Use of Waste from the Food Industry and Applications of the Fermentation Process to Create Sustainable Cosmetic Products: A Review

Abstract

1. Introduction

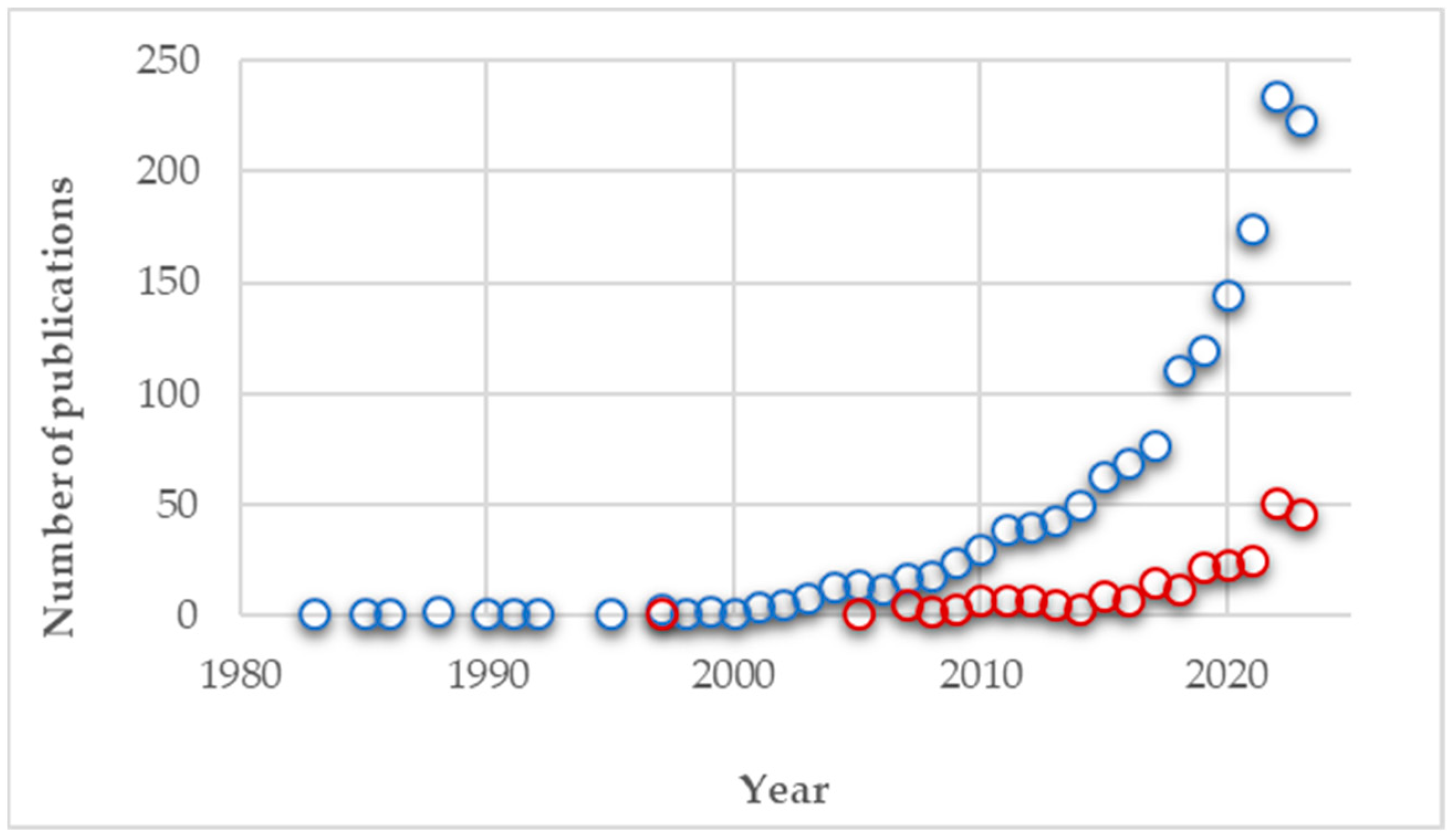

2. Methods

3. Results and Discussion

3.1. European Green Deal

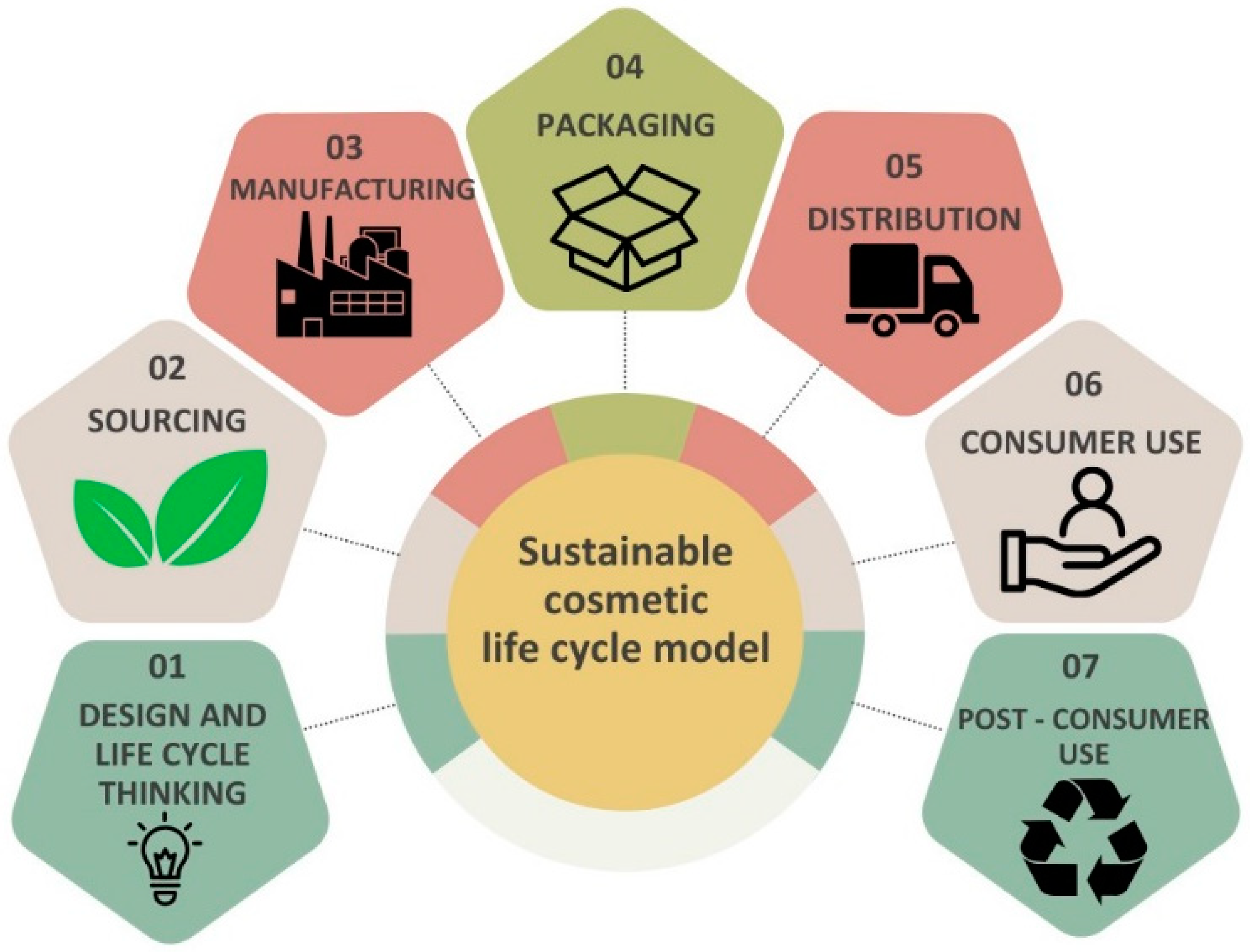

3.2. Sustainable Cosmetic Products

3.2.1. Design and Life Cycle Thinking (LCT)

3.2.2. Sourcing of Raw Materials

3.2.3. Manufacturing

3.2.4. Packaging

3.2.5. Distribution

3.2.6. Consumer and Post-Consumer Use

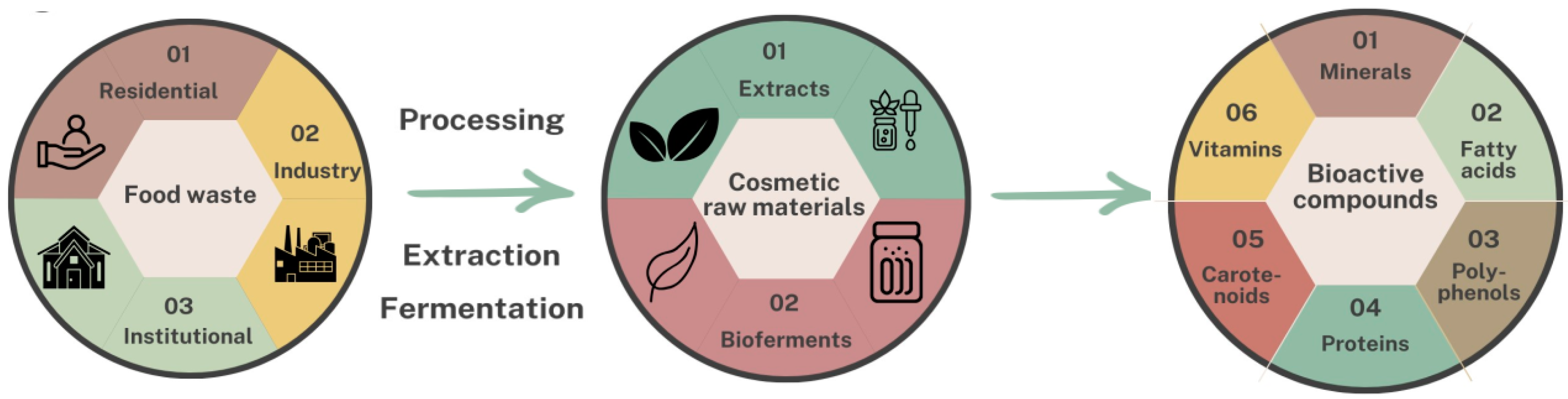

3.3. Food Waste as Sustainable Raw Materials

3.3.1. Upcycling

3.3.2. Extraction Methods of Recovering Bioactive Compounds from Food Waste

3.3.3. Cosmetic Properties of Phytochemicals Derived from Agri-Food Waste

3.4. Bioactive Compounds from Fruits Waste

3.4.1. Citrus Waste

3.4.2. Banana Waste

3.4.3. Mango Waste

3.4.4. Apple Waste

3.4.5. Avocado Waste

3.4.6. Olive Waste

3.4.7. Grapes Waste

3.4.8. Pomegranate Waste

3.4.9. Coffee Waste

3.5. Bioactive Compounds from Vegetable Waste

3.5.1. Tomato Waste

3.5.2. Carrot Waste

3.5.3. Potato Waste

3.6. Bioactive Compounds from Animal Waste

3.7. Bioferments

3.8. Bioferments in the Cosmetic Industry

4. Summary and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bom, S.; Jorge, J.; Ribeiro, H.M.; Marto, J. A step forward on sustainability in the cosmetics industry: A review. J. Clean. Prod. 2019, 225, 270–290. [Google Scholar] [CrossRef]

- Sahota, A. Sustainability: How the Cosmetics Industry is Greening Up, 1st ed.; John Wiley & Sons Ltd.: London, UK, 2014. [Google Scholar]

- precedenceresearch.com. Available online: https://www.precedenceresearch.com/cosmetics-market (accessed on 31 January 2024).

- Kolling, C.; Ribeiro, J.L.D.; De Medeiros, J.F. Performance of the cosmetics industry from the perspective of Corporate Social Responsibility and Design for Sustainability. Sustain. Prod. Consum. 2022, 30, 171–185. [Google Scholar] [CrossRef]

- Acharya, S.; Bali, S.; Bhatia, B.S. Exploring Consumer Behavior towards Sustainability of Green Cosmetics. In Proceedings of the International Conference on Advances in Electrical, Computing, Communication and Sustainable Technologies (ICAECT), Bhilai, India, 19–20 February 2021. [Google Scholar]

- Fortunati, S.; Martiniello, L.; Morea, D. The Strategic Role of the Corporate Social Responsibility and Circular Economy in the Cosmetic Industry. Sustainability 2020, 12, 5120. [Google Scholar] [CrossRef]

- Rocca, R.; Acerbi, F.; Fumagalli, L.; Taisch, M. Sustainability paradigm in the cosmetics industry: State of the art. Clean. Waste Syst. 2022, 3, 100057. [Google Scholar] [CrossRef]

- cosmeticseurope.eu. Available online: https://www.cosmeticseurope.eu/files/4214/6521/4452/GSP_Brochure.pdf (accessed on 31 January 2024).

- Bom, S.; Ribeiro, H.M.; Marto, J. Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability 2020, 12, 1437. [Google Scholar] [CrossRef]

- Goyal, N.; Jerold, F. Biocosmetics: Technological advances and future outlook. Environ. Sci. Pollut. Res. 2023, 30, 25148–25169. [Google Scholar] [CrossRef]

- Fang, X.; Gao, B.; Zhong, D.; Wang, L.; Borrion, A.; Huang, W.; Xu, S.; Cui, S. Closing the food waste loop: Analysis of the agronomic performance and potential of food waste disposal products. J. Clean. Prod. 2023, 382, 135174. [Google Scholar] [CrossRef]

