Waste-Based Vertical Planting System Proposal to Increase Productivity in Sustainable Horticulture; “PETREE”

Abstract

1. Introduction

1.1. Global Problems of Small-Scale Producers

1.1.1. Land Scarcity and Loss

- Rising and expanding urbanization is one of the biggest threats to small-scale producers on a worldwide scale. Industrial growth and rising commercial land grabbing compete with local and small-scale agriculture, forcing farmers to lose land all over the world [4]. The impact of urbanization on small-scale producers is a well-documented issue, especially in regions where industrial growth and urban expansion have led to the displacement of local farmers and loss of agricultural land [1].

- Land degradation as well as water and soil management issues, disproportionately affected smallholders and their limited resources. Land degradation encompasses desertification, soil erosion, and salinization, all of which degrade and impair agriculture quality and productivity, particularly in developing countries [9].

1.1.2. Economic Challenges

- Limited Access to Credit and Investment Problems: Almost all small-scale producers continue to struggle to access loans and investments necessary to upgrade to new technology, infrastructure, and sustainable practices, reducing productivity and competitiveness [10]. Access to credit and investment is a major challenge for small-scale producers around the world. The World Bank reports that 65% of micro, small, and medium enterprises (MSMEs) in developing countries have unmet financing needs [11]. This translates to a financing gap of USD 1.5 trillion globally. The International Labor Organization (ILO): The ILO estimates that 90% of formal businesses globally are MSMEs, and they provide employment for more than half of the global workforce [6]. Limited access to finance can hinder the growth and job creation potential of these businesses. The FAO highlights those small-scale farmers, who play a crucial role in global food security, are particularly constrained by limited access to credit [1,6]. This can limit their ability to invest in productivity-enhancing technologies, such as irrigation systems and improved seeds. Market Volatility and Instability small farmers and producers, particularly in underdeveloped regions and countries, are frequently subjected to fluctuating market conditions and price politics in which they lack bargaining power, leaving them vulnerable to exploitation by middlemen and price drops, which have a vulnerable impact on their income and resilience [12].

- Resource Constraints: Small-scale horticultural producers frequently have limitations in accessing crucial resources, including land, water, seeds, fertilizers, financing, and technology. The limited availability of resources substantially impacts their ability to produce and generate profit. For instance, a study conducted in Kenya [13] revealed that small-scale horticultural farmers needed help in obtaining high-quality seeds and fertilizers, which restricted their crop productivity. Small-scale horticultural producers in Turkey also frequently face challenges because of their limited access to resources, which hinders their production and their capacity to compete in the market [13].

- Market Constraints: Global markets often present challenges for small-scale horticulture producers in terms of competition, price volatility, and access to markets. A study in Chile [14] revealed that small-scale fruit producers faced difficulties in accessing export markets due to stringent quality standards and competition from larger producers. Similarly, small-scale horticulture producers in Turkey face market challenges such as price volatility, competition from larger producers, and difficulty in accessing export markets. These constraints affect their profitability and market penetration [15].

1.1.3. Social Problems

- The fragmentation of land due to inheritance contributes to global issues such as poverty, limited opportunities, and climate change, prompting individuals to relocate to urban areas at a young age. This inevitable migration causes less developed countries to experience a slowdown in the productivity and intellectual capacity of the agricultural labor force, which has been present in rural communities for millennia [12].

- The aging population and loss of agriculture power are also a rising problem in underdeveloped regions when the “youth leave” workforce ages, small-scale farmers and producers confront significant barriers to the adoption of new technology and innovations that are critical for adjusting to changing conditions [16].

- Social factors such as gender inequities, lack of education, and limited access to extension services can further marginalize small-scale horticulture producers. A study in Tanzania [17] highlighted how female farmers faced challenges in accessing agricultural training and resources, impacting their production capabilities. Social factors, including gender disparities, limited access to education and extension services, and land ownership issues, also contribute to the challenges faced by small-scale horticulture producers in Turkey. Women farmers may face additional barriers in accessing resources and support for their agricultural activities [8].

1.1.4. Additional Challenges

- Global Climate Change is still a major problem for all, in which increasingly variable weather and season conditions, water scarcity, earthquakes, droughts, and over-flooding have threatened and skewed overall agricultural production and small-producer stability in income [15]. Small-scale horticulture producers are vulnerable to the adverse effects of climate change, including unpredictable weather patterns, droughts, floods, and pest outbreaks. Research in Vietnam demonstrated how climate variability has impacted small-scale vegetable producers, leading to crop losses and reduced incomes [18].

- Lack of Infrastructure and Support Services: The quality of infrastructure always affects the quality of life, particularly in developing countries. Limited access to infrastructure, including roads, storage facilities, extension services, and communication technology, might restrict market access, information sharing, and optimal practices implementation. The absence of proper infrastructure, including storage facilities, transportation networks, and market linkages, hinders the efficiency of small-scale horticulture production. In India, small-scale vegetable producers struggle with post-harvest losses due to inadequate cold storage facilities, as highlighted in a report by ICRISAT [19]. The inadequate infrastructure, including storage facilities, transportation networks, and market linkage systems, poses significant challenges for small-scale horticulture producers in Turkey. The lack of proper infrastructure leads to post-harvest losses and limits market access for producers [15].

