Impact of Alkaline Concentration on the Mechanical Properties of Geopolymer Concrete Made up of Fly Ash and Sugarcane Bagasse Ash

Abstract

:1. Introduction

2. Materials and Methods

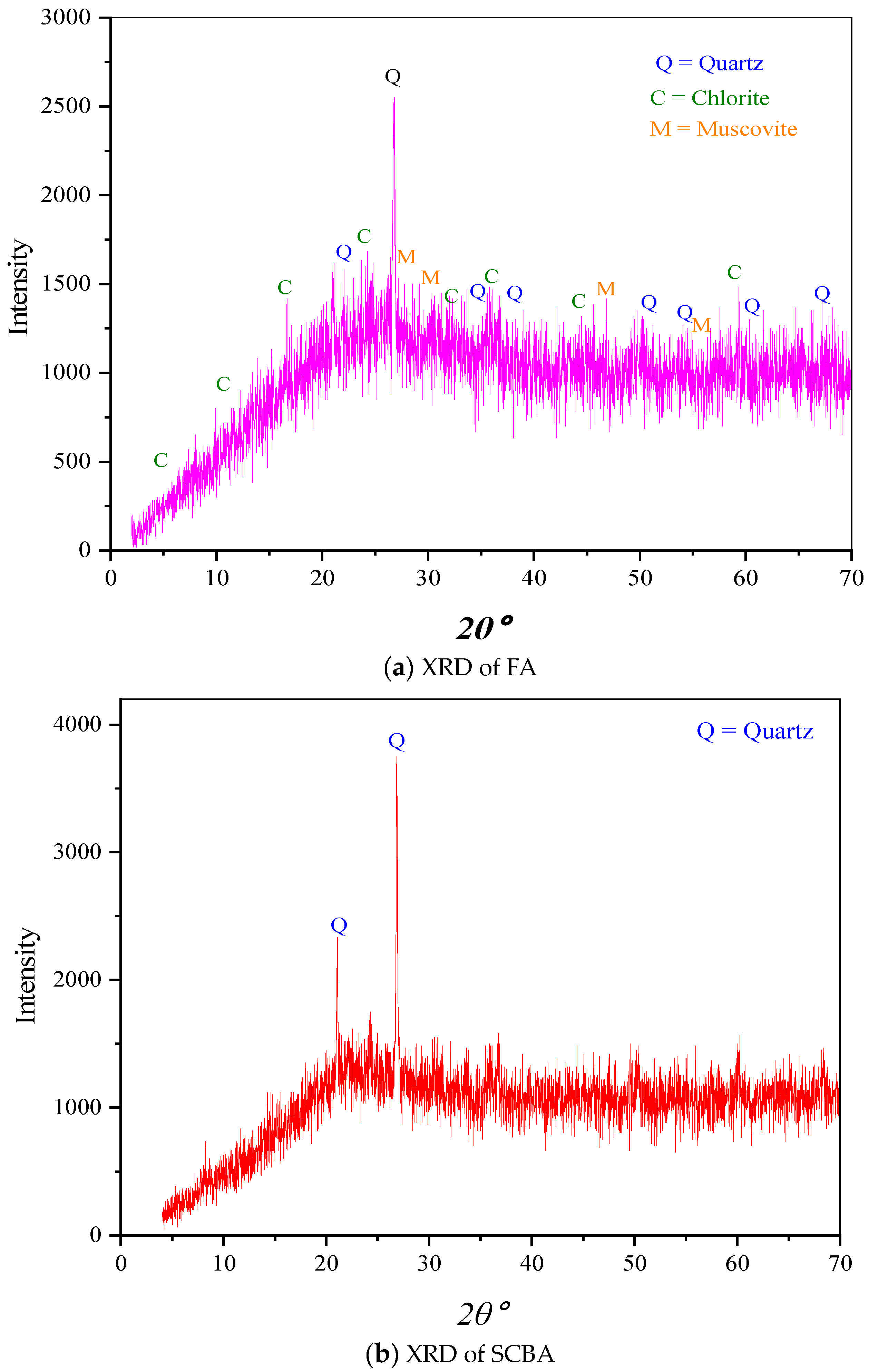

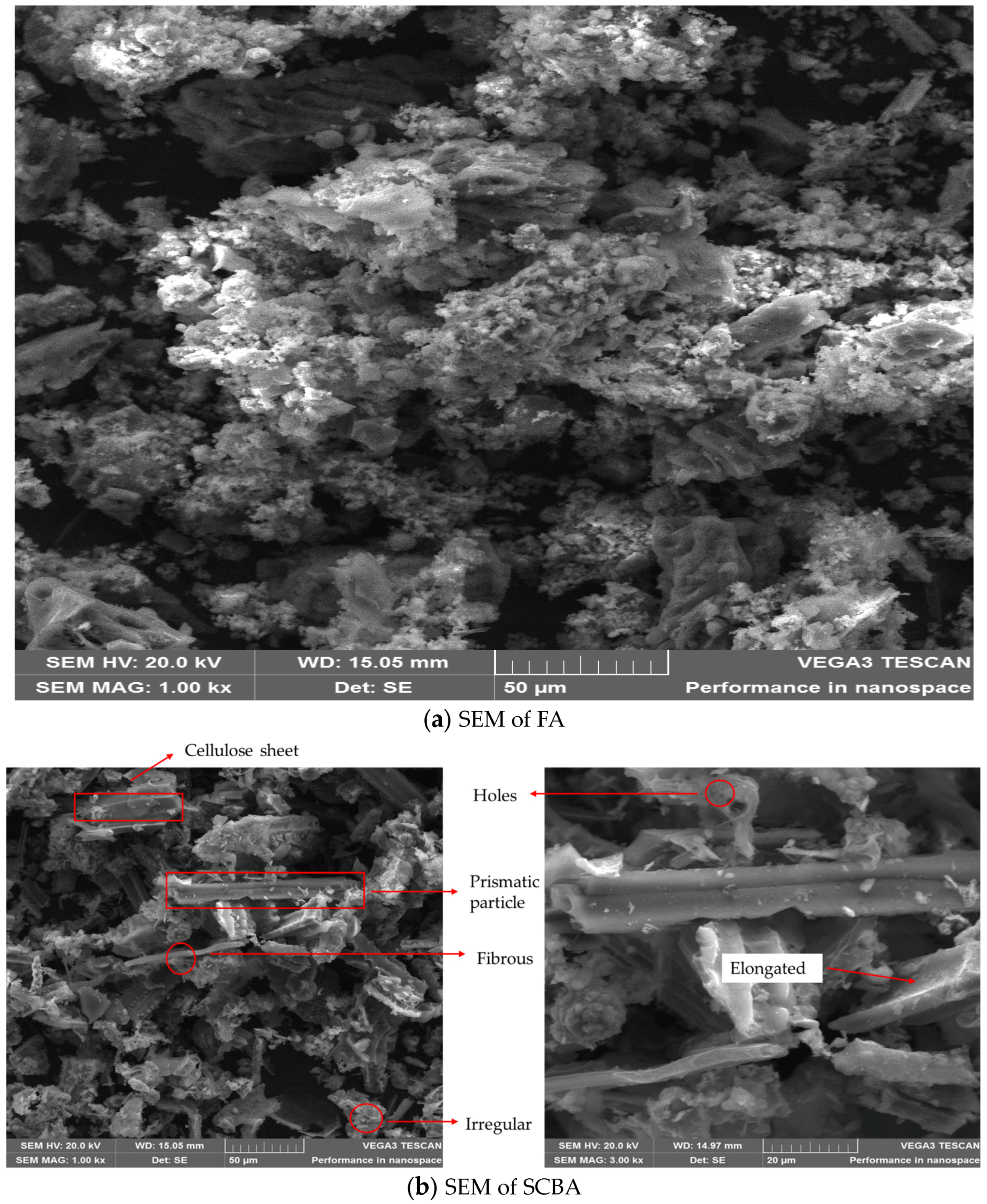

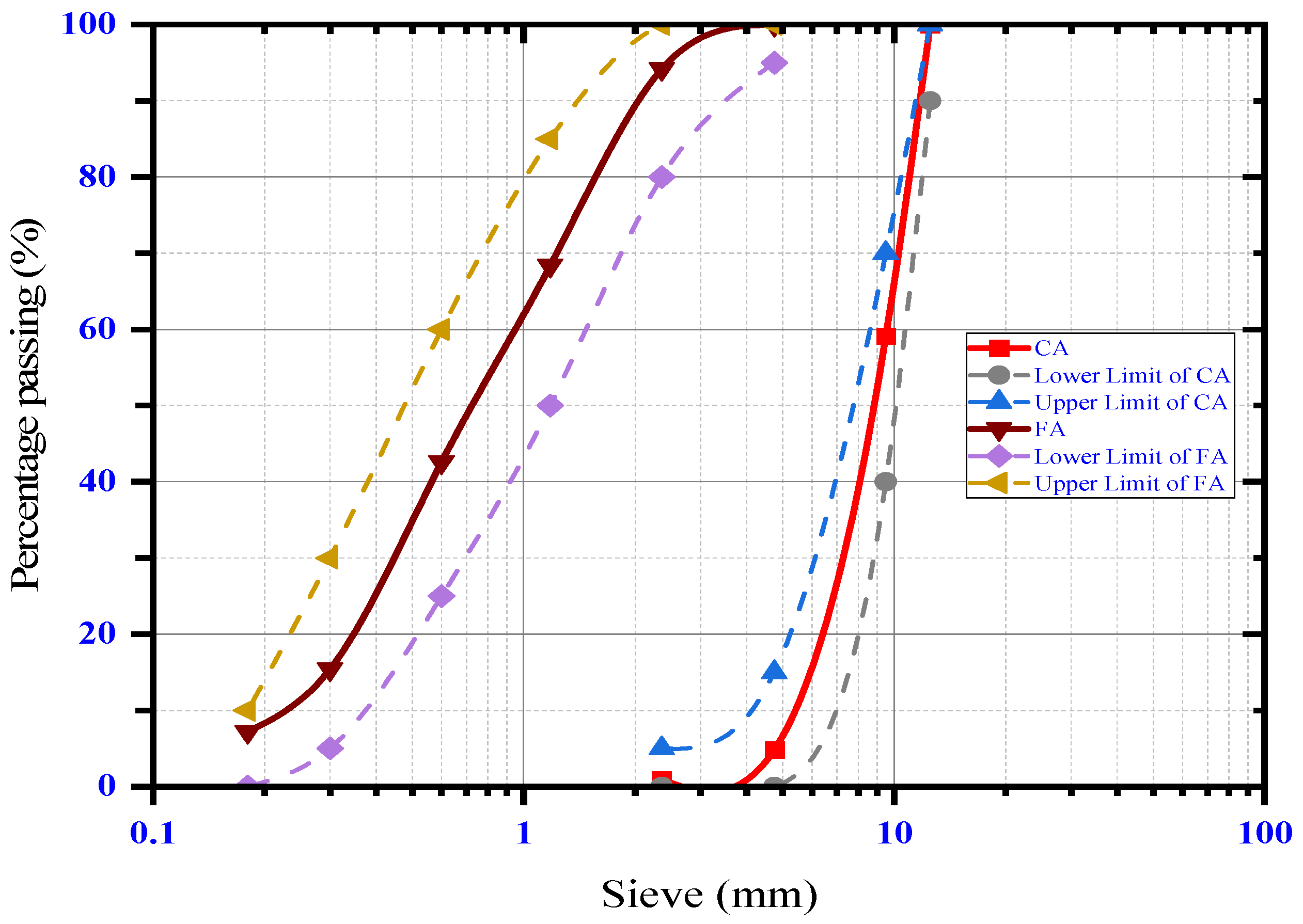