- Morganti, P.F.; Gao, X.; Vukovic, N.; Gagliardini, A.; Lohani, A.; Morganti, G. Food Loss and Food Waste for Green Cosmetics and Medical Devices for a Cleaner Planet. Cosmetics 2022, 9, 19. [Google Scholar] [CrossRef]

- Communication from the Commission to the European Parliament, The European Council, The Council, The European Economic and Social Committee and The Committee of the Regions. The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2019:640:FIN (accessed on 15 March 2024).

- Szpilko, D.; Ejdys, J. European green deal-research directions. A systematic literature review. Ekon. I Sr. 2022, 82, 8–38. [Google Scholar] [CrossRef]

- Leskinen, S. Sustainability in the Cosmetic Industry Value Chain. Bachelor’s Thesis, International Business Oulu University of Applied Sciences, Oulu, Finland, 2020. [Google Scholar]

- Eckert, E.; Kovalevska, O. Sustainability in the European Union: Analyzing the Discourse of the European Green Deal. J. Risk Financ. Manag. 2021, 14, 80. [Google Scholar] [CrossRef]

- On the Path to a Climate-Neutral Europe by 2050. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en (accessed on 15 March 2024).

- Communication from the Commission to the European Parliament, The European Council, The Council, The European Economic and Social Committee and The Committee of the Regions. Chemicals Strategy for Sustainability Towards a Toxic-Free Environment. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0667 (accessed on 15 March 2024).

- Hitce, J.; Xu, J.; Brossat, M.; Frantz, M.C.; Dublanchet, A.-C.; Philippe, M.; Dalko-Csiba, M. UN sustainable development goals: How can sustainable/green chemistry contribute? Green chemistry as a source of sustainable innovations in the cosmetic industry. Curr. Opin. Green Sustain. Chem. 2018, 13, 164–169. [Google Scholar] [CrossRef]

- Salvioni, D.M.; Almici, A. Transitioning Toward a Circular Economy: The Impact of Stake-holder Engagement on Sustainability Culture. Sustainability 2020, 12, 8641. [Google Scholar] [CrossRef]

- Amberg, N.; Fogarassy, C. Green Consumer Behavior in the Cosmetics Market. Resources 2019, 8, 137. [Google Scholar] [CrossRef]

- Kolling, C.; Ribeiro, J.L.D.; Morea, D.; Iazzolino, G. Corporate social responsibility and circular economy from the perspective of consumers: A cross-cultural analysis in the cosmetic industry. Corp. Soc. Responsib. Environ. Manag. 2023, 30, 1226–1243. [Google Scholar] [CrossRef]

- cosmeticseurope.eu. Available online: https://cosmeticseurope.eu/green-action-case-studies-environmental-sustainability-cosmetics-industry/beiersdorf/ (accessed on 15 March 2024).

- cosmeticseurope.eu. Available online: https://cosmeticseurope.eu/green-action-case-studies-environmental-sustainability-cosmetics-industry/estee-lauder (accessed on 15 March 2024).

- cosmeticseurope.eu. Available online: https://cosmeticseurope.eu/green-action-case-studies-environmental-sustainability-cosmetics-industry/loreal/ (accessed on 15 March 2024).

- The Official Website of the Council of the EU and the European Council. Available online: https://www.consilium.europa.eu/media/69109/st16723-en23.pdf (accessed on 15 March 2024).

