Abstract

The use of individual biogas plants can be a means of solving many energy-environmental and financial-economic problems. The article aims to assess the prerequisites and consequences of using biogas plants at the macro and micro levels to search for opportunities to reduce the cost of their installation and make them more affordable for individual farms. The need for the use of biogas plants by farms is determined by the fact that these farms have a raw material base; the growing cost of energy resources pushes them to search for new sources of profit. At the micro level, the costs of biogas plants in the conditions of companies and individual farms in the Slovak Republic are evaluated. At the macro level, the aggravation of energy and agricultural problems and the need to transition to green technologies require a comprehensive approach to their solution. The article investigated the cost of purchasing and operating biogas plants based on a private company’s data. It assessed the cost of the construction of a biogas plant and more. The analysis of biogas plant operation results showed that its purchase and use by a farm can be financially unprofitable but bring significant benefits in the energy, environmental, and social dimensions.

1. Introduction

In the modern world, biogas plants are considered an ecological way to produce energy from organic wastes such as agricultural, domestic, food, industrial, and raw materials. Biogas production from agricultural waste in biogas plants has been recognized in the EU as a promising technology for transitioning to a green economy, solving environmental and energy problems, and overcoming financial difficulties. Thus, to solve the problem of energy supply in the period of a sharp rise in energy prices, the EU countries not only expanded the supply of natural gas from such gas supplier countries as Denmark, America, and others but also intensified efforts to develop renewable energy sources, in particular biogas production. A network of biogas plants has long been in operation in many European countries, such as Denmark, Italy, Germany, Poland, and others.

The potential efficiency of biogas plants for improving energy supply and reducing the country’s dependence on energy supplies has been shown in the works of many scientists. However, biogas plant operations also have several problems and limitations that should be considered when calculating their financial and economic efficiency and determining their benefits. Therefore, to provide a general overview of the advantages and disadvantages of biogas production regarding energy security and sustainability, the fundamental role of biogas plants, along with its positive and negative aspects, needs to be considered. Firstly, we must state that bioenergy is how energy security and sustainability can be achieved. [1]. The most significant advantages of biogas production are the following: (i) production of energy; (ii) transformation of organic waste into high-quality fertilizers; (iii) reduction of workload in firewood collection and cooking; (iv) positive environmental externalities in the form of protection of water, soil, air, and woody vegetation; (v) economic benefits via energy and fertilizer substitution, additional income sources, and rising yields of animal farming and agriculture; (vi) import substitution and environmental protection; (vii) greenhouse effect reduction [2]. On the other hand, there are unambiguously some disadvantages to biogas energy production, the greatest being monetary barriers and high initial investment [3]. For decades, measurements of the performance of biogas plants have been discussed by many researchers [4,5,6]. Wu, D. et al. presented some of the challenges related to biogas plants and their operations, for instance, improper mixing ratios resulting in process instability, seasonal availability of different waste in different regions, and extra capital costs such as transportation [6]. According to the European Commission, every euro invested in research and innovation of the agrobioeconomy should bring an additional 10 euros by 2025. Also, the agrobioeconomy brings over 2 billion EUR and gives jobs to around 20 million employees, making up 9% of the employment in the European Union, to which Slovakia belongs.

The output of the biogas plant is biogas and fertilizer. Biogas is a clean household energy fuel, so it increases income as it turns farm waste into wealth; slurry enriches the soil with nutrients, which in turn increases agricultural productivity [7].

Biogas has economic benefits because it provides households with gas, electricity, and fertilizers, but the cost of digesters is a significant limitation in biogas production. The study from 2022 also concluded that the technology of biogas plants is the solution to the energy crisis. Their cost-benefit analysis showed that a small biogas plant was the most profitable and that the government needed to provide subsidies for the installation of biogas plants to incentivize potential users [8].

Different authors also agree with the conclusions of the previous researchers. The authors of the study from 2021 assessed the socio-economic significance of biogas plants. They concluded that the installation of a biogas plant had a direct and indirect positive impact on farm productivity, time savings, air pollution, and income structure, which confirms the economic importance of introducing biogas plants for rural households, not only as an alternative source of energy but also an additional source of income [9].

After analyzing the operation of about 5000 biogas plants in Germany, a new method was developed to evaluate their overall performance. The method focuses on four aspects of the evaluation: biogas production, biogas utilization, environmental impact, and financial and economic efficiency. The evaluation of biogas plants showed that biogas utilization has the greatest potential to improve performance by increasing external heat utilization [5].

Analyses of the production parameters of biogas plants, including the reduction of carbon emissions, have shown that electricity from biogas is one of the most promising areas of energy and can become an additional source of income for farmers in Poland [10].

Based on the results of a comprehensive analysis of the development of biogas plants in Poland over 15 years, significant obstacles and high investment risks for the construction of biogas plants in Poland were highlighted [11]. One of the most problematic aspects of biogas plant operations in Poland is the supply of raw materials. As a result of calculating the theoretical annual development potential of biogas plants in Poland, it was found that under the conditions of a certificate system to support the operation of biogas plants, it is economically favorable to use waste for fermentation. In contrast, the operation of biogas plants on corn silage is economically unfeasible [12].

A comparative analysis of the use of different sources of raw materials for biogas plants, from manure to substrate plants (cucurbits, grass) to external substrates produced in the food industry (biological waste) and food residues, has shown that the amount of biogas produced per unit of substrate depends on the quality of the substrate and its components. Sunflower and maize are the most suitable, but alternative energy plants (clover) can also be used [13].

The analysis of exogenous and endogenous determinants of the development of agricultural biogas plants as a chance for diversification of agriculture was carried out in Poland. The structure of raw materials for agricultural biogas production was also analyzed, which allowed us to highlight some problematic points [14].

The problems of regular feedstock supply for biogas production are considered in the study from 2010. The necessity to ensure a regular and uninterrupted supply of raw materials throughout the year was emphasized. The following factors influencing biogas production were identified: political, environmental, energy, and rural development. It is established that producing electricity from agricultural raw materials in biogas plants is one of the most promising energy-political concepts of sustainable development, especially ecological—the economic feasibility of biogas plant development on large farms [15].

The features of the unique biogas plant, which is based on organic by-products from local industry and algae, were investigated [16]. It was shown that this biogas plant solves a critical environmental problem for the municipality and the citizens affected by the odor of rotting algae discharged into Koge Bay. In this way, several issues are solved simultaneously—environmental, energy, and ecological.