2.1. Materials Acquisition and Preparation

2.2. Mix Proportions, Mixing, Casting and Curing

2.3. Testing Specimens

3. Results and Discussion

3.1. Workability

3.2. Compressive Strength

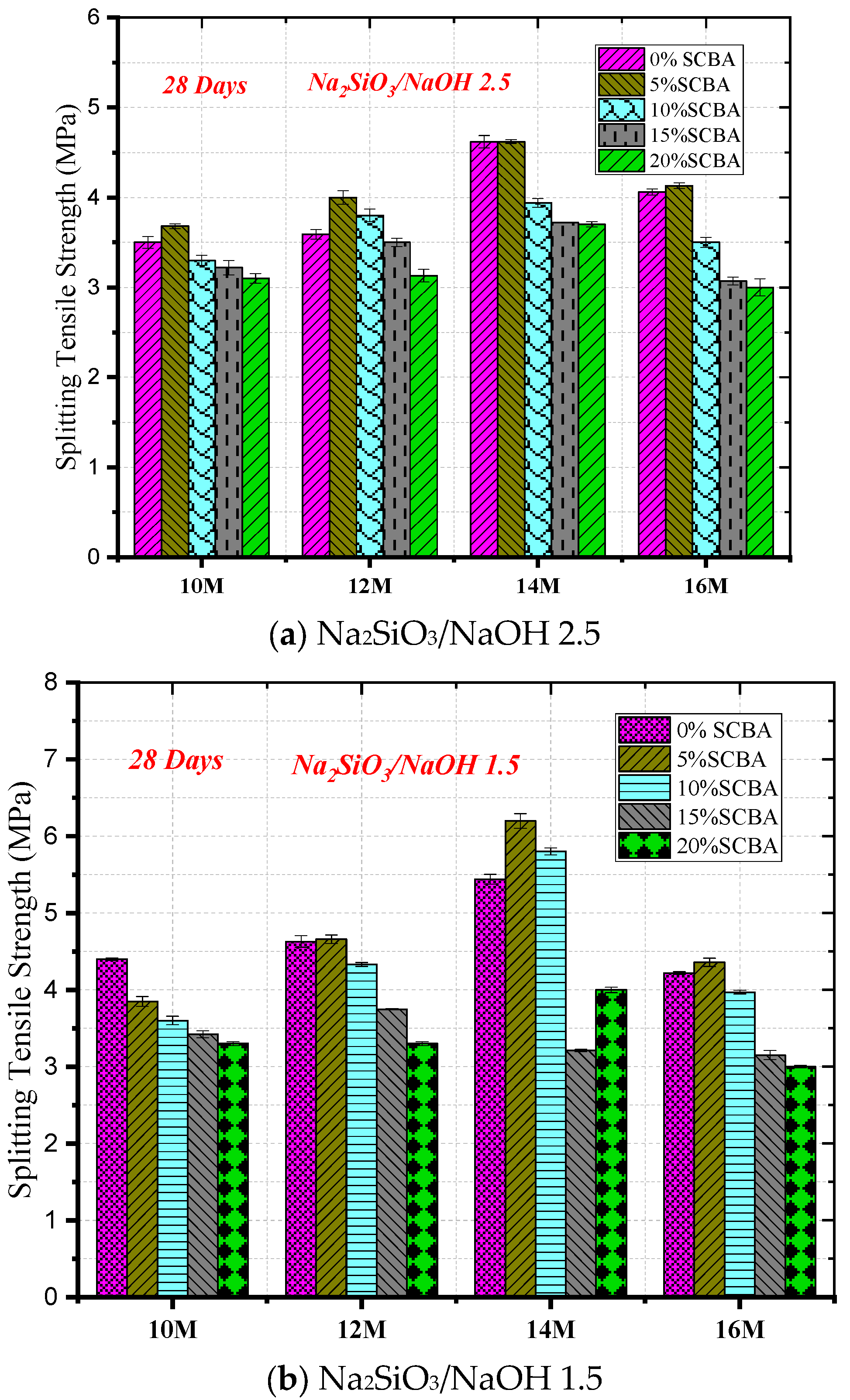

3.3. Tensile Strength

3.4. Flexural Strength

