Advancing Sustainable Development: Broad Applications of Passive Radiative Cooling

Abstract

:1. Introduction

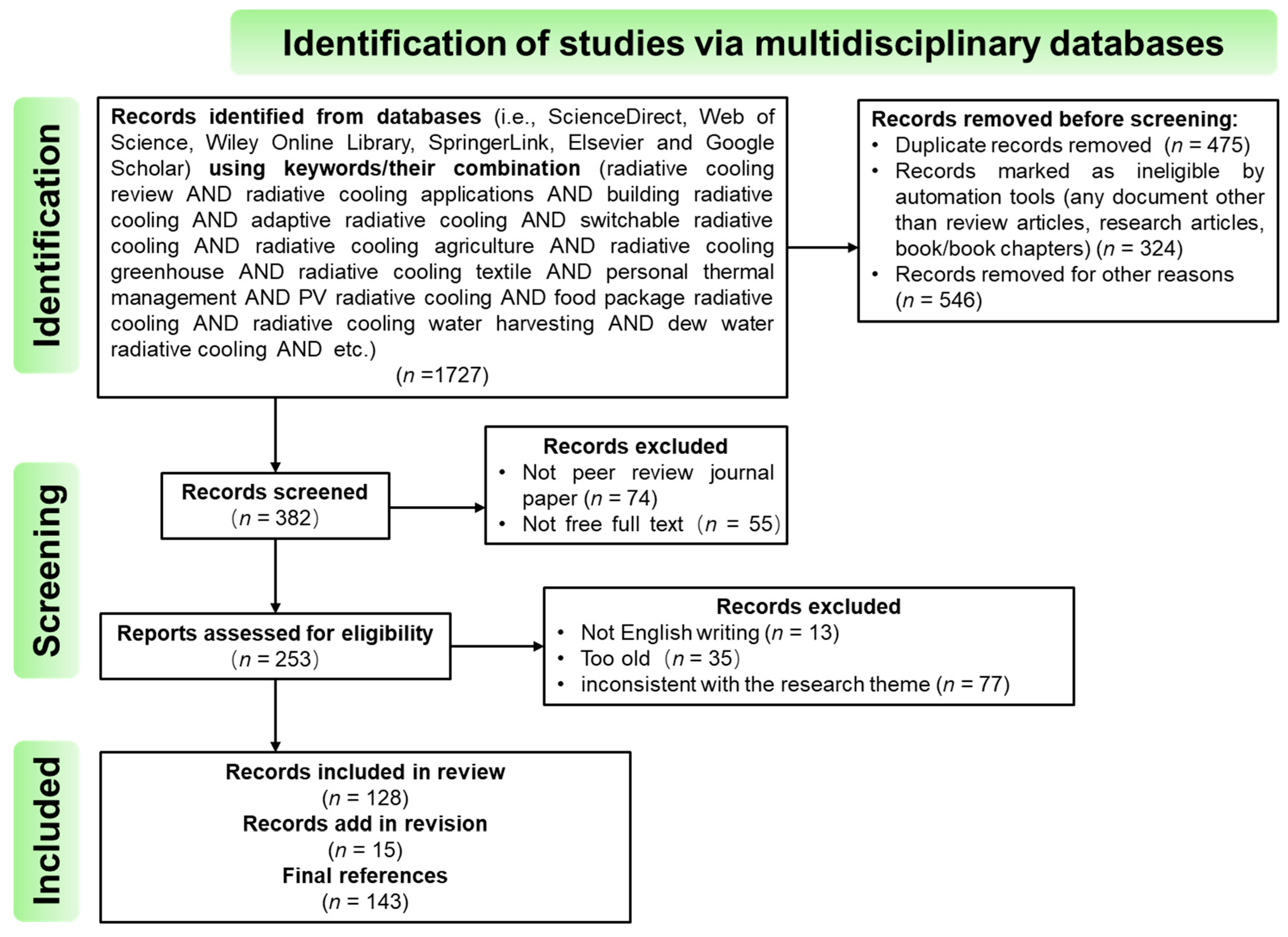

2. Methodological Approaches

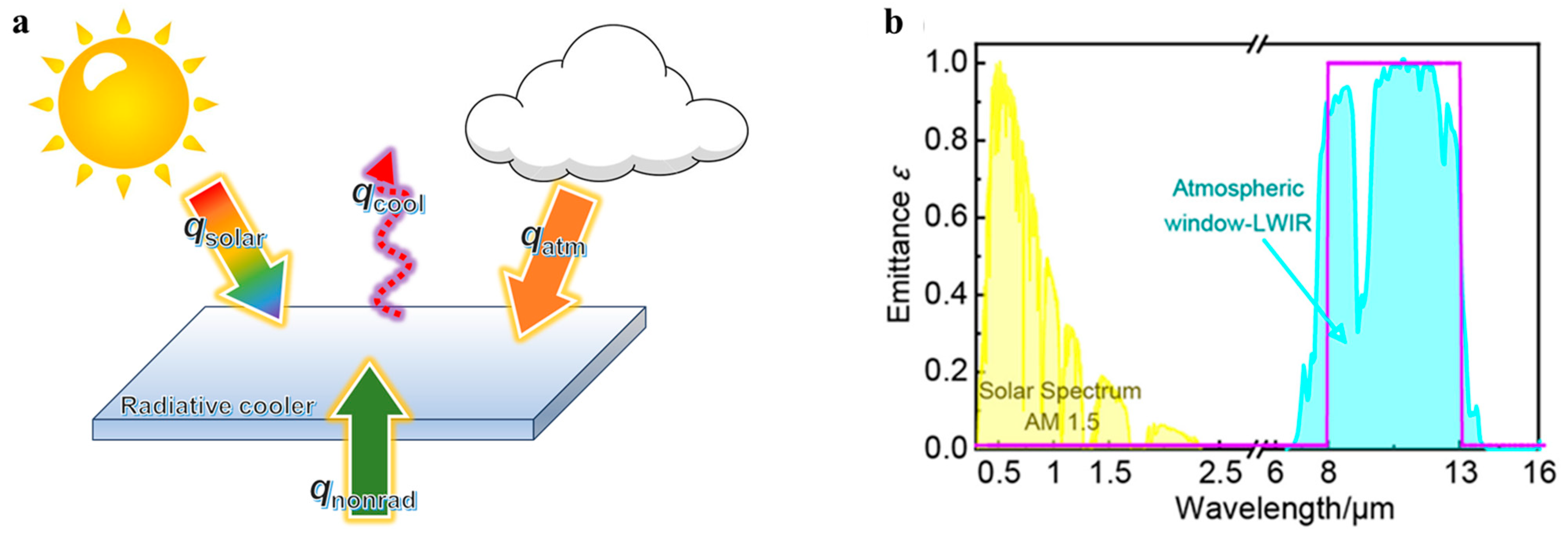

3. Fundamentals of Passive Radiative Cooling

4. Promising Applications of Passive Radiative Cooling

4.1. Building Cooling

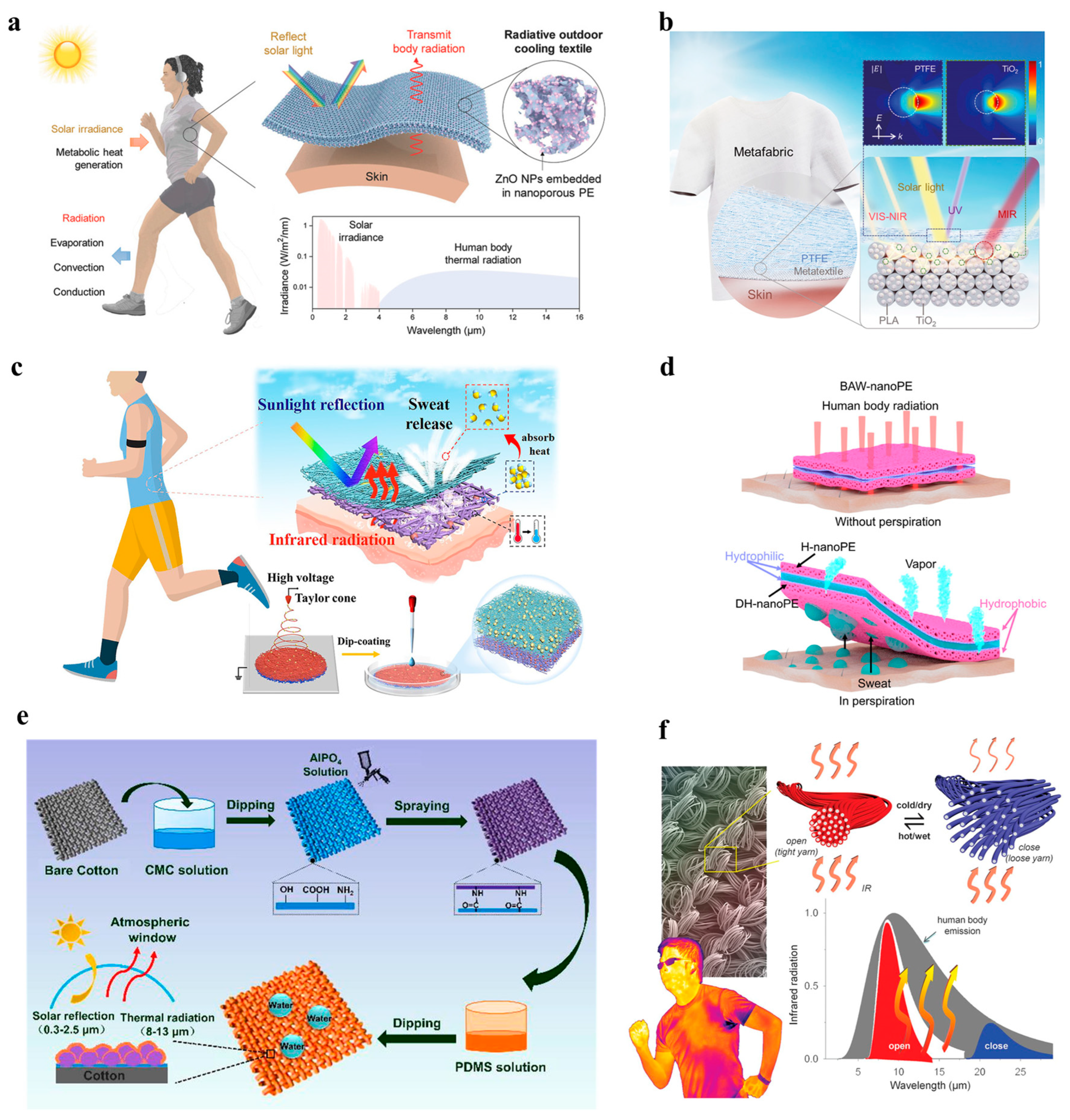

4.2. Personal Thermal Management

4.3. Other Applications

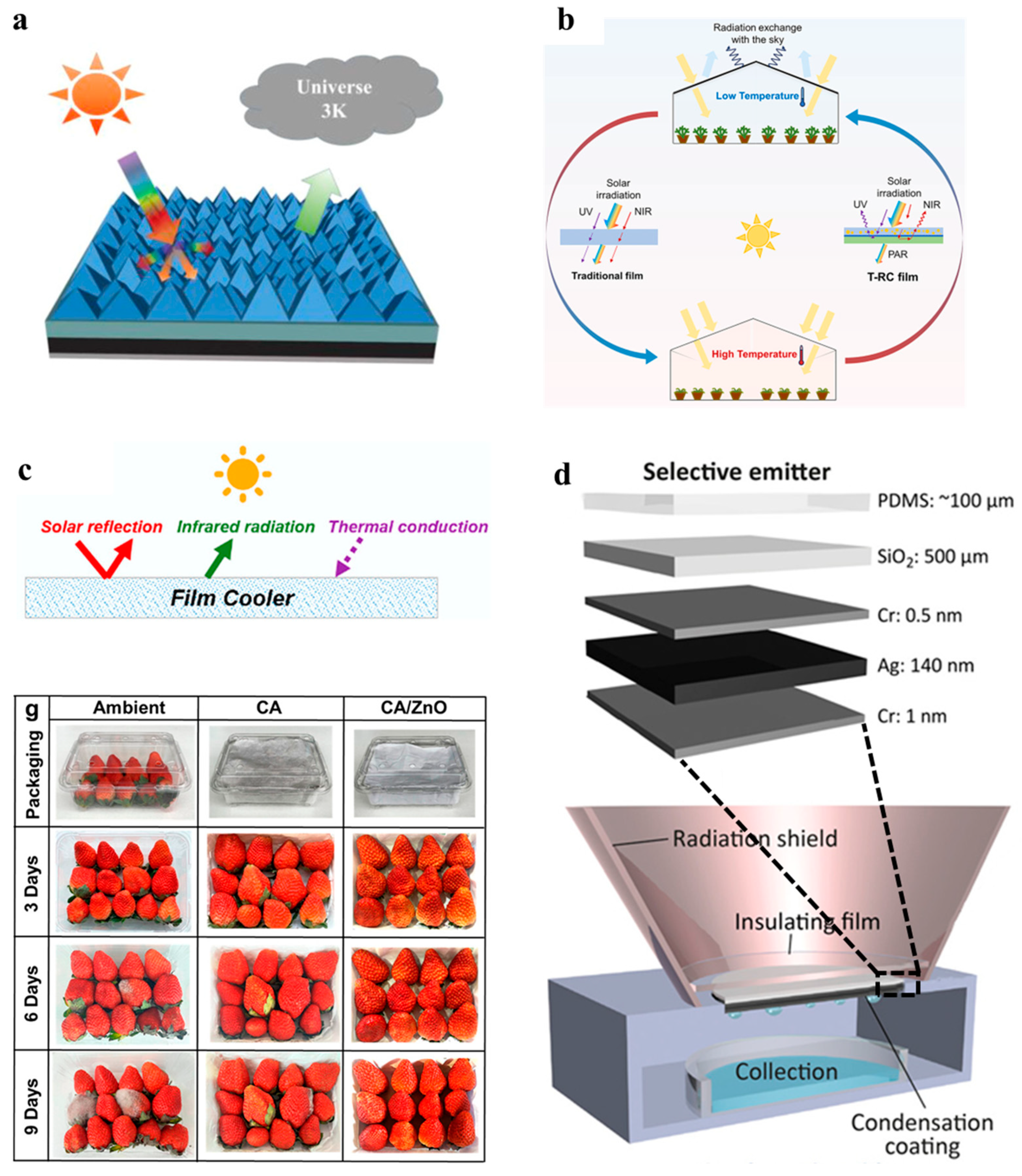

4.3.1. Photovoltaics Cooling

4.3.2. Greenhouse Temperature Regulation

4.3.3. Food Preservation and Packaging

4.3.4. Dew Water Harvesting

5. Outlook

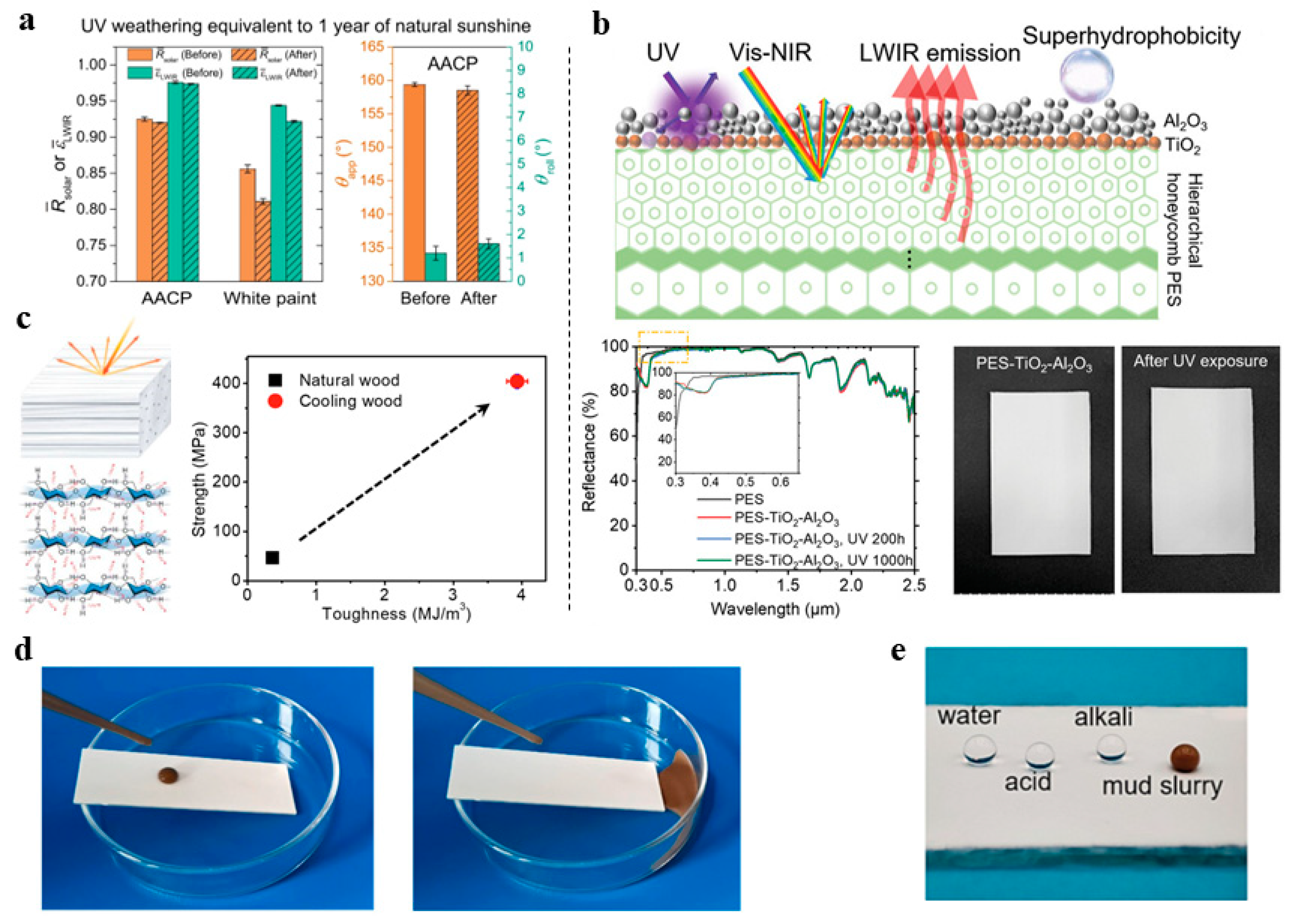

- Enhancement of Durability and Self-Cleaning Properties: The long-term performance and reliability of passive radiative coolers are contingent upon their ability to preserve their optical characteristics—specifically, high solar reflectivity and MIR emissivity—even when subjected to environmental adversities such as pollutant deposition, chemical contamination, and physical weathering. To address these challenges, nano-engineered surfaces with self-cleaning properties emerge as a promising research frontier, which could substantially mitigate degradation and maintain efficiency over prolonged outdoor deployment. Superhydrophobic surfaces, characterized by their exceptional water-repellent properties, are among the most prominent features for self-cleaning applications. Advances in material sciences have enabled the development of innovative approaches to enhance the hydrophobicity of materials. Techniques such as the application of nanoscale particle coatings such as modified silica, the construction of micro and nano-porous structures, and the modification of surface patterning, are all viable strategies that have been explored to repel liquid contaminants effectively. However, the pursuit of extreme superhydrophobicity often leads to delicate structural designs, which can compromise the durability of the material. Therefore, striking a balance between the