- Pérez-Rivero, C.; López-Gómez, J.P. Unlocking the Potential of Fermentation in Cosmetics: A Review. Fermentation 2023, 9, 463. [Google Scholar] [CrossRef]

- Ciardiello, T.; Pinto, D.; Marotta, L.; Giuliani, G.; Rinaldi, F. Effects of Fermented Oils on Alpha-Biodiversity and Relative Abundance of Cheek Resident Skin Microbiota. Cosmetics 2020, 7, 34. [Google Scholar] [CrossRef]

- ISO 16128-1:2016(en); Guidelines on Technical Definitions and Criteria for Natural and Organic Cosmetic Ingredients and Products—Part 1: Definitions for Ingredients. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- ISO 16128-2:2017(en); Cosmetics—Guidelines on Technical Definitions and Criteria for Natural and Organic Cosmetic Ingredients—Part 2: Criteria for Ingredients and Products. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- Lee, M.S.J.; Kwon, K.H. Future perspective safe cosmetics: Focused on associated with ISO natural organic index. J. Cosmet. Dermatol. 2022, 21, 6619–6627. [Google Scholar] [CrossRef]

- Bozza, A.; Campi, C.; Garelli, S.; Ugazio, E.; Battaglia, L. Current regulatory and market frameworks in green cosmetics: The role of certification. Sustain. Chem. Pharm. 2022, 30, 100851. [Google Scholar] [CrossRef]

- Suphasomboon, T.; Vassanadumrongdee, S. Multi-stakeholder perspectives on sustainability transitions in the cosmetic industry. Sustain. Prod. Consum. 2023, 38, 225–240. [Google Scholar] [CrossRef]

- Amrina, U.; Hidayatno, A.; Zagloel, T.Y.M. A Model-Based Strategy for Developing Sustainable Cosmetics Small and Medium Industries with System Dynamics. J. Open Innov. Technol. Mark. Complex. 2021, 7, 225. [Google Scholar] [CrossRef]

- Shapiro, K.G.; White, A.L. Right from the start: Product stewardship through life-cycle design. Corp. Environ. Strategy 1999, 6, 15–23. [Google Scholar] [CrossRef]

- Rocca, R.; Acerbi, F.; Fumagalli, L.; Taisch, M. Development of an LCA-based tool to assess the environmental sustainability level of cosmetics products. Int. J. Life Cycle Assess. 2023, 28, 1261–1285. [Google Scholar] [CrossRef]

- Herrero, M.; Laca, A.; Laca, A.; Díaz, M. Chapter 15—Application of life cycle assessment to food industry wastes. In Food Industry Wastes: Assessment and Recuperation of Commodities, 2nd ed.; Kosseva, M.R., Webb, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 331–353. [Google Scholar] [CrossRef]

- Demichelis, F.; Fiore, S.; Onofrio, M. Pre-treatments aimed at increasing the biodegradability of cosmetic industrial waste. Process Saf. Environ. Prot. 2018, 118, 245–253. [Google Scholar] [CrossRef]

- Ordu, M.; Der, O. Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers 2023, 15, 2933. [Google Scholar] [CrossRef]

- Mondello, A.; Salomone, R.; Mondello, G. Exploring circular economy in the cosmetic industry: Insights from a literature review. Environ. Impact Assess. Rev. 2024, 105, 107443. [Google Scholar] [CrossRef]

- Longo, S.; Cellura, M.; Luu, L.Q.; Nguyen, T.Q.; Rincione, R.; Guarino, F. Circular economy and life cycle thinking applied to the biomass supply chain: A review. Renew. Energy 2024, 220, 119598. [Google Scholar] [CrossRef]

- Guilbot, J.; Kerverdo, S.; Milius, A.; Escolac, R.; Pomrehn, F. Life cycle assessment of surfactants: The case of an alkyl polyglucoside used as a self-emulsifier in cosmetics. Green Chem. 2013, 15, 3337. [Google Scholar] [CrossRef]

- Aguiar, J.B.; Martins, A.M.; Almeida, C.; Ribeiro, H.M.; Marto, J. Water sustainability: A waterless life cycle for cosmetic products. Sustain. Prod. Consum. 2022, 32, 35–51. [Google Scholar] [CrossRef]

- Philippe, M.; Didillon, B.; Gilbert, L. Industrial commitment to green and sustainable chemistry: Using renewable materials & developing eco-friendly processes and ingredients in cosmetics. Green Chem. 2012, 14, 952–956. [Google Scholar] [CrossRef]

- Michel, M.M.; Tytkowska, M.; Reczek, L.; Trach, Y.; Siwiec, T. Technological Conditions for the Coagulation of Wastewater from Cosmetic Industry. J. Ecol. Eng. 2019, 20, 78–85. [Google Scholar] [CrossRef]

- Foschi, E. System Innovation and Life Cycle Thinking in Packaging Value Chain: The Circularity of Plastics. Ph.D. Thesis, University of Bologna, Bologna, Italy, 2020. [Google Scholar] [CrossRef]

- Cinelli, P.; Coltelli, M.B.; Signori, F.; Morganti, P.; Lazzeri, A. Cosmetic Packaging to Save the Environment: Future Perspectives. Cosmetics 2019, 6, 26. [Google Scholar] [CrossRef]

- Ibrahim, I.D.; Hamam, Y.; Sadiku, E.R.; Ndambuki, J.M.; Kupolati, W.K.; Jamiru, T.; Eze, A.A.; Snyman, J. Need for Sustainable Packaging: An Overview. Polymers 2022, 14, 4430. [Google Scholar] [CrossRef]

- Gatt, I.J.; Refalo, P. Reusability and recyclability of plastic cosmetic packaging: A life cycle assessment. Resour. Conserv. Recycl. Adv. 2022, 15, 200098. [Google Scholar] [CrossRef]

- Drobac, J.; Alivojvodic, V.; Maksic, P.; Stamenovic, M. Green Face of Packaging-Sustainability Issues of the Cosmetic Industry Packaging. In Proceedings of the 7th International Conference of Materials and Manufacturing Engineering, Thessaloniki, Greece, 2–3 July 2020. [Google Scholar]

- Saha, T.; Hoque, E.; Mahbub, T. Chapter 13—Biopolymers for Sustainable Packaging in Food, Cosmetics, and Pharmaceuticals. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Al-Oqla, F.M., Sapuan, S.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 197–214. [Google Scholar] [CrossRef]

- Pereira de Carvalho, A.; Barbieri, J.C. Innovation and Sustainability in the Supply Chain of a Cosmetics Company: A Case Study. J. Technol. Manag. Innov. 2012, 7, 2. [Google Scholar] [CrossRef]

- Martins, A.M.; Marto, J.M. A sustainable life cycle for cosmetics: From design and development to post-use phase. Sustain. Chem. Pharm. 2023, 35, 101178. [Google Scholar] [CrossRef]

- Jaouhari, Y.; Travaglia, F.; Giovannelli, L.; Picco, A.; Bordiga, M. From Industrial Food Waste to Bioactive Ingredients: A Review on the Sustainable Management and Transformation of Plant-Derived Food Waste. Foods 2023, 12, 2183. [Google Scholar] [CrossRef]

- Barbulova, A.; Colucci, G.; Fabio Apone, F. New Trends in Cosmetics: By-Products of Plant Origin and Their Potential Use as Cosmetic Active Ingredients. Cosmetics 2015, 2, 82–92. [Google Scholar] [CrossRef]

- Singh, A.; Gajbhiye, S. Upcycling ingredients in cosmetic industry. Int. J. Curr. Sci. 2022, 12, 474–479. [Google Scholar]

- Difonzo, G.; Grassi, S.; Paciulli, M. Upcycling of Agro-Food Chain By-Products to Obtain High-Value-Added Foods. Foods 2022, 11, 2043. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Asioli, D.; Banovic, M.; Perito, M.A.; Peschel, A.O.; Stancu, V. Defining upcycled food: The dual role of upcycling in reducing food loss and waste. Trends Food Sci. Technol. 2023, 132, 132–137. [Google Scholar] [CrossRef]

- Rakesh, B.; Mahendran, R. Upcycling of food waste and food loss-A sustainable approach in the food sector. Trends Food Sci. Technol. 2024, 143, 104274. [Google Scholar] [CrossRef]

- Reid, J. What a Waste! Exploring the Circular Economy for Cosmetics Products. Ph.D. Thesis, The University of Auckland, Auckland, New Zealand, 2022. [Google Scholar]

- Altintzoglou, T.; Aschemann-Witzel, J. Trade-offs in food systems; How does upcycling edible resources fit in the big picture? Trends Food Sci. Technol. 2024, 143, 104246. [Google Scholar] [CrossRef]

- Faria-Silva, C.; Ascenso, A.; Costa, A.M.; Marto, J.; Carvalheiro, M.; Ribeiro, H.M.; Simões, S. Feeding the skin: A new trend in food and cosmetics convergence. Trends Food Sci. Technol. 2020, 95, 21–32. [Google Scholar] [CrossRef]

