Integrating Renewable Energy in Transportation: Challenges, Solutions, and Future Prospects on Photovoltaic Noise Barriers

Abstract

:1. Introduction

2. Characteristics of PVNBs

2.1. Performance

2.2. Materials

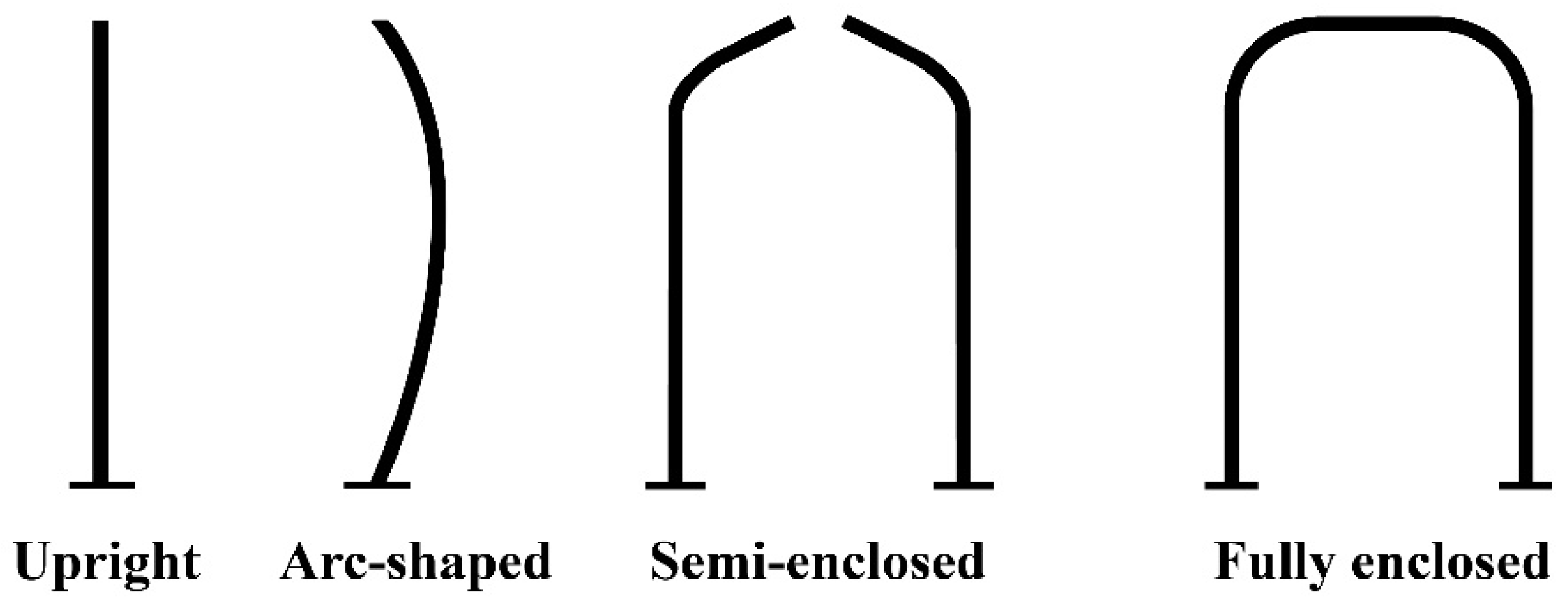

2.3. Shape

3. Research and Application Status

3.1. Research Status

3.2. Patent Status

3.3. Application Overview

4. Application Problems and Solutions

4.1. Rationality of Site Selection

4.2. Safety

4.2.1. Glare Impact

4.2.2. The Impact of Flying Debris and Vehicle Emissions

4.2.3. The Impact of Bird Strikes

4.2.4. The Construction Techniques

4.3. Noise Reduction Effect

4.4. Generation Efficiency

4.4.1. Solar Radiation Intensity

4.4.2. Wind Speed

4.4.3. Dust Contaminants

4.4.4. Shadow Occlusion

4.4.5. Position and Angle of the Photovoltaic Module Layout

4.4.6. Electricity Loss

4.4.7. Device Options

4.5. Durability

4.6. Operation and Maintenance

4.7. Departmental Collaboration

5. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Hwang, H.S.; Yun, S.; Kim, J.-C.; Lee, D. Numerical analysis on the cooling and electrical performances of photovoltaic noise barrier. Appl. Therm. Eng. 2023, 235, 121361. [Google Scholar] [CrossRef]

