Bibliometric and Co-Occurrence Study of the Production of Bioethanol and Hydrogen from African Palm Rachis (2003–2023)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bibliometric Analysis

2.2. Co-Occurrence Study

2.3. Relevant Publications Analysis

3. Results and Discussion

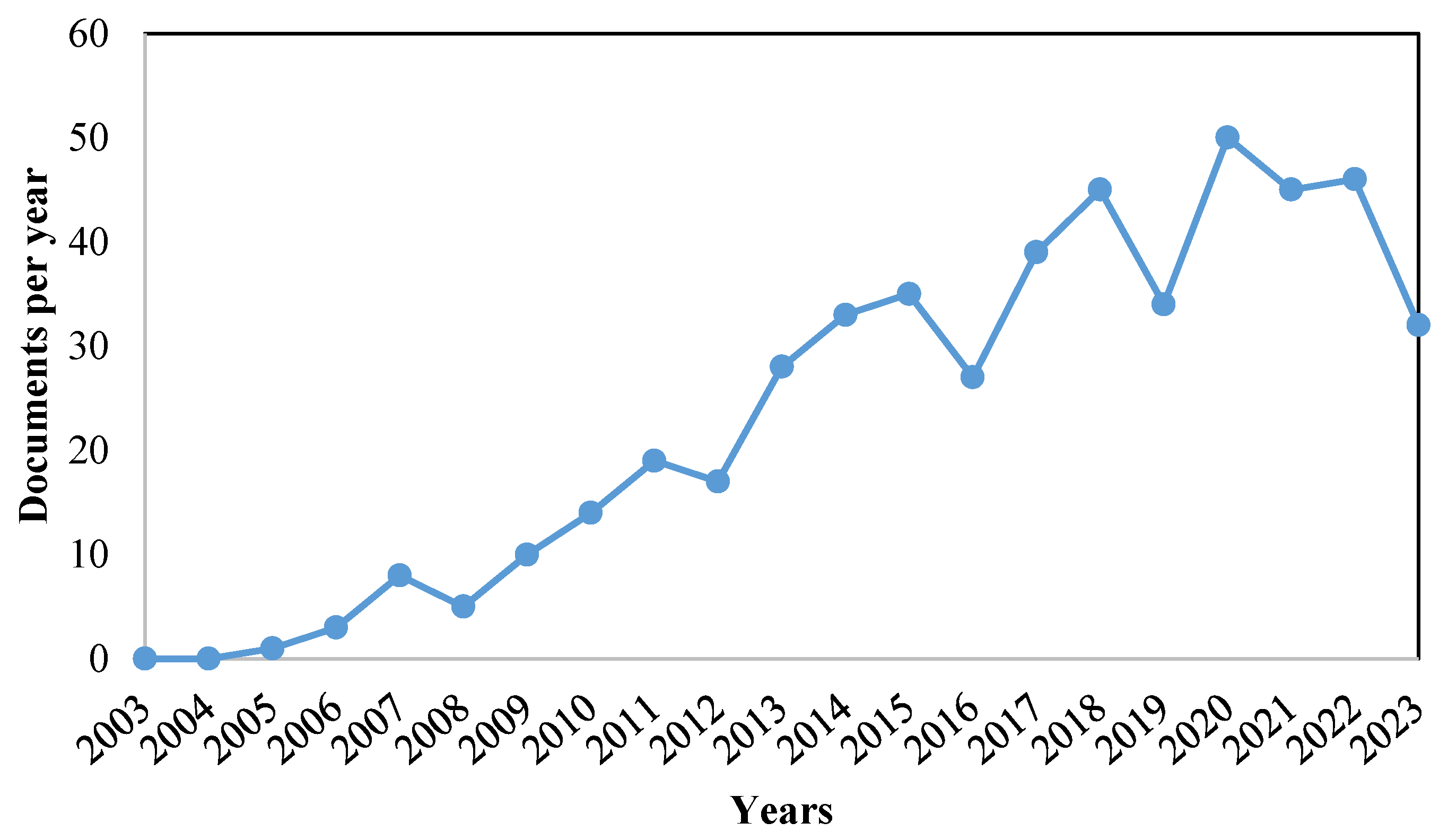

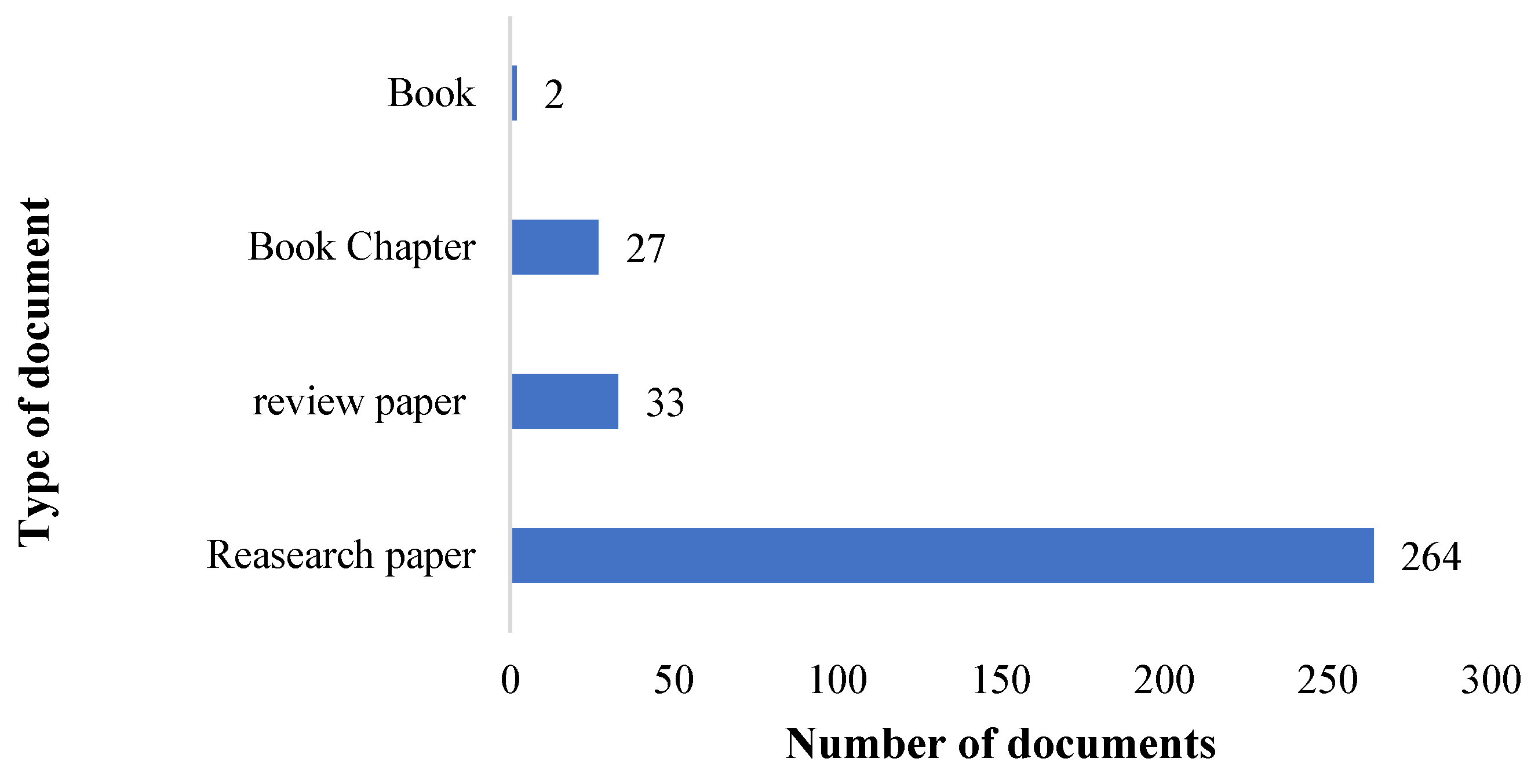

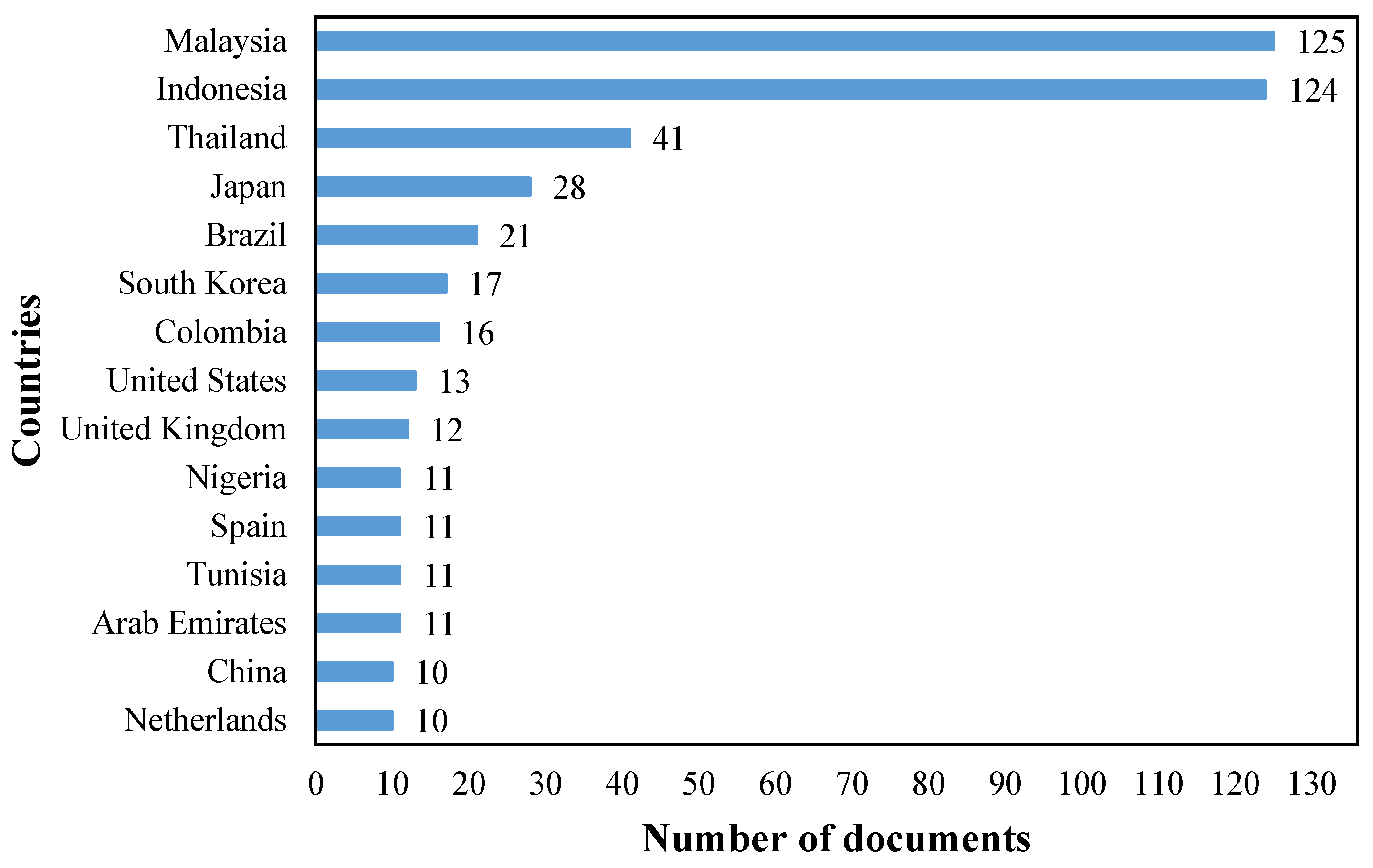

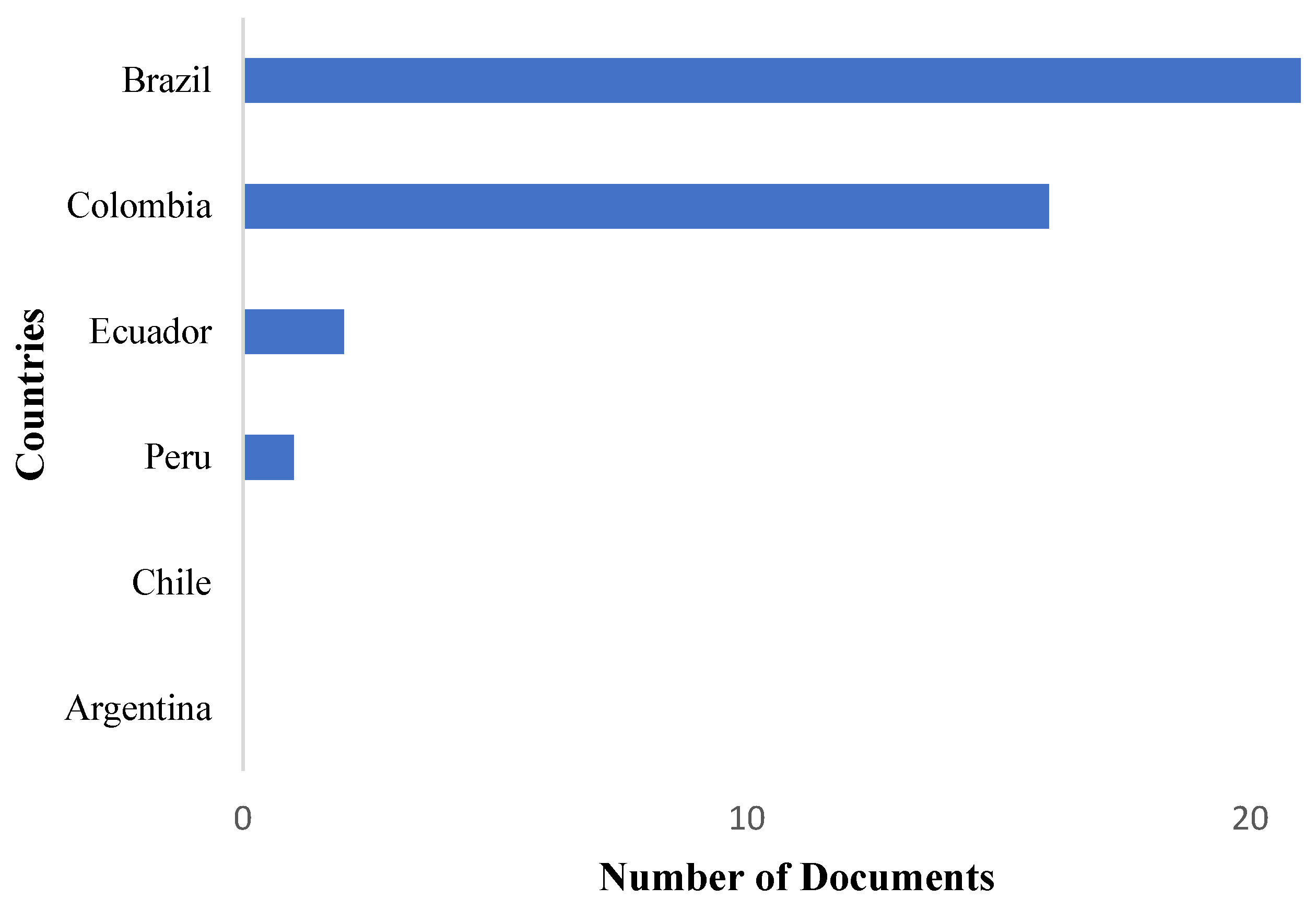

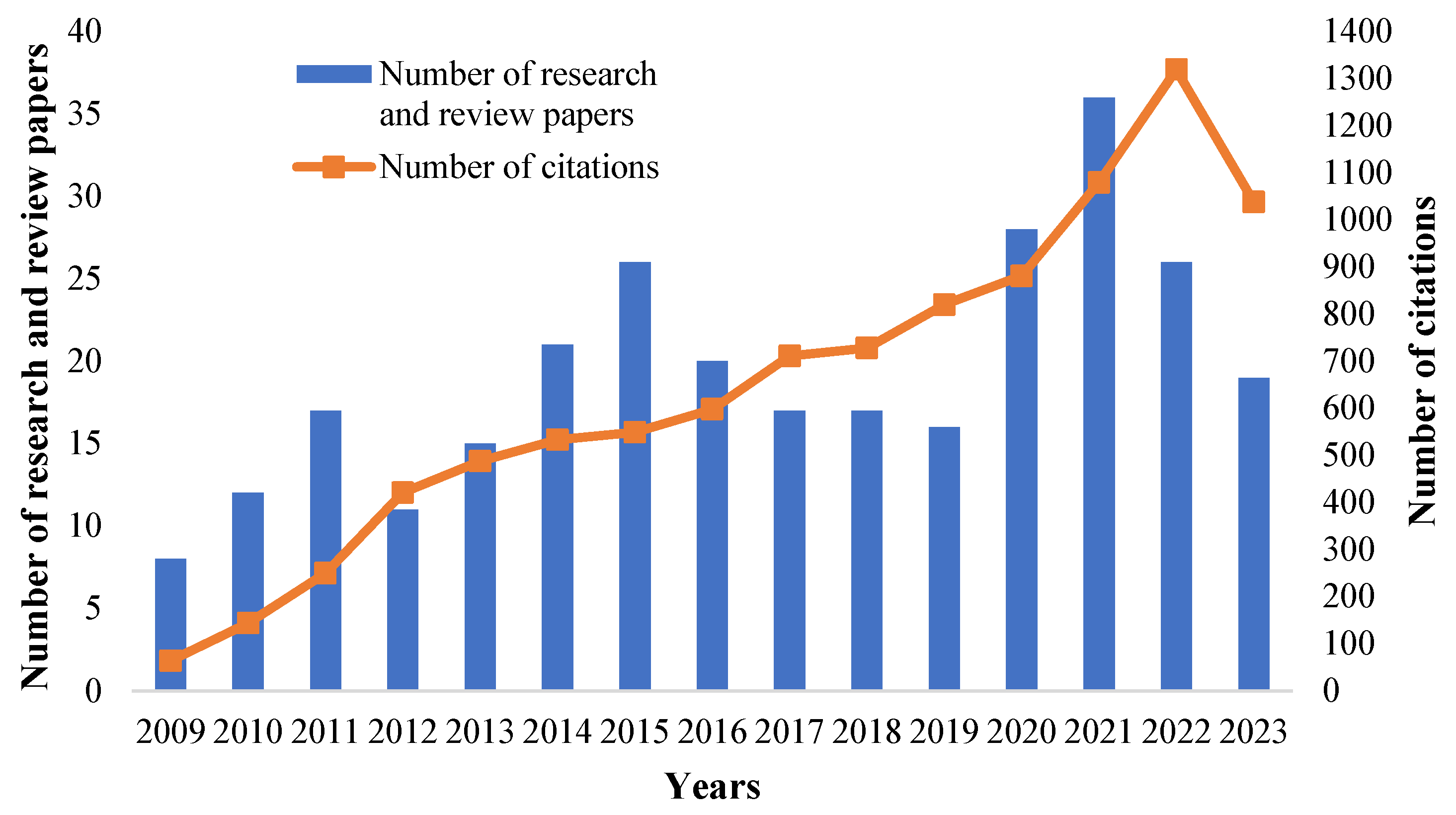

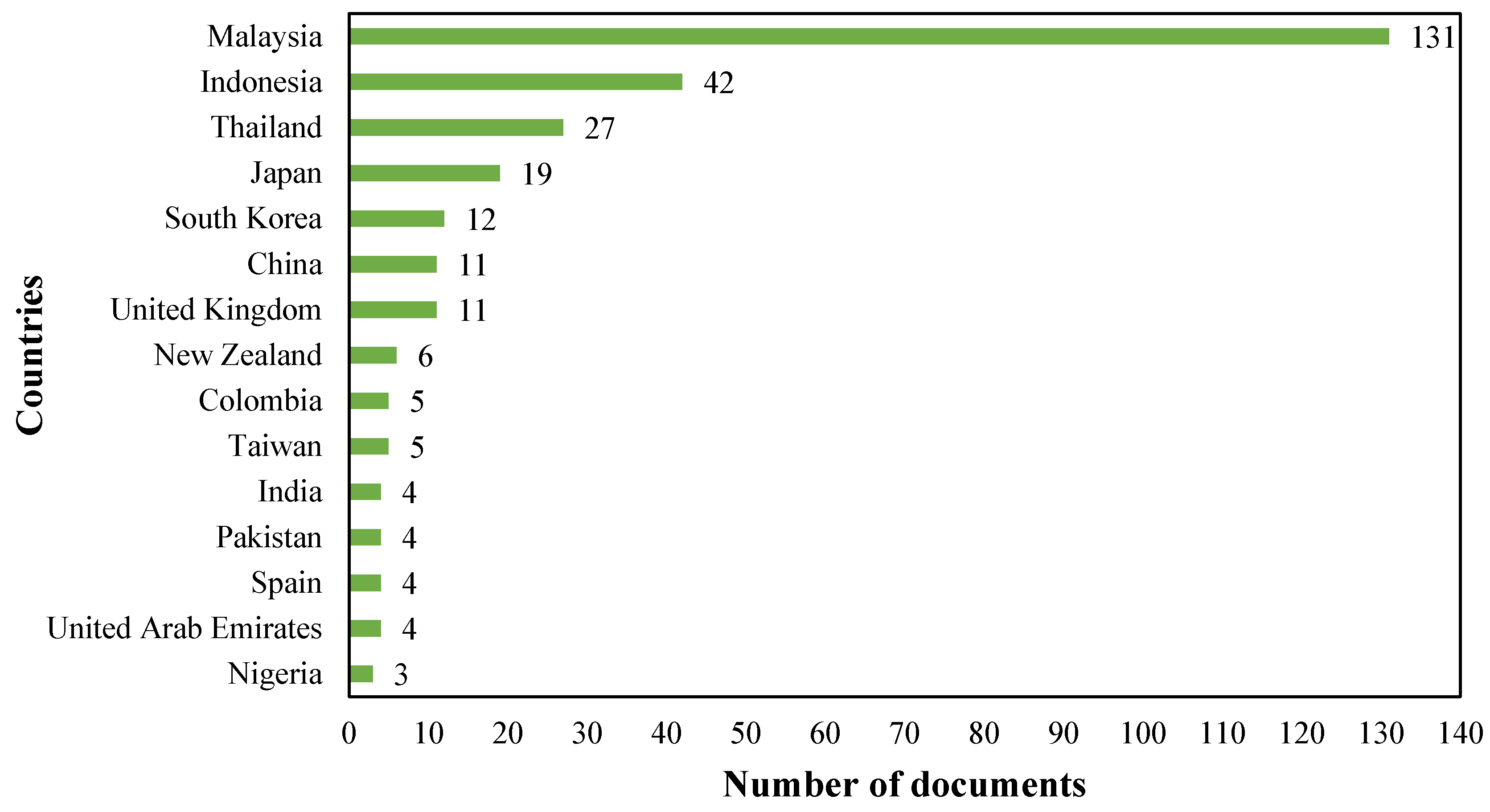