- Porter, S.D.; Reay, D.S.; Bomberg, E.; Higgins, P. Avoidable food losses and associated production-phase greenhouse gas emissions arising from application of cosmetic standards to fresh fruit and vegetables in Europe and the UK. J. Clean. Prod. 2018, 10, 869–878. [Google Scholar] [CrossRef]

- Del Rio Osorio, L.L.; Flórez-López, E.; Grande-Tovar, C.D. The Potential of Selected Agri-Food Loss and Waste to Contribute to a Circular Economy: Applications in the Food, Cosmetic and Pharmaceutical Industries. Molecules 2021, 26, 515. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef]

- Fernández-Ochoa, A.; Leyva-Jiménez, F.J.; Pimentel-Moral, S.; Villegas-Aguilar, M.C.; Alañón, M.E.; Segura-Carreterom, A.; Cádiz-Gurrea, M. Revalorisation of Agro-Industrial Wastes into High Value-Added Products. In Sustainable Bioconversion of Waste to Value Added Products; Inamuddin Khan, A., Ed.; Springer: Cham, Switzerland, 2021; pp. 229–245. [Google Scholar] [CrossRef]

- Sharma, C.; Deutsch, J.M. Upcycling in the context of biotechnology-based solutions for food quality, loss, and consumer perception. Curr. Opin. Biotechnol. 2023, 81, 102920. [Google Scholar] [CrossRef]

- Baiano, A. Recovery of Biomolecules from Food Wastes—A Review. Molecules 2014, 19, 14821–14842. [Google Scholar] [CrossRef]

- Pinto, D.; Cádiz-Gurrea, M.; Silva, A.M.; Delerue-Matos, C.; Rodrigues, F. Chapter 25—Cosmetics-food waste recovery. In Food Waste Recovery, 2nd ed.; Galanakis, C.M., Cockle, C., Eds.; Processing Technologies, Industrial Techniques, and Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 503–528. [Google Scholar] [CrossRef]

- Mellou, F.; Varvaresou, A.; Papageorgiou, S. Renewable sources: Applications in personal care formulations. Int. J. Cosmet. Sci. 2019, 41, 517–525. [Google Scholar] [CrossRef]

- Chauhan, S.; Pandit, N.K.; Mohanty, A.; Meena, S.S. Resource recovery of bioactive compounds from food waste and their diverse industrial applications. Biomass Convers. Biorefin. 2023. [Google Scholar] [CrossRef]

- Nayak, A.; Bhushan, B. An overview of the recent trends on the waste valorization techniques for food wastes. J. Environ. Manag. 2019, 233, 352–370. [Google Scholar] [CrossRef]

- Rodrigues de Albuquerque, B.; Gomes Corrêa, R.C.; De Lima Sampaio, S.; Barros, L. Bioactive Compounds from Food and Its By-products: Current Applications and Future Perspectives. In Food Waste Conversion; Gonzalez, C.N.A., Gómez-García, R., Kuddus, M., Eds.; Humana: New York, NY, USA, 2023; Volume 7, pp. 3–41. [Google Scholar] [CrossRef]

- Bangar, S.P.; Chaudhary, V.; Kajla, P.; Balakrishnan, G.; Phimolsiripol, Y. Strategies for upcycling food waste in the food production and supply chain. Trends Food Sci. Technol. 2024, 143, 104314. [Google Scholar] [CrossRef]

- Bridgens, B.; Powell, M.; Farmer, G.; Walsh, C.; Reed, E.; Royapoor, M.; Gosling, P.; Hall, J.; Heidrich, O. Creative upcycling: Reconnecting people, materials and place through making. J. Clean. Prod. 2018, 189, 145–154. [Google Scholar] [CrossRef]

- Caldera, S.; Jayasinghe, R.; Desha, C.; Dawes, L.; Ferguson, S. Evaluating Barriers, Enablers and Opportunities for Closing the Loop through ‘Waste Upcycling’: A Systematic Literature Review, Journal of Sustainable Development of Energy. Water Environ. Syst. 2022, 10, 1080367. [Google Scholar] [CrossRef]

- Da Silva, R.F.; Carneiro, C.N.; de Sousa, C.B.D.C.; Gomez, F.J.; Espino, M.; Boiteux, J.; Fernández, M.D.L.Á.; Silva, M.F.; Dias, F.D.S. Sustainable extraction bioactive compounds procedures in medicinal plants based on the principles of green analytical chemistry: A review. Microchem. J. 2022, 175, 107184. [Google Scholar] [CrossRef]

- Kumar, K.; Yadav, A.N.; Kumar, V.; Vyas, P.; Dhaliwal, H.S. Food waste: A potential bioresource for extraction of nutraceuticals and bioactive compounds. Bioresour. Bioprocess. 2017, 4, 18. [Google Scholar] [CrossRef]

- Dauber, C.; Parente, E.; Zucca, M.P.; Gámbaro, A.; Vieitez, I. Olea europea and By-Products: Extraction Methods and Cosmetic Applications. Cosmetics 2023, 10, 112. [Google Scholar] [CrossRef]

- Donno, D.; Turrini, F.; Boggia, R.; Guido, M.; Gamba, G.; Mellano, M.G.; Riondato, I.; Beccaro, G.L. Vitis vinifera L. Pruning Waste for Bud-Preparations as Source of Phenolic Compounds–Traditional and Innovative Extraction Techniques to Produce New Natural Products. Plants 2021, 10, 2233. [Google Scholar] [CrossRef]

- Dikmetas, D.N.; Devecioglu, D.; Özünal, Z.G.; Demiroz, A.; Yavuz, E.; Sirkeci, C.B.; Karbancioglu-Guler, F.; Kahveci, D. From waste to remedy: Extraction and utilization of food waste-derived bioactive components in wound healing. Trends Food Sci. Technol. 2024, 145, 104347. [Google Scholar] [CrossRef]

- Kumar, M.; Dahuja, A.; Tiwari, S.; Punia, S.; Tak, Y.; Amarowicz, R.; Bhoite, A.G.; Singh, S.; Joshi, S.; Panesar, P.S.; et al. Recent trends in extraction of plant bioactives using green technologies: A review. Food Chem. 2021, 353, 129431. [Google Scholar] [CrossRef]

- Panzella, L.; Moccia, F.; Nasti, R.; Marzorati, S.; Verotta, L.; Napolitano, A. Bioactive Phenolic Compounds From Agri-Food Wastes: An Update on Green and Sustainable Extraction Methodologies. Front. Nutr. 2020, 7, 60. [Google Scholar] [CrossRef]

- More, P.R.; Jambrak, A.R.; Arya, S.S. Green, environment-friendly and sustainable techniques for extraction of food bioactive compounds and waste valorization. Trends Food Sci. Technol. 2022, 128, 296–315. [Google Scholar] [CrossRef]

- Belwal, T.; Chemat, F.; Venskutonis, P.R.; Cravotto, G.; Jaiswal, D.K.; Bhatt, I.D.; Devkota, H.P.; Luo, Z. Recent advances in scaling-up of non-conventional extraction techniques: Learning from successes and failures. TrAC Trends Anal. Chem. 2020, 127, 115895. [Google Scholar] [CrossRef]

- Ludek, S.; Wawrzyńczak, A.; Nowak, I.; Feliczak-Guzik, A. Synthesis of Lipid Nanoparticles Incorporated with Ferula assa-foetida L. Extract. Cosmetics 2022, 9, 129. [Google Scholar] [CrossRef]

- Pereira, J.A.M.; Berenguer, C.V.; Câmara, J.S. Delving into Agri-Food Waste Composition for Antibacterial Phytochemicals. Metabolites 2023, 13, 634. [Google Scholar] [CrossRef]

- Hou, H.S.; Bonku, E.M.; Zhai, R.; Zeng, R.; Hou, Y.L.; Yang, Z.H.; Quan, C. Extraction of essential oil from Citrus reticulate Blanco peel and its antibacterial activity against Cutibacterium acnes (formerly Propionibacterium acnes). Heliyon 2019, 5, e02947. [Google Scholar] [CrossRef]

- Ferreyra, S.; Bottini, R.; Fontana, A. Background and Perspectives on the Utilization of Canes’ and Bunch Stems’ Residues from Wine Industry as Sources of Bioactive Phenolic Compounds. J. Agric. Food Chem. 2023, 71, 8699–8730. [Google Scholar] [CrossRef]

- Matos, M.S.; Romero-Díez, R.; Álvarez, A.; Bronze, M.R.; Rodríguez-Rojo, S.; Mato, R.B.; Cocero, M.J.; Matias, A.A. Polyphenol-Rich Extracts Obtained from Winemaking Waste Streams as Natural Ingredients with Cosmeceutical Potential. Antioxidants 2019, 8, 355. [Google Scholar] [CrossRef]

