Anaerobic Co-Digestion of Agro-Industrial Waste Mixtures for Biogas Production: An Energetically Sustainable Solution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Organic Waste Characterization

2.2. Anaerobic Digestion Process

2.3. Gas Sample

2.4. Kinetic Modeling

3. Results and Discussion

3.1. Initial Characterization

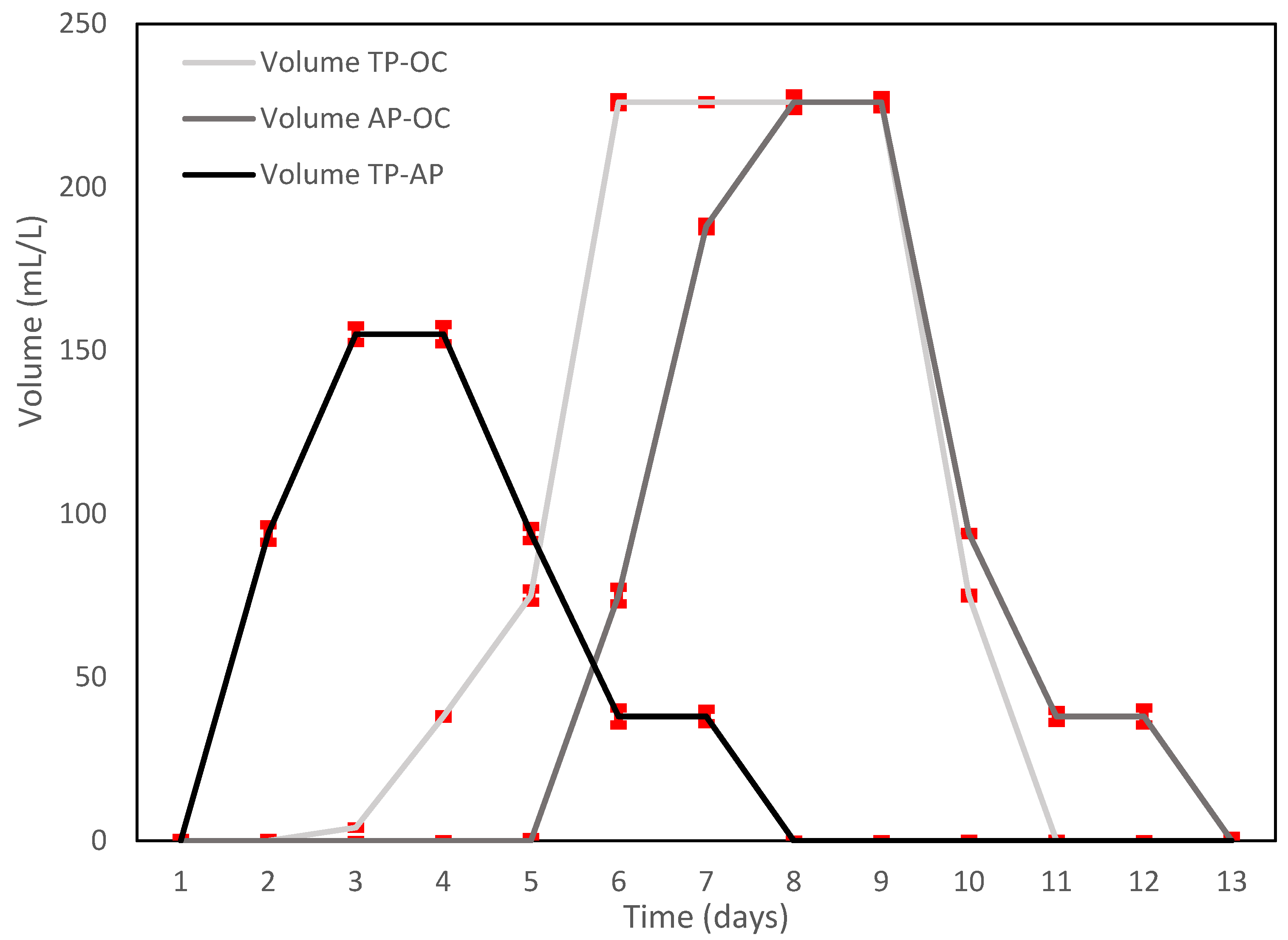

3.2. Biogas Production

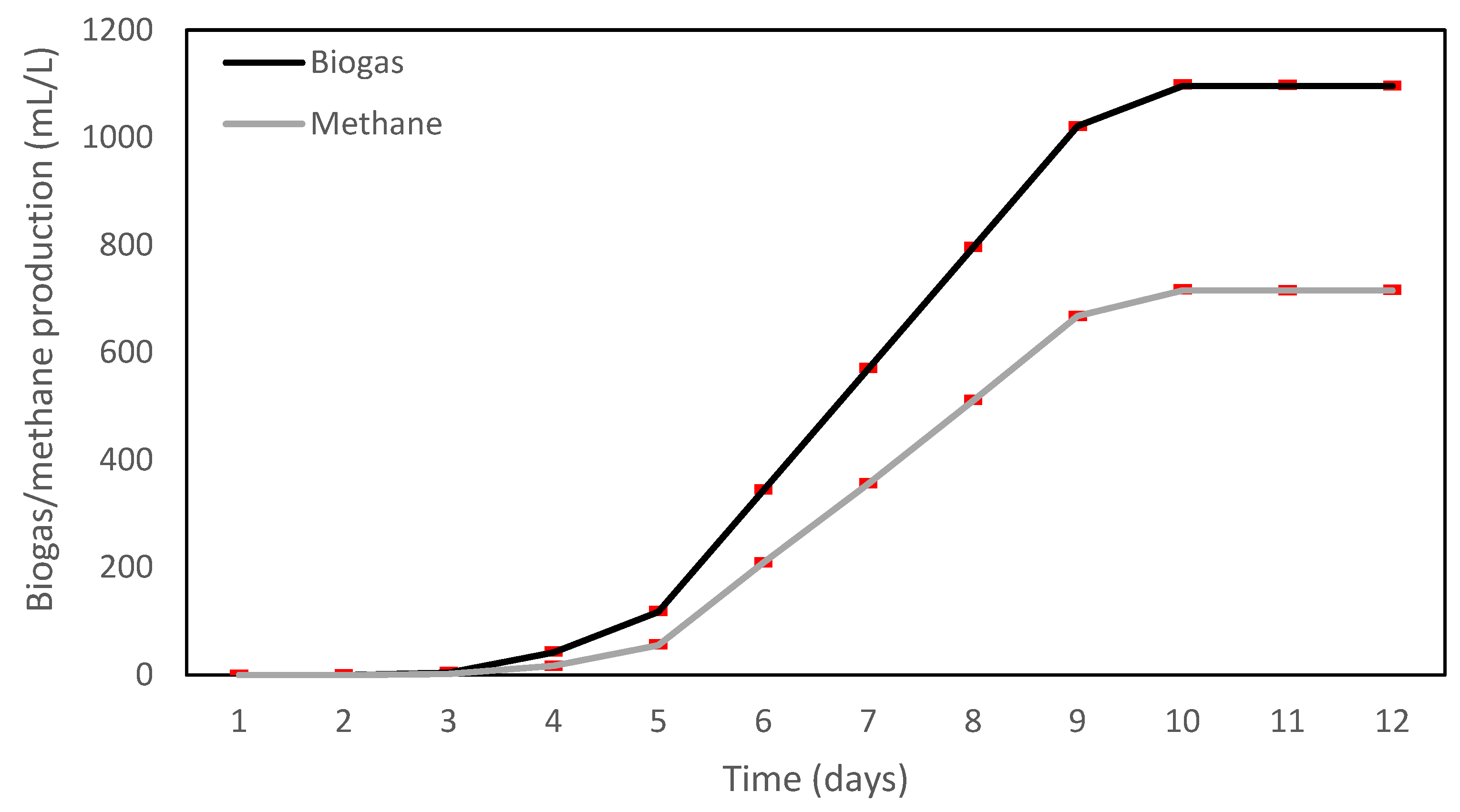

3.2.1. Tomato Pomace and Olive Cake Mixture (TP-OC)

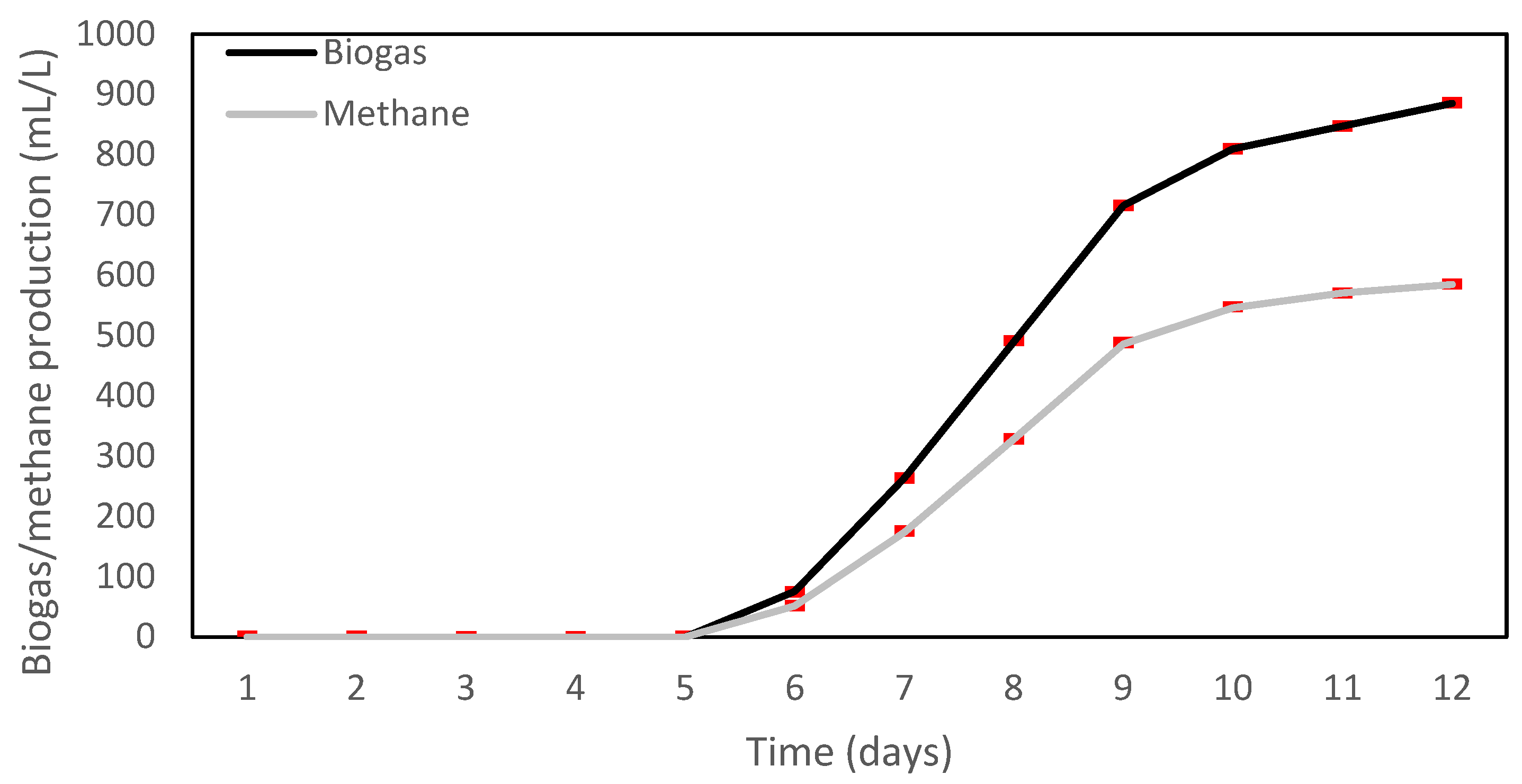

3.2.2. Apple Pomace and Olive Cake Mixture (AP-OC)