Other authors analyzed and assessed the economic feasibility of a biogas reactor. According to the results, the estimated net present value, profitability, and annuity were high, confirming that constructing a biogas plant is a favorable and feasible project. However, it requires government subsidies at the initial stage [17]. The main contribution of this paper is the evaluation of the economic and financial feasibility of biogas plants under the conditions of the Slovak Republic. The presented manuscript is focused on recent urging issues by evaluating biogas plants’ use at the macro and micro level to search for opportunities to reduce the installation cost and make it more affordable for individual farms while contributing to better waste management. At the same time, this topic is one of the most critical research subjects supported by European Union research grants.

In 2015, the authors proposed a methodology for assessing the efficiency and productivity of farms with biogas plants [18]. The study of the input characteristics of environmental, social, and corporate management made it possible to determine the weighting coefficients for the contribution of individual criteria to the resulting farm productivity assessment and propose a concept for managing such firms [18].

Some authors conclude that biogas production benefits farms, the environment, and society and can consequently be a tool for effective waste management [19].

The authors carried out a fairly critical analysis of the biogas plants in 2019 [20]. A study of development trends and factors that promote/block the use of biogas showed the decisive role of government subsidies, which supported high growth rates in the number of biogas installations until the end of 2012, after which their decline was observed. When determining the profitability of a biogas plant, its size and initial cost were taken into account. The researchers concluded that the most common electrical capacity of the station is 1 MW, and its construction costs range from 4.2–4.8 million euros. In addition, actual on-site measurements show a variable biogas composition, while engine emissions are comparable to those of natural gas.

Features of the construction and operation of biogas plants in India to meet energy needs in rural areas were studied by Kalia and Singh (2004) [21]. In the process of designing and evaluating the Himshakti biogas plant project, it was found that if stones from the excavation were used to construct the plants, the cost of these plants could be 9 percent lower. A methodology for detailed analyses of energy consumption in biogas plants, which will make it possible to evaluate and develop proposals for its improvement, is proposed by Lindkvist et al. (2017) [22].

Crucial to the revenues that biogas plants can generate are heat prices. To investigate the influence of this factor, 602 biogas plant operators in Germany were surveyed, obtaining 1035 price points. An average price of 1.91 EUR/kWh at the contract level, an average revenue of 2.1 EUR/kWh at the plant level, and wide price variations across different uses were found. The higher the price of electricity, the more profitable the biogas plant will be because the revenue from the sale of the produced electricity will be higher, and there will be more savings on electricity costs. This should be learned by policymakers when setting subsidies for biogas plants. In the context of rising electricity prices, the subsidy may be smaller because of the expected profit from the biogas plant operation [23].

One of the main reasons why research focused on biogas and biogas plants is so important for society is that they may play a significant role in the transition to a circular economy, which is the economic model of the future. The environmental effect of biogas plants is that they help reduce deforestation and harmful emissions and improve soil fertility and indoor air pollution [1]. The environmental impact of biogas plants is that they help reduce deforestation and harmful emissions, improve soil fertility, and reduce indoor air pollution [1]. Hence, electricity generation from biogas has environmental benefits (reduces emissions and improves environmental performance) and social benefits, but continuous government support for biogas projects is required [24]. Biogas plants are particularly important for stabilizing the electricity system by providing electricity during peak demand periods during the day, as well as for digestate, which is the second product. On the one hand, a great challenge for plant owners; on the other hand, it can be seen as an even greater opportunity for agriculture to become an additional source of revenue [25].

Sørensen and Jørgensen (2022) consider biogas production one of the elements of the bioeconomy and, using input-output analysis, assess the direct and indirect creation of new jobs in biogas plants [18]. The analysis proved that an increase in biogas production by 10% of the available agricultural manure would result in a permanent increase of 342 jobs and an additional annual income of around EUR 21 million [26].

Pfau et al. (2017) found in empirical studies that biogas production can contribute to the achievement of renewable energy policy goals and the transition to a bio-economy, encouraging farmers to collect, use, or sell their biomass (and thus increasing the availability of biomass and their income), allowing the development of new technologies to improve the efficiency of biological stations, but is still underused and not stimulated effectively financially [27].

The EU Act on the Promotion of Renewable Energy Production has led to a rapid increase in the number of biogas plants and a corresponding increase in the share of energy produced from agricultural biogas or renewable sources. In Slovakia, biomass has the highest technical potential among all renewable energy sources while also being a long term, stable energy source with less dependence on seasonal climate fluctuations [28]. That is why the construction of biogas plants will represent a real increase in income with a beneficial effect on the environment and a decrease in the share of imported gas used for heating [28].

Thus, according to the results of analyzing the literature on the problems of biogas plant use, we can conclude that, as a method of waste processing, biogas plants help to solve energy and environmental problems, increase the quality of life of farmers, and address financial and economic issues by providing an additional source of income by producing biogas used for electricity and heat production. This increases the energy and financial independence of farms and the country.

At the same time, there are several problems related to the supply of feedstock to biogas plants, their energy efficiency, and economic viability, which are related to electricity and natural gas prices, as well as perceived government subsidies. The problems also include the high cost of biogas plants, the habit of traditional use of straw and waste as bedding or fertilizer, the insufficient amount of raw materials for processing, and the need for incentives to switch to new waste treatment technologies. Currently, the state does not make sufficient efforts to explain the advantages of biogas plants and provide financial support to farmers. Consequently, many farmers do not fully understand the full range of positive consequences of biogas plant use, including the possibility of obtaining a positive financial and economic effect.

In addition to the direct financial and economic benefits of biofuel production, there are also indirect benefits through environmental effects. Household waste, in particular the manure of cattle, pigs, sheep, horses, and other animals, poultry manure, food waste, vegetable matter, and toilet waste, can significantly pollute the environment and lead to adverse environmental phenomena such as the penetration of various microorganisms into the soil. In the case of poultry and water bodies (bacteria, viruses), fungal spores, and helminth eggs, many of which are potentially dangerous for humans, animals, and plants, they increase the risk of spreading diseases such as botulism, salmonellosis, dysentery, etc.

It should be noted that the useful effect of a biogas plant cannot always be assessed only in monetary terms because:

- Firstly, the replacement of mineral fertilizers with biofertilizers is a transition to a new quality of farming—organic, i.e., environmentally friendly, which has some positive long term consequences for public health;

- Secondly, recycling and decontaminating animal and crop waste is a transition to a new quality of life.

In general, the positive consequences of the use of biogas plants include a set of financial, economic, environmental, and social benefits: utilization and disinfection of animal and crop wastes; improvement of the quality of life of the population, production of environmentally friendly products; improvement of energy supply in rural areas; and additional employment for the people.