- Nordmann, T.; Clavadetscher, L. PV on noise barriers. Prog. Photovolt. Res. Appl. 2004, 12, 485–495. [Google Scholar] [CrossRef]

- Wadhawan, S.R.; Pearce, J.M. Power and energy potential of mass-scale photovoltaic noise barrier deployment: A case study for the U.S. Renew. Sustain. Energy Rev. 2017, 80, 125–132. [Google Scholar] [CrossRef]

- Soares, L.; Wang, H. Sustainability impact of photovoltaic noise barriers with different design configurations. Transp. Res. Part D Transp. Environ. 2023, 116, 103624. [Google Scholar] [CrossRef]

- Santhakumari, M.; Sagar, N. A review of the environmental factors degrading the performance of silicon wafer-based photovoltaic modules: Failure detection methods and essential mitigation techniques. Renew. Sustain. Energy Rev. 2019, 110, 83–100. [Google Scholar] [CrossRef]

- JT/T 646.4-2016; Highway Noise Barriers—Part 4:Technical Requirements and Examining Methods of Acoustics Materials. Ministry of Transport of the People’s Republic of China: Beijing, China, 2016.

- Ungureanu, V.-I.; Miclea, R.-C.; Korodi, A.; Silea, I. A novel approach against sun glare to enhance driver safety. Appl. Sci. 2020, 10, 3032. [Google Scholar] [CrossRef]

- Arenas, C.; Leiva, C.; Vilches, L.F.; Cifuentes, H.; Rodríguez-Galán, M. Technical specifications for highway noise barriers made of coal bottom ash-based sound absorbing concrete. Constr. Build. Mater. 2015, 95, 585–591. [Google Scholar] [CrossRef]

- Tokunaga, M.; Sogabe, M.; Santo, T.; Ono, K. Dynamic response evaluation of tall noise barrier on high speed railway structures. J. Sound Vib. 2016, 366, 293–308. [Google Scholar] [CrossRef]

- Van Renterghem, T.; Forssén, J.; Attenborough, K.; Jean, P.; Defrance, J.; Hornikx, M.; Kang, J. Using natural means to reduce surface transport noise during propagation outdoors. Appl. Acoust. 2015, 92, 86–101. [Google Scholar] [CrossRef]

- Watts, G.R.; Morgan, P.A. Acoustic performance of an interference-type noise-barrier profile. Appl. Acoust. 1996, 49, 1–16. [Google Scholar] [CrossRef]

- Cobo, P.; Simón, F. Multiple-layer microperforated panels as sound absorbers in buildings: A review. Buildings 2019, 9, 53. [Google Scholar] [CrossRef]

- Jang, E.-S. Sound absorbing properties of selected green material-A review. Forests 2023, 14, 1366. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pispola, G. Properties of transparent sound-absorbing panels for use in noise barriers. J. Acoust. Soc. Am. 2007, 121, 214–221. [Google Scholar] [CrossRef]

- Sha, Y.; Yang, K.; Chen, H. Research on acoustic properties of laminated aluminum foam panels. J. Vib. Eng. Technol. 2024, 12, 2025–2033. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, C. Study on reducing railway noise by porous concrete sound-absorbing panel. Mater. Res. Innov. 2015, 19, S5-1156–S5-1160. [Google Scholar] [CrossRef]

- Karhu, M.; Lindroos, T.; Uosukainen, S. Manufacturing and modelling of sintered micro-porous absorption material for low frequency applications. Appl. Acoust. 2014, 85, 150–160. [Google Scholar] [CrossRef]

- Sousa, L.; Pereira, L.; Montes-González, D.; Ramos, D.; Amado-Mendes, P.; Barrigón-Morillas, J.M.; Godinho, L. Experimental analysis and simulation of a porous absorbing layer for noise barriers. Appl. Sci. 2023, 13, 2638. [Google Scholar] [CrossRef]

- Hasmaden, F.; Zorer Gedik, G.; Yüğrük Akdağ, N. An approach to the design of photovoltaic noise barriers and a case study from Istanbul, Turkey. Environ. Sci. Pollut. Res. 2022, 29, 33609–33626. [Google Scholar] [CrossRef] [PubMed]

