A Review of the Biomass Valorization Hierarchy

Abstract

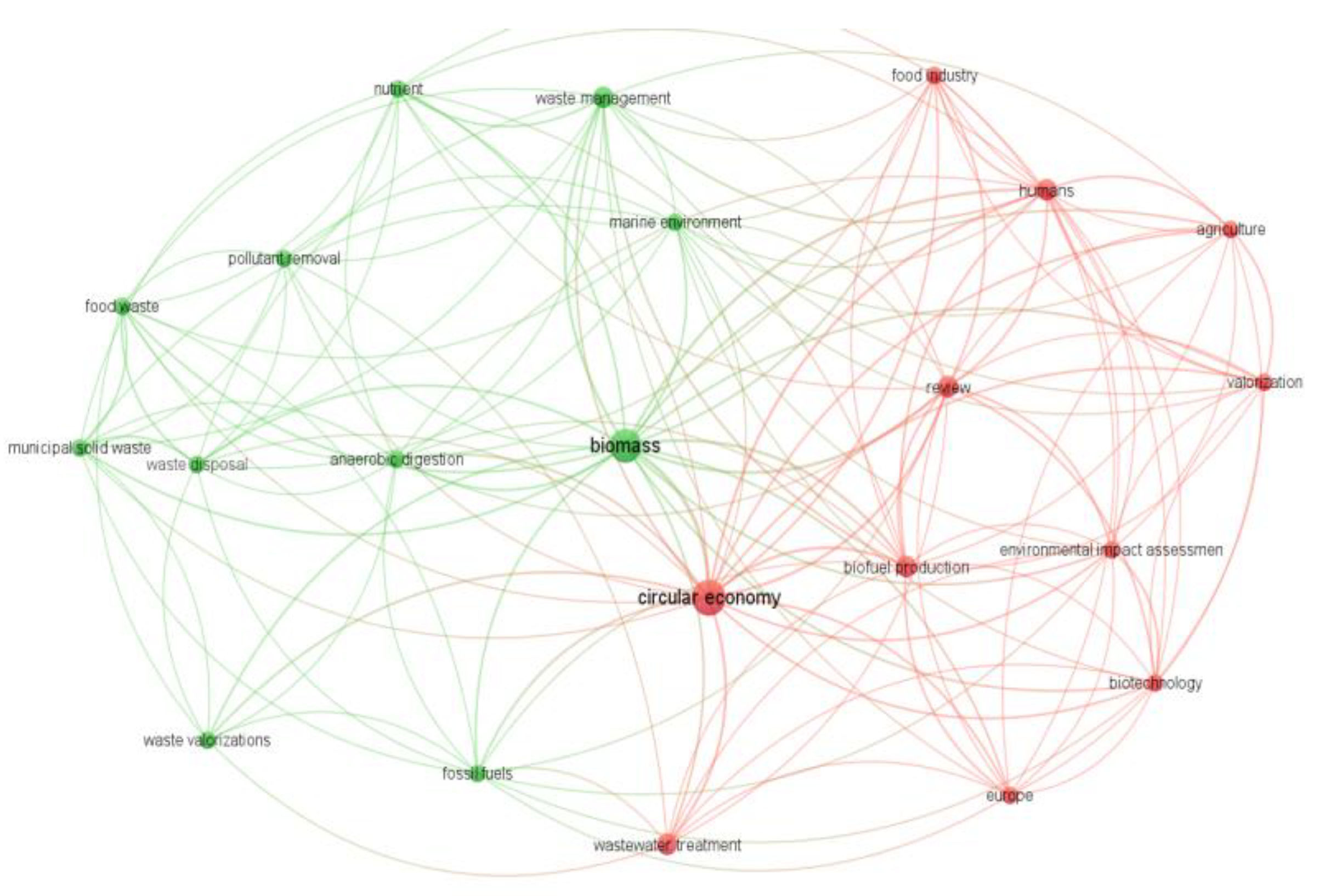

:1. Introduction

2. Extraction of Valuable Products from Biomass

3. Agricultural and Food Waste as Animal Feeding Product Sources

| Agricultural Waste | Application | Reference |

|---|---|---|

| olive cake | replacing beef cattle | [41] |

| fruit pomaces | broiler feed | [42] |

| grape marc and tomato pomace | feed dairy ewes | [43] |

| olive cake | Holstein dairy cattle | [44] |

| olive cake | deed cattle | [13] |

| cassava peels, cereal-grain waste | feed pigs, ducks, cattle | [45] |

| list of agricultural waste | micro protein for animal feed | [46] |

| list of agro-industrial waste | plethora of useful value-added bio-products | [40] |

