Probabilistic Embodied Carbon Assessments for Alkali-Activated Concrete Materials

Abstract

1. Introduction

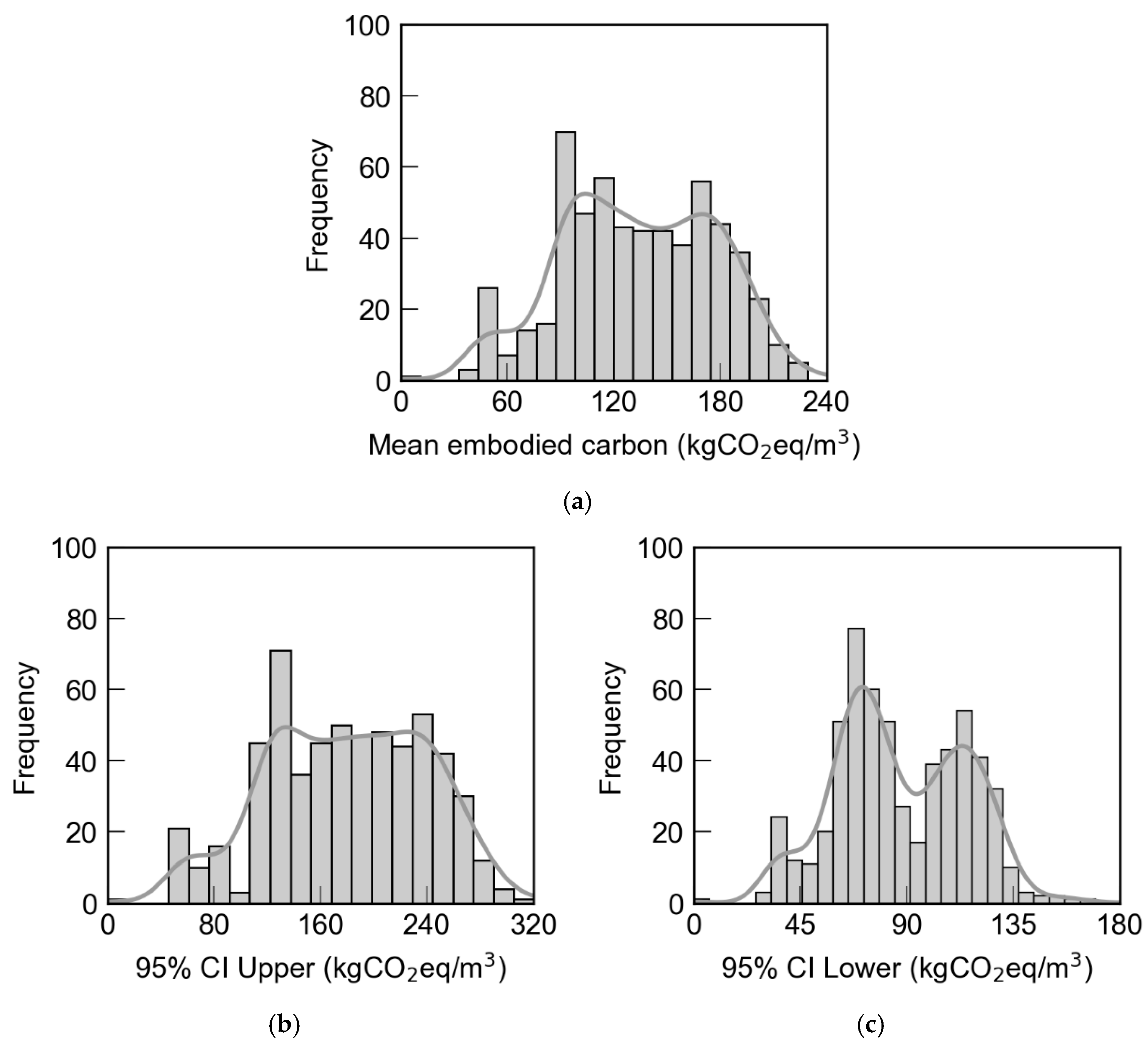

2. Methodology

2.1. Data Collection

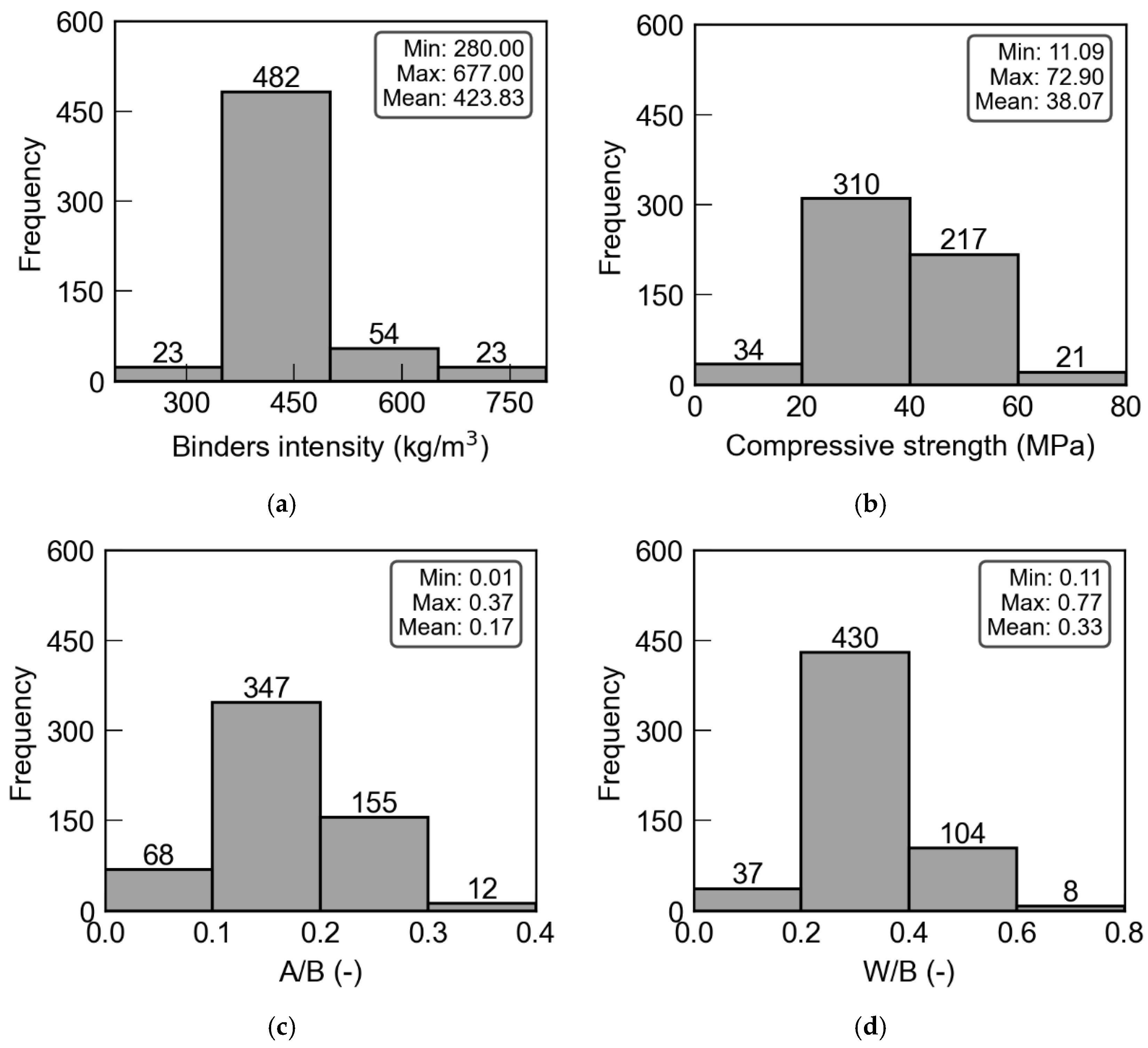

2.2. Database Characteristics

2.3. Environmental Assessments

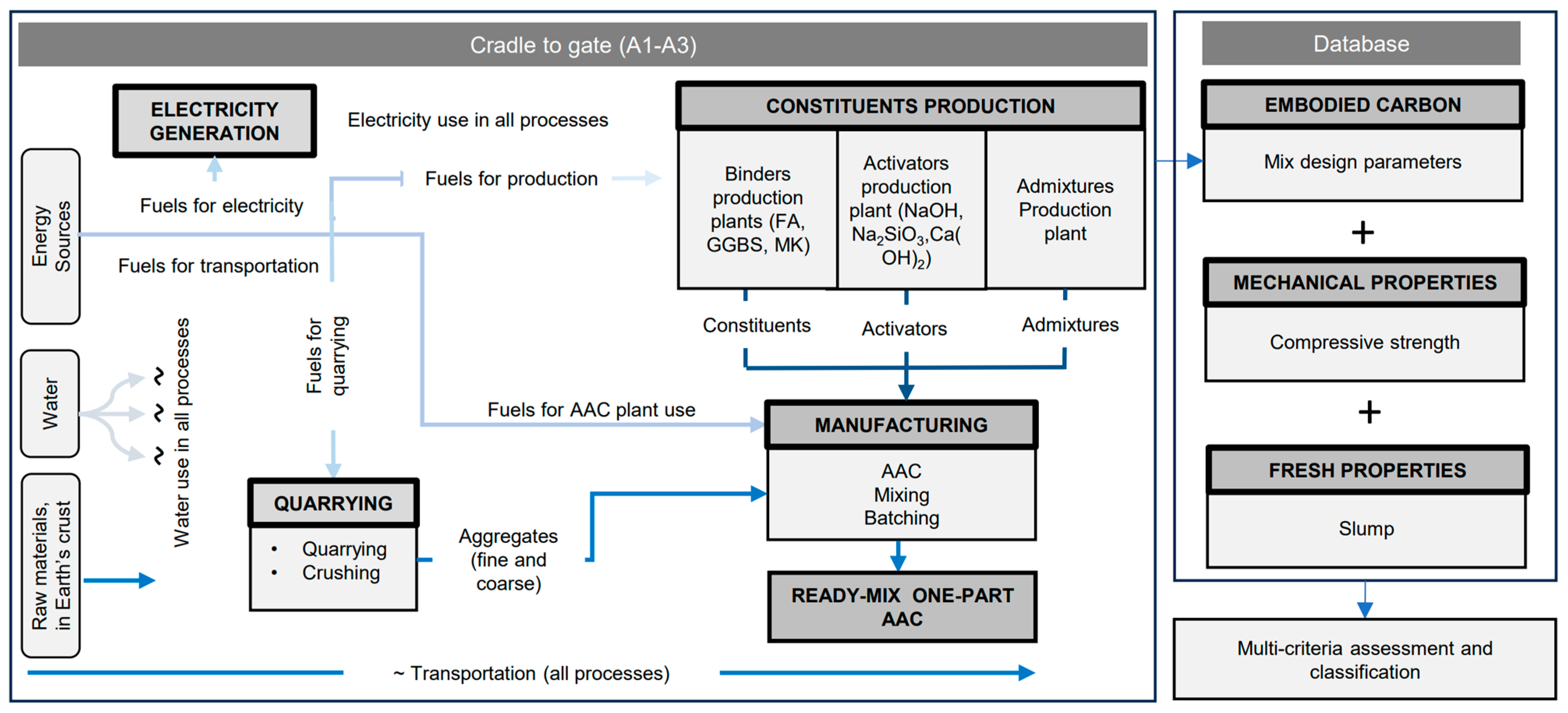

2.3.1. Procedures and Boundaries

2.3.2. Inventory and Assessment

2.3.3. Multicriteria Evaluation

3. Assessment Results

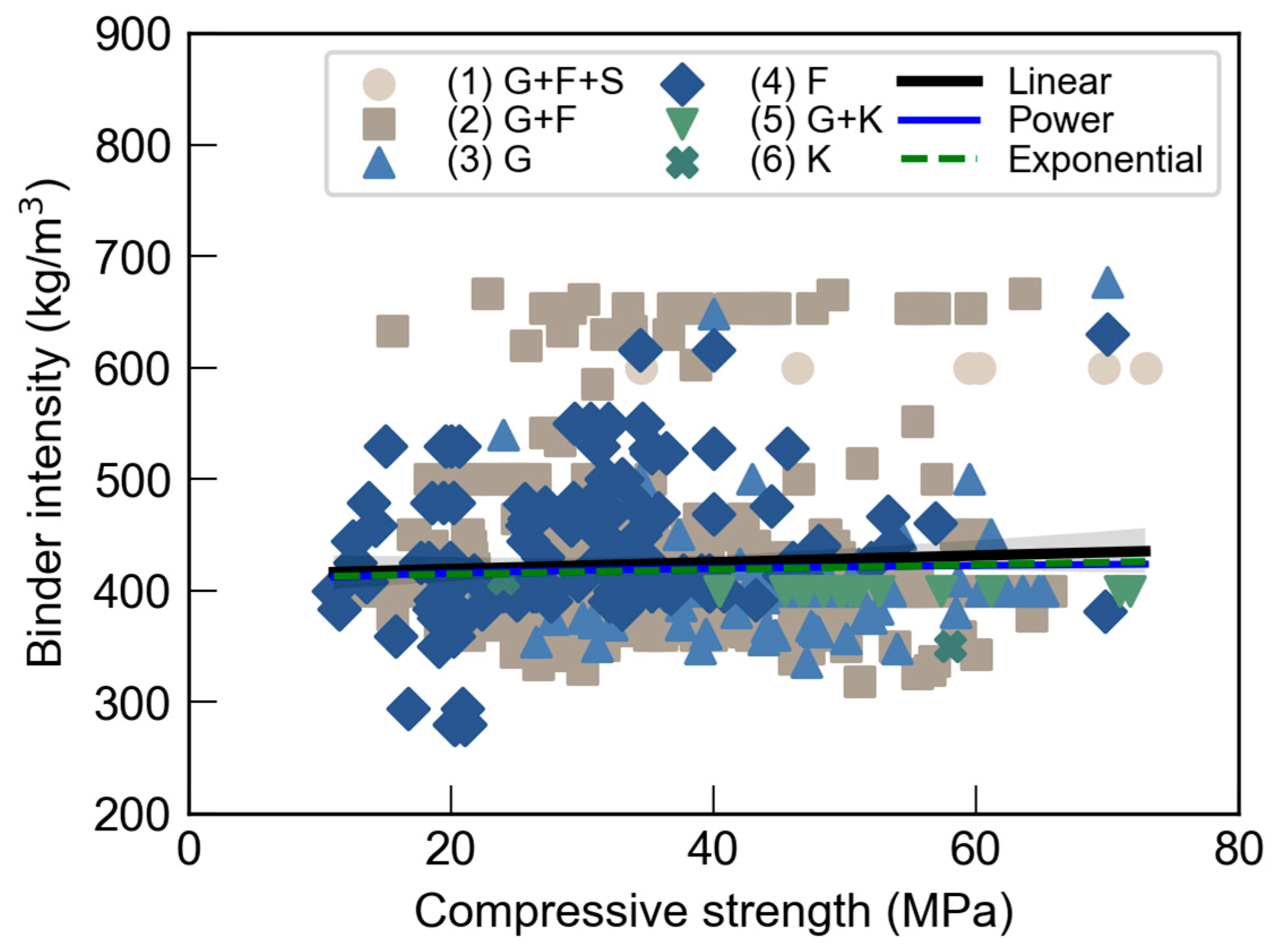

3.1. Embodied Carbon and Mix Constituents

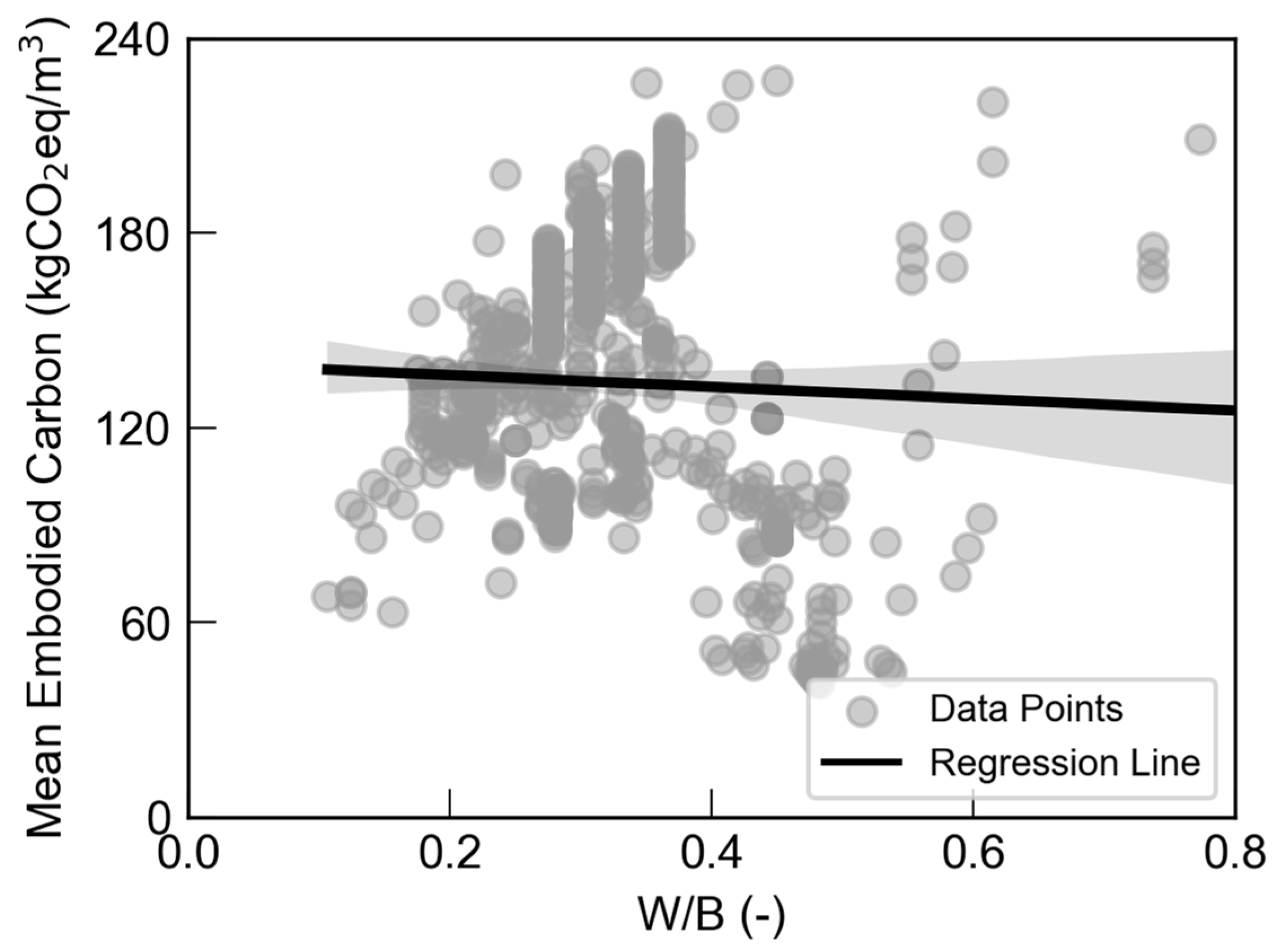

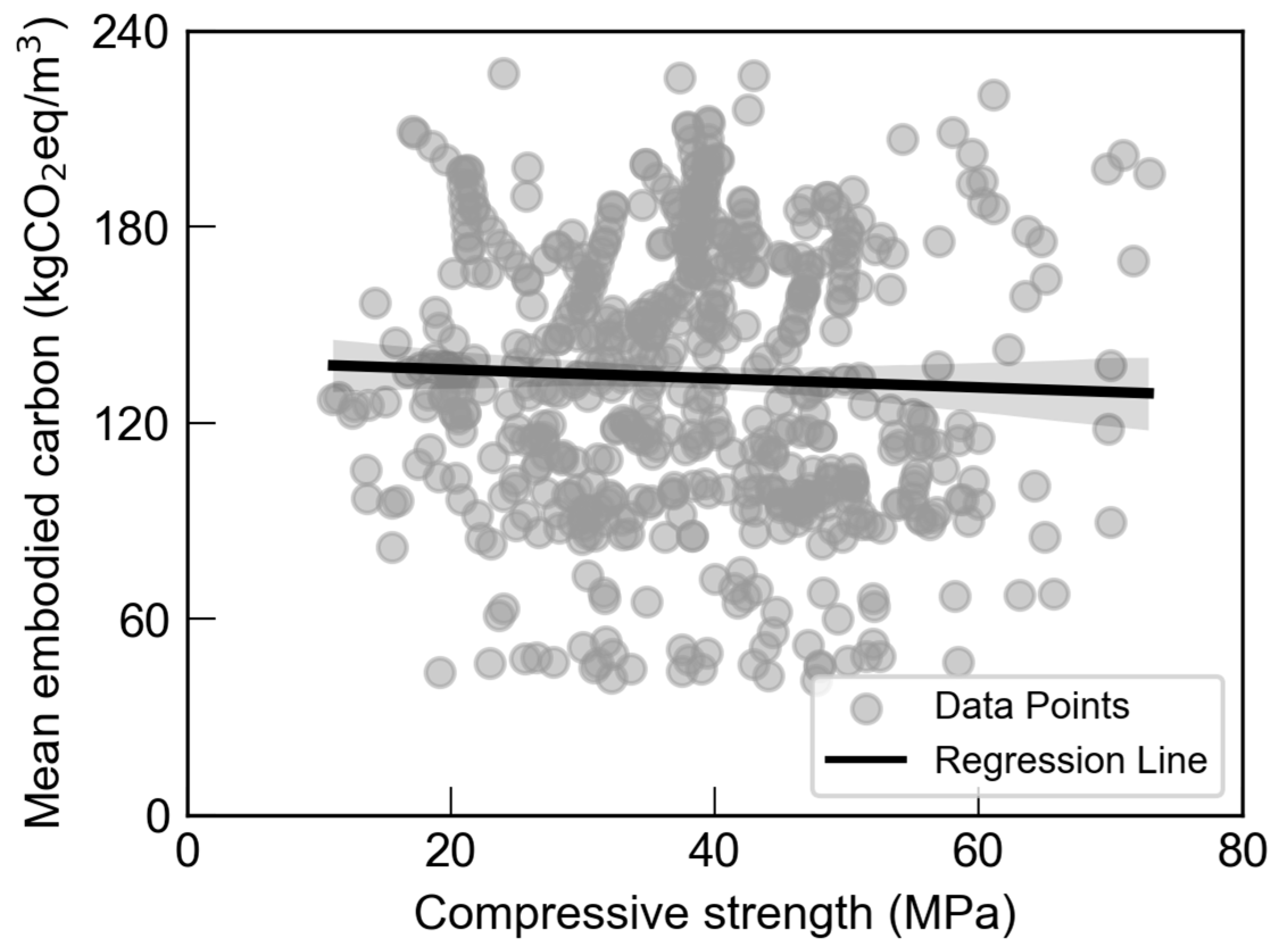