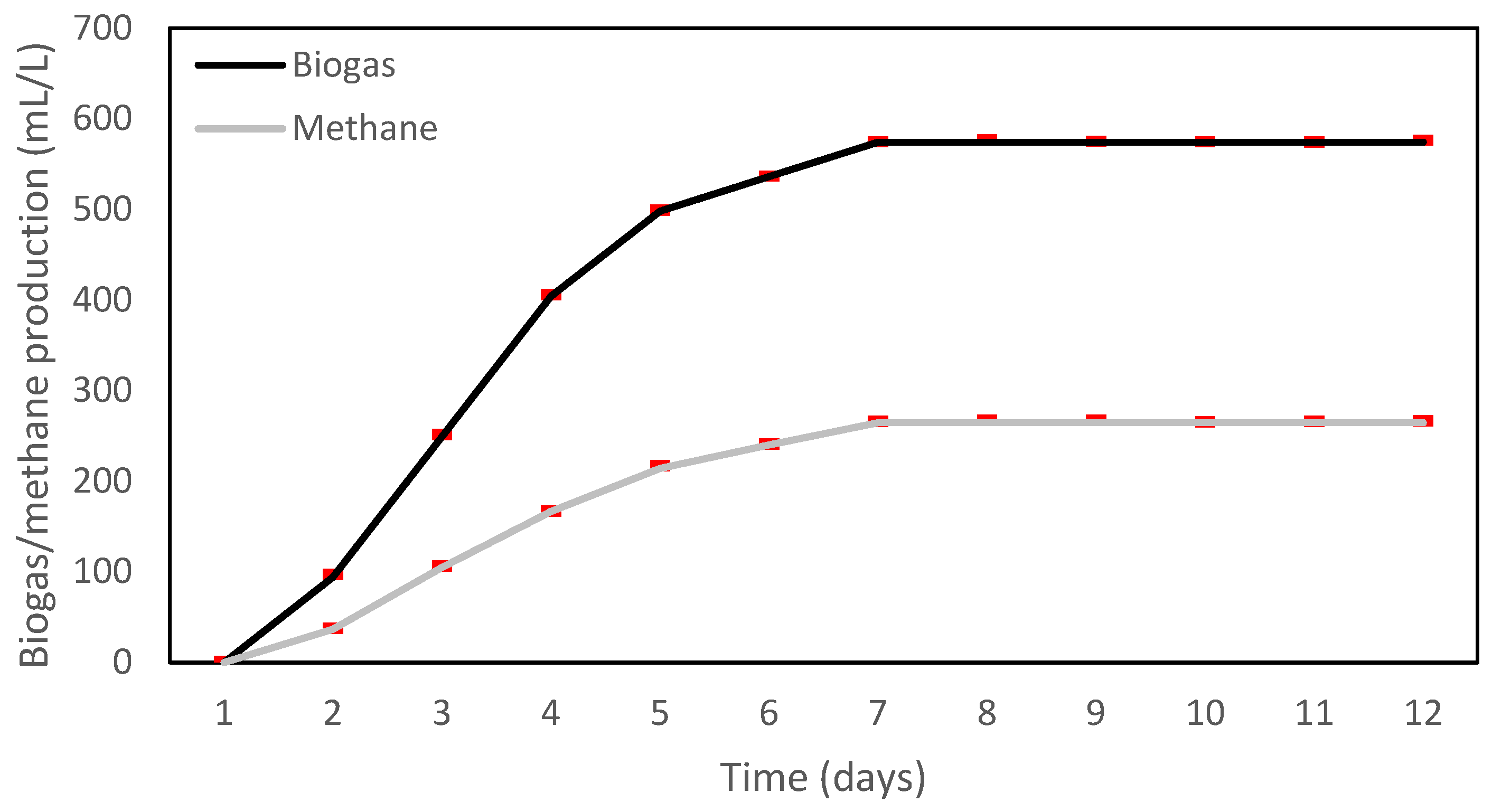

3.2.3. Tomato and Apple Pomace Mixture (TP-AP)

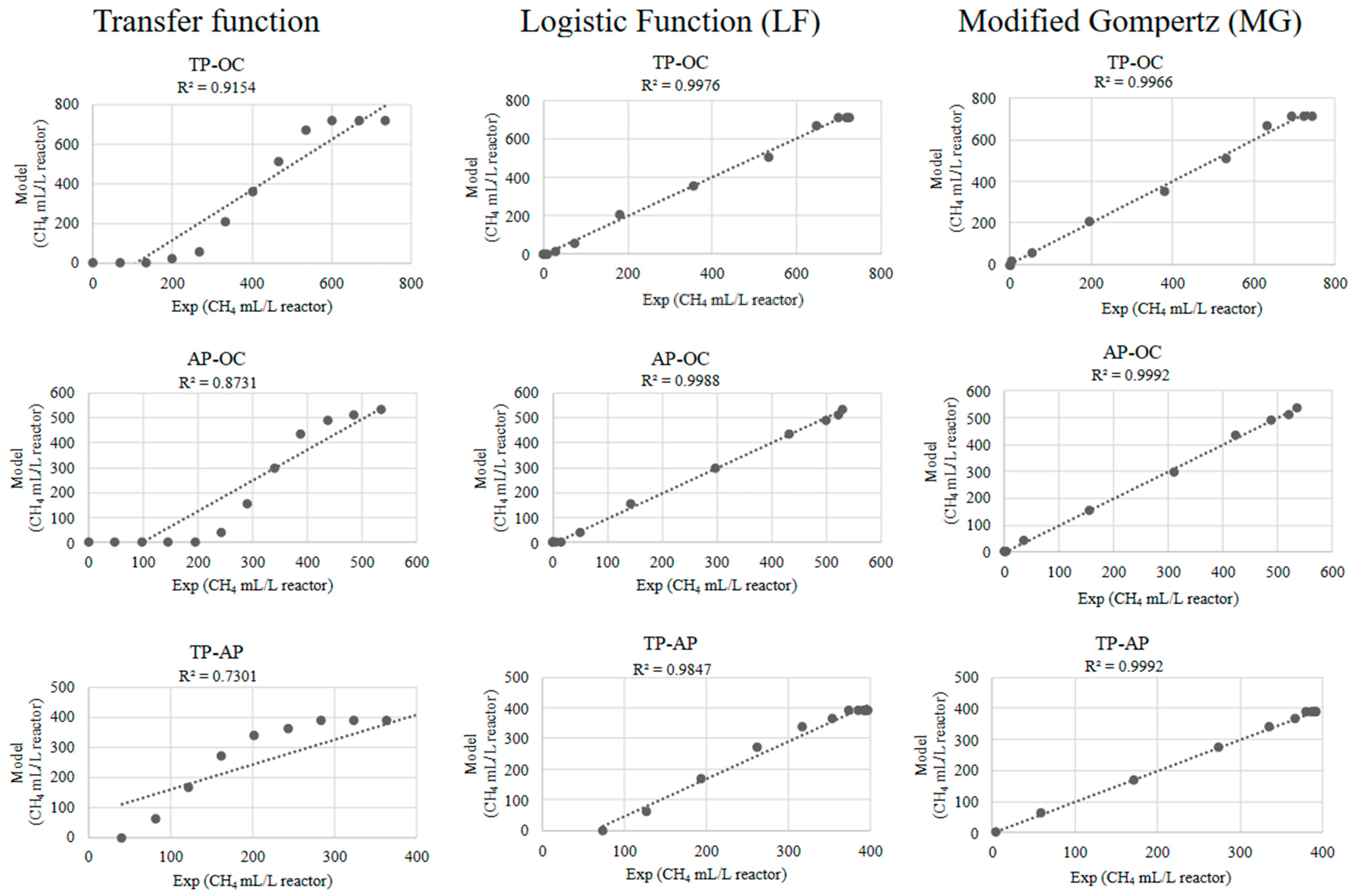

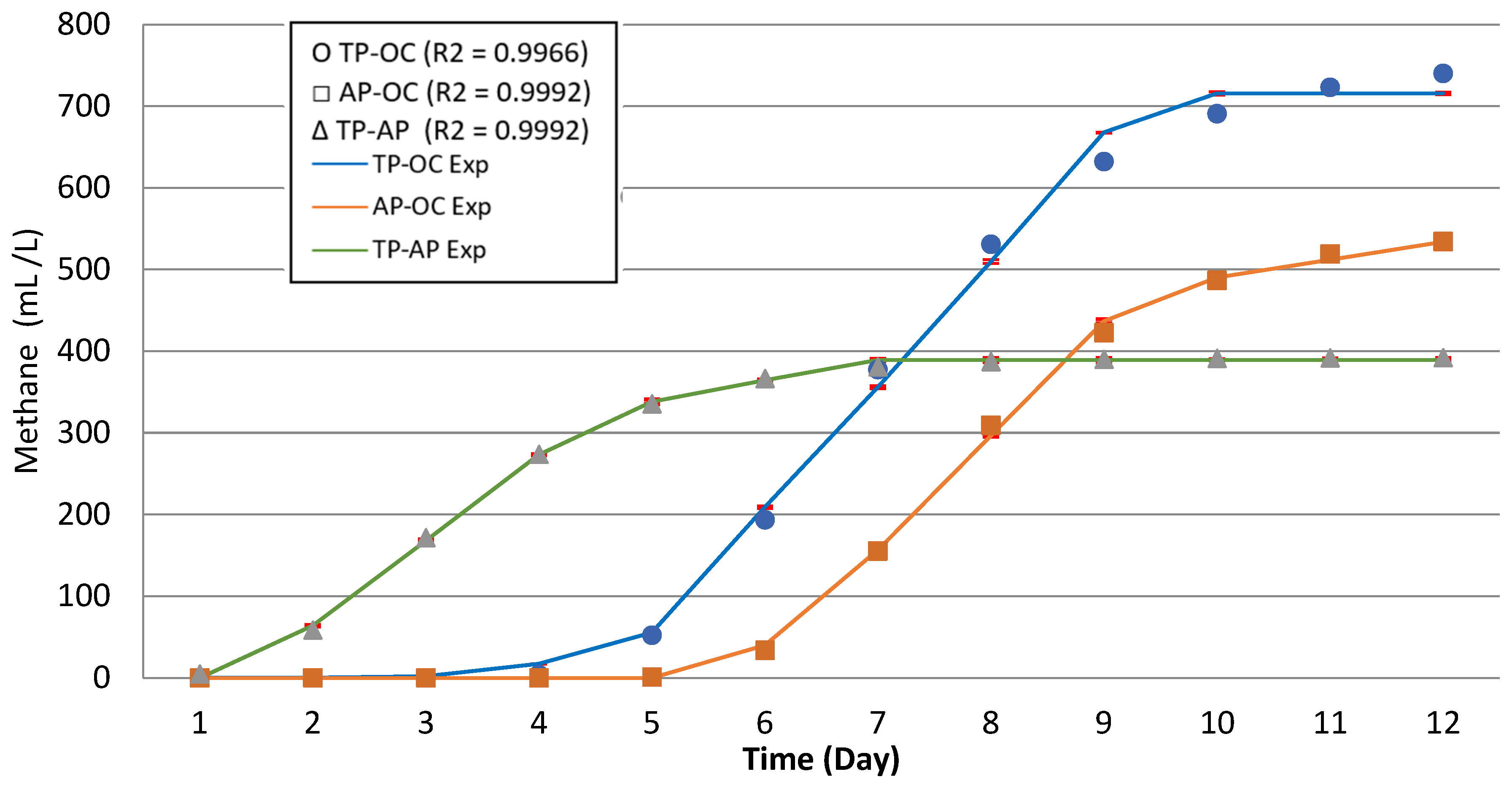

3.3. Kinetic Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Day | Biogas (mg/L) Minimum | Biogas (mg/L) Maximum | Biogas (mg/L) Average | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TP-OC | AP-OC | TP-AP | TP-OC | AP-OC | TP-AP | TP-OC | AP-OC | TP-AP | |

| 1 | 432 ± 2.52 | 469 ± 2.97 | 498 ± 1.28 | 454 ± 1.01 | 488 ± 0.16 | 512 ± 1.99 | 443 ± 0.44 | 479 ± 0.35 | 505 ± 2.54 |