- Cueto, J.A.d.; von Roedern, B. Long-term transient and metastable effects in cadmium telluride photovoltaic modules. Prog. Photovolt. Res. Appl. 2006, 14, 615–628. [Google Scholar] [CrossRef]

- Kettle, J.; Aghaei, M.; Ahmad, S.; Fairbrother, A.; Irvine, S.; Jacobsson, J.J.; Kazim, S.; Kazukauskas, V.; Lamb, D.; Lobato, K.; et al. Review of technology specific degradation in crystalline silicon, cadmium telluride, copper indium gallium selenide, dye sensitised, organic and perovskite solar cells in photovoltaic modules: Understanding how reliability improvements in mature technologies can enhance emerging technologies. Prog. Photovolt. Res. Appl. 2022, 30, 1365–1392. [Google Scholar] [CrossRef]

- Bognár, Á.; Kusnadi, S.; Slooff, L.H.; Tzikas, C.; Loonen, R.C.G.M.; de Jong, M.M.; Hensen, J.L.M.; Debije, M.G. The solar noise barrier project 4: Modeling of full-scale luminescent solar concentrator noise barrier panels. Renew. Energy 2020, 151, 1141–1149. [Google Scholar] [CrossRef]

- Wojciechowski, K.; Forgács, D.; Rivera, T. Industrial opportunities and challenges for perovskite photovoltaic technology. Sol. RRL 2019, 3, 1900144. [Google Scholar] [CrossRef]

- Mohd. Ali, J.S.; Krishnaswamy, V. An assessment of recent multilevel inverter topologies with reduced power electronics components for renewable applications. Renew. Sustain. Energy Rev. 2018, 82, 3379–3399. [Google Scholar] [CrossRef]

- Hayibo, K.S.; Pearce, J.M. Optimal inverter and wire selection for solar photovoltaic fencing applications. Renew. Energy Focus 2022, 42, 115–128. [Google Scholar] [CrossRef]

- Rubio, C.; Candelas, P.; Belmar, F.; Gomez-Lozano, V.; Uris, A. Subwavelength slit acoustic metamaterial barrier. J. Phys. D Appl. Phys. 2015, 48, 395501. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Trematerra, A. Metamaterials acoustic barrier. Appl. Acoust. 2021, 181, 108172. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Wu, Q.; Chen, H.; Chen, J.J.; Yu, Y.K.; Tracy, S.; Huang, G.L. A Fano-based acoustic metamaterial for ultra-broadband sound barriers. Proc. R. Soc. A Math. Phys. Eng. Sci. 2021, 477, 20210024. [Google Scholar] [CrossRef]

- Poe, C.; Plovnick, A.; Hodges, T.; Hastings, A.; Dresley, S.; John, A. Highway Renewable Energy: Photovoltaic Noise Barriers; John, A., Ed.; FHWA-HEP-17-088; Volpe National Transportation Systems Center: Cambridge, MA, USA, 2017.

- Ginelli, E.; Pozzi, G. Dynamic relationship between landscape and new energy system categories. City Territ. Archit. 2018, 5, 18. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, D.; Jiang, L.; Zhang, Z.; He, S.; Gao, M. Numerical simulation on influence of noise barrier on thermal performance for natural draft wet cooling towers. Case Stud. Therm. Eng. 2021, 28, 101403. [Google Scholar] [CrossRef]

- Li, H.; Li, X.-Z.; Zheng, J. Vibration characteristics of fully enclosed sound barriers on railway bridges under the movement of trains. Adv. Civ. Eng. 2021, 2021, 2939504. [Google Scholar] [CrossRef]

- Yang, W.; Ouyang, D.; Deng, E.; He, X.; Zou, Y.; Huang, Y. Aerodynamic characteristics of two noise barriers (fully enclosed and semi-enclosed) caused by a passing train: A comparative study. J. Wind Eng. Ind. Aerodyn. 2022, 226, 105028. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, W.; Deng, E.; Wang, Y.; He, X.; Huang, Y.; Zou, Y. Aerodynamic characteristics of the train–SENB (semi-enclosed noise barrier) system: A high-speed model experiment and LES study. J. Wind Eng. Ind. Aerodyn. 2023, 232, 105251. [Google Scholar] [CrossRef]

