Development and Evaluation of Vegetable Resin Bio-Binders as Technological Alternatives to Bitumen

Abstract

1. Introduction

2. Objective of the Study

- Task 1: The development of bio-binders composed of VR in unmodified form, such as waste olive oil (no longer suitable for human consumption), and various additives such as crumb rubber from end-of-life tyres, Styrene-Butadiene-Styrene, and polyethylene waxes to investigate different oil/rosin ratios and different polymer contents;

- Task 2: Assessment of the conventional properties (penetration depth and softening point) and the rheological responses of the developed bio-binders;

- Task 3: Manufacturing a bio-asphalt mixture with two of the bio-binders studied and investigating the mechanical properties using the Marshall Stability test and the Indirect Tensile Strength test.

- Task 4: Comparison of the results to the threshold values required for road construction materials set by an Italian road agency technical specification.

3. Materials and Methods

- Vegetable resin (VR);

- Styrene-Butadiene-Styrene (SBS) polymer;

- Waste olive oil (WOO);

- Polyethylene wax (PEW);

- Crumb rubber from end-of-life tyres (CR).

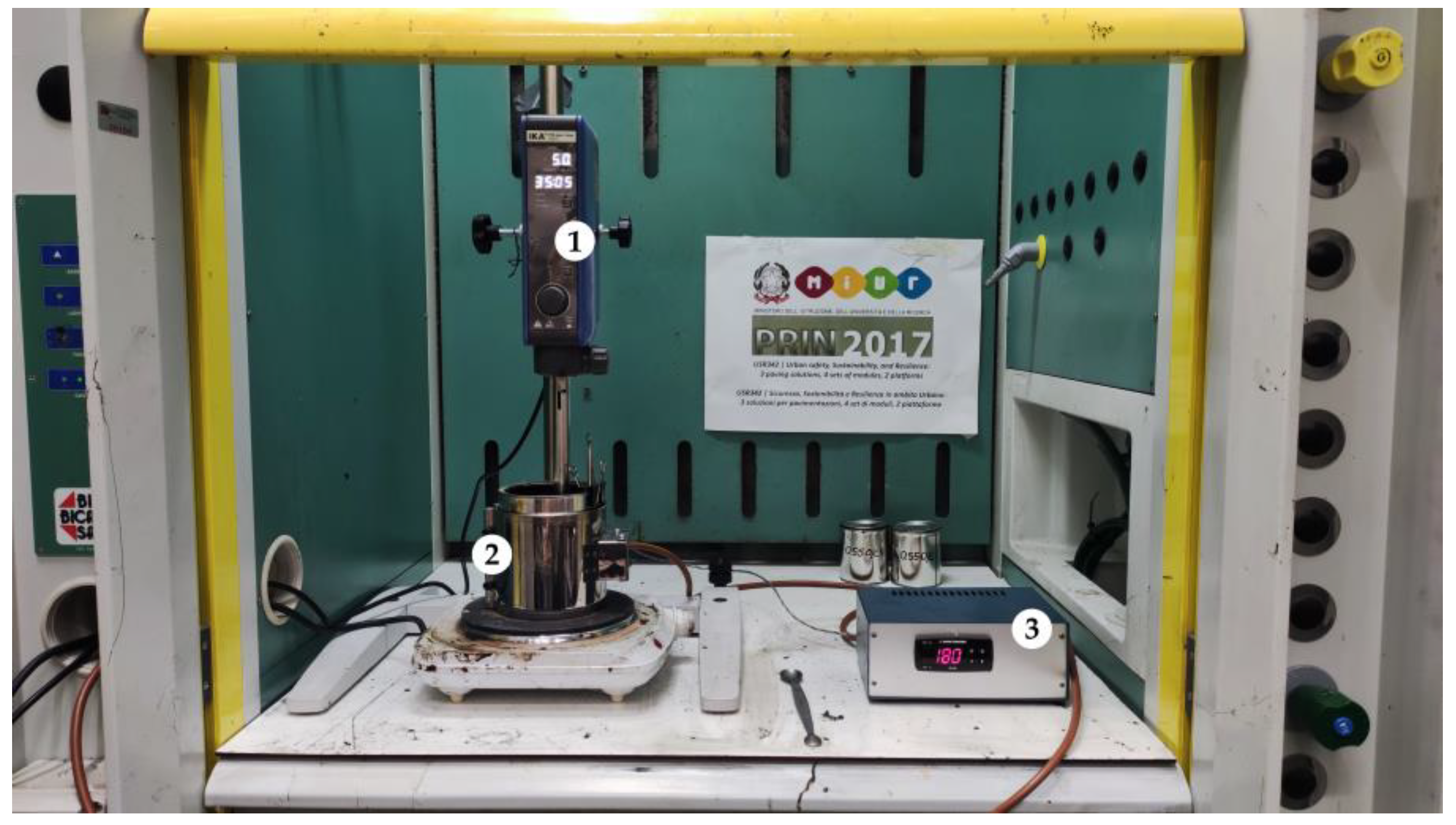

3.1. Preparation of Bio-Binders

3.2. Conventional Measurements

3.3. Rheological Analysis

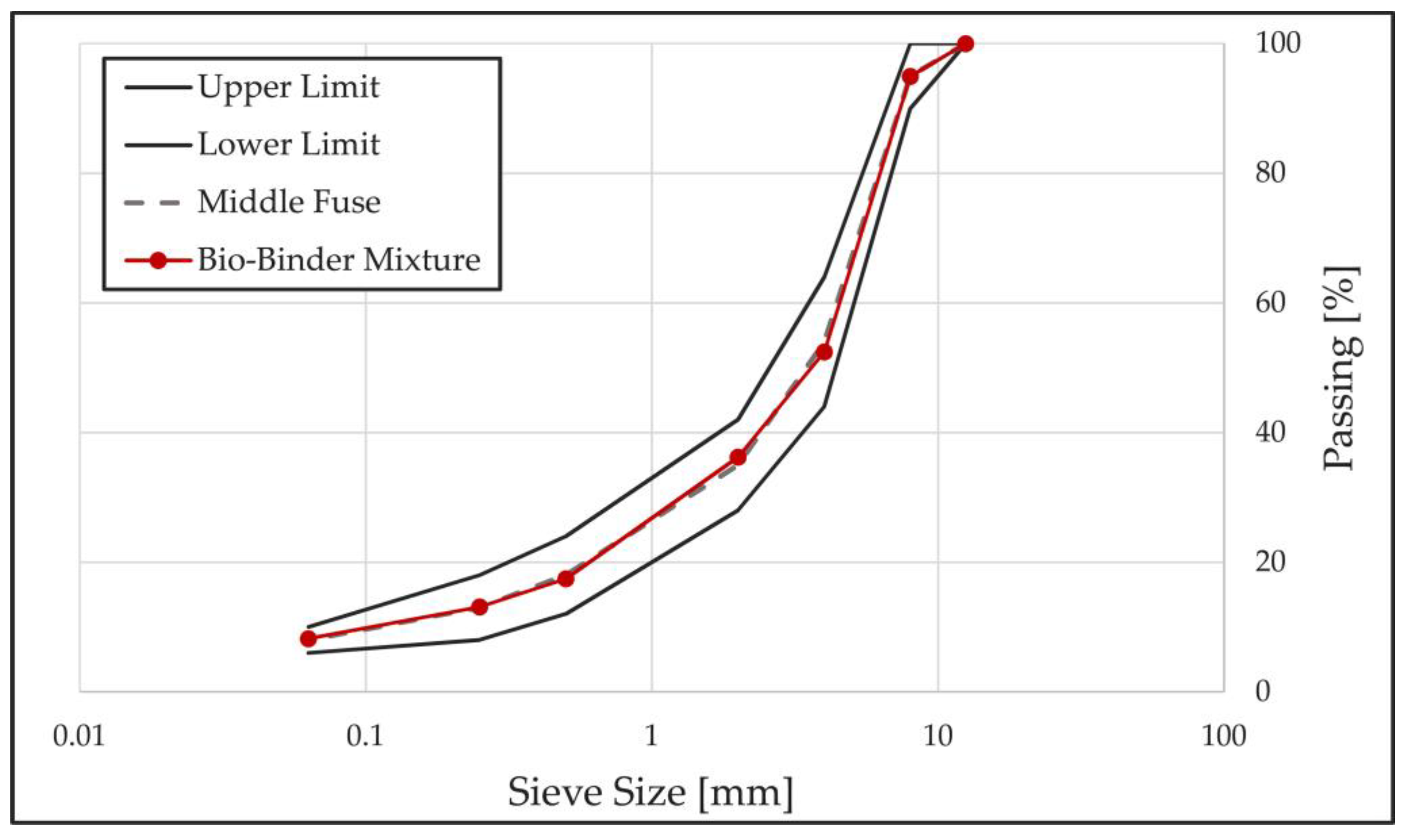

3.4. Bio-Binder Mixtures and Mechanical Analysis

