Sustainable Infrastructure Maintenance: Crack Depth Detection in Tunnel Linings via Natural Temperature Variations and Infrared Imaging

Abstract

:1. Introduction

2. Experimental Model Design

2.1. Specimen and Defect Preparation

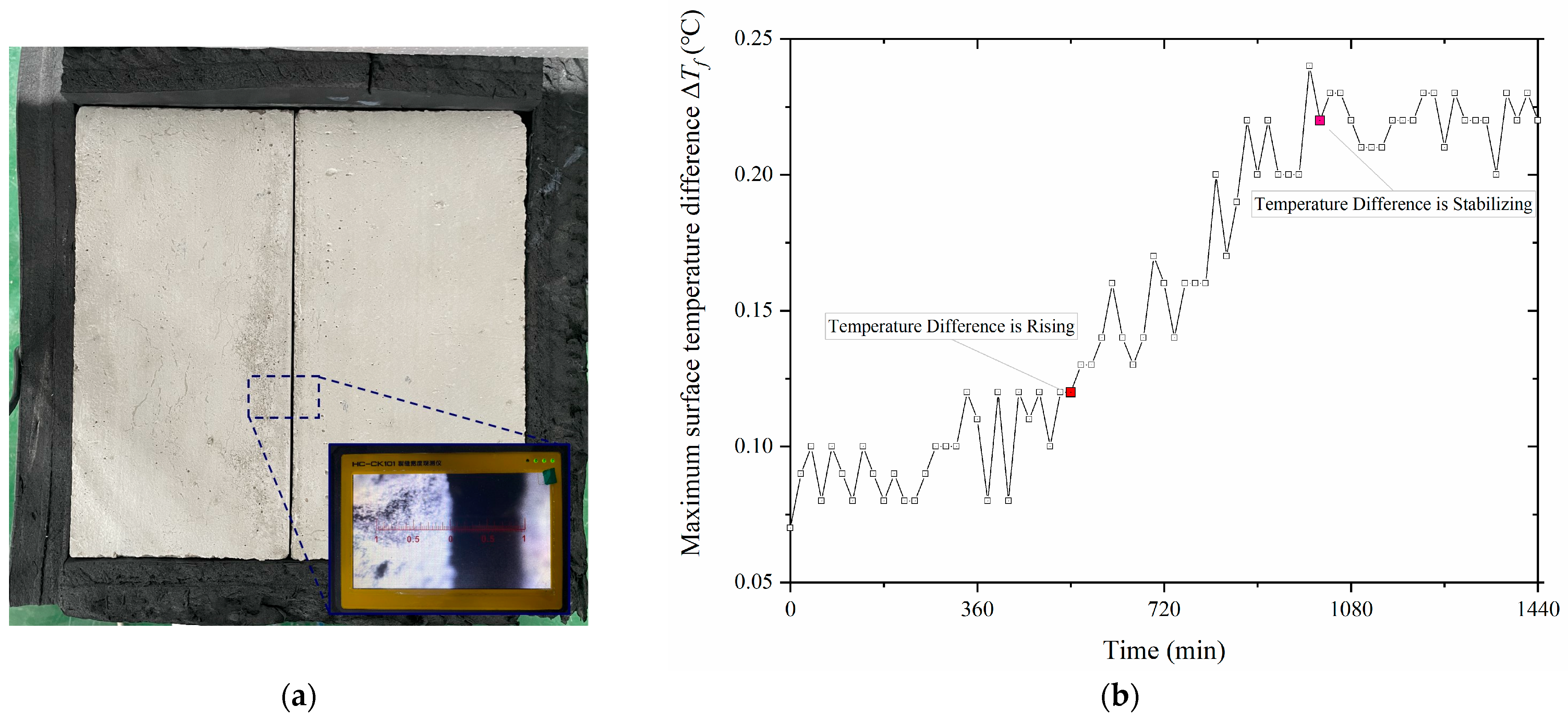

2.2. Sensor Arrangement and Data Acquisition Method

2.3. Experimental Operation Procedure

- Ensure the proper alignment of the infrared thermal imager to encompass the entire detection area within its operational range.

- Utilize an STC803-S/II constant-temperature heating device to facilitate the heating of the thermal excitation surface, thereby facilitating the transfer of heat to the data acquisition surface. Concurrently, ensure the regulation of indoor temperature to uphold the specified temperature difference (ΔTN) between the thermal excitation surface and the data acquisition surface within the predetermined range.

- Surface temperature data of the specimen are monitored until the temperature variation remains within 0.5 °C, indicating that the specimen has reached a steady-state heat conduction condition. At this point, heating is discontinued, and the infrared thermal image of the specimen’s surface is recorded.