The opposing sides of biogas plant operation include difficulties with raw material supply, problems with logistics and seasonality, high cost of equipment and materials for biogas plant construction, technical aspects: irregularity of methane emission process during the period of processing of one load, and labor intensity of separate stages of production (filling the reactor with raw material and removing sludge from it). Also, due to limited land resources, their use for growing energy plants or raw materials for biogas plants reduces the area of possible grain crops for food.

The increased attention to ensuring energy, financial, and economic efficiency of biogas plants is because business is expected to shift from the dominance of ethical and environmental priorities to the principles of rationality, efficiency, and pragmatism very soon. In the mid-term perspective of 5–7 years, entrepreneurs will again return to the need to support the trend of developing environmentally friendly production, but they will already take into account the need to ensure its profitability.

It should be noted that most of the works we studied were written in the fields of bioenergy and biology and studied the technical and technological details of biogas plants and biogas production. All this is important for the efficient operation of biogas plants, but aspects of economic feasibility are not sufficiently covered in the studied literature. Therefore, our work focuses on the benefits of a biogas plant at macro- and micro-levels and the search for the possibility of reducing the cost of construction of biogas plants by roughly calculating the purchase of a separate biogas plant and its installation, provided that the individual works are performed independently (as, for example, in the work by Kalia and Singh (2004) [21]. From a practical point of view, it can serve as an argument for adjusting the state agricultural policy. It is a question of providing financial assistance to farmers (soft loans) for the construction of biogas plants, which would be more appropriate and effective than the current system of subsidizing agriculture. The realization of this research is based on the author’s involvement in the long term strategic project of the European Union—URANOS. This project’s main goal is the creation of a database and knowledge base to support strategic planning and decision-making processes in the area of adaptation towards climate change minimalization of agricultural soil degradation, which directly reflects the long term goal of RIS3—decreasing the chance of risk in the process of ensuring production functions of agricultural soils related to climate change. The main goal of the presented study was to find ways to decrease the costs of constructing biogas plants. This is through performing a calculation of the costs of purchasing a biogas plant as well as its installation costs. The authors also conducted a literature search with an emphasis on the main topic of this paper. The results in the literature were compared to the results obtained in this research.

2. Materials and Methods

The information basis for writing the article was the open-access data of firms engaged in the production and sale of biogas plants in different countries, as well as the data of a private firm that has been using a biogas plant since 2010.