3.2. Concrete Properties

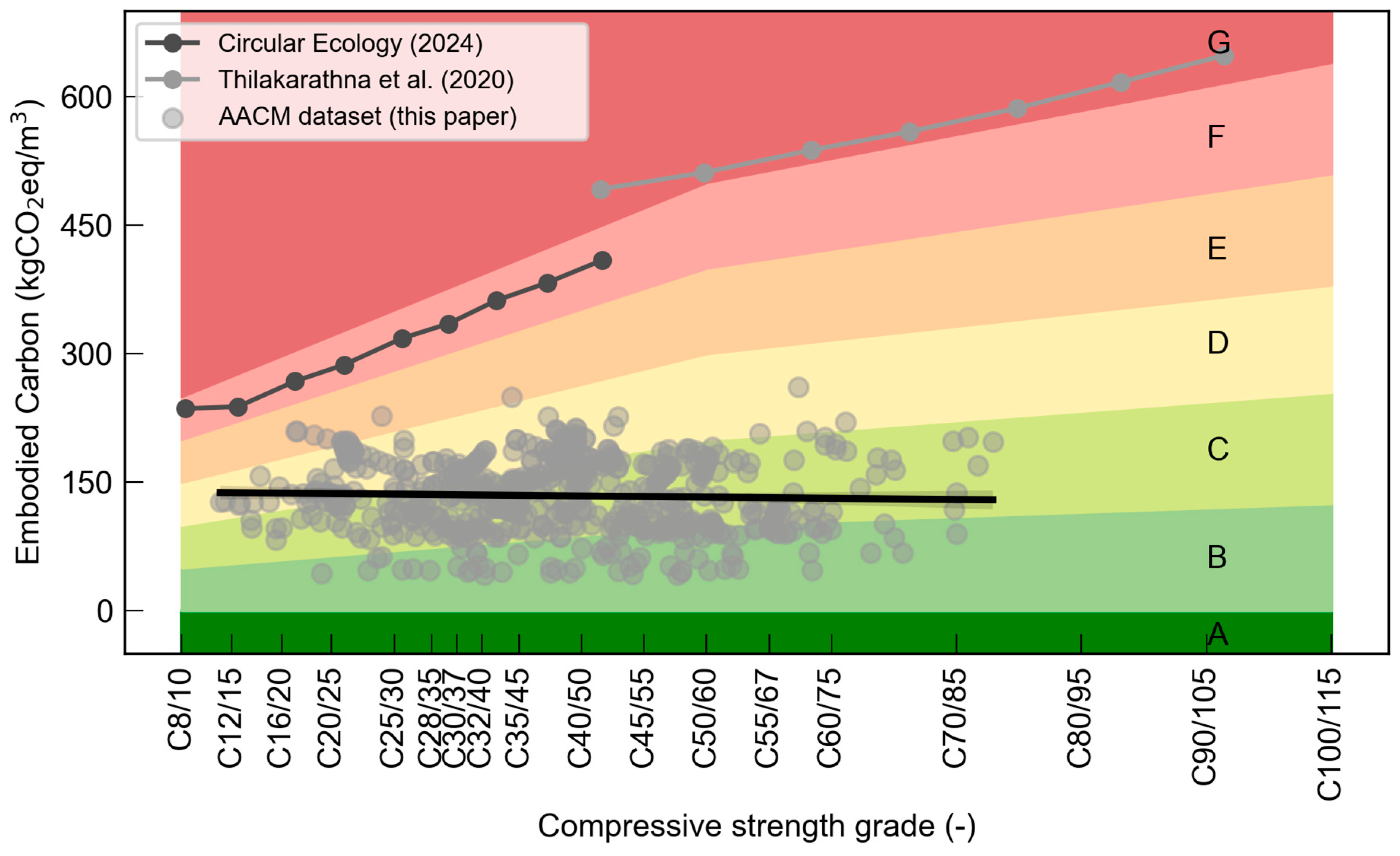

3.3. Multicriteria Assessment

3.4. Classification Scheme

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, K.H.; Jung, Y.B.; Cho, M.S.; Tae, S.H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, X.; Xie, T.; Wang, X. Eco-, economic-and mechanical-efficiencies of using precast rejects as coarse aggregates in self-compacting concrete. Case Stud. Constr. Mater. 2022, 17, e01591. [Google Scholar] [CrossRef]

- Witte, A.; Garg, N. Quantifying the global warming potential of low carbon concrete mixes: Comparison of existing life cycle analysis tools. Case Stud. Constr. Mater. 2024, 20, e02832. [Google Scholar] [CrossRef]

- Oh, D.Y.; Noguchi, T.; Kitagaki, R.; Park, W.J. CO2 emission reduction by reuse of building material waste in the Japanese cement industry. Renew. Sustain. Energy Rev. 2014, 38, 796–810. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete—A review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar]

- Xia, B.; Ding, T.; Xiao, J. Life cycle assessment of concrete structures with reuse and recycling strategies: A novel framework and case study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. Sustainable management of waste-to-energy facilities. Renew. Sustain. Energy Rev. 2014, 33, 719–728. [Google Scholar] [CrossRef]

- Flower, D.J.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Küpfer, C.; Bastien-Masse, M.; Fivet, C. Reuse of concrete components in new construction projects: Critical review of 77 circular precedents. J. Clean. Prod. 2023, 383, 135235. [Google Scholar] [CrossRef]

- Garcia-Troncoso, N.; Bompa, D.V.; de la Fuente, A. Reuse Potential Evaluation Procedures for Reinforced Concrete Elements from Large Panel System Buildings: A Systematic Review, Framework and Repurpose Scenarios; Technical Report; University of Surrey: Guildford, UK, 2024. [Google Scholar]