3. Thermal Conduction Effects of Cracks under Natural Temperature Difference Conditions

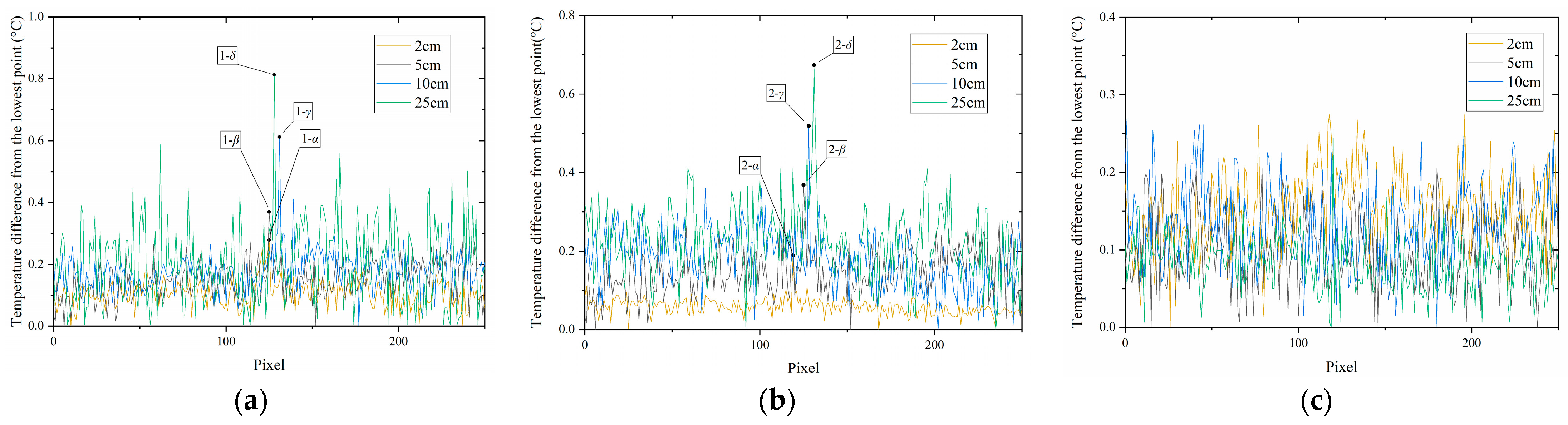

3.1. Test Results

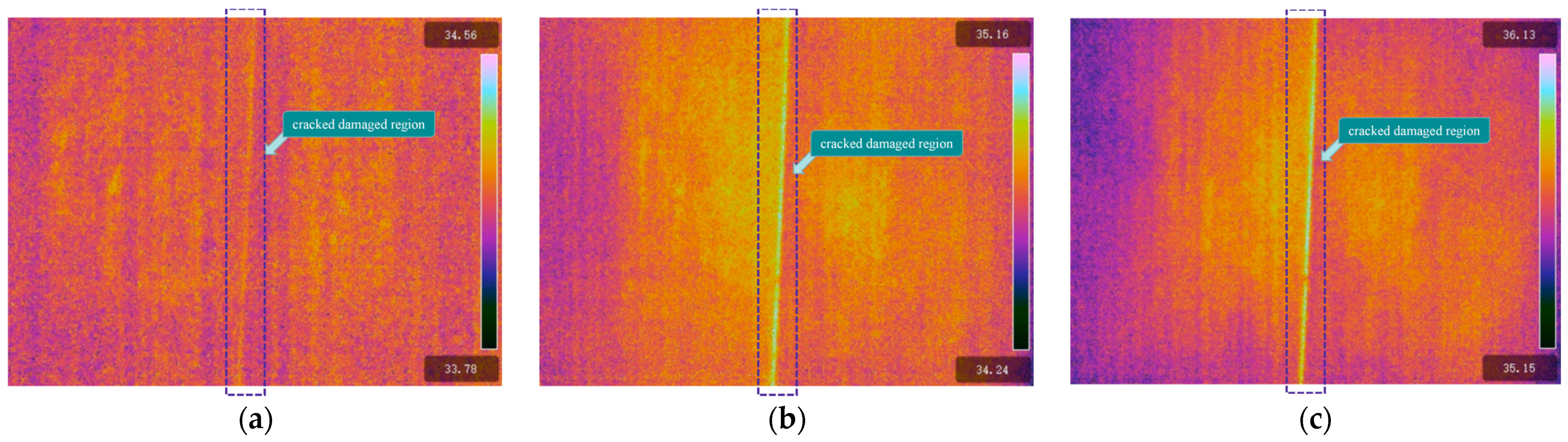

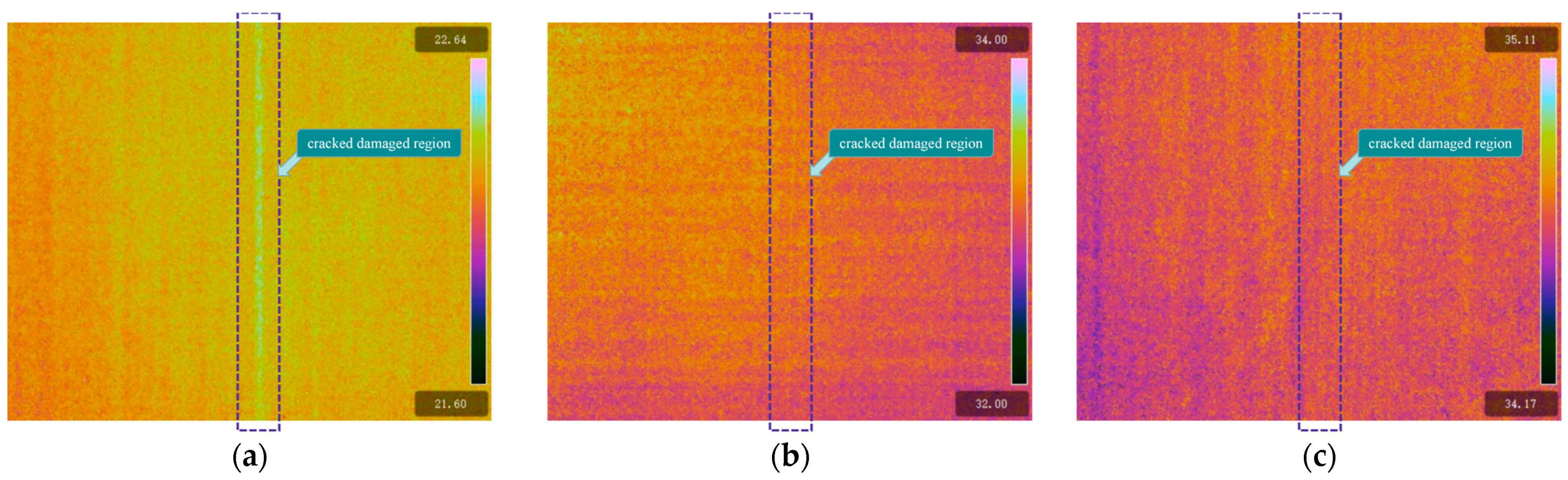

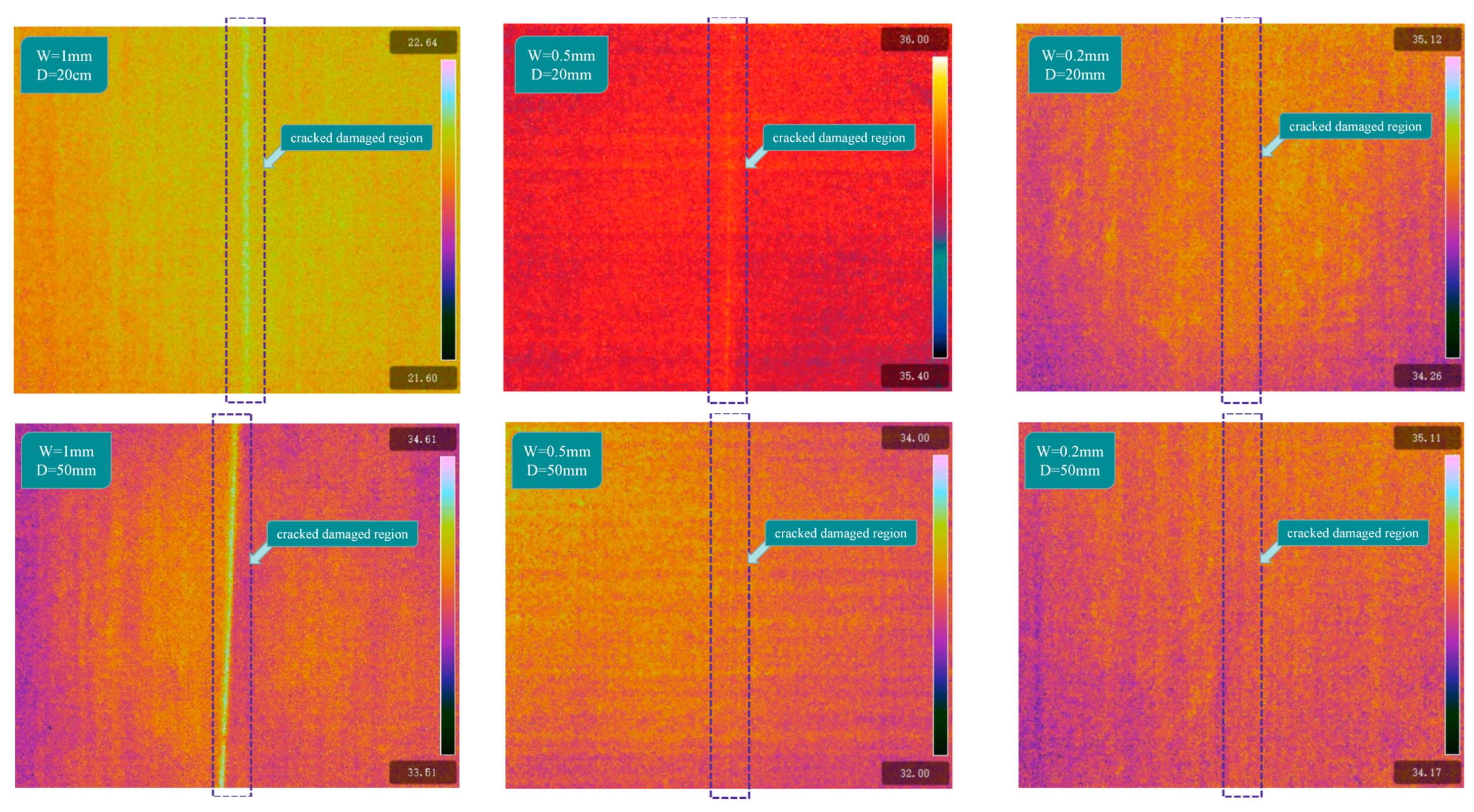

3.2. The Impact of Crack Width

3.3. The Impact of Crack Depth

4. Simulation Method

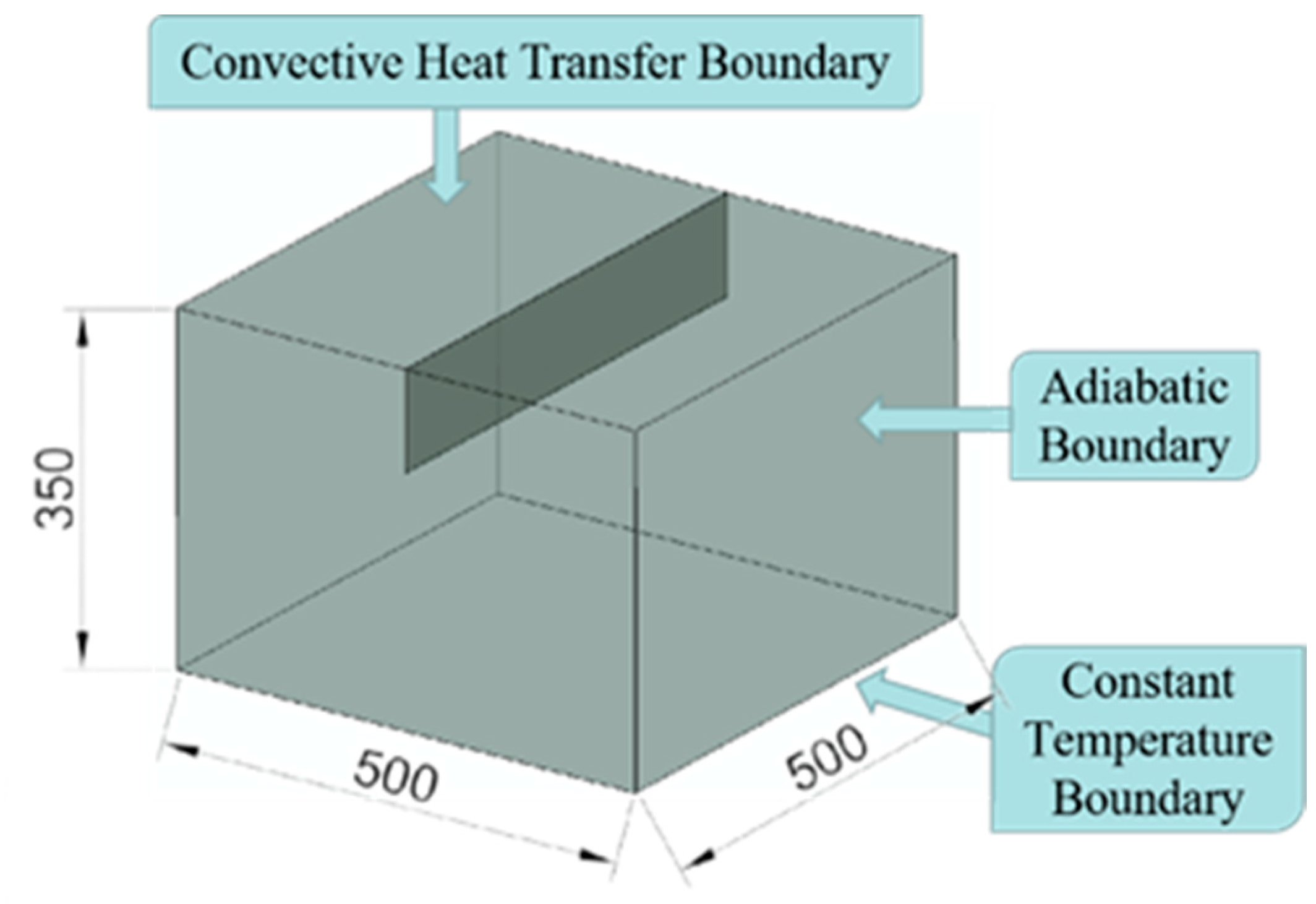

4.1. FEM Simulation Model

4.2. Material Properties

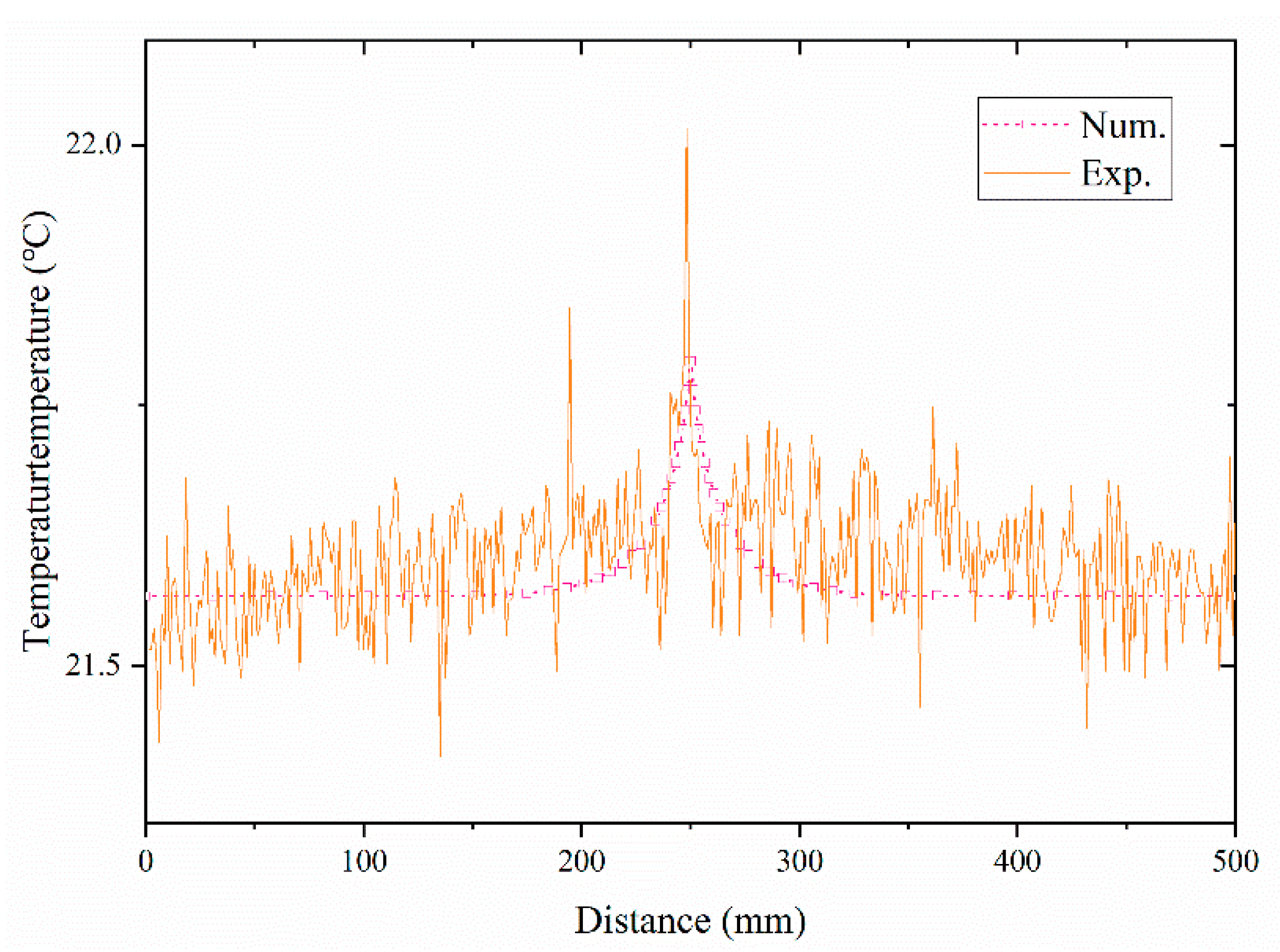

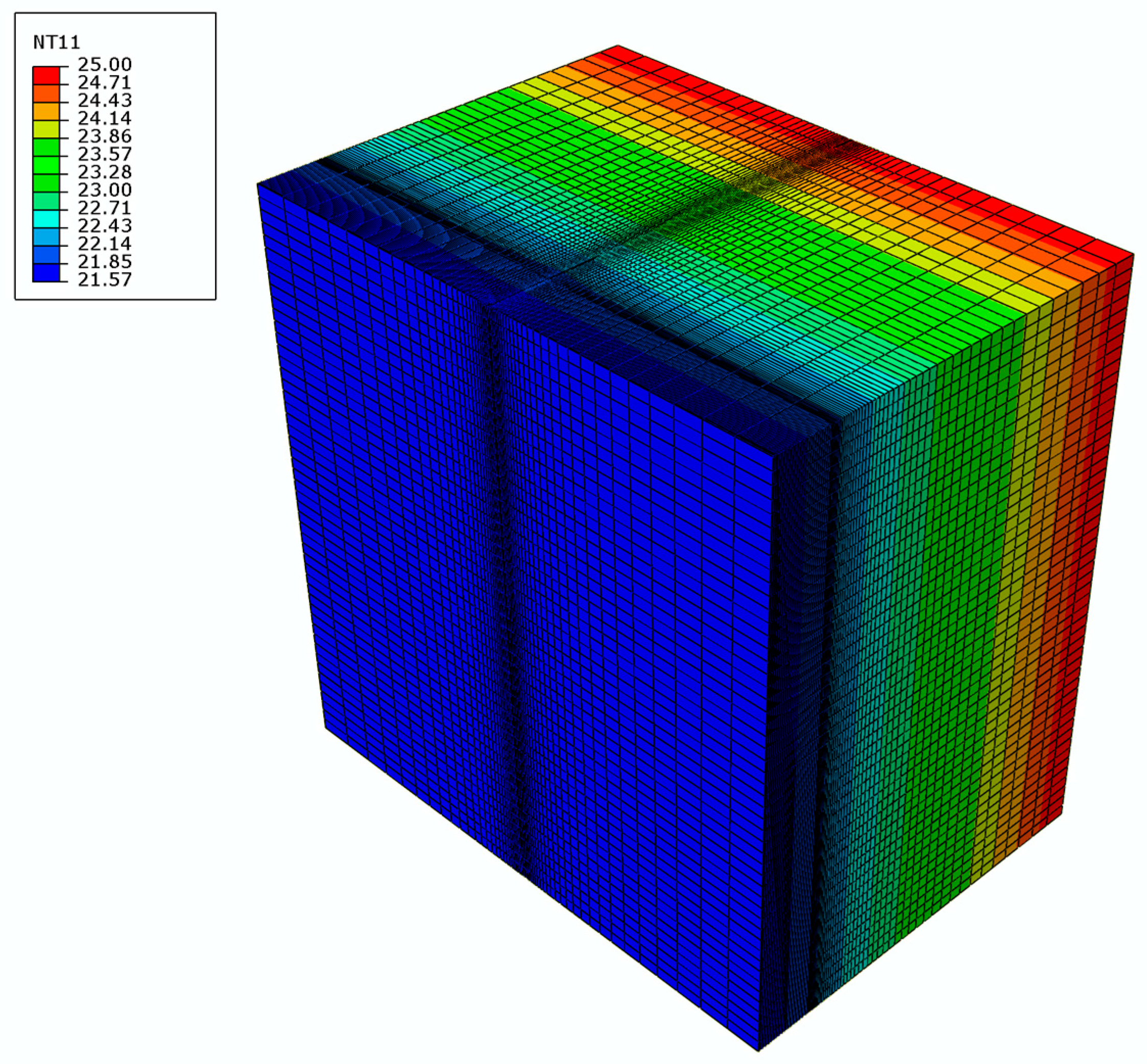

4.3. Simulation Results and Experimental Validation

4.4. The Impact of Environmental Temperature Difference