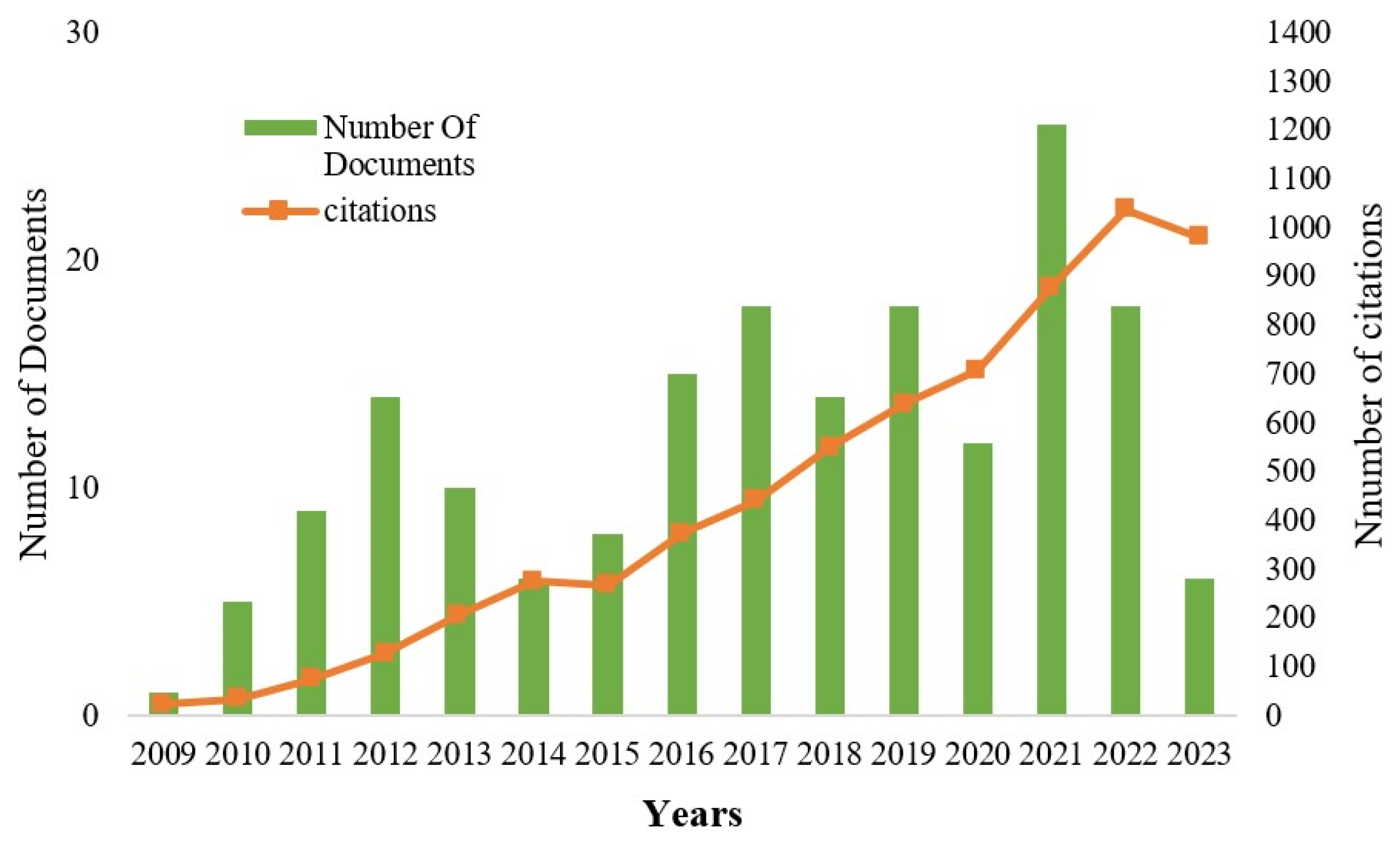

3.1. Bibliometric Analysis for “Bioethanol and Palm”

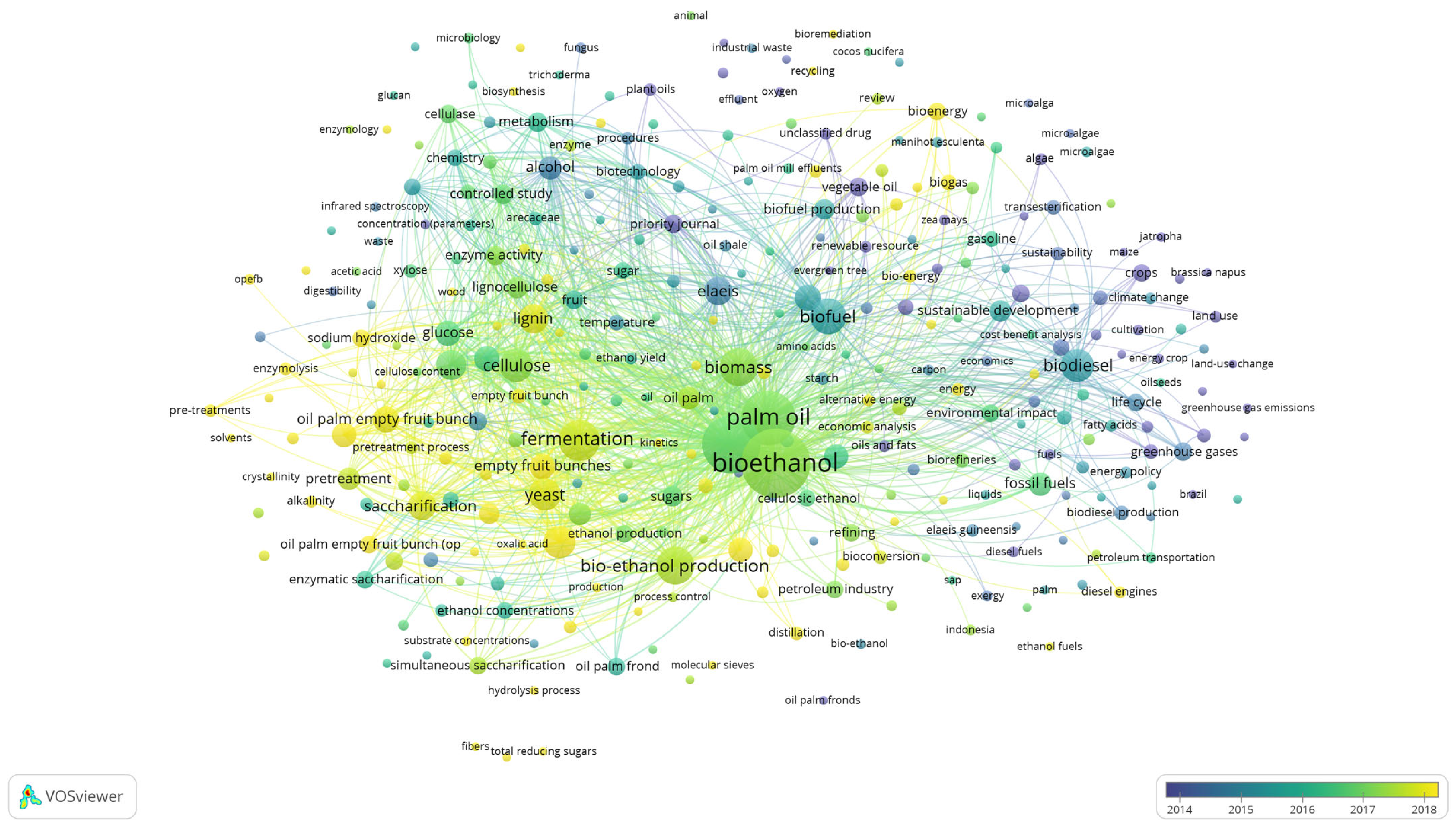

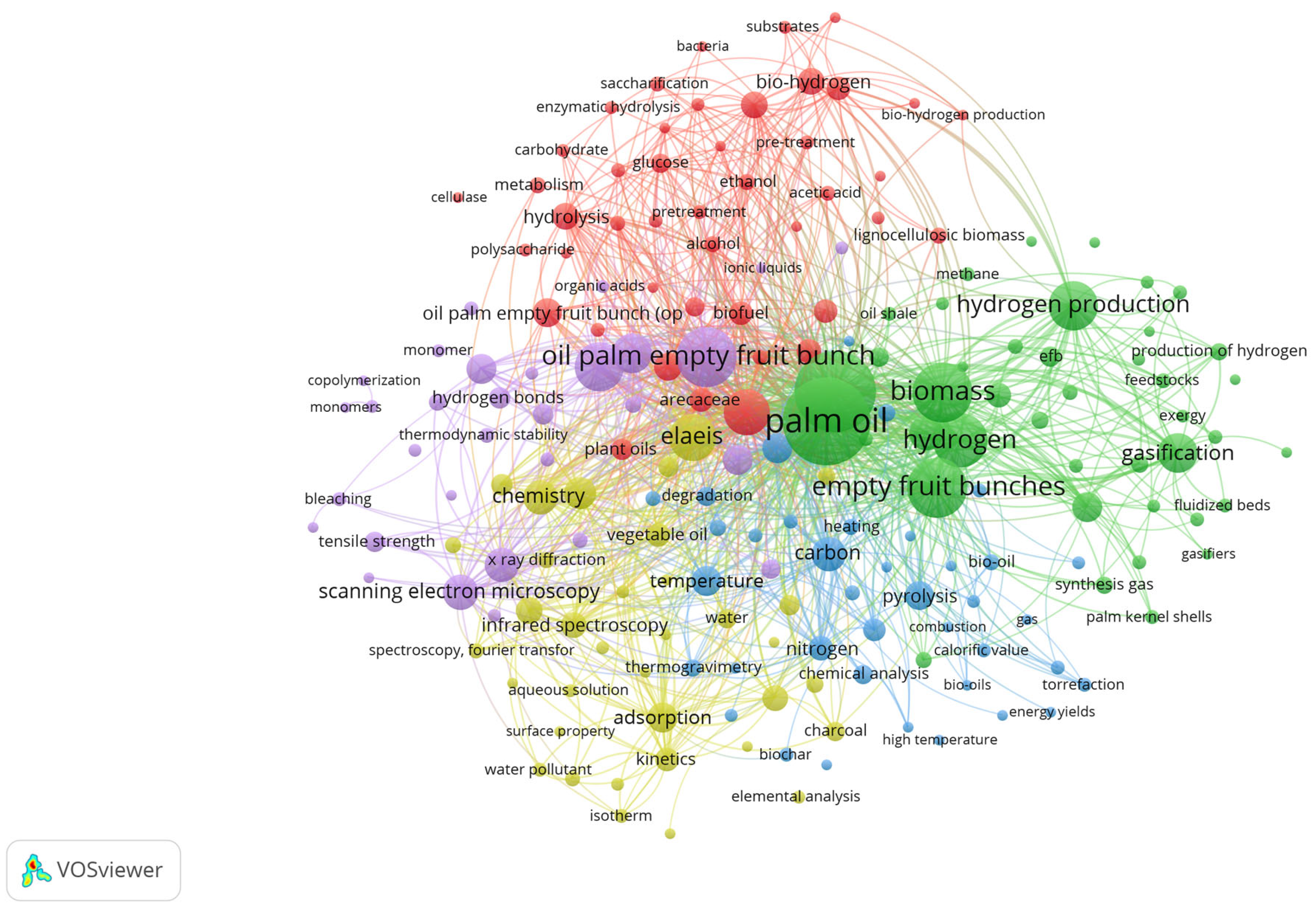

Co-Occurrence Study and Research Trend for the Path “Bioethanol AND Palm”