4. Results and Discussion

4.1. Conventional Measurement

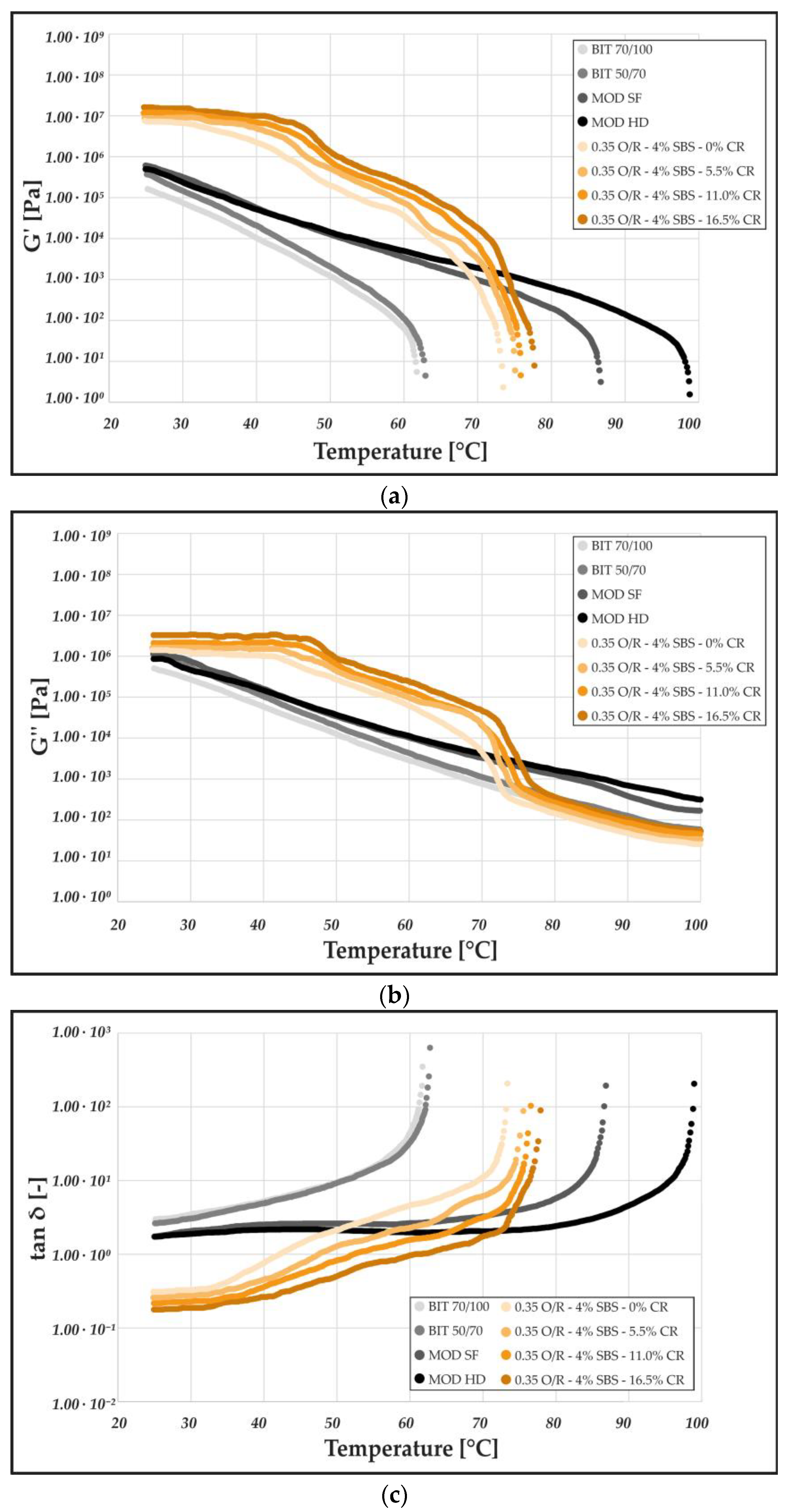

4.2. Rheological Analysis

4.3. Bio-Binder Mixtures and Mechanical Performance

5. Conclusions

- The alternative binders exhibited higher values of penetration depth and softening point in comparison to traditional bitumen.

- From a rheological perspective, the bio-binders studied exhibited a comparable behaviour to polymer-modified bitumen to some extent, as they have a transition phase shifted to higher temperatures and high moduli. However, bio-binders showed higher storage modulus at service temperature, which may affect the in-situ properties of the resultant mixtures.