4. Biological Conversion of Biomass

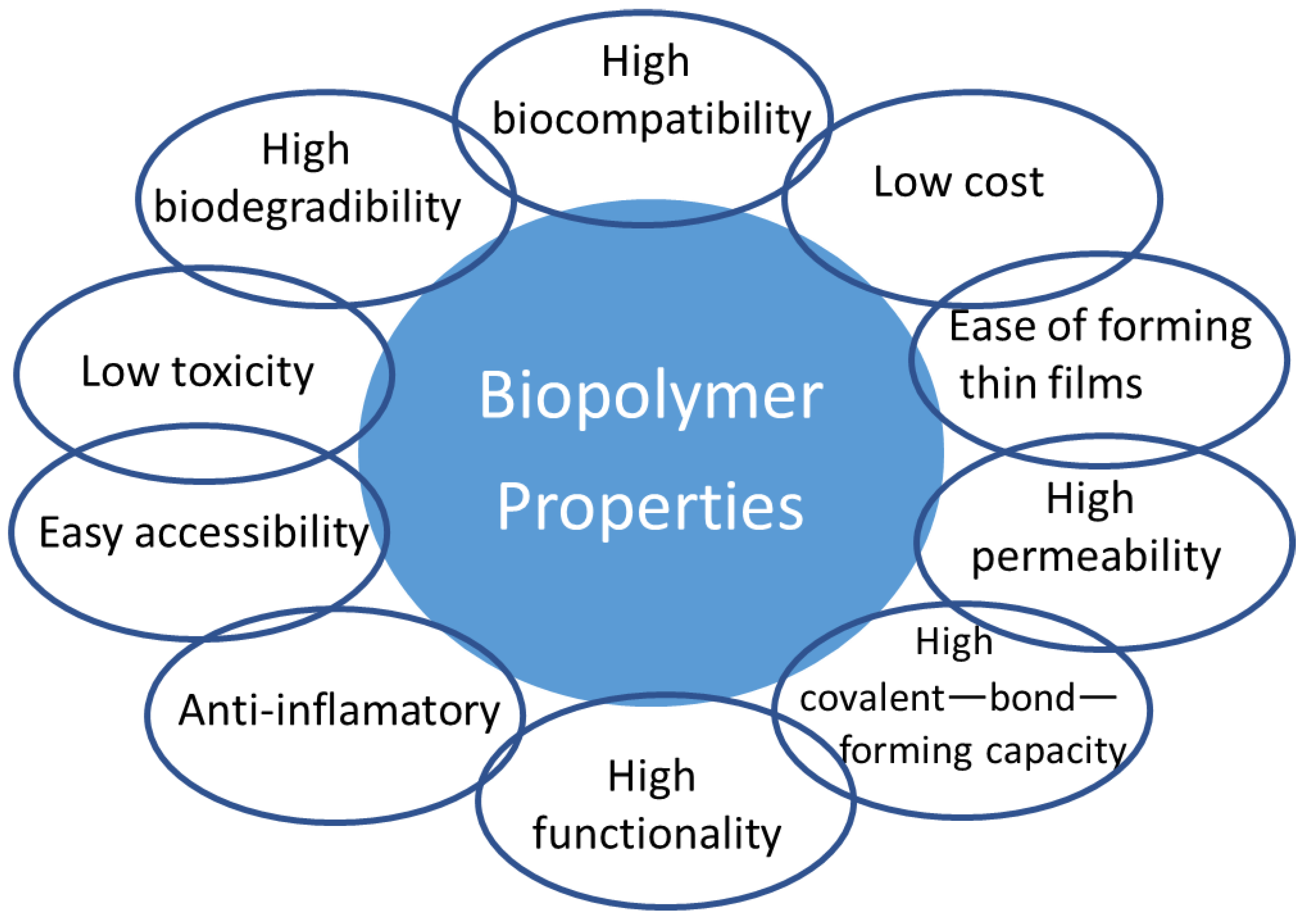

5. Conversion of Biomass and Biomass Waste into Biopolymers

6. Biomass Applied as Green Construction Materials

7. Thermochemical Conversion of Biomass into Combustibles

7.1. Torrefaction

7.2. Liquefaction

7.3. Pyrolysis

7.4. Gasification

7.5. Combustion

| Solid Waste | Process | Reference |

|---|---|---|

| olive tree waste | torrefactions | [92] |

| sorghum straw | torrefactions | [93] |

| pinewood sawdust | torrefactions | [94] |

| pequi fruit seeds | torrefactions | [95] |

| pine wood chips | gasification | [96] |

| solid waste and hazardous waste | gasification | [97] |

| rice straw | gasification | [98] |

| vineyard, tomato plant residues, canary pine needles, and pennisetum setaceum | gasification | [99] |

| biomass (e.g., agricultural, woody biomass waste) | gasification | [100] |

| algal biomass (microalgae) | liquefaction | [101] |

| Jatropha curcas seed | liquefaction | [102] |

| domestic sewage from ponds | liquefaction | [103] |

| pine wood shavings | liquefaction | [104] |

| citrus limetta or sweet lime | liquefaction | [105] |

| sugarcane leaves and tops | pyrolysis | [106] |

| waste biomass from coffee | pyrolysis | [107] |

| pinyon wood chips | pyrolysis | [108] |

| beech, poplar, spruce, and wheat straw | pyrolysis | [109] |

| rice husk | pyrolysis | [110] |

| winemaking industry wastes | combustion | [111] |

| tobacco | combustion | [112] |

| dairy waste | combustion | [113] |

8. Biomass Converted into Adsorbent Materials

8.1. Waste Biomass Applications Without Any Treatment

8.2. Biochar Production

8.2.1. Biochar Production Through Pyrolysis

8.2.2. Biochar Production Through Hydrothermal Processes

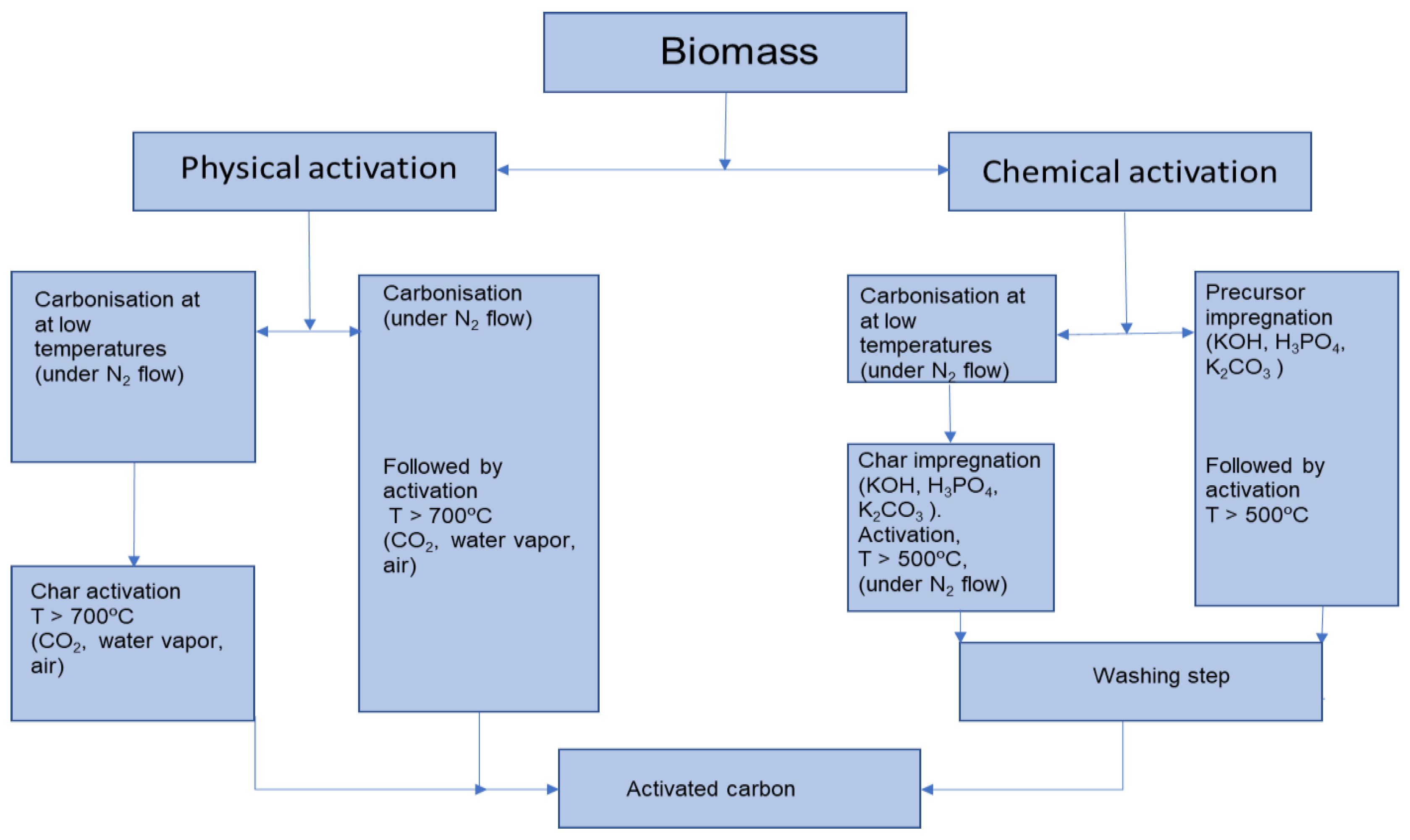

8.3. Activated Carbon Production

9. Composting Product

10. Conclusions and Future Perspectives

- (1)

- The first process recommended is feeding people. However, it should be noted that food safety must be safeguarded if excess food is directed to feed people. Following the hierarchy proposed to valorize biomass waste, mainly food waste, is sometimes not profitable. Also, some researchers have concluded that following the proposed hierarchy for the valuation of food waste does not always allow a reduction in environmental impacts.

- (2)

- Feeding animals is a way to valorize biomass waste. Unpredictability in the nutritional content and availability of some food and agrowaste was mentioned as one of the limitations in their incorporation into animal diets. In reality, the costs of implementing nobler recovery processes direct food waste to applications with lower added value or lower prioritization.

- (3)

- Although some disposal methods are convenient, such as the use of biomass as fertilizer, they have environmental and economic costs. Biomass with a high cellulose content and fabric-forming ability is a suitable raw material for preparing cellulose-based products instead of being used as a fertilizer or being incinerated. Biomass with a high content of hemicellulose is more easy to biodegrade than cellulose. Finally, biomass with a high content of lignin, which is a crosslinked aromatic polymer, is the main challenge in lignocellulosic biomass valorization. Therefore, plant trunks are more difficult to biodegrade than other types of common straw. However, biomass containing a high amount of lignin can be used for biorefinery purposes [162].

- (4)

- When compared to other techniques like incineration, thermal treatment, and microbiological fermentation, thermochemical valorization is recommended mainly if biomass resources come from a variety of sources and types. However, biomass and biomass wastes present some disadvantages when compared to fossil fuels, such as low energy density, high collection costs, presence of alkali metals, and relatively high nitrogen content [163].

- (5)

- By employing biomass waste as a precursor to produce biochar and activated carbons, which can be successfully used as adsorbents in water and wastewater treatment, three different worries of solid and liquid waste valorization could be solved. When green technologies are adopted, AC costs are reduced, and liquid effluents can be treated and reused.