- Anna Malinowska, M.; Billet, K.; Drouet, S.; Munsch, T.; Unlubayir, M.; Tungmunnithum, D.; Giglioli-Guivarc’h, N.; Hano, C.; Lanoue, A. Grape Cane Extracts as Multifunctional Rejuvenating Cosmetic Ingredient: Evaluation of Sirtuin Activity, Tyrosinase Inhibition and Bioavailability Potential. Molecules 2020, 25, 2203. [Google Scholar] [CrossRef]

- Wawrzyńczak, A. Cosmetic and Pharmaceutic Products with Selected Natural and Synthetic Substances for Melasma Treatment and Methods of Their Analysis. Cosmetics 2023, 10, 86. [Google Scholar] [CrossRef]

- Bucci, P.L.; Santos, M.V.; Montanari, J.; Zaritzky, N. Nanoferulic: From a by-product of the beer industry toward the regeneration of the skin. J. Cosmet. Dermatol. 2020, 19, 2958–2964. [Google Scholar] [CrossRef]

- Parisi, M.; Verrillo, M.; Luciano, M.A.; Caiazzo, G.; Quaranta, M.; Scognamiglio, F.; Di Meo, V.; Villani, A.; Cantelli, M.; Gallo, L.; et al. Use of Natural Agents and Agrifood Wastes for the Treatment of Skin Photoaging. Plants 2023, 12, 840. [Google Scholar] [CrossRef]

- Martínez-Inda, B.; Esparza, I.; Moler, J.A.; Jiménez-Moreno, N.; Ancín-Azpilicueta, C. Valorization of agri-food waste through the extraction of bioactive molecules. Prediction of their sunscreen action. J. Environ. Manag. 2023, 325, 116460. [Google Scholar] [CrossRef]

- Bassam, S.M.; Ali, D.E.; Awwad, Z.M.; Mahmoud, S.A.; Abou-Taleb, B.A. Development and characterization of plant derived wastes Nano-formulation loaded in thermo-reversible gel for burn healing: An effort towards Sustainable Development. J. Drug Deliv. Sci. Technol. 2024, 95, 105543. [Google Scholar] [CrossRef]

- de Mello, V.; de Mesquita Júnior, G.A.; Alvim, J.G.E.; Costa, J.D.C.D.; Vilela, F.M.P. Recent patent applications for coffee and coffee by-products as active ingredients in cosmetics. Int. J. Cosmet. Sci. 2023, 45, 267–287. [Google Scholar] [CrossRef]

- Majchrzak, W.; Motyl, I.; Smigielski, K. Biological and Cosmetical Importance of Fermented Raw Materials: An Overview. Molecules 2022, 27, 4845. [Google Scholar] [CrossRef]

- Faria, D.J.; Azevedo de Carvalho, A.P.; Conte-Junior, C.A. Valorization of Fermented Food Wastes and Byproducts: Bioactive and Valuable Compounds, Bioproduct Synthesis, and Applications. Fermentation 2023, 9, 920. [Google Scholar] [CrossRef]

- Alonso, S.; Rendueles, M.; Díaz, M. Feeding strategies for enhanced lactobionic acid production from whey by Pseudomonas taetrolens. Bioresour. Technol. 2013, 134, 134–142. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Panesar, P.S.; Mehariya, S. (Eds.) Microbial Exopolysaccharides: Production and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar] [CrossRef]

- Sun, M.L.; Liu, S.B.; Qiao, L.P.; Chen, X.L.; Pang, X.; Shi, M.; Zhang, X.Y.; Qin, Q.L.; Zhou, B.C.; Zhang, Y.Z. A novel exopolysaccharide from deep-sea bacterium Zunongwangia profunda SM-A87: Low-cost fermentation, moisture retention, and antioxidant activities. Appl. Microbiol. Biotechnol. 2014, 98, 7437–7445. [Google Scholar] [CrossRef]

- Bae, J.T.; Ko, H.J.; Kim, G.B.; Pyo, H.B.; Lee, G.S. Protective Effects of Fermented Citrus unshiu Peel Extract against Ultraviolet-A-induced Photoageing in Human Dermal Fibrobolasts. Phytother. Res. 2012, 26, 1851–1856. [Google Scholar] [CrossRef]

- Venil, C.K.; Devi, P.R.; Ahmad, W.A. Agro-Industrial Waste as Substrates for the Production of Bacterial Pigment. In Valorisation of Agro-Industrial Residues—Volume I: Biological Approaches. Applied Environmental Science and Engineering for a Sustainable Future; Zakaria, Z., Boopathy, R., Dib, J., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Martínez, O.; Sánchez, A.; Font, X.; Barrena, R. Enhancing the bioproduction of value-added aroma compounds via solid-state fermentation of sugarcane bagasse and sugar beet molasses: Operational strategies and scaling-up of the process. Bioresour. Technol. 2018, 263, 136–144. [Google Scholar] [CrossRef]

- Hadj Saadoun, J.; Bertani, G.; Levante, A.; Vezzosi, F.; Ricci, A.; Bernini, V.; Lazzi, C. Fer-mentation of Agri-Food Waste: A Promising Route for the Production of Aroma Compounds. Foods 2021, 10, 707. [Google Scholar] [CrossRef]

- Rajabimashhadi, Z.; Gallo, N.; Salvatore, L.; Lionetto, F. Collagen Derived from Fish Industry Waste: Progresses and Challenges. Polymers 2023, 15, 544. [Google Scholar] [CrossRef]

- Khan, S.; Tauseef, I.; Ikram, M.; Rauf, S.; Saeed, R.F.; Sadiqi, S.; Lone, N.A.; Ali, L.; Subhan, F. Extraction of Fish Collagen Peptides from Fish Waste Through Fermentation Using Lactobacillus bacteria. Life Sci. 2023, 4, 365–371. [Google Scholar] [CrossRef]

- Song, Z.; Liu, H.; Chen, L.; Chen, L.; Zhou, C.; Hong, P.; Deng, C. Characterization and comparison of collagen extracted from the skin of the Nile tilapia by fermentation and chemical pre-treatment. Food Chem. 2021, 340, 128139. [Google Scholar] [CrossRef]

- Costa, E.M.; Oliveira, A.S.; Silva, S.; Ribeiro, A.B.; Pereira, C.F.; Ferreira, C.; Casanova, F.; Pereira, J.O.; Freixo, R.; Pintado, M.E.; et al. Spent Yeast Waste Streams as a Sustainable Source of Bioactive Peptides for Skin Applications. Int. J. Mol. Sci. 2023, 24, 2253. [Google Scholar] [CrossRef]

- Wanninger, A.; Deckenhoff, V.; Goj, C.; Jackszis, L.; Pastewski, J.; Rajabi, S.; Rubbert, L.V.; Niederrhein, H.H. Upcycling of plant residuals to cosmetic ingredients. Int. J. Agric. Eng. Technol. Soc. Sci. 2022, 1, 1. [Google Scholar]

- Rana, G.K.; Singh, Y.; Mishra, S.P.; Rahangdale, H.K. Potential Use of Banana and Its By-products: A Review. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1827–1832. [Google Scholar] [CrossRef]

- Thanyapanich, N.; Jimtaisong, A.; Rawdkuen, S. Functional Properties of Banana Starch (Musa spp.) and Its Utilization in Cosmetics. Molecules 2021, 26, 3637. [Google Scholar] [CrossRef]

- Bhavania, M.; Moryab, S.; Saxenaa, D.; Awuchi, C.G. Bioactive, antioxidant, industrial, and nutraceutical applications of banana peel. Int. J. Food Prop. 2023, 26, 1277–1289. [Google Scholar] [CrossRef]

- Ehiowemwenguan, G.; Emoghene, A.O.; Inetianbo, R.J.E. Antibacterial and phytochemical analysis of Banana fruit peel. J. Pharm. 2014, 4, 18–25. [Google Scholar] [CrossRef]

- Klinkajorn, S.; Sukhasem, S. Production of mango seed butter for cosmetic use. In Proceedings of the III Asian Horticultural Congress—AHC, Bangkok, Thailand, 15–17 December 2020. [Google Scholar] [CrossRef]

- Barreira, J.C.M.; Arraibi, A.A.; Ferreira, I.C.F.R. Bioactive and functional compounds in apple pomace from juice and cider manufacturing: Potential use in dermal formulations. Trends Food Sci. Technol. 2019, 90, 76–87. [Google Scholar] [CrossRef]

