Bio-Based Plastics in Product Design: The State of the Art and Challenges to Overcome

Abstract

1. Introduction

2. Background

2.1. Bio-Based Plastics

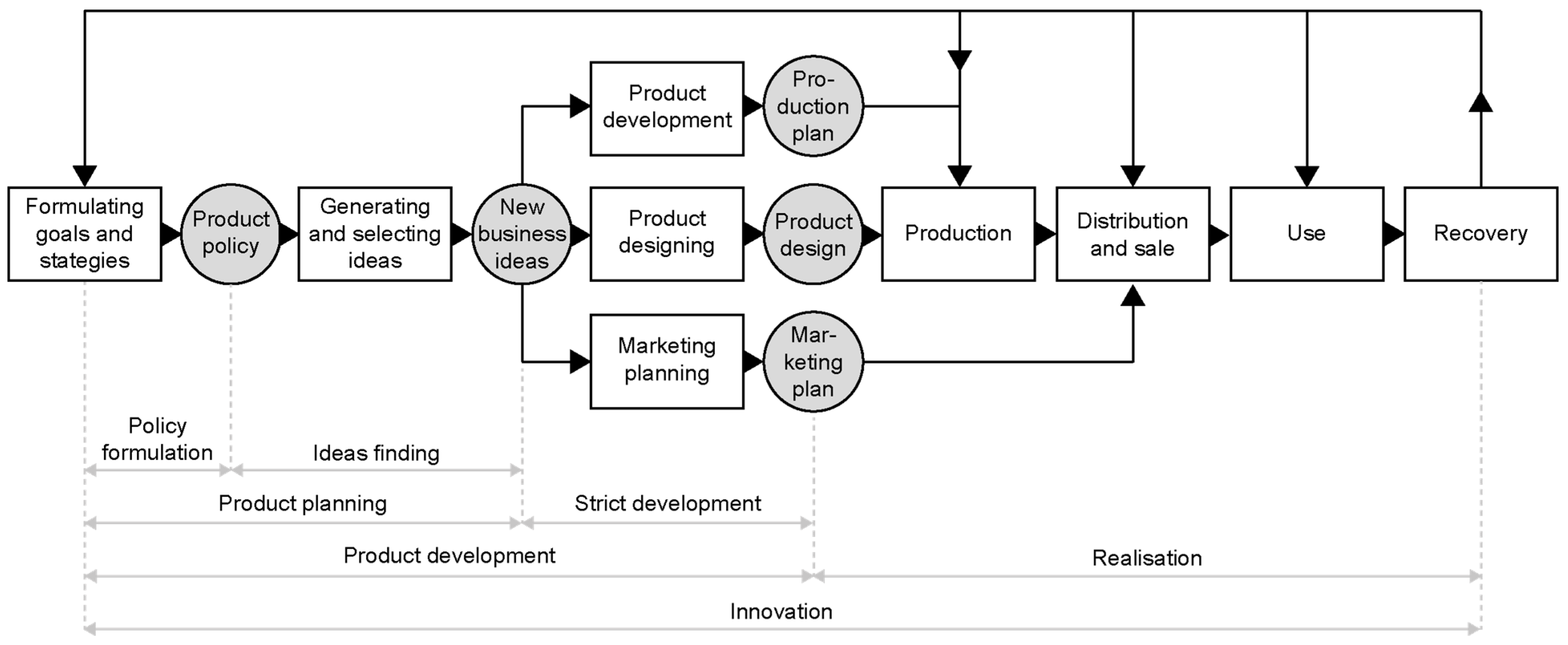

2.2. Product Innovation Process

3. Method

3.1. Design Analysis

3.2. Interviews

4. Results

4.1. Results Design Analysis

4.2. Results of Semi-Structured Interviews

4.2.1. Gap in Engineering and Sustainability Knowledge

4.2.2. Lack of End-of-Life Infrastructure and Regulations

4.2.3. High Costs and Limited Availability

4.2.4. Marketing Value and Challenges

5. Discussion

5.1. Sustainability and Circularity

5.2. Innovation

5.3. Role of Product Development

6. Conclusions

- When using bio-based plastics, carbon is stored in the product. Aim for carbon sequestration by applying circular principles such as product life extension and recycling before incineration or biodegradation.