- (6)

- A hierarchy to value biomass and biomass wastes is included in Figure 3. However, a more all-encompassing approach is necessary to value these wastes, which includes collaboration between different interdisciplinary players (scientists, social entities, industrial representatives, consumers, and policymakers).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive (EU) 2018/851 of the European Parliament and of the Council, of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA relevance). Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj/eng (accessed on 2 April 2024).

- Council Directive 1999/31/EC, of 26 April 1999, on the Landfill of Waste. Official Journal L 182, 16/07/1999 P. 0001-0019. (EUR-Lex-31999L0031-EN (europa.eu)). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A31999L0031 (accessed on 2 April 2024).

- Han, B.; Weatherley, A.J.; Mumford, K.; Bolan, N.; He, J.-Z.; Stevens, G.W.; Chen, D. Modification of naturally abundant resources for remediation of potentially toxic elements: A review. J. Hazard Mater. 2022, 421, 126755. [Google Scholar] [CrossRef] [PubMed]

- Chin, J.Y.; Chng, L.M.; Leong, S.S.; Yeap, S.P.; Yasin, N.H.M.; Toh, P.Y. Removal of synthetic dye by Chlorella vulgaris Microalgae as natural adsorbent. Arab. J. Sci. Eng. 2020, 45, 7385–7395. [Google Scholar] [CrossRef]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Mujtaba, M.; Fraceto, L.F.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; de Medeiros, G.A.; Pereira, A.D.E.S.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic biomass from agricultural waste to the circular economy: A review with focus on biofuels, biocomposites and bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Rehman, A.; Nazir, G.; Heo, K.; Hussain, S.; Ikram, M.; Akhter, Z.; Algaradah, M.M.; Mahmood, Q.; Fouda, A.M. A focused review on lignocellulosic biomass-derived porous carbons for effective pharmaceuticals removal: Current trends, challenges and future prospects. Sep. Purif. Technol. 2024, 330, 125356. [Google Scholar] [CrossRef]

- Ferreira, S.; Monteiro, E.; Brito, P.; Vilarinho, C. Biomass resources in Portugal: Current status and prospects. Renew. Sustain. Energy Rev. 2017, 78, 1221–1235. [Google Scholar] [CrossRef]

- Karić, N.; Maia, A.S.; Teodorović, A.; Atanasova, N.; Langergraber, G.; Crini, G.; Ribeiro, A.R.; Đolić, M. Bio-waste valorisation: Agricultural wastes as biosorbents for removal of (in)organic pollutants in wastewater treatment. Chem. Eng. J. Adv. 2022, 9, 100239. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Food Waste Index Report 2024. Think Eat Save: Tracking Progress to Halve Global Food Waste. Available online: https://wedocs.unep.org/20.500.11822/45230 (accessed on 3 May 2024).

- Food waste—European Food Banks Federation—FEBA (eurofoodbank.org). Available online: https://www.eurofoodbank.org/our-mission-impact-values/food-waste/ (accessed on 3 May 2024).

- Chataut, G.; Bhatta, B.; Joshi, D.; Subedi, K.; Kafle, K. Greenhouse gases emission from agricultural soil: A review. J. Agric. Food Res. 2023, 11, 100533. [Google Scholar] [CrossRef]

- Kumar, A.; Mishra, R.; Verma, K.; Aldosari, S.; Maity, C.; Verma, S.; Patel, R.; Thakur, V. A comprehensive review of various biopolymer composites and their applications: From biocompatibility to self-healing. Mater. Today Sustain. 2023, 23, 100431. [Google Scholar] [CrossRef]

- Arodudu, O.; Holmatov, B.; Voinov, A. Ecological impacts and limits of biomass use: A critical review. Clean Technol. Environ. Policy 2020, 22, 1591–1611. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Purkait, S.; Bag, A.; Chattopadhyay, R.R. Evaluation of antimicrobial and antioxidant efficacy of hydro ethanol extract of peels of Kufri Chandramukhi, Kufri Chipsona-3, and Kufri Jyoti potato varieties alone and in combination. J. Food Saf. 2021, 41, e12901. [Google Scholar] [CrossRef]

- Parsa, A.; Van De Wiel, M.; Schmutz, U.; Fried, J.; Black, D.; Roderick, I. Challenging the food waste hierarchy. J. Environ. Manag. 2023, 344, 118554. [Google Scholar] [CrossRef] [PubMed]

- Muscat, A.; de Olde, E.; de Boer, I.; Ripoll-Bosch, R. The battle for biomass: A systematic review of food-feed-fuel competition. Glob. Food Secur. 2020, 25, 100330. [Google Scholar] [CrossRef]

- Fritsch, C.; Staebler, A.; Happel, A.; Cubero Márquez, M.A.; Aguiló-Aguayo, I.; Abadias, M.; Gallur, M.; Cigognini, I.M.; Montanari, A.; López, M.J.; et al. Processing, Valorization and Application of Bio-Waste Derived Compounds from Potato, Tomato, Olive and Cereals: A Review. Sustainability 2017, 9, 1492. [Google Scholar] [CrossRef]

- Awad, A.M.; Kumar, P.; Ismail-Fitry, M.R.; Jusoh, S.; Ab Aziz, M.F.; Sazili, A.Q.; Awad, A.M.; Kumar, P.; Ismail-Fitry, M.R.; Jusoh, S.; et al. Green extraction of bioactive compounds from plant biomass and their application in meat as natural antioxidant. Antioxidants 2021, 10, 1465. [Google Scholar] [CrossRef]

- Mahari, W.A.W.; Waiho, K.; Fazhan, H.; Necibi, M.C.; Hafsa, J.; Ben Mrid, R.; Fal, S.; El Arroussi, H.; Peng, W.; Tabatabaei, M.; et al. Progress in valorisation of agriculture, aquaculture and shellfish biomass into biochemicals and biomaterials towards sustainable bioeconomy. Chemosphere 2022, 291, 133036. [Google Scholar] [CrossRef]

- Castanheiro, J.E. Valorization of Limonene over acid solid catalysts. Essent. Oils Extr. Methods Appl. 2023, 8, 173–183. [Google Scholar]

- Nath, P.C.; Ojha, A.; Debnath, S.; Sharma, M.; Nayak, P.K.; Sridhar, K.; Inbaraj, B.S. Valorization of food waste as animal feed: A step towards sustainable food waste management and circular bioeconomy. Animals 2023, 13, 1366. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.M.; Mohamed, A.; Sahena, F.; Jahurul, M.H.A.; Ghafoor, K.; Norulaini, N.A.N.; Omar, A.K.M. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436. [Google Scholar] [CrossRef]

- Nakhle, L.; Kfoury, M.; Mallard, I.; Landy, D.; Greige-Gerges, H. Methods for extraction of bioactive compounds from plant and animal matter using deep eutectic solvents. In Deep Eutectic Solvents for Medicine, Gas Solubilization and Extraction of Natural Substances; Fourmentin, S., Costa Gomes, M., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Martins, R.; Barbosa, A.; Advinha, B.; Sales, H.; Pontes, R.; Nunes, J. Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes 2023, 11, 2255. [Google Scholar] [CrossRef]

- Kaoui, S.; Chebli, B.; Zaidouni, S.; Basaid, K.; Mir, Y. Deep eutectic solvents as sustainable extraction media for plants and food samples: A review. Sustain. Chem. Pharm. 2023, 31, 100937. [Google Scholar] [CrossRef]

- Usman, M.; Nakagawa, M.; Cheng, S. Emerging trends in green extraction techniques for bioactive natural products. Processes 2023, 11, 3444. [Google Scholar] [CrossRef]

- Teodoro, A.J. Bioactive Compounds of Food: Their Role in the Prevention and Treatment of Diseases. Oxidative Med. Cell Longev. 2019, 11, 3765968. [Google Scholar] [CrossRef]

