture absorption, thermal conductivity and noise mitigation of clay based plasters: The influence of mineralogical and textural characteristics. Appl. Clay Sci. 2016, 132, 498–507. [Google Scholar] [CrossRef]

- Ghavami, K.; Toledo Filho, R.D.; Barbosa, N.P. Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 1999, 21, 39–48. [Google Scholar] [CrossRef]

- Yetgin, Ş.; Çavdar, Ö.; Çavdar, A. The effects of the fiber contents on the mechanic properties of the adobes. Constr. Build. Mater. 2008, 22, 222–227. [Google Scholar] [CrossRef]

- Galán-Marín, C.; Rivera-Gómez, C.; Petric, J. Clay-based composite stabilized with natural polymer and fibre. Constr. Build. Mater. 2010, 24, 1462–1468. [Google Scholar] [CrossRef]

- Alavéz-Ramírez, R.; Montes-García, P.; Martínez-Reyes, J.; Altamirano-Juárez, D.C.; Gochi-Ponce, Y. The use of sugarcane bagasse ash and lime to improve the durability and mechanical properties of compacted soil blocks. Constr. Build. Mater. 2012, 34, 296–305. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Zak, P.; Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. The influence of natural reinforcement fibers, gypsum and cement on compressive strength of earth bricks materials. Constr. Build. Mater. 2016, 106, 179–188. [Google Scholar] [CrossRef]

- Kumar, N.; Barbato, M. Effects of sugarcane bagasse fibers on the properties of compressed and stabilized earth blocks. Constr. Build. Mater. 2022, 315, 125552. [Google Scholar] [CrossRef]

- Zhou, Y.; Trabelsi, A.; El Mankibi, M. A review on the properties of straw insulation for buildings. Constr. Build. Mater. 2022, 330, 127215. [Google Scholar] [CrossRef]

- Bouchefra, I.; Bichri, F.Z.E.; Chehouani, H.; Benhamou, B. Mechanical and thermophysical properties of compressed earth brick rienforced by raw and treated doum fibers. Constr. Build. Mater. 2022, 318, 126031. [Google Scholar] [CrossRef]

- DIN 18945:2013-08; Earth Blocks—Terms and Definitions, Requirements, Test Methods. Germany Institute of Standartization: Berlin, Germany, 2013; p. 30.

- Calatan, G.; Hegyi, A.; Dico, C.; Mircea, C. Determining the optimum addition of vegetable materials in adobe bricks. Procedia Technol. 2016, 22, 259–265. [Google Scholar] [CrossRef]

- Lagouin, M.; Laborel-Préneron, A.; Magniont, C.; Geoffroy, S.; Aubert, J.E. Effects of organic admixtures on the fresh and mechanical properties of earth-based plasters. J. Build. Eng. 2021, 41, 102379. [Google Scholar] [CrossRef]

- Hamard, E.; Morel, J.C.; Salgado, F.; Marcom, A.; Meunier, N. A procedure to assess the suitability of plaster to protect vernacular earthen architecture. J. Cult. Herit. 2013, 14, 109–115. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Jannat, N.; Latif Al-Mufti, R.; Hussien, A.; Abdullah, B.; Cotgrave, A. Influence of sawdust particle sizes on the physico-mechanical properties of unfired clay blocks. Designs 2021, 5, 57. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S.; Nikbakht, E. Incorporation of waste materials in the manufacture of masonry bricks: An update review. J. Build. Eng. 2019, 21, 37–54. [Google Scholar] [CrossRef]

- Seco, A.; Urmeneta, P.; Prieto, E.; Marcelino, S.; García, B.; Miqueleiz, L. Estimated and real durability of unfired clay bricks: Determining factors and representativeness of the laboratory tests. Constr. Build. Mater. 2017, 131, 600–605. [Google Scholar] [CrossRef]

- Adams, R.I.; Bhangar, S.; Dannemiller, K.C.; Eisen, J.A.; Fierer, N.; Gilbert, J.A.; Green, J.L.; Marr, L.S.; Miller, S.L.; Siegel, J.A.; et al. Ten questions concerning the microbiomes of buildings. Build. Environ. 2016, 109, 224–234. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).