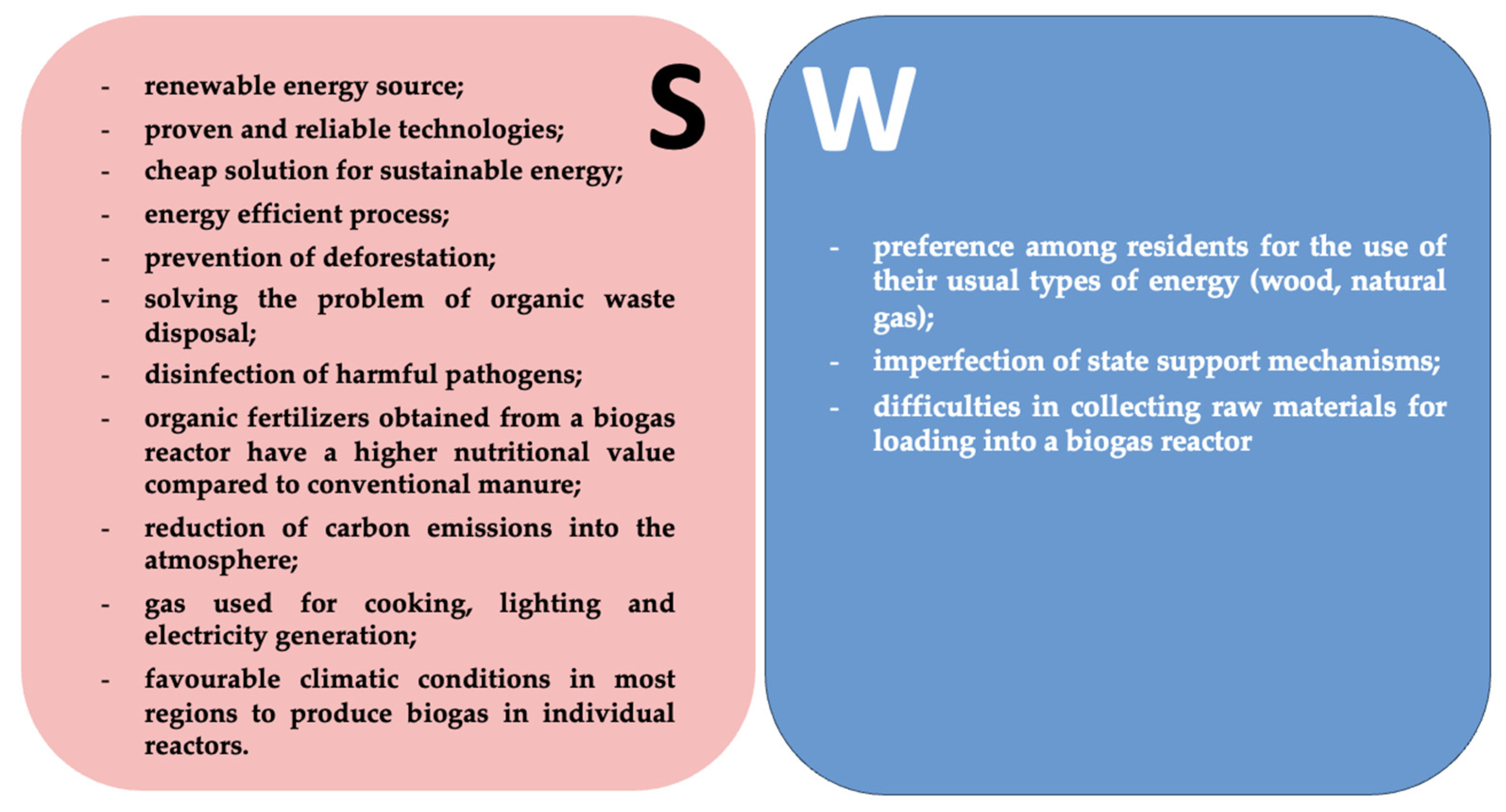

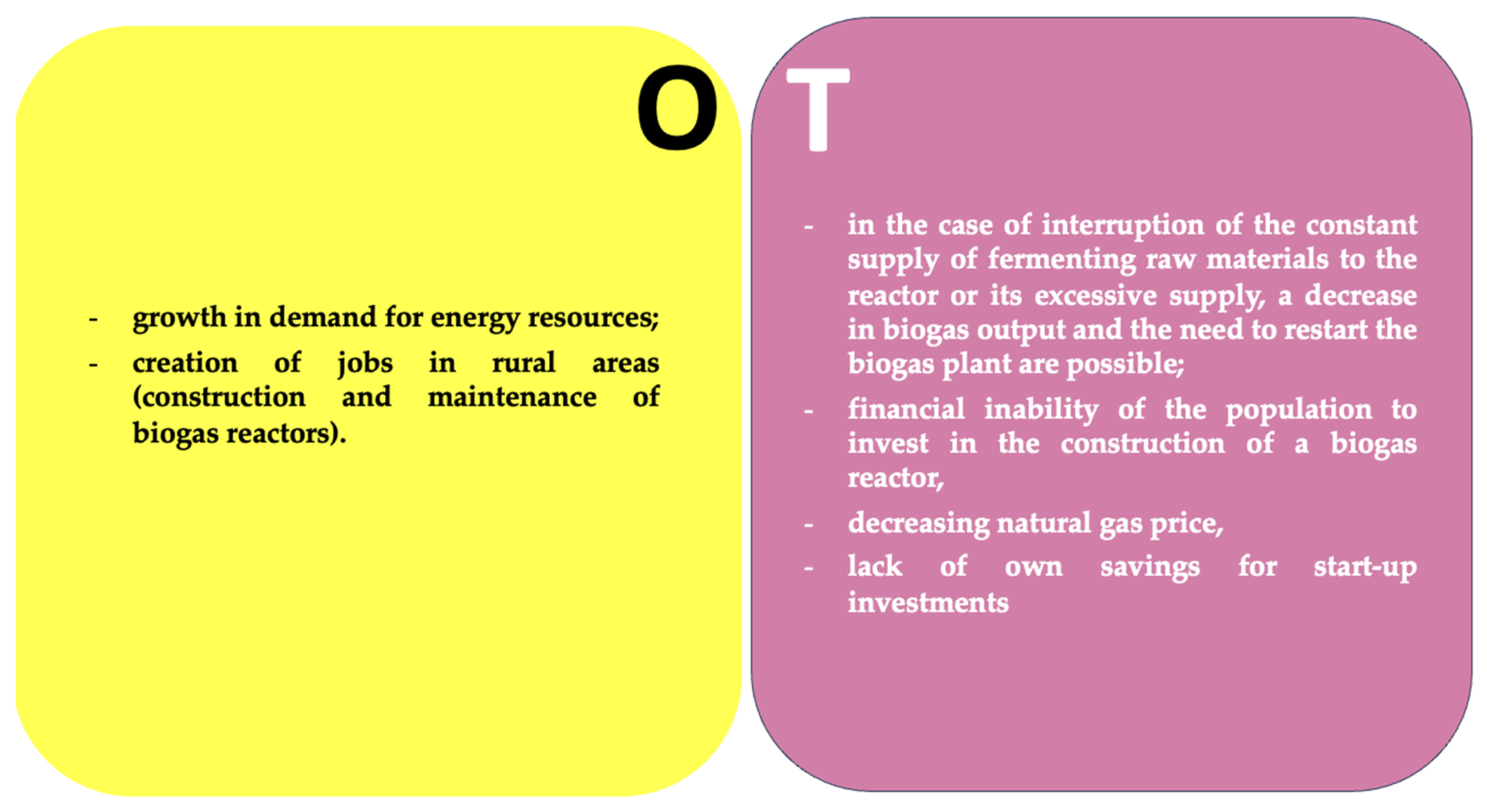

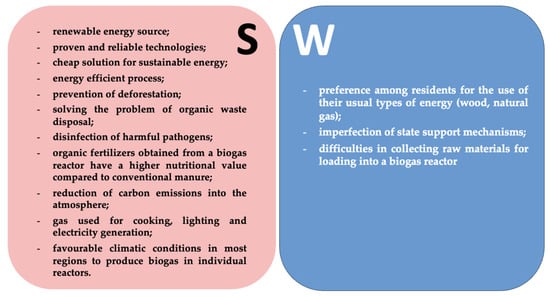

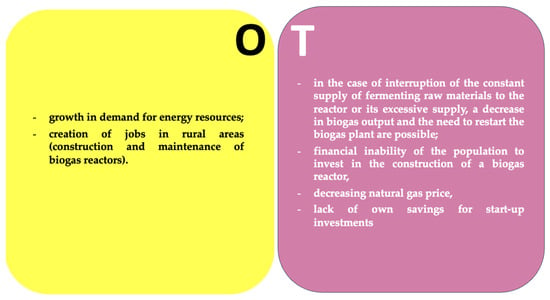

To determine the set of positive consequences and problematic moments of biogas plant functioning, the analytical method and the method of cause-and-effect relations were used. By the method of complex analysis and generalization of results of scientific research and practice, conclusions were drawn about the role of biogas plants in solving agrarian, environmental, and state energy problems in the state. Along with the method of generalization, SWOT analysis was used to determine the advantages and risks of the biogas plant project implementation, which is a very helpful tool to pinpoint relevant factors. Standard SWOT analysis was used in this paper to identify internal factors—strengths and weaknesses, as well as opportunities and threats—as external factors for biogas plants.

Based on the study of materials on the websites of companies that manufacture and install biogas plants on a turnkey basis, as well as unique literature that describes the process of construction and installation of biogas plants, an approximate (conditional) list of works for the installation of biogas plants was drawn up, and the number of necessary materials was determined according to the construction standards. Using data from the European Statistical Commission allowed us to determine the prices and calculate the approximate cost of construction work. All calculations are rather conventional, as they were made on the example of a small biogas plant and using data from a company whose name was asked not to be disclosed for ethical reasons.

The calculation of the operating costs of biogas plants was made based on the financial materials of private farming, which is not part of the group of large agricultural enterprises and has no significant influence on the local market with/x products and food and specializes in crop production. When calculating the biogas plant performance, we relied on the documentation of producers of biogas plants, which are placed on their sites, as well as generally known proportions: 1 m3 of biogas can produce 2–2.5 kW of electricity and up to 2.5–3 kWh of heat energy; when producing heat, 1 m3 of natural gas is equal to 1.5 m3 of biogas. According to Eurostat statistical data, gas prices in Europe have been decreasing since the end of 2022; on 25 May 2023, for the first time in two years, they dropped below 300 USD/thousand m3. The price dropped 13 times from the record values of the first days of spring 2022—3892 USD/ thousand m3.