robustness of the material and its self-cleaning efficiency is crucial. In parallel, photocatalysis-induced self-cleaning technologies offer a complementary mechanism for sustaining the cleanliness of radiative coolers. By employing photocatalytic materials such as ZnO, CdS and ZrO2, these surfaces leverage the redox potential of photocatalysts to degrade pollutants upon exposure to light. Contrary to the water-repellent approach, these technologies often capitalize on hydrophilic properties to isolate contaminants from cooler surfaces, thus achieving purification. The pursuit of these nanotechnology and advanced material science strategies demands rigorous sustainability assessments to ensure that the environmental footprint of passive radiative cooling technologies is thoroughly evaluated and minimized. Current research on the durability of radiative coolers tends to focus on mechanical resilience (such as impact, tensile, and compressive strength), UV aging, waterproofing, and dust self-cleaning capabilities. However, to propel radiative cooling technology further into mainstream applications, there is a pressing need to extend durability assessments to more extreme conditions. This includes exposure to fire, extreme temperatures, and corrosive agents such as acids and bases, which represent the next frontier for research and development in this field. The integration of self-cleaning properties into radiative coolers, while maintaining their intrinsic durability, represents a sophisticated balance of material science and engineering. As the field advances, the exploration of these novel surfaces must be accompanied by comprehensive environmental impact studies to ensure that the long-term stability and sustainability of radiative cooling technologies are not compromised as we strive for larger-scale implementation.

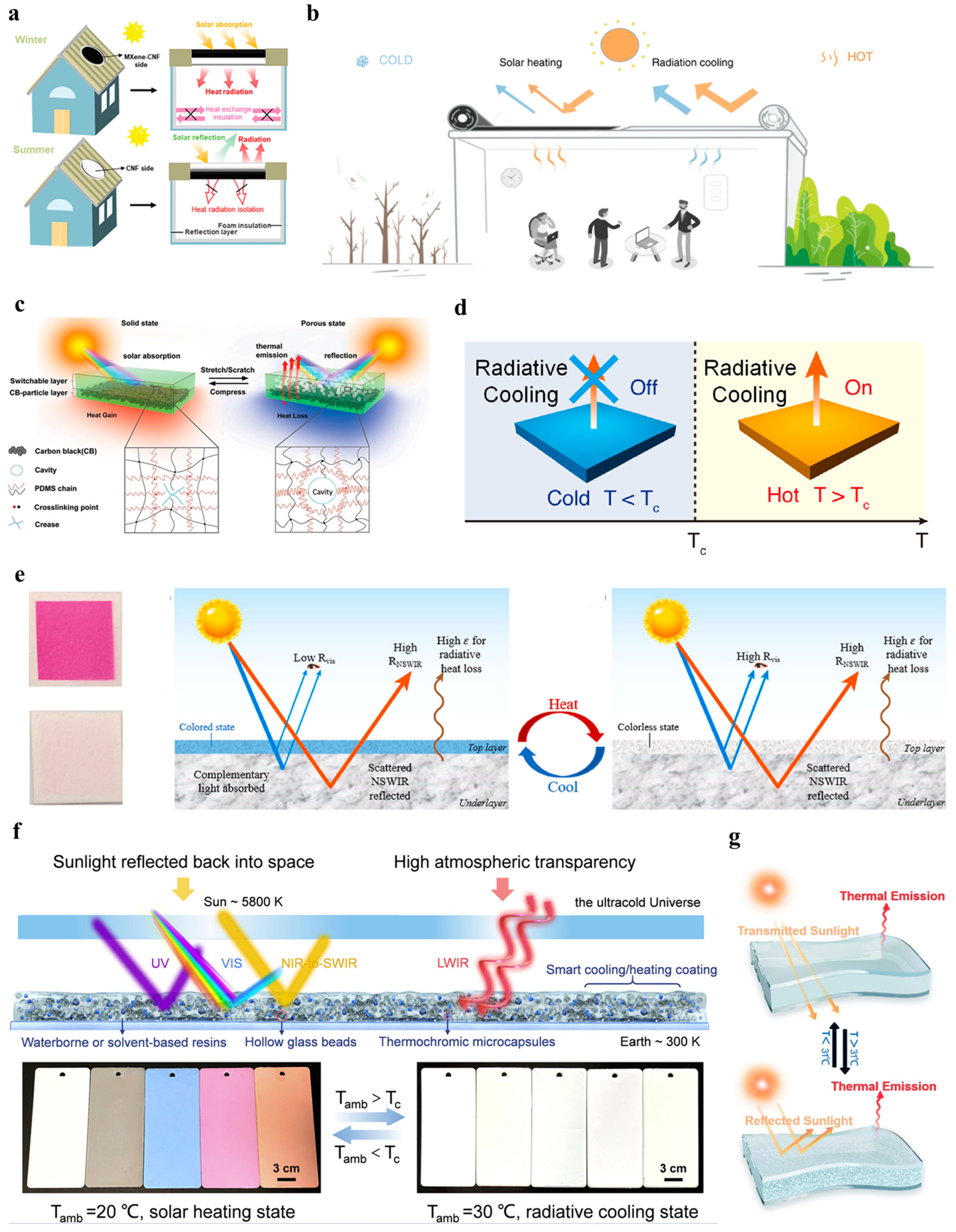

