Recycling of Retired Wind Turbine Blades into Modifiers for Composite-Modified Asphalt Pavements: Performance Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Virgin Bitumen

2.1.2. Recycled Wind Turbine Blades (rWTBs)

2.1.3. Silane Coupling Agent

2.1.4. Styrene–Butadiene Rubber

2.1.5. SBS

2.1.6. Sulfur

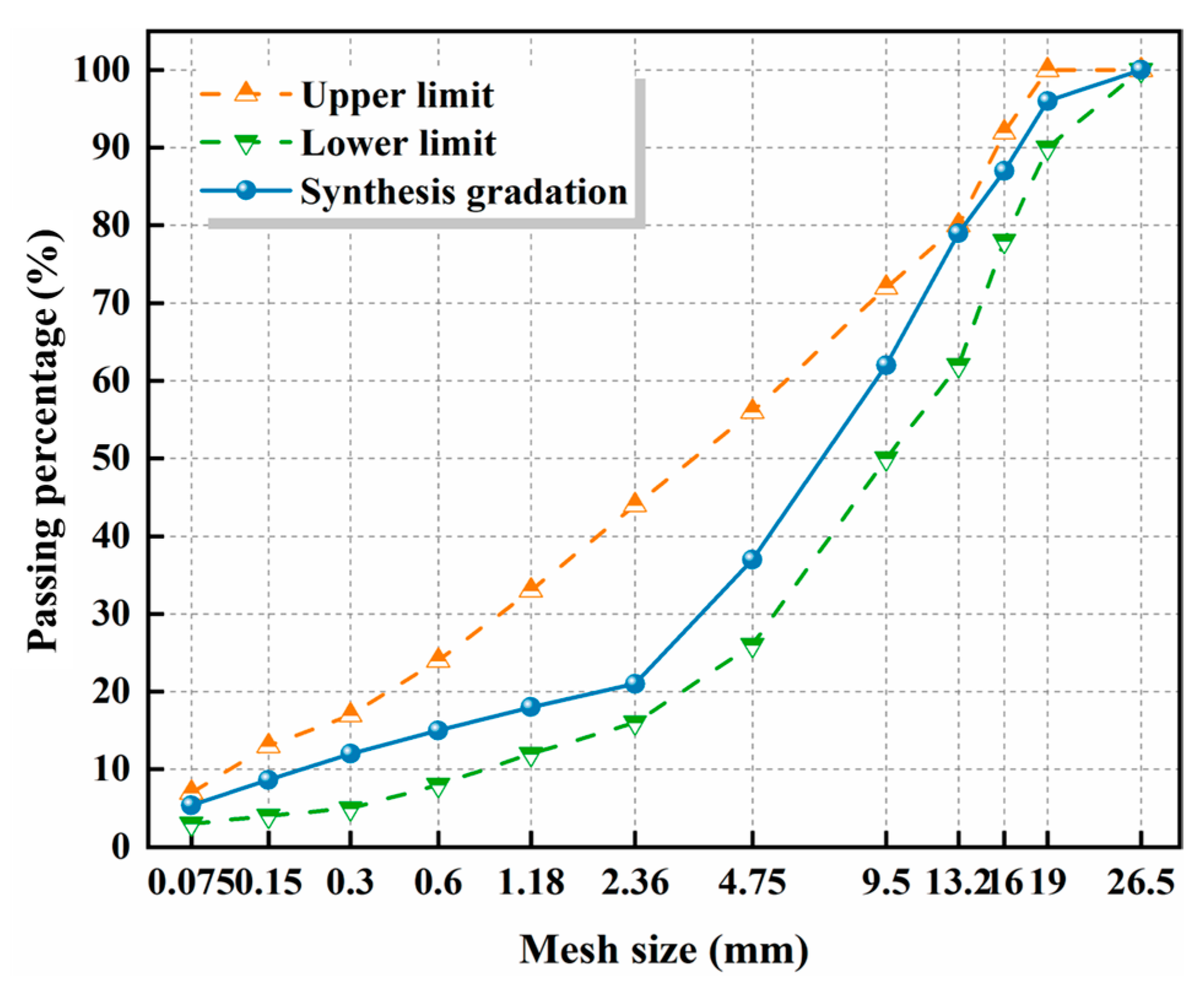

2.1.7. Aggregates

2.2. Preparation of rWTB-Based Asphalt Modifiers

2.2.1. rWTB Modifier

2.2.2. Si-rWTB Modifier

2.2.3. R-rWTB Modifier

2.2.4. R-Si-rWTB Modifier

2.3. Preparation of Different rWTB-Modified Asphalts

2.4. Preparation of Different rWTB/SBS-Modified Asphalt

2.5. Preparation of rWTB/SBS-Composite-Modified Asphalt Mixtures before and after Aging

2.6. Test Methods

2.6.1. Scanning Electron Microscopy (SEM)

2.6.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.6.3. Immersed Marshall Test