- Land ownership problems persist in most impoverished countries. Small-scale producers and farmers continue to experience insecure land tenure rights, which have a significant impact on long-term planning and sustainable land management practices by smallholders. This problem persists in most impoverished countries. Small-scale producers and farmers continue to experience insecure land tenure rights, which significantly hinders long-term investment and adoption of sustainable land management practices by smallholders [20,21].

1.1.5. Possibilities for the Future

2. Exploring the Greenhouse Technology

- Advancements in materials: The introduction of new materials such as glass, polycarbonate, and plastics revolutionized greenhouse construction, allowing for better insulation, light transmission, and durability.

- Automation and control systems: The integration of automation, sensors, and control systems enabled precise monitoring and adjustment of environmental conditions within greenhouses, optimizing plant growth and resource use efficiency.

- Sustainable practices: The emphasis on sustainability led to the adoption of energy-efficient technologies, water-saving irrigation systems, and integrated pest management strategies in greenhouse production.

- Vertical planting and hydroponics: Innovations in vertical planting and hydroponic systems expanded the capacity for crop production in limited spaces, increasing productivity and resource efficiency.

- Climate resilience: Greenhouse systems have been developed to withstand climate variability and extreme weather events, ensuring a stable and reliable food supply throughout the year.

2.1. Early Innovations Started and Developed in between (17th–19th Centuries)

- Focus on Exotic Plants: Initial applications primarily centered on cultivating luxurious and prized exotic plants, colonialization led to a concentration on cultivating valuable ornamental adaptive plants, reflecting new scientific curiosity and botanical interests.

2.2. Commercial Expansion (20th Century)

- The emergence of greenhouse vegetables: Fresh veggies, particularly tomatoes, cucumbers, and other high-value, high-consumption vegetables, are now available year-round. As a result of rising production speed, quality, and industrial needs in the greenhouse environment, these items have increasingly become commercially valuable greenhouse products around the globe [28].

- As soilless and “controlled environment agriculture” (CEA) techniques became more common in industrial agriculture, greenhouses improved productivity by allowing precise control over environmental conditions such as temperature, humidity, and nutrient distribution [28].

2.3. Modernization and Diversification (in the Twenty-First Century)

- Sustainability Concerns: As global environmental consciousness has grown, the energy utilized in greenhouses has led to the abandoning of traditional energy types in favor of alternative energy sources. It began to encourage the use of technology. Independent and, when appropriate, hybrid uses of renewable energy integration have evolved, particularly for solar, wind, heat pump, and related applications. Rising environmental concerns have prompted the use of water-saving methods [29,30].

- Expansion and Diversification: Large-scale specialized greenhouses to satisfy industrial needs have grown worldwide, adapting to varied climates and crops, and have begun to specialize in flowers, fruits, and even medicinal plants [28].

- The emergence of new systems and integration is evident in the adoption of innovative methods such as vertical planting and soilless integrated aquaculture agriculture (IAA) systems. These approaches, along with the increasing trend of regional production, provide opportunities for optimizing resources and integrating production with essential services in urban areas [30,31].

2.4. Future of Greenhouse Systems (Later Twenty-First Century)

- Integration of Internet of Things (IoT) and automation for real-time monitoring and control.

- Adoption of renewable energy sources like solar power for sustainable energy supply.

- Implementation of water-saving irrigation systems and nutrient management practices.

- Utilization of vertical planting and hydroponic systems to maximize space utilization.

- Incorporation of climate-resilient strategies to mitigate the impact of extreme weather events.

2.5. Pros and Cons of Industrial Greenhouse Systems

2.6. Vertical Planting Systems (VPS)

2.7. Traditional Planting Systems, Greenhouses, and Vertical Planting Systems Comparison

3. Sustainability Futures in Planting Systems

- Organic waste refers to the byproducts of plants, such as plant debris, food leftovers, and other organic matter. If not handled appropriately, these materials can become waste which is as critical as the planting outputs and can easily be converted into valuable assets [44].

- Composting is a highly effective method for converting plant remnants, trimmings, manure, and more agricultural refuse into compost that is abundant in nutrients. It is effective in domestic gardens, small-scale farms, and large-scale agricultural operations. The utilization of compost and organic fertilizers derived from agricultural waste enhances soil fertility, increases crop output, and perhaps obviates the necessity for synthetic chemical fertilizers [44].

- Biogas production is a highly efficient approach to waste management, particularly in underdeveloped nations. Waste is converted into biogas, a renewable energy source that may be used for cooking, heating, and generating electricity. The EU is promoting the implementation of extensive biogas production to effectively handle agricultural waste and enhance sustainable agriculture. Biogas effectively manages agricultural waste and generates cleaner, more efficient energy, reducing air and water pollution and enhancing quality of life [45].