- Adaptive Cooling Power Modulation: The static nature of traditional passive radiative cooling technologies does not accommodate the dynamic cooling demand imposed by diurnal and seasonal temperature variations, nor does it account for the diverse climatic conditions across different geographical regions. The integration of adaptive mechanisms, capable of modulating radiative cooling power, is therefore a significant research frontier. Materials with tunable emissivity, such as thermochromic, shape-memory, and phase-change materials, offer promising pathways for achieving adaptive cooling capabilities. The synthesis and in-depth characterization of these materials are paramount, with a focus on tailoring their transition temperatures to align with the common temperature ranges encountered in building environments for optimal thermal control. Addressing the phenomenon of hysteresis, which is often observed in temperature-responsive materials, is crucial. This phenomenon, where the transition temperatures for activation and deactivation differ, can lead to inefficiencies in thermal regulation. Minimizing the hysteresis loop is essential for achieving more agile and precise temperature control. Furthermore, the potential of materials responding to other stimuli such as humidity and light intensity should not be overlooked, especially in applications that may benefit from such specific responsiveness. The integration of intelligent control systems is another critical component of adaptive cooling strategies. Optimizing control for standalone radiative coolers may be insufficient for the sophisticated thermal management expectations of modern urban buildings. A holistic approach to intelligent thermal management necessitates the seamless integration of these radiative coolers with conventional heating, ventilation, and air conditioning systems. Such a synergistic system would be responsive not only to ambient temperatures but also aligned with the broader energy and climate control strategies of the structure. The future of intelligent thermal management based on radiative cooling is an interdisciplinary venture that marries the advancements in material science with the complexities of control engineering.