The income discounting method was used to determine the efficiency of using the biogas plant as an investment project. The discount rate used was the amount of the loan interest rate and the projected inflation rate of 2.5% (ECB projections).

A regression using ordinary least squares was also constructed to determine the measure of the cost-benefit and income-benefit ratios (the initial data recalculated in logarithmic form). The resulting ratios showed a possible percentage increase in profits with a change in one case—expenditure—and the other, 1%.

3. Results

The SWOT analysis of the construction and operation of each individual biogas plant is summarized in Figure 1 and Figure 2. SWOT analysis demonstrates that the strengths and opportunities of biogas plants far outweigh the weaknesses and threats that can be easily overcome through various regulatory mechanisms.

Figure 1.

Internal factors of biogas SWOT analysis. Source: Malik et al., 2020 [29]; Shkarivska et al., 2020 [30]; Shpychak et al., 2015 [31]; Tokarchuk et al., 2020 [32].

Figure 2.

External factors of biogas SWOT analysis. Source: Malik et al., 2020 [29]; Shkarivska et al., 2020 [30]; Shpychak et al., 2015 [31]; Tokarchuk et al., 2020 [32].

The main goal of the SWOT analysis is to demonstrate the potential of biogas plants as well as the opportunities, threats, and challenges they may face, what strengths can be promoted as advantages of biogas plants by renewable energy communities, and more. This SWOT analysis can help both private and state investors decide whether to invest in this green source’s production. In this SWOT analysis, strengths seem to bear the greatest significance and weight. These promote the advantages of biogas and biogas plants in social as well as environmental aspects. According to the URSO statistics, 111 biogas stations with a total output of 103 MW were established in Slovakia by the end of July 2015 and 108 in 2020. Now, the implementation of biogas and biomethane projects in Slovakia faces several financial problems. Firstly, the lack of own savings farms for start-up investments and difficulties in obtaining a loan—as a rule, this is only about 20–25% of the initial capital costs. Bank borrower requirements are often too stringent for individual investors (for example, farmers) to raise the necessary capital. From the bank’s point of view, clients often lack the technical knowledge in this area and the correct calculation of a sufficient number of indicators to assess the risk/return for individual projects adequately. Some risks are difficult to determine, such as the security of feedstock supply or the non-compliance of biogas with stringent gas quality standards for injection into national distribution networks. This may affect the loan parameters (increase the percentage, shorten the term).

State support can simplify obtaining a loan for a biogas plant. We conducted a SWOT analysis to assess the advantages and problems of the installation and operation of biogas plants, which will help to understand whether the state should support their implementation.

The above SWOT analysis demonstrates that the strengths and opportunities of biogas plants far outweigh the weaknesses and threats that can be easily overcome through various regulatory mechanisms. Therefore, it makes sense for the state to support farmers in their desire to install a biogas plant by providing both preferential financing and explaining the advantages and possibilities of installing a biogas plant on a separate farm.

We assessed the financial aspects of the implementation of biogas plants at the micro level to determine the direction of state support for farmers. For a rough estimate of the cost of purchasing and operating a biogas plant, the following figures can be used: based on market offers from biogas plant companies, the total cost of a biogas plant without land costs is EUR 936.6 (USD 500) per 1 m3 of reactor capacity, 30–40% of the total cost is for a metal reactor, and construction works can be up to 25% of the biogas plant cost. The cost of each project is calculated based on material prices, the availability of materials, and labor. On average, the cost of its installation, considering transport and design works, can be about EUR 150–200 thousand, and the cost of the reactor is shown in Table 1.

Table 1.

Cost of a biogas plant and its characteristics, as presented on the specialized sales site [33].

When buying a biogas plant, the fact that the manufacturer reduces its cost, despite the increase in the volume of the reactor should be taken into account, which, accordingly, increases the ability to process a large amount of raw material per year. Thus, there is a financial opportunity to buy more biogas, especially with the possibility of its subsequent operation by several farms. However, in this case, it should be kept in mind that the costs of gas and water supply, logistics of raw material supply, and sales of products will also increase.

Based on data from a private farm that is not a large agricultural enterprise and has no significant impact on the local market for farm products and food, although it specializes in crop production, and with the purchase of a biogas plant he sells energy, we analyzed the cost of implementing a 2448 m3 biogas plant project (2010–2020). In 2010, the cost of installing and commissioning a 2448 m3 biogas plant was EUR 3.6 million. A soft loan of EUR 1.5 million at 7 percent interest was taken to purchase the biogas plant. The amortization period was assumed to be 15 years. The estimated profitability, according to the documents, is 3.3% per year, and the average annual profit of the farmer should be at the level of EUR 100 thousand. The biogas plant was used to produce and sell electricity. The ratio of sold and owned electricity consumption during 10 years was on average 60–80%. The forecasts of average annual expenses and incomes, which were taken into account by the private farmer when estimating the biogas plant as an investment project, are given in Table 2 (depreciation is not accelerated, equal shares).

Table 2.

Data for financial calculations: cost and annual profit for the biogas stations based on forecast data from a private entity.

By discounting total annual income and total annual costs by the rate of 9.5 (7%—the average market rate of credit and 2.5%—the average annual rate of inflation), we got the following indicators in Table 3.

Table 3.

Discounted income and expenses of a biogas plant (EUR, thousand).

Thus, the NPV for 15 years of operation of the biogas plant was EUR 1.2 million, which made the biogas plant an attractive enough project.

As for the actual economic indicators of the biogas plant operation, according to data provided by the private sector, only four years from 2014 to 2017 were profitable for the period of operation of the biogas plant from 2012 to 2020 (Table 4).

Table 4.

Financial indicators of the biogas station based on data from a private company, EUR.

Profit was only generated if the portion of electricity sold was more than 70%. This is because the main component of efficiency is the expression of additional benefits from the sale of electricity. For waste treatment’s ecological and economic efficiency, both the financial savings on energy resources obtained by processing waste and the income from the sale are important. The difference in the price of natural gas and the cost of production of own biogas reduces direct material costs in the cost structure of the main production, and the income from sale increases the profit. Thus, the potential profit of biofuel production on a farm is determined based on its needs for energy resources and the possibility of realizing the produced electricity.

The loss rate in the first two years was at the level of 10–11% due to loan repayments, and in the last years (2018–2020), it was 1–2%. The expiry of state subsidies and the need to apply for them due to changes in the legislative requirements, where the focus was shifted from biomass processing to agricultural waste, worsened the situation with the profitability of the biogas plant.