- Mulching is the practice of applying organic materials or plastic to the soil surface to retain moisture and suppress weed growth. Utilizing agricultural solid waste as mulch aids in the preservation of nutrients and moisture, and the inhibition of weed proliferation. Mulching safeguards the soil from erosion and fluctuations in temperature, thus enhancing the well-being and production of crops. Utilizing agricultural waste as mulch helps to preserve soil moisture [43].

- Biomass conversion involves the transformation of organic materials, such as plants or agricultural waste, into electricity or other valuable products. Thermochemical and biochemical conversion processes transform agricultural waste into biofuels, biochemicals, and bioplastics [45].

- Combustion is the process of burning biomass to produce heat and energy. Due to the emission of carbon dioxide into the carbon cycle, fossil fuel combustion is considered less sustainable compared to other methods.

- Fermentation is the process by which crops, sugarcane are transformed into biofuels such as ethanol or biodiesel. They provide a more sustainable alternative to fossil fuels in transportation and other industries.

- Pyrolysis is a process that involves heating biomass in the absence of oxygen to produce biochar, bio-oil, and syngas. Biochar can enhance soil fertility, whereas bio-oil and syngas can be converted into biofuels and other valuable commodities [45].

- Gasification is a process that transforms biomass into syngas through partial oxidation. Syngas can produce electricity or can be converted into chemicals and liquid fuels.

- Proper disposal of chemical waste is necessary for pesticides, fertilizers, and cleaning products.

- Output water, the term “greenhouse, output water” refers to the amount of freshwater that becomes contaminated during its usage and needs to be treated before being released back into the environment. Within greenhouses, this covers water that has become polluted with fertilizers, insecticides, and other chemicals that farmers use for cultivation. To minimize greywater, one must use strategies such as integrated pest management and effective nutrition management to decrease the amounts of contaminants [46].

- Harnessing greenhouse waste heat in sustainable systems, greenhouses generate substantial heat through the absorption of sunlight and the use of heating devices. The heat generated in conventional greenhouse systems is energy that is not utilized efficiently. Currently, modern methods can harness this thermal energy and utilize it for many sustainable applications. Three fundamental criteria can be used to assess the correct utilization of energy [11].

- Direct connection: Establish a physical link between greenhouses and adjacent structures (such as residences, schools, etc.), using insulated pipes to directly transmit heat.

- District heating systems involve the integration of greenhouses into larger networks to provide heat to many buildings in a neighborhood.

- Heat pumps are utilized to capture heat from the air inside a greenhouse and transfer it to other buildings at elevated temperatures.

3.1. Reusing Packaging Materials in Greenhouse System

3.2. Long-Term Plastic Sustainability in Greenhouse Production

- Reduce/involve utilizing existing plastic derivatives and developing alternative materials with lower carbon footprints to minimize consumption.

- To establish waste management methods that facilitate the utilization of recycled or used plastic materials in greenhouse manufacturing without the need for further recycling.

3.3. Possibilities of Reusing “Obsolete” Plastic Products in Agriculture

- Designing or selecting long-lastingproducts, plant pots, pot trays, and other similar products that will be utilized in the greenhouse.

- Selecting eco-conscious options (such as biodegradable materials) and examining the characteristics of consumer goods derived from organic waste.

- The changeover process can be achieved by predominantly advocating for the use of recycled samples in practical applications.

3.3.1. Reusable Pots and Trays

3.3.2. Recycled Plastic Mulch Films

3.3.3. Biodegradable Plastic Alternatives

3.4. Future Possibilities of Plastic Usage in VPS

3.4.1. Sustainable Plastic Alternatives

3.4.2. Smart Plastic Technologies

3.4.3. Circular Economy Approaches

3.4.4. Nanotechnology Applications

3.4.5. Carbon Footprint Reduction

4. Introduction PETREE

4.1. Design Principles and Potentials

- The PETREE system is specifically developed to accommodate the needs of both rural and urban areas.

- The system consists of multiple portable stations that may be quickly set up on different terrains, including small and narrow areas that are too uneven and fragmented to accommodate an effective greenhouse.

- The Petree system offers straightforward installation and transportation possibilities with its autonomous station design and modular structure.

- The design aims to optimize convenience by ensuring quick assembly, disassembly, part replacement, and maintenance in a compact package.