- Scalability and Manufacturing Research: Due to breakthroughs in nanophotonics and materials science, passive radiative cooling technology has made significant strides, offering superior optical performance and cooling effects. However, it is crucial to recognize the accompanying complexity of the manufacturing process and the high production costs involved. Materials commonly used in radiative coolers to enhance infrared emission, such as Al2O3, TiO2, and SiO2, often require processing techniques that include vacuum etching, photolithography, and magnetron sputtering. These methods not only add substantial manufacturing costs but also present obstacles to scaling up production due to their intricate nature. The key to transitioning these technologies from lab-scale prototypes to widespread commercial applications lies in the innovation of scalable and cost-effective manufacturing processes. In this context, roll-to-roll (R2R) manufacturing emerges as a promising technique. R2R is a continuous production process for thin-film materials that is simpler and more cost-efficient compared to traditional methods, making it an ideal choice for the mass production of radiative coolers. A cost-effective strategy in the long run is the preparation of radiative coolers based on inorganic polymers, which can be inexpensively produced through processes such as painting, dip-coating, or spraying onto various substrates to form direct radiative cooling structures. The incorporation of the phase inversion technique is a successful practice that allows the formation of porous structures, which integrate light-scattering air voids. This technique achieves the requisite high solar reflectance for radiative cooling without introducing metal reflector layers such as aluminum or silver, thus avoiding the need for micro and nano fabrication technologies. Consequently, this reduces the overall manufacturing cost and complexity and circumvents environmental concerns associated with the use of metal substances. Additionally, developing methodologies for standardized quality control will be vital to ensure the reliability and performance of radiative coolers at scale. Addressing these manufacturing challenges is the key to enabling the commercial adoption of passive radiative cooling technologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, J.Y.; Han, D.L.; Li, Z.C.; Yang, L.; Lu, S.G.; Zhong, Z.F.; Chen, J.P.; Zhang, Q.M.; Qian, X.S. Electrocaloric Cooling Materials and Devices for Zero-Global-Warming-Potential, High-Efficiency Refrigeration. Joule 2019, 3, 1200–1225. [Google Scholar] [CrossRef]

- Kumma, N.; Kruthiventi, S.S.H. Current status of refrigerants used in domestic applications: A review. Renew. Sustain. Energy Rev. 2024, 189, 114073. [Google Scholar] [CrossRef]

- Abas, N.; Kalair, A.R.; Khan, N.; Haider, A.; Saleem, Z.; Saleem, M.S. Natural and synthetic refrigerants, global warming: A review. Renew. Sustain. Energy Rev. 2018, 90, 557–569. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int. J. Refrig.-Rev. Int. Du Froid 2016, 64, 61–79. [Google Scholar] [CrossRef]

- de Paula, C.H.; Duarte, W.M.; Rocha, T.T.M.; de Oliveira, R.N.; de Paoli Mendes, R.; Maia, A.A.T. Thermo-economic and environmental analysis of a small capacity vapor compression refrigeration system using R290, R1234yf, and R600a. Int. J. Refrig. 2020, 118, 250–260. [Google Scholar] [CrossRef]

- Hossain, M.M.; Gu, M. Radiative Cooling: Principles, Progress, and Potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef]

- Catalanotti, S.; Cuomo, V.; Piro, G.; Ruggi, D.; Silvestrini, V.; Troise, G.J.S.E. The radiative cooling of selective surfaces. Solar Energy 1975, 17, 83–89. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Hjortsberg, A. Radiative Cooling to Low-Temperatures—General-Considerations and Application to Selectively Emitting Sio Films. J. Appl. Phys. 1981, 52, 4205–4220. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Wang, S.; Wang, X.; Jiang, Y.; Li, J.; Xu, W.; Zhu, B.; Zhu, J. Recent Progress in Daytime Radiative Cooling: Advanced Material Designs and Applications. Small Methods 2022, 6, e2101379. [Google Scholar] [CrossRef] [PubMed]

- Atiganyanun, S.; Plumley, J.B.; Han, S.J.; Hsu, K.; Cytrynbaum, J.; Peng, T.L.; Han, S.M.; Han, S.E. Effective Radiative Cooling by Paint-Format Microsphere-Based Photonic Random Media. ACS Photonics 2018, 5, 1181–1187. [Google Scholar] [CrossRef]

- Chae, D.; Kim, M.; Jung, P.H.; Son, S.; Seo, J.; Liu, Y.; Lee, B.J.; Lee, H. Spectrally Selective Inorganic-Based Multilayer Emitter for Daytime Radiative Cooling. ACS Appl. Mater. Interfaces 2020, 12, 8073–8081. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, H.; Okada, K.; Jinno, K.; Ota, T. Fabrication of radiative cooling devices using Si2N2O nano-particles. J. Ceram. Soc. Jpn. 2016, 124, 1185–1187. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, L.; Raman, A.; Fan, S. Radiative cooling to deep sub-freezing temperatures through a 24-h day-night cycle. Nat. Commun. 2016, 7, 13729. [Google Scholar] [CrossRef]

- Berdahl, P. Radiative cooling with MgO and/or LiF layers. Appl. Opt. 1984, 23, 370. [Google Scholar] [CrossRef]

- Gao, W.; Lei, Z.Y.; Wu, K.; Chen, Y.P. Reconfigurable and Renewable Nano-Micro-Structured Plastics for Radiative Cooling. Adv. Funct. Mater. 2021, 31, 2100535. [Google Scholar] [CrossRef]

- Aili, A.; Wei, Z.Y.; Chen, Y.Z.; Zhao, D.L.; Yang, R.G.; Yin, X.B. Selection of polymers with functional groups for daytime radiative cooling. Mater. Today Phys. 2019, 10, 100127. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, Q.; Zhou, J.; Deng, X.; Cui, J. Switchable Cavitation in Silicone Coatings for Energy-Saving Cooling and Heating. Adv. Mater. 2020, 32, e2000870. [Google Scholar] [CrossRef]

- Wong, R.Y.M.; Tso, C.Y.; Fu, S.; Chao, C.Y.H. Maxwell-Garnett permittivity optimized micro-porous PVDF/PMMA blend for near unity thermal emission through the atmospheric window. Sol. Energy Mater. Sol. Cells 2022, 248, 112003. [Google Scholar] [CrossRef]

- Yang, X.B.; Geng, J.L.; Tan, X.Y.; Liu, M.; Yao, S.M.; Tu, Y.T.; Li, S.S.; Qiao, Y.L.; Qi, G.G.; Xu, R.Z.; et al. A flexible PDMS@ZrO film for highly efficient passive radiative cooling. Inorg. Chem. Commun. 2023, 151, 110586. [Google Scholar] [CrossRef]

- Zhai, H.T.; Fan, D.S.; Li, Q. Scalable and paint-format colored coatings for passive radiative cooling. Sol. Energy Mater. Sol. Cells 2022, 245, 111853. [Google Scholar] [CrossRef]

- Wang, T.; Wu, Y.; Shi, L.; Hu, X.; Chen, M.; Wu, L. A structural polymer for highly efficient all-day passive radiative cooling. Nat. Commun. 2021, 12, 365. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.Y.; Tso, C.Y.; Ha, J.; Wong, Y.M.; Chao, C.Y.H.; Huang, B.L.; Qiu, H.H. Field investigation of a photonic multi-layered TiO passive radiative cooler in sub-tropical climate. Renew. Energy 2020, 146, 44–55. [Google Scholar] [CrossRef]

- Harrison, A.W.; Walton, M.R. Radiative Cooling of TiO2 White Paint. Sol. Energy 1978, 20, 185–188. [Google Scholar] [CrossRef]

- Mandal, J.; Yang, Y.; Yu, N.F.; Raman, A.P. Paints as a Scalable and Effective Radiative Cooling Technology for Buildings. Joule 2020, 4, 1350–1356. [Google Scholar] [CrossRef]

- Chae, D.; Son, S.; Lim, H.; Jung, P.-H.; Ha, J.; Lee, H. Scalable and paint-format microparticle–polymer composite enabling high-performance daytime radiative cooling. Mater. Today Phys. 2021, 18, 100389. [Google Scholar] [CrossRef]

- Tong, Z.; Peoples, J.; Li, X.; Yang, X.; Bao, H.; Ruan, X. Electronic and phononic origins of BaSO as an ultra-efficient radiative cooling paint pigment. Mater. Today Phys. 2022, 24, 100658. [Google Scholar] [CrossRef]