| 2 | 440 ± 1.29 | 470 ± 0.82 | 554 ± 2.78 | 452 ± 0.78 | 479 ± 1.71 | 569 ± 2.89 | 446 ± 1.48 | 475 ± 2.27 | 562 ± 0.25 |

| 3 | 526 ± 2.38 | 498 ± 1.13 | 645 ± 2.85 | 562 ± 2.48 | 505 ± 1.19 | 661 ± 0.92 | 544 ± 1.08 | 502 ± 2.79 | 653 ± 0.56 |

| 4 | 642 ± 2.58 | 488 ± 1.48 | 589 ± 1.48 | 678 ± 0.81 | 502 ± 2.19 | 598 ± 1.33 | 660 ± 0.04 | 495 ± 0.19 | 594 ± 2.87 |

| 5 | 878 ± 0.96 | 656 ± 1.04 | 476 ± 0.63 | 892 ± 2.59 | 679 ± 0.16 | 487 ± 1.46 | 885 ± 0.63 | 668 ± 0.61 | 482 ± 1.56 |

| 6 | 978 ± 2.21 | 867 ± 1.92 | 366 ± 2.44 | 985 ± 2.02 | 871 ± 0.37 | 369 ± 1.03 | 982 ± 2.17 | 869 ± 0.27 | 368 ± 2.95 |

| 7 | 1297 ± 2.78 | 922 ± 2.35 | 344 ± 2.22 | 1356 ± 0.82 | 952 ± 2.79 | 356 ± 1.30 | 1327 ± 0.25 | 937 ± 2.09 | 350 ± 0.58 |

| 8 | 1330 ± 2.13 | 925 ± 1.14 | 357 ± 1.83 | 1352 ± 1.20 | 943 ± 2.27 | 372 ± 2.88 | 1341 ± 0.59 | 934 ± 0.28 | 365 ± 1.53 |

| 9 | 992 ± 0.45 | 917 ± 2.00 | 332 ± 0.42 | 998 ± 0.66 | 932 ± 0.24 | 341 ± 0.97 | 995 ± 1.42 | 925 ± 0.32 | 337 ± 0.58 |

| 10 | 622 ± 0.83 | 879 ± 1.51 | 331 ± 2.79 | 650 ± 2.31 | 892 ± 2.13 | 335 ± 1.19 | 636 ± 0.68 | 886 ± 0.48 | 333 ± 1.61 |

| 11 | 622 ± 0.22 | 790 ± 2.40 | 328 ± 0.49 | 634 ± 2.53 | 802 ± 2.67 | 336 ± 2.69 | 628 ± 2.11 | 796 ± 2.61 | 332 ± 1.08 |

| 12 | 438 ± 1.64 | 759 ± 2.48 | 317 ± 0.29 | 468 ± 2.59 | 781 ± 0.80 | 338 ± 2.16 | 453 ± 2.11 | 770 ± 1.29 | 328 ± 2.25 |

| Day | Methane (mg/L) Minimum | Methane (mg/L) Maximum | Methane (mg/L) Average | Methane (%) | Other Gases (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TP-OC | AP-OC | TP-AP | TP-OC | AP-OC | TP-AP | TP-OC | AP-OC | TP-AP | TP-OC | AP-OC | TP-AP | TP-OC | AP-OC | TP-AP | |

| 1 | 150 ± 2.46 | 98 ± 1.15 | 312 ± 1.15 | 182 ± 1.08 | 112 ± 2.42 | 342 ± 2.00 | 166 ± 0.45 | 105 ± 0.46 | 327 ± 2.68 | 37 ± 0.70 | 22 ± 0.08 | 65 ± 0.07 | 63 ± 0.7 | 78 ± 0.45 | 35 ± 0.75 |

| 2 | 164 ± 2.35 | 105 ± 0.19 | 376 ± 0.65 | 182 ± 0.36 | 111 ± 0.59 | 391 ± 0.53 | 173 ± 1.57 | 108 ± 1.66 | 384 ± 1.97 | 39 ± 0.22 | 23 ± 0.95 | 68 ± 0.81 | 61 ± 0.4 | 77 ± 0.57 | 32 ± 0.81 |

| 3 | 230 ± 2.72 | 143 ± 2.82 | 412 ± 1.93 | 249 ± 2.98 | 147 ± 2.64 | 461 ± 2.27 | 240 ± 2.23 | 145 ± 1.34 | 437 ± 2.31 | 44 ± 0.32 | 29 ± 0.13 | 67 ± 0.01 | 56 ± 0.37 | 71 ± 0.95 | 33 ± 0.54 |

| 4 | 249 ± 1.43 | 134 ± 0.44 | 401 ± 0.09 | 276 ± 1.72 | 145 ± 1.98 | 411 ± 1.45 | 263 ± 2.3 | 140 ± 1.31 | 406 ± 2.09 | 40 ± 0.83 | 28 ± 0.54 | 68 ± 0.61 | 60 ± 0.74 | 72 ± 0.37 | 32 ± 0.50 |

| 5 | 435 ± 0.69 | 230 ± 1.58 | 328 ± 1.96 | 464 ± 2.54 | 252 ± 1.74 | 339 ± 1.00 | 450 ± 2.56 | 241 ± 1.34 | 334 ± 1.42 | 51 ± 0.64 | 36 ± 0.31 | 69 ± 0.10 | 49 ± 0.39 | 64 ± 0.56 | 31 ± 0.38 |

| 6 | 689 ± 2.78 | 450 ± 1.89 | 248 ± 0.29 | 645 ± 0.15 | 467 ± 0.92 | 259 ± 1.07 | 667 ± 1.57 | 459 ± 0.01 | 254 ± 2.11 | 68 ± 0.89 | 53 ± 0.50 | 69 ± 0.86 | 32 ± 0.73 | 47 ± 0.26 | 31 ± 0.29 |

| 7 | 843 ± 2.81 | 579 ± 0.01 | 225 ± 0.04 | 878 ± 1.14 | 588 ± 2.35 | 239 ± 1.06 | 861 ± 1.13 | 584 ± 0.55 | 232 ± 2.66 | 65 ± 0.50 | 62 ± 0.77 | 66 ± 0.38 | 35 ± 0.01 | 38 ± 0.28 | 34 ± 0.16 |