- Sabău, M.; Bompa, D.V.; Silva, L.F. Comparative carbon emission assessments of recycled and natural aggregate concrete: Environmental influence of cement content. Geosci. Front. 2021, 12, 101235. [Google Scholar] [CrossRef]

- Thorne, J.; Bompa, D.V.; Funari, M.F.; Garcia-Troncoso, N. Environmental impact evaluation of low-carbon concrete incorporating fly ash and limestone. Clean. Mater. 2024, 12, 100242. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T.; Jeong, J.; Jeong, J. Mix design optimization and environmental impact assessment of low-carbon materials containing alkali-activated slag and high CaO fly ash. Constr. Build. Mater. 2021, 267, 120932. [Google Scholar] [CrossRef]

- Bianco, I.; Tomos, B.A.D.; Vinai, R. Analysis of the environmental impacts of alkali-activated concrete produced with waste glass-derived silicate activator—A LCA study. J. Clean. Prod. 2021, 316, 128383. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Experimental assessment and constitutive modelling of rubberised one-part alkali-activated concrete. Constr. Build. Mater. 2022, 353, 129161. [Google Scholar] [CrossRef]

- Komnitsas, K.; Soultana, A.; Bartzas, G. Marble waste valorization through alkali activation. Minerals 2021, 11, 46. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and valorisation of wastes through use in producing alkali-activated cement materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. Compressive and splitting tensile impact properties of rubberised one-part alkali-activated concrete. J. Build. Eng. 2023, 71, 106596. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kontoni, D.P.N. A critical review of rheological models in self-compacting concrete for sustainable structures. Sci. Rep. 2023, 13, 21296. [Google Scholar] [CrossRef]

- Shahbaz, M.; Behfarnia, K. Thermal strength of the alkali-activated slag concrete. AUT J. Civ. Eng. 2020, 4, 303–314. [Google Scholar]

- Geraldo, R.H.; Ouellet-Plamondon, C.M.; Muianga, E.A.; Camarini, G. Alkali-activated binder containing wastes: A study with rice husk ash and red ceramic. Cerâmica 2017, 63, 44–51. [Google Scholar] [CrossRef]

- Zhang, R.; Li, F.; Zhou, S.; Su, Y.; Liu, D.; Niu, Q. Alkali activators with different cations turning volcanic ash into eco-friendly geopolymers. Proc. Inst. Civ. Eng.-Eng. Sustain. 2024, 177, 111–124. [Google Scholar] [CrossRef]

- Zhang, B.; He, P.; Poon, C.S. An innovative way to enhance the high temperature properties of alkali activated cement mortars prepared by using glass powder as precursor. Mater. Struct. 2021, 54, 160. [Google Scholar] [CrossRef]

- Komkova, A.; Habert, G. Optimal supply chain networks for waste materials used in alkali-activated concrete fostering circular economy. Resour. Conserv. Recycl. 2023, 193, 106949. [Google Scholar] [CrossRef]

- Mitoulis, S.A.; Bompa, D.V.; Argyroudis, S. Sustainability and climate resilience metrics and trade-offs in transport infrastructure asset recovery. Transp. Res. Part D Transp. Environ. 2023, 121, 103800. [Google Scholar] [CrossRef]

- Kamazani, M.A.; Dixit, M.K. Multi-objective optimization of embodied and operational energy and carbon emission of a building envelope. J. Clean. Prod. 2023, 428, 139510. [Google Scholar] [CrossRef]

- Echenagucia, T.M.; Moroseos, T.; Meek, C. On the tradeoffs between embodied and operational carbon in building envelope design: The impact of local climates and energy grids. Energy Build. 2023, 278, 112589. [Google Scholar] [CrossRef]

- Wang, S.; Xia, P.; Chen, K.; Gong, F.; Wang, H.; Wang, Q.; Zhao, Y.; Jin, W. Prediction and optimization model of sustainable concrete properties using machine learning, deep learning and swarm intelligence: A review. J. Build. Eng. 2023, 80, 108065. [Google Scholar] [CrossRef]

- Bompa, D.V.; Xu, B.; Corbu, O. Evaluation of one-part slag–fly-ash alkali-activated mortars incorporating waste glass powder. J. Mater. Civ. Eng. 2022, 34, 05022001. [Google Scholar] [CrossRef]

- Zhang, C.; Bompa, D.V.; Biswal, S.; Wang, Y. Performance of one-part alkali-activated materials incorporating fly ash and slag. In Proceedings of the 15th fib International PhD Symposium in Civil Engineering, Budapest, Hungary, 28–30 August 2024. [Google Scholar]

- Marvila, M.T.; de Azevedo, A.R.G.; Júnior, J.A.T.L.; Vieira, C.M.F. Activated alkali cement based on blast furnace slag: Effect of curing type and concentration of Na20. J. Mater. Res. Technol. 2023, 23, 4551–4565. [Google Scholar] [CrossRef]

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef]

- Palomo, A.; Maltseva, O.; Garcia-Lodeiro, I.; Fernández-Jiménez, A. Portland versus alkaline cement: Continuity or clean break:“A key decision for global sustainability”. Front. Chem. 2021, 9, 705475. [Google Scholar] [CrossRef] [PubMed]

- Batista, R.P.; Trindade, A.C.C.; Borges, P.H.; Silva, F.D.A. Silica fume as precursor in the development of sustainable and high-performance MK-based alkali-activated materials reinforced with short PVA fibers. Front. Mater. 2019, 6, 77. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, C.; Liang, Y.; Luo, J.; Wang, X.; Feng, Y.; Li, Y.; Wang, Q.; Abomohra, A.E.F. Life cycle assessment and impact correlation analysis of fly ash geopolymer concrete. Materials 2021, 14, 7375. [Google Scholar] [CrossRef] [PubMed]

- EN 15978; Sustainability of Construction Works. Assessment Of Environmental Performance of Buildings. CEN: Brussels, Belgium, 2011.

- Fernando, S.; Gunasekara, C.; Law, D.W.; Nasvi, M.C.M.; Setunge, S.; Dissanayake, R. Life cycle assessment and cost analysis of fly ash–rice husk ash blended alkali-activated concrete. J. Environ. Manag. 2021, 295, 113140. [Google Scholar] [CrossRef] [PubMed]

- Miettinen, P.; Hämäläinen, R.P. How to benefit from decision analysis in environmental life cycle assessment (LCA). Eur. J. Oper. Res. 1997, 102, 279–294. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednárová, L.; Petrovský, J. Improving the Process of Product Design in a Phase of Life Cycle Assessment (LCA). Processes 2023, 11, 2579. [Google Scholar] [CrossRef]

- García-Troncoso, N.; Hidalgo-Astudillo, S.; Tello-Ayala, K.; Vanegas-Alman, N.; Bompa, D.V. Preparation and performance of sugarcane bagasse ash pavement repair mortars. Case Stud. Constr. Mater. 2023, 19, e02563. [Google Scholar] [CrossRef]