- Araújoa, R.G.; Rodriguez-Jassoa, R.M.; Ruiza, H.A.; Pintadob, M.M.E.; Aguilara, C.N. Avocado by-products: Nutritional and functional properties. Trends Food Sci. Technol. 2018, 80, 51–60. [Google Scholar] [CrossRef]

- Buzzi, R.; Gugel, I.; Costa, S.; Molesini, S.; Boreale, S.; Baldini, E.; Marchetti, N.; Vertuani, S.; Pinelli, P.; Urciuoli, S.; et al. Up-Cycling of Olea europaea L. Ancient Cultivars Side Products: Study of a Combined Cosmetic–Food Supplement Treatment Based on Leaves and Olive Mill Wastewater Extracts. Life 2023, 13, 1509. [Google Scholar] [CrossRef]

- Cádiz-Gurrea, M.D.L.; Pinto, D.; Delerue-Matos, C.; Rodrigues, F. Olive Fruit and Leaf Wastes as Bioactive Ingredients for Cosmetics—A Preliminary Study. Antioxidants 2021, 10, 245. [Google Scholar] [CrossRef]

- Castro, M.L.; Ferreira, J.P.; Pintado, M.; Ramos, O.L.; Borgesand, S.; Baptista-Silva, S. Grape By-Products in Sustainable Cosmetics: Nanoencapsulation and Market Trends. Appl. Sci. 2023, 13, 9168. [Google Scholar] [CrossRef]

- Ferreira, S.M.; Santos, L. A Potential Valorization Strategy of Wine Industry by-Products and Their Application in Cosmetics-Case Study: Grape Pomace and Grapeseed. Molecules 2022, 27, 969. [Google Scholar] [CrossRef]

- Dini, I.; Laneri, S. The New Challenge of Green Cosmetics: Natural Food Ingredients for Cosmetic Formulations. Molecules 2021, 26, 3921. [Google Scholar] [CrossRef]

- Wasilewski, T.; Hordyjewicz-Baran, Z.; Zarębska, M.; Stanek, N.; Zajszły-Turko, E.; Tomaka, M.; Bujak, T.; Nizioł-Łukaszewska, Z. Sustainable Green Processing of Grape Pomace Using Micellar Extraction for the Production of Value-Added Hygiene Cosmetics. Molecules 2022, 27, 2444. [Google Scholar] [CrossRef]

- Ko, K.; Dadmohammadi, Y.; Abbaspourrad, A. Nutritional and Bioactive Components of Pomegranate Waste Used in Food and Cosmetic Applications: A Review. Foods 2021, 10, 657. [Google Scholar] [CrossRef]

- Boggia, R.; Turrini, F.; Villa, C.; Lacapra, C.; Zunin, P.; Parod, B. Green Extraction from Pomegranate Marcs for the Production of Functional Foods and Cosmetics. Pharmaceuticals 2016, 9, 63. [Google Scholar] [CrossRef]

- Rodrigues, R.; Oliveira, M.B.P.P.; Alves, R.C. Chlorogenic Acids and Caffeine from Coffee By-Products: A Review on Skincare Applications. Cosmetics 2023, 10, 12. [Google Scholar] [CrossRef]

- Ramos da Costa, A.K. Design of a Cosmetic Formulation with a Deep Eutectic System Coffee Extract. Master’s Thesis, NOVA University Lisbon, Lisbon, Portugal, 2022. [Google Scholar]

- Ballesteros, L.F.; Ramirez, M.J.; Orrego, C.E.; Teixeira, J.A.; Mussatto, S.I. Optimization of autohydrolysis conditions to extract antioxidant phenolic compounds from spent coffee grounds. J. Food Eng. 2017, 199, 1–8. [Google Scholar] [CrossRef]

- Peschel, W.; Sanchez-Rabaneda, F.; Diekmann, W.; Plescher, A.; Gartzia, I.; Jimenez, D.; Lamuela-Raventos, R.; Buxaderas, S.; Codina, C.C. An industrial approach in the search of natural antioxidants from vegetable and fruit wastes. Food Chem. 2006, 97, 137–150. [Google Scholar] [CrossRef]

- Vasyliev, G.; Khrokalo, L.; Hladun, K.; Skiba, M.; Vorobyova, V. Valorization of tomato pomace: Extraction of value-added components by deep eutectic solvents and their application in the formulation of cosmetic emulsions. Biomass Convers. Biorefinery 2022, 12, 95–111. [Google Scholar] [CrossRef]

- Šeregelj, V.; Vulić, J.; Ćetković, G.; Čanadanovć-Brunet, J.; Šaponjac, V.T.; Stajčić, S. Chapter 9—Natural bioactive compounds in carrot waste for food applications and health benefits. In Studies in Natural Products Chemistry; Rahman, A., Ed.; Elsevier: Abingdon, UK, 2020; Volume 67, pp. 307–344. [Google Scholar] [CrossRef]

- Igielska-Kalwat, J.; Wawrzyńczak, A.; Nowak, I. β-Carotene as an exemplary carotenoid and its application in cosmetic industry. Chemik 2012, 66, 140–144. [Google Scholar]

- Tiwari, S.; Yawale, P.; Upadhyay, N. Carotenoids: Extraction strategies and potential applications for valorization of under-utilized waste biomass. Food Biosci. 2022, 48, 101812. [Google Scholar] [CrossRef]

- Ikram, A.; Rasheed, A.; Khan, A.A.; Khan, R.; Ahmad, M.; Bashir, R.; Mohamed, M.H. Exploring the health benefits and utility of carrots and carrot pomace: A systematic review. Int. J. Food Prop. 2024, 27, 180–193. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Olejnik, A.; Świtek, S.; Bzducha-Wróbel, A.; Kubiak, P.; Kujawska, M.; Lewandowicz, G. Bioactive compounds of potato (Solanum tuberosum L.) juice: From industry waste to food and medical applications. Crit. Rev. Plant Sci. 2022, 41, 52–89. [Google Scholar] [CrossRef]

- Vishala, P.; Vipula, P.; Priyanka, S.; Unnatic, P. Biosynthesis and Development of Novel Method for Commercial Production of Biosurfactant utilizing waste potato peels. Indian Drugs 2020, 57, 1. [Google Scholar] [CrossRef]

- RedCorn, R.; Fatemi, S.; Engelberth, A.S. Comparing End-Use Potential for Industrial Food-Waste Sources. Engineering 2018, 4, 371–380. [Google Scholar] [CrossRef]

- Kaur, B.; Panesar, P.S.; Anal, A.K.; Chu-Ky, S. Recent Trends in the Management of Mango By-products. Food Rev. Int. 2023, 39, 4159–4179. [Google Scholar] [CrossRef]

- Di Michele, A.; Pagano, C.; Allegrini, A.; Blasi, F.; Cossignani, L.; Raimo, E.D.; Faieta, M.; Oliva, E.; Pittia, P.; Primavilla, S.; et al. Hazelnut Shells as Source of Active Ingredients: Extracts Preparation and Characterization. Molecules 2021, 26, 6607. [Google Scholar] [CrossRef]

- Alfano, A.; D’ambrosio, S.; Cimini, D.; Falco, L.; D’Agostino, M.; Finamore, R.; Schiraldi, C. No Waste from Waste: Membrane-Based Fractionation of Second Cheese Whey for Potential Nutraceutical and Cosmeceutical Applications, and as Renewable Substrate for Fermentation Processes Development. Fermentation 2022, 8, 514. [Google Scholar] [CrossRef]

- Dini, I. The Potential of Algae in the Nutricosmetic Sector. Molecules 2023, 28, 4032. [Google Scholar] [CrossRef]

- Altintzoglou, T.; Honkanen, P.; Whitaker, R.D. Influence of the involvement in food waste reduction on attitudes towards sustainable products containing seafood by-products. J. Clean. Prod. 2021, 285, 125487. [Google Scholar] [CrossRef]

- Kulka, K.; Sionkowska, A. Chitosan Based Materials in Cosmetic Applications: A Review. Molecules 2023, 28, 1817. [Google Scholar] [CrossRef]

- Chintong, S.; Phatvej, W.; Rerk-Am, U.; Waiprib, Y.; Klaypradit, W. In Vitro Antioxidant, Antityrosinase, and Cytotoxic Activities of Astaxanthin from Shrimp Waste. Antioxidants 2019, 8, 128. [Google Scholar] [CrossRef]

- Ahmed, M.; Verma, A.K.; Patel, R. Collagen extraction and recent biologi-cal activities of collagen peptides derived from sea-food waste: A review. Sustain. Chem. Pharm. 2020, 18, 100315. [Google Scholar] [CrossRef]

- Sionkowska, A.; Adamiak, K.; Musiał, K.; Gadomska, M. Collagen Based Materials in Cosmetic Applications: A Review. Materials 2020, 13, 4217. [Google Scholar] [CrossRef]

- Sharma, P.; Gaurb, V.K.; Kimd, S.-H.; Pandeye, A. Microbial strategies for bio-transforming food waste into resources. Bioresour. Technol. 2020, 299, 122580. [Google Scholar] [CrossRef]

- Waqas, M.; Rehan, M.; Khan, M.; Nizami, D.A.-S. Conversion of food waste to fermentation products. In Encyclopedia of Food Security and Sustainability; Ferranti, P., Berry, E., Jock, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 501–509. [Google Scholar]

- Yoseph, C.; Avanti, C.; Hadiwidjaja, M.; Briliani, K. The importance of fermented plant extract for anti-aging in cosmetics product. World J. Pharm. Res. 2021, 10, 1330–1343. Available online: https://www.wjpr.net/abstract_file/17168 (accessed on 15 March 2024).