3.5. Correlation between the Mechanical Properties

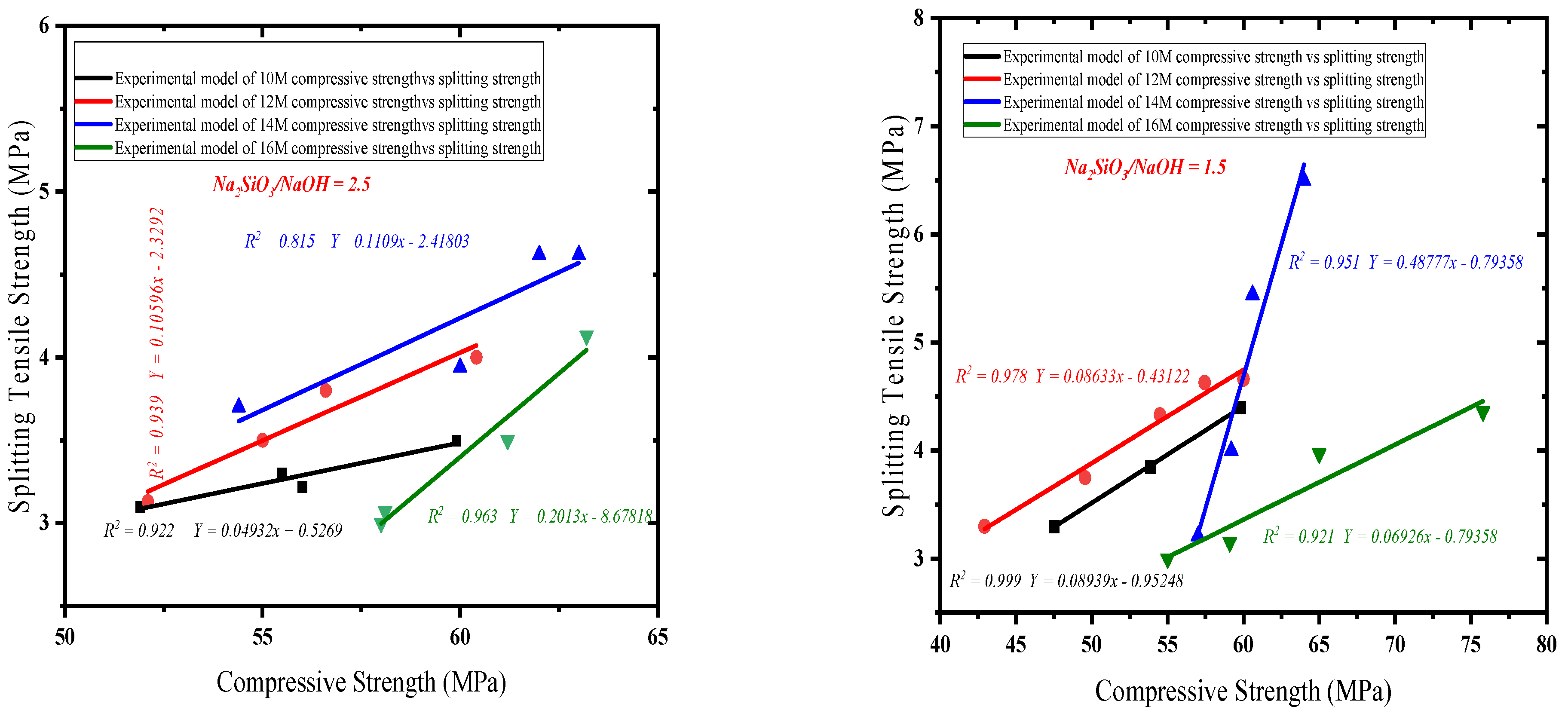

3.5.1. Splitting Tensile Strength vs. Compressive Strength

3.5.2. Flexural Strength vs. Compressive Strength

4. Conclusions

- 1-

- An increase in the molarity of the sodium hydroxide solution decreases the slump because the higher concentration of the sodium hydroxide solution enhanced the leaching of silica and alumina from GPC, which raised the mixture’s viscosity and lowered its water content. Remarkably, the reported slump values for all combinations demonstrated acceptable workability.

