Valorization of Energetic Materials from Obsolete Military Ammunition Through Life Cycle Assessment (LCA): A Circular Economy Approach to Environmental Impact Reduction

Abstract

1. Introduction

1.1. Transformation to a Circular Economy

1.2. The Promotion of Circular Economy in the Armed Forces

1.3. Applications in the National Economy Explosives Obtained from Withdrawn Military Ammunition and Related Materials

1.4. Review of Explosives Disposal Methods

- Controlled detonation in a closed chamber.

- 2.

- Chemical conversion and degradation.

- 3.

- 4.

1.5. Life Cycle Assessment (LCA) of Explosives as an Indicator of Their Overall Environmental Impact

- “bottom-up” process models.

- “top-down” macroeconomic environmental models.

2. Materials and Methods

2.1. Goal and Scope Definition

2.2. Life Cycle Inventory, Impact Assessments, and Simapro Software

3. Results and Discussion

4. Conclusions

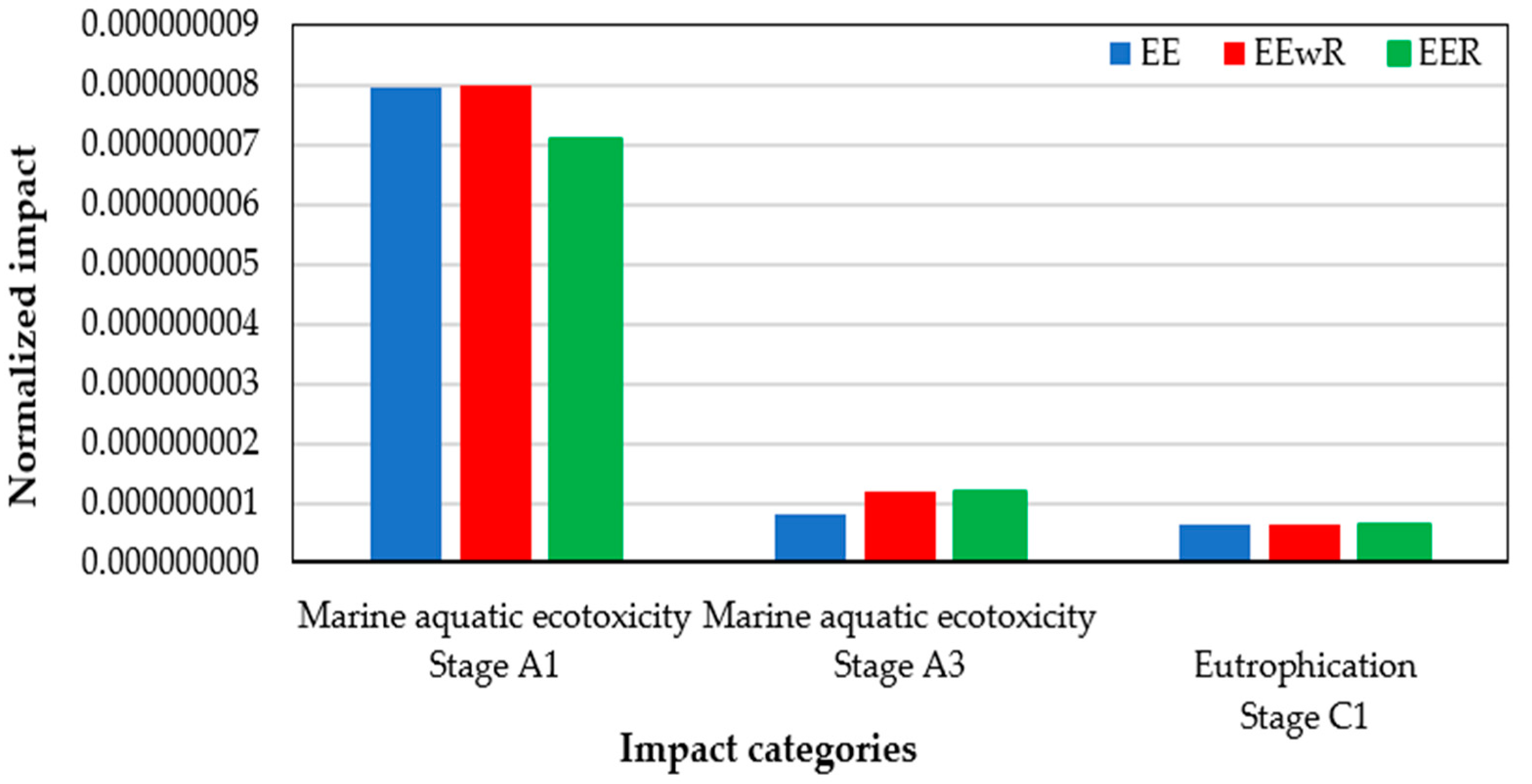

- All materials affect the MAETP the most, with the use of recycled nitrocellulose powder reducing the impact.