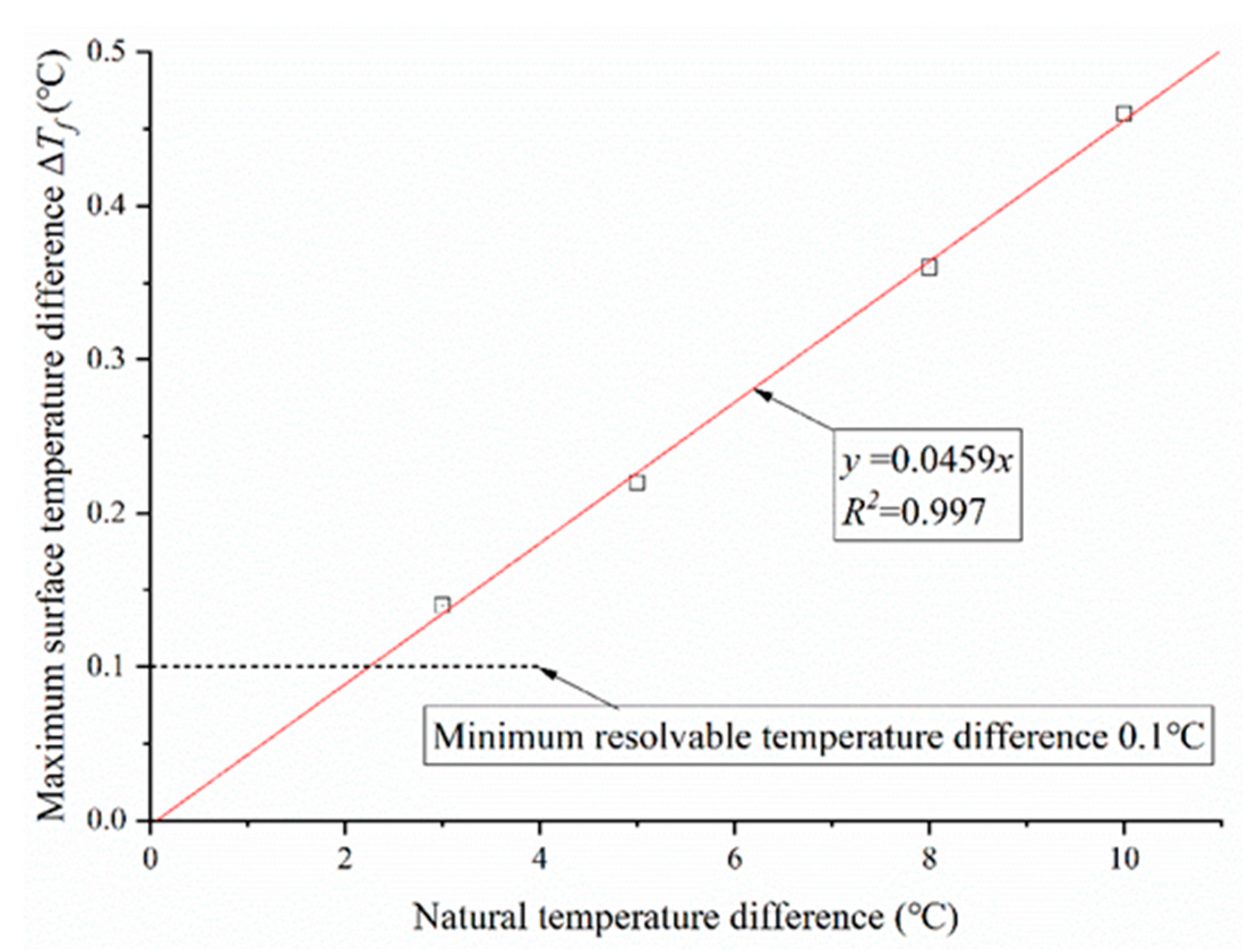

- In the temperature contour maps of the inner lining surface, a noticeable temperature distinction exists between the healthy area and the cracked area, and this contrast becomes more pronounced with increasing natural temperature differences. Consequently, as the natural temperature difference augments, the viability of infrared detection also improves. It is noteworthy that the high-temperature region associated with cracks remains relatively constant, suggesting that fluctuations in environmental temperature differences do not substantially affect the extent of the low-temperature region on the specimen’s surface.