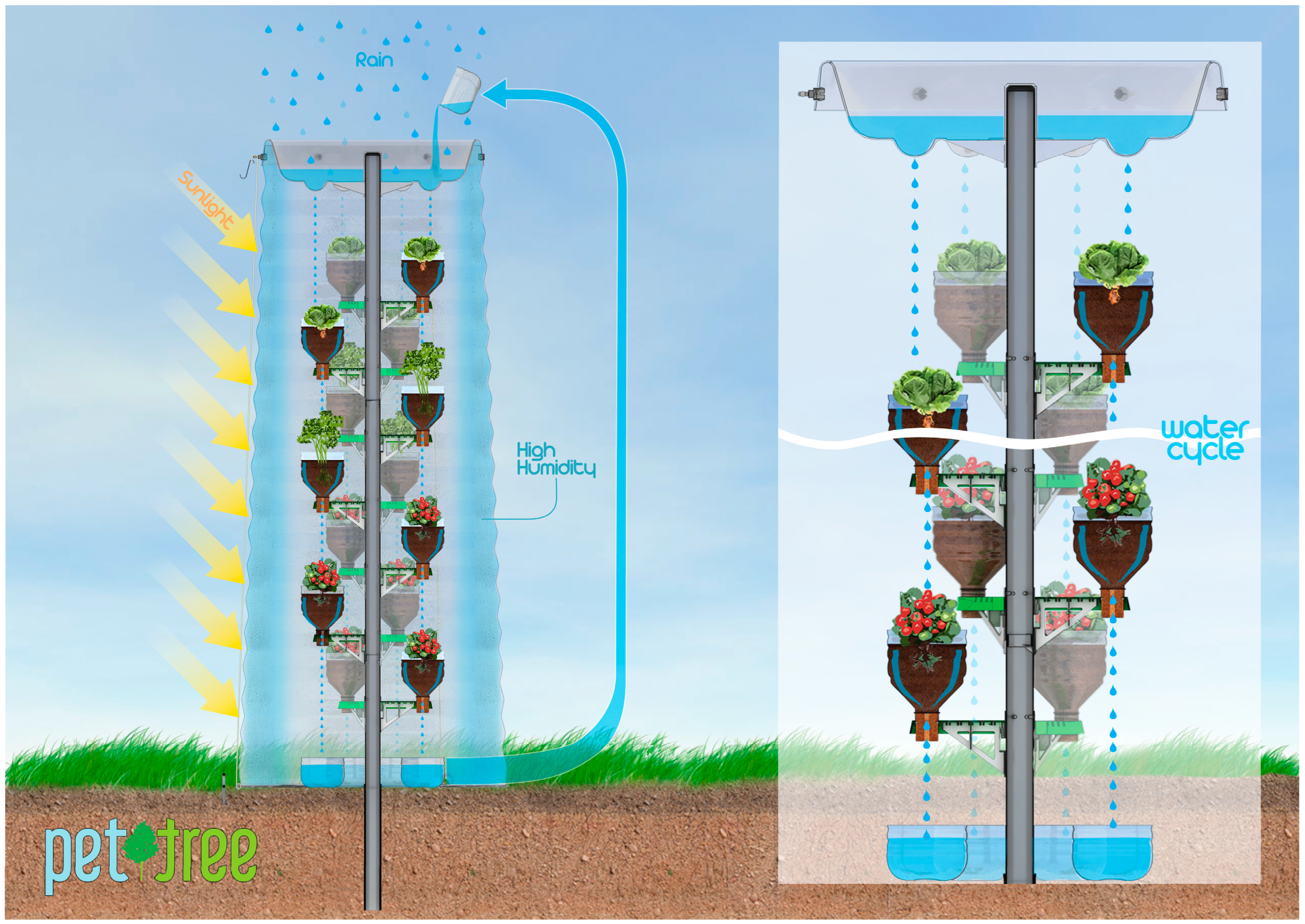

- Independent stations are self-contained plant cultivation systems that utilize drip irrigation. They employ waste PET bottles, namely 5 L, in this project, which are positioned vertically in a multi-layered and staggered configuration.

- Each station has been purposefully engineered to collect rainwater or maintain output within a closed system, utilizing a limited amount of water through the principles of drip irrigation. The optimal capacity of these stations is to minimize both water and energy losses.

- Mobility potential allows small producers, especially those with limited land, to sustain their output levels by improving the productivity of their unused land.

- The Petree system, characterized by its autonomous station design and self-contained approach, can be tailored to sustainable agriculture, even in environments with limited land and infrastructure resources.

- Closed units offer regulated environmental conditions, including control overheat, light, and humidity. PETREE’s separate unitary and closed system structure ensures effective utilization and conservation of water and heat inputs. In addition, it collects any surplus irrigation water at the base, which is beneficial in situations when both water conservation and a moist atmosphere are desired.

- The system is specifically intended to be well-suited for use in dry environmental circumstances. It is highly sensitive to water usage, making it appropriate for both regular watering and drip irrigation.

- The system possesses the capacity to adjust and conform to various usage conditions (such as luminosity, thermal insulation) By adjusting the tint of the outer cover to match the specific light requirements of each plant, we can regulate its permeability.

- PETREE is very suitable for mid-industrial plant production. In terms of manufacturability, the PETREE system is suitable for the existing low- and medium-quality industrial infrastructures of developing countries. The materials used have been selected to be highly compatible with recycling.

- Overall, the system design of PETREE fulfilled the user-friendly design approaches and sustainability principles.

- In addition, it provides the opportunity to eliminate potential diseases and similar problems in the most harmless and economical way.

- Petree stations have a specific engineering that enables natural gathering and accumulation of rainfall.