- Regarding the mechanical characteristics, the results suggest that higher oil/rosin ratios (0.55 O/R) may be better suited for use as a rejuvenator for high percentages of RAP, whereas lower ratios (0.35 O/R) allow for use in traditional mixtures. Thus, the findings encourage further investigation of these alternative binders.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Secretariat General. EU Voluntary Review on Progress in the Implementation of the 2030 Agenda; European Commission: Luxembourg, 2023. [Google Scholar]

- European Commission. The European Green Deal. COM (2019) 640 Final. Available online: https://eur-lex.europa.eu/Resource.%20Html?Uri=cellar:B828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_2&format=PDF (accessed on 15 January 2024).

- European Commission. Buying Green! A Handbook on Green Public Procurement, 3rd ed.; European Commission: Brussels, Belgium, 2016; ISBN 978-92-79-57821-2. [Google Scholar]

- European Commission. Joint Research Centre. Institute for Prospective Technological Studies. Revision of Green Public Procurement Criteria for Road Design, Construction and Maintenance: Technical Report and Criteria Proposal; Publications Office: Luxembourg, 2016. [Google Scholar]

- Moura, C.; Nascimento, L.; Loureiro, C.; Rodrigues, M.; Oliveira, J.; Silva, H. Viability of Using High Amounts of Steel Slag Aggregates to Improve the Circularity and Performance of Asphalt Mixtures. Appl. Sci. 2022, 12, 490. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Waste Tyres Crumb Rubber as a Sustainability Enhancer for Polymer-Modified and Hybrid Polymer-Modified Bitumen. Int. J. Pavement Eng. 2022, 23, 4357–4371. [Google Scholar] [CrossRef]

- Vaiana, R.; De Rose, M.; Perri, G. Microsurfacing: A Predictive Macrotexture Model from Mix Design Parameters. Constr. Build. Mater. 2023, 409, 133961. [Google Scholar] [CrossRef]

- Vaiana, R.; Iuele, T.; Gallelli, V.; Tighe, S.L. Warm Mix Asphalt by Water-Containing Methodology: A Laboratory Study on Workability Properties versus Micro-Foaming Time. Can. J. Civ. Eng. 2014, 41, 183–190. [Google Scholar] [CrossRef]

- Peralta, J.; Silva, H.M.R.D.; Williams, R.C.; Rover, M.; Machado, A.V.A. Development of an Innovative Bio-Binder Using Asphalt-Rubber Technology. Int. J. Pavement Res. Technol. 2013, 6. [Google Scholar] [CrossRef]

- Makoundou, C.; Sangiorgi, C.; Johansson, K.; Wallqvist, V. Development of Functional Rubber-Based Impact-Absorbing Pavements for Cyclist and Pedestrian Injury Reduction. Sustainability 2021, 13, 11283. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Usman, A. A Systematic Review of Bio-Asphalt for Flexible Pavement Applications: Coherent Taxonomy, Motivations, Challenges and Future Directions. J. Clean. Prod. 2020, 249, 119357. [Google Scholar] [CrossRef]

- Blanc, J.; Hornych, P.; Sotoodeh-Nia, Z.; Williams, C.; Porot, L.; Pouget, S.; Boysen, R.; Planche, J.-P.; Lo Presti, D.; Jimenez, A.; et al. Full-Scale Validation of Bio-Recycled Asphalt Mixtures for Road Pavements. J. Clean. Prod. 2019, 227, 1068–1078. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Souliman, M.I.; Alavi, M.Z.; Salazar, L.G.L. Influence of Hydrogreen Bioasphalt on Viscoelastic Properties of Reclaimed Asphalt Mixtures. Transp. Res. Rec. 2013, 2371, 13–22. [Google Scholar] [CrossRef]

- Praticò, F.G.; Vaiana, R.; Giunta, M.; Iuele, T.; Moro, A. Recycling PEMs Back to TLPAs: Is That Possible notwithstanding RAP Variability? Appl. Mech. Mater. 2013, 253, 376–384. [Google Scholar] [CrossRef]

- Martínez-Boza, F.; Partal, P.; Conde, B.; Gallegos, C. Steady-State Flow Behaviour of Synthetic Binders. Fuel 2001, 80, 357–365. [Google Scholar] [CrossRef]

- Álvarez-Barajas, R.; Cuadri, A.A.; Delgado-Sánchez, C.; Navarro, F.J.; Partal, P. Non-Bituminous Binders Formulated with Bio-Based and Recycled Materials for Energy-Efficient Roofing Applications. J. Clean. Prod. 2023, 393, 136350. [Google Scholar] [CrossRef]