- Explore and pilot the use of drop-in and dedicated bio-based plastics and get on a learning curve. Dedicated bio-based plastics with unique properties (e.g., biodegradability) offer many opportunities for the future. The market is young and promising, with new bio-based plastics and applications being developed in increasing pace.

- Ensure proper consumer information, for instance on correct disposal, and prevent misleading claims about safety or sustainability.

- Be critical of LCAs, but do not let it be a reason for inaction. The available data do teach us that we need to carefully consider the biomass type and location, and the intended recovery of the product, and this is a valuable starting point.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CA | Cellulose Acetate |

| EVA | Ethylene-vinyl acetate |

| PA | Polyamide |

| PE | Polyethylene |

| PEF | Polyethylene furanoate |

| PET | Polyethylene terephthalate |

| PHA | Polyhydroxyalkanoates |

| PLA | Polylactic acid |

| PP | Polypropylene |

| TPE | Thermoplastic elastomers |

References

- Plastics Europe. Plastics—The Facts 2022; Plastics Europe: Brussels, Belgium, 2022. [Google Scholar]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Progress in Polymer Science Biobased Plastics and Bionanocomposites: Current Status and Future Opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable Polymers from Renewable Resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef]

- Skoczinski, P.; Carus, M.; Tweddle, G.; Ruiz, P.; de Guzman, D.; Ravenstijn, J.; Käb, H.; Hark, N.; Dammer, L.; Raschka, A. Bio-Based Building Blocks and Polymers—Global Capacities, Production and Trends 2022–2027; nova-Institute GmbH (Ed.): Hürth, Germany, 2023. [Google Scholar] [CrossRef]

- United Nations. UNSD Classification of Individual Consumption According to Purpose (COICOP) 2018; United Nations: New York, NY, USA, 2018. [Google Scholar]

- IfBB—Institute for Bioplastics and Biocomposites. Biopolymers—Facts and Statistics 2021; IfBB—Institute for Bioplastics and Biocomposites: Hanover, Germany, 2021. [Google Scholar]

- European Commission. Communication—EU Policy Framework on Biobased, Biodegradable and Compostable Plastics; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- European Commission Biobased, Biodegradable and Compostable Plastics. Available online: https://environment.ec.europa.eu/topics/plastics/biobased-biodegradable-and-compostable-plastics_en (accessed on 19 April 2023).

- Kakadellis, S.; Rosetto, G. Achieving a Circular Bioeconomy for Plastics. Science 2021, 373, 49–50. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N.L. Environmental Performance Comparison of Bioplastics and Petrochemical Plastics: A Review of Life Cycle Assessment (LCA) Methodological Decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life Cycle Assessment of Bio-Based and Fossil-Based Plastic: A Review. J. Clean. Prod. 2020, 261, 121158. [Google Scholar] [CrossRef]

- Spierling, S.; Röttger, C.; Venkatachalam, V.; Mudersbach, M.; Herrmann, C.; Endres, H.J. Bio-Based Plastics—A Building Block for the Circular Economy? Procedia CIRP 2018, 69, 573–578. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Kulikowska, D.; Bernat, K. Effect of Bio-Based Products on Waste Management. Sustainability 2020, 12, 2088. [Google Scholar] [CrossRef]

- Bakker, C.; Balkenende, R. A Renewed Recognition of the Materiality of Design in a Circular Economy: The Case of Bio-Based Plastics. In Material Experiences 2: Expanding Territories of Materials and Design; Elsevier: Amsterdam, The Netherlands, 2021; pp. 193–206. ISBN 9780128192443. [Google Scholar]