- For natural temperature differences of 3 °C, 5 °C, 8 °C, and 10 °C, the maximum surface temperature differences (ΔTf) on the lining surface are 0.14 °C, 0.22 °C, 0.36 °C, and 0.46 °C, respectively. Considering the minimum resolvable temperature difference of the infrared thermal imager, which is 0.1 °C, it can be concluded that when the natural temperature difference between the inner and outer sides of the lining is 3 °C or greater, infrared thermal imaging technology can effectively be employed to detect cracks in concrete lining with a crack width exceeding 1 mm and a crack depth of 5 cm or more.

4.5. Results and Discussion

5. Conclusions

- During the winter season, the surrounding rock temperature in the tunnel is higher than the environmental temperature inside the tunnel. A heat transfer phenomenon is observed from the rock–soil body to the surface of the lining. The healthy region on the inner surface of the lining appears as a low-temperature area, while the cracked region presents as a high-temperature area.

- The temperature contrast among distinct regions on the inner surface of the lining escalates proportionally with the inherent temperature difference between the interior and exterior, along with the depth of cracks. However, it diminishes as the crack width expands. Specifically, for crack widths of 1 mm and 0.5 mm (both with a crack depth of 50 mm and a natural temperature difference of 5 °C), the maximum surface temperature differences are 0.23 °C and 0.16 °C, respectively.

- The relationship between the crack depth (D) and the natural temperature difference (ΔTN), the maximum surface temperature difference (ΔTf), and the crack width (W) can be expressed as . This formula enables the rapid detection and diagnosis of lining crack depth defects.