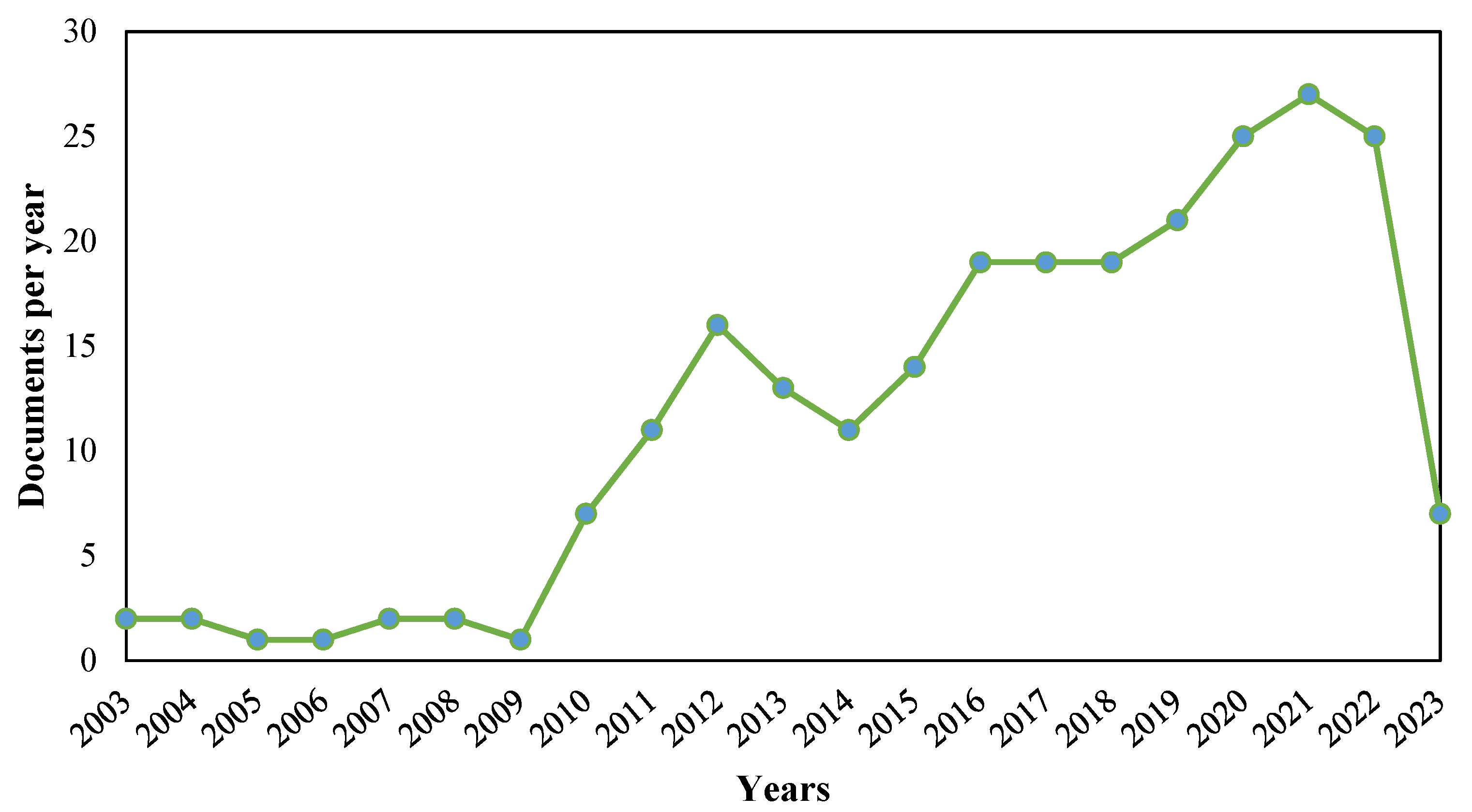

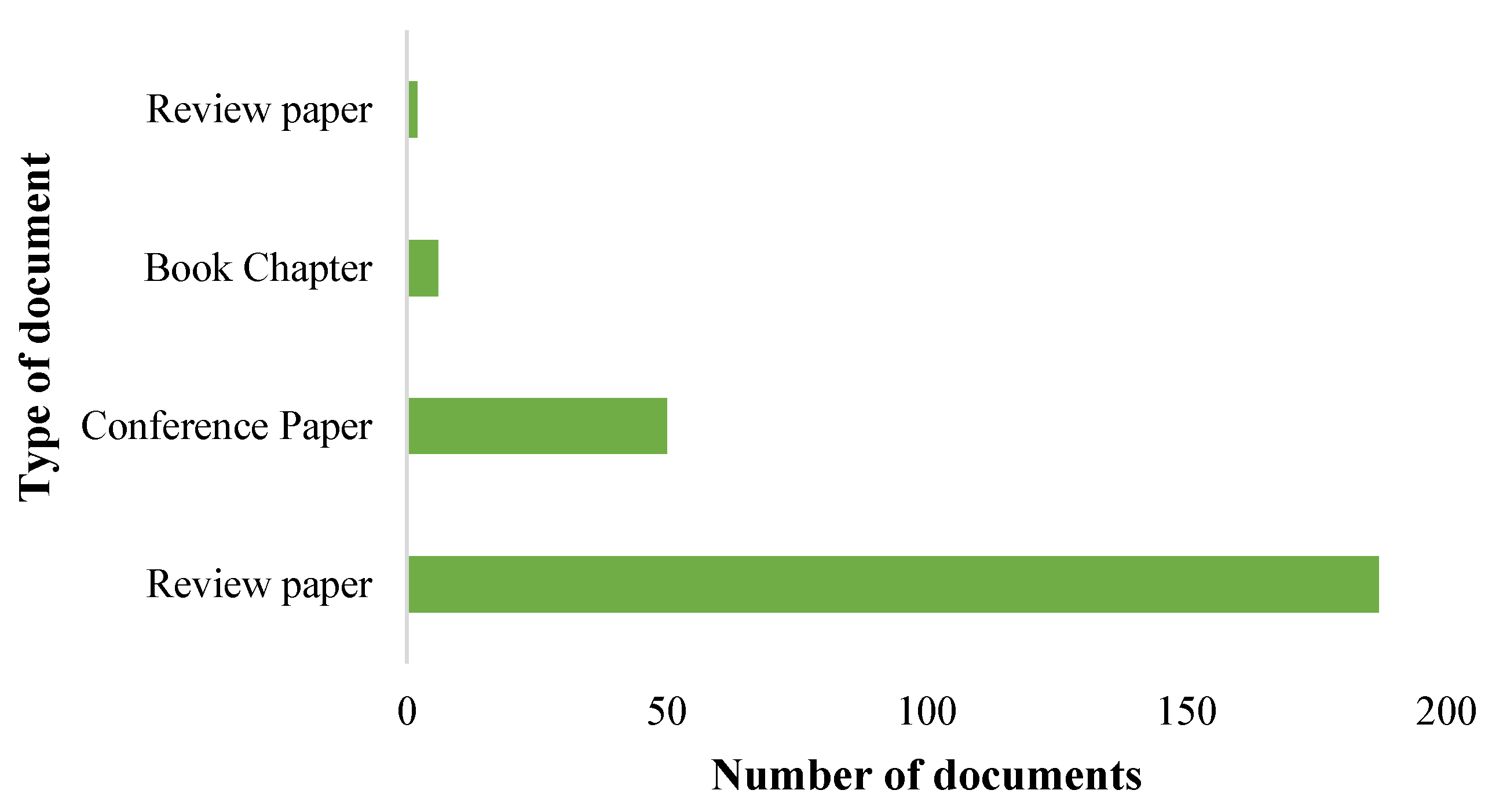

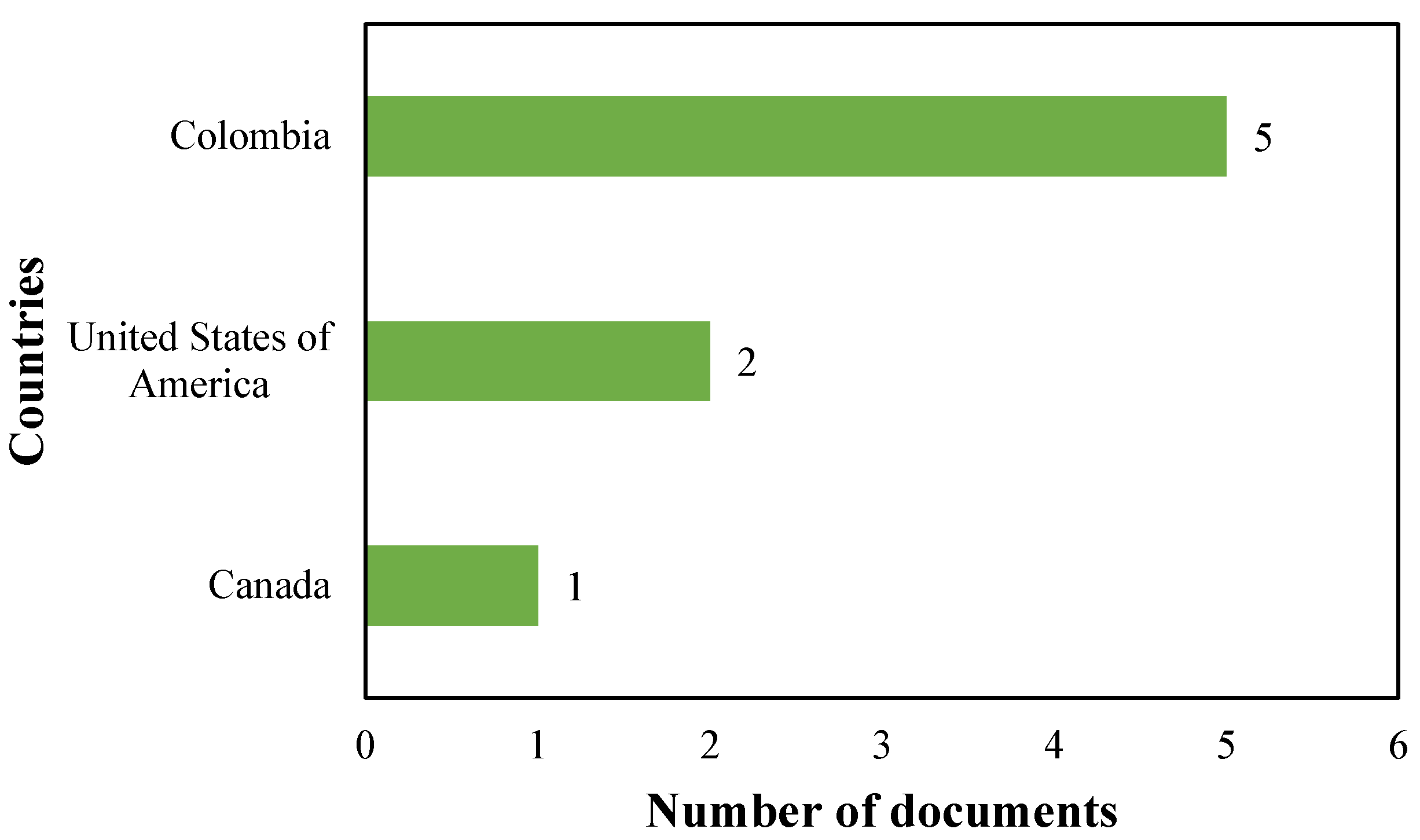

3.2. Bibliometric Analysis “Hydrogen and Palm and Empty Bunches”

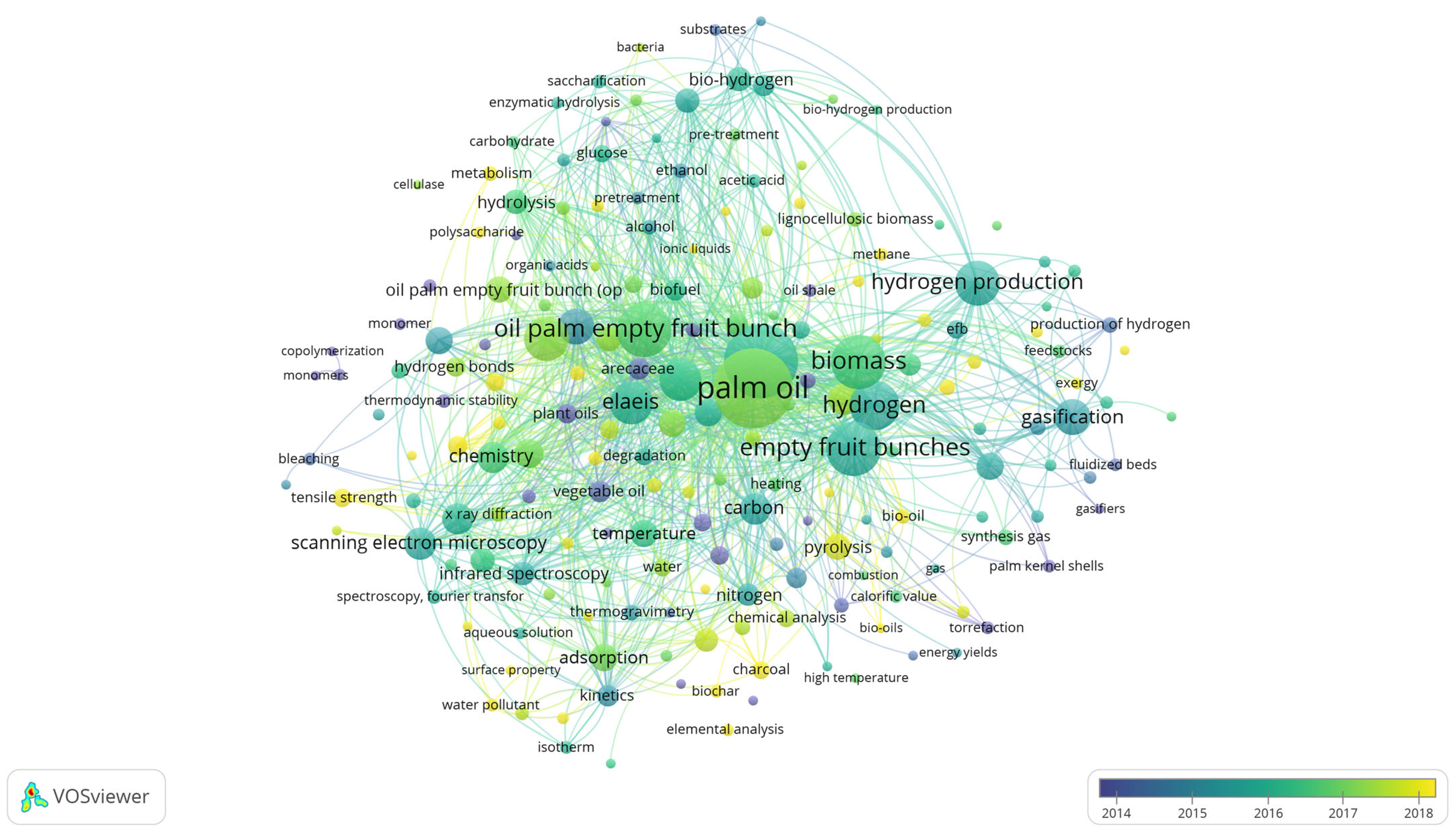

Co-Occurrence and Trends Study for the Research Path “Hydrogen and Palm and Empty Bunches”

4. Deep Insights in Bioethanol Production from Palm Oil Rachis

5. Deep Insights in Hydrogen Production from African Palm Rachis

5.1. Gasification

Type of Gasification Reactors

5.2. Dark Fermentation

5.3. Hydrogen Purification Technologies

5.3.1. Cryogenic Separation

5.3.2. Membranes Separation

5.3.3. PSA System Separation

5.4. Concept of Biorefinery Applied to the Palm Rachis

6. Technological Advances and Challenges

6.1. Oil Palm Technological Trends

6.2. Barriers and Challenges

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Höök, M.; Tang, X. Depletion of fossil fuels and anthropogenic climate change-A review. Energy Policy 2013, 52, 797–809. [Google Scholar] [CrossRef]

- Yeşilyurt, M.K.; Erol, D.; Yaman, H.; Doğan, B. Effects of using ethyl acetate as a surprising additive in SI engine pertaining to an environmental perspective. Int. J. Environ. Sci. Technol. 2022, 19, 9427–9456. [Google Scholar] [CrossRef]

- Srifa, A.; Faungnawakij, K.; Itthibenchapong, V.; Assabumrungrat, S. Roles of monometallic catalysts in hydrodeoxygenation of palm oil to green diesel. Chem. Eng. J. 2015, 278, 249–258. [Google Scholar] [CrossRef]

- Cifuentes-Espinosa, J.A.; Feintrenie, L.; Monzón-Alvarado, C.; Schmook, B.; Mesa-Jurado, M.A. Oil palm growers’ prospects for sustainable oil palm production. A case study from Campeche, Mexico. Agric. Syst. 2023, 212, 103780. [Google Scholar] [CrossRef]

- Jalani, N.F.; Aziz, A.A.; Wahab, N.A.; Hassan, W.H.W.; Zainal, N.H. Application of Palm Kernel Shell Activated Carbon for the Removal of Pollutant and Color in Palm Oil Mill Effluent Treatment. J. Earth Environ. Health Sci. 2016, 2, 15. [Google Scholar] [CrossRef]

- Raketh, M.; Kongjan, P.; O-Thong, S.; Mamimin, C.; Jariyaboon, R.; Promnuan, K. Life cycle assessment (LCA) and economic analysis of two-stage anaerobic process of co-digesting palm oil mill effluent (POME) with concentrated latex wastewater (CLW) for biogas production. Process Saf. Environ. Prot. 2024, 192, 450–459. [Google Scholar] [CrossRef]