- Sivamaruthi, B.S.; Chaiyasut, C.; Kesika, P. Cosmeceutical Importance Of Fermented Plant Extracts: A Short Review. Int. J. Appl. Pharm. 2018, 10, 31–34. [Google Scholar] [CrossRef]

- Singh, V.K. Bioferments in beauty infusing antioxidant and microbiome benefits into skin. Cosmet. Toilet. 2022, 137, 59–68. [Google Scholar]

- Otsuka, A.; Moriguchi, C.; Shigematsu, Y.; Tanabe, K.; Haraguchi, N.; Iwashita, S.; Tokudome, Y.; Kitagaki, H. Fermented Cosmetics and Metabolites of Skin Microbiota—A New Approach to Skin Health. Fermentation 2022, 8, 703. [Google Scholar] [CrossRef]

- Nga, H.S.; Keea, P.E.; Yima, H.S.; Chenb, P.-T.; Weic, Y.-H.; Chi-Wei Lan, J. Recent advances on the sustainable approaches for conversion and reutilization of food wastes to valuable bioproducts. Bioresour. Technol. 2020, 302, 122889. [Google Scholar] [CrossRef]

- Herman, A.; Herman, A.O. Biological Activity of Fermented Plant Extracts for Potential Dermal Applications. Pharmaceutics 2023, 15, 2775. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhou, J.; Zhang, N.; Xing, X.; Zhao, L.; Zhou, F. In vivo study of orange peel fermentation and improvement of androgen overproduction causing acne. Food Biosci. 2023, 56, 103124. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, H.; Liu, H.; Ma, R.; Ma, J.; Fang, H. Fermentation by Multiple Bacterial Strains Improves the Production of Bioactive Compounds and Antioxidant Activity of Goji Juice. Molecules 2019, 24, 3519. [Google Scholar] [CrossRef]

- Dulf, F.V.; Vodnar, D.C.; Socaciu, C. Effects of solid-state fermentation with two filamentous fungi on the total phenolic contents, flavonoids, antioxidant activities and lipid frac-tions of plum fruit (Prunus domestica L.) by-products. Food Chem. 2016, 209, 27–36. [Google Scholar] [CrossRef]

- Makhamrueang, N.; Raiwa, A.; Jiaranaikulwanitch, J.; Kaewarsar, E.; Butrungrod, W.; Sirilun, S. Beneficial Bio-Extract of Camellia sinensis var. assamica Fermented with a Combination of Probiotics as a Potential Ingredient for Skin Care. Cosmetics 2023, 10, 85. [Google Scholar] [CrossRef]

- Ho, C.-C.; Ng, S.-C.; Chuang, H.-L.; Wen, C.S.-Y.; Mahalakshmi, C.-H.B.; Huang, C.-Y.; Kuo, W.-W. Extracts of Jasminum sambac flowers fermented by Lactobacillus rhamnosus inhibit H2O2- and UVB-induced aging in human dermal fibroblasts. Environ. Toxicol. 2021, 36, 607–619. [Google Scholar] [CrossRef]

- Her, Y.; Lee, T.K.; Ahn, J.H.; Lim, S.S.; Kang, B.G.; Park, J.S.; Kim, B.; Sim, H.; Lee, J.C.; Kim, H.S.; et al. Chemical Composition of a Novel Distillate from Fermented Mixture of Nine Anti-Inflammatory Herbs and Its UVB-Protective Efficacy in Mouse Dorsal Skin via Attenuating Collagen Disruption and Inflammation. Molecules 2020, 26, 124. [Google Scholar] [CrossRef]

- Chae, G.Y.; Ha, B.J. The Comparative Evaluation of Fermented and Non-fermented Soybean Extract on Antioxidation and Whitening. Toxicol. Res. 2011, 27, 205–209. [Google Scholar] [CrossRef]

- Song, P.H.; Park, G.-R.; Kim, Y.-H.; Jung, D.H.; Ku, S.-K.; Song, C.-H. Hair-Growth-Promoting Effects of Fermented Red Ginseng Marc and Traditional Polyherb Formula in C57BL/6 Mice. Appl. Sci. 2021, 11, 1195. [Google Scholar] [CrossRef]

- Stanek-Wandzel, N.; Zarębska, M.; Wasilewski, T.; Hordyjewicz-Baran, Z.; Zajszły-Turko, E.; Tomaka, M.; Bujak, T.; Ziemlewska, A.; Nizioł-Łukaszewska, Z. Kombucha fermentation as a modern way of processing vineyard by-products into cosmetic raw materials. Int. J. Cosmet. Sci. 2023, 45, 834–850. [Google Scholar] [CrossRef]

- Shukla, P.; Anand, S.; Srivastava, P.; Mishra, A. Hyaluronic acid production by utilizing agro-industrial waste cane molasses. 3 Biotech 2022, 12, 208. [Google Scholar] [CrossRef]

- Minervini, F.; Comitini, F.; De Boni, A.; Fiorino, G.M.; Rodrigues, F.; Tlais, A.Z.A.; Carafa, I.; De Angelis, M. Sustainable and Health-Protecting Food Ingredients from Bioprocessed Food by-Products and Wastes. Sustainability 2022, 14, 15283. [Google Scholar] [CrossRef]

- Taser, B.; Ozkan, H.; Adiguzel, A.; Orak, T.; Baltaci, M.O.; Taskin, M. Preparation of chitosan from waste shrimp shells fermented with Paenibacillus jamilae BAT1. Int. J. Biol. Macromol. 2021, 183, 1191–1199. [Google Scholar] [CrossRef]

- Gupta, P.L.; Rajput, M.; Oza TTrivedi, U.; Sanghvi, G. Eminence of Microbial Products in Cosmetic Industry. Nat. Prod. Bioprospect. 2019, 9, 267–278. [Google Scholar] [CrossRef]

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.K.; Kulshrestha, S. Microbial Fermentation and Its Role in Quality Improvement of Fermented Foods. Fermentation 2020, 6, 106. [Google Scholar] [CrossRef]

| ISO 16128 Standard | COSMOS Standard |

|---|---|

| The guide does not contain precise requirements and criteria. | The guide contain precise requirements and criteria. |

| Risk of different interpretations of the guidelines. | A clear interpretation of the standard. |

| It only applies to raw materials and cosmetic formulas. | A comprehensive approach to: raw materials, recipes, packaging, marketing claims, production and storage of cosmetics, as well as environmental aspects. |

| Lack of external control. | Audit once a year. |

| There are no definitions of natural and organic cosmetics, there are only definitions of natural and organic raw materials. | A clear definition of naturality for both finished products and raw materials. |

| It contains only recommendations regarding the use of natural solvents and the principles of Green Chemistry. | It contains requirements regarding the use of natural solvents and the principles of Green Chemistry. |

| It does not regulate the issue of preservatives permitted in natural cosmetics, allowing the use of all preservatives in accordance with the legislation, including: parabens and phenoxyethanol. | It precisely defines the preservatives allowed in natural and organic cosmetics. |

| No requirements for fragrance substances, which makes possible using, for example, synthetic fragrance compositions. | Strictly defined requirements for fragrances. |

| Criteria | Rating |

|---|---|

| Origin of the raw material | Natural (from agriculture or wild origin) |

| Produced by microorganisms | |

| Upcycled | |

| Method of processing the raw material | Physical processes (grinding, pressing, extraction) |

| Chemical reaction according to the Green Chemistry approach | |

| Biotechnological processes | |

| Biodegradability of raw material | Readily biodegradable according to OECD 301 A, B, C, D, E, F regulations: if 60% (or 70% for some tests) of the organic carbon in the material is converted to CO2 within a 10-day window, and 100% within 28 days. |