2.6.4. Freeze–Thaw Splitting Test

2.6.5. Wheel Tracking Test (WTT)

3. Results and Discussion

3.1. Microstructure of rWTB-Based Asphalt Modifiers

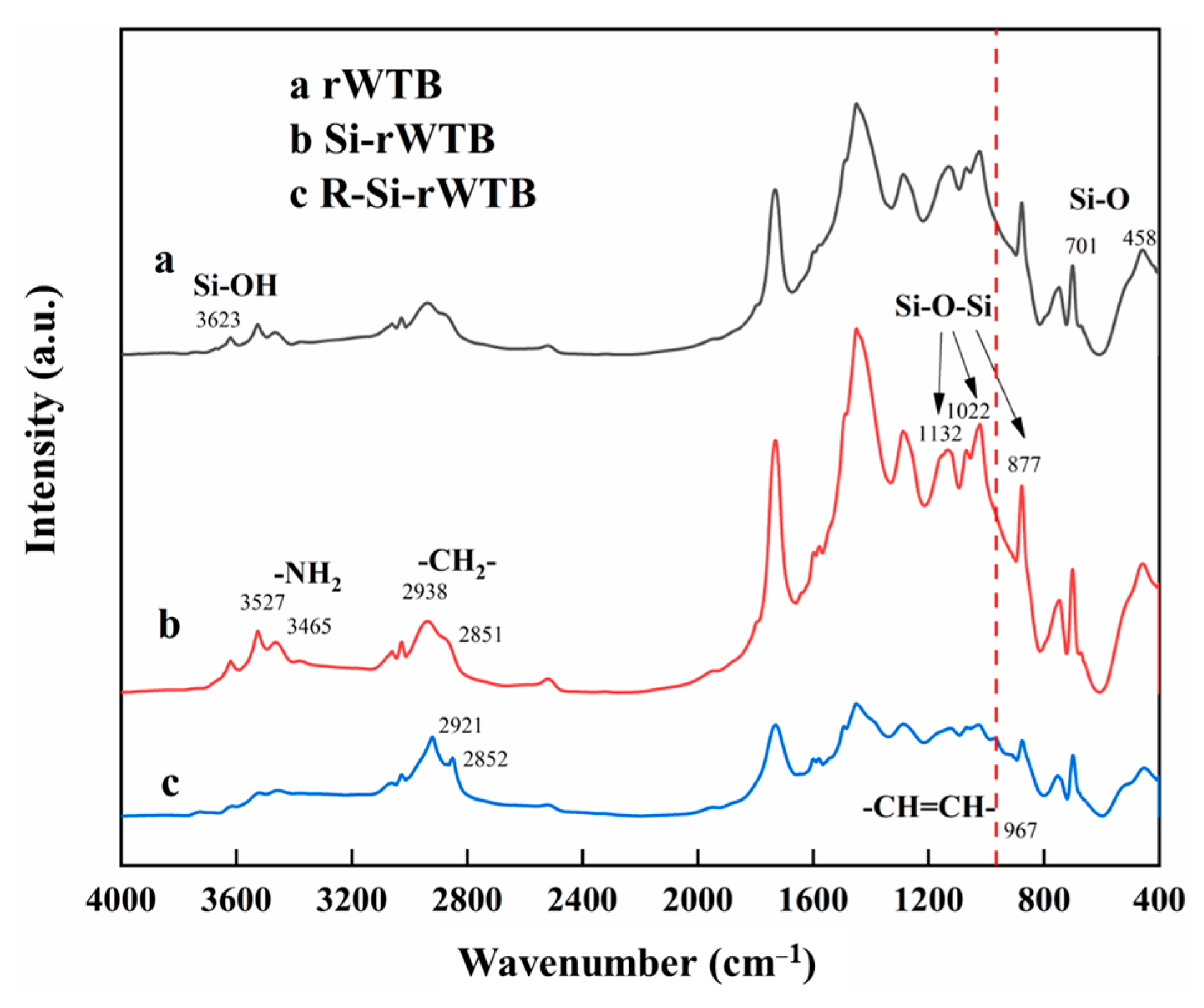

3.2. Molecular Structure of Different rWTB Asphalt Modifiers

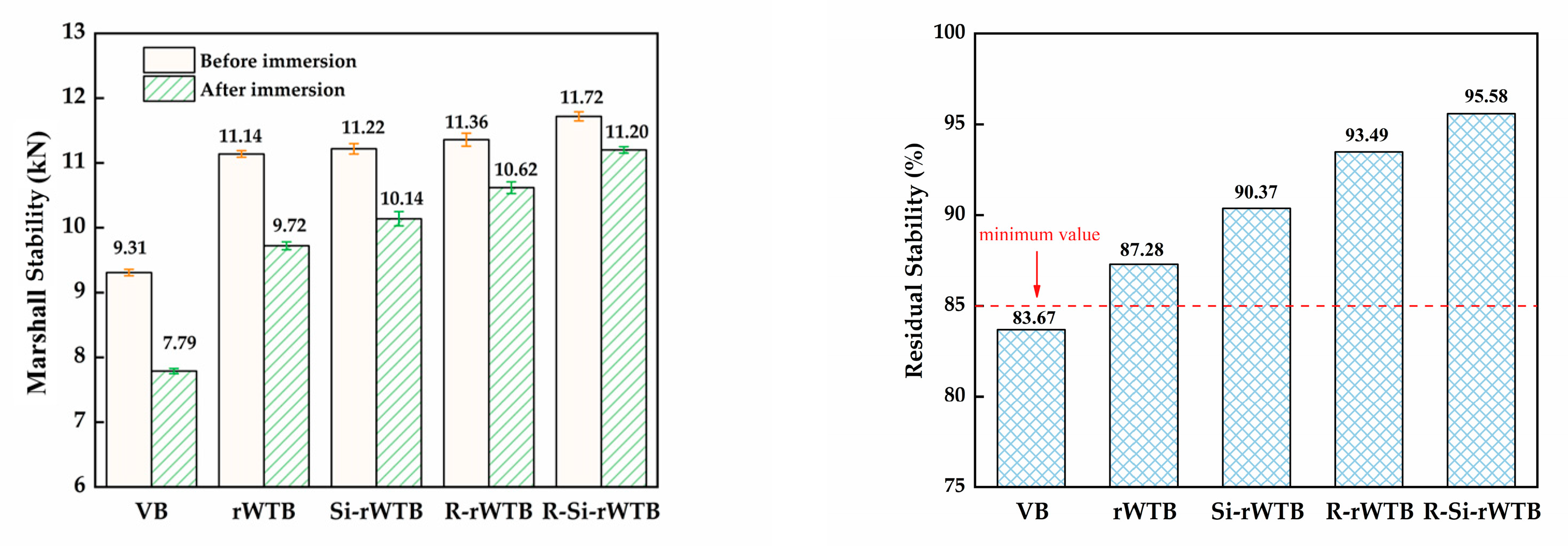

3.3. Effect of rWTB-Based Asphalt Modifiers on Marshall Stability before and after Immersion

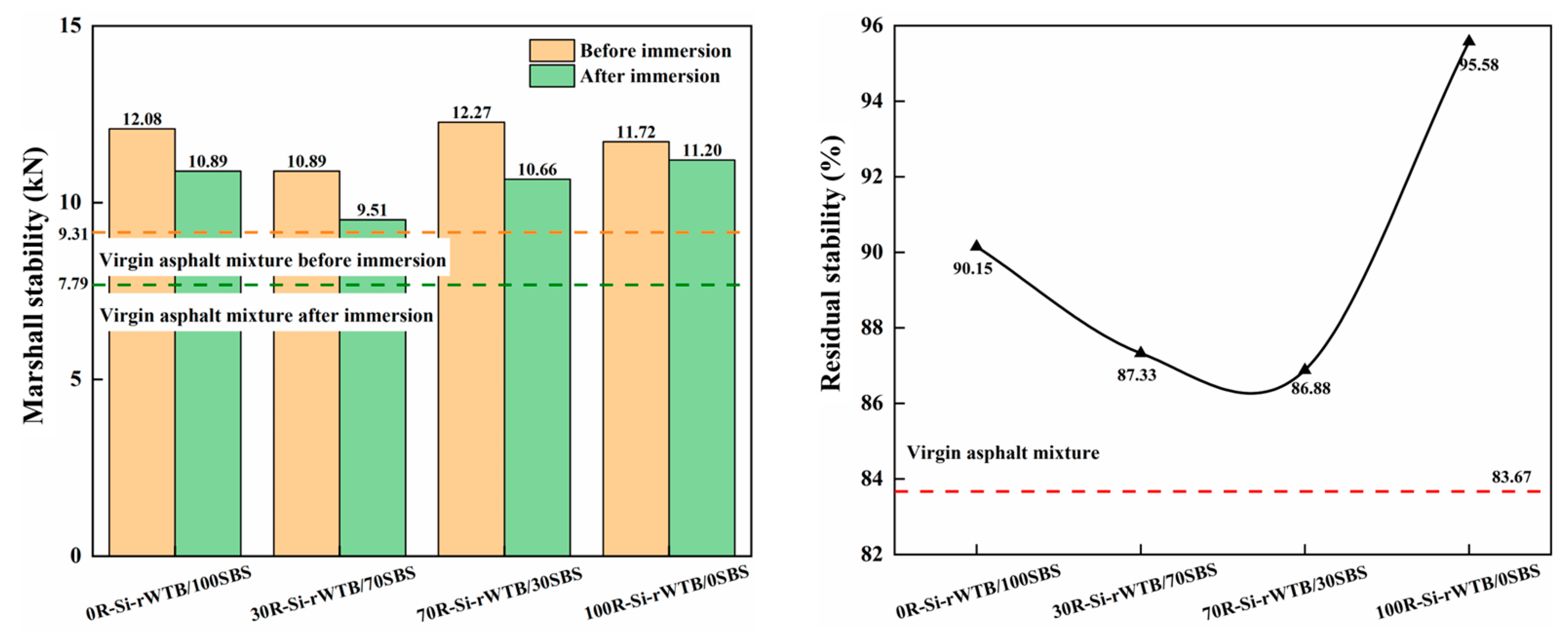