- 2-

- Increasing the molarity of NaOH in the mix increases the compressive strength; however, the compressive strength decreases after a certain point. This is because sodium hydroxide produces the alkaline environment that geopolymer gels require to bind together.

- 3-

- Increasing the NaOH concentration can accelerate the aluminosilicates’ breakdown, promoting the rapid formation of geopolymer gels and achieving excellent compressive strength.

- 4-

- The splitting tensile strength of fly ash−sugarcane bagasse ash-based GPC produced with 10, 12, 14, and 16 M mixes has demonstrated a comparable pattern to compressive strength at all the replacement levels in most cases.

- 5-

- The flexural strength decreased as the substitution of SCBA concentration increased. As the concentration of NaOH increased, the flexural strength value initially increased to 14 M and subsequently decreased at 16 M.

- 6-

- The findings of the regression analysis demonstrated that there was a substantial correlation between the suggested model equations and the experimental data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abbas, S.N.; Qureshi, M.I.; Abid, M.M.; Zia, A.; Tariq, M.A.U.R. An Investigation of Mechanical Properties of Fly Ash Based Geopolymer and Glass Fibers Concrete. Sustainability 2022, 14, 10489. [Google Scholar] [CrossRef]

- Alahmari, T.S.; Abdalla, T.A.; Rihan, M.A.M. Review of Recent Developments Regarding the Durability Performance of Eco-Friendly Geopolymer Concrete. Buildings 2023, 13, 3033. [Google Scholar] [CrossRef]

- Alawi Al-Sodani, K.A. Mix design, mechanical properties and durability of the rubberized geopolymer concrete: A review. Case Stud. Constr. Mater. 2022, 17, e01480. [Google Scholar] [CrossRef]

- Haddad, R.H.; Alshbuol, O. Production of geopolymer concrete using natural pozzolan: A parametric study. Constr. Build. Mater. 2016, 114, 699–707. [Google Scholar] [CrossRef]

- Moradikhou, A.B.; Safehian, M.; Golafshani, E.M. High-strength geopolymer concrete based on coal washing waste. Constr. Build. Mater. 2023, 362, 129675. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.-W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of glass wastes for the development of geopolymer composites—Durability, thermal and microstructural properties: A review. Constr. Build. Mater. 2019, 222, 673–687. [Google Scholar] [CrossRef]

- Shumuye, E.D.; Zhao, J.; Wang, Z. Effect of the Curing Condition and High-Temperature Exposure on Ground-Granulated Blast-Furnace Slag Cement Concrete. Int. J. Concr. Struct. Mater. 2021, 15, 15. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of Elevated Temperature on Mechanical Properties of High-Volume Fly Ash-Based Geopolymer Concrete, Mortar and Paste Cured at Room Temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef] [PubMed]

- Kotop, M.A.; El-Feky, M.S.; Alharbi, Y.R.; Abadel, A.A.; Binyahya, A.S. Engineering properties of geopolymer concrete incorporating hybrid nano-materials. Ain Shams Eng. J. 2021, 12, 3641–3647. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.; ElBatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef]

- Pratap, B.; Mondal, S.; Hanumantha Rao, B. NaOH molarity influence on mechanical and durability properties of geopolymer concrete made with fly ash and phosphogypsum. Structures 2023, 56, 105035. [Google Scholar] [CrossRef]

- Nagajothi, S.; Elavenil, S.; Angalaeswari, S.; Natrayan, L.; Mammo, W.D.; Putra Jaya, R. Durability Studies on Fly Ash Based Geopolymer Concrete Incorporated with Slag and Alkali Solutions. Adv. Civ. Eng. 2022, 2022, 7196446. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the Development of Fly Ash-Based Geopolymer Concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar] [CrossRef]

- Amin, M.; Elsakhawy, Y.; Abu el-hassan, K.; Abdelsalam, B.A. Behavior evaluation of sustainable high strength geopolymer concrete based on fly ash, metakaolin, and slag. Case Stud. Constr. Mater. 2022, 16, e00976. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Part, W.K.; Ramli, M.; Cheah, C.B. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Constr. Build. Mater. 2015, 77, 370–395. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chalee, W. Effect of sodium hydroxide concentration on chloride penetration and steel corrosion of fly ash-based geopolymer concrete under marine site. Constr. Build. Mater. 2014, 63, 303–310. [Google Scholar] [CrossRef]