- Li, X.; Peoples, J.; Yao, P.; Ruan, X. Ultrawhite BaSO4 Paints and Films for Remarkable Daytime Subambient Radiative Cooling. ACS Appl. Mater. Interfaces 2021, 13, 21733–21739. [Google Scholar] [CrossRef]

- Farooq, A.S.; Zhang, P.; Gao, Y.F.; Gulfam, R. Emerging radiative materials and prospective applications of radiative sky cooling—A review. Renew. Sustain. Energy Rev. 2021, 144, 110910. [Google Scholar] [CrossRef]

- Nilsson, T.M.; Niklasson, G.A.; Granqvist, C.G. A solar reflecting material for radiative cooling applications: ZnS pigmented polyethylene. Sol. Energy Mater. Sol. Cells 1992, 28, 175–193. [Google Scholar] [CrossRef]

- Huang, J.; Li, M.Z.; Fan, D.S. Core-shell particles for devising high-performance full-day radiative cooling paint. Appl. Mater. Today 2021, 25, 101209. [Google Scholar] [CrossRef]

- Lv, J.P.; Tang, M.Z.; Quan, R.H.; Chai, Z.Y. Synthesis of solar heat-reflective ZnTiO pigments with novel roof cooling effect. Ceram. Int. 2019, 45, 15768–15771. [Google Scholar] [CrossRef]

- Lim, Y.-F. Novel materials and concepts for regulating infra-red radiation: Radiative cooling and cool paint. In Energy Saving Coating Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 113–131. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Howell, J.R.; Mengüç, M.P.; Daun, K.; Siegel, R. Thermal Radiation Heat Transfer; CRC press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Zevenhoven, R.; Fält, M. Radiative cooling through the atmospheric window: A third, less intrusive geoengineering approach. Energy 2018, 152, 27–33. [Google Scholar] [CrossRef]

- Fenollosa, R.; Ramiro-Manzano, F.; Garín, M.; Alcubilla, R. Thermal Emission of Silicon at Near-Infrared Frequencies Mediated by Mie Resonances. ACS Photonics 2019, 6, 3174–3179. [Google Scholar] [CrossRef]

- Olivieri, L.; Tenorio, J.A.; Revuelta, D.; Navarro, L.; Cabeza, L.F. Developing a PCM-enhanced mortar for thermally active precast walls. Constr. Build. Mater. 2018, 181, 638–649. [Google Scholar] [CrossRef]

- Lu, X.; Xu, P.; Wang, H.L.; Yang, T.; Hou, J. Cooling potential and applications prospects of passive radiative cooling in buildings: The current state-of-the-art. Renew. Sustain. Energy Rev. 2016, 65, 1079–1097. [Google Scholar] [CrossRef]

- Mooney, C.; Dennis, B. The World Is about to Install 700 Million Air Conditioners. The Washington Post, 31 May 2016. [Google Scholar]

- Prada, M.; Prada, I.F.; Cristea, M.; Popescu, D.E.; Bungău, C.; Aleya, L.; Bungău, C.C. New solutions to reduce greenhouse gas emissions through energy efficiency of buildings of special importance–Hospitals. Sci. Total Environ. 2020, 718, 137446. [Google Scholar] [CrossRef]

- Staffell, I.; Pfenninger, S.; Johnson, N. A global model of hourly space heating and cooling demand at multiple spatial scales. Nat. Energy 2023, 8, 1328–1344. [Google Scholar] [CrossRef]

- Xu, L.; Shen, Y.; Ding, Y.; Wang, L. Superhydrophobic and Ultraviolet-Blocking Cotton Fabrics Based on TiO2/SiO2 Composite Nanoparticles. J. Nanosci. Nanotechnol. 2018, 18, 6879–6886. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Zhang, W.; Sun, Z.; Pan, M.; Tian, F.; Li, X.; Ye, M.; Deng, X. Durable radiative cooling against environmental aging. Nat. Commun. 2022, 13, 4805. [Google Scholar] [CrossRef]

- Li, M.; Lin, C.; Li, K.; Ma, W.; Dopphoopha, B.; Li, Y.; Huang, B. A UV-Reflective Organic-Inorganic Tandem Structure for Efficient and Durable Daytime Radiative Cooling in Harsh Climates. Small 2023, 19, e2301159. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Zhai, Y.; He, S.; Gan, W.; Wei, Z.; Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J.; et al. A radiative cooling structural material. Science 2019, 364, 760–763. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.D.; Xue, C.H.; Ji, Z.Y.; Huang, M.C.; Jiang, Z.H.; Liu, B.Y.; Deng, F.Q.; An, Q.F.; Guo, X.J. Superhydrophobic Porous Coating of Polymer Composite for Scalable and Durable Daytime Radiative Cooling. ACS Appl. Mater. Interfaces 2022, 14, 51307–51317. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Chen, Z.C.; Qian, C.L.; Li, Q.; Chen, X.M. Durable and mechanically robust superhydrophobic radiative cooling coating. Chem. Eng. J. 2023, 478, 147341. [Google Scholar] [CrossRef]

- Chen, Y.; Mandal, J.; Li, W.; Smith-Washington, A.; Tsai, C.C.; Huang, W.; Shrestha, S.; Yu, N.; Han, R.P.S.; Cao, A.; et al. Colored and paintable bilayer coatings with high solar-infrared reflectance for efficient cooling. Sci. Adv. 2020, 6, eaaz5413. [Google Scholar] [CrossRef]

- Tao, S.; Guan, F.Q.; Chen, F.H.; Chen, M.X.; Fang, Z.G.; Lu, C.H.; Xu, Z.Z. Construction of colorful super-omniphobic emitters for high-efficiency passive radiative cooling. Compos. Commun. 2021, 28, 100975. [Google Scholar] [CrossRef]

- Xu, J.; Wan, R.; Xu, W.; Ma, Z.; Cheng, X.; Yang, R.; Yin, X. Colored radiative cooling coatings using phosphor dyes. Mater. Today Nano 2022, 19, 100239. [Google Scholar] [CrossRef]

- Xi, W.; Liu, Y.D.; Zhao, W.X.; Hu, R.; Luo, X.B. Colored radiative cooling: How to balance color display and radiative cooling performance. Int. J. Therm. Sci. 2021, 170, 107172. [Google Scholar] [CrossRef]

- Srinivasarao, M. Nano-Optics in the Biological World: Beetles, Butterflies, Birds, and Moths. Chem. Rev. 1999, 99, 1935–1962. [Google Scholar] [CrossRef]

- Baek, K.; Kim, Y.; Mohd-Noor, S.; Hyun, J.K. Mie Resonant Structural Colors. ACS Appl. Mater. Interfaces 2020, 12, 5300–5318. [Google Scholar] [CrossRef] [PubMed]

- Yalçın, R.A.; Blandre, E.; Joulain, K.; Drévillon, J. Colored radiative cooling coatings with nanoparticles. ACS Photonics 2020, 7, 1312–1322. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Q.; Wang, Y.; Lv, Y.; Ma, R. Photonic-Structure Colored Radiative Coolers for Daytime Subambient Cooling. Nano Lett. 2022, 22, 4925–4932. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Droguet, B.; Shen, Q.; Zhang, Y.; Parton, T.G.; Shan, X.; Parker, R.M.; De Volder, M.F.L.; Deng, T.; Vignolini, S.; et al. Structurally Colored Radiative Cooling Cellulosic Films. Adv. Sci. 2022, 9, e2202061. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Xiao, P.; Li, S.; Deng, F.; Ni, F.; Zhang, C.; Gu, J.; Yang, J.; Kuo, S.W.; Geng, F. Engineering Structural Janus MXene-nanofibrils Aerogels for Season-Adaptive Radiative Thermal Regulation. Small 2023, 19, 2302509. [Google Scholar] [CrossRef]

- Li, X.; Sun, B.; Sui, C.; Nandi, A.; Fang, H.; Peng, Y.; Tan, G.; Hsu, P.C. Integration of daytime radiative cooling and solar heating for year-round energy saving in buildings. Nat. Commun. 2020, 11, 6101. [Google Scholar] [CrossRef]

- Ono, M.; Chen, K.; Li, W.; Fan, S. Self-adaptive radiative cooling based on phase change materials. Opt. Express 2018, 26, A777–A787. [Google Scholar] [CrossRef]

- Tang, K.; Dong, K.; Li, J.; Gordon, M.P.; Reichertz, F.G.; Kim, H.; Rho, Y.; Wang, Q.; Lin, C.Y.; Grigoropoulos, C.P.; et al. Temperature-adaptive radiative coating for all-season household thermal regulation. Science 2021, 374, 1504–1509. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xie, M.; An, Y.Z.; Tao, Y.J.; Sun, J.Y.; Ji, C. All-season thermal regulation with thermochromic temperature-adaptive radiative cooling coatings. Sol. Energy Mater. Sol. Cells 2022, 246, 111883. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.A.; Chen, M.; Gu, M.; Wu, L.M. Scalable and waterborne titanium-dioxide-free thermochromic coatings for self-adaptive passive radiative cooling and heating. Cell Rep. Phys. Sci. 2022, 3, 100782. [Google Scholar] [CrossRef]