- Furthermore, it will prove to be a very efficient remedy for ensuring product safety and safeguarding against animal interference.

4.2. Assembly of a System UNIT

4.3. Technical Specifications for the PETREE System

4.4. Advantages and Possibilities of PETREE a New Hybrid VPS

4.4.1. Flexibility

4.4.2. Adaptability to Challenging Terrain

4.4.3. Space Utilization

4.4.4. Production Efficiency

4.4.5. Versatility and Customization

4.4.6. Resource Efficiency

4.4.7. Closed-Circuit Autonomous Stations

4.4.8. Pesticide and Disease Control

4.4.9. Climate Adaptability

4.4.10. Enhancing Livelihoods

4.4.11. Cost Effectiveness and Availability

4.4.12. Operational Cost Efficiency

4.4.13. Energy Consumption and Carbon Footprint

4.4.14. Adaptability in Rural Environment

- Space utilization: PETREE’s vertical planting technique optimizes space utilization in densely populated metropolitan areas with limited land availability by effectively exploiting vertical space. Urban farmers can cultivate crops in compact areas like rooftops, balconies, or vacant indoor spaces.

- Resources efficiency: PETREE’s design prioritizes resource efficiency through the implementation of efficient water and nutrient distribution systems. This is particularly crucial in urban settings where resources like water and land are limited. PETREE reduces water use and limits the discharge of nutrients, making it an environmentally viable option for urban agriculture.

- Local food production: PETREE enables urban inhabitants to cultivate fresh produce in their local area, thereby diminishing the carbon emissions linked to the transportation of food from rural regions to cities. This enhances the stability and ability of urban residents to access food while decreasing reliance on distant food distribution networks.

- Community engagement: PETREE systems in urban contexts can function as platforms for community interaction and education regarding sustainable agriculture. PETREE fosters a feeling of camaraderie and a strong bond with the natural world in urban settings by uniting individuals through the cultivation of food.

4.5. Assessment of the Potential Benefits and Implementation of the PETREE System in Developing Countries Similar to Turkey

- Utilization of Non-Agricultural Idle Lands: A PETREE-inspired system could enable small-scale producers to cultivate crops even on non-agricultural idle lands, thereby expanding their production capacity and enhancing food security.

- Increased Productivity: The system’s standardized infrastructure and controlled environment would enhance crop yields, enabling producers to optimize their output even in fragmented and limited land parcels [61].

- Socio-Economic Empowerment: By providing small-scale producers with access to modern technology and sustainable farming practices, a PETREE-like system could contribute to their economic empowerment and resilience in the face of socio-cultural challenges.

- Feasibility and Applicability

4.6. Future Steps for Enhanced Viability

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. Land Degradation Neutrality: The Key to Sustainable Development. 2021. Available online: https://www.fao.org/platforms/green-agriculture/areas-of-work/natural-resources-biodiversity-green-production/land-degradation-neutrality/ (accessed on 28 December 2023).

- World Bank. No Time to Waste: The Social Imperative for Climate Action; World Bank: Washington, DC, USA, 2019; Available online: https://www.nytimes.com/2023/03/18/opinion/world-bank-climate-change.html (accessed on 28 December 2023).

- IFAD. Rural Finance for Development. Available online: https://www.ifad.org/en/rural-finance (accessed on 2 January 2024).

- FAO. State of the Agricultural Markets 2023. Available online: https://www.fao.org/documents/card/en?details=cc7724en (accessed on 28 December 2023).

- World Bank. Migration and Development Brief 35: Rural Out-Migration and Rural Development. 2021. Available online: https://www.knomad.org/publication/migration-and-development-brief-35 (accessed on 2 January 2024).

- Food and Agriculture Organization of the United Nations. The State of Food and Agriculture 2020; FAO: Rome, Italy, 2020.

- Davidson, J. The Greenhouse: A History of the Invention that Changed the World; Frances Lincoln Publishers: London, UK, 2011. [Google Scholar]

- Akça, M.; Öztürk, M.S. Türkiye’de küçük ölçekli tarımsal üretimde karşılaşılan sorunlar ve çözüm önerileri. Uluslararası Sos. Araştırmalar Derg. 2018, 11, 1012–1023. [Google Scholar]

- Mason, J.; Bertram, R. Vertical Farming: The Growing Trend in Urban Agriculture; Timber Press: Portland, OR, USA, 2014. [Google Scholar]

- Mitchell, P. Glasshouse Crop Production; CABI: Wallingford, UK, 2019. [Google Scholar]

- United Nations Conference on Trade and Development. Trade and Development Report 2021: From Recovery to Transformation: Escaping the Inequality Trap. Available online: https://unctad.org/publication/trade-and-development-report-2021 (accessed on 5 January 2024).