- Laxmi, V.; Thakre, C.; Vijay, R. Evaluation of noise barriers based on geometries and materials: A review. Environ. Sci. Pollut. Res. 2022, 29, 1729–1745. [Google Scholar] [CrossRef]

- Jurevicius, D.; Evans, T. Investigation of additional insertion loss from T-profile and absorptive noise barriers. In Proceedings of the Acoustics 2015, Hunter Valley, Sydney, 15–18 November 2015; pp. 1–11. [Google Scholar]

- Zhang, X.; Ren, X.; Yang, L.; Song, G.; Wen, D.; Shi, G. Acoustic–vibration characteristics and low–structural–noise optimization design of upright sound barrier for rail transit. Int. J. Rail Transp. 2024, 1–19. [Google Scholar] [CrossRef]

- Hajek, J.J.; Blaney, C. Evaluation of T-profile highway noise barriers. Transp. Res. Rec. 1983, 983, 8–17. [Google Scholar]

- Weber, C.; Atkinson, K. A systematic approach for arriving at reasonable heights and locations for noise barriers adjacent to railway lines. In Proceedings of the Noise and Vibration Mitigation for Rail Transportation Systems, Munich, Germany, 4–8 September 2008; pp. 243–249. [Google Scholar]

- De Schepper, E.; Van Passel, S.; Manca, J.; Thewys, T. Combining photovoltaics and sound barriers—A feasibility study. Renew. Energy 2012, 46, 297–303. [Google Scholar] [CrossRef]

- Nordmann, T.; Froelich, A.; Goetzberger, A.; Kleiss, G.; Hille, G.; Reise, C.; Wiemken, E.; Van Dijk, T.; Betcke, J.; Pearsall, N. The potential of PV noise barrier technology in Europe. In Proceedings of the Sixteenth European Photovoltaic Solar Energy Conference, Glasgow, Scotland, 1–5 May 2020; pp. 2912–2916. [Google Scholar]

- Goetzberger, A.; Kleiss, G.; Castello, S.; Hille, G.; Reise, C.; Wiemken, E.; Betcke, J.; Van Dijk, V.; Pearsall, N.; Hynes, K. Evaluation of the Potential of PV Noise Barrier Technology for Electricity Production and Market Share; TNC GmbH: Freiburg, Germany, 1999. [Google Scholar]

- Hu, H.; Zha, X.; Lyu, R.; Qiu, M.; Zhong, H.; Li, Z.; Pan, Q. Recent advances of energy harvesting technologies in road based on photovoltaic power generation. Mater. Rev. 2022, 36, 133–144. [Google Scholar]

- Myong, S.Y.; Jeon, S.W. Efficient outdoor performance of esthetic bifacial a-Si:H semi-transparent PV modules. Appl. Energy 2016, 164, 312–320. [Google Scholar] [CrossRef]

- Kanellis, M.; de Jong, M.M.; Slooff, L.; Debije, M.G. The solar noise barrier project: 1. Effect of incident light orientation on the performance of a large-scale luminescent solar concentrator noise barrier. Renew. Energy 2017, 103, 647–652. [Google Scholar] [CrossRef]

- Zimmerman, R.; Panda, A.; Bulović, V. Techno-economic assessment and deployment strategies for vertically-mounted photovoltaic panels. Appl. Energy 2020, 276, 115149. [Google Scholar] [CrossRef]

- Vallati, A.; Vollaro, R.d.L.; Tallini, A.; Cedola, L. Photovoltaics noise barrier: Acoustic and energetic study. Energy Procedia 2015, 82, 716–723. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, Y.; Sun, Y.F.; Zhang, H. Development analysis of solar photovoltaic application technology in road field based on patentometrics. Transp. Res. 2022, 8, 108–119. [Google Scholar]

- Prasad, D.; Snow, M. Designing with Solar Power: A Source Book for Building Integrated Photovoltaics (BIPV), 1st ed.; Routledge: London, UK, 2005. [Google Scholar]

- Village, H.W.; Waikoloa, H. 1994 IEEE First World Conference on Photovoltaic Energy Conversion; IEEE: Waikoloa, HI, USA, 1994. [Google Scholar]

- Wei, D. Shanghai solar photovoltaic power generation urgently needs government re-assistance. China Constr. News Sunshine Energy 2008, 38–40. [Google Scholar]

- Energy, H.R. Photovoltaic Noise Barriers; Office of Natural Environment: Washington, DC, USA, 2017.