- Tarazona, J.V.; de Alba-Gonzalez, M.; Bedos, C.; Benoit, P.; Bertrand, C.; Crouzet, O.; Dagès, C.; Dorne, J.L.C.; Fernandez-Agudo, A.; Focks, A.; et al. A conceptual framework for landscape-based environmental risk assessment (ERA) of pesticides. Environ. Int. 2024, 191, 108999. [Google Scholar] [CrossRef]

- Carrao, A.M.; Coleman, J.C.; Kumari, H. Benzophenone-3 and ethylhexyl methoxycinnamate UV filters in freshwater environments: A Laurentian Great Lakes data needs analysis for assessing environmental risk. Environ. Adv. 2021, 5, 100110. [Google Scholar] [CrossRef]

- Suhartini, S.; Ainur, N.; Mardawati, E.; Hidayat, N. Biorefining of oil palm empty fruit bunches for bioethanol and xylitol production in Indonesia: A review Internal Rate of Return. Renew. Sustain. Energy Rev. 2022, 154, 111817. [Google Scholar] [CrossRef]

- Mączyńska, J.; Krzywonos, M.; Kupczyk, A.; Tucki, K.; Sikora, M.; Pińkowska, H.; Bączyk, A.; Wielewska, I. Production and use of biofuels for transport in Poland and Brazil—The case of bioethanol. Fuel 2019, 241, 989–996. [Google Scholar] [CrossRef]

- Guimarães, C.E.C.; Neto, F.S.; Bizerra, V.d.C.; Nascimento, J.G.A.D.; Valério, R.B.R.; Junior, P.G.d.S.; Braz, A.K.d.S.; Melo, R.L.F.; Serpa, J.d.F.; de Lima, R.K.C.; et al. Sustainable bioethanol production from first- and second-generation sugar-based feedstocks: Advanced bibliometric analysis. Bioresour. Technol. Rep. 2023, 23, 101543. [Google Scholar] [CrossRef]

- Rony, Z.I.; Mofijur, M.; Hasan, M.; Rasul, M.; Jahirul, M.; Ahmed, S.F.; Kalam, M.; Badruddin, I.A.; Khan, T.Y.; Show, P.-L. Alternative fuels to reduce greenhouse gas emissions from marine transport and promote UN sustainable development goals. Fuel 2023, 338, 127220. [Google Scholar] [CrossRef]

- Sundalian, M.; Larissa, D.; Suprijana, O. Contents and utilization of palm oil fruit waste. Biointerface Res. Appl. Chem. 2021, 11, 10148–10160. [Google Scholar] [CrossRef]

- Baudoin, A.; Bosc, P.M.; Bessou, C. Review of the Diversity of Palm oil Production Systems in Indonesia; Working Paper 219; Center for International Forestry Research: Bogor, Indonesia, 2017; p. 84. [Google Scholar]