The regression analysis of the profit-to-expenditure ratio showed that the profit-to-expenditure ratio was less than the income ratio (co-effects 0.88 and 1.44, respectively). However, an R-square = 8% regression of profit on income means there is no linear relationship, possibly due to the presence of subsidies, so we do not present this regression in the article. Profit is negatively affected by the operating costs of the biogas plant, depreciation (about 50%), maintenance (Jenbacher repair service, 10%), the high ongoing costs of operating and maintaining the plant, as well as the cost of materials and labor [24].

- procurement (payment, collection, and transport of raw materials);

- water consumption for cleaning the farm and breeding the feedstock;

- fueling and operation of the biogas plant;

- monitoring, inspection, and repair of the biogas plant;

- storage of biofertilizer;

- distribution and utilization of biogas.

A regression analysis of the dependence of profit on expenses is given in Table 5.

Table 5.

Regression analysis of the dependence of profit on costs.

As world practice shows, it is possible to save money on the biogas plant project by performing part of the work and some elements of installation independently. For example, many construction materials (digging of pits, construction of protective hedges) can be performed independently, and any hermetically sealed container can be used as a reactor or welded from steel sheets.

There are three main categories of costs associated with biogas plants:

- The cost of construction and materials;

- The cost of operation and maintenance;

- Interest if a loan is taken for the construction of a biogas plant (on average, banks charge 7–9% per annum for a soft loan under state aid).

A government subsidy can compensate for the high costs of loan repayment during the first few years. Therefore, the state should bear part of the cost of financing biogas plants by directly subsidizing their installation through private measures or reimbursing the loan amount to compensate for the interest rate. Usually, the share of equity capital in the total capital costs of a prominent investment project (and the construction of a biogas plant is the same for a single farm), according to the data of a specialized investment company, is from 10 to 50% [30].

The proportion of the distribution of own and public funds in the financing of the biogas plant depends on several factors:

- cost of a biogas plant: the greater it is, the greater the need for subsidies;

- financial situation of the farm;

- the level of risk—the propensity to invest with a high level of risk is higher for investment companies, and the state is focused on the macro-economic effect, which also increases the risk threshold of its investments;

- positive external macroeconomic effects that justify a government subsidy.

The percentage of funding from the state is determined according to the parameters of each individual project. To overcome financial obstacles, farmers use different approaches, including attracting sponsors—energy companies or large agro-firms—or farmers can form agricultural co-operatives. Market-based financing methods, such as green bonds or investment company trust funds, can be used [34]. There are many financing models, but not all farm managers are aware of them.

Also consider the possibility of reducing the cost of the first item during the construction phase of the biogas plant premises. The construction cost includes all the traditional costs necessary for the construction of an industrial facility (cost of land acquisition or lease, foundations, preparation and installation of the reactor, gas system, storage and mixing tanks for raw materials and fertilizer, storage tanks for biogas and biofertilizer, wages of workers, etc.) and depends on factors such as the model and size of the biogas plant, quantity and cost of materials required, a number of working days, and the wages of maintenance staff.

Table 6 gives an estimate of the estimated cost of construction and commissioning of an individual biogas plant with a volume of 2500 m3, provided that the farm performs construction work independently.

Table 6.

Approximate estimates for construction and commissioning of an individual biogas plant with a capacity of 2500 m3.

Thus, if the construction works are performed independently, the cost of implementing a biogas plant in 2022 would be 1,105,536 euros, which is significantly lower than the cost of purchasing a biogas plant package of work for its commissioning in the case of the example we considered of a private farm (EUR 3.6 million in 2010). With inflation of 2.5% over the years, the cost could have risen to EUR 3.69 million. However, it appears to be lower. We assume that this is the result of independent construction work, as well as the fact that the decrease in costs is also due to the overall cost reduction of biogas plants as a result of their wide use and technical progress.

In general, the purchase and utilization of biogas plants at the farm level, provided that a state subsidy is received, can be break-even: while being financially unprofitable in some years, it can bring significant benefits in the energy, environmental, and social dimensions. When assessing the macro- and microeconomic financial and economic efficiency of biogas plant construction, it is necessary to take into account the fact that the use of individual biogas plants contributes to the integrated solution of agricultural and energy problems.

4. Discussion

The necessity to spread biogas plants in Slovakia at the macro level is determined by the financial, economic, and energy problems of the current period and the need to follow the “green” course of sustainable development, which is the main direction of EU policy. The need for the use of biogas plants by farms is determined by the fact that, firstly, these farms have a raw material base: in addition to household waste, there is also waste from auxiliary farms, the increase of which leads to an increase in the negative impact on the environment. Secondly, the growing cost of energy resources worsens the financial and economic condition of the country and individual farms and pushes them to search for new sources of profit. A SWOT analysis of the use of individual biogas plants allowed us to demonstrate the obstacles to the expansion of the use of individual biogas plants in agriculture in Slovakia. Our results of SWOT analysis were similar to the results of a study conducted by authors Brudermann T. et al., although they concluded their research pointing to results indicating strong drive by external factors, which was different in our case [36]. In general, the construction of individual biogas plants operating on crop and livestock waste is bio-energy efficient and economically beneficial for society.

The study of the financial and economic aspects of the purchase and operation of biogas plants based on the experience of a private company, as well as the assessment of the cost of construction of biogas plants, considering the possibility of self-performance of some of the works, showed the possibility of significant cost reduction in the latter case.

We estimate the total cost of the biogas plant start-up work to be EUR 1,105,536 if the individual works were carried out independently, whereas the project for the purchase and installation of biogas plants in 2010 cost EUR 3.6 million. According to a similar study, in Latvia, biogas plants seem to be more expensive. Total investment was calculated to be 3,600,000 EUR, solely plant expenses being 2,892,384 EUR [37].

5. Conclusions

Based on the data obtained from the private farm, we have tested the profitability of the project for a biogas plant of 2448 m3. The estimated NPV for 15 years of operation of the biogas plant was EUR 1.2 million, which made the biogas plant an attractive enough project. In fact, only four years from 2014 to 2017 were profitable for the period of exploitation of the biogas plant from 2012 to 2020.

According to our estimates, it is possible to reduce the cost of commissioning and commissioning of the biogas plant if individual works are carried out independently (EUR 1,105,536 in 2022. against EUR 3.6 million in 2010). According to the analysis of the private company data, the profit was realized only if the share of electricity sold was more than 70%. If energy prices rose, as was very likely in the current volatile global energy markets, they would be at a loss.