- Carbone, P.A.; Melo, A.P.; Rodrigues, L.L. Energy use and carbon footprint of tomato production in heated greenhouses in southern Italy. J. Clean. Prod. 2019, 229, 1427–1436. [Google Scholar] [CrossRef]

- Mazinga, M.A.; Ochieng, J.; Odhiambo, G.O. Factors influencing access to quality seeds and fertilizers by smallholder vegetable farmers in Kenya. Afr. J. Agric. Res. 2018, 13, 2074–2082. [Google Scholar]

- Ocampo, M.A.; Lara, M.A.; Muñoz, S. Challenges faced by small-scale fruit producers in accessing export markets: The case of Chile. Sustainability 2019, 11, 400. [Google Scholar]

- Tarım ve Orman Bakanlığı. Available online: https://www.tarimorman.gov.tr/ (accessed on 25 December 2023).

- Gómez-Barbero, M.; Anastasiou, E.; Fountas, S.; Voulgaraki, M.; Psiroukis, V.; Koutsiaras, M.; Kriezi, O.; Lazarou, E.; Vatsanidou, A.; Fu, L.; et al. Precision farming technologies for crop protection: A meta-analysis. Smart Agric. Technol. 2023, 5, 100323. [Google Scholar] [CrossRef]

- Mbilinyi, D.P.; Laswai, H.S.; Mamiro, P. Gender and access to agricultural extension services in Tanzania: The case of smallholder farmers in Morogoro and Iringa regions. J. Gend. Stud. 2016, 25, 429–443. [Google Scholar]

- Nguyen, T.P.; Watanabe, M. Climate variability and its impact on smallholder vegetable production in Vietnam. Clim. Dev. 2017, 9, 458–469. [Google Scholar]

- ICRISAT. Post-Harvest Losses in Vegetables: A Case Study of India; International Crops Research Institute for the Semi-Arid Tropics: Hyderabad, India, 2020. [Google Scholar]

- Deininger, K.; Feder, G. Land Rights and Agricultural Development in Sub-Saharan Africa: Issues and Opportunities; World Bank Highlights the Link between Insecure Land Tenure and Limited Agricultural Development in Sub-Saharan Africa; The World Bank: Washington, DC, USA, 2009. [Google Scholar]

- Cotula, L.; Vermeulen, S.; Leonard, R. Land Tenure and Administration in FRAMES; FAO Examines the Connection between Secure Land Rights and Sustainable Land Management Practices; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2008; Available online: https://www.fao.org/publications/card/en/c/c6ded0bb-c052-5802-9659-b93746c82019/ (accessed on 28 December 2023).

- Thompson, H.S.; Cockshull, K.E. Principles of Horticulture, 6th ed; Pearson Education: Upper Saddle River, NJ, USA, 2009; p. 14. [Google Scholar]

- O’Neill, M. Greenhouse technology and its role in future agriculture. J. Agric. Innov. 2020, 15, 110–125. [Google Scholar]

- Sikora, V.; Bicer, Y. Greenhouse systems and techniques: A review. Int. J. Agric. Biol. Eng. 2017, 10, 1–10. [Google Scholar]

- Demir, E.; Topcu, S.; Kaya, E. Greenhouse cultivation: A sustainable approach for modern agriculture. J. Sustain. Agric. 2019, 23, 245–258. [Google Scholar]

- Proksch, G.; Horn, E.; Lee, G. Urban integration of aquaponics: Advancing integrated food systems for the circular city. Urban Reg. Agric. 2022, 403–430. [Google Scholar] [CrossRef]

- Hao, X.; Papadopoulos, A.P.; Gruda, N. Future greenhouse production systems: Trends and challenges. Acta Hortic. 2018, 1209, 37–46. [Google Scholar]

- Wang, C.; Chen, Y.; Sun, M.; Wu, J. Potential of technological innovation to reduce the carbon footprint of urban facility agriculture: A food–energy–water–waste nexus perspective. J. Environ. Manag. 2023, 339, 117806. [Google Scholar] [CrossRef] [PubMed]

- Garcia, J. Greenhouse technology: The future of horticulture. Horticulture 2019, 5, 9. [Google Scholar]

- Bakker, J.C. Greenhouse pest management: Current challenges and future prospects. In Integrated Pest Management in the Tropics; Springer: Singapore, 2018; pp. 247–258. [Google Scholar]

- Sonneveld, C.; Voogt, W. Plant Nutrition in Greenhouse Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Rizzotti, R. Vertical Farming: People and Technologies for Sustainable Urban Agriculture; Springer: Berlin/Heidelberg, Germany, 2019; p. 30. [Google Scholar]

- Despommier, E. Vertical Farms: The Growing Revolution in Urban Agriculture; Penguin Books: London, UK, 2014. [Google Scholar]

- Sanyal, P.; Ahmed, E.; Ismaiel, A.; Ashokkumar, M.; Xu, X.; Pan, S.; Hu, H. Land use change for global horticulture and its implications for sustainability. Trends Food Sci. Technol. 2021, 114, 138–149. [Google Scholar] [CrossRef]

- Ji, Y.; Kusuma, P.; Marcelis, L.F. Vertical farming. Curr. Biol. 2023, 33, R471–R473. [Google Scholar] [CrossRef]

- Rosenqvist, E.; Ottosen, C.O. Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Allen, T.; Prosperi, P. Modeling Sustainable Food Systems. Environ. Manag. 2016, 57, 956–975. [Google Scholar] [CrossRef]

- Kacira, M.; Batal, D. Greenhouse Engineering: Sustainable Controlled Environment Agriculture; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Cornell Waste Management Institute. Composting; Cornell Waste Management Institute: Ithaca, NY, USA, 2023; Available online: https://cwmi.css.cornell.edu/ (accessed on 15 January 2024).