- Roda, A.; Lucini, L.; Torchio, F.; Dordoni, R.; De Faveri, D.M.; Lambri, M. Metabolite profiling and volatiles of pineapple wine and vinegar obtained from pineapple waste. Food Chem. 2017, 229, 734–742. [Google Scholar] [CrossRef]

- Castanheiro, J.E. Acetoxylation of alpha-pinene over activated carbons. In Advances in Chemistry Research; Taylor, J.C., Ed.; Nova Science Pub. Inc.: New York, NY, USA, 2020; Volume 65, pp. 251–262. ISBN 978-1-53618-711-3. [Google Scholar]

- Mehri, D.; Perendeci, N.A.; Goksungur, Y. Utilization of whey for red pigment production by Monascus purpureus in submerged fermentation. Fermentation 2021, 7, 75. [Google Scholar] [CrossRef]

- Ozturk, B.; Winterburn, J.; Gonzalez-Miquel, M. Orange peel waste valorisation through limonene extraction using bio-based solvents. Biochem. Eng. J. 2019, 151, 107298. [Google Scholar] [CrossRef]

- Paredes-Laverde, M.; Silva-Agredo, J.; Torres-Palma, R.A. Removal of norfloxacin in deionized, municipal water and urine using rice (Oryza sativa) and coffee (Coffea arabica) husk wastes as natural adsorbents. J. Environ. Manag. 2018, 213, 98–108. [Google Scholar] [CrossRef]

- Hikal, W.M.; Mahmoud, A.A.; Said-Al Ahl, H.A.H.; Bratovcic, A.; Tkachenko, K.G.; Kaˇc´aniov´a, M.; Rodriguez, R.M. Pineapple (Ananas comosus L. Merr.), waste streams, characterisation and valorisation: An Overview. Open J. Ecol. 2021, 11, 610–634. [Google Scholar] [CrossRef]

- Roman-Benn, A.; Contador, C.A.; Li, M.-W.; Lam, H.-M.; Ah-Hen, K.; Ulloa, P.E.; Ravanal, M.C. Pectin: An overview of sources, extraction and applications in food products, biomedical, pharmaceutical and environmental issues. Food Chem. Adv. 2023, 2, 100192. [Google Scholar] [CrossRef]

- Ritala, A.; Häkkinen, S.T.; Toivari, M.; Wiebe, M.G. Single cell protein—State-of-the-art, industrial landscape and patents 2001–2016. Front. Microbiol. 2017, 8, 2009. [Google Scholar] [CrossRef]

- Hasan, Z.; Lateef, M. Transforming food waste into animal feeds: An in-depth overview of conversion technologies and environmental benefits. Environ. Sci. Pollut. Res. 2024, 31, 17951–17963. [Google Scholar] [CrossRef] [PubMed]

- McBride, M. Agricultural and Environmental Metrics, Turning Food Waste into Feed: Benefits and Trade-Offs for Nature. 2021. Available online: https://www.worldwildlife.org/blogs/sustainability-works/posts/turning-food-waste-into-feed-benefits-and-trade-offs-for-nature (accessed on 3 May 2024).

- Phiri, R.; Rangappa, S.M.; Siengchin, S. Agro-waste for renewable and sustainable green production: A review. J. Clean. Prod. 2024, 434, 139989. [Google Scholar] [CrossRef]

- Yafetto, L.; Odamtten, G.T.; Wiafe-Kwagyan, M. Valorization of agro-industrial wastes into animal feed through microbial fermentation: A review of the global and Ghanaian case. Heliyon 2023, 9, e14814. [Google Scholar] [CrossRef] [PubMed]

- Chiofalo, V.; Liotta, L.; Presti, V.L.; Gresta, F.; Di Rosa, A.R.; Chiofalo, B. Effect of dietary olive cake supplementation on performance, carcass characteristics, and meat quality of beef cattle. Animals 2020, 10, 1176. [Google Scholar] [CrossRef] [PubMed]

- Erinle, T.J.; Adewole, D.I. Fruit pomaces—Their nutrient and bioactive components, effects on growth and health of poultry species, and possible optimization techniques. Anim. Nutr. 2022, 9, 357–377. [Google Scholar] [CrossRef]

- Buffa, G.; Mangia, N.P.; Cesarani, A.; Licastro, D.; Sorbolini, S.; Pulina, G.; Nudda, A. Agroindustrial By-Products from Tomato, Grape and Myrtle Given at Low Dosage to Lactating Dairy Ewes: Effects on Rumen Parameters and Microbiota. Ital. J. Anim. Sci. 2020, 19, 1462. [Google Scholar] [CrossRef]

- Floridia, V.; Russo, N.; D’alessandro, E.; Lopreiato, V.; Pino, A.; Amato, A.; Liotta, L.; Caggia, C.; Randazzo, C.L. Effect of olive cake supplementation on faecal microbiota profile of Holstein and Modicana dairy cattle. Microbiol. Res. 2023, 277, 127510. [Google Scholar] [CrossRef]

- Ajila, C.M.; Brar, S.K.; Verma, M.; Tyagi, R.D.; Godbout, S.; Valéro, J.R. Bio-processing of agro-byproducts to animal feed. Crit. Rev. Biotechnol. 2012, 32, 382–400. [Google Scholar] [CrossRef]

- Rasool, K.; Hussain, S.; Shahzad, A.; Miran, W.; Mahmoud, K.A.; Ali, N.; Almomani, F. Comprehensive insights into sustainable conversion of agricultural and food waste into microbial protein for animal feed production. Rev. Environ. Sci. Bio/Technol. 2023, 22, 527–562. [Google Scholar] [CrossRef]

- Nzeteu, C.; Coelho, F.; Davis, E.; Trego, A.; O’flaherty, V. Current Trends in Biological Valorization of Waste-Derived Biomass: The Critical Role of VFAs to Fuel A Biorefinery. Fermentation 2022, 8, 445. [Google Scholar] [CrossRef]

- Chen, M.; Lin, Y.; Xu, T.; Yan, X.; Jiang, H.; Leng, L.; Zeng, Z.; Wang, X.; Zhan, H. Valorization of alcohol industry residues into solid, gaseous and liquid biofuels: A comprehensive review. Renew. Energy 2025, 238, 121981. [Google Scholar] [CrossRef]

- Garside, M. Global Plastic Production 1950-2022. Global Plastic Production | Statista. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 5 May 2024).

- Geyer, R. Production, use, and fate of synthetic polymers. In Plastic Waste and Recycling. Environmental Impact, Societal Issues, Prevention, and Solutions; Letcher, T.M., Ed.; Academic Press: London, UK, 2020; pp. 13–32. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation rates of plastics in the environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Rahman, H.; Bhoi, P.R. An overview of non-biodegradable bioplastics. J. Clean. Prod. 2021, 294, 126218. [Google Scholar] [CrossRef]

- Baranwal, J.; Barse, B.; Fais, A.; Delogu, G.L.; Kumar, A. Biopolymer: A sustainable material for food and medical applications. Polymers 2022, 14, 983. [Google Scholar] [CrossRef]

- Caruso, M.R.; D’agostino, G.; Milioto, S.; Cavallaro, G.; Lazzara, G. A review on biopolymer-based treatments for consolidation and surface protection of cultural heritage materials. J. Mater. Sci. 2023, 58, 12954–12975. [Google Scholar] [CrossRef]

- Batista, A.; Nunes, M.; Raymundo, A.; Gouveia, L.; Sousa, I.; Cordobés, F.; Guerrero, A.; Franco, J. Microalgae biomass interaction in biopolymer gelled systems. Food Hydrocoll. 2011, 25, 817–825. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Sheikh, M.F.; Zolfagharian, A.; Bodaghi, M. Biopolymeric sustainable materials and their emerging applications. J. Environ. Chem. Eng. 2022, 10, 108159. [Google Scholar] [CrossRef]

- Jabeen, N.; Atif, M. Polysaccharides based biopolymers for biomedical applications: A review. Polym. Adv. Technol. 2024, 35, e6203. [Google Scholar] [CrossRef]

- Rech, A.; Siamos, E.; Nicholas, P.; Daugaard, A.E. Recyclable Extrudable Biopolymer Composites from Alginate and Lignocellulosic Biomass Waste. ACS Sustain. Chem. Eng. 2023, 11, 8939–8947. [Google Scholar] [CrossRef]

- Available online: https://www.european-bioplastics.org/market-update-2020-bioplastics-continue-to-become-mainstream-as-the-global-bioplastics-market-is-set-to-grow-by-36-percent-over-the-next-5-years/ (accessed on 5 April 2024).