- Mei, X.; Wang, T.; Chen, M.; Wu, L.M. A self-adaptive film for passive radiative cooling and solar heating regulation. J. Mater. Chem. A 2022, 10, 11092–11100. [Google Scholar] [CrossRef]

- Dastidar, S.; Alam, M.M.; Crispin, X.; Zhao, D.; Jonsson, M.P. Janus cellulose for self-adaptive solar heating and evaporative drying. Cell Rep. Phys. Sci. 2022, 3, 101196. [Google Scholar] [CrossRef]

- Du, K.K.; Li, Q.; Lyu, Y.B.; Ding, J.C.; Lu, Y.; Cheng, Z.Y.; Qiu, M. Control over emissivity of zero-static-power thermal emitters based on phase-changing material GST. Light Sci. Appl. 2017, 6, e16194. [Google Scholar] [CrossRef]

- Xu, Z.; Luo, H.; Zhu, H.; Hong, Y.; Shen, W.; Ding, J.; Kaur, S.; Ghosh, P.; Qiu, M.; Li, Q. Nonvolatile Optically Reconfigurable Radiative Metasurface with Visible Tunability for Anticounterfeiting. Nano Lett. 2021, 21, 5269–5276. [Google Scholar] [CrossRef]

- Abdollahramezani, S.; Hemmatyar, O.; Taghinejad, H.; Krasnok, A.; Kiarashinejad, Y.; Zandehshahvar, M.; Alù, A.; Adibi, A. Tunable nanophotonics enabled by chalcogenide phase-change materials. Nanophotonics 2020, 9, 1189–1241. [Google Scholar] [CrossRef]

- Tachikawa, S.; Ohnishi, A.; Okamoto, A.; Nakamura, Y. Development of a variable emittance radiator based on a perovskite manganese oxide. J. Thermophys. Heat Transf. 2003, 17, 264–268. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, D.S.; Li, Q. Flexible perovskite-based photonic stack device for adaptive thermal management. Mater. Des. 2022, 219, 110719. [Google Scholar] [CrossRef]

- Granqvist, C.G. Recent progress in thermochromics and electrochromics: A brief survey. Thin Solid Film. 2016, 614, 90–96. [Google Scholar] [CrossRef]

- An, Y.D.; Fu, Y.; Dai, J.G.; Yin, X.B.; Lei, D.Y. Switchable radiative cooling technologies for smart thermal management. Cell Rep. Phys. Sci. 2022, 3. [Google Scholar] [CrossRef]

- Zeng, S.; Pian, S.; Su, M.; Wang, Z.; Wu, M.; Liu, X.; Chen, M.; Xiang, Y.; Wu, J.; Zhang, M.; et al. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling. Science 2021, 373, 692–696. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.; Li, W.; Zhang, Q.; Li, D.; Liu, X.; Wang, Y.; Xu, N.; Wu, Z.; Li, J.; Li, X.; et al. Subambient daytime radiative cooling textile based on nanoprocessed silk. Nat. Nanotechnol. 2021, 16, 1342–1348. [Google Scholar] [CrossRef]

- Hsu, P.C.; Li, X. Photon-engineered radiative cooling textiles. Science 2020, 370, 784–785. [Google Scholar] [CrossRef]

- Steketee, J. Spectral emissivity of skin and pericardium. Phys. Med. Biol. 1973, 18, 686–694. [Google Scholar] [CrossRef]

- Cai, L.; Song, A.Y.; Li, W.; Hsu, P.C.; Lin, D.; Catrysse, P.B.; Liu, Y.; Peng, Y.; Chen, J.; Wang, H.; et al. Spectrally Selective Nanocomposite Textile for Outdoor Personal Cooling. Adv. Mater. 2018, 30, e1802152. [Google Scholar] [CrossRef]

- Cai, L.L.; Peng, Y.C.; Xu, J.W.; Zhou, C.Y.; Zhou, C.X.; Wu, P.L.; Lin, D.C.; Fan, S.H.; Cui, Y. Temperature Regulation in Colored Infrared-Transparent Polyethylene Textiles. Joule 2019, 3, 1478–1486. [Google Scholar] [CrossRef]

- Hsu, P.C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef]

- Liu, R.; Wang, X.W.; Yu, J.R.; Wang, Y.; Zhu, J.; Hu, Z.M. A Novel Approach to Design Nanoporous Polyethylene/Polyester Composite Fabric via TIPS for Human Body Cooling. Macromol. Mater. Eng. 2018, 303, 1700456. [Google Scholar] [CrossRef]

- Peng, Y.C.; Chen, J.; Song, A.Y.; Catrysse, P.B.; Hsu, P.C.; Cai, L.L.; Liu, B.F.; Zhu, Y.Y.; Zhou, G.M.; Wu, D.S.; et al. Nanoporous polyethylene microfibres for large-scale radiative cooling fabric. Nat. Sustain. 2018, 1, 105–112. [Google Scholar] [CrossRef]

- Song, Y.-N.; Lei, M.-Q.; Lei, J.; Li, Z.-M. Spectrally selective polyvinylidene fluoride textile for passive human body cooling. Mater. Today Energy 2020, 18, 100504. [Google Scholar] [CrossRef]

- Song, Y.N.; Li, Y.; Yan, D.X.; Lei, J.; Li, Z.M. Novel passive cooling composite textile for both outdoor and indoor personal thermal management. Compos. Part A-Appl. Sci. Manuf. 2020, 130, 105738. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Shao, Z.; Li, Y.; Su, Y.; Zhang, Q.; Hou, C.; Wang, H. A Moisture-Wicking Passive Radiative Cooling Hierarchical Metafabric. ACS Nano 2022, 16, 2188–2197. [Google Scholar] [CrossRef] [PubMed]

- Alberghini, M.; Hong, S.; Lozano, L.M.; Korolovych, V.; Huang, Y.; Signorato, F.; Zandavi, S.H.; Fucetola, C.; Uluturk, I.; Tolstorukov, M.Y.; et al. Sustainable polyethylene fabrics with engineered moisture transport for passive cooling. Nat. Sustain. 2021, 4, 715–724. [Google Scholar] [CrossRef]

- Hu, R.; Wang, N.; Hou, L.; Liu, J.; Cui, Z.; Zhang, C.; Zhao, Y. Bilayer Nanoporous Polyethylene Membrane with Anisotropic Wettability for Rapid Water Transportation/Evaporation and Radiative Cooling. ACS Appl. Mater. Interfaces 2022, 14, 9833–9843. [Google Scholar] [CrossRef] [PubMed]

- Zhong, S.J.; Yi, L.M.; Zhang, J.W.; Xu, T.Q.; Xu, L.; Zhang, X.; Zuo, T.; Cai, Y. Self-cleaning and spectrally selective coating on cotton fabric for passive daytime radiative cooling. Chem. Eng. J. 2021, 407, 127104. [Google Scholar] [CrossRef]

- Cui, C.F.; Lu, J.; Zhang, S.Q.; Su, J.J.; Han, J. Hierarchical-porous coating coupled with textile for passive daytime radiative cooling and self-cleaning. Sol. Energy Mater. Sol. Cells 2022, 247, 111954. [Google Scholar] [CrossRef]

- Hsu, P.C.; Liu, C.; Song, A.Y.; Zhang, Z.; Peng, Y.; Xie, J.; Liu, K.; Wu, C.L.; Catrysse, P.B.; Cai, L.; et al. A dual-mode textile for human body radiative heating and cooling. Sci. Adv. 2017, 3, e1700895. [Google Scholar] [CrossRef]

- Abebe, M.G.; De Corte, A.; Rosolen, G.; Maes, B. Janus-Yarn Fabric for Dual-Mode Radiative Heat Management. Phys. Rev. Appl. 2021, 16, 054013. [Google Scholar] [CrossRef]

- Zhang, X.A.; Yu, S.; Xu, B.; Li, M.; Peng, Z.; Wang, Y.; Deng, S.; Wu, X.; Wu, Z.; Ouyang, M.; et al. Dynamic gating of infrared radiation in a textile. Science 2019, 363, 619–623. [Google Scholar] [CrossRef]

- Catrysse, P.B.; Fan, S. Radiative cooling textiles using industry-standard particle-free nonporous micro-structured fibers. Nanophotonics 2024, 13, 649–657. [Google Scholar] [CrossRef]

- Xu, P.; Xiang, B.; Zhong, W.; Wu, Y.; Zhang, Y.; Chang, Y.; Lei, W.; Zhang, R. Biodegradable, scalable and flexible fiber membrane for green passive radiative cooling. Sol. Energy Mater. Sol. Cells 2023, 253, 112209. [Google Scholar] [CrossRef]