- Zheng, J.; Canarini, A.; Fujii, K.; Mmari, W.N.; Kilasara, M.M.; Funakawa, S. Cropland intensification mediates the radiative balance of greenhouse gas emissions and soil carbon sequestration in maize systems of sub-Saharan Africa. Glob. Change Biol. 2023, 29, 1514–1529. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Das, S.K.; Shrivastava, S. Siliceous fly ash and blast furnace slag based geopolymer concrete under ambient temperature curing condition. Struct. Concr. 2021, 22, E341–E351. [Google Scholar] [CrossRef]

- Pham, T.T.; Nguyen, N.L.; Nguyen, T.T.; Nguyen, T.T.; Pham, T.H. Effects of superplasticizer and water–binder ratio on mechanical properties of one-part alkali-activated geopolymer concrete. Buildings 2023, 13, 1835. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Zhu, X.; Jiang, T.; Tufail, R.F. A comprehensive study on the factors affecting the workability and mechanical properties of ambient cured fly ash and slag based geopolymer concrete. Appl. Sci. 2021, 11, 8722. [Google Scholar] [CrossRef]

- Komkova, A.; Habert, G. Environmental impact assessment of alkali-activated materials: Examining impacts of variability in constituent production processes and transportation. Constr. Build. Mater. 2023, 363, 129032. [Google Scholar] [CrossRef]

- Haruna, S.; Mohammed, B.S.; Wahab, M.M.A.; Liew, M.S. Effect of paste aggregate ratio and curing methods on the performance of one-part alkali-activated concrete. Constr. Build. Mater. 2020, 261, 120024. [Google Scholar] [CrossRef]

- Abhilash, P.; Sashidhar, C.; Reddy, I.R. Strength properties of Fly ash and GGBS based Geo-polymer Concrete. Int. J. Chem. Tech. Res. 2016, 9, 350–356. [Google Scholar]

- Aliabdo, A.A.; Abd Elmoaty, M.; Salem, H.A. Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 123, 581–593. [Google Scholar] [CrossRef]

- Adam, A. Strength and Durability Properties of Alkali Activated Slag and Fly Ash-Based Geopolymer Concrete. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2009. [Google Scholar]

- Barnard, R. Mechanical Properties of Fly Ash/Slag Based Geopolymer Concrete with the Addition of Macro Fibres. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2014. [Google Scholar]

- Behfarnia, K.; Shojaci, M.; Mohebi, R. Compressive strength and flexural strength of alkali-activated slag concrete designed by Taguchi method. Asian J. Civ. Eng. 2015, 4, 505–513. [Google Scholar]

- Bernal, S.A.; De Gutiérrez, R.M.; Provis, J.L. Engineering and durability properties of concretes based on alkali-activated granulated blast furnace slag/metakaolin blends. Constr. Build. Mater. 2012, 33, 99–108. [Google Scholar] [CrossRef]

- Chi, M. Effects of dosage of alkali-activated solution and curing conditions on the properties and durability of alkali-activated slag concrete. Constr. Build. Mater. 2012, 35, 240–245. [Google Scholar] [CrossRef]

- Deb, P.S. Durability of Fly Ash Based Geopolymer Concrete. Master’s Thesis, Curtin University, Perth, Australia, 2013. [Google Scholar]

- Hadi, M.N.; Zhang, H.; Parkinson, S. Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J. Build. Eng. 2019, 23, 301–313. [Google Scholar] [CrossRef]

- Jawahar, J.G.; Mounika, G. Strength properties of fly ash and GGBS based geopolymer concrete. Asian J. Civ. Eng. 2016, 17, 127–135. [Google Scholar]

- Kar, A.; Halabe, U.B.; Ray, I.; Unnikrishnan, A. Nondestructive characterizations of alkali activated fly ash and/or slag concrete. Eur. Sci. J. 2013, 9, 52–74. [Google Scholar]

- Kusbiantoro, A.; Nuruddin, M.F.; Shafiq, N.; Qazi, S.A. The effect of microwave incinerated rice husk ash on the compressive and bond strength of fly ash based geopolymer concrete. Constr. Build. Mater. 2012, 36, 695–703. [Google Scholar] [CrossRef]

- Lavanya, G.; Jegan, J. Evaluation of relationship between split tensile strength and compressive strength for geopolymer concrete of varying grades and molarity. Int. J. Appl. Eng. Res. 2015, 10, 35523–35527. [Google Scholar]

- Lee, N.K.; Lee, H.K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- Mallikarjuna Rao, G.; Gunneswara Rao, T.D. A quantitative method of approach in designing the mix proportions of fly ash and GGBS-based geopolymer concrete. Aust. J. Civ. Eng. 2018, 16, 53–63. [Google Scholar] [CrossRef]

- Muthadhi, A.; Vanjinathan, J.; Durai, D. Experimental investigations on geo polymer concrete based on class C fly ash. Indian J. Sci. Technol. 2016, 9, 1–5. [Google Scholar] [CrossRef][Green Version]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Uy, B.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016, 73, 136–146. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- Parthiban, K.; Saravanarajamohan, K.; Shobana, S.; Bhaskar, A.A. Effect of replacement of slag on the mechanical properties of fly ash based geopolymer concrete. Int. J. Eng. Technol. 2013, 5, 2555–2559. [Google Scholar]

- Phoo-Ngernkham, T.; Phiangphimai, C.; Damrongwiriyanupap, N.; Hanjitsuwan, S.; Thumrongvut, J.; Chindaprasirt, P. A mix design procedure for alkali-activated high-calcium fly ash concrete cured at ambient temperature. Adv. Mater. Sci. Eng. 2018, 2018, 2460403. [Google Scholar] [CrossRef]

- Rafeet, A.; Vinai, R.; Soutsos, M.; Sha, W. Guidelines for mix proportioning of fly ash/GGBS based alkali activated concretes. Constr. Build. Mater. 2017, 147, 130–142. [Google Scholar] [CrossRef]

- Kumar, S. Development and determination of mechanical properties of fly ash and slag blended geopolymer concrete. Int. J. Sci. Eng. Res. 2013, 4. Available online: https://www.ijser.org/researchpaper/Development-and-Determination-of-Mechanical-properties-of-fly-ash-and-slag-blended-geo-polymer-concrete.pdf (accessed on 10 December 2024).

- Topark-Ngarm, P.; Chindaprasirt, P.; Sata, V. Setting time, strength, and bond of high-calcium fly ash geopolymer concrete. J. Mater. Civ. Eng. 2015, 27, 04014198. [Google Scholar] [CrossRef]

- Vignesh, P.; Vivek, K. An experimental investigation on strength parameters of flyash based geopolymer concrete with GGBS. Int. Res. J. Eng. Technol. 2015, 2, 135–142. [Google Scholar]

- Vinai, R.; Rafeet, A.; Soutsos, M.; Sha, W. The role of water content and paste proportion on physico-mechanical properties of alkali activated fly ash–ggbs concrete. J. Sustain. Metall. 2016, 2, 51–61. [Google Scholar] [CrossRef]

- Wardhono, A.; Gunasekara, C.; Law, D.W.; Setunge, S. Comparison of long term performance between alkali activated slag and fly ash geopolymer concretes. Constr. Build. Mater. 2017, 143, 272–279. [Google Scholar] [CrossRef]

- Xie, T.; Ozbakkaloglu, T. Behavior of low-calcium fly and bottom ash-based geopolymer concrete cured at ambient temperature. Ceram. Int. 2015, 41, 5945–5958. [Google Scholar] [CrossRef]