- Aslani, F.; Asif, Z. Properties of Ambient-Cured Normal and Heavyweight Geopolymer Concrete Exposed to High Temperatures. Materials 2019, 12, 740. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Ekinci, E.; Türkmen, İ.; Kantarci, F.; Karakoç, M.B. The improvement of mechanical, physical and durability characteristics of volcanic tuff based geopolymer concrete by using nano silica, micro silica and Styrene-Butadiene Latex additives at different ratios. Constr. Build. Mater. 2019, 201, 257–267. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Rangaraju, P.R. Study on the effect of selected parameters on the alkali-silica reaction of aggregate in ground glass fiber and fly ash-based geopolymer mortars. Constr. Build. Mater. 2021, 271, 121549. [Google Scholar] [CrossRef]

- El-said, A.; Awad, A.; Ahmad, M.; Sabri, M.M.S.; Deifalla, A.F.; Tawfik, M. The Mechanical Behavior of Sustainable Concrete Using Raw and Processed Sugarcane Bagasse Ash. Sustainability 2022, 14, 11181. [Google Scholar] [CrossRef]

- Abdalla, T.A.; Koteng, D.O.; Shitote, S.M.; Matallah, M. Mechanical and durability properties of concrete incorporating silica fume and a high volume of sugarcane bagasse ash. Results Eng. 2022, 16, 100666. [Google Scholar] [CrossRef]

- Torres de Sande, V.; Sadique, M.; Pineda, P.; Bras, A.; Atherton, W.; Riley, M. Potential use of sugar cane bagasse ash as sand replacement for durable concrete. J. Build. Eng. 2021, 39, 102277. [Google Scholar] [CrossRef]

- Jha, P.; Sachan, A.K.; Singh, R.P. Agro-waste sugarcane bagasse ash (ScBA) as partial replacement of binder material in concrete. Mater. Today Proc. 2021, 44, 419–427. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Sujumnongtokul, P.; Posi, P. Durability and Mechanical Properties of Pavement Concrete Containing Bagasse Ash. Mater. Today Proc. 2019, 17, 1612–1626. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Use of increasing amounts of bagasse ash waste to produce self-compacting concrete by adding limestone powder waste. J. Clean. Prod. 2013, 57, 308–319. [Google Scholar] [CrossRef]

- Abdalla, T.A.; Koteng, D.O.; Shitote, S.M.; Matallah, M. Mechanical Properties of Eco-friendly Concrete Made with Sugarcane Bagasse Ash. Civ. Eng. J. 2022, 8, 1227–1239. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Zajdel, P. Sustainable approach of using sugarcane bagasse ash in cement-based composites: A systematic review. Case Stud. Constr. Mater. 2021, 15, e00698. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N. Sodium hydroxide effect on the mechanical properties of flyash-slag based geopolymer concrete. Struct. Concr. 2020, 22, E368–E379. [Google Scholar] [CrossRef]

- Ghafoor, M.T.; Khan, Q.S.; Qazi, A.U.; Sheikh, M.N.; Hadi, M.N.S. Influence of alkaline activators on the mechanical properties of fly ash based geopolymer concrete cured at ambient temperature. Constr. Build. Mater. 2021, 273, 121752. [Google Scholar] [CrossRef]

- Alghannam, M.; Albidah, A.; Abbas, H.; Al-Salloum, Y. Influence of Critical Parameters of Mix Proportions on Properties of MK-Based Geopolymer Concrete. Arab. J. Sci. Eng. 2021, 46, 4399–4408. [Google Scholar] [CrossRef]

- Tanu, H.M.; Unnikrishnan, S. Mechanical Strength and Microstructure of GGBS-SCBA based Geopolymer Concrete. J. Mater. Res. Technol. 2023, 24, 7816–7831. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Aziz, I.H.; Abdullah, M.M.A.B.; Mohd Salleh, M.A.A.; Azimi, E.A.; Chaiprapa, J.; Sandu, A.V. Strength development of solely ground granulated blast furnace slag geopolymers. Constr. Build. Mater. 2020, 250, 118720. [Google Scholar] [CrossRef]

- Bezabih, T.; Kanali, C.; Thuo, J. Effects of teff straw ash on the mechanical and microstructural properties of ambient cured fly ash-based geopolymer mortar for onsite applications. Results Eng. 2023, 18, 101123. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Newark, DE, USA, 2019.

- ASTM C496/C496M-04; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. iTeh Standards: Newark, DE, USA, 2004.

- ASTM C78-02; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). iTeh Standards: Newark, DE, USA, 2002.