- Chen, C.; Jia, X.; Li, X.; Shi, M.; Hu, J.; Song, M.; Wu, S.; Dai, H.; Wang, X.; Geng, H. Scalable wet-spinning of wearable chitosan-silica textile for all-day radiative cooling. Chem. Eng. J. 2023, 475, 146307. [Google Scholar] [CrossRef]

- Craiut, L.; Bungau, C.; Bungau, T.; Grava, C.; Otrisal, P.; Radu, A.-F. Technology Transfer, Sustainability, and Development, Worldwide and in Romania. Sustainability 2022, 14, 15728. [Google Scholar] [CrossRef]

- Trapani, K.; Millar, D.L.; Smith, H.C.M. Novel offshore application of photovoltaics in comparison to conventional marine renewable energy technologies. Renew. Energy 2013, 50, 879–888. [Google Scholar] [CrossRef]

- Menke, S.M.; Ran, N.A.; Bazan, G.C.; Friend, R.H. Understanding Energy Loss in Organic Solar Cells: Toward a New Efficiency Regime. Joule 2018, 2, 25–35. [Google Scholar] [CrossRef]

- Otth, D.H.; Ross, R. Assessing Photovoltaic Module Degradation and Lifetime from Long Term Environmental Tests. In Proceedings of the 29th Institute of Environmental Sciences Technical Meeting, Los Angeles, CA, USA, 19–21 April 1983; pp. 121–126. [Google Scholar]

- Radziemska, E. The effect of temperature on the power drop in crystalline silicon solar cells. Renew. Energy 2003, 28, 1–12. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Solar Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Xuan, Q.; Pei, G. Comprehensive photonic approach for diurnal photovoltaic and nocturnal radiative cooling. Sol. Energy Mater. Sol. Cells 2018, 178, 266–272. [Google Scholar] [CrossRef]

- Smestad, G.P.; Krebs, F.C.; Lampert, C.M.; Granqvist, C.G.; Chopra, K.; Mathew, X.; Takakura, H. Reporting Solar Cell Efficiencies in Solar Energy Materials and Solar Cells; Elsevier: Amsterdam, The Netherlands, 2008; Volume 92, pp. 371–373. [Google Scholar]

- Gentle, A.; Smith, G. Is enhanced radiative cooling of solar cell modules worth pursuing? Sol. Energy Mater. Sol. Cells 2016, 150, 39–42. [Google Scholar] [CrossRef]

- Zhu, L.X.; Raman, A.; Wang, K.X.; Abou Anoma, M.; Fan, S.H. Radiative cooling of solar cells. Optica 2014, 1, 32–38. [Google Scholar] [CrossRef]

- Lu, Y.H.; Chen, Z.C.; Ai, L.; Zhang, X.P.; Zhang, J.; Li, J.; Wang, W.Y.; Tan, R.Q.; Dai, N.; Song, W.J. A Universal Route to Realize Radiative Cooling and Light Management in Photovoltaic Modules. Solar Rrl 2017, 1, 1700084. [Google Scholar] [CrossRef]

- Lee, E.; Luo, T.F. Black body-like radiative cooling for flexible thin-film solar cells. Sol. Energy Mater. Sol. Cells 2019, 194, 222–228. [Google Scholar] [CrossRef]

- Zhou, Y.; Jia, C.; Lu, K.; Wang, C.; Ma, L.; Liu, L. Energy-efficient colorful silicon photovoltaic modules driven by transparent-colored radiative cooling. Sol. Energy Mater. Sol. Cells 2023, 259, 112459. [Google Scholar] [CrossRef]

- Coelho, J.P.; Oliveira, P.B.D.; Cunha, J.B. Greenhouse air temperature predictive control using the particle swarm optimisation algorithm. Comput. Electron. Agric. 2005, 49, 330–344. [Google Scholar] [CrossRef]

- Aznar-Sanchez, J.A.; Velasco-Munoz, J.F.; Lopez-Felices, B.; Roman-Sanchez, I.M. An Analysis of Global Research Trends on Greenhouse Technology: Towards a Sustainable Agriculture. Int. J. Environ. Res. Public Health 2020, 17, 664. [Google Scholar] [CrossRef] [PubMed]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Wang, S.C.; Zhang, J.; Liu, L.; Yang, F.; Zhang, Y.H. Evaluation of cooling property of high density polyethylene (HDPE)/titanium dioxide (TiO) composites after accelerated ultraviolet (UV) irradiation. Sol. Energy Mater. Sol. Cells 2015, 143, 120–127. [Google Scholar] [CrossRef]

- Liu, C.H.; Ay, C.; Tsai, C.Y.; Lee, M.T. The Application of Passive Radiative Cooling in Greenhouses. Sustainability 2019, 11, 6703. [Google Scholar] [CrossRef]

- Zou, H.; Wang, C.X.; Yu, J.Q.; Huang, D.F.; Yang, R.G.; Wang, R.Z. Eliminating greenhouse heat stress with transparent radiative cooling film. Cell Rep. Phys. Sci. 2023, 4. [Google Scholar] [CrossRef]

- Tassou, S.A.; De-Lille, G.; Ge, Y.T. Food transport refrigeration—Approaches to reduce energy consumption and environmental impacts of road transport. Appl. Therm. Eng. 2009, 29, 1467–1477. [Google Scholar] [CrossRef]

- Gemili, S.; Yemenicioglu, A.; Altinkaya, S.A. Development of cellulose acetate based antimicrobial food packaging materials for controlled release of lysozyme. J. Food Eng. 2009, 90, 453–462. [Google Scholar] [CrossRef]

- Marrez, D.A.; Abdelhamid, A.E.; Darwesh, O.M. Eco-friendly cellulose acetate green synthesized silver nano-composite as antibacterial packaging system for food safety. Food Packag. Shelf Life 2019, 20, 100302. [Google Scholar] [CrossRef]

- Gouvêa, D.M.; Mendonça, R.C.S.; Soto, M.L.; Cruz, R.S. Acetate cellulose film with bacteriophages for potential antimicrobial use in food packaging. LWT-Food Sci. Technol. 2015, 63, 85–91. [Google Scholar] [CrossRef]

- Li, J.; Liang, Y.; Li, W.; Xu, N.; Zhu, B.; Wu, Z.; Wang, X.; Fan, S.; Wang, M.; Zhu, J. Protecting ice from melting under sunlight via radiative cooling. Sci. Adv. 2022, 8, eabj9756. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Mo, C.Q.; Tang, X.L.; Lei, X.J. Hierarchically Porous Cellulose-Based Radiative Cooler for Zero-Energy Food Preservation. Acs Sustain. Chem. Eng. 2023, 11, 7745–7754. [Google Scholar] [CrossRef]

- Chen, Y.N.; Wang, Z.Y.; Dai, Y.T.; Yang, D.Y.; Qiu, F.X.; Li, Y.Q.; Zhang, T. Green Food Packaging with Integrated Functions of High-Efficiency Radiation Cooling and Freshness Monitoring. ACS Sustain. Chem. Eng. 2023, 11, 15135–15145. [Google Scholar] [CrossRef]

- Mishra, R.K. Fresh water availability and its global challenge. Br. J. Multidiscip. Adv. Stud. 2023, 4, 1–78. [Google Scholar] [CrossRef]

- Ng, K.C.; Thu, K.; Kim, Y.; Chakraborty, A.; Amy, G. Adsorption desalination: An emerging low-cost thermal desalination method. Desalination 2013, 308, 161–179. [Google Scholar] [CrossRef]

- Linares, R.V.; Li, Z.Y.; Abu-Ghdaib, M.; Wei, C.H.; Amy, G.; Vrouwenvelder, J.S. Water harvesting from municipal wastewater via osmotic gradient: An evaluation of process performance. J. Membr. Sci. 2013, 447, 50–56. [Google Scholar] [CrossRef]

- Ghermandi, A.; Messalem, R. Solar-driven desalination with reverse osmosis: The state of the art. Desalin. Water Treat. 2009, 7, 285–296. [Google Scholar] [CrossRef]

- Tareemi, A.A.; Sharshir, S.W. A state-of-art overview of multi-stage flash desalination and water treatment: Principles, challenges, and heat recovery in hybrid systems. Sol. Energy 2023, 266, 112157. [Google Scholar] [CrossRef]

- Khoshrou, I.; Nasr, M.R.J.; Bakhtari, K. New opportunities in mass and energy consumption of the Multi-Stage Flash Distillation type of brackish water desalination process. Sol. Energy 2017, 153, 115–125. [Google Scholar] [CrossRef]