- Zheng, J.; Li, X.; Qiu, X.; Liu, D.; Zhao, S.; Qian, Y. Field study on train-induced aerodynamic pressure near the entrance of fully enclosed sound barriers. Veh. Syst. Dyn. 2023, 61, 1277–1294. [Google Scholar] [CrossRef]

- Lopez-Garcia, J.; Casado, A.; Sample, T. Electrical performance of bifacial silicon PV modules under different indoor mounting configurations affecting the rear reflected irradiance. Sol. Energy 2019, 177, 471–482. [Google Scholar] [CrossRef]

- Zdyb, A.; Żelazna, A.; Krawczak, E. Photovoltaic system integrated into the noise barrier–energy performance and life cycle assessment. J. Ecol. Eng. 2019, 20, 183–188. [Google Scholar] [CrossRef]

- Nordmann, T.; Frolich, A.; Dürr, M.; Goetzberger, A. First experience with a bifacial PV noise barrier. In Proceedings of the Sixteenth European Photovoltaic Solar Energy Conference, Glasgow, Scotland, 1–5 May 2020; pp. 1777–1782. [Google Scholar]

- Chaichan, M.T.; Kazem, H.A. Experimental analysis of solar intensity on photovoltaic in hot and humid weather conditions. Int. J. Sci. Eng. Res. 2016, 7, 91–96. [Google Scholar]

- Swider, D.J.; Beurskens, L.; Davidson, S.; Twidell, J.; Pyrko, J.; Prüggler, W.; Auer, H.; Vertin, K.; Skema, R. Conditions and costs for renewables electricity grid connection: Examples in Europe. Renew. Energy 2008, 33, 1832–1842. [Google Scholar] [CrossRef]

- González, A.; Riba, J.-R.; Rius, A.; Puig, R. Optimal sizing of a hybrid grid-connected photovoltaic and wind power system. Appl. Energy 2015, 154, 752–762. [Google Scholar] [CrossRef]

- Pillai, G.G.; Putrus, G.A.; Georgitsioti, T.; Pearsall, N.M. Near-term economic benefits from grid-connected residential PV (photovoltaic) systems. Energy 2014, 68, 832–843. [Google Scholar] [CrossRef]

- Khatib, T.; Deria, R. East-west oriented photovoltaic power systems: Model, benefits and technical evaluation. Energy Convers. Manag. 2022, 266, 115810. [Google Scholar] [CrossRef]

- Lin, S.; Zhang, J.; Ai, L.; Lu, Y.; Wang, L.; Song, W. Advances in antireflection coatings on photovoltaic glass. Mater. Rev. 2019, 33, 3588–3595. [Google Scholar]

- Law, A.M.; Kujovic, L.; Togay, M.; Greenhalgh, R.C.; Infante-Ortega, L.C.; Liu, X.; Walls, J.M. A broadband multilayer antireflection coating for thin film CdSeTe/CdTe solar cells. IEEE J. Photovolt. 2024, 14, 305–310. [Google Scholar] [CrossRef]

- Han, J.; Wan, C.; Fang, H.; Bai, Y. Development of self-floating fibre reinforced polymer composite structures for photovoltaic energy harvesting. Compos. Struct. 2020, 253, 112788. [Google Scholar] [CrossRef]

- Li, S.; Ma, T.; Wang, D. Photovoltaic pavement and solar road: A review and perspectives. Sustain. Energy Technol. Assess. 2023, 55, 102933. [Google Scholar] [CrossRef]

- Kaewpirom, S.; Kunwong, D. Curing behavior and cured film performance of easy-to-clean UV-curable coatings based on hybrid urethane acrylate oligomers. J. Polym. Res. 2012, 19, 9995. [Google Scholar] [CrossRef]

- Benemann, J.; Chehab, O.; Schaar-Gabriel, E. Building-integrated PV modules. Sol. Energy Mater. Sol. Cells 2001, 67, 345–354. [Google Scholar] [CrossRef]

- Visconti, P.; Lay-Ekuakille, A.; Primiceri, P.; Cavalera, G. Wireless energy monitoring system of photovoltaic plants with smart anti-theft solution integrated with control unit of household electrical consumption. Int. J. Smart Sens. Intell. Syst. 2016, 9, 681–708. [Google Scholar] [CrossRef]