The purchase and use of biogas plants by a farm under the condition of state subsidy may be unprofitable at the level of the individual farm but can bring significant benefits to society in the energy, environmental, and social dimensions. So, regarding the performance of the biogas plant, the anaerobic digestion of organic waste in the bioreactor produces:

- Biogas has approximately 60% methane, 38% carbon dioxide, and 2% hydrogen sulfide and moisture. After purification from hydrogen sulphide and moisture, it is used as natural gas in conventional gas appliances with minimal modification.

- Biofertilizers without the smell of pus have a moisture content of 95% and contain all the necessary complex of nutrients NPK, which is not the case with manure, which overripens in heaps because nitrogen fertilizers evaporate by 80%. In Europe, a tonne of biohumus with a moisture content of 40–60% costs approximately EUR 500. Thanks to biofertilizers it is possible to increase yields by 10–20%, and the output will be environmentally friendly (organic) products grown without mineral fertilizers and herbicides (weed seeds on biogas plants lose germination). Organic products cost at least twice as much as conventional ones.

That is, not enough positive direct effects at the micro level will be covered by indirect benefits at the macro level. The positive influence of biogas plants will spread to such industries as agriculture (waste processing and biofuel production, improvement of farmers’ living standards, energy sector: consumption of biogas for heat production, electricity, or transport); production and maintenance of biogas plants will receive a strong impulse. Environmental protection: reduction of greenhouse gas emissions and improvement of air quality.

SWOT analysis of the use of individual biogas plants has confirmed their value for society and financial and economic feasibility at the micro level. Increasing the number of individual biogas plants will allow the state to take a step towards solving the environmental problem of waste processing and create the possibility of additional electricity production and additional income for farmers. In the future, it will save budget funds, which are now spent on subsidies for agriculture. Agrarians will be able to process waste into biofertilizers, biofuels, and electricity. Manufacturers of biogas equipment will expand sales of their products and gain profit, which can give a multiplicative impetus to the development of production in neighboring industries. Thus, the total financial and economic effect will significantly exceed the benefit of an individual farm. Therefore, it is advisable to envisage such a direction in state aid to agriculture as stimulating the purchase and operation of biogas plants by farms, which forms the basis for future savings of public funds and solves environmental, financial, and economic problems. In order to make a balanced transition, a plan should be developed and followed to reorient agricultural subsidies from land size to the criterion of the level of use of modern technologies, including using a biogas plant in the framework of the EU Green Policy.

Several technical details of biogas plant operation have been overlooked in this paper—fluctuations in biogas production during the winter months and insufficient use of dynamic investment appraisal methods defined in terms of cash flows. Also unexplored is the problem of feedstock supply for biogas plants—agricultural waste may not be enough to keep the plant running, which may require the use of biomass for the biogas plant. In turn, this creates a dilemma between the efficiency of utilizing land for crops to produce grain for food consumption, or to produce bioenergy. A more detailed analysis of these points is the subject of future research.

The implementation of methods of processing waste and biomass into biofuels through the installation of biogas plants seems to be quite accessible. The stemming recommendation is the stimulation and support of farms, which should bring many positive effects to agriculture as well as energetics. That way, the energetic independence of farmers can increase, and the current situation of the environment can get better through waste recycling. This can be a great opportunity to decrease fuel costs and earn additional income in the case of the sale of biofuels or their purchase by the state, as well as contribute to innovative technologies within the “green course” development of the European economy.

Author Contributions

Conceptualization, P.B. and S.B.; methodology, S.B.; validation, I.A. and Y.B.; formal analysis, I.A.; investigation, S.O.; resources, I.A.; data curation, P.H.; writing—original draft preparation, S.B.; writing—review and editing, S.O., P.B. and P.H.; visualization, Y.B.; supervision, P.B.; project administration, P.H.; funding acquisition, P.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

3rd Party Data. Restrictions apply to the availability of these data. Data were obtained from the company owning the biogas plant that wants to remain anonymous and are available from the author Stefaniia Belinska with the permission of the company.

Conflicts of Interest

Author Stefaniia Belinska was employed by Grant Thornton Audit, s.r.o. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Barnes, D.F.; Khandker, S.R.; Samad, H.A. Energy poverty in rural Bangladesh. Energy Policy 2011, 39, 894–904. [Google Scholar] [CrossRef]

- Alayi, R.; Shamel, A.; Kasaeian, A.; Harasii, H.; Topchlar, M.A. The role of biogas to sustainable development (aspects environmental, security and economic). J. Chem. Pharm. Res. 2016, 8, 112–118. [Google Scholar]

- Feng, Y.; Shoaib, M.; Akram, R.; Alnafrah, I.; Ai, F.; Irfan, M. Assessing and prioritizing biogas energy barriers: A sustainable roadmap for energy security. Renew. Energy 2024, 223, 120053. [Google Scholar] [CrossRef]

- Effenberger, M.; Lehner, A.; Đatkov, Đ.; Gronauer, A. Performance figures of Bavarian agricultural biogas plants. Contemp. Agric. Eng. 2009, 35, 219–227. [Google Scholar]

- Djatkov, D.; Effenberger, M.; Lehner, A.; Martinov, M.; Tesic, M.; Gronauer, A. New method for assessing the performance of agricultural biogas plants. Renew. Energy 2012, 40, 104–112. [Google Scholar] [CrossRef]

- Wu, D.; Peng, X.; Li, L.; Yang, P.; Peng, Y.; Liu, H.; Wang, X. Commercial biogas plants: Review on operational parameters and guide for performance optimization. Fuel 2021, 303, 121282. [Google Scholar] [CrossRef]

- Yalew, A.W. Economic contributions and synergies of biogas with the SDGs in Ethiopia. Energy Nexus 2021, 3, 100017. [Google Scholar] [CrossRef]

- Bedana, D.; Kamruzzaman, M.; Rana, J.; Mustafi, B.; Talukder, R.K. Financial and functionality analysis of a biogas plant in Bangladesh. Heliyon 2022, 8, e10727. [Google Scholar] [CrossRef]

- Iqbal, N.; Sakhani, M.A.; Khan, A.R.; Rehman, A.U.; Ajmal, Z.; Khan, M.Z. Socioeconomic impacts of domestic biogas plants on rural households to strengthen energy security. Environ. Sci. Pollut. Res. 2021, 28, 27446–27456. [Google Scholar] [CrossRef]

- Rzeznik, W.; Mielcarek, P. Agricultural Biogas Plants in Poland. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; pp. 1760–1765. [Google Scholar]