- Coppen, J.J.W.; Coppen, J.J.W.; Hone, G.A. Gum Naval Stores: Turpentine and Rosin from Pine Resin; Non-Wood Forest Products; Food and Agriculture Organization of the United Nations: Rome, Italy, 1995; ISBN 978-92-5-103684-6. [Google Scholar]

- Yadav, B.K.; Gidwani, B.; Vyas, A. Rosin: Recent Advances and Potential Applications in Novel Drug Delivery System. J. Bioact. Compat. Polym. 2016, 31, 111–126. [Google Scholar] [CrossRef]

- Silvestre, A.J.D.; Gandini, A. Rosin: Major Sources, Properties and Applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 67–88. ISBN 978-0-08-045316-3. [Google Scholar]

- Fuentes-Audén, C.; Martínez-Boza, F.J.; Navarro, F.J.; Partal, P.; Gallegos, C. Formulation of New Synthetic Binders: Thermomechanical Properties of Resin/Recycled Polymer Blends. Polym. Eng. Sci. 2012, 52, 242–249. [Google Scholar] [CrossRef]

- Martínez-Boza, F.; Partal, P.; Conde, B.; Gallegos, C. Influence of Temperature and Composition on the Linear Viscoelastic Properties of Synthetic Binders. Energy Fuels 2000, 14, 131–137. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.; Gallegos, C. Effect of Composition and Processing on the Linear Viscoelasticity of Synthetic Binders. Eur. Polym. J. 2005, 41, 1429–1438. [Google Scholar] [CrossRef]

- Castro-Alonso, M.J.; Espinosa, L.V.; Franco Marcelino, P.R.; Vasconcelos Savasini, K.; Dos Santos, J.C.; Moraes, R.; Da Silva, S.S.; Bernucci, L.L.B. Physicochemical and Aging Characterisation of Bio-Binders from Pine Wood Resin for Paving Applications. Road Mater. Pavement Des. 2023, 24, 229–244. [Google Scholar] [CrossRef]

- Jiménez Del Barco Carrión, A.; Lo Presti, D.; Chailleux, E.; Airey, G.D. Rheological Investigation on the Ageing Performance of Bio-Recycled Asphalt Binders and Mixtures. Road Mater. Pavement Des. 2023, 24, 538–553. [Google Scholar] [CrossRef]

- Espinosa Ruiz, L.V. Analysis of Bio-Binders for Paving as a Total Substitute for Asphalt Binder. Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2020. [Google Scholar]

- Rossi, C.O.; Caputo, P.; Loise, V.; Ashimova, S.; Teltayev, B.; Sangiorgi, C. A New Green Rejuvenator: Evaluation of Structural Changes of Aged and Recycled Bitumens by Means of Rheology and NMR. In RILEM 252-CMB Symposium; Poulikakos, L.D., Cannone Falchetto, A., Wistuba, M.P., Hofko, B., Porot, L., Di Benedetto, H., Eds.; RILEM Bookseries; Springer International Publishing: Cham, Switzerland, 2019; Volume 20, pp. 177–182. ISBN 978-3-030-00475-0. [Google Scholar]

- Jiménez Del Barco-Carrión, A.; Pérez-Martínez, M.; Themeli, A.; Lo Presti, D.; Marsac, P.; Pouget, S.; Hammoum, F.; Chailleux, E.; Airey, G.D. Evaluación Del Efecto Rejuvenecedor de Bio-Materiales Sobre Ligantes Para Mezclas Con Alto Contenido de Asfalto Recuperado. Mater. Constr. 2017, 7, 130. [Google Scholar] [CrossRef]

- Espinosa, L.V.; Gadler, F.; Mota, R.V.; Vasconcelos, K.; Bernucci, L.L.B. Comparison of the Rheological and the Thermal Behaviour of a Neat Asphalt Binder and a Wood-Based Binder for Pavement Surface Layer. Road Mater. Pavement Des. 2021, 22, S702–S717. [Google Scholar] [CrossRef]

- Jiménez Del Barco Carrión, A.; Carvajal-Muñoz, J.S.; Lo Presti, D.; Airey, G. Intrinsic Adhesive and Cohesive Assessment of the Moisture Sensitivity of Bio-Rejuvenated Recycled Asphalt Binders. Road Mater. Pavement Des. 2019, 20, S347–S364. [Google Scholar] [CrossRef]

- Espinosa, L.V.; Vasconcelos, K.; Alvarez, A.E.; Bhasin, A.; Bernucci, L. Moisture Damage Susceptibility of a Wood-Based Bio-Binder for Total Replacement of Asphalt Binders. Road Mater. Pavement Des. 2023, 1–11. [Google Scholar] [CrossRef]