- Venkatachalam, V.; Spierling, S.; Horn, R.; Endres, H.J. LCA and Eco-Design: Consequential and Attributional Approaches for Bio-Based Plastics. Proc. Procedia CIRP 2018, 69, 579–584. [Google Scholar] [CrossRef]

- Álvarez-chávez, C.R.; Edwards, S.; Moure-eraso, R.; Geiser, K. Sustainability of Bio-Based Plastics: General Comparative Analysis and Recommendations for Improvement. J. Clean. Prod. 2012, 23, 47–56. [Google Scholar] [CrossRef]

- Brockhaus, S.; Petersen, M.; Kersten, W. A Crossroads for Bioplastics: Exploring Product Developers’ Challenges to Move beyond Petroleum-Based Plastics. J. Clean. Prod. 2016, 127, 84–95. [Google Scholar] [CrossRef]

- Cardon, L.; Lin, J.W.; de Groote, M.; Ragaert, K.; Kopecká, J.; Koster, R. Challenges for Bio-Based Products in Sustainable Value Chains. Environ. Eng. Manag. J. 2011, 10, 1077–1080. [Google Scholar] [CrossRef]

- ASTM D883-22; Standard Terminology Relating to Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Carus, M.; Dammer, L.; Puente, Á.; Raschka, A.; Arendt, O. ; nova-Institut GmbH. Bio-Based Drop-in, Smart Drop-in and Dedicated Chemicals; nova-Institut GmbH: Hürth, Germany, 2017. [Google Scholar]

- Jeswani, H.K.; Krüger, C.; Kicherer, A.; Antony, F.; Azapagic, A. A Methodology for Integrating the Biomass Balance Approach into Life Cycle Assessment with an Application in the Chemicals Sector. Sci. Total Environ. 2019, 687, 380–391. [Google Scholar] [CrossRef]

- Kindler, A.; Zelder, O. Biotechnological and Chemical Production of Monomers from Renewable Raw Materials. In Advances in Polymer Science, vol 293; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–33. [Google Scholar] [CrossRef]

- Lambert, S.; Wagner, M. Environmental Performance of Bio-Based and Biodegradable Plastics: The Road Ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef] [PubMed]

- Sheldon, R.A.; Norton, M. Green Chemistry and the Plastic Pollution Challenge: Towards a Circular Economy. Green Chem. 2020, 22, 6310–6322. [Google Scholar] [CrossRef]

- Lenk, F.; Bröring, S.; Herzog, P.; Leker, J. On the Usage of Agricultural Raw Materials—Energy or Food? An Assessment from an Economics Perspective. Biotechnol. J. 2007, 2, 1497–1504. [Google Scholar] [CrossRef]

- Zanchetta, E.; Damergi, E.; Patel, B.; Borgmeyer, T.; Pick, H.; Pulgarin, A.; Ludwig, C. Algal Cellulose, Production and Potential Use in Plastics: Challenges and Opportunities. Algal Res. 2021, 56, 102288. [Google Scholar] [CrossRef]

- Roozenburg, N.F.M.; Eekels, J. Product Design: Fundamentals and Methods; Wiley: Hoboken, NJ, USA, 1995. [Google Scholar]

- Balkenende, R.; Bakker, C. Designing for a Circular Economy: Make, Use and Recover Products. In Sustainable Fashion in a Circular Economy; Niinimäki, K., Ed.; Aalto University: Espoo, Finland, 2018; pp. 76–95. ISBN 978-952-60-0090-9. [Google Scholar]

- Bos, P.; Bakker, C.; Balkenende, R.; Sprecher, B. Bio-Based Plastics in Durable Applications: The Future of Sustainable Product Design? A Design Review. In Proceedings of the DRS2022, Bilbao, Spain, 25 June–3 July 2022. [Google Scholar] [CrossRef]

- Bioplastics Magazine. Available online: www.bioplasticsmagazine.com (accessed on 26 July 2021).