| Toxicity to aquatic organisms | Non-toxic |

| Fair trade | The raw material comes from fair trade |

| Source of Food Waste | Type of Waste | Cosmetic Ingredients | Bioactive Components | Properties | Refs. |

|---|---|---|---|---|---|

| Citrus fruit | Peel, Pulp, Seeds | Extracts, active powder, peeling | Phenolic acids (hydroxybenzoic acid, caffeic acid), flavones (apigenin-glucoside, diosmetin-glucoside), flavanones (hesperidin, naringin, eriocitrin, narirutin) | Antioxidant, anti-inflammatory, anti-bacterial | [88] |

| Grapes | Seeds and peels | Extracts, Oil | Coumaric acid, caffeic acid, ferulic acid, chlorogenic acid, cinnamic acid, neochlorogenic acid, p-hydroxybenzoic acid, protocatechuic acid, vanillic acid, gallic acid, proanthocyanidins, quercetin 3-o-gluuronide, quercetin, stilbenes (resveratrol) | Antioxidant, anti-inflammatory, antimicrobial against Staphylococcus aureus, sun protection factor (SPF) booster, anti-tyrosinase activities (skin whitening), anti-elastase, anti-collagenase activities (anti-aging), cellular protective effect against oxidative damage, anti-acne | [121,122,124] |

| Banana | Peels, Pulp | Extracts, powder starch | Gallocatechin, anthocyanins, delphindin, cyaniding, catecholamine | Starch: thickener, stabilizer, gelling agent | [112,113,114] |

| Mango | Peels and kernel | Extracts, butter | Gallic acid, ellagic acid, gallates, gallotannins, condensed tannins, quercetin, isoquercetin, fisetin, mangiferin | Antioxidant, anti-bacterial, hydrating, reducing transepidermal water loss (TEWL) | [78,116,139] |

| Apple | Peels and pomace | Extracts, emollients, active powder | Pectins, epicatechin, catechins, anthocyanins, quercetin glycosides, chlorogenic acid, caffeic acid, ferulic acid, hydroxycinnamates, phloretin, glycosides, procyanidins, triterpenoids (ursolic acid, oleanolic acid) | Pectins: thickener, stabilizer | [117] |

| Pomegranate | Peels and pericarp | Extracts, oil | Gallic acid, cyanidin-3,5-diglucoside, cyanidin-3-diglucoside, delphinidin-3,5-diglucoside | Anti-inflammatory, anti-pain, burn wound healing, whitening, antibacterial, antifungal, anti-aging, inhibition of glycation | [125,126] |

| Avocado | Peels and seeds | Extracts, oil | Epicatechin, catechin, gallic acid, chlorogenic acid, cyanidin 3-glucoside, homogentisic acid | Antioxidant, anti-inflammatory, anti-microbial, anti-fungal, photo-protective | [118] |

| Olive | Leaves, pomace, seeds | Extracts, oil | Pectins and oligosaccharides, sugars: mannitol, cellulose, hemicellulose; phenols and polyphenols, triterpenes, fatty acids, squalene, essential amino acids, malonic acid, carotenoids, tocopherols, minerals (K, Ca, Na) | Pectins, oligosaccharides: Improvement in physical/structural properties of emulsions, oxidative stability, viscosity, texture, sensory characteristics, and shelf-life of products | [79,119,120] |

| Carrot | Pomace | Extract, oil | Phenols, β-carotene | Antioxidant, anti-ageing, colorant, aroma | [132,133,134,135] |

| Potato | Peels | Extract | Gallic acid, caffeic acid, vanillic acid, pectins, chlorogenic acid, carotene, lycopene, lutein | Antioxidant, anti-microbial, anti-inflammatory | [130,136,137] |

| Tomato | Seed, pomace | Extract, oil | Carotenoids (lycopene), phenolic acids, chlorogenic acid, gallic acid, ferulic acid, quercetin | Antioxidant, anti-inflammatory, antifungal | [131] |

| Coffee | Grounds, pulp, husks, beans | Extracts, peeling | Polyphenols, tannins, chlorogenic acids, caffeine, melanoidins | Anti-inflammatory, antimicrobial, anti-cellulite, improvement in blood circulation | [127,128,129] |

| Hazelnuts | Skin and roasted husk | Extract | Phenolic compounds (proanthocyanidins A and B) | Antioxidant, antifungal | [140] |

| Raw Material | Microorganisms | Properties | Refs. |

|---|---|---|---|

| Citrus unshiu peel | Schizophyllum commune QG143 | Anti-aging, anti-photoaging | [103] |

| Lemon peel | Lactobacillus lactis | Skin whitening, reduction of discoloration, antioxidant | [156] |

| Goji berry (Lycium barbarum L.) | Lactobacillus rhamnosus, Lactobacillus reuteri, Bacillus velezensis or Lactobacillus rhamnosus, Lactobacillus plantarum, Bacillus velezensis, Bacillus licheniformis | Anti-oxidant, anti-aging, skin whitening | [157] |

| Plum pomace and seeds | Aspergillus niger and Rhizopus oligosporus | Anti-oxidant, moisturizing | [158] |

| Camellia sinensis (Miang tea) | Lacticaseibacillus rhamnosus, Lactiplantibacillus plantarum, Saccharomyces cerevisiae | Anti-oxidant, tyrosinase inhibition (skin whitening), reduction of discoloration, collagenase inhibition (anti-aging) | [159] |

| Jasminum sambac flowers | Lactobacillus rhamnosus | Antioxidant, anti-aging, anti-photoaging induced by UVB radiation, | [160] |

| Angelica gigas, Lonicera japonica, Dictamnus dasycarpus Turcz., D. opposita Thunb., Ulmus davidiana var. japonica, Hordeum vulgare var. hexastichon Aschers., Xanthium strumarium L., Cnidium officinale, Houttuynia cordata Thunb. | Lactobacillus fermentum | Protection against UVB-induced damage, anti-inflammatory | [161] |

| Soybean | Bifidobacterium animalis, Saccharomyces cerevisiae, Bacillus subtilis | Improved skin hydration and elasticity, anti-oxidant, skin whitening and reduction of discoloration | [162] |

| Red ginseng | Lactobacillus brevis, Saccharomyces cerevisiae | Anti-wrinkle, skincare, anti-inflammatory, anti-allergenic | [27,151] |

| Red ginseng marc | Lactobacillus casei, Saccharomyces cerevisiae, Rhodobacter capsulatus | Promoting effects on the hair growth cycle | [163] |

| Carrot root | Bacillus ginsengisoli | Anti-oxidant, reduced skin dullness, anti-aging, anti-wrinkle | [132] |

| Radish root | Lactobacillus casei | Anti-oxidant, anti-aging, healing of damaged cells, toxin removal, skin nourishing | [148] |

| Wine industry by-products | Kombucha SCOBY (Symbiotic Cultures of Bacteria and Yeasts) consortium | Moisturizing, anti-oxidant, anti-aging | [164] |

| Agro-industrial waste cane molasses | Streptococcus zooepidemicus MTCC 3523 | Moisturizing, anti-aging | [165] |

| Whey | Leuconostoc mesenteroides, Lactobacillus jensenii, Lactobacillus acidophilus | Antioxidant, anti-inflammatory | [166] |

| Yogurt whey | Lacticaseibacillus casei | Increased production of lactic acid, hydrating properties | [166] |

| Waste shrimp shells | Paenibacillus jamilae BAT1 | Antimicrobial and antioxidant | [167] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krzyżostan, M.; Wawrzyńczak, A.; Nowak, I. Use of Waste from the Food Industry and Applications of the Fermentation Process to Create Sustainable Cosmetic Products: A Review. Sustainability 2024, 16, 2757. https://doi.org/10.3390/su16072757

Krzyżostan M, Wawrzyńczak A, Nowak I. Use of Waste from the Food Industry and Applications of the Fermentation Process to Create Sustainable Cosmetic Products: A Review. Sustainability. 2024; 16(7):2757. https://doi.org/10.3390/su16072757

Chicago/Turabian StyleKrzyżostan, Monika, Agata Wawrzyńczak, and Izabela Nowak. 2024. "Use of Waste from the Food Industry and Applications of the Fermentation Process to Create Sustainable Cosmetic Products: A Review" Sustainability 16, no. 7: 2757. https://doi.org/10.3390/su16072757

APA StyleKrzyżostan, M., Wawrzyńczak, A., & Nowak, I. (2024). Use of Waste from the Food Industry and Applications of the Fermentation Process to Create Sustainable Cosmetic Products: A Review. Sustainability, 16(7), 2757. https://doi.org/10.3390/su16072757