- Hongen, Z.; Feng, J.; Qingyuan, W.; Ling, T.; Xiaoshuang, S. Influence of Cement on Properties of Fly-Ash-Based Concrete. ACI Mater. J. 2017, 114, 745–753. [Google Scholar] [CrossRef]

- Hongen, Z.; Ling, T.; Xiaoshuang, S.; Wang, Q. Influence of curing condition on compressive strength of low-calcium y ash-based geopolymer concrete. J. Residuals Sci. Technol. 2017, 14, 1544. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Xie, T.; Visintin, P.; Zhao, X.; Gravina, R. Mix design and mechanical properties of geopolymer and alkali activated concrete: Review of the state-of-the-art and the development of a new unified approach. Constr. Build. Mater. 2020, 256, 119380. [Google Scholar] [CrossRef]

- Ding, Y.; Shi, C.J.; Li, N. Fracture properties of slag/fly ash-based geopolymer concrete cured in ambient temperature. Constr. Build. Mater. 2018, 190, 787–795. [Google Scholar] [CrossRef]

- Yang, K.H.; Song, J.K.; Song, K.I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. One part alkali activated materials: A state-of-the-art review. J. Build. Eng. 2022, 57, 104871. [Google Scholar] [CrossRef]

- EN 1992-1-1:2023; Eurocode 2. Design of Concrete Structures. General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. European Committee for Standardisation: Brussels, Belgium, 2023.

- Li, C.; Jiang, L.; Li, S. Effect of limestone powder addition on threshold chloride concentration for steel corrosion in reinforced concrete. Cem. Concr. Res. 2020, 131, 106018. [Google Scholar] [CrossRef]

- Sun, B.; Ye, G.; De Schutter, G. A review: Reaction mechanism and strength of slag and fly ash-based alkali-activated materials. Constr. Build. Mater. 2022, 326, 126843. [Google Scholar] [CrossRef]

- Rao, A.K.; Kumar, D.R. Effect of various alkaline binder ratio on geopolymer concrete under ambient curing condition. Mater. Today Proc. 2020, 27, 1768–1773. [Google Scholar]

- Ouellet-Plamondon, C.; Habert, G. Life cycle assessment (LCA) of alkali-activated cements and concretes. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Woodhead Publishing: Sawston, UK, 2015; pp. 663–686. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Visintin, P.; Xie, T.; Bennett, B. A large-scale life-cycle assessment of recycled aggregate concrete: The influence of functional unit, emissions allocation and carbon dioxide uptake. J. Clean. Prod. 2020, 248, 119243. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Butera, A.; Hao, J.L.; Wang, J. Effects of mix design and functional unit on life cycle assessment of recycled aggregate concrete: Evidence from CO2 concrete. Constr. Build. Mater. 2022, 348, 128712. [Google Scholar] [CrossRef]

- Ma, C.; Long, G.; Shi, Y.; Xie, Y. Preparation of cleaner one-part geopolymer by investigating different types of commercial sodium metasilicate in China. J. Clean. Prod. 2018, 201, 636–647. [Google Scholar] [CrossRef]

- Panesar, D.K. Supplementary cementing materials. In Developments in the Formulation and Reinforcement of Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 55–85. [Google Scholar]

- Hammond, G.; Jones, C.; Lowrie, E.F.; Tse, P. Embodied carbon. In The Inventory of Carbon and Energy (ICE); Version (2.0); Building Services Research & Information Association: Berkshire, UK, 2011. [Google Scholar]

- Guo, S.; Ma, C.; Long, G.; Xie, Y. Cleaner one-part geopolymer prepared by introducing fly ash sinking spherical beads: Properties and geopolymerization mechanism. J. Clean. Prod. 2019, 219, 686–697. [Google Scholar] [CrossRef]

- Black, L. Low clinker cement as a sustainable construction material. Sustain. Constr. Mater. 2016, 415–457. In Sustainability of Construction Materials, 2nd ed.; Woodhead Publishing Series in Civil and Structural Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 415–457. [Google Scholar] [CrossRef]

- Wang, X. CO2 and Cost-Based Optimum Design of Sustainable Metakaolin-Modified Concrete. J. Renew. Mater. 2022, 10, 2431–2450. [Google Scholar] [CrossRef]

- Setiawan, A.A.; Hardjasaputra, H.; Soegiarso, R. Embodied carbon dioxide of fly ash based geopolymer concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2023; Volume 1195. [Google Scholar]

- IPCC. ipcc-nggi. 1996. Available online: https://www.ipcc-nggip.iges.or.jp/public/gl/guidelin/ch2ref2.pdf (accessed on 5 June 2024).

- European Federation of Concrete Admixture Associations. Environmental Declaration Superplasticizing Admixtures—2002, EFCA. Available online: http://www.efca.info/admixtures/environmental-and-sustainability-aspects/environmental-product-declarations-epd/ (accessed on 10 December 2024).

- Ferroglobe Silica Fume. An Environmental Product Declaration. ASTM International. 2024. Available online: https://pcr-epd.s3.us-east-2.amazonaws.com/1107.EPD_Ferroglobe_Silica_Fume.pdf (accessed on 10 December 2024).

- Bundesförderung für Energie- und Ressourceneffizienz in der Wirtschaft—Zuschuss. Informationsblatt CO2-Faktoren. 2023. Available online: https://www.bafa.de/SharedDocs/Downloads/DE/Energie/eew_infoblatt_co2_faktoren_2023.pdf?__blob=publicationFile&v=5 (accessed on 10 December 2024).

- Richardson, S.; Hyde, K.; Connaughton, J. Uncertainty assessment of comparative design stage embodied carbon assessments. In Embodied Carbon in Buildings; Pomponi, F., De Wolf, C., Moncaster, A., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Keyhani, M.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P. Discrepancy in Embodied Carbon Calculations for Concrete Materials. In Proceedings of the Euro-Mediterranean Conference for Environmental Integration (EMCEI-23), Cosenza, Italy, 2–5 October 2023. [Google Scholar]

- Pomponi, F.; Moncaster, A. Scrutinising embodied carbon in buildings: The next performance gap made manifest. Renew. Sustain. Energy Rev. 2018, 81, 2431–2442. [Google Scholar] [CrossRef]

- DeRousseau, M.A.; Arehart, J.H.; Kasprzyk, J.R.; Srubar, W.V., III. Statistical variation in the embodied carbon of concrete mixtures. J. Clean. Prod. 2020, 275, 123088. [Google Scholar] [CrossRef]

- Pomponi, F.; D’Amico, B.; Moncaster, A.M. A method to facilitate uncertainty analysis in LCAs of buildings. Energies 2017, 10, 524. [Google Scholar] [CrossRef]

- Vafaei, N.; Ribeiro, R.A.; Camarinha-Matos, L.M. Normalization techniques for multi-criteria decision making analytical hierarchy process case study. In Technological Innovation for Cyber-Physical Systems, Proceedings of the 7th IFIP WG 5.5/SOCOLNET Advanced Doctoral Conference on Computing, Electrical and Industrial Systems, DoCEIS 2016, Costa de Caparica, Portugal, 11–13 April 2016; Proceedings 7; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 261–269. [Google Scholar]