- Gonçalves, T.d.S.; Oro, C.E.D.; Wancura, J.H.C.; dos Santos, M.S.N.; Junges, A.; Dallago, R.M.; Tres, M.V. Challenges for energy guidelines in crop-based liquid biofuels development in Brazil. Next Sustain. 2023, 2, 100002. [Google Scholar] [CrossRef]

- Hassan, M.A.; Farid, M.A.A.; Zakaria, M.R.; Ariffin, H.; Andou, Y.; Shirai, Y. Palm oil expansion in Malaysia and its countermeasures through policy window and biorefinery approach. Environ. Sci. Policy 2024, 153, 103671. [Google Scholar] [CrossRef]

- Bušić, A.; Marđetko, N.; Kundas, S.; Morzak, G.; Belskaya, H.; Šantek, M.I.; Komes, D.; Novak, S.; Šantek, B. Bioethanol production from renewable raw materials and its separation and purification: A review. Food Technol. Biotechnol. 2018, 56, 289–311. [Google Scholar] [CrossRef]

- Hossain, M.; Jewaratnam, J.; Ganesan, P. Prospect of hydrogen production from oil palm biomass by thermochemical process: A review. Int. J. Hydrog. Energy 2016, 41, 16637–16655. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Ahmad Farid, M.A.; Hafid, H.S.; Andou, Y.; Hassan, M.A. Practical role of oil palm fronds in Malaysia’s sustainable palm oil industry. Ind. Crops Prod. 2024, 222, 119753. [Google Scholar] [CrossRef]

- Pak, S.B.i.n.; Lee, Y. Common but differentiated? Policymakers’ priorities of social acceptance for expanding hydrogen refueling stations in Japan and Korea. Int. J. Hydrog. Energy 2024, 89, 799–809. [Google Scholar] [CrossRef]

- Romero-Padilla, A.; Hernández-Juárez, M.; Arana-Coronado, O.A.; García-Sánchez, R.C.; Malaga, J.; Segarra, E. Impacto de la producción de biocombustibles en Estados Unidos en el Mercado de maíz (Zea mays L.) en México. Agrociencia 2014, 48, 653–665. [Google Scholar]

- Mondal, P.; Sadhukhan, A.K.; Gupta, P.; Ganguly, A. Bioethanol-gasoline blend a promising fuel for motorized two-wheelers: Optimization of operating conditions for minimum regulated emissions. Int. J. Environ. Sci. Technol. 2022, 20, 11391–11406. [Google Scholar] [CrossRef]

- Castillo, E. Production of Cellulosic Ethanol from Palm Empty Fruit Bunches: The Perspective of Ecopetrol. Palmas 2016, 2, 115–118. [Google Scholar]

- Mayorga, B. Sacarificación y Fermentación Simultánea (SSF) de Raquis de Palma Africana (Elaeis guineensis) Pretratado con Ácido y Álcali para la Producción de Etanol de Segunda Generación. Bachelor’s Thesis, Pontifical Catholic University of Ecuador, Quinto, Ecuador, 2013; 204p. [Google Scholar]

- Appiah-Nkansah, N.B.; Zhang, K.; Rooney, W.; Wang, D. Ethanol production from mixtures of sweet sorghum juice and sorghum starch using very high gravity fermentation with urea supplementation. Ind. Crops Prod. 2018, 111, 247–253. [Google Scholar] [CrossRef]

- Prasad, R.K.; Chatterjee, S.; Mazumder, P.B.; Gupta, S.K.; Sharma, S.; Vairale, M.G.; Datta, S.; Dwivedi, S.K.; Gupta, D.K. Bioethanol production from waste lignocelluloses: A review on microbial degradation potential. Chemosphere 2019, 231, 588–606. [Google Scholar] [CrossRef]

- Rabemanolontsoa, H.; Saka, S. Various pretreatments of lignocellulosics. Bioresour. Technol. 2016, 199, 83–91. [Google Scholar] [CrossRef]

- Tu, W.C.; Hallett, J.P. Recent advances in the pretreatment of lignocellulosic biomass. Curr. Opin. Green Sustain. Chem. 2019, 20, 11–17. [Google Scholar] [CrossRef]

- Maurya, D.P.; Singla, A.; Negi, S. An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 2015, 5, 597–609. [Google Scholar] [CrossRef]

- Amin, F.R.; Khalid, H.; Zhang, H.; Rahman, S.U.; Zhang, R.; Liu, G.; Chen, C. Pretreatment methods of lignocellulosic biomass for anaerobic digestion. AMB Express 2017, 7, 72. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; De Vries, H.; Luque, R. Mechanical pretreatments of lignocellulosic biomass: Towards facile and environmentally sound technologies for biofuels production. RSC Adv. 2014, 4, 48109–48127. [Google Scholar] [CrossRef]

- Bensah, E.C.; Mensah, M. Chemical pretreatment methods for the production of cellulosic ethanol: Technologies and innovations. Int. J. Chem. Eng. 2013, 2013, 1–21. [Google Scholar] [CrossRef]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.B.; Ramakrishnan, S. Chemical and physicochemical pretreatment of lignocellulosic biomass: A review. Enzyme Res. 2011, 2011, 1–17. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. A comprehensive review on pre-treatment strategy for lignocellulosic food industry waste: Challenges and opportunities. Bioresour. Technol. 2016, 199, 92–102. [Google Scholar] [CrossRef]

- Azelee, N.I.W.; Jahim, J.M.; Rabu, A.; Murad, A.M.A.; Bakar, F.D.A.; Illias, R.M. Efficient removal of lignin with the maintenance of hemicellulose from kenaf by two-stage pretreatment process. Carbohydr. Polym. 2014, 99, 447–453. [Google Scholar] [CrossRef] [PubMed]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Chaturvedi, V.; Verma, P. Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process. Technol. 2019, 199, 106244. [Google Scholar] [CrossRef]

- Gutiérrez-Rojas, I.; Moreno-Sarmiento, N.; Montoya, D. Mechanisms and regulation of enzymatic hydrolysis of cellulose in filamentous fungi: Classical cases and new models. Rev. Iberoam. Micol. 2015, 32, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Mussatto, S.; Teixeira, J. Lignocellulose as raw material in fermentation processes. Appl. Microbiol. Microb. Biotechnol. 2010, 2, 897–907. [Google Scholar]

- Susmozas, A.; Martín-Sampedro, R.; Ibarra, D.; Eugenio, M.E.; Iglesias, R.; Manzanares, P.; Moreno, A.D. Process strategies for the transition of 1G to advanced bioethanol production. Processes 2020, 8, 1310. [Google Scholar] [CrossRef]

- Arias, N.A.; Eduardo, C.; Guerrero, M. Del laboratorio a la simulación: Evaluación de pretratamientos para la obtención de bioetanol a partir de residuos de brócoli. Jóvenes Cienc. 2023, 21, 1–11. [Google Scholar]

- Zhou, Z.; Peng, S.; Jing, Y.; Wei, S.; Zhang, Q.; Ding, H.; Li, H. Exploration of separate hydrolysis and fermentation and simultaneous saccharification and co-fermentation for acetone, butanol, and ethanol production from combined diluted acid with laccase pretreated Puerariae Slag in Clostridium beijerinckii ART44. Energy 2023, 279, 128063. [Google Scholar] [CrossRef]

- Budiyono; Agustiani, V.; Khoiriyah, L.; Matin, H.H.A.; Rachmawati, S. Effect of hydrogen peroxide acetic acid pretreatment on kapok (ceiba pentandra) fruit peel waste for bioethanol production using separated hydrolysis and fermentation methods. Mater. Today Proc. 2022, 63, S73–S77. [Google Scholar] [CrossRef]

- Sitinjak, E.M.; Masmur, I.; Sitanggang, Y.; Pratikha, R.S.; Nainggolan, F.; Yatasya, F.A.; Afandi, T.; Tarigan, K.; Hutajulu, P.E.; Destty, N.V.M.; et al. A Study on Cellulose from Oil Palm Biomass as a Source of Bioethanol Production. Cellul. Chem. Technol. 2023, 57, 369–375. [Google Scholar] [CrossRef]

- Maryana, R.; Bardant, T.B.; Ihsan, D.M.; Das, A.K.; Irawan, Y.; Rizal, W.A.; Triwahyuni, E.; Muryanto; Utami, A.R.I.; Sudiyani, Y. Reducing sugars and bioethanol production from oil palm empty fruit bunch by applying a batch and continuous pretreatment process with low temperature and pressure. Biomass Convers. Biorefinery 2022, 14, 11155–11164. [Google Scholar] [CrossRef]

- Quek, J.D.; Lee, K.M.; Lim, S.; Tey, W.Y.; Kang, H.S.; Quen, L.K. Delignification of oil palm empty fruit bunch via ultrasound-assisted deep eutectic solvent pretreatment. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012007. [Google Scholar] [CrossRef]

- Triwahyuni, E. Muryanto Valorization of oil palm empty fruit bunch for bioethanol production through separate hydrolysis and fermentation (SHF) using immobilized cellulolytic enzymes. IOP Conf. Ser. Earth Environ. Sci. 2020, 439, 012018. [Google Scholar] [CrossRef]

- Derman, E.; Abdulla, R.; Marbawi, H.; Sabullah, M.K.; Gansau, J.A.; Ravindra, P. Simultaneous Saccharification and Fermentation of Empty Fruit Bunches of Palm for Bioethanol Production Using a Microbial Consortium of S. cerevisiae and T. harzianum. Fermentation 2022, 8, 295. [Google Scholar] [CrossRef]

- Sahlan, M.; Muryanto; Hermansyah, H.; Wijarnako, A.; Gozan, M.; Lischer, K.; Ahmudi, A.; Pujianto, P. Ethanol production by encapsulated rhizopus oryzae from oil palm empty fruit bunch. Evergreen 2020, 7, 92–96. [Google Scholar] [CrossRef]

- Sanjuan-Acosta, M.J.; Tobón-Manjarres, K.; Sánchez-Tuirán, E.; Ojeda-Delgado, K.A.; González-Delgado, Á.D. An optimization approach based on superstructures for bioethanol production from african palm kernel shells. Polish J. Environ. Stud. 2021, 30, 2293–2300. [Google Scholar] [CrossRef]

- Mohd Yusof, S.J.H.; Roslan, A.M.; Ibrahim, K.N.; Abdullah, S.S.S.; Zakaria, M.R.; Hassan, M.A.; Shirai, Y. Life cycle assessment for bioethanol production from oil palm frond juice in an oil palm based biorefinery. Sustainability 2019, 11, 6928. [Google Scholar] [CrossRef]

- Lee, Z.Y.; Liew, P.Y.; Woon, K.S.; Tan, L.S.; Tamunaidu, P.; Klemeš, J.J. Life-Cycle Environmental and Cost Analysis of Palm Biomass-based Bio-Ethanol Production in Malaysia. Chem. Eng. Trans. 2021, 89, 85–90. [Google Scholar] [CrossRef]