- Bravo, T.; Maury, C. Sound attenuation and absorption by micro-perforated panels backed by anisotropic fibrous materials: Theoretical and experimental study. J. Sound Vib. 2018, 425, 189–207. [Google Scholar] [CrossRef]

- Gostein, M.; Pelaez, S.A.; Deline, C.; Habte, A.; Hansen, C.W.; Marion, B.; Newmiller, J.; Sengupta, M.; Stein, J.S.; Suez, I. Measuring Irradiance for Bifacial PV Systems. In Proceedings of the IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 0896–0903. [Google Scholar]

- Ow, L.F.; Ghosh, S. Urban cities and road traffic noise: Reduction through vegetation. Appl. Acoust. 2017, 120, 15–20. [Google Scholar] [CrossRef]

- Qiao, F.; Wang, J.; Yao, S.; Guo, K.; Xia, P. Research on the development and application of photovoltaic sound barriers. Eng. Tech. Stud. 2020, 5, 241–242. [Google Scholar]

- Liu, B.Y.H.; Jordan, R.C. The interrelationship and characteristic distribution of direct, diffuse and total solar radiation. Sol. Energy 1960, 4, 1–19. [Google Scholar] [CrossRef]

- Buni, M.J.; Al-Walie, A.A.; Al-Asadi, K.A. Effect of solar radiation on photovoltaic cell. Int. Res. J. Adv. Eng. Sci. 2018, 3, 47–51. [Google Scholar]

- Liu, L.; Wang, Q.; Lin, H.; Li, H.; Sun, Q. Power generation efficiency and prospects of floating photovoltaic systems. Energy Procedia 2017, 105, 1136–1142. [Google Scholar] [CrossRef]

- Sun, C.; Zou, Y.; Qin, C.; Zhang, B.; Wu, X. Temperature effect of photovoltaic cells: A review. Adv. Compos. Hybrid Mater. 2022, 5, 2675–2699. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, M.; Pachauri, R.K.; Dinesh Babu, K.N. Comprehensive review on effect of dust on solar photovoltaic system and mitigation techniques. Sol. Energy 2019, 191, 596–622. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.A.; Sopian, K. A review of dust accumulation and cleaning methods for solar photovoltaic systems. J. Clean. Prod. 2020, 276, 123187. [Google Scholar] [CrossRef]

- El-Shobokshy, M.S.; Hussein, F.M. Effect of dust with different physical properties on the performance of photovoltaic cells. Sol. Energy 1993, 51, 505–511. [Google Scholar] [CrossRef]

- Toth, S.; Muller, M.; Miller, D.C.; Moutinho, H.; To, B.; Micheli, L.; Linger, J.; Engtrakul, C.; Einhorn, A.; Simpson, L. Soiling and cleaning: Initial observations from 5-year photovoltaic glass coating durability study. Sol. Energy Mater. Sol. Cells 2018, 185, 375–384. [Google Scholar] [CrossRef]

- Trzmiel, G.; Głuchy, D.; Kurz, D. The impact of shading on the exploitation of photovoltaic installations. Renew. Energy 2020, 153, 480–498. [Google Scholar] [CrossRef]

- Brecl, K.; Topič, M. Self-shading losses of fixed free-standing PV arrays. Renew. Energy 2011, 36, 3211–3216. [Google Scholar] [CrossRef]

- Faturrochman, G.J.; de Jong, M.M.; Santbergen, R.; Folkerts, W.; Zeman, M.; Smets, A.H.M. Maximizing annual yield of bifacial photovoltaic noise barriers. Sol. Energy 2018, 162, 300–305. [Google Scholar] [CrossRef]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature dependent photovoltaic (PV) efficiency and its effect on PV production in the world–A review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef]

- Jin, J.X.; Wang, J.; Yang, R.H.; Zhang, T.L.; Mu, S.; Fan, Y.J.; Xing, Y.Q. A superconducting magnetic energy storage with dual functions of active filtering and power fluctuation suppression for photovoltaic microgrid. J. Energy Storage 2021, 38, 102508. [Google Scholar] [CrossRef]

- Qian, Z.; Chen, M.; Yang, Y.; Zhong, T.; Zhang, F.; Zhu, R.; Zhang, K.; Zhang, Z.; Sun, Z.; Ma, P.; et al. Vectorized dataset of roadside noise barriers in China using street view imagery. Earth Syst. Sci. Data 2022, 14, 4057–4076. [Google Scholar] [CrossRef]