3.4. Moisture-Induced Damage Results of R-Si-rWTB/SBS-Composite-Modified Asphalt Mixtures

3.4.1. Immersed Marshall Test Result

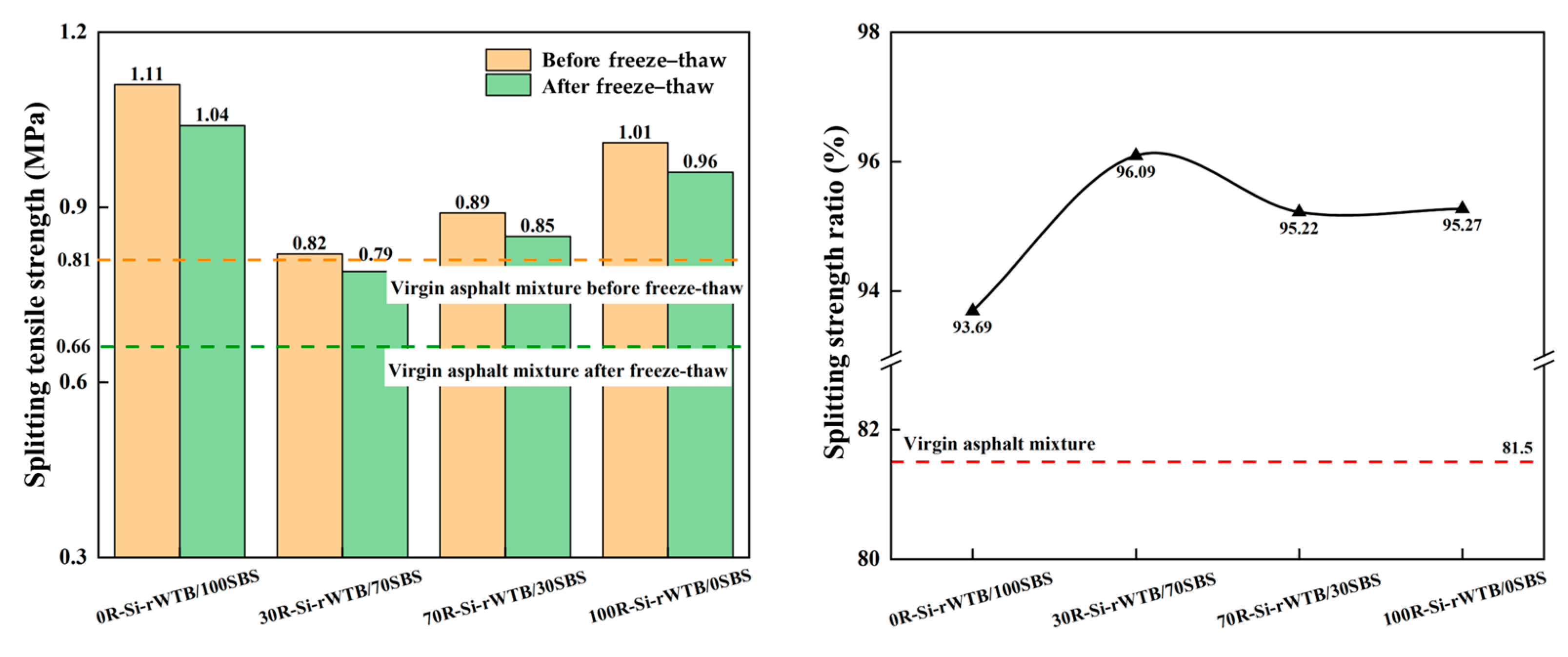

3.4.2. Freeze–Thaw Splitting Test Result

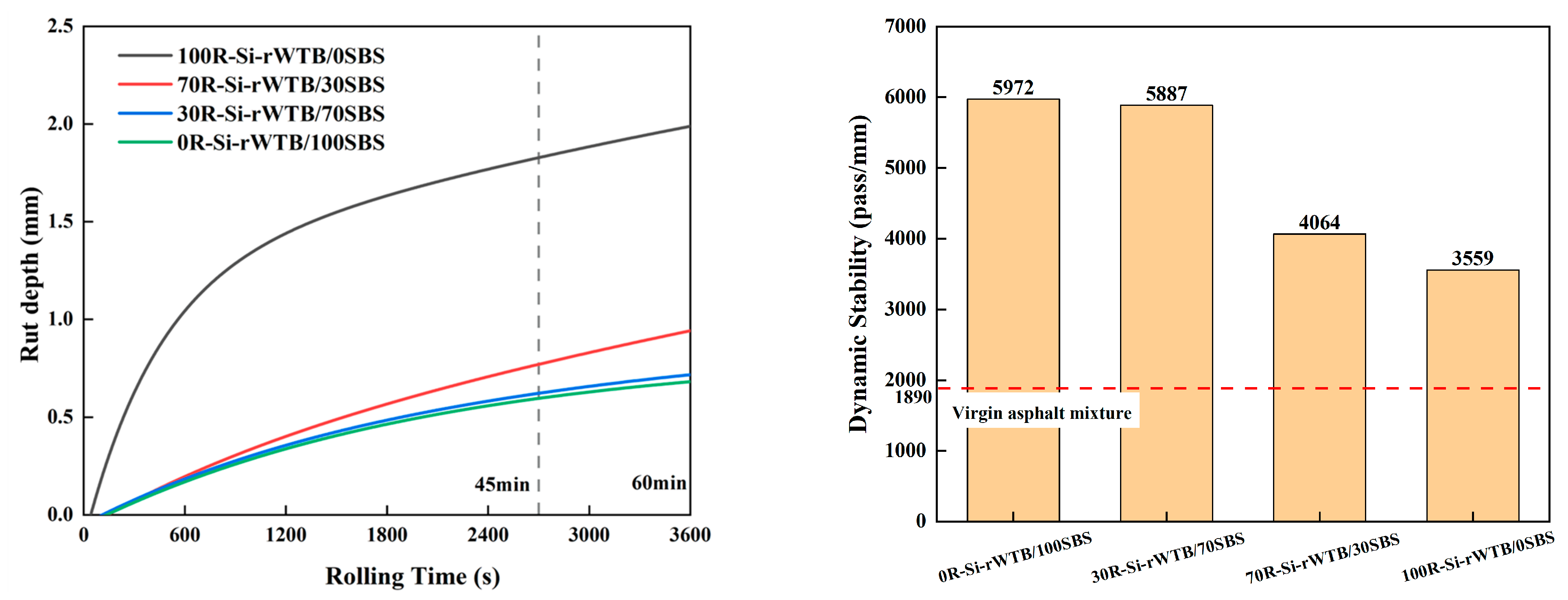

3.5. High-Temperature Performance Results of R-Si-rWTB/SBS-Composite-Modified Asphalt Mixtures

3.6. Effect of Aging on Moisture-Induced Damage of R-Si-rWTB/SBS-Composite-Modified Asphalt Mixtures