- Dezeen. Available online: www.dezeen.com (accessed on 26 July 2021).

- Bioplastics News. Available online: https://bioplasticsnews.com (accessed on 26 July 2021).

- Ashby, M.; Johnson, K. What Influences Product Design? In Materials and Design: The Art and Science of Material Selection in Product Design; Elsevier: Amsterdam, The Netherlands, 2010; pp. 8–27. [Google Scholar]

- UNSD Standard Country or Area Codes for Statistical Use (M49). Available online: https://unstats.un.org/unsd/methodology/m49/ (accessed on 2 August 2023).

- Corbin, J.M.; Strauss, A. Grounded Theory Research: Procedures, Canons, and Evaluative Criteria. Qual. Sociol. 1990, 13, 3–21. [Google Scholar] [CrossRef]

- IKEA IKEA Recalls HEROISK and TALRIKA Bowls, Plates, and Mugs. Available online: https://edu.nl/t7aqm (accessed on 19 November 2021).

- Lee, S.Y. Bacterial Polyhydroxyalkanoates. Biotechnol. Bioeng. 1995, 49, 1–14. [Google Scholar] [CrossRef]

- Scarpa GEA. Available online: https://us.scarpa.com/gea-1 (accessed on 22 March 2022).

- Fujitsu Fujitsu Introduces the World’s First Biodegradable Computer Mouse. Available online: https://edu.nl/vb63f (accessed on 24 March 2023).

- Vaude Skarvan Biobased Pants—Trekking Pants Made of Biobased Polyamide PA 6.10. Available online: https://edu.nl/ard4m (accessed on 22 March 2022).

- Vivobarefoot BIO: WEAR MORE PLANTS. Available online: https://edu.nl/9ch84 (accessed on 11 November 2021).

- On Running CyclonTM. Available online: https://www.on-running.com/en-nl/collection/cyclon (accessed on 28 March 2023).

- Vert, M.; Doi, Y.; Hellwich, K.-H.; Hess, M.; Hodge, P.; Kubisa, P.; Rinaudo, M.; Schué, F. Terminology for Biorelated Polymers and Applications (IUPAC Recommendations 2012). Trends Biomater. Artif. Organs 2012, 25, 161–171. [Google Scholar] [CrossRef]

- Muñoz, I.; Flury, K.; Jungbluth, N.; Rigarlsford, G.; Canals, L.M.; King, H. Life Cycle Assessment of Bio-Based Ethanol Produced from Different Agricultural Feedstocks. Int. J. Life Cycle Assess. 2014, 19, 109–119. [Google Scholar] [CrossRef]

- Kymäläinen, T.; Vehmas, K.; Kangas, H.; Majaniemi, S.; Vainio-Kaila, T. Consumer Perspectives on Bio-Based Products and Brands—A Regional Finnish Social Study with Future Consumers. Sustainability 2022, 14, 3665. [Google Scholar] [CrossRef]

- Findrik, E.; Meixner, O. Drivers and Barriers for Consumers Purchasing Bioplastics—A Systematic Literature Review. J. Clean. Prod. 2023, 410, 137311. [Google Scholar] [CrossRef]

- Anderson, G.; Shenkar, N. Potential Effects of Biodegradable Single-Use Items in the Sea: Polylactic Acid (PLA) and Solitary Ascidians. Environ. Pollut. 2021, 268, 115364. [Google Scholar] [CrossRef] [PubMed]

- Nandakumar, A.; Chuah, J.A.; Sudesh, K. Bioplastics: A Boon or Bane? Renew. Sustain. Energy Rev. 2021, 147, 111237. [Google Scholar] [CrossRef]