- Yusof, S.J.H.M.; Roslan, A.M.; Ibrahim, K.N.; Abdullah, S.S.S.; Zakaria, M.R.; Hassan, M.A.; Shirai, Y. Environmental performance of bioethanol production from oil palm frond petiole sugars in an integrated palm biomass biorefinery. IOP Conf. Ser. Mater. Sci. Engineering. 2018, 368, 012004. [Google Scholar] [CrossRef]

- Vaskan, P.; Pachón, E.R.; Gnansounou, E. Techno-economic and life-cycle assessments of biorefineries based on palm empty fruit bunches in Brazil. J. Clean. Prod. 2018, 172, 3655–3668. [Google Scholar] [CrossRef]

- Prapaspongsa, T.; Musikavong, C.; Gheewala, S.H. Life cycle assessment of palm biodiesel production in Thailand: Impacts from modelling choices. 2017, co-product utilisation, improvement technologies, and land use change. J. Clean. Prod. 2017, 153, 435–447. [Google Scholar] [CrossRef]

- Suwajittanont, P.; Thongrak, P.; Srinophakun, T.R. Techno-economic analysis of commercial-scale bioethanol production from oil palm trunk and empty fruit bunch. Agric. Nat. Resour. 2022, 56, 825–836. [Google Scholar] [CrossRef]

- Cortés-sánchez, M.D.; Gata-montero, E.M.; Pipió-ternero, A.; Rodríguez-rivas, Á.; Manuel, J. Biocombustibles: Tipos y estrategias de producción. MoleQla Rev. Cienc. Univ. Pablo Olavide 2019, 35, 6. [Google Scholar]

- Chuayboon, S.; Abanades, S. Continuous solar-driven gasification of oil palm agricultural bio waste for high-quality syngas production. Waste Manag. 2022, 154, 303–311. [Google Scholar] [CrossRef]

- Barco-Burgos, J.; Carles-Bruno, J.; Eicker, U.; Saldana-Robles, A.L.; Alcántar-Camarena, V. Hydrogen-rich syngas production from palm kernel shells (PKS) biomass on a downdraft allothermal gasifier using steam as a gasifying agent. Energy Convers. Manag 2021, 245, 114592. [Google Scholar] [CrossRef]

- Aprianti, N.; Faizal, M.; Said, M.; Nasir, S. H2-rich syngas production by sorption enhanced steam gasification of palm empty fruit bunch. Comptes Rendus Chim. 2022, 25, 155–167. [Google Scholar] [CrossRef]

- Lim, M.; Tamili, S.N.A.; Sulaiman, S.A. Gasification of pre-treated palm based empty fruit bunches: Effect of alkali metal content. IOP Conf. Ser. Earth Environ. Sci. 2020, 442, 012006. [Google Scholar] [CrossRef]

- Chuayboon, S.; Abanades, S. Carbon-neutral synfuel production via continuous solar H2O and CO2 gasification of oil palm empty fruit bunch. Energy 2023, 281, 128212. [Google Scholar] [CrossRef]

- Pranolo, S.H.; Waluyo, J.; Putro, F.A.; Adnan, M.A.; Kibria, M.G. Gasification process of palm kernel shell to fuel gas: Pilot-scale experiment and life cycle analysis. Int. J. Hydrog. Energy 2023, 48, 2835–2848. [Google Scholar] [CrossRef]

- Wee, A.N.C.H.; Erison, A.E.; Edward Anyek, E.H.; Pakpahan, G.R.; Lim, J.R.; Tiong, A.N.T. Techno-economic assessment of hydrogen production via steam reforming of palm oil mill effluent. Sustain. Energy Technol. Assess. 2022, 53, 102575. [Google Scholar] [CrossRef]

- Salehmin, M.N.I.; Tiong, S.K.; Mohamed, H.; Zainal, B.S.; Lim, S.S.; Mohd Yasin, N.H.; Zakaria, Z. Sustainable bioenergy from palm oil mill effluent: Advancements in upstream and downstream engineering with techno-economic and environmental assessment. J. Ind. Eng. Chem. 2024, 133, 122–147. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, L.; Wei, W.; Jin, H.; Guo, L. Hydrogen production by sewage sludge gasification in supercritical water with high heating rate batch reactor. Energy 2023, 238, 121740. [Google Scholar] [CrossRef]

- Weijin, G.; Zizheng, Z.; Yue, L.; Qingyu, W.; Lina, G. Hydrogen production and phosphorus recovery via supercritical water gasification of sewage sludge in a batch reactor. Waste Manag. 2019, 96, 198–205. [Google Scholar] [CrossRef] [PubMed]

- Safari, F.; Salimi, M.; Tavasoli, A.; Ataei, A. Non-catalytic conversion of wheat straw, walnut shell and almond shell into hydrogen rich gas in supercritical water media. Chinese J. Chem. Eng. 2016, 24, 1097–1103. [Google Scholar] [CrossRef]

- Castello, D.; Rolli, B.; Kruse, A.; Fiori, L. Supercritical water gasification of biomass in a ceramic reactor: Long-time batch experiments. Energies 2017, 10, 1734. [Google Scholar] [CrossRef]

- Hejazi, B. Heat integration and waste minimization of biomass steam gasification in a bubbling fluidized bed reactor. Biomass Bioenergy 2022, 159, 106409. [Google Scholar] [CrossRef]

- Rabea, K.; Michailos, S.; Akram, M.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. An improved kinetic modelling of woody biomass gasification in a downdraft reactor based on the pyrolysis gas evolution. Energy Convers. Manag. 2022, 258, 115495. [Google Scholar] [CrossRef]

- Santamaria-Padilla, L.; Badillo-Hernandez, U.; Alvarez, J.; Alvarez-Icaza, L. On the nonlinear dynamics of biomass throated tubular gasification reactors. Comput. Chem. Eng. 2022, 163, 107828. [Google Scholar] [CrossRef]

- Li, X.; Yan, P.; Ma, C.; Wang, J. Structural design and optimization of a solar spouted bed reactor of biomass gasification. Appl. Therm. Eng. 2021, 194, 117058. [Google Scholar] [CrossRef]

- Sivasangar, S.; Zainal, Z.; Salmiaton, A.; Taufiq-Yap, Y.H. Supercritical water gasification of empty fruit bunches from oil palm for hydrogen production. Fuel 2015, 143, 563–569. [Google Scholar] [CrossRef]

- Navarro-Díaz, M.; Martinez-Sanchez, M.E.; Valdez-Vazquez, I.; Escalante, A.E. A framework for integrating functional and microbial data: The case of dark fermentation H2 production. Int. J. Hydrog. Energy 2020, 45, 31706–31718. [Google Scholar] [CrossRef]

- Bahadur, D.; Singh, A.; Bhatnagar, A. A review on biomass based hydrogen production technologies. Int. J. Hydrogen Energy 2021, 47, 1461–1480. [Google Scholar] [CrossRef]

- Tian, H.; Li, J.; Yan, M.; Wah, Y.; Wang, C.; Wang, X. Organic waste to biohydrogen: A critical review from technological development and environmental impact analysis perspective. Appl. Energy 2019, 256, 113961. [Google Scholar] [CrossRef]

- Kannah, R.Y.; Kavitha, S.; Preethi; Karthikeyan, O.P.; Kumar, G.; Dai-Viet, N.V.; Banu, J.R. Techno-economic assessment of various hydrogen production methods—A review. Bioresour. Technol. 2021, 319, 124175. [Google Scholar] [CrossRef]

- Noblecourt, A.; Christophe, G.; Larroche, C.; Fontanille, P. Hydrogen production by dark fermentation from pre-fermented depackaging food wastes. Bioresour. Technol. 2018, 247, 864–870. [Google Scholar] [CrossRef]

- Ranjan, B.; Elbeshbishy, E.; Hafez, H.; Lee, H. Bioresource Technology Hydrogen production from sugar beet juice using an integrated biohydrogen process of dark fermentation and microbial electrolysis cell. Bioresour. Technol. 2015, 198, 223–230. [Google Scholar] [CrossRef]

- Mishra, P.; Thakur, S.; Mahapatra, D.M.; Wahid, Z.A.; Liu, H.; Singh, L. Impacts of nano-metal oxides on hydrogen production in anaerobic digestion of palm oil mill effluent—A novel approach. Int. J. Hydrogen Energy 2018, 43, 2666–2676. [Google Scholar] [CrossRef]

- Alvarez-Guzmán, C.L.; Cisneros, S. Biohydrogen production from cheese whey powder by Enterobacter asburiae: Effect of operating conditions on hydrogen yield and chemometric study of the fermentative metabolites. Energy Rep. 2020, 6, 1170–1180. [Google Scholar] [CrossRef]

- Khongkliang, P.; Jehlee, A.; Kongjan, P. High efficient biohydrogen production from palm oil mill effluent by two-stage dark fermentation and microbial electrolysis under thermophilic condition. Int. J. Hydrogen Energy 2019, 44, 31841–31852. [Google Scholar] [CrossRef]

- Dreschke, G.; Papirio, S.; Scala, A.; Lens, P.N.L.; Esposito, G. High rate continuous biohydrogen production by hyperthermophilic Thermotoga neapolitana. Bioresour. Technol. 2019, 293, 122033. [Google Scholar] [CrossRef]

- Prieto, P.B.; Antonio, J.; Dobladez, D.; Ismael, V.; Maté, Á. Recuperación de Hidrógeno de Mezclas Gaseosas Mediante un Proceso PSA. Ph.D. Thesis, Universidad Complutense De Madrid Facultad De Ciencias Químicas Departamento De Ingeniería Química, Madrid, Spain, 2018. [Google Scholar]

- Clemente, C. Estudio de la Separación de Hidrógeno por Membranas Metálicas Densas de Paladio; E.T.S.I. Industriales (UPM): Madrid, Spain, 2018. [Google Scholar]

- Casalvázquez Zamora, R.; Gutierrez Ortiz, F. Purificación de Hidrógeno Mediante un Sistema PSA; Universidad de Sevilla: Sevilla, Spain, 2020; Available online: https://hdl.handle.net/11441/106139 (accessed on 1 October 2024).