- Naenudon, S.; Wongsa, A.; Ekprasert, J.; Sata, V.; Chindaprasirt, P. Enhancing the properties of fly ash-based geopolymer concrete using recycled aggregate from waste ceramic electrical insulator. J. Build. Eng. 2023, 68, 106132. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 2009, 22, 1073–1078. [Google Scholar] [CrossRef]

- Perez-Cortes, P.; Escalante-Garcia, J.I. Gel composition and molecular structure of alkali-activated metakaolin-limestone cements. Cem. Concr. Res. 2020, 137, 106211. [Google Scholar] [CrossRef]

- Görhan, G.; Kürklü, G. The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos. Part B Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- Elyamany, H.E.; Abd Elmoaty, A.E.M.; Elshaboury, A.M. Setting time and 7-day strength of geopolymer mortar with various binders. Constr. Build. Mater. 2018, 187, 974–983. [Google Scholar] [CrossRef]

- Kantarcı, F.; Türkmen, İ.; Ekinci, E. Optimization of production parameters of geopolymer mortar and concrete: A comprehensive experimental study. Constr. Build. Mater. 2019, 228, 116770. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Alam, S.; Das, S.K.; Rao, B.H. Strength and durability characteristic of alkali activated GGBS stabilized red mud as geo-material. Constr. Build. Mater. 2019, 211, 932–942. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. Mix design development of fly ash and ground granulated blast furnace slag based geopolymer concrete. J. Build. Eng. 2018, 20, 712–722. [Google Scholar] [CrossRef]

- Pavithra, P.; Srinivasula Reddy, M.; Dinakar, P.; Hanumantha Rao, B.; Satpathy, B.K.; Mohanty, A.N. A mix design procedure for geopolymer concrete with fly ash. J. Clean. Prod. 2016, 133, 117–125. [Google Scholar] [CrossRef]

- Liang, X.; Ji, Y. Mechanical properties and permeability of red mud-blast furnace slag-based geopolymer concrete. SN Appl. Sci. 2021, 3, 23. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of alkali reactions on the rheology of one-part 3D printable geopolymer concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Zakira, U.; Zheng, K.; Xie, N.; Birgisson, B. Development of high-strength geopolymers from red mud and blast furnace slag. J. Clean. Prod. 2023, 383, 135439. [Google Scholar] [CrossRef]

- Bheem, P.; Somenath, M.; Bendadi, H.R. Synthesis of alkali-activated mortar using phosphogypsum-neutralised bauxite residue. Environ. Geotech. 2023; ahead of print. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C.; Spangenberg, J.; Mehrali, M. Hardening evolution of geopolymers from setting to equilibrium: A review. Cem. Concr. Compos. 2020, 114, 103729. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Dawood Abdul Khadar, S. Molarity activity effect on mechanical and microstructure properties of geopolymer concrete: A review. Case Stud. Constr. Mater. 2022, 16, e01014. [Google Scholar] [CrossRef]

- Their, J.M.; Özakça, M. Developing geopolymer concrete by using cold-bonded fly ash aggregate, nano-silica, and steel fiber. Constr. Build. Mater. 2018, 180, 12–22. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Gashti, M.F. Effects of alkaline solution/binder and Na2SiO3/NaOH ratios on fracture properties and ductility of ambient-cured GGBFS based heavyweight geopolymer concrete. Structures 2021, 32, 2118–2129. [Google Scholar] [CrossRef]

- Alomayri, T.; Adesina, A.; Das, S. Influence of amorphous raw rice husk ash as precursor and curing condition on the performance of alkali activated concrete. Case Stud. Constr. Mater. 2021, 15, e00777. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N. Microstructure, strength, and durability of eco-friendly concretes containing sugarcane bagasse ash. Constr. Build. Mater. 2018, 184, 258–268. [Google Scholar] [CrossRef]

| Oxides | Raw SCBA | Processed SCBA | FA |

|---|---|---|---|

| SiO2 | 81.32 | 76 | 54 |

| Al2O3 | 5.51 | 9 | 19.6 |

| Fe2O3 | 6.95 | 4.2 | 6.9 |

| CaO | 1.71 | 3.1 | 7.9 |

| K2O | 2.68 | 3.83 | 2.2 |

| MgO | - | 2.7 | 6.9 |

| P2O2 | 0.5 | 0.69 | 0.34 |

| TiO2 | 0.65 | 0.46 | 0.88 |

| MnO | 0.39 | 0.2 | 0.1 |

| LOI | 10.20 | 0.97 | 1.87 |

| Aggregates | Fineness Modulus | Specific Gravity | Water Absorption (%) | Density (kg/m3) | Voids Ratio (%) | Crush Value (%) | Impact Value (%) |

|---|---|---|---|---|---|---|---|

| Coarse agg | - | 2.66 | 3.6 | 1468 | 42 | 17.6 | 6.2 |

| Fine agg | 2.60 | 2.61 | 3.5 | 1677 | 28 | - | - |

| Mix ID | FA | SCBA | Coarse Agg | Fine Agg | Alkaline Solution | S. P | NaOH M |