- Klein, F.; Emberger-Klein, A.; Menrad, K.; Möhring, W.; Blesin, J.M. Influencing Factors for the Purchase Intention of Consumers Choosing Bioplastic Products in Germany. Sustain. Prod. Consum. 2019, 19, 33–43. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; Ghani, A.A. Expanding Policy for Biodegradable Plastic Products and Market Dynamics of Bio-Based Plastics: Challenges and Opportunities. Sustainability 2021, 13, 6170. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics & Catalysing Action; Ellen MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- van den Oever, M.; Molenveld, K. Replacing Fossil Based Plastic Performance Products by Bio-Based Plastic Products—Technical Feasibility. N. Biotechnol. 2017, 37, 48–59. [Google Scholar] [CrossRef]

- Krüger, C.; Kicherer, A.; Kormann, C.; Raupp, N. Biomass Balance: An Innovative and Complementary Method for Using Biomass as Feedstock in the Chemical Industry. In Designing Sustainable Technologies, Products and Policies; Shah, P., Bansal, A., Singh, R.K., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 101–107. ISBN 9783319669809. [Google Scholar]

- Barr, S. Environmental action in the home: Investigating the “value-action” gap. Geography 2006, 91, 43–54. [Google Scholar] [CrossRef]

- Simon-Kucher & Partners. Global Sustainability Study 2021—Consumers are Key Players for a Sustainable Future; Simon-Kucher & Partners: Bonn, Germany, 2021. [Google Scholar]

- Young, W.; Hwang, K.; McDonald, S.; Oates, C.J. Sustainable consumption: Green consumer behaviour when purchasing products. Sustain. Dev. 2010, 18, 20–31. [Google Scholar] [CrossRef]

| Bio-based plastic | Plastics produced, at least partially, from renewable biological resources [2,3] |

| Biodegradable plastic | Plastics that can be degraded by naturally occurring micro-organisms such as bacteria, fungi, and algae [20] |

| Drop-in bio-based plastic | Bio-based plastics with identical chemical structure and properties as their fossil-based equivalent (e.g., bio-PE, bio-PET, and bio-PP) [6,21] |

| Dedicated bio-based plastic | Bio-based plastics which have a new chemical structure and do not have an identical fossil-based counterpart (e.g., PLA, PHA, and some PA grades) [6,21] |

| Aesthetics | The extent to which the aesthetics of the product—the shape, colour, texture, and gloss—appear to have been influenced by the use of bio-based plastics. |

| Functionality | The extent to which the performance (the ability to meet its function) and the durability (the ability to resist degradation and damage over time) of the product have, or have not, improved due to the use of bio-based plastics, according to the manufacturer. |

| Sustainability | The documented choice of feedstock and the extent to which the recovery has been considered in the design and business model. No Life Cycle Assessments (LCAs) were conducted for the products analysed in this study due to the unavailability of reliable information. |

| Marketing and Communication | The marketing approach emphasising the added value of bio-based plastics. |

| I# | Interviewee(s) Position and Geographical Location Western Europe (W-EU) Northern Europe (N-EU) East Asia (E-Asia) | Company Size Small (<10) Medium (10–100) Large (>100) | Product Category | Bio-Based Plastic Type Dedicated (D) Traceable Drop-in (T) Biomass Balance (B) | |

|---|---|---|---|---|---|

| 1 | Product designer (W-EU) | small | Household appliances and utensils | PE | (T) |

| 2 | Co-founder, creative director, product designer (W-EU) | small | Household appliances and utensils | PLA | (D) |

| 3 | Founder, operational manager (E-Asia) | small | Toys and sports, Information and communication | PLA | (D) |

| 4 | Chief Executive Officer (CEO) (N-EU) | large | Household appliances and utensils | PA | (D) |

| 5 | Head of Materials (N-EU) | large | Toys and sports | PE | (T) |

| 6 | Head of R&D (W-EU) | large | Stationary and drawing | PHA PLA | (D) (D) |

| 7 | Production manager (N-EU) | small | Personal effects | PE | (T) |

| 8 | 1. CEO, 2. Product engineer (W-EU) | medium | Toys and sports | PE | (T) |

| 9 | Material and innovation developer (N-EU) | large | Furniture | PE | (T) |

| 10 | Circular Sustainability Manager (N-EU) | medium | Household appliances and utensils, Toys and sports | PE TPE | (T) (T) |