- Patel, J.B.; Tiwana, P.; Seidler, N.; Morse, G.E.; Lozman, O.R.; Johnston, M.B.; Herz, L.M. Effect of ultraviolet radiation on organic photovoltaic materials and devices. ACS Appl. Mater. Interfaces 2019, 11, 21543–21551. [Google Scholar] [CrossRef]

- Lokanath, S.V.; Skarbek, B.; Schindelholz, E.J. Degradation processes and mechanisms of PV wires and connectors. In Durability and Reliability of Polymers and Other Materials in Photovoltaic Modules; Yang, H.E., French, R.H., Bruckman, L.S., Eds.; William Andrew Applied Science Publishers: Amsterdam, The Netherlands, 2019; pp. 217–233. [Google Scholar]

- Zhong, T.; Zhang, K.; Chen, M.; Wang, Y.; Zhu, R.; Zhang, Z.; Zhou, Z.; Qian, Z.; Lv, G.; Yan, J. Assessment of solar photovoltaic potentials on urban noise barriers using street-view imagery. Renew. Energy 2021, 168, 181–194. [Google Scholar] [CrossRef]

- Cerón, I.; Caamaño-Martín, E.; Neila, F.J. ‘State-of-the-art’ of building integrated photovoltaic products. Renew. Energy 2013, 58, 127–133. [Google Scholar] [CrossRef]

| Year | Location | PVNB’s Appearance in Figure 1 | Scale | Characteristics | Reference |

|---|---|---|---|---|---|

| 1989 | A13 freeway, Switzerland | (a) | The installed capacity is 100 kW, with an annual power generation of 100 MWh and a total length of 800 m. | The world’s first PVNB, featuring polycrystalline silicon photovoltaic modules tilted at a 45° angle toward the east and mounted on the upper structure of a 2 m high noise barrier. It has a total photovoltaic module area of 970 square meters and is still operational today. | [2,29] |

| 1995 | Giebenach A2 freeway, Switzerland | (b) | The installed capacity is 100 kWp, with an average power generation of 850 kWh/kWp. | The characteristic of this PVNB is that the photovoltaic modules are installed in two layers at an angle at the top and middle of the traditional noise barrier. | [2] |

| 1996 | Alpha A1 highway, Switzerland | (c) | The installed capacity is 75 kWp. | Equipped with 24 microinverters, the lower row of photovoltaic modules is shaded during the summer months. | [2] |

| 1998 | Highways near Amsterdam, Netherlands | (d) | It is 1.6 km long, generating 176,000 kWh of electricity per year. | It was the longest and largest PVNB in the Netherlands at the time. | [29] |

| 1998 | A96 highway in Munich, Germany | (e) | The installed capacity is 8.77 kWp, with an average generation of 751 kWh/kWp. | The photovoltaic modules are laid out in cassettes and equipped with a single inverter, integrating acoustic insulation and sound absorption. The module operating temperature is 40.9 ℃. | [2] |

| 1998 | A96 highway in Munich, Germany | (e) | The installed capacity is 9.13 kWp, with an average power generation of 814 kWh/kWp. | The photovoltaic modules are arranged in a tile format and equipped with a single inverter, integrating sound insulation and absorption. The module operating temperature is 43.9 °C. | [2] |

| 1998 | A96 highway in Munich, Germany | (f) | The installed capacity is 10.08 kWp, with an average generation of 794 kWh/kWp. | The photovoltaic modules are arranged in a zigzag pattern and equipped with a single inverter, serving as a sound-insulating barrier. The operating temperature of the modules is 27 °C. | [2] |

| 1997 | Aubrugg, Switzerland | (g) | The installed capacity is 8.27 kWp, with an average power generation of 681 kWh/kWp. | It is the world’s first bifacial power generation PVNB with ASE bifacial prototypes, serving as an acoustic isolation-type noise barrier. The module operating temperature is 26.5 °C. In the first two years of operation, its power generation efficiency was only 60% of what was expected. | [2,56] |

| 1999 | Wallisellen, Switzerland | (h) | The installation capacity of 9.65 kWp results in an average power generation of 497 kWh/kWp. | The photovoltaic modules are arranged in a zigzag fashion and equipped with 45 microinverters, serving as a composite sound-absorbing and sound-insulating noise barrier. The module operating temperature is 43.9 °C. It is near a railway line, but electromagnetic interference is not a problem. | [2] |