- Manke, N.D.; Williams, R.C.; Sotoodeh-Nia, Z.; Cochran, E.W.; Porot, L.; Chailleux, E.; Pouget, S.; Olard, F.; Barco Carrion, A.J.D.; Planche, J.-P.; et al. Performance of a Sustainable Asphalt Mix Incorporating High RAP Content and Novel Bio-Derived Binder. Road Mater. Pavement Des. 2021, 22, 812–834. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Abe, A.A.; Tarsi, G.; Sangiorgi, C.; Gallo, F.; Oliviero Rossi, C. Preliminary Study on New Alternative Binders through Re-Refined Engine Oil Bottoms (REOBs) and Industrial By-Product Additives. Molecules 2021, 26, 7269. [Google Scholar] [CrossRef]

- Espinosa, L.V.; Gadler, F.; Mota, R.V.; Guatimosim, F.V.; Camargo, I.; Vasconcelos, K.; Barros, R.M.D.V.; Bernucci, L.L.B. Multi-Scale Study of Bio-Binder Mixtures as Surface Layer: Laboratory Evaluation and Field Application and Monitoring. Constr. Build. Mater. 2021, 287, 122982. [Google Scholar] [CrossRef]

- Yu, F.; Shi, Y.; Liu, S.; Yuan, B.; Xie, C.; Yu, S. Efficient Hydrogenation of Rosin and A-Pinene Catalyzed by Amphiphilic Ni–W–B Catalysts. Colloids Surf. A Physicochem. Eng. Asp. 2024, 686, 133368. [Google Scholar] [CrossRef]

- Zhou, D.; Wang, L.; Chen, X.; Wei, X.; Liang, J.; Tang, R.; Xu, Y. Reaction Mechanism Investigation on the Esterification of Rosin with Glycerol over Annealed Fe3O4/MOF-5 via Kinetics and TGA-FTIR Analysis. Chem. Eng. J. 2020, 401, 126024. [Google Scholar] [CrossRef]

- Aqsha, A.; Winoto, H.P.; Adhi, T.P.; Adisasmito, S.; Ramli, Y.; Siddiq, L.; Pratama, F.B.; Ramdani, M.R.; Indarto, A. Sequential Esterification—Diels-Alder Reactions for Improving Pine Rosin Durability within Road Marking Paint. Molecules 2023, 28, 5236. [Google Scholar] [CrossRef]

- Praticò, F.G.; Perri, G.; De Rose, M.; Vaiana, R. Comparing Bio-Binders, Rubberised Asphalts, and Traditional Pavement Technologies. Constr. Build. Mater. 2023, 400, 132813. [Google Scholar] [CrossRef]

- Read, J.; Whiteoak, D.; Hunter, R.N. The Shell Bitumen Handbook; Thomas Telford: London, UK, 2003; ISBN 0-7277-3220-X. [Google Scholar]

- Penki, R.; Rout, S.K. Next-Generation Bitumen: A Review on Challenges and Recent Developments in Bio-Bitumen Preparation and Usage. Biomass Conv. Bioref. 2023, 13, 9583–9600. [Google Scholar] [CrossRef]

- Huang, S.-C. (Ed.) Advances in Asphalt Materials: Road and Pavement Construction; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Waltham, MA, USA, 2015; ISBN 978-0-08-100269-8. [Google Scholar]

- Caputo, P.; Miriello, D.; Bloise, A.; Baldino, N.; Mileti, O.; Ranieri, G.A. A Comparison and Correlation between Bitumen Adhesion Evaluation Test Methods, Boiling and Contact Angle Tests. Int. J. Adhes. Adhes. 2020, 102, 102680. [Google Scholar] [CrossRef]

- Galooyak, S.S.; Dabir, B.; Nazarbeygi, A.E.; Moeini, A. Rheological Properties and Storage Stability of Bitumen/SBS/Montmorillonite Composites. Constr. Build. Mater. 2010, 24, 300–307. [Google Scholar] [CrossRef]

- Zhao, M.L.; Zhao, Z.J. Study on Noise Reduction Mechanism and Surface Performance of Crumb Rubber Micro-Surfacing Material. Key Eng. Mater. 2014, 599, 257–260. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Azienda Nazionale Autonoma Delle Strade (ANAS). Capitolato Speciale Di Appalto. Parte Norme Tecniche. Pavimentazioni Stradali/Autostradali; Italian Specifications; Azienda Nazionale Autonoma Delle Strade (ANAS): Rome, Italy, 2009. [Google Scholar]

- EN 1426:2015; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 15326:2007; Bitumen and Bituminous Binders—Measurement of Density and Specific Gravity—Capillary-Stoppered Pyknometer Method. European Committee for Standardization: Brussels, Belgium, 2007.