- FAO. Sustainable Agriculture and Food Systems; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2023.

- Mekkonen, M.M.; Hoekstra, A.Y. National Water Footprint Accounts: The Green, Blue, and Grey Water Footprint of Production and Consumption; Value of Water Research Report Series No. 50; UNESCO-IHE Institute for Water Education: Delft, The Netherlands, 2011. [Google Scholar]

- Tilman, D.; Cassman, K.G.; Matson, P.A.; Naylor, R.; Polasky, S. Agricultural sustainability and intensive production practices. Nature 2001, 418, 671–677. [Google Scholar] [CrossRef]

- Bavec, M.; Bavec, F.; Gril, J. Sustainable Greenhouse Systems; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- González-García, G.; Rezaei, A. Energy consumption and economic feasibility of different heating systems for greenhouse cultivation in a cold climate. J. Food Eng. 2015, 159, 1–9. [Google Scholar]

- Matthews, C.; Moran, F.; Jaiswal, A.K. A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021, 283, 125263. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics; World Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- Lakhiar, I.A.; Yan, H.; Zhang, J.; Wang, G.; Deng, S.; Bao, R.; Zhang, C.; Syed, T.N.; Wang, B.; Zhou, R.; et al. Plastic Pollution in Agriculture as a Threat to Food Security, the Ecosystem, and the Environment: An Overview. Agronomy 2024, 14, 548. [Google Scholar] [CrossRef]

- Kijchavengkul, T.; Auras, R.; Rubino, M.; Selke, S.; Ngouajio, M.; Fernandez, R.T. Biodegradation and hydrolysis rate of aliphatic aromatic polyester. Polym. Degrad. Stab. 2010, 95, 2641–2647. [Google Scholar] [CrossRef]

- Thomas, R.J.; O’Hare, G.; Coyle, D. Understanding technology acceptance in smart agriculture: A systematic review of empirical research in crop production. Technol. Forecast. Soc. Change 2023, 189, 122374. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Innocenzo, M.; Raguso, F.; Torretta, L. Recycling of plastic: A review on its origins, recent developments, and future challenges. Recycling 2015, 1, 220–242. [Google Scholar]

- Vink, E.T.H.; Davies, S.; Kolstad, J.J. The eco-profile for current Ingeo polylactide production. Ind. Biotechnol. 2014, 10, 125–133. [Google Scholar]

- Garg, S.; Rumjit, N.P.; Roy, S. Smart agriculture and nanotechnology: Technology, challenges, and new perspective. Adv. Agrochem. 2023. [Google Scholar] [CrossRef]

- Notarnicola, B.; Salomone, R.; Petti, L.; Renzulli, P.A.; Roma, R.; Cerutti, A.K. Life Cycle Assessment in the Agri-Food Sector: Case Studies, Methodological Issues; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Samarakoon, U.; Weerasinghe SH, K.; Ranathunga, U.; Dharmasena, P.B.; Prasad, R. Vertical Farming Systems and Sustainable Agriculture: A Review. Int. J. Agric. Biol. 2020, 24, 449–457. [Google Scholar]

- Tong, G.H.Y.; Hu, Y.; Wong, M.C. Urban Agriculture and Vertical Farming: Global Scenario, Opportunities, and Challenges. Sustainability 2021, 13, 3794. [Google Scholar]

- Gupta, R.; Gera, R.; Choudhary, P.; Sehgal, V.K. Vertical Farming Techniques and Sustainable Urban Agriculture: A Review. Int. J. Agric. Biol. 2021, 25, 243–254. [Google Scholar]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Giuliani, C.; Maggio, A.; Orrù, L.; Vivaldi, G.A.; Beone, G.M.; Branca, T.A. Food safety and nutritional quality of greenhouse and indoor cropping systems: A critical review. Agronomy 2020, 10, 875. [Google Scholar]

- Zhang, Y.; Bai, G.; Jin, S. Applications of vertical farming systems for greenhouse production: A review. Agric. Biol. Res. 2020, 36, 405–416. [Google Scholar]

- Lee, J.H.; Kim, H.K.; Kim, J.K. Greenhouse as a control tool for microclimate changes to improve crop productivity and adaptability. Sustainability 2019, 11, 4403. [Google Scholar]

- Aksoy, M.A.; Newman, C. Agricultural Trade Reform and Poverty in the Mediterranean Countries: A General Equilibrium Analysis; World Bank Publications: Washington, DC, USA, 2007. [Google Scholar]