| 8 | 895 ± 1.88 | 571 ± 2.27 | 203 ± 0.50 | 940 ± 2.57 | 581 ± 1.73 | 221 ± 1.10 | 918 ± 0.22 | 576 ± 1.28 | 212 ± 2.33 | 68 ± 0.52 | 62 ± 0.72 | 58 ± 0.24 | 32 ± 0.53 | 38 ± 0.95 | 42 ± 0.15 |

| 9 | 688 ± 0.4 | 568 ± 1.94 | 192 ± 0.34 | 702 ± 1.85 | 572 ± 2.99 | 206 ± 1.73 | 695 ± 1.78 | 570 ± 1.57 | 199 ± 2.19 | 70 ± 0.91 | 62 ± 1.00 | 59 ± 0.29 | 30 ± 0.45 | 38 ± 0.83 | 41 ± 0.71 |

| 10 | 402 ± 0.54 | 498 ± 2.02 | 147 ± 2.78 | 412 ± 2.69 | 511 ± 1.96 | 163 ± 0.29 | 407 ± 0.53 | 505 ± 0.21 | 155 ± 2.15 | 64 ± 0.92 | 57 ± 0.43 | 47 ± 0.15 | 36 ± 0.97 | 43 ± 0.68 | 53 ± 0.13 |

| 11 | 399 ± 2.62 | 449 ± 0.49 | 142 ± 2.77 | 411 ± 2.52 | 461 ± 2.21 | 160 ± 1.92 | 405 ± 0.78 | 455 ± 1.75 | 151 ± 2.62 | 64 ± 0.75 | 57 ± 0.72 | 45 ± 1.00 | 36 ± 0.07 | 43 ± 0.97 | 55 ± 0.64 |

| 12 | 162 ± 1.40 | 445 ± 2.81 | 139 ± 0.49 | 180 ± 1.40 | 453 ± 0.39 | 143 ± 1.34 | 171 ± 2.44 | 449 ± 0.22 | 141 ± 1.37 | 38 ± 0.01 | 58 ± 0.43 | 43 ± 0.32 | 62 ± 0.05 | 42 ± 0.20 | 57 ± 0.39 |

References

- Perussello, C.A.; Zhang, Z.; Marzocchella, A.; Tiwari, B.K. Valorization of Apple Pomace by Extraction of Valuable Compounds. Compr. Rev. Food Sci. Food Saf. 2017, 16, 776–796. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Huang, J.; Luo, W.; Chen, K.; Yu, W.; Zhang, W.; Huang, C.; Yang, J.; Huang, Y. Prediction for odor gas generation from domestic waste based on machine learning. Waste Manag. 2023, 156, 264–271. [Google Scholar] [CrossRef] [PubMed]

- Kılmanoğlu, H.; Hoşoğlu, M.İ.; Güneşer, O.; Yüceer, Y.K. Optimization of pretreatment and enzymatic hydrolysis conditions of tomato pomace for production of alcohols and esters by Kluyveromyces marxianus. LWT 2021, 138, 110728. [Google Scholar] [CrossRef]

- Lorenzini, M.; Simonato, B.; Slaghenaufi, D.; Ugliano, M.; Zapparoli, G. Assessment of yeasts for apple juice fermentation and production of cider volatile compounds. LWT 2019, 99, 224–230. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Maziotis, A. The Cost of Reducing Municipal Unsorted Solid Waste: Evidence from Municipalities in Chile. Sustainability 2021, 13, 6607. [Google Scholar] [CrossRef]

- Dhamodharan, K.; Kumar, V.; Kalamdhad, A.S. Effect of different livestock dungs as inoculum on food waste anaerobic digestion and its kinetics. Bioresour. Technol. 2015, 180, 237–241. [Google Scholar] [CrossRef]

- Suhartini, S.; Nurika, I.; Paul, R.; Melville, L. Estimation of Biogas Production and the Emission Savings from Anaerobic Digestion of Fruit-based Agro-industrial Waste and Agricultural crops residues. Bioenergy Res. 2021, 14, 844–859. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Senthil Kumar, P.; Varjani, S. Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review. Bioresour. Technol. 2022, 343, 126126. [Google Scholar] [CrossRef]

- Aravani, V.P.; Sun, H.; Yang, Z.; Liu, G.; Wang, W.; Anagnostopoulos, G.; Syriopoulos, G.; Charisiou, N.D.; Goula, M.A.; Kornaros, M.; et al. Agricultural and livestock sector’s residues in Greece & China: Comparative qualitative and quantitative characterization for assessing their potential for biogas production. Renew. Sustain. Energy Rev. 2022, 154, 111821. [Google Scholar] [CrossRef]

- Gomez, C. Biogas as an energy option: An overview. In The Biogas Handbook; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 1–16. [Google Scholar] [CrossRef]

- Iriarte, A.; Yáñez, P.; Villalobos, P.; Huenchuleo, C.; Rebolledo-Leiva, R. Carbon footprint of southern hemisphere fruit exported to Europe: The case of Chilean apple to the UK. J. Clean. Prod. 2021, 293, 126118. [Google Scholar] [CrossRef]

- Schwartz, M.; Marchant, R.; Kern, W.; Wicha, J. Circular bioeconomy and valorization of waste from the apple processing industry. IDESIA 2022, 40, 95–102. [Google Scholar] [CrossRef]

- ODEPA. Boletín de Hortalizas, Junio 2021. Ministerio de Agricultura, Gobierno de Chile. Available online: https://www.odepa.gob.cl/publicaciones/boletines/boletin-de-hortalizas-junio-2021 (accessed on 21 February 2024).