- EN 12697-30:2019; Bituminous Mixtures—Test Methods—Part 30: Specimen Preparation by Impact Compactor. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12697-34:2020; Bituminous Mixtures—Test Methods—Part 34: Marshall Test. European Committee for Standardization: Brussels, Belgium, 2020.

- EN 12697-23; Bituminous Mixtures—Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. European Committee for Standardization: Brussels, Belgium, 2018.

- EN 12697-8; Bituminous Mixtures—Test Methods—Part 8: Determination of Void Characteristics of Bituminous Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- Munera, J.C.; Ossa, E.A. Polymer Modified Bitumen: Optimization and Selection. Mater. Des. 2014, 62, 91–97. [Google Scholar] [CrossRef]

- Lo Presti, D.; Airey, G. Tyre Rubber-Modified Bitumens Development: The Effect of Varying Processing Conditions. Road Mater. Pavement Des. 2013, 14, 888–900. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, L.; Bin, X.; Cao, D.; Li, J.; Zhao, K. Performance of SBS Modifier-Crumb Rubber Composite Modified Asphalt Used as an Anti-Wear Layer of Perpetual Pavement. Int. J. Pavement Eng. 2022, 23, 4097–4111. [Google Scholar] [CrossRef]

- Ogundipe, O.M. Marshall Stability and Flow of Lime-Modified Asphalt Concrete. Transp. Res. Procedia 2016, 14, 685–693. [Google Scholar] [CrossRef]

- Bethary, R.T.; Subagio, B.S.; Rahman, H.; Suaryana, N. Effect of Recycled Materials on Marshall Performance of Hot Asphalt Mixture (HMA—RAP). IOP Conf. Ser. Mater. Sci. Eng. 2019, 508, 012048. [Google Scholar] [CrossRef]

| Blend Name | VR [%] | WOO [%] | PEW [%] | SBS [%] | CR [%] |

|---|---|---|---|---|---|

| Base Formulation | 40 | 25 | 10 | 10 | 15 |

| 0.55 O/R-6% SBS | 43.2 | 23.8 | 10.8 | 6.0 | 16.2 |

| 0.55 O/R-4% SBS | 44.1 | 24.3 | 11.0 | 4.0 | 16.6 |

| 0.55 O/R-2% SBS | 45.0 | 24.8 | 11.3 | 2.0 | 16.9 |

| 0.45 O/R-6% SBS | 46.2 | 20.8 | 10.8 | 6.0 | 16.2 |

| 0.45 O/R-4% SBS | 47.2 | 21.2 | 11.0 | 4.0 | 16.6 |

| 0.45 O/R-2% SBS | 48.2 | 21.6 | 11.3 | 2.0 | 16.9 |

| 0.35 O/R-6% SBS | 49.6 | 17.4 | 10.8 | 6.0 | 16.2 |

| 0.35 O/R-4% SBS | 50.7 | 17.7 | 11.0 | 4.0 | 16.6 |

| 0.35 O/R-2% SBS | 51.7 | 18.1 | 11.3 | 2.0 | 16.9 |

| Blend Name | VR [%] | WOO [%] | PEW [%] | SBS [%] | CR [%] |

|---|---|---|---|---|---|

| 0.35 O/R-4% SBS-16.6%CR | 50.7 | 17.7 | 11.0 | 4.0 | 16.6 |

| 0.35 O/R-4% SBS-11.0%CR | 54.2 | 19.0 | 11.8 | 4.0 | 11.0 |

| 0.35 O/R-4% SBS-5.5%CR | 57.7 | 20.2 | 12.6 | 4.0 | 5.5 |

| 0.35 O/R-4% SBS-0.0%CR | 61.3 | 21.4 | 13.3 | 4.0 | 0.0 |

| ID Mixture | Aggregate Bulk Specific Gravity [g/cm3] | Bio-Binder Density [g/cm3] | Percentage of Bio-Binder on the Aggregate Weight [%] | Mixture Theoretical Maximum Density [g/cm3] |

|---|---|---|---|---|

| B50/70 | 2.800 | 1.002 | 4.80 | 2.554 |

| 0.55 O/R-4% SBS | 2.800 | 1.026 | 5.50 | 2.568 |

| 0.35 O/R-4% SBS | 2.800 | 1.032 | 5.50 | 2.570 |

| Blend Name | Penetration (dmm) | SDPEN (dmm) | Softening Point (°C) | SDSP (°C) | IP |