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, W.; Lai, H.; Liu, Y.; Yang, W.; Zhu, Z. Field and laboratory study of cracking and safety of secondary lining for an existing highway tunnel in loess ground. Tunn. Undergr. Space Technol. 2019, 88, 35–46. [Google Scholar] [CrossRef]

- Xiong, L.; Zhang, D.; Zhang, Y. Water leakage image recognition of shield tunnel via learning deep feature representation. J. Vis. Commun. Image Represent. 2020, 71, 102708. [Google Scholar] [CrossRef]

- Zhou, P.; Lin, M.; Zhou, F.; Gong, L.; Ao, W. Bearing characteristics and failure mechanism of a novel plate-short anchor structure for tunnel crack reinforcement. Eng. Fail. Anal. 2022, 135, 106160. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, J.; Zhang, Y. Failure Behavior of Tunnel Lining Caused by Concrete Cracking: A Case Study. J. Fail. Anal. Prev. 2019, 19, 1158–1173. [Google Scholar] [CrossRef]

- Tan, X.; Bao, Y. Measuring crack width using a distributed fiber optic sensor based on optical frequency domain reflectometry. Measurement 2021, 172, 108945. [Google Scholar] [CrossRef]

- Jia, Y.; Tang, L.; Ming, P.; Xie, Y. Ultrasound-excited thermography for detecting microcracks in concrete materials. NDT & E Int. Indep. Nondestruct. Test. Eval. 2019, 101, 62–71. [Google Scholar]

- Kumar, V.; Morris, I.M.; Lopez, S.A.; Glisic, B. Identifying Spatial and Temporal Variations in Concrete Bridges with Ground Penetrating Radar Attributes. Remote Sens. 2021, 13, 1846. [Google Scholar] [CrossRef]

- Li, X.; Lu, X.; Li, M.; Hao, J.; Xu, Y. Numerical Study on Evaluating the Concrete-Bedrock Interface Condition for Hydraulic Tunnel Linings Using the SASW Method. Appl. Sci. 2018, 8, 2428. [Google Scholar] [CrossRef]

- Merioua, A.; Bezzar, A.; Ghomari, F. Non-destructive Electrical Methods for Measuring the Physical Characteristics of Porous Materials. J. Nondestruct. Eval. 2015, 34, 1–12. [Google Scholar] [CrossRef]

- Ikebata, K.; Kobayashi, Y.; Oda, K.; Nakamura, K. Evaluation of Unfilled Sheath in Concrete Structures Using Response Waveform in Time Domain. Appl. Sci. 2021, 11, 11402. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, L.; Zhang, S.; Jia, Y.; Tian, H.; Liang, J. Research on visualisation of plain concrete crack depth detection based on tracer and hand-held radar. Nondestruct. Test. Eval. 2023. ahead of print. [Google Scholar] [CrossRef]

- Zhan, H.; Jiang, H.; Jiang, R. Three-dimensional images generated from diffuse ultrasound wave: Detections of multiple cracks in concrete structures. Struct. Health Monit. 2020, 19, 12–25. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A.; Christou, P.; Kalogirou, S.A. Infrared thermography (IRT) applications for building diagnostics: A review. Appl. Energy 2014, 134, 531–549. [Google Scholar] [CrossRef]

- Garrido, I.; Lagüela, S.; Arias, P. Infrared Thermography’s Application to Infrastructure Inspections. Infrastructures 2018, 3, 35. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [PubMed]

- Pozzer, S.; Pravia, Z.M.; Rezazadeh Azar, E.; Dalla Rosa, F. Statistical analysis of favorable conditions for thermographic inspection of concrete slabs. J. Civ. Struct. Health Monit. 2020, 10, 609–626. [Google Scholar] [CrossRef]

- Tejedor, B.; Barreira, E.; Almeida, R.M.; Casals, M. Thermographic 2D U-value map for quantifying thermal bridges in building façades. Energy Build. 2020, 224, 110176. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Sfarra, S.; Klein, M.; Maldague, X. Solar loading thermography: Time-lapsed thermographic survey and advanced thermographic signal processing for the inspection of civil engineering and cultural heritage structures. Infrared Phys. Technol. 2017, 82, 56–74. [Google Scholar] [CrossRef]

- Tomita, K.; Chew, M.Y.L. A Review of Infrared Thermography for Delamination Detection on Infrastructures and Buildings. Sensors 2022, 22, 423. [Google Scholar] [CrossRef]

- Bauer, E.; Milhomem, P.M.; Aidar, L.A.G. Evaluating the damage degree of cracking in facades using infrared thermography. J. Civil Struct. Health Monitor. 2018, 8, 517–528. [Google Scholar] [CrossRef]

- Jo, J.; Jadidi, Z. A high precision crack classification system using multi-layered image processing and deep belief learning. Struct. Infrastruct. Eng. 2020, 16, 297–305. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.; Moreira, M. An infrared thermography passive approach to assess the effect of leakage points in buildings. Energy Build. 2017, 140, 224–235. [Google Scholar] [CrossRef]

- Moropoulou, A.; Avdelidis, N.P.; Karoglou, M.; Delegou, E.T.; Alexakis, E.; Keramidas, V. Multispectral Applications of Infrared Thermography in the Diagnosis and Protection of Built Cultural Heritage. Appl. Sci. 2018, 8, 284. [Google Scholar] [CrossRef]

- Yousefi, B.; Sfarra, S.; Ibarra-Castanedo, C.; Avdelidis, N.P.; Maldague, X.P.V. Thermography data fusion and nonnegative matrix factorization for the evaluation of cultural heritage objects and buildings. J. Thermal Anal. Calorimetry 2019, 136, 943–955. [Google Scholar] [CrossRef]