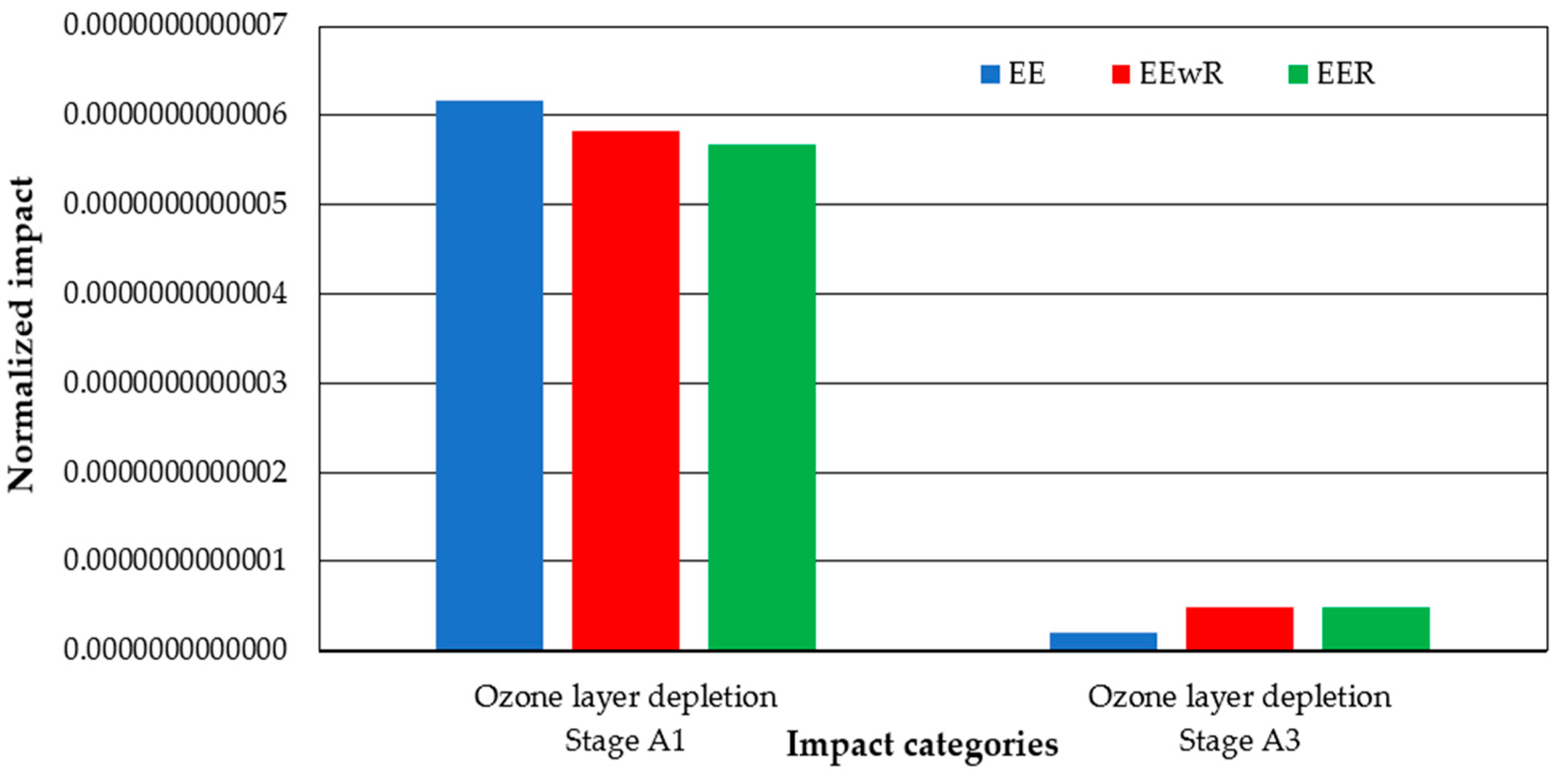