- Hernández, D.; Fernández, H.; Rebolledo, R.; Tenreiro., C.; Gabriel, D. Evaluation of sustainable manufacturing of pellets combining wastes from olive oil and forestry industries. Ind. Crops Prod. 2019, 134, 338–346. [Google Scholar] [CrossRef]

- Rodríguez-Monroy, C.; Mármol-Acitores, G.; Nilsson-Cifuentes, G. Electricity generation in Chile using non-conventional renewable energy sources—A focus on biomass. Renew. Sustain. Energy Rev. 2018, 81, 937–945. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, Y.; Zheng, L.; Wang, Z.; Dai, X. Perspective on enhancing the anaerobic digestion of waste activated sludge. J. Hazard. Mater. 2020, 389, 121847. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Fariñas, B.; Oliva, A.; Rodríguez-Galán, M.; Esposito, G.; García-Martín, J.F.; Rodríguez-Gutiérrez, G.; Serrano, A.; Fermoso, F. Environmental assessment of olive mill solid waste valorization via anaerobic digestion versus olive pomace oil extraction. Processes 2020, 8, 626. [Google Scholar] [CrossRef]

- Castro, R.; Solís, M.; Chicatto, V.; Solís, A. Biogas production through co-digestion of cattle waste and agricultural residues of tomato cultivation (Solanum lycopersicum L.). Rev. Int. Contam. Ambient. 2020, 36, 529–539. [Google Scholar] [CrossRef]

- Ampese, L.C.; Ziero, H.D.D.; Velásquez, J.; Sganzerla, W.G.; Martins, G.; Forster-Carneiro, T. Apple pomace management by anaerobic digestion and composting: A life cycle assessment. Biofuels Bioprod. Biorefining 2023, 17, 29–45. [Google Scholar] [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Dai, X.; Li, X.; Zhang, D.; Chen, Y.; Dai, L. Simultaneous enhancement of methane production and methane content in biogas from waste activated sludge and perennial ryegrass anaerobic co-digestion: The effects of pH and C/N ratio. Bioresour. Technol. 2016, 216, 323–330. [Google Scholar] [CrossRef]

- Bolen, T.J.; Hasan, M.; Conway, T.; Sanchez, P.; Rahman, A.; Azam, H. Feasibility assessment of biogas production from the anaerobic co-digestion of cheese whey, grease interceptor waste and pulped food waste for WRRF. Energy 2022, 254, 124144. [Google Scholar] [CrossRef]

- Parra-Orobio, B.A.; Donoso-Bravo, A.; Torres-Lozada, P. Digestión anaerobia de residuos de alimentos. Predicción de la producción de metano mediante la comparación de modelos cinéticos. Ing. Compet. 2017, 19, 210. [Google Scholar] [CrossRef]

- Dennis, A.; Burke, P.E. Dairy Waste Anaerobic Digestion Handbook. In Options for Recovering Beneficial Products from Dairy Manure; Environmental Energy Company: Olympia, WA, USA, 2001; pp. 17–19. Available online: https://www.build-a-biogas-plant.com/PDF/DigesterBiogasHandbook.pdf (accessed on 17 February 2023).

- Jeldres, R.I.; Uribe, L.; Cisternas, L.A.; Gutierrez, L.; Leiva, W.H.; Valenzuela, J. The effect of clay minerals on the process of flotation of copper ores—A critical review. Appl. Clay Sci. 2019, 170, 57–69. [Google Scholar] [CrossRef]

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar] [CrossRef]

- Luongo, V.; Policastro, G.; Ghimire, A.; Pirozzi, F.; Fabbricino, M. Repeated-Batch Fermentation of Cheese Whey for Semi-Continuous Lactic Acid Production Using Mixed Cultures at Uncontrolled pH. Sustainability 2019, 11, 3330. [Google Scholar] [CrossRef]

- Mihelcic, J.R.; Zimmerman, J.B. Environmental Engineering: Fundamentals, Sustainability, Design; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Ahmed, E.; Fukuma, N.; Hanada, M.; Nishida, T. Insects as novel ruminant feed and a potential mitigation strategy for methane emissions. Animals 2021, 11, 2648. [Google Scholar] [CrossRef] [PubMed]

- Alibardi, L.; Cossu, R. Effects of carbohydrate, protein and lipid content of organic waste on hydrogen production and fermentation products. Waste Manag. 2016, 47, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Markou, G.; Angelidaki, I.; Georgakakis, D. Carbohydrate-enriched cyanobacterial biomass as feedstock for bio-methane production through anaerobic digestion. Fuel 2013, 111, 872–879. [Google Scholar] [CrossRef]

- Ministerio Secretaría General de la Presidencia, Chile. Decreto 4. Reglamento Para el Manejo de Lodos Generados en Plantas de Tratamiento de Aguas Servidas. Available online: https://www.bcn.cl/leychile/navegar?i=1007456&f=2010-04-26 (accessed on 5 January 2023).

- de Rossi, E.; Tavares, M.H.F.; Teleken, J.G.; Cremonez, P.A.; Christ, D.; Gomes, S.D.; Aparecido Bariccatti, R. Production of biogas by microorganisms with saccharine sorghum straw as substrate with or without alkaline and citric pretreatment. Renew. Energy 2022, 197, 617–626. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Rincon, M.; Rincon, N.; Alvarez, J.M.; Chirinos, I. Biodegradability of prepared food waste under mesophilic and thermophilics conditions using a complete mix anaerobic reactor. Cienc. Ing. Neogranadina 2014, 24, 29. [Google Scholar] [CrossRef]

- Yu, H.Q.; Fang, H.H.P. Acidification of mid- and high-strength dairy wastewaters. Water Res. 2001, 35, 3697–3705. [Google Scholar] [CrossRef] [PubMed]

- Akbay, H.E.G.; Deniz, F.; Mazmanci, M.A.; Deepanraj, B.; Dizge, N. Investigation of anaerobic degradability and biogas production of the starch and industrial sewage mixtures. Sustain. Energy Technol. Assess. 2022, 52, 102054. [Google Scholar] [CrossRef]

- Sánchez-Santillán, P.; Meneses-Mayo, M.; Miranda-Romero, L.A.; Santellano-Estrada, E.; Alarcón-Zúñiga, B. Fribrinolytic activity and gas production by Pleurotus ostreatus-IE8 and Fomes fomentarius—EUM1 in bagasse cane. Rev. MVZ Córdoba 2015, 20, 4907–4916. [Google Scholar] [CrossRef]