| 11 | Sustainability Leader (W-EU) | large | Household appliances and utensils | PP | (B) |

| 12 | Group leader * (W-EU) | large | Personal effects | PA | (D) |

| Formulating goals and strategies | Company vision, company drivers, laws and regulation. |

| Product designing and development | Product aesthetics, material properties and quality, design and development process, material choice. |

| Marketing planning | Bio-based plastic market, marketing strategy, consumer perspective. |

| Production | Production and certification processes, material and production price, influence of plastic producer. |

| Recovery | Recovery options and infrastructure, consumer influence on recovery. |

| Type of Bio-Based Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Total per Category | CA | EVA | PA | PE | PHA | PLA | PP | TPE | ||

| Category | 1. Clothing and Footwear | 11 | 4 | 2 | 5 | |||||

| 2. Furniture | 5 | ① | 1 | 3 | ||||||

| 3. Household appliances and utensils | 13 | ① | ⑧ | ② | ① | 1 | ||||

| 4. Information and communication | 6 | 1 | ③ | 2 | ||||||

| 5. Personal effects | 5 | 2 | ② | ① | ||||||

| 6. Recreation: Toys and sports | 17 | 1 | ⑪ | ④ | ① | |||||

| 7. Stationary and drawing materials | 3 | ① | ② | |||||||

| Total | 60 | 3 | 4 | 6 | 21 | 2 | 14 | 1 | 9 | |

| Aesthetics | Functionality | Sustainability | Marketing and Communication | ||||||||||||||||||||||

| Shape | Colour | Performance compared to fossil-based equivalent | Durability compared to fossil-based equivalent | Feedstock generation | Recovery mentioned by company | Bio-based communicated in/on: | |||||||||||||||||||

| Similar to fossil-based equivalent product | Specific design for bio-based material | Similar to fossil-based equivalent product | Specific colours for bio-based material | (Potentially) less | Similar | Better | (Potentially) less | Similar | Better | 1st | 2nd | 3rd | Reuse | Repair | Recycle | Biodegrade | Incinerate | Recovery arrangements from company | Product | Product name | Description | Campaign | Packaging | ||

| Category | 1 | 10 | 1 | 8 | 3 | 10 | 1 | 11 | 6 | 4 | 1 | 6 | 3 | 2 | 2 | 3 | 5 | 2 | 5 | 11 | 8 | 3 | |||

| 2 | 5 | 3 | 2 | 1 | 4 | 1 | 4 | 4 | 1 | 1 | 4 | 3 | 5 | 3 | 1 | ||||||||||

| 3 | 12 | 1 | 5 | 8 | 1 | 12 | 2 | 11 | 8 | 5 | 5 | 1 | 13 | 2 | 10 | 13 | 6 | 11 | |||||||

| 4 | 6 | 4 | 2 | 5 | 1 | 1 | 5 | 3 | 3 | 3 | 5 | 2 | 4 | 4 | 6 | 3 | 4 | ||||||||

| 5 | 5 | 5 | 5 | 1 | 4 | 2 | 3 | 1 | 1 | 1 | 1 | 5 | 2 | 1 | |||||||||||

| 6 | 17 | 9 | 8 | 15 | 2 | 1 | 16 | 11 | 6 | 6 | 1 | 13 | 3 | 4 | 4 | 1 | 10 | 17 | 6 | 15 | |||||

| 7 | 2 | 1 | 1 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 1 | |||||||||||

| Total | 57 | 3 | 36 | 24 | 2 | 54 | 4 | 6 | 54 | 0 | 38 | 21 | 1 | 20 | 4 | 33 | 17 | 7 | 11 | 13 | 35 | 60 | 29 | 35* | |