- Van Roijen, E.C.; Miller, S.A. A review of bioplastics at end-of-life: Linking experimental biodegradation studies and life cycle impact assessments. Resour. Conserv. Recycl. 2022, 181, 106236. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Barrow, C.J.; Adhikari, B. The future of bioplastics in food packaging: An industrial perspective. Food Packag. Shelf Life 2024, 43, 101279. [Google Scholar] [CrossRef]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Gao, S.; Zhang, D.; Wang, C.; Chu, F. Bio-based polymeric materials synthesized from renewable resources: A mini-review. Resour. Chem. Mater. 2023, 2, 223–230. [Google Scholar] [CrossRef]

- Wang, Z.; Ganewatta, M.S.; Tang, C. Sustainable polymers from biomass: Bridging chemistry with materials and processing. Prog. Polym. Sci. 2020, 101, 101197. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S. Sustainability and Life Cycle Assessment of Thermoplastic Polymers for Packaging: A Review on Fundamental Principles and Applications. Macromol. Mater. Eng. 2022, 307, 2100794. [Google Scholar] [CrossRef]

- Jannat, N.; Al-Mufti, R.L.; Hussien, A.; Abdullah, B.; Cotgrave, A. Influences of agro-wastes on the physico-mechanical and durability properties of unfired clay blocks. Constr. Build. Mater. 2022, 318, 126011. [Google Scholar] [CrossRef]

- Zeidabadi, Z.A.; Bakhtiari, S.; Abbaslou, H.; Ghanizadeh, A.R. Synthesis, characterization and evaluation of biochar from agricultural waste biomass for use in building materials. Constr. Build. Mater. 2018, 181, 301–308. [Google Scholar] [CrossRef]

- Deraman, R.; Nawi, M.N.; Mydin, M.A.O.; Ismail, M.H.; Nordin, N.D.M.; Sari, M.W.; Mohd-Danuri, M.S. Production of roof board insulation using agricultural wastes towards sustainable building material. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 99, 66–89. [Google Scholar] [CrossRef]

- Mydin, M.A.O. Thermal and durability properties of sustainable green lightweight foamed concrete incorporating eco-friendly sugarcane fibre. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 94, 60–78. [Google Scholar] [CrossRef]

- Suhaili, S.S.; Mydin, M.A.O.; Awang, W. Influence of mesocarp fibre inclusion on thermal properties of foamed concrete. J. Adv. Res. Fluid Mech. Therm. Sci. 2024, 87, 1–11. Available online: https://semarakilmu.com.my. (accessed on 10 May 2024).

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural waste management strategies for environmental sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef]

- Ngayakamo, B.; Onwualu, A.P. Recent advances in green processing technologies for valorisation of eggshell waste for sustainable construction materials. Heliyon 2022, 8, e09649. [Google Scholar] [CrossRef] [PubMed]

- IEA Bioenergy Report 2023, Tecnology Collaboration Programme. How Bioenergy Contributes to a Sustainable Future. Chapter 7, Biomass Combustion—Bioenergy Review 2023. Available online: https://www.ieabioenergyreview.org/ (accessed on 10 May 2024).

- Naqvi, S.R.; Jamshaid, S.; Naqvi, M.; Farooq, W.; Niazi, M.B.K.; Aman, Z.; Zubair, M.; Ali, M.; Shahbaz, M.; Inayat, A.; et al. Potential of biomass for bioenergy in Pakistan based on present case and future perspectives. Renew. Sustain. Energy Rev. 2018, 81, 1247–1258. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.-C.; Loha, C.; Akinlabi, E.T. An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on Biomass Gasification: Gasifiers, Gasifying mediums, and Operational parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Elhassan, M.; Abdullah, R.; Kooh, M.R.R.; Chau, Y.-F.C. Hydrothermal liquefaction: A technological review on reactor design and operating parameters. Bioresour. Technol. Rep. 2023, 21, 101314. [Google Scholar] [CrossRef]

- Buelvas, A.; Quintero-Coronel, D.A.; Vanegas, O.; Ortegon, K.; Bula, A.; Mesa, J.; González-Quiroga, A. Gasification of solid biomass or fast pyrolysis bio-oil: Comparative energy and exergy analyses using AspenPlus®. Eng. Rep. 2024, 6, 12825. [Google Scholar] [CrossRef]

- Tshikovhi, A.; Motaung, T.E. Technologies and Innovations for Biomass Energy Production. Sustainability 2023, 15, 12121. [Google Scholar] [CrossRef]

- Saleh, T.A. A review on the technologies for converting biomass into carbon-based materials: Sustainability and economy. Bioresour. Technol. Rep. 2024, 25, 101771. [Google Scholar] [CrossRef]

- Maulinda, L.; Husin, H.; Arahman, N.; Rosnelly, C.N.; Syukri, N.; Nurhazanah; Nasution, F.; Ahmadi. The influence of pyrolysis time and temperature on the composition and properties of bio-oil prepared from Tanjong leaves (Mimusops elengi). Sustainability 2023, 15, 13851. [Google Scholar] [CrossRef]

- Lehto, J.; Oasmaa, A.; Solantausta, Y.; Kytö, M.; Chiaramonti, D. Review of fuel oil quality and combustion of fast pyrolysis bio-oils from lignocellulosic biomass. Appl. Energy 2014, 116, 178–190. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, Y.; Li, S.; Yuan, Y.; Zhang, D.; Wu, Y.; Xie, H.; Brindhadevi, K.; Pugazhendhi, A.; Xia, C. A review of biomass pyrolysis gas: Forming mechanisms, influencing parameters, and product application upgrades. Fuel 2023, 347, 128461. [Google Scholar] [CrossRef]

- Meng, X.; Jong, W.; Fu, N.; Verkooijen, A.H.M. Biomass gasification in a 100 kWth steam-oxygen blown circulating fluidized bed gasifier: Effects of operational conditions on product gas distribution and tar formation. Biomass Bioenergy 2011, 35, 2910–2924. [Google Scholar] [CrossRef]

- Yang, H.; Chen, H. Biomass gasification for synthetic liquid fuel production. In Gasification for Synthetic Fuel Production; Luque, R., Speight, J.G., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 241–275. [Google Scholar] [CrossRef]

- Ram, V.; Salkuti, S.R. An Overview of Major Synthetic Fuels. Energies 2023, 16, 2834. [Google Scholar] [CrossRef]

- Valderrama Rios, M.L.; González, A.M.; Lora, E.; Almazán del, O.O.A. Reduction of tar generated during biomass gasification: A review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Hupa, M.; Karlström, O.; Vainio, E. Biomass combustion technology development—It is all about chemical details. Proc. Combust. Inst. 2017, 36, 113–134. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and Co-combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Banerjee, N. Biomass to Energy—An Analysis of Current Technologies, Prospects, and Challenges. BioEnergy Res. 2023, 16, 683–716. [Google Scholar] [CrossRef]

- Shafizadeh, A.; Danesh, P. Biomass and Energy Production: Thermochemical Methods. In Biomass, Biorefineries and Bioeconomy; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Martín-Pascual, J.; Jódar, J.; Rodríguez, M.L.; Zamorano, M. Determination of the optimal operative conditions for the torrefaction of olive waste biomass. Sustainability 2020, 12, 6411. [Google Scholar] [CrossRef]