- Laguna, L.; Castro, M.; Cassiani, D.; Leon-Pulido, J.; Gonzalez-Delgado, A.D. Computer-Aided Exergy Evaluation of Direct Empty Fruit Bunches (EFB) Gasification and PSA Technology for Hydrogen Production. Indian J. Sci. Technol. 2018, 11, 1–8. [Google Scholar] [CrossRef]

- Muñoz, J.; Posada, A. Simulación de la Producción de Hidrógeno y Metanol a Partir de la Gasificación de Cascarilla de Arroz con Vapor. Dyna 2011, 78, 122–131. [Google Scholar]

- Silva, E.; Escobar, J.; Garcia, J.; Barrera, J. Bioenergía y biorrefinerías para caña de azúcar y palma de aceite. Palmas 2016, 37, 119–136. [Google Scholar]

- Sanjuan-Acosta, M.; Tobon-Manjarres, K.; Meramo-Hurtado, S.; Ojeda-Delgado, K.; Gonzalez-Delgado, Á. Bioethanol Production Process from Palm Rachis Using the Computer-Assisted Intrinsic Safety Index Method. Int. J. Acad. Eng. Res. 2018, 2, 8–11. [Google Scholar]

- Arteaga-Díaz, S.; Sanjuan-Acosta, M.J.; González-Delgado, Á.D. Computer-aided environmental evaluation of bioethanol production from empty palm fruit bunches using oxalic acid pretreatment and molecular sieves. Chem. Eng. Trans. 2018, 70, 2113–2118. [Google Scholar] [CrossRef]

- Bamidele, A.; Cheng, C.K. Biorefinery for the Production of Biodiesel, Hydrogen and Synthesis Gas Integrated with CHP from Oil Palm in Malaysia. Chem. Prod. Process Model. 2016, 11, 26300. [Google Scholar] [CrossRef]

- Niño-Villalobos, A.; Puello-Yarce, J.; González-Delgado, Á.D.; Ojeda, K.A.; Sánchez-Tuirán, E. Biodiesel and Hydrogen Production in a Combined Palm and Jatropha Biomass Biorefinery: Simulation, Techno-Economic, and Environmental Evaluation. ACS Omega 2020, 5, 7074–7708. [Google Scholar] [CrossRef] [PubMed]

- Vargas-Mira, A.; Zuluaga-García, C.; González-Delgado, Á.D. A Technical and Environmental Evaluation of Six Routes for Industrial Hydrogen Production from Empty Palm Fruit Bunches. ACS Omega 2019, 4, 15457–15470. [Google Scholar] [CrossRef]

- Pacheco-Perez, K.; Baia-Olivares, M.; Meza-Gonzalez, D.; Gonzalez-Delgado, A.D. Exergy analysis of hydrogen production from palm oil solid wastes using indirect gasification. Indian J. Sci. Technol. 2018, 11, 1–6. [Google Scholar] [CrossRef]

- Arteaga, S.; González, J.; Ojeda, K.; Pájaro, M.; González, A. Computer-Aided Exergy Analysis of a Palm Based-Biorefinery for Producing Palm Oil, Kernel Oil and Hydrogen. Contemp. Eng. Sci. 2018, 11, 537–545. [Google Scholar] [CrossRef]

- Gonzalez-Delgado, A.D.; Parejo, V.; Herrera, T. Computer-aided environmental evaluation of bio-hydrogen production from residual biomass of palm cultivation. Contemp. Eng. Sci. 2017, 10, 773–783. [Google Scholar] [CrossRef]

- PérezZúñiga, D.L.; Barrios-Luna, E.J.; González-Delgado, A.D.; Peralta-Ruiz, Y.Y. Computer aided evaluation of large-scale bio-hydrogen production from empty palm fruit bunches. Int. J. ChemTech Res. 2017, 10, 295–302. [Google Scholar]

- Peralta-Ruiz, Y.; Saavedra, D.X.; González-Delgado, Á. Exergy based evaluation of large-scale hydrogen production from African palm rachis. Aust. J. Basic Appl. Sci. 2016, 10, 168–175. [Google Scholar]

- Perez-Zúñiga, D.L.; Barrios, E.J.L.; Peralta-Ruiz, Y.Y.; González-Delgado, A.D. Techno-Economic Sensitivity of Bio-Hydrogen Production from Empty Palm Fruit Bunches under Colombian Conditions. Chem. Eng. Trans. 2016, 52, 1117–1122. [Google Scholar] [CrossRef]

- Momoh, E.O.; Osofero, A.I. Recent developments in the application of oil palm fibers in cement composites. Front. Struct. Civ. Eng. 2020, 14, 94–108. [Google Scholar] [CrossRef]

- Anuar, N.I.S.; Zakaria, S.; Gan, S.; Chia, C.H.; Wang, C.; Harun, J. Comparison of the morphological and mechanical properties of oil Palm EFB fibres and kenaf fibres in nonwoven reinforced composites. Ind. Crops Prod. 2019, 127, 55–65. [Google Scholar] [CrossRef]

- Paltseva, J.; Searle, S.; Malins, C. Potential for Advanced Biofuel Production from Palm Residues in Indonesia; International Council on Clean Transportation: Washington, DC, USA, 2016; pp. 1–17. [Google Scholar]

- Nair, S.N.; Dasari, A. Development and Characterization of Natural-Fiber-Based Composite Panels. Polymers 2022, 14, 2079. [Google Scholar] [CrossRef] [PubMed]

- Faizi, M.K.; Abu Bakar, S.; Majid, M.S.A.; Tamrin, S.B.M.; Israr, H.A.; Rahman, A.A.; Guan, N.Y.; Razlan, Z.M.; Kamis, N.A.; Khairunizam, W. Tensile characterizations of oil palm empty fruit bunch (Opefb) fibres reinforced composites in various epoxy/fibre fractions. Biointerface Res. Appl. Chem. 2022, 12, 6148–6163. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Rizal, S. Investigation of thermal conductivity and physical properties of oil palm trunks/ramie fiber reinforced biopolymer hybrid composites as building bio-insulation. Mater. Today Proc. 2022, 60, 373–377. [Google Scholar] [CrossRef]

- Mydin, M.A.O. Mechanical and Durability Properties of Foamed Concrete with the Addition of Oil Palm Trunk Fibre. Int. J. Sustain. Constr. Eng. Technol. 2022, 13, 9–24. [Google Scholar] [CrossRef]

- Husna, A.F.; Febrianti, F.; Syah, H.H.; Pangaribuan, R.A.; Surbakti, T.A.; Sihombing, J.L.; Pulungan, A.N. Conversion of Cellulose from Palm Oil Middle Waste (Elaeis guineensis) into Bio-oil Products as Alternative Fuel. Egypt. J. Chem. 2022, 65, 61–67. [Google Scholar] [CrossRef]

- Ameen, M.; Zamri, N.M.; May, S.T.; Azizan, M.T.; Aqsha, A.; Sabzoi, N.; Sher, F. Effect of acid catalysts on hydrothermal carbonization of Malaysian oil palm residues (leaves, fronds, and shells) for hydrochar production. Biomass Convers. Biorefinery 2022, 12, 103–114. [Google Scholar] [CrossRef]

- Saritpongteeraka, K.; Natisupacheevin, K.; Tan, C.; Rehman, S.; Charnnok, B.; Vaurs, L.P.; Leu, S.-Y.; Chaiprapat, S. Comparative assessment between hydrothermal treatment and anaerobic digestion as fuel pretreatment for industrial conversion of oil palm empty fruit bunch to methane and electricity-A preparation study to full scale. Fuel 2022, 310, 122479. [Google Scholar] [CrossRef]

- Arbuto, J.; Martínez, T.; Murrieta, F. Evaluación técnico-económica de la producción de bioetanol a partir de residuos lignocelulósicos Technical and economical evaluation of bioethanol production from lignocelulosic residues. Tecnol. Ciencia Educ. 2008, 23, 23–30. [Google Scholar]

- Jácome-Pilco, C.; García-Culqui, R.; Guevara-Narváez, L.; Moreta-Guangasi, T. Revalorización del bagazo de caña de azúcar (Saccharum officinarum) como residuo importante para la agroindustria. 593 Digit. Publ. CEIT 2023, 8, 134–148. [Google Scholar] [CrossRef]

- Martinez, D.; Suarez, C. Technical, Economic, and Exergetic Evaluation of Six Emerging Topologies for Bioethanol Production from Oil Palm Rachis. Bachelor’s Thesis, University of Cartagena, Cartagena/Bolivar, Colombia, 2019. [Google Scholar]

- Anu; Kumar, A.; Jain, K.K.; Singh, B. Process optimization for chemical pretreatment of rice straw for bioethanol production. Renew. Energy 2020, 156, 1233–1243. [Google Scholar] [CrossRef]

- Herrera-Rodriguez, T.C.; Ramos-Olmos, M.; Gonzalez-Delgado, A.D. A joint economic evaluation and FP2O techno-economic resilience approach for evaluation of suspension PVC production. Results Eng. 2024, 24, 103069. [Google Scholar] [CrossRef]

| Advantages and Disadvantages | SSF (Saccharification and Fermentation) | SHF (Separate Hydrolysis and Fermentation) | SSCF (Simultaneal Saccharification and Co-Fermentation) | SHCF (Separate Hydrolysis and Cofermentation) | CBP (Consolidated Bioprocessing) |

|---|---|---|---|---|---|

| Advantages | Time efficiency. High ethanol yield. Low cost. Reduced risk of contamination. | Optimization of separate hydrolysis and fermentation conditions. Flexible selection of microorganisms and enzymes. | Enzymatic efficiency. High bioethanol yield. Lower risk of contamination. | High bioethanol yield. Low cost. Lower risk of contamination. | Energy-efficient. Lower operating cost. Simplified process control. |

| Disadvantages | Inflexible selection of microorganisms and enzymes. Difficulty in process control | Higher cost. Contaminating effects on microorganisms. Lower ethanol yield | Difficulty in process control. Limitations in the selection of microorganisms. | Difficulty in process control. Limitations in the selection of microorganisms. | Lack of suitable organisms. Lower versatility. |

| Type of Reactor | Substrate Used | Variables | Reference |

|---|---|---|---|

| Stainless steel tubular micro-reactor | Walnut shell, wheat straw. | Time of reaction, yield of the gas. | [68] |

| Ceramic reactor | Dry biomass | Comparison of bioreactor materials | [69] |

| Bubbling fluidized bed reactor | Biomass | Heat integration alternative | [70] |

| Downflow reactor | Wood biomass | Reactor modeling, gas evolution, reduction, and combustion reactions. | [71] |

| Coupling combustion reactor | Biomass | Upper secondary air height, upper secondary air ratio, and upper secondary air injection. | [70] |

| Biomass gasification tubular reactor | Biomass | Robust stability, steady state, transient behavior, bifurcation behavior, and multiplicity behavior. | [72] |

| Peak-bed solar reactor | Biomass | Modelling of the reactor | [73] |

| Supercritical reactor | Empty fruit bunches | Pressure, temperature | [74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo-Gracia, L.Á.; Urbina-Suarez, N.A.; González-Delgado, Á.D. Bibliometric and Co-Occurrence Study of the Production of Bioethanol and Hydrogen from African Palm Rachis (2003–2023). Sustainability 2025, 17, 146. https://doi.org/10.3390/su17010146

Castillo-Gracia LÁ, Urbina-Suarez NA, González-Delgado ÁD. Bibliometric and Co-Occurrence Study of the Production of Bioethanol and Hydrogen from African Palm Rachis (2003–2023). Sustainability. 2025; 17(1):146. https://doi.org/10.3390/su17010146

Chicago/Turabian StyleCastillo-Gracia, Luis Ángel, Néstor Andrés Urbina-Suarez, and Ángel Darío González-Delgado. 2025. "Bibliometric and Co-Occurrence Study of the Production of Bioethanol and Hydrogen from African Palm Rachis (2003–2023)" Sustainability 17, no. 1: 146. https://doi.org/10.3390/su17010146

APA StyleCastillo-Gracia, L. Á., Urbina-Suarez, N. A., & González-Delgado, Á. D. (2025). Bibliometric and Co-Occurrence Study of the Production of Bioethanol and Hydrogen from African Palm Rachis (2003–2023). Sustainability, 17(1), 146. https://doi.org/10.3390/su17010146