|---|---|---|---|---|---|---|---|

| GPC0-10 | 500 | 0 | 1000 | 700 | 175 | 12.5 | 10 |

| GPC5-10 | 475 | 25 | 1000 | 700 | 175 | 12.5 | 10 |

| GPC10-10 | 450 | 50 | 1000 | 700 | 175 | 12.5 | 10 |

| GPC15-10 | 425 | 75 | 1000 | 700 | 175 | 12.5 | 10 |

| GPC20-10 | 400 | 100 | 1000 | 700 | 175 | 12.5 | 10 |

| GPC0-12 | 500 | 0 | 1000 | 700 | 175 | 12.5 | 12 |

| GPC5-12 | 475 | 25 | 1000 | 700 | 175 | 12.5 | 12 |

| GPC10-12 | 450 | 50 | 1000 | 700 | 175 | 12.5 | 12 |

| GPC1512 | 425 | 75 | 1000 | 700 | 175 | 12.5 | 12 |

| GPC20-12 | 400 | 100 | 1000 | 700 | 175 | 12.5 | 12 |

| GPC0-14 | 500 | 0 | 1000 | 700 | 175 | 12.5 | 14 |

| GPC5-14 | 475 | 25 | 1000 | 700 | 175 | 12.5 | 14 |

| GPC10-14 | 450 | 50 | 1000 | 700 | 175 | 12.5 | 14 |

| GPC15-14 | 425 | 75 | 1000 | 700 | 175 | 12.5 | 14 |

| GPC20-14 | 400 | 100 | 1000 | 700 | 175 | 12.5 | 14 |

| GPC0-16 | 500 | 0 | 1000 | 700 | 175 | 12.5 | 16 |

| GPC5-16 | 475 | 25 | 1000 | 700 | 175 | 12.5 | 16 |

| GPC10-16 | 450 | 50 | 1000 | 700 | 175 | 12.5 | 16 |

| GPC15-16 | 425 | 75 | 1000 | 700 | 175 | 12.5 | 16 |

| GPC20-16 | 400 | 100 | 1000 | 700 | 175 | 12.5 | 16 |

| Na2SiO3/NaOH 2.5 | ||

|---|---|---|

| NaOH molarity | Equations | |

| 10 M | Y = 0.04932x + 0.5269 | (1) |

| 12 M | Y = 0.10596x − 2.3292 | (2) |

| 14 M | Y= 0.1109x − 2.41803 | (3) |

| 16 M | Y = 0.2013x − 8.67818 | (4) |

| Na2SiO3/NaOH 1.5 | ||

| NaOH molarity | Equations | |

| 10 M | Y = 0.08939x − 0.95248 | (5) |

| 12 M | Y = 0.08633x − 0.43122 | (6) |

| 14 M | Y = 0.48777x − 0.79358 | (7) |

| 16 M | Y = 0.06926x − 0.79358 | (8) |

| Na2SiO3/NaOH 2.5 | ||

|---|---|---|

| NaOH molarity | Equations | |

| 10 M | Y = 0.34008x − 11.69282 | (9) |

| 12 M | Y = 0.18108x − 2.40095 | (10) |

| 14 M | Y = 0.18962x − 1.90198 | (11) |

| 16 M | Y = 0.48684x − 21.86886 | (12) |

| Na2SiO3/NaOH 1.5 | ||

| NaOH molarity | Equations | |

| 10 M | Y = 0.18817x − 2.54255 | (13) |

| 12 M | Y = 0.11587x − 1.39236 | (14) |

| 14 M | Y = 0.67945x − 30.21794 | (15) |

| 16 M | Y = 0.1140x − 0.47941 | (16) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rihan, M.A.M.; Alahmari, T.S.; Onchiri, R.O.; Gathimba, N.; Sabuni, B. Impact of Alkaline Concentration on the Mechanical Properties of Geopolymer Concrete Made up of Fly Ash and Sugarcane Bagasse Ash. Sustainability 2024, 16, 2841. https://doi.org/10.3390/su16072841

Rihan MAM, Alahmari TS, Onchiri RO, Gathimba N, Sabuni B. Impact of Alkaline Concentration on the Mechanical Properties of Geopolymer Concrete Made up of Fly Ash and Sugarcane Bagasse Ash. Sustainability. 2024; 16(7):2841. https://doi.org/10.3390/su16072841

Chicago/Turabian StyleRihan, Mohammed Ali M., Turki S. Alahmari, Richard Ocharo Onchiri, Naftary Gathimba, and Bernadette Sabuni. 2024. "Impact of Alkaline Concentration on the Mechanical Properties of Geopolymer Concrete Made up of Fly Ash and Sugarcane Bagasse Ash" Sustainability 16, no. 7: 2841. https://doi.org/10.3390/su16072841

APA StyleRihan, M. A. M., Alahmari, T. S., Onchiri, R. O., Gathimba, N., & Sabuni, B. (2024). Impact of Alkaline Concentration on the Mechanical Properties of Geopolymer Concrete Made up of Fly Ash and Sugarcane Bagasse Ash. Sustainability, 16(7), 2841. https://doi.org/10.3390/su16072841