| Formulating goals and strategies | ||

| Opportunities | n | |

| 1.1 | Companies have a vision to be more sustainable and see bio-based plastics as a way to accomplish this. | 10 |

| 1.2 | Companies see using bio-based plastics as a start to transition away from fossil resources. | 5 |

| 1.3 | Companies see bio-based plastics as a means to sustainable sourcing in applications where recycled plastics are not permitted (e.g., food contact). | 3 |

| Barriers | ||

| 1.4 | Laws and regulations are lacking (e.g., regarding the differentiation between plastics or the end-of-life arrangements). Companies are waiting for rules, which slows development. | 6 |

| Product designing and development | ||

| Opportunities | n | |

| 2.1 | Use the product’s aesthetics (mainly colour) to communicate bio-based plastic use. | 6 |

| 2.2 | More and higher quality bio-based plastics are emerging on the market. | 3 |

| 2.3 | Drop-in plastics can be exchanged with fossil-based plastics without the need for additional research. | 3 |

| 2.4 | Dedicated bio-based plastics can offer unique advanced properties. | 2 |

| Barriers | ||

| 2.5 | Product developers question whether bio-based plastics are truly a sustainable material choice. | 9 |

| 2.6 | Many unknowns concerning new plastics ask for expensive and time-consuming R&D. | 7 |

| 2.7 | Biodegradable plastics are avoided in durable products due to the concern that they will decompose in the use phase. | 7 |

| 2.8 | The choice of available bio-based plastics is limited. | 4 |

| Marketing planning | ||

| Opportunities | n | |

| 3.1 | The market for bio-based plastics is growing. | 9 |

| 3.2 | Emphasising the sustainability of bio-based plastics in the marketing strategy. | 5 |

| Barriers | ||

| 3.3 | Consumers lack understanding about bio-based plastics and their difference from fossil-based plastics. | 10 |

| 3.4 | Consumers are not willing to pay more for bio-based plastic products. | 5 |

| 3.5 | Marketing bio-based plastics as sustainable and safe can backfire and harm the company’s reputation. | 4 |

| Production | ||

| Opportunities | n | |

| 4.1 | Biomass balance enables companies to continue using familiar production and certification processes while gradually shifting to bio-based materials. | 3 |

| Barriers | ||

| 4.2 | Bio-based plastics are more expensive than fossil-based ones. | 9 |

| 4.3 | Only a few bio-based plastics producers dominate the market. | 9 |

| 4.4 | Using new plastics brings challenges to the production process. | 4 |

| Recovery | ||

| Opportunities | n | |

| 5.1 | Bio-based plastics have a lower carbon footprint compared to fossil-based plastics. | 4 |

| Barriers | ||

| 5.2 | Consumers are uncertain about how to dispose of bio-based plastic products after use. | 6 |

| 5.3 | Infrastructure for recycling new types of plastics is lacking. | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bos, P.; Ritzen, L.; van Dam, S.; Balkenende, R.; Bakker, C. Bio-Based Plastics in Product Design: The State of the Art and Challenges to Overcome. Sustainability 2024, 16, 3295. https://doi.org/10.3390/su16083295

Bos P, Ritzen L, van Dam S, Balkenende R, Bakker C. Bio-Based Plastics in Product Design: The State of the Art and Challenges to Overcome. Sustainability. 2024; 16(8):3295. https://doi.org/10.3390/su16083295

Chicago/Turabian StyleBos, Puck, Linda Ritzen, Sonja van Dam, Ruud Balkenende, and Conny Bakker. 2024. "Bio-Based Plastics in Product Design: The State of the Art and Challenges to Overcome" Sustainability 16, no. 8: 3295. https://doi.org/10.3390/su16083295

APA StyleBos, P., Ritzen, L., van Dam, S., Balkenende, R., & Bakker, C. (2024). Bio-Based Plastics in Product Design: The State of the Art and Challenges to Overcome. Sustainability, 16(8), 3295. https://doi.org/10.3390/su16083295