- Frattini, D.; Occhicone, A.; Ferone, C.; Cioffi, R. Fibre-reinforced geopolymer concretes for sensible heat thermal energy storage: Simulations and environmental impact. Materials 2021, 14, 414. [Google Scholar] [CrossRef] [PubMed]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Jiang, M.; Chen, X.; Rajabipour, F.; Hendrickson, C.T. Comparative life cycle assessment of conventional, glass powder, and alkali-activated slag concrete and mortar. J. Infrastruct. Syst. 2014, 20, 04014020. [Google Scholar] [CrossRef]

- Hammad, N.; El-Nemr, A.; Hasan, H.E.D. The performance of fiber GGBS based alkali-activated concrete. J. Build. Eng. 2021, 42, 102464. [Google Scholar] [CrossRef]

- Hammad, N.; ElNemr, A.M.; Hassan, H.E.D. Flexural performance of reinforced Alkali-activated concrete beams incorporating steel and structural Macro synthetic polypropylene fiber. Constr. Build. Mater. 2022, 324, 126634. [Google Scholar] [CrossRef]

- Van Deventer, J.S.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Atabey, İ.İ.; Karahan, O.; Bilim, C.; Atiş, C.D. The influence of activator type and quantity on the transport properties of class F fly ash geopolymer. Constr. Build. Mater. 2020, 264, 120268. [Google Scholar] [CrossRef]

- Ove Arup &; Partners Limited. Embodied Carbon Classification Scheme for Concrete. Arup. Online. 2023. Available online: https://www.arup.com/globalassets/downloads/insights/e/embodied-carbon-classification-scheme-for-concrete/embodied-carbon-classification-scheme-for-concrete-report.pdf (accessed on 10 December 2024).

- Circular Ecology. ICE Database v3. 2024. Available online: https://circularecology.com/news/ice-database-v3-launched (accessed on 10 December 2024).

- Institution of Civil Engineers. Low Carbon Concrete Routemap—Setting the Agenda for a Path to Net Zero. 2023. Available online: https://www.ice.org.uk/media/q12jkljj/low-carbon-concrete-routemap.pdf (accessed on 10 December 2024).

- OneClick LCA. LCA CEM I. 2023. Available online: https://oneclicklca.com (accessed on 10 December 2024).

- Thilakarathna, P.S.M.; Seo, S.; Baduge, K.K.; Lee, H.; Mendis, P.; Foliente, G. Embodied carbon analysis and benchmarking emissions of high and ultra-high strength concrete using machine learning algorithms. J. Clean. Prod. 2020, 262, 121281. [Google Scholar] [CrossRef]

- Xu, L.; Wang, X.; Guan, C.; Wu, W.; Zhang, L. The Effect of Activators on the Mechanical Properties and Microstructure of Alkali-Activated Nickel Slag. Adv. Civ. Eng. 2020, 2020, 1764108. [Google Scholar] [CrossRef]

- Wang, X.; Wu, W.; Zhang, L.; Fu, L.; Li, X. Preparation of one-part alkali-activated nickel slag binder using an optimal ball milling process. Constr. Build. Mater. 2022, 322, 125902. [Google Scholar] [CrossRef]

- Gluth, G.J.G.; Lehmann, C.; Rübner, K.; Kühne, H.C. Geopolymerization of a silica residue from waste treatment of chlorosilane production. Mater. Struct. 2013, 46, 1291–1298. [Google Scholar] [CrossRef]

- Li, L.; Lu, J.X.; Zhang, B.; Poon, C.S. Rheology behavior of one-part alkali activated slag/glass powder (AASG) pastes. Constr. Build. Mater. 2020, 258, 120381. [Google Scholar] [CrossRef]

- Ye, N.; Chen, Y.; Yang, J.; Liang, S.; Hu, Y.; Xiao, B.; Huang, Q.; Shi, Y.; Hu, J.; Wu, X. Co-disposal of MSWI fly ash and Bayer red mud using an one-part geopolymeric system. J. Hazard. Mater. 2016, 318, 70–78. [Google Scholar] [CrossRef]

- Almalkawi, A.T.; Hamadna, S.; Soroushian, P. One-part alkali activated cement based volcanic pumice. Constr. Build. Mater. 2017, 152, 367–374. [Google Scholar] [CrossRef]

- Kadhim, A.; Sadique, M.; Al-Mufti, R.; Hashim, K. Long-term performance of novel high-calcium one-part alkali-activated cement developed from thermally activated lime kiln dust. J. Build. Eng. 2020, 32, 101766. [Google Scholar] [CrossRef]

- Çetintaş, R.; Soyer-Uzun, S. Relations between structural characteristics and compressive strength in volcanic ash based one–part geopolymer systems. J. Build. Eng. 2018, 20, 130–136. [Google Scholar] [CrossRef]

- Liew, Y.M.; Heah, C.Y.; Li, L.Y.; Jaya, N.A.; Abdullah, M.M.A.B.; Tan, S.J.; Hussin, K. Formation of one-part-mixing geopolymers and geopolymer ceramics from geopolymer powder. Constr. Build. Mater. 2017, 156, 9–18. [Google Scholar] [CrossRef]

- Luo, Y.; Bao, S.; Zhang, Y. Preparation of one-part geopolymeric precursors using vanadium tailing by thermal activation. J. Am. Ceram. Soc. 2020, 103, 779–783. [Google Scholar] [CrossRef]

- Chen, W.; Peng, R.; Straub, C.; Yuan, B. Promoting the performance of one-part alkali-activated slag using fine lead-zinc mine tailings. Constr. Build. Mater. 2020, 236, 117745. [Google Scholar] [CrossRef]

| Materials (kg/m3) | Carbon Factors (kgCO2eq/kg) | Reference |

|---|---|---|

| Ca(OH)2 | 0.76 | [103] |

| Na2SiO3 | 1.514 | [102] |

| NaOH | 0.68 | [103] |

| Superplasticiser | 2.388 | [104] |

| Micro silica | 0.028 | [105] |

| Borax | 1.520 | [106] |

| OPC | 0.912 | [98] |

| GGBS | 0.0416 | [98] |

| FA | 0.004 | [98] |

| MK | 0.40 | [101] |

| Water | 0.000344 | [98] |

| Coarse Aggregates | 0.01577 | [98] |

| Fine Aggregates | 0.00747 | [98] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almonayea, N.; Garcia-Troncoso, N.; Xu, B.; Bompa, D.V. Probabilistic Embodied Carbon Assessments for Alkali-Activated Concrete Materials. Sustainability 2025, 17, 152. https://doi.org/10.3390/su17010152

Almonayea N, Garcia-Troncoso N, Xu B, Bompa DV. Probabilistic Embodied Carbon Assessments for Alkali-Activated Concrete Materials. Sustainability. 2025; 17(1):152. https://doi.org/10.3390/su17010152

Chicago/Turabian StyleAlmonayea, Nouf, Natividad Garcia-Troncoso, Bowen Xu, and Dan V. Bompa. 2025. "Probabilistic Embodied Carbon Assessments for Alkali-Activated Concrete Materials" Sustainability 17, no. 1: 152. https://doi.org/10.3390/su17010152

APA StyleAlmonayea, N., Garcia-Troncoso, N., Xu, B., & Bompa, D. V. (2025). Probabilistic Embodied Carbon Assessments for Alkali-Activated Concrete Materials. Sustainability, 17(1), 152. https://doi.org/10.3390/su17010152