- El-Dessouky, H.T.; Ettouney, H.M.; Al-Roumi, Y. Multi-stage flash desalination: Present and future outlook. Chem. Eng. J. 1999, 73, 173–190. [Google Scholar] [CrossRef]

- Khan, M.A.; Ngo, H.H.; Guo, W.; Liu, Y.; Chang, S.W.; Nguyen, D.D.; Nghiem, L.D.; Liang, H. Can membrane bioreactor be a smart option for water treatment? Bioresour. Technol. Rep. 2018, 4, 80–87. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.R.; Comas, J.; Rodriguez-Roda, I.; Le-Clech, P. Efficiently combining water reuse and desalination through forward osmosis—Reverse osmosis (FO-RO) hybrids: A critical review. Membranes 2016, 6, 37. [Google Scholar] [CrossRef]

- Holloway, R.W.; Achilli, A.; Cath, T.Y. The osmotic membrane bioreactor: A critical review. Environ. Sci. -Water Res. Technol. 2015, 1, 581–605. [Google Scholar] [CrossRef]

- Tu, Y.D.; Wang, R.Z.; Zhang, Y.N.; Wang, J.Y. Progress and Expectation of Atmospheric Water Harvesting. Joule 2018, 2, 1452–1475. [Google Scholar] [CrossRef]

- Ejeian, M.; Wang, R.Z. Adsorption-based atmospheric water harvesting. Joule 2021, 5, 1678–1703. [Google Scholar] [CrossRef]

- Bengtsson, L. The global atmospheric water cycle. Environ. Res. Lett. 2010, 5, 025202. [Google Scholar] [CrossRef]

- Wahlgren, R.V. Atmospheric water vapour processor designs for potable water production: A review. Water Res. 2001, 35, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Song, H.; Xu, X.; Shahsafi, A.; Qu, Y.; Xia, Z.; Ma, Z.; Kats, M.A.; Zhu, J.; Ooi, B.S.; et al. Vapor condensation with daytime radiative cooling. Proc.Natl. Acad. Sci. USA 2021, 118, e2019292118. [Google Scholar] [CrossRef]

- Haechler, I.; Park, H.; Schnoering, G.; Gulich, T.; Rohner, M.; Tripathy, A.; Milionis, A.; Schutzius, T.M.; Poulikakos, D. Exploiting radiative cooling for uninterrupted 24-hour water harvesting from the atmosphere. Sci. Adv. 2021, 7, eabf3978. [Google Scholar] [CrossRef]

- Xi, Z.; Li, S.; Yu, L.; Yan, H.; Chen, M. All-Day Freshwater Harvesting by Selective Solar Absorption and Radiative Cooling. ACS Appl. Mater. Interfaces 2022, 14, 26255–26263. [Google Scholar] [CrossRef]

- Li, Y.; Lin, C.; Huang, J.; Chi, C.; Huang, B. Spectrally Selective Absorbers/Emitters for Solar Steam Generation and Radiative Cooling-Enabled Atmospheric Water Harvesting. Glob. Chall. 2021, 5, 2000058. [Google Scholar] [CrossRef]

- Chen, Z.; Dong, M.; Wang, C. Passive interfacial photothermal evaporation and sky radiative cooling assisted all-day freshwater harvesting: System design, experiment study, and performance evaluation. Appl. Energy 2024, 355, 122254. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, J.; Fu, B.; Song, C.; Shang, W.; Tao, P.; Deng, T. All-Day Freshwater Harvesting through Combined Solar-Driven Interfacial Desalination and Passive Radiative Cooling. ACS Appl. Mater. Interfaces 2020, 12, 47612–47622. [Google Scholar] [CrossRef] [PubMed]

- Trosseille, J.; Mongruel, A.; Royon, L.; Beysens, D. Effective substrate emissivity during dew water condensation. Int. J. Heat Mass Transf. 2022, 183, 122078. [Google Scholar] [CrossRef]

- Yang, R.; Wang, M.; Du, M.; Wang, X.; Tang, G. Droplet effect on the infrared transmittance of radiative cooler for direct water condensation. Sol. Energy Mater. Sol. Cells 2022, 238, 111615. [Google Scholar] [CrossRef]

- Huang, M.; Tang, G.; Ren, X.; Sun, Q.; Du, M. Effects of microstructure and moisture content on the radiative properties of porous films for radiative cooling. Sol. Energy 2023, 262, 111855. [Google Scholar] [CrossRef]

| Literature | Key Materials | Location | Cooling Power | Temperature Drop |

|---|---|---|---|---|

| Raman et al. [9] | HfO2, SiO2 | Stanford, CA, USA | 40.1 W/m2 | 4.9 °C |

| Atiganyanun et al. [11] | SiO2 | Albuquerque, NM, USA | - | 4.7 °C |

| Chae et al. [12] | Al2O3, Si3N4, and SiO2 | Seoul, South Korea | >60 W/m2 | 8.2 °C |

| Chen et al. [14] | Si3N4, Si, Al | Stanford, CA, USA | - | 37.4 °C (in winter) |

| Gao et al. [16] | PMAA | - | - | 7.5 °C |

| Aili et al. [17] | PVDF, Ag | Boulder, CO, USA | - | 6 °C (nighttime) 9 °C (daytime) |

| Zhai et al. [20] | PMDS, ZrO2 | Wuhan, Hubei, China | - | 16.1 °C |

| Jeong T et al. [23] | TiO2, SiO2 | Hong Kong, China | 136.3 W/m2 | 7.2 °C |

| Chae al. [26] | Al2O3, SiO2 | Seoul, South Korea | 100 W/m2 | 7.9 °C |

| Li et al. [28] | BaSO4, Si | West Lafayette, IN, USA | 117 W/m2 | >4.5 °C |

| Huang et al. [31] | ZnO, SiO2 | Nanjing, Jiangsu, China | - | 5.3 °C (nighttime) 4.1 °C (daytime) |

| Lv et al. [32] | ZnTiO3 | Riverside, CA, USA | - | 14.9 °C |

| Literature | Stimulation Mechanism | Structure/Materials | Control Performance |

|---|---|---|---|

| Yang et al. [58] | Active | Janus-structured bilayer Aerogel, MXene-CNF | αsolar changes from ~97.5% to ~12% |

| Li et al. [59] | Active | Rollable structure powered by electricity Polyimide, PDMS, CuO, Ag | Hot state: 71.6 W/m2 cooling; Cold state: 643.4 W/m2 heating |

| Zhao et al. [18] | Active | Porous bilayer film PDMS, Silicone | Heating mode: αsolar = 95%; Cooling mode: Rsolar = 93% |

| Fan et al. [60] | Passive | Planar photonic multilayer system VO2 | Cooling “off” state: ~0 °C temperature drop; Cooling “on” state: ~9 °C temperature drop |

| Tang et al. [61] | Passive | Mechanically flexible coating structure VO2 doped with tungsten WxV1-xO2 | ε changes from 0.20 (when Tamb < 15 °C) to 0.90 (when Tamb > 30 °C) |

| Wang J et al. [62] | Passive | Bilayer coating bottom layer: P(VdF-HFP) top layer: thermochromic microcapsule | Rsolar changes from 91.25% to 72.71% |

| Wang T et al. [63] | Passive | Reversible thermochromic chameleon microcapsules | Modulation capacity of ΔTcooling-heating = 9.5 °C |

| Xue et. al. [64] | Passive | Sandwich structure PNIPAm, PVDF | Modulation capacity of ΔRvis = 70.0% and ΔTvis = 86.3% |

| Dastidar et al. [65] | Passive | Janus structure film Cellulose, carbon nanotube | Dry state: Rsolar = 88%; wet state: αsolar = 60% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, L.; Bai, S.; Lin, K.; Kwok, C.T.; Chen, S.; Zhu, Y.; Tso, C.Y. Advancing Sustainable Development: Broad Applications of Passive Radiative Cooling. Sustainability 2024, 16, 2346. https://doi.org/10.3390/su16062346

Liang L, Bai S, Lin K, Kwok CT, Chen S, Zhu Y, Tso CY. Advancing Sustainable Development: Broad Applications of Passive Radiative Cooling. Sustainability. 2024; 16(6):2346. https://doi.org/10.3390/su16062346

Chicago/Turabian StyleLiang, Lin, Shengxi Bai, Kaixin Lin, Chui Ting Kwok, Siru Chen, Yihao Zhu, and Chi Yan Tso. 2024. "Advancing Sustainable Development: Broad Applications of Passive Radiative Cooling" Sustainability 16, no. 6: 2346. https://doi.org/10.3390/su16062346

APA StyleLiang, L., Bai, S., Lin, K., Kwok, C. T., Chen, S., Zhu, Y., & Tso, C. Y. (2024). Advancing Sustainable Development: Broad Applications of Passive Radiative Cooling. Sustainability, 16(6), 2346. https://doi.org/10.3390/su16062346