- Liu, X.; Yao, Z.; Cong, H.; Zhao, L.; Huo, L.; Song, J. Effects of operating conditions and pre-densification on the torrefaction products of sorghum straw. Int. J. Agric. Biol. Eng. 2020, 13, 219–225. [Google Scholar] [CrossRef]

- Yang, Y.; Qu, X.; Huang, G.; Ren, S.; Dong, L.; Sun, T.; Liu, P.; Li, Y.; Lei, T.; Cai, J. Insight into lignocellulosic biomass torrefaction kinetics with case study of pinewood sawdust torrefaction. Renew. Energy 2023, 215, 118941. [Google Scholar] [CrossRef]

- Silveira, E.A.; Barcelo, R.; Lamas, G.C.; Rodrigues, P.P.d.O.; Chaves, B.S.; Protásio, T.d.P.; Rousset, P.; Ghesti, G. Biofuel from agro-industrial residues as sustainable strategy for CO2 mitigation: Statistical optimization of pequi seeds torrefaction. Energy Convers. Manag. 2024, 304, 118222. [Google Scholar] [CrossRef]

- Ngo, S.I.; Nguyen, T.D.; Lim, Y.-I.; Song, B.-H.; Lee, U.-D.; Choi, Y.-T.; Song, J.-H. Performance evaluation for dual circulating fluidized-bed steam gasifier of biomass using quasi-equilibrium three-stage gasification model. Appl. Energy 2011, 88, 5208–5220. [Google Scholar] [CrossRef]

- Mazzoni, L.; Ahmed, R.; Janajreh, I. Plasma gasification of two waste streams: Municipal solid waste and hazardous waste from the oil and gas industry. Energy Procedia 2017, 105, 4159–4166. [Google Scholar] [CrossRef]

- Liu, L.; Huang, Y.; Cao, J.; Liu, C.; Dong, L.; Xu, L.; Zha, J. Experimental study of biomass gasification with oxygen-enriched air in fluidized bed gasifier. Sci. Total. Environ. 2018, 626, 423–433. [Google Scholar] [CrossRef]

- Díaz, L.; Fuentes, R.; R-Díaz, J.; Rodríguez, K.; González, L. Enhancing sustainable energy production in the Canary Islands: Valorization of local biomass resources through thermochemical processes. Biomass Bioenergy 2024, 188, 107327. [Google Scholar] [CrossRef]

- Lee, D.; Nam, H.; Seo, M.W.; Lee, S.H.; Tokmurzin, D.; Wang, S.; Park, Y.-K. Recent progress in the catalytic thermochemical conversion process of biomass for biofuels. Chem. Eng. J. 2022, 447, 137501. [Google Scholar] [CrossRef]

- López-Linares, J.C.; Ballesteros, I.; Tourán, J.; Cara, C.; Castro, E.; Ballesteros, M.; Romero, I. Optimization of uncatalyzed steam explosion pretreatment of rapeseed straw for biofuel production. Bioresour. Technol. 2015, 190, 97–105. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, J.; Zhu, Z.; Zhang, Y.; Zhao, Y.; Li, R.; Watson, J.; Li, B.; Liu, Z. Simultaneous production of biocrude oil and recovery of nutrients and metals from human feces via hydrothermal liquefaction. Energy Convers. Manag. 2017, 134, 340–346. [Google Scholar] [CrossRef]

- Couto, E.A.; Pinto, F.; Varela, F.; Reis, A.; Costa, P.; Calijuri, M.L. Hydrothermal liquefaction of biomass produced from domestic sewage treatment in high-rate ponds. Renew. Energy 2018, 118, 644–653. [Google Scholar] [CrossRef]

- Arlete, T.; Ozkan, S.; Ribeiro, A.P.; Cristino, A.F.; dos Santos, R.G. Thermochemical liquefaction of biomass with ionic liquids: Exploring a sustainable pathway for a cleaner bio-oils production. J. Clean. Prod. 2024, 434, 140114. [Google Scholar] [CrossRef]

- Acharya, S.; Kishore, N. Influence of reaction parameters on biofuels derived from solvothermal liquefaction of Citrus limetta fruit wastes. Biomass Bioenergy 2024, 184, 107183. [Google Scholar] [CrossRef]

- Pattiya, A.; Suttibak, S. Fast pyrolysis of sugarcane residues in a fluidised bed reactor with a hot vapour filter. J. Energy Inst. 2017, 90, 110–119. [Google Scholar] [CrossRef]

- Cho, D.-W.; Tsang, D.C.; Kim, S.; Kwon, E.E.; Kwon, G.; Song, H. Thermochemical conversion of cobalt-loaded spent coffee grounds for production of energy resource and environmental catalyst. Bioresour. Technol. 2018, 270, 346–351. [Google Scholar] [CrossRef] [PubMed]

- Jahromi, H.; Agblevor, F.A. Hydrodeoxygenation of aqueous-phase catalytic pyrolysis oil to liquid hydrocarbons using multifunctional nickel catalyst. Ind. Eng. Chem. Res. 2018, 57, 13257–13268. [Google Scholar] [CrossRef]

- de Wild, P.; Uil, H.D.; Reith, J.; Kiel, J.; Heeres, H. Biomass valorisation by staged degasification. J. Anal. Appl. Pyrolysis 2009, 85, 124–133. [Google Scholar] [CrossRef]

- Zou, X.; Zhai, M.; Liu, G.; Wang, T.; Guo, L.; Zhang, Y.; Liaquat, R. In-depth understanding of the microscopic mechanism of biochar carbonaceous structures during thermochemical conversion: Pyrolysis, combustion and gasification. Fuel 2024, 361, 130732. [Google Scholar] [CrossRef]

- Cardarelli, A.; Barbanera, M. Hydrochar from winemaking industry wastes as solid biofuel: A thermal and kinetic analysis of pyrolysis and combustion. Fuel 2024, 372, 132256. [Google Scholar] [CrossRef]

- Migliaccio, R.; Cerciello, F.; Oliano, M.; Russo, C.; Apicella, B.; Senneca, O. Effect of oxidative atmospheres on thermochemical degradation of tobacco: Discriminating between oxidative pyrolysis and combustion. Fuel 2024, 374, 132313. [Google Scholar] [CrossRef]

- Azam, M.Z.; Ashraf, M.; Aslam, Z.; Kamal, M.S.; Aslam, U. Combustion and pyrolysis of dairy waste: A kinetic analysis and prediction of experimental data through Artificial Neural Network (ANN). Therm. Sci. Eng. Prog. 2024, 53, 102746. [Google Scholar] [CrossRef]

- Adegoke, K.A.; Akinnawo, S.O.; Adebusuyi, T.A.; Ajala, O.A.; Adegoke, R.O.; Maxakato, N.W.; Bello, O.S. Modified biomass adsorbents for removal of organic pollutants: A review of batch and optimization studies. Int. J. Environ. Sci. Technol. 2023, 20, 11615–11644. [Google Scholar] [CrossRef]

- Liu, Y.; Biswas, B.; Hassan, M.; Naidu, R. Green Adsorbents for Environmental Remediation: Synthesis Methods, Ecotoxicity, and Reusability Prospects. Processes 2024, 12, 1195. [Google Scholar] [CrossRef]

- Singh, N.; Nagpal, G.; Agrawal, S. Rachna Water purification by using Adsorbents: A Review. Environ. Technol. Innov. 2018, 11, 187–240. [Google Scholar] [CrossRef]

- Aragaw, T.A.; Bogale, F.M. Biomass-based adsorbents for removal of dyes from wastewater: A Review. Front. Environ. Sci. 2021, 9, 764958. [Google Scholar] [CrossRef]

- Katubi, K.M.; Amari, A.; Harharah, H.N.; Eldirderi, M.M.; Tahoon, M.A.; Ben Rebah, F. Aloe vera as Promising Material for Water Treatment: A Review. Processes 2021, 9, 782. [Google Scholar] [CrossRef]