| 2000 | Wallisellen, Switzerland | - | With an installation capacity of 8.2 kWp, the average power generation is 446 kWh/kWp. | The photovoltaic modules are arranged in a vertical box layout and equipped with a single inverter, serving as a composite sound-absorbing and sound-insulating noise barrier. The module operating temperature is 34.8 °C. It was the first thin-film PVNB. | [2] |

| 2007 | Near Tullamarine Airport, Melbourne, Australia | (j) | The total length is 500 m. | A total of 210 pieces of 106 kg amorphous silicon solar panels are vertically installed on top of a 4 m high precast concrete structure. The decrease in power generation efficiency caused by the vertical installation is acceptable. There have been no security issues or thefts, and the installation is positioned high enough for drivers to notice without the effects of glare. | [29] |

| 2007 | Seoul, South Korea | - | The installed capacity is 100 kW. | By vertically installing photovoltaic modules, the noise barrier serves sound absorption, sound insulation, power generation, and landscape enhancement functions. | - |

| 2008 | North Extension of Rail Transit Line 3, Shanghai, China | - | Approximately 360 m in length, with a power output of 10 kW. | Amorphous silicon solar cell modules are used for grid-connected power generation. They are installed in a single row, with existing frames used on the top, bottom, left, and right edges. This system can generate over 6000 kWh per year, which is sufficient to meet the lighting needs along the route. | [51] |

| 2012 | A22 highway, Brennero, Italy | (k) | - | It is the world’s first large-scale project combining photovoltaics with noise barriers. | [30] |

| 2013 | Munich, Germany | (l) | The installed capacity is 7.544 MW. | The photovoltaic modules are vertically installed on the noise barrier screen to provide sound insulation and power generation. | - |

| 2017 | Seoul, South Korea | (m) | The installation scale is 30 kW, generating 30,000 kWh of electricity annually. | The PVNB screen consists of three parts: the lower part is the sound-absorbing screen, the middle part is the transparent screen, and the upper part is the photovoltaic module vertical screen. This is the typical form of a PVNB. | - |

| 2020 | Tullnerfeld, Austria | (n) | Installed on the south-facing outer side of the noise barrier along the railway line, with a total installation capacity of 30 kWp. | The photovoltaic modules are installed at three different inclinations of 0°, 15°, and 30° on the noise barrier. This photovoltaic test system also includes an independent 10 kVA 16.7 Hz inverter. | - |

| 2023 | Hongmei South Road, Shanghai, China | (o) | With a total installed capacity of 1.5 MW, the total electricity generation will exceed 37.5 million kWh over the operational lifespan. | China’s first elevated soundproof shed photovoltaic project, with lightweight flexible photovoltaic modules installed on the outer facade of the soundproof shed. It enables on-site power consumption and surplus power to be fed into the grid. | - |

| 2023 | Elevated Friendship Avenue, Wuhan, China | (p) | It is approximately 300 m in length. | Replacing the closed noise barrier facade and the top acrylic sound insulation board with double-sided photovoltaic power generation components. | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Zhang, X.; Wang, Q. Integrating Renewable Energy in Transportation: Challenges, Solutions, and Future Prospects on Photovoltaic Noise Barriers. Sustainability 2024, 16, 2358. https://doi.org/10.3390/su16062358

Wu Q, Zhang X, Wang Q. Integrating Renewable Energy in Transportation: Challenges, Solutions, and Future Prospects on Photovoltaic Noise Barriers. Sustainability. 2024; 16(6):2358. https://doi.org/10.3390/su16062358

Chicago/Turabian StyleWu, Qiong, Xiaofeng Zhang, and Qi Wang. 2024. "Integrating Renewable Energy in Transportation: Challenges, Solutions, and Future Prospects on Photovoltaic Noise Barriers" Sustainability 16, no. 6: 2358. https://doi.org/10.3390/su16062358

APA StyleWu, Q., Zhang, X., & Wang, Q. (2024). Integrating Renewable Energy in Transportation: Challenges, Solutions, and Future Prospects on Photovoltaic Noise Barriers. Sustainability, 16(6), 2358. https://doi.org/10.3390/su16062358