- Swinnen, J.; Vandeplas, A. The Stages of Agricultural Transformation in Emerging Economies: Causes and Conse-quences. Am. J. Agric. Econ. 2017, 100, 1082–1101. [Google Scholar]

| Aspect | Vertical Planting System | Traditional Planting System |

|---|---|---|

| Space Utilization | High, utilizes vertical space efficiently, suitablefor urban areas with limited land. | Requires significant horizontal land area, making it less suitable for urban environments where space is limited. |

| Production Efficiency | High yields per unit area due to controlled environment and intensive production methods. | Yields depend on soil quality, weather conditions, and traditional farming practices; may be lower per unit area compared to VPS. |

| Resource Consumption | Can be highly resource-efficient with optimized water and nutrient delivery systems. | Potentially more water and nutrient wastage due to less precise delivery methods. |

| Initial Investment | Relatively high due to complex infrastructure and technology needs | Lower initial investment as it requires simpler infrastructure and equipment. |

| Operational Costs | Can be variable depending on energy consumption, labor, and technology maintenance. | Generally lower operational costs but can be labor-intensive depending on the scale and mechanization of the farm. |

| Crop Suitability | Suitable for leafy greens, herbs, and some small fruits. | Suitable for a wide variety of crops, including root vegetables, grains, and orchard fruits which may not be feasible in VPS. |

| Climate Independence | More independent of external climate due to controlled environment. | Directly dependent on external climate conditions, making crops vulnerable to weather extremes and seasonal variations. |

| Social and Environmental Benefits | Promotes local food production, reduces transportation emissions, and improves urban green spaces. | Requires more land and can lead to deforestation and loss of natural habitats; however, it supports biodiversity in agricultural ecosystems if managed sustainably. |

| Traditional Agriculture | Traditional Greenhouse System | Vertical Planting System (VPS) | |

|---|---|---|---|

| Water Consumption | Moderate-high (varies with crops and practices) | High (intensive irrigation, potential water stress) | Potentially low (closed-loop system, precise delivery) |

| Energy Consumption | Moderate (pumping machinery) | Moderate (climate control, lighting, machinery) | High (controlled environments, lighting) |

| Land Use | High (large areas, potential deforestation) | Moderate (greenhouses, land availability considerations) | Very low (vertical layers, urban suitability) |

| Carbon Footprint | Variable, depends on practices, transportation, and land-use change | High (energy use, potential deforestation) | Potentially low (renewable energy, reduced land impact) |

| Category | Type | Material | Function | Environmental Impact | Reuse Strategies |

|---|---|---|---|---|---|

| Pots | PP, PE, HDPE (high density polyethylene) | Growing seedlings plants | Leaching of chemical pollution | Reusable pots, washing and reuse systems, biodegradable pots | |

| Containers | Trays | PP, PE, HDPE | Transplanting seedlings, supporting pots | Same as pots | Same as pots |

| Packs | PE, PVC | Sowing seeds, starting seedlings | Same as pots, potential PVC toxicity | Biodegradable alternatives, reusable trays | |

| Film Mulch | PE, LDPE (low density polyethylene) | Suppress weeds, retain moisture, regulate temperature | Microplastic pollution, non-biodegradable | Biodegradable mulch films, perforated mulch for reuse, cover crops | |

| Mulch and Covers | Row Covers | PE, LDPE | Protect crops from pests, weather | Same as film mulch | Same as film mulch |

| Greenhouse Structures | PVC, Polycarbonate | Building greenhouse frames, panels | Limited recyclability, potential PVC toxicity | Durable materials, designed for disassembly, explore alternatives | |

| Irrigation | Tubing | PE, PVC | Transporting water throughout the greenhouse | Same as greenhouse structures | Durable materials, leak repairs, explore alternatives |

| Connectors | PE, PVC | Connecting irrigation components | Same as tubing | Same as tubing | |

| Other | Shrink Wrap | PVC, PE | Securing transplants, bundling products | Same as greenhouse structures | Minimize use, explore alternatives |

| Netting | PE | Insect netting, bird netting | Microplastic pollution, non-biodegradable | Durable materials, repair damaged nets, explore alternatives |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gürsu, H. Waste-Based Vertical Planting System Proposal to Increase Productivity in Sustainable Horticulture; “PETREE”. Sustainability 2024, 16, 3125. https://doi.org/10.3390/su16083125

Gürsu H. Waste-Based Vertical Planting System Proposal to Increase Productivity in Sustainable Horticulture; “PETREE”. Sustainability. 2024; 16(8):3125. https://doi.org/10.3390/su16083125

Chicago/Turabian StyleGürsu, Hakan. 2024. "Waste-Based Vertical Planting System Proposal to Increase Productivity in Sustainable Horticulture; “PETREE”" Sustainability 16, no. 8: 3125. https://doi.org/10.3390/su16083125

APA StyleGürsu, H. (2024). Waste-Based Vertical Planting System Proposal to Increase Productivity in Sustainable Horticulture; “PETREE”. Sustainability, 16(8), 3125. https://doi.org/10.3390/su16083125