- Sfarra, S.; Yao, Y.; Zhang, H.; Perilli, S.; Scozzafava, M.; Avdelidis, N.P.; Maldague, X.P.V. Precious walls built in indoor environments inspected numerically and experimentally within long-wave infrared (LWIR) and radio regions. J. Therm. Anal. Calorim. 2019, 137, 1083–1111. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, L.; Jia, Y.; Zhang, S. Scheme Design and Experimental Study of Selective Thermal Stimulation for Concrete Microcracks Based on IR Thermography. J. Nondestruct. Eval. 2021, 40, 32. [Google Scholar] [CrossRef]

- Park, M.J.; Kim, J.; Jeong, S.; Jang, A.; Bae, J.; Ju, Y.K. Machine Learning-Based Concrete Crack Depth Prediction Using Thermal Images Taken under Daylight Conditions. Remote Sens. 2022, 14, 2151. [Google Scholar] [CrossRef]

- Qiu, J.; Pei, C.; Liu, H.; Chen, Z. Quantitative evaluation of surface crack depth with laser spot thermography. Int. J. Fatigue 2017, 101, 80–85. [Google Scholar] [CrossRef]

- Pan, M.; He, Y.; Tian, G.; Chen, D.; Luo, F. Defect characterisation using pulsed eddy current thermography under transmission mode and NDT applications. Ndt & E Int. 2012, 52, 28–36. [Google Scholar]

| Sample Number | Crack Width W/mm | Crack Depth D/cm |

|---|---|---|

| 1-α | 1 | 20 |

| 1-β | 50 | |

| 1-γ | 100 | |

| 1-δ | 250 | |

| 2-α | 0.5 | 20 |

| 2-β | 50 | |

| 2-γ | 100 | |

| 2-δ | 250 | |

| 3-α | 0.2 | 20 |

| 3-β | 50 | |

| 3-γ | 100 | |

| 3-δ | 250 |

| Material | Concrete | Air |

|---|---|---|

| Thermal Conductivity/(W·m−1·K−1) | 1.28 | 0.026 |

| Specific Heat Capacity/(J·kg−1·K−1) | 970 | 1013 |

| Density/(kg·m−3) | 2242.5 | 1.164 |

| Sample Number | ΔTf (Num.)/°C | ΔTf (Exp.)/°C | Error/°C |

|---|---|---|---|

| 1-α | 0.11 | 0.15 | +0.04 |

| 1-β | 0.22 | 0.23 | +0.01 |

| 1-γ | 0.36 | 0.38 | +0.02 |

| 1-δ | 0.54 | 0.60 | +0.06 |

| 2-α | 0.10 | 0.12 | +0.02 |

| 2-β | 0.19 | 0.16 | −0.03 |

| 2-γ | 0.27 | 0.26 | −0.01 |

| 2-δ | 0.37 | 0.36 | −0.01 |

| Sample Number | W/mm | D/cm |

|---|---|---|

| 1-ε | 1 | 175 |

| 2-ε | 0.5 | 175 |

| 4-α | 1.5 | 20 |

| 4-β | 50 | |

| 4-δ | 100 | |

| 4-ε | 175 | |

| 4-γ | 250 | |

| 5-α | 2 | 20 |

| 5-β | 50 | |

| 5-δ | 100 | |

| 5-ε | 175 | |

| 5-γ | 250 |

| D/mm | W/mm | |||

|---|---|---|---|---|

| 0.5 | 1 | 1.5 | 2.0 | |

| 2 | 0.020 | 0.022 | 0.023 | 0.023 |

| 5 | 0.037 | 0.044 | 0.048 | 0.050 |

| 10 | 0.054 | 0.072 | 0.080 | 0.086 |

| 17.5 | 0.068 | 0.096 | 0.113 | 0.124 |

| 25 | 0.073 | 0.108 | 0.133 | 0.150 |

| Sample Number | ΔTN/°C | ΔTf/°C | W/mm | D/mm | Error/% | |

|---|---|---|---|---|---|---|

| Calculation | Actual | |||||

| 1-β | 8 | 0.36 | 1.0 | 43.54 | 50 | −12.92 |

| 1-γ | 5 | 0.38 | 1.0 | 106.10 | 100 | +6.10 |

| 1-γ | 10 | 0.71 | 1.0 | 93.24 | 100 | −6.76 |

| 2-β | 5 | 0.19 | 0.5 | 42.38 | 50 | −15.44 |

| 2-γ | 5 | 0.27 | 0.5 | 90.56 | 100 | −9.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, W.; Liu, X.; Li, Z. Sustainable Infrastructure Maintenance: Crack Depth Detection in Tunnel Linings via Natural Temperature Variations and Infrared Imaging. Sustainability 2024, 16, 3731. https://doi.org/10.3390/su16093731

Gu W, Liu X, Li Z. Sustainable Infrastructure Maintenance: Crack Depth Detection in Tunnel Linings via Natural Temperature Variations and Infrared Imaging. Sustainability. 2024; 16(9):3731. https://doi.org/10.3390/su16093731

Chicago/Turabian StyleGu, Wenchuan, Xuezeng Liu, and Zhen Li. 2024. "Sustainable Infrastructure Maintenance: Crack Depth Detection in Tunnel Linings via Natural Temperature Variations and Infrared Imaging" Sustainability 16, no. 9: 3731. https://doi.org/10.3390/su16093731

APA StyleGu, W., Liu, X., & Li, Z. (2024). Sustainable Infrastructure Maintenance: Crack Depth Detection in Tunnel Linings via Natural Temperature Variations and Infrared Imaging. Sustainability, 16(9), 3731. https://doi.org/10.3390/su16093731