- Devi, M.K.; Manikandan, S.; Oviyapriya, M.; Selvaraj, M.; Assiri, M.A.; Vickram, S.; Subbaiya, R.; Karmegam, N.; Ravindran, B.; Chang, S.W.; et al. Recent advances in biogas production using Agro-Industrial Waste: A comprehensive review outlook of Techno-Economic analysis. Bioresour. Technol. 2022, 363, 127871. [Google Scholar] [CrossRef]

| Model | Equation |

|---|---|

| Transfer function | |

| Logistic Function (LF) | |

| Modified Gompertz (MG) |

| Properties | Unit | TP-OC | AP-OC | TP-AP |

|---|---|---|---|---|

| Total Solids (TS) | g TS/L | 71.7 ± 0.01 | 78.6 ± 0.01 | 50.1 ± 0.02 |

| Total Solids | Mass % | 7.0 ± 0.01 | 7.5 ± 0.01 | 4.5 ± 0.01 |

| Fixed Solids (FS) | g FS/L | 12.26 ± 0.03 | 11 ± 0.02 | 9.43 ± 0.01 |

| Volatile Solids (VS) | g VS/L | 59.5 ± 0.01 | 67.6 ± 0.03 | 40.5 ± 0.01 |

| pH | DI | 4.8 ± 0.02 | 4.68 ± 0.02 | 4.19 ± 0.02 |

| COD | mgO2/L | 9670 ± 2.00 | 8716 ± 1.00 | 8444 ± 1.20 |

| BOD | mgO2/L | 8850 ± 1.50 | 7700 ± 1.00 | 7350 ± 1.40 |

| Moisture content a | Mass % | 85.58 ± 0.01 | 83.42 ± 0.01 | 58.3 ± 0.01 |

| Proteins b | Mass % | 7.62 ± 0.02 | 30.95 ± 0.01 | 8.7 ± 0.01 |

| Fats b | Mass % | 4.68 ± 0.01 | 8.67 ± 0.01 | 8.7 ± 0.03 |

| Carbohydrates b | Mass % | 25.45 ± 0.05 | 57.1 ± 0.04 | 65.3 ± 0.01 |

| Fiber b | Mass % | 52.45 ± 0.02 | 51.75 ± 0.06 | 86.7 ± 0.01 |

| Ashes b | Mass % | 2.78 ± 0.02 | 3.17 ± 0.01 | 1.8 ± 0.01 |

| Calorific value b | MJ/kg | 18.04 ± 0.01 | 21.30 ± 0.01 | 21.92 ± 0.01 |

| Total phenolic content a | mg/g GAE | 3.08 ± 0.05 | 234.1 ± 0.04 | 13.23 ± 0.03 |

| Properties | Unit | Apple Pomace | Tomato Pomace | Olive Cake | |||

|---|---|---|---|---|---|---|---|

| Ca | mg/kg | 3702.00 ± 0.17 | 4201.00 ± 0.15 | 2232.00 ± 0.20 | |||

| Mg | mg/kg | 112.00 ± 0.03 | 1052.00 ± 0.01 | 2054.00 ± 0.01 | |||

| Cd | mg/kg | <0.5 | <0.5 | <0.5 | |||

| Pb | mg/kg | <0.5 | <0.5 | <0.5 | |||

| Cu | mg/kg | 3.95 ± 0.01 | 2.95 ± 0.01 | 1.35 ± 0.01 | |||

| Fe | mg/kg | 0.49 ± 0.01 | 140.49 ± 0.01 | 150.43 ± 0.01 | |||

| Mn | mg/kg | 0.57 ± 0.01 | 334.24 ± 0.01 | 464.24 ± 0.01 | |||

| Zn | mg/kg | 1.50 ± 0.01 | 21.50 ± 0.01 | 11.50 ± 0.01 | |||

| Hg | mg/kg | <0.5 | <0.5 | <0.5 | |||

| As | mg/kg | <0.5 | <0.5 | <0.5 | |||

| Properties | Unit | TP-OC | AP-OC | TP-AP |

|---|---|---|---|---|

| Total Solids (TS) | g TS/L | 5.24 ± 0.01 | 6.03 ± 0.01 | 6.48 ± 0.01 |

| Fixed Solids (FS) | g FS/L | 4.39 ± 0.01 | 3.59 ± 0.01 | 3.99 ± 0.02 |

| Volatile Solids (VS) | g VS/L | 0.84 ± 0.01 | 2.44 ± 0.03 | 2.48 ± 0.01 |

| pH | DI | 7.26 ± 0.01 | 7.17 ± 0.01 | 7.31 ± 0.01 |

| COD | mgO2/L | 2475 ± 1.10 | 4850 ± 1.30 | 4978 ± 1.00 |

| BOD | mgO2/L | 4900 ± 0.90 | 5800 ± 1.60 | 5500 ± 1.20 |

| BOD/COD | DI | 1.98 ± 0.01 | 1.19 ± 0.01 | 1.10 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández, D.; Pinilla, F.; Rebolledo-Leiva, R.; Aburto-Hole, J.; Díaz, J.; Quijano, G.; González-García, S.; Tenreiro, C. Anaerobic Co-Digestion of Agro-Industrial Waste Mixtures for Biogas Production: An Energetically Sustainable Solution. Sustainability 2024, 16, 2565. https://doi.org/10.3390/su16062565

Hernández D, Pinilla F, Rebolledo-Leiva R, Aburto-Hole J, Díaz J, Quijano G, González-García S, Tenreiro C. Anaerobic Co-Digestion of Agro-Industrial Waste Mixtures for Biogas Production: An Energetically Sustainable Solution. Sustainability. 2024; 16(6):2565. https://doi.org/10.3390/su16062565

Chicago/Turabian StyleHernández, Diógenes, Fernando Pinilla, Ricardo Rebolledo-Leiva, Joaquín Aburto-Hole, Joaquín Díaz, Guillermo Quijano, Sara González-García, and Claudio Tenreiro. 2024. "Anaerobic Co-Digestion of Agro-Industrial Waste Mixtures for Biogas Production: An Energetically Sustainable Solution" Sustainability 16, no. 6: 2565. https://doi.org/10.3390/su16062565