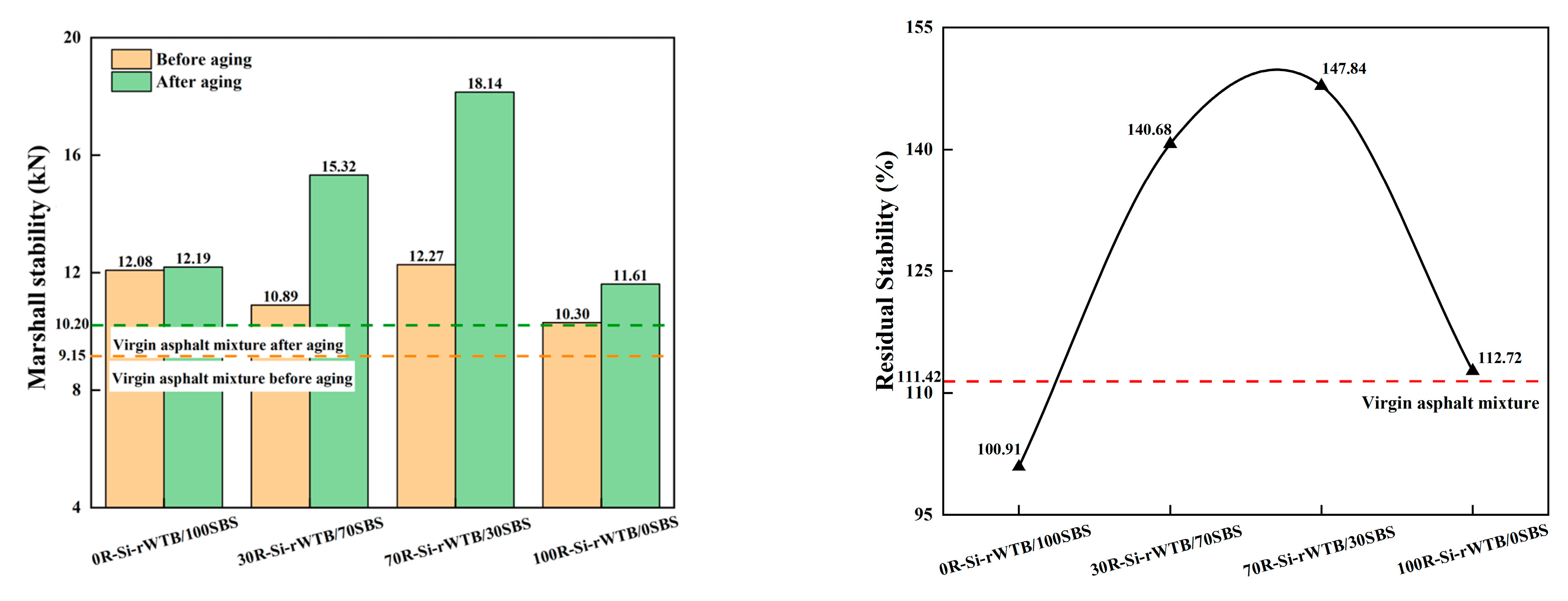

3.6.1. Immersed Marshall Test Result

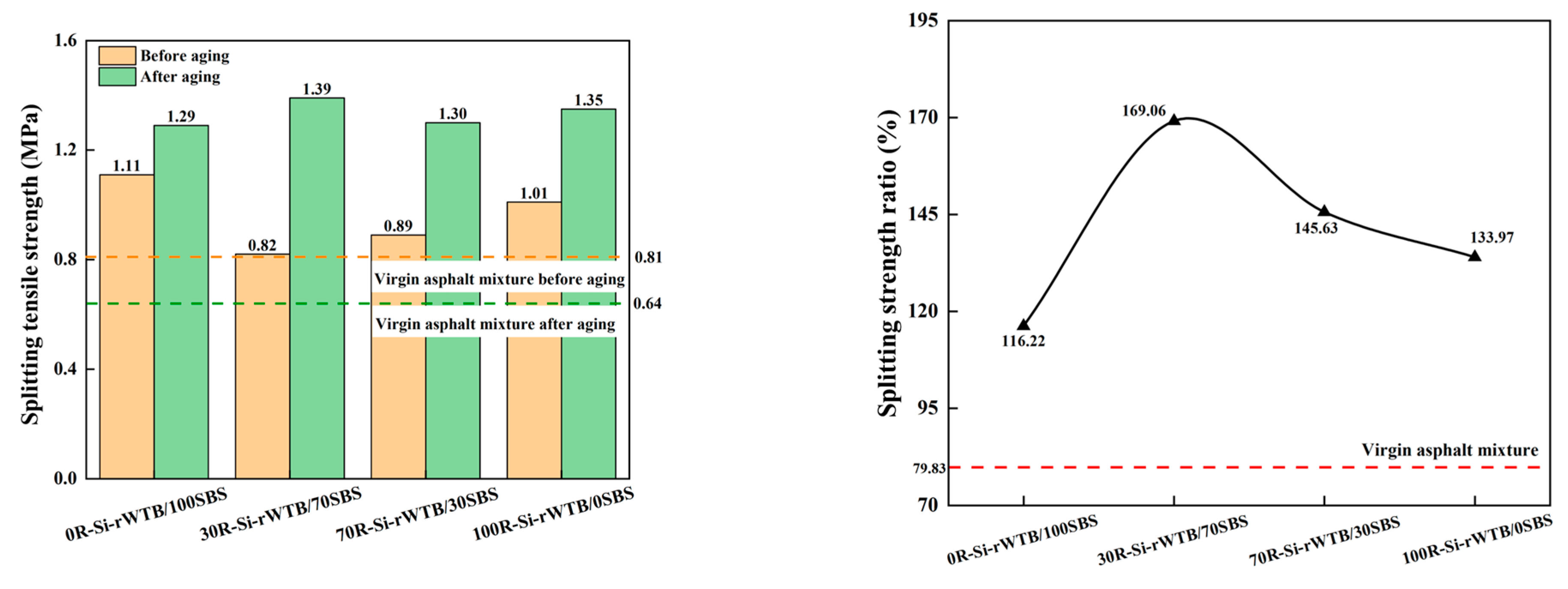

3.6.2. Freeze–Thaw Splitting Test Result

4. Conclusions

- The SEM and FTIR results indicated that, after silane and rubber treatments, the silane was successfully grafted onto the rWTB surface to increase compatibility with organic substances; additionally, the microstructure in the presence of rWTB was tougher, and almost all fibers were inside the rubber with no interfaces.

- The moisture stability results demonstrated that the R-Si-rWTB modifier contributed to substantially increasing the resistance of the asphalt mixture to moisture-induced damage, increasing the residual Marshall stability from 83.67% to 95.6% after water immersion. When mixed with 70% SBS, the residual Marshall stability remained at 87.33%.

- The freeze–thaw test results showed that the splitting strength of the virgin asphalt mixture was higher both before and after freeze–thaw treatment when R-Si-rWTB was added; furthermore, the freeze–thaw splitting strength ratio of the modified asphalt mixtures remained higher, roughly between 93% and 96%, in comparison with that (81.5%) of the virgin mixture, showing that the R-Si-rWTB modifier effectively increased the resistance of the asphalt mixtures to freeze–thaw damage.