- Cansado, I.P.d.P.; Geraldo, P.F.; Mourão, P.A.M.; Castanheiro, J.E.; Carreiro, E.P. Suhas Utilization of Biomass Waste at Water Treatment. Resources 2024, 13, 37. [Google Scholar] [CrossRef]

- Wei, W.; Shang, N.; Zhang, X.; Liu, W.; Zhang, T.; Wu, M. A green 3-step combined modification for the preparation of biomass sorbent from waste chestnut thorns shell to efficient removal of methylene blue. Bioresour. Technol. 2022, 360, 127593. [Google Scholar] [CrossRef]

- Šoštarić, T.D.; Petrović, M.S.; Pastor, F.T.; Lončarević, D.R.; Petrović, J.T.; Milojković, J.V.; Stojanović, M.D. Study of heavy metals biosorption on native and alkali-treated apricot shells and its application in wastewater treatment. J. Mol. Liq. 2018, 259, 340–349. [Google Scholar] [CrossRef]

- Bello, O.S.; Adegoke, K.A.; Olaniyan, A.A.; Abdulazeez, H. Dye adsorption using biomass wastes and natural adsorbents: Overview and future prospects. Desalination Water Treat. 2013, 53, 1292–1315. [Google Scholar] [CrossRef]

- Hashmi, Z.; Jatoi, A.S.; Nadeem, S.; Anjum, A.; Imam, S.M.; Jangda, H. Comparative analysis of conventional to biomass-derived adsorbent for wastewater treatment: A review. Biomass Convers. Biorefinery 2024, 14, 45–76. [Google Scholar] [CrossRef]

- Zhu, L.; Lei, H.; Zhang, Y.; Zhang, X.; Bu, Q.; Wei, Y. A Review of biochar derived from pyrolysis and its application in biofuel production. SF J. Mater. Chem. Eng. 2018, 1, 1007. [Google Scholar]

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Jain, A.; Balasubramanian, R.; Srinivasan, M. Hydrothermal conversion of biomass waste to activated carbon with high porosity: A review. Chem. Eng. J. 2016, 283, 789–805. [Google Scholar] [CrossRef]

- Ponnusamy, V.K.; Nagappan, S.; Bhosale, R.R.; Lay, C.-H.; Nguyen, D.D.; Pugazhendhi, A.; Chang, S.W.; Kumar, G. Review on sustainable production of biochar through hydrothermal liquefaction: Physico-chemical properties and applications. Bioresour. Technol. 2020, 310, 123414. [Google Scholar] [CrossRef]

- Parsa, M.; Nourani, M.; Baghdadi, M.; Hosseinzadeh, M.; Pejman, M. Biochars derived from marine macroalgae as a mesoporous by-product of hydrothermal liquefaction process: Characterization and application in wastewater treatment. J. Water Process. Eng. 2019, 32, 100942. [Google Scholar] [CrossRef]

- Pedersen, T.H.; Rosendahl, L.A. Production of fuel range oxygenates by supercritical hydrothermal liquefaction of lignocellulosic model systems. Biomass Bioenergy 2015, 83, 206–215. [Google Scholar] [CrossRef]

- García-Morato, R.; Román, S.; Ledesma, B.; Coronella, C. Co-Hydrothermal Carbonization of Grass and Olive Stone as a Means to Lower Water Input to HTC. Resources 2023, 12, 85. [Google Scholar] [CrossRef]

- Vallejo, F.; Diaz-Robles, L.A.; Germain, I.; Sabio, E. Economic and Feasibility Analysis of Bioenergy Production from Sawdust via Hydrothermal Carbonisation for a Circular Economy. Chem. Eng. Trans. 2023, 103, 841–846. [Google Scholar] [CrossRef]

- Biller, P.; Ross, A. Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresour. Technol. 2011, 102, 215–225. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Jena, M.K.; Hakeem, I.G.; Patel, S.; Veluswamy, G.; Thulasiraman, A.V.; Surapaneni, A.; Shah, K. A critical review of biochar versus hydrochar and their application for H2S removal from biogas. Rev. Environ. Sci. Bio/Technology 2024, 23, 699–737. [Google Scholar] [CrossRef]

- Otowa, T.; Nojima, Y.; Miyazaki, T. Development of KOH activated high surface area carbon and its application to drinking water purification. Carbon 1997, 35, 1315–1319. [Google Scholar] [CrossRef]

- Tadda, M.A.; Ahsan, A.; Shitu, A.; ElSergany, M.; Arunkumar TJose, B.; Razzaque, M.A.; Nik Daud, N.N. A review on activated carbon: Process, application and prospects. J. Adv. Civ. Eng. Pract. Res. 2016, 2, 7–13. [Google Scholar]

- Cansado, I.P.d.P.; Belo, C.R.; Mourão, P.A.M. Pesticides abatement using activated carbon produced from a mixture of synthetic polymers by chemical activation with KOH and K2CO3. Environ. Nanotechnol. Monit. Manag. 2019, 12, 100261. [Google Scholar] [CrossRef]

- Cansado, I.P.d.P.; Mourão, P.A.M.; Belo, C.R. Using Tectona Grandis Biomass to Produce Valuable Adsorbents for Pesticide Removal from Liquid Effluent. Materials 2022, 15, 5842. [Google Scholar] [CrossRef]

- Chew, T.W.; H’ng, P.S.; Abdullah, B.C.T.G.L.C.; Chin, K.L.; Lee, C.L.; Hafizuddin, B.M.S.M.N.; TaungMai, L. A Review of Bio-Based Activated Carbon Properties Produced from Different Activating Chemicals during Chemicals Activation Process on Biomass and Its Potential for Malaysia. Materials 2023, 16, 7365. [Google Scholar] [CrossRef]

- Heidarinejad, Z.; Dehghani, M.H.; Heidari, M.; Javedan, G.; Ali, I.; Sillanpää, M. Methods for preparation and activation of activated carbon: A review. Environ. Chem. Lett. 2020, 18, 393–415. [Google Scholar] [CrossRef]

- Duan, D.; Chen, D.; Huang, L.; Zhang, Y.; Zhang, Y.; Wang, Q.; Xiao, G.; Zhang, W.; Lei, H.; Ruan, R. Activated carbon from lignocellulosic biomass as catalyst: A review of the applications in fast pyrolysis process. J. Anal. Appl. Pyrolysis 2021, 158, 105246. [Google Scholar] [CrossRef]

- Ferreira, P.; Fonseca, I.; Ramos, A.; Vital, J.; Castanheiro, J. Acetylation of glycerol over heteropolyacids supported on activated carbon. Catal. Commun. 2011, 12, 573–576. [Google Scholar] [CrossRef]

- Abd, A.A.; Othman, M.R.; Kim, J. A review on application of activated carbons for carbon dioxide capture: Present performance, preparation, and surface modification for further improvement. Environ. Sci. Pollut. Res. 2021, 28, 43329–43364. [Google Scholar] [CrossRef]

- Carrott, P.; Cansado, I.; Carrott, M.R. Carbon molecular sieves from PET for separations involving CH4, CO2, O2 and N2. Appl. Surf. Sci. 2006, 252, 5948–5952. [Google Scholar] [CrossRef]

- Soonmin, H.; Kabbashi, N.A. Review on activated carbon: Synthesis, properties and applications. Int. J. Eng. Trends Technol. 2021, 69, 124–139. [Google Scholar] [CrossRef]

- Satyam, S.; Patra, S. Innovations and challenges in adsorption-based wastewater remediation: A comprehensive review. Heliyon 2024, 10, e29573. [Google Scholar] [CrossRef] [PubMed]

- Al Kausor, M.; Gupta, S.S.; Bhattacharyya, K.G.; Chakrabortty, D. Montmorillonite and modified montmorillonite as adsorbents for removal of water soluble organic dyes: A review on current status of the art. Inorg. Chem. Commun. 2022, 143, 109686. [Google Scholar] [CrossRef]

- Cansado, I.; Mourão, P.; Falcão, A.; Carrott, M.R.; Carrott, P. The influence of the activated carbon post-treatment on the phenolic compounds removal. Fuel Process. Technol. 2012, 103, 64–70. [Google Scholar] [CrossRef]