- Igliński, B.; Piechota, G.; Iwański, P.; Skarzatek, M.; Pilarski, G. 15 Years of the Polish agricultural biogas plants: Their history, current status, biogas potential and perspectives. Clean Technol. Environ. Policy 2020, 22, 281–307. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Iglińska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plants in Poland: Investment process, economical and environmental aspects, biogas potential. Renew. Sustain. Energy Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Vindiš, P.; Muršec, B.; Lakota, M.; Stajnko, D.; Sagadin, M. Biogas produced from energy plants. In Proceedings of the 37th International Symposium’Actual Tasks on Agricultural Engineering, Opatija, Croatia, 10–13 February 2009; Volume 10, pp. 247–255. [Google Scholar]

- Chodkowska-Miszczuk, J.; Szymanska, D. Agricultural biogas plants-A chance for diversification of agriculture in Poland. Renew. Sustain. Energy Rev. 2013, 20, 514–518. [Google Scholar] [CrossRef]

- Kirstukas, J.; Kilciauskaite, L. Economic potential for biogas plants in agricultural enterprises. Manag. Theory Stud. Rural. Bus. Infrastruct. Dev. 2010, 24, 71–77. [Google Scholar]

- Landt, C.; Gaarsmand, R.; Palsberg, A.; Kjær, T.; Goldberg-Larsen, F. Planning for Biogas Plant in Denmark. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; ETA-Florence Renewable Energies: Firenze, Italy, 2016; pp. 1571–1578. [Google Scholar]

- Obileke, K.; Makaka, G.; Nwokolo, N.; Meyer, E.L.; Mukumba, P. Economic Analysis of Biogas Production via Biogas Digester Made from Composite Material. Chemengineering 2022, 6, 67. [Google Scholar] [CrossRef]

- Kasem, E.; Trenz, O.; Hrebicek, J.; Faldik, O. Mathematical model for sustainability assessment of agriculture farms with biogas plants. In Proceedings of the 33rd International Conference Mathematical Methods in Economics, Cheb, Czechia, 9–11 September 2015; pp. 343–348. [Google Scholar]

- Cucui, G.; Ionescu, C.A.; Goldbach, I.R.; Coman, M.D.; Marin, E.L.M. Quantifying the Economic Effects of Biogas Installations for Organic Waste from Agro-Industrial Sector. Sustainability 2018, 10, 2582. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A. Italian Biogas Plants: Trend, Subsidies, Cost, Biogas Composition and Engine Emissions. Energies 2019, 12, 979. [Google Scholar] [CrossRef]

- Kalia, A.K.; Singh, S.P. Development of a biogas plant. Energy Sources 2004, 26, 707–714. [Google Scholar] [CrossRef]

- Lindkvist, E.; Johansson, M.T.; Rosenqvist, J. Methodology for Analysing Energy Demand in Biogas Production Plants—A Comparative Study of Two Biogas Plants. Energies 2017, 10, 1822. [Google Scholar] [CrossRef]

- Herbes, C.; Halbherr, V.; Braun, L. Factors influencing prices for heat from biogas plants. Appl. Energy 2018, 221, 308–318. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, Y. Economic analysis of large-scale farm biogas power generation system considering environmental benefits based on LCA: A case study in China. J. Clean. Prod. 2020, 258, 120985. [Google Scholar] [CrossRef]

- Czekała, W.; Jasiński, T.; Grzelak, M.; Witaszek, K.; Dach, J. Biogas Plant Operation: Digestate as the Valuable Product. Energies 2022, 15, 8275. [Google Scholar] [CrossRef]

- Sørensen, J.F.L.; Jørgensen, H.P. Rural Development Potential in the Bioeconomy in Developed Countries: The Case of Biogas Production in Denmark. Sustainability 2022, 14, 11077. [Google Scholar] [CrossRef]

- Pfau, S.F.; Hagens, J.E.; Dankbaar, B. Biogas between renewable energy and bio-economy policies—Opportunities and constraints resulting from a dual role. Energy Sustain. Soc. 2017, 7, 17. [Google Scholar] [CrossRef]

- Janíček, F.; Perný, M.; Šály, V.; Némethová, J. Biogas Stations in Slovakia—Current State. Transactions on Electrical. Engineering 2018, 7, 79–85. [Google Scholar]

- Maлiк, M.; Шпикyляк, O.; Maмчyp, B. Peaлiзaцiя цiлeй cтaлoгo poзвиткy Укpaїни в кoнтeкcтi тpaнcфopмaцiї ocoбиcтих ceлянcьких гocпoдapcтв y ciмeйнi фepмepcькi. Екoнoмiкa Пpиpoдoкopиcтyвaння I Стaлий Poзвитoк 2020, 26, 21–31. [Google Scholar]

- Шкapiвcькa, Л.I.; Дaвидюк, Г.B.; Климeнкo, I.I.; Дoвбaш, H.I. Bикopиcтaння вiдхoдiв бioгaзoвих ycтaнoвoк для yдoбpeння ciльcькoгocпoдapcьких кyльтyp. Агpoeкoлoгiчний Жypнaл 2020, 1, 75–82. [Google Scholar]

- Шпичaк, O.M.; Бoднap, O.B. Енepгeтичний пiдхiд щoдo oцiнки тpaнcфopмaцiй в ciльcькoмy гocпoдapcтвi чepeз пpизмy фiзioкpaтичних пoглядiв y кoнтeкcтi iннoвaцiйних пpoцeciв. Екoнoмiкa АПК 2015, 15, 5–16. [Google Scholar]

- Tokarchuk, D.; Prishlyak, N.; Palamarenko, Y. Methodology for calculating the economic efficiency of waste use for the production of biofuels in comparison with their traditional use. Slovak Sci. J. 2020, 47, 12–29. [Google Scholar]

- Fluid 2021. Prices of Biogas Plant. Available online: http://www.fluid-biogas.com/?page_id=185 (accessed on 5 February 2023).

- IEA. Outlook for Biogas and Prospects for Organic Growth. 2020. Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth (accessed on 15 February 2023).

- Zorg Biogas. 2023. Available online: https://zorg-biogas.com/ (accessed on 19 February 2023).

- Brudermann, T.; Mitterhuber, C.; Posch, A. Agricultural biogas plants—A systematic analysis of strengths, weaknesses, opportunities and threats. Energy Policy 2015, 76, 107–111. [Google Scholar] [CrossRef]

- Kremljak, Z. Economy of biogas plants. In Proceedings of the 28th DAAAM International Symposium, Zadar, Croatia, 8–11 November 2017; pp. 0136–0143. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).