- The rut test results showed that the rut depth development of the 30R-Si-rWTB/70SBS asphalt mixture was close to that of the 0R-Si-rWTB/100SBS asphalt mixture, and their dynamic stabilities were also close to each other (5887 and 5972 passes/mm, respectively), indicating that 30% R-Si-rWTB did not notably affect the resistance of the asphalt mixture to high-temperature deformation.

- The moisture and freeze–thaw test results suggested that the resistances of the 30R-Si-rWTB/70SBS asphalt mixture to moisture and freeze–thaw treatment increased after a short aging duration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cooperman, A.; Eberle, A.; Lantz, E. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options. Resour. Conserv. Recy. 2021, 168, 105439. [Google Scholar] [CrossRef]

- Jani, H.K.; Kachhwaha, S.S.; Nagababu, G.; Das, A. A brief review on recycling and reuse of wind turbine blade materials. Mater. Today Proc. 2022, 62, 7124–7130. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Fingersh, L.; Hand, M.; Laxson, A. Wind Turbine Design Cost and Scaling Model; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2006. [Google Scholar]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A comparative life cycle assessment between landfilling and co-processing of waste from decommissioned Irish wind turbine blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

- Geiger, R.; Hannan, Y.; Travia, W.; Naboni, R.; Schlette, C. Composite wind turbine blade recycling-value creation through Industry 4.0 to enable circularity in repurposing of composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 012016. [Google Scholar] [CrossRef]

- Aramide, F.; Atanda, P.; Olorunniwo, O. Mechanical properties of a polyester fibre glass composite. Int. J. Compos. Mater. 2012, 2, 147–151. [Google Scholar]

- Mathew, M.; Padaki, N.V.; Rocha, L.; Gomes, J.; Alagirusamy, R.; Deopura, B.; Fangueiro, R. Tribological properties of the directionally oriented warp knit GFRP composites. Wear 2007, 263, 930–938. [Google Scholar] [CrossRef]

- Alam, S.; Habib, F.; Irfan, M.; Iqbal, W.; Khalid, K. Effect of orientation of glass fiber on mechanical properties of GRP composites. J. Chem. Soc. Pak. 2010, 32, 265–269. [Google Scholar]

- Fitchett, B.; Ladwig, K. Wind Turbine Blade Recycling-Preliminary Assessment; Electric Power Research Institute: Washington, DC, USA, 2020. [Google Scholar]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kozub, B.; Bąk, A.; Balamurugan, P.; Uthayakumar, M.; Furtos, G. Tackling the circular economy challenges—Composites recycling: Used tyres, wind turbine blades, and solar panels. J. Compos. Sci. 2021, 5, 243. [Google Scholar] [CrossRef]

- Yang, J.; Meng, F.; Zhang, L.; McKechnie, J.; Chang, Y.; Ma, B.; Hao, Y.; Li, X.; Pender, K.; Yang, L.; et al. Solutions for recycling emerging wind turbine blade waste in China are not yet effective. Commun. Earth Environ. 2023, 4, 466. [Google Scholar] [CrossRef]

- Diez-Cañamero, B.; Mendoza, J.M.F. Circular economy performance and carbon footprint of wind turbine blade waste management alternatives. Waste Manag. 2023, 164, 94–105. [Google Scholar] [CrossRef] [PubMed]

- Beauson, J.; Laurent, A.; Rudolph, D.; Jensen, J.P. The complex end-of-life of wind turbine blades: A review of the European context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Thomason, J.; Yang, L.; Meier, R. The properties of glass fibres after conditioning at composite recycling temperatures. Compos. Part A Appl. Sci. Manuf. 2014, 61, 201–208. [Google Scholar] [CrossRef]

- Lin, J.; Guo, Z.; Hong, B.; Xu, J.; Fan, Z.; Lu, G.; Wang, D.; Oeser, M. Using recycled waste glass fiber reinforced polymer (GFRP) as filler to improve the performance of asphalt mastics. J. Clean. Prod. 2022, 336, 130357. [Google Scholar] [CrossRef]

- Yang, Q.; Hong, B.; Lin, J.; Wang, D.; Zhong, J.; Oeser, M. Study on the reinforcement effect and the underlying mechanisms of a bitumen reinforced with recycled glass fiber chips. J. Clean. Prod. 2020, 251, 119768. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; Liu, W.; Zhao, X. Partially replacing Styrene-Butadiene-Styrene (SBS) with other asphalt binder modifier: Feasibility study. Constr. Build. Mater. 2020, 249, 118752. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable practice in pavement engineering through value-added collective recycling of waste plastic and waste tyre rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Nie, Y.; Liu, Q.; Xiang, Z.; Zhong, S.; Huang, X. Performance and Modification Mechanism of Recycled Glass Fiber of Wind Turbine Blades and SBS Composite-Modified Asphalt. Appl. Sci. 2023, 13, 6335. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transportation: Beijing, China, 2011.