- Malini, K.; Selvakumar, D.; Kumar, N. Activated carbon from biomass: Preparation, factors improving basicity and surface properties for enhanced CO2 capture capacity—A review. J. CO2 Util. 2023, 67, 102318. [Google Scholar] [CrossRef]

- Mekuria, D.; Diro, A.; Melak, F.; Asere, T.G. Adsorptive Removal of Methylene Blue Dye Using Biowaste Materials: Barley Bran and Enset Midrib Leaf. J. Chem. 2022, 2022, 4849758. [Google Scholar] [CrossRef]

- Iwanow, M.; Gärtner, T.; Sieber, V.; König, B. Activated carbon as catalyst support: Precursors, preparation, modification and characterization. Beilstein J. Org. Chem. 2020, 16, 1188–1202. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Wang, N.; He, Y.; Zhao, K.; Lin, X.; He, X.; Chen, A.; Wu, G.; Zhang, J.; Yan, B.; Luo, L.; et al. Greenhouse gas emission characteristics and influencing factors of agricultural waste composting process: A review. J. Environ. Manag. 2024, 354, 120337. [Google Scholar] [CrossRef]

- Yin, J.; Xie, M.; Yu, X.; Feng, H.; Wang, M.; Zhang, Y.; Chen, T. A review of the definition, influencing factors, and mechanisms of rapid composting of organic waste. Environ. Pollut. 2024, 342, 123125. [Google Scholar] [CrossRef]

- Pajura, R. Composting municipal solid waste and animal manure in response to the current fertilizer crisis—A recent review. Sci. Total. Environ. 2024, 912, 169221. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Y.; Li, Y.; Liu, Y.; Jiang, H.; Li, H.; Yuan, Y.; Chen, Y.; Zou, B. Improving the humification by additives during composting: A review. Waste Manag. 2023, 158, 93–106. [Google Scholar] [CrossRef]

- EU Soil Strategy for 2030 Reaping the Benefits of Healthy Soils for People, Food, Nature and Climate. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, 2021. Soil Strategy—European Commission. Available online: https://european-union.europa.eu/index_en (accessed on 3 June 2024).

- Kumar, S.; Negi, S.; Mandpe, A.; Singh, R.V.; Hussain, A. Rapid composting techniques in Indian context and utilization of black soldier fly for enhanced decomposition of biodegradable wastes—A comprehensive review. J. Environ. Manag. 2018, 227, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.; Zhang, H.; Fu, Q.; Zhong, M.; Li, R.; Zhai, B.; Wang, Z.; Zhou, L. Effects of four additives in pig manure composting on greenhouse gas emission reduction and bacterial community change. Bioresour. Technol. 2019, 292, 121896. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, T.; Tsang, D.C.; Li, G. Effects of external additives: Biochar, bentonite, phosphate, on co-composting for swine manure and corn straw. Chemosphere 2020, 248, 125927. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, M.K.; Lin, C.; Hoang, H.G.; Sanderson, P.; Dang, B.T.; Bui, X.T.; Nguyen, N.S.H.; Vo, D.-V.N.; Tran, H.T. Evaluate the role of biochar during the organic waste composting process: A critical review. Chemosphere 2022, 299, 134488. [Google Scholar] [CrossRef]

- Suthar, S.; Singh, N.K. Fungal pretreatment facilitates the rapid and valuable composting of waste cardboard. Bioresour. Technol. 2022, 344, 126178. [Google Scholar] [CrossRef]

- Majbar, Z.; El Madani, F.-Z.; Khalis, M.; Lahlou, K.; Ben Abbou, M.; Majbar, E.B.; Bourhia, M.; Al-Huqail, A.A.; El Askary, A.; Khalifa, A.S.; et al. Farmers’ perceptions and willingness of compost production and use to contribute to environmental sustainability. Sustainability 2021, 13, 13335. [Google Scholar] [CrossRef]

- Cai, C.; Wang, Z.; Ma, L.; Xu, Z.; Yu, J.; Li, F. Cotton stalk valorization towards bio-based materials, chemicals, and biofuels: A review. Renew. Sustain. Energy Rev. 2024, 202, 114651. [Google Scholar] [CrossRef]

- Wei, Y.; Rodriguez-Illera, M.; Guo, X.; Vollebregt, M.; Li, X.; Rijnaarts, H.H.; Chen, W.-S. The complexities of decision-making in food waste valorization: A critical review. J. Environ. Manag. 2024, 359, 120989. [Google Scholar] [CrossRef]

| Waste | Extracted Compounds | Applications | Reference |

|---|---|---|---|

| tomato residues | phenolic compounds | antioxidant, antimicrobial, anticarcinogenic | [18] |

| pineapple peels | acetic acid | clear vinegar | [29] |

| orange peels | limonene | [21] | |

| pine | pinene | [30] | |

| agrowaste extracts | ferulic and syringic acid | compounds with antimicrobial and antioxidant potential | [15] |

| whey waste | red pigment | pigment | [31] |

| orange peels | limonene | exploited for food, pharmaceutical, and cosmetic industrial applications | [32] |

| agricultural by-products | antibiotics | [33] | |

| pineapple waste | group of proteases | applications in food, textiles, and cosmetics | [34] |

| tomato residues | lycopene | applications in food, textiles, and cosmetics | [18] |

| citrus | pectin | interest in food, pharmaceuticals, and cosmetic | [35] |

| plant biomass | bioactive compounds | natural antioxidants in meat | [19] |

| Solid Waste | Application | Reference |

|---|---|---|

| empty fruit bunch with mesocarp fiber, sugarcane bagasse with coconut husk and with mesocarp fiber, coconut husk with an empty fruit bunch | roof board thermal insulation | [68] |

| sugar cane | improve durability and thermal properties of cement | [69] |

| mesocarp fiber | improve thermal properties of foamed concrete | [70] |

| agrowaste | bio-brickets | [71] |

| eggshell powder, sawdust powder, coconut husk powder | unfired clay blocks | [67] |

| eggshell waste | cement production | [72] |

| Raw Material | Applications | References |

|---|---|---|

| Review on the use of biomass-based adsorbents | Dye removal | [117] |

| Aloe vera | Biosorbents | [118] |

| Subble, Tectona Grandis, Adansonia digitata L., and bamboo flowers | Methylene blue | [119] |

| Chestnut thorn shell | Methylene blue | [120] |

| Apricot shells treated by NaOH | Cu2+, Zn2+ and Pb2+ | [121] |

| Cashew nut shell | Red corant | [122] |

| List with a diversity of natural agrowastes | Mainly metal cations and dyes | [116,123] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cansado, I.P.d.P.; Mourão, P.A.M.; Castanheiro, J.E.; Geraldo, P.F.; Suhas; Suero, S.R.; Cano, B.L. A Review of the Biomass Valorization Hierarchy. Sustainability 2025, 17, 335. https://doi.org/10.3390/su17010335

Cansado IPdP, Mourão PAM, Castanheiro JE, Geraldo PF, Suhas, Suero SR, Cano BL. A Review of the Biomass Valorization Hierarchy. Sustainability. 2025; 17(1):335. https://doi.org/10.3390/su17010335

Chicago/Turabian StyleCansado, Isabel Pestana da Paixão, Paulo Alexandre Mira Mourão, José Eduardo Castanheiro, Pedro Francisco Geraldo, Suhas, Silvia Román Suero, and Beatriz Ledesma Cano. 2025. "A Review of the Biomass Valorization Hierarchy" Sustainability 17, no. 1: 335. https://doi.org/10.3390/su17010335

APA StyleCansado, I. P. d. P., Mourão, P. A. M., Castanheiro, J. E., Geraldo, P. F., Suhas, Suero, S. R., & Cano, B. L. (2025). A Review of the Biomass Valorization Hierarchy. Sustainability, 17(1), 335. https://doi.org/10.3390/su17010335