|---|---|---|---|---|---|

| 0.55 O/R-6% SBS | 175 | 5.8 | 88.3 | 0.5 | 9.7 |

| 0.55 O/R-4% SBS | 191 | 7.6 | 89.1 | 0.3 | 10.2 |

| 0.55 O/R-2% SBS | 204 | 5.6 | 90.0 | 0.4 | 10.6 |

| 0.45 O/R-6% SBS | 120 | 5.3 | 92.3 | 0.5 | 8.6 |

| 0.45 O/R-4% SBS | 142 | 6.6 | 93.2 | 0.4 | 9.4 |

| 0.45 O/R-2% SBS | 180 | 8.5 | 91.2 | 0.3 | 10.2 |

| 0.35 O/R-6% SBS | 78 | 6.5 | 94.9 | 0.4 | 7.4 |

| 0.35 O/R-4% SBS | 84 | 3.4 | 93.0 | 0.5 | 7.5 |

| 0.35 O/R-2% SBS | 94 | 3.8 | 95.5 | 0.3 | 8.1 |

| BIT 70/100 | 84 | 3.3 | 48.0 | 0.2 | −0.4 |

| BIT 50/70 | 54 | 1.4 | 51.2 | 0.4 | −0.7 |

| MOD SF | 60 | 1.5 | 70.8 | 0.5 | 3.5 |

| MOD HD | 50 | 1.6 | 78.1 | 0.3 | 4.1 |

| Blend Name | Penetration (dmm) | SDPEN (dmm) | Softening Point (°C) | SDSP (°C) | IP |

|---|---|---|---|---|---|

| 0.35 O/R-4% SBS-16.6%CR | 84 | 3.4 | 93.0 | 0.5 | 7.5 |

| 0.35 O/R-4% SBS-11.0%CR | 91 | 3.0 | 90.5 | 0.3 | 7.4 |

| 0.35 O/R-4% SBS-5.5%CR | 69 | 1.8 | 92.7 | 0.3 | 6.8 |

| 0.35 O/R-4% SBS-0.0%CR | 73 | 2.6 | 99.0 | 0.3 | 7.6 |

| ID Mixture | Stability [kN] | SDS [kN] | Flow [mm] | Marshall Quotient [kN/mm] | Air Voids [%] |

|---|---|---|---|---|---|

| Technical Specification Thresholds | >10.000 | - | - | 3.0 ÷ 4.5 | 3.0 ÷ 6.0 |

| 50/70 | 11.846 | 0.575 | 1.877 | 6.310 | 3.94 |

| 0.55 O/R-4% SBS | 10.120 | 0.509 | 1.460 | 7.010 | 3.46 |

| 0.35 O/R-4% SBS | 10.940 | 0.507 | 1.350 | 8.100 | 4.25 |

| ID Mixture | Load [N] | SDLoad [N] | ITS [MPa] | Air Voids [%] |

|---|---|---|---|---|

| Technical Specification Thresholds | - | - | >0.720 | 3.0 ÷ 6.0 |

| 50/70 | 12,570 | 272.2 | 1.265 | 3.83 |

| 0.55 O/R-4% SBS | 4780 | 126.8 | 0.475 | 3.33 |

| 0.35 O/R-4% SBS | 7906 | 323.0 | 0.785 | 4.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Rose, M.; Vaiana, R.; Rossi, C.O.; Caputo, P. Development and Evaluation of Vegetable Resin Bio-Binders as Technological Alternatives to Bitumen. Sustainability 2024, 16, 2437. https://doi.org/10.3390/su16062437

De Rose M, Vaiana R, Rossi CO, Caputo P. Development and Evaluation of Vegetable Resin Bio-Binders as Technological Alternatives to Bitumen. Sustainability. 2024; 16(6):2437. https://doi.org/10.3390/su16062437

Chicago/Turabian StyleDe Rose, Manuel, Rosolino Vaiana, Cesare Oliviero Rossi, and Paolino Caputo. 2024. "Development and Evaluation of Vegetable Resin Bio-Binders as Technological Alternatives to Bitumen" Sustainability 16, no. 6: 2437. https://doi.org/10.3390/su16062437

APA StyleDe Rose, M., Vaiana, R., Rossi, C. O., & Caputo, P. (2024). Development and Evaluation of Vegetable Resin Bio-Binders as Technological Alternatives to Bitumen. Sustainability, 16(6), 2437. https://doi.org/10.3390/su16062437