| Parameter | Test Result | Requirement | Standard |

|---|---|---|---|

| Penetration (0.1 mm) | 65 | 60–80 | ASTM D5 |

| Softening point (°C) | 48.2 | ≥43 | ASTM D36 |

| Viscosity at 135 °C (Pa·s) | 0.46 | ≤3 | ASTM D4402 |

| Ductility at 15 °C (cm) | >100 | >100 | ASTM D113 |

| Property | Description |

|---|---|

| Purity | Analytically pure |

| Appearance | Colorless and transparent liquid |

| Gravity (25 °C, g/cm3) | 0.946 |

| Boiling point/°C | 217 |

| pH | >7 (after hydrolysis) |

| Solubility | Soluble in water |

| Item | Unit | Description |

|---|---|---|

| Appearance | \ | White particle |

| Moisture content | % | ≤0.5 |

| Relative molecular weight | 104 | 20~30 |

| Styrene content | % | 26~35 |

| Rubber content | % | ≥90 |

| Item | Unit | Description |

|---|---|---|

| Appearance | \ | White particle |

| S/B proportion | \ | 40/60 |

| Oil-filling content | % | 0 |

| Volatile content | % | ≤0.7 |

| Ash content | % | ≤0.20 |

| Elongation at break | % | ≥730 |

| Melt flow rate | g/10 min | 0.10~5.00 |

| Item | Unit | Description |

|---|---|---|

| Appearance | \ | Yellow powder |

| Density | g/cm3, at 23 °C | 1.98 |

| Boiling point | °C | 460 |

| Burning point | °C | 270 |

| Melting point | °C | 115 |

| Ash content | % | 0.003 |

| Solubility | \ | Water-insoluble |

| Category | Test Item | Test Result | Requirement |

|---|---|---|---|

| Coarse (>2.36 mm) | Apparent density, g/cm3 | 2.864 | ≥2.60 |

| Absorption (%) | 1.71 | ≤2.0 | |

| Crushing value (%) | 16.2 | ≤26 | |

| Robustness (%) | 3.2 | ≤12 | |

| Fine (˂2.36 mm) | Apparent density, g/cm3 | 2.749 | ≥2.50 |

| Robustness (%) | 2.6 | ≤12 | |

| Sand equivalent (%) | 83.3 | ≥60 |

| Attribution | Wavenumber (cm−1) | Vibration Type |

|---|---|---|

| Si-OH | 3623 | Stretching |

| -NH2 | 3527, 3456 | Stretching |

| -CH2- | 2938 | Asymmetric stretching |

| -CH2- | 2851 | Symmetric stretching |

| Si-O-Si | 1132, 1022 | Asymmetric stretching |

| -CH = CH- | 967 | Out-of-plane bending |

| Si-O-Si | 877 | Symmetric stretching |

| Si-O-Si | 701, 458 | Bending |

| Mixture | MS/kN | MS1/kN | MS Increase/% | MS1 Increase/% |

|---|---|---|---|---|

| 30~40 min | 48 h | 30~40 min | 48 h | |

| VB | 9.31 | 7.79 | 0 | 0 |

| rWTB | 11.14 | 9.72 | 20 | 25 |

| Si-rWTB | 11.22 | 10.14 | 21 | 30 |

| R-rWTB | 11.36 | 10.62 | 22 | 36 |

| R-Si-rWTB | 11.72 | 11.20 | 26 | 44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Wang, X.; Chen, W.; Yang, T.; Bian, X.; Xu, X. Recycling of Retired Wind Turbine Blades into Modifiers for Composite-Modified Asphalt Pavements: Performance Evaluation. Sustainability 2024, 16, 2343. https://doi.org/10.3390/su16062343

Li P, Wang X, Chen W, Yang T, Bian X, Xu X. Recycling of Retired Wind Turbine Blades into Modifiers for Composite-Modified Asphalt Pavements: Performance Evaluation. Sustainability. 2024; 16(6):2343. https://doi.org/10.3390/su16062343

Chicago/Turabian StyleLi, Peixin, Xiaodan Wang, Weijie Chen, Tao Yang, Xiaoya Bian, and Xiong Xu. 2024. "Recycling of Retired Wind Turbine Blades into Modifiers for Composite-Modified Asphalt Pavements: Performance Evaluation" Sustainability 16, no. 6: 2343. https://doi.org/10.3390/su16062343

APA StyleLi, P., Wang, X., Chen, W., Yang, T., Bian, X., & Xu, X. (2024). Recycling of Retired Wind Turbine Blades into Modifiers for Composite-Modified Asphalt Pavements: Performance Evaluation. Sustainability, 16(6), 2343. https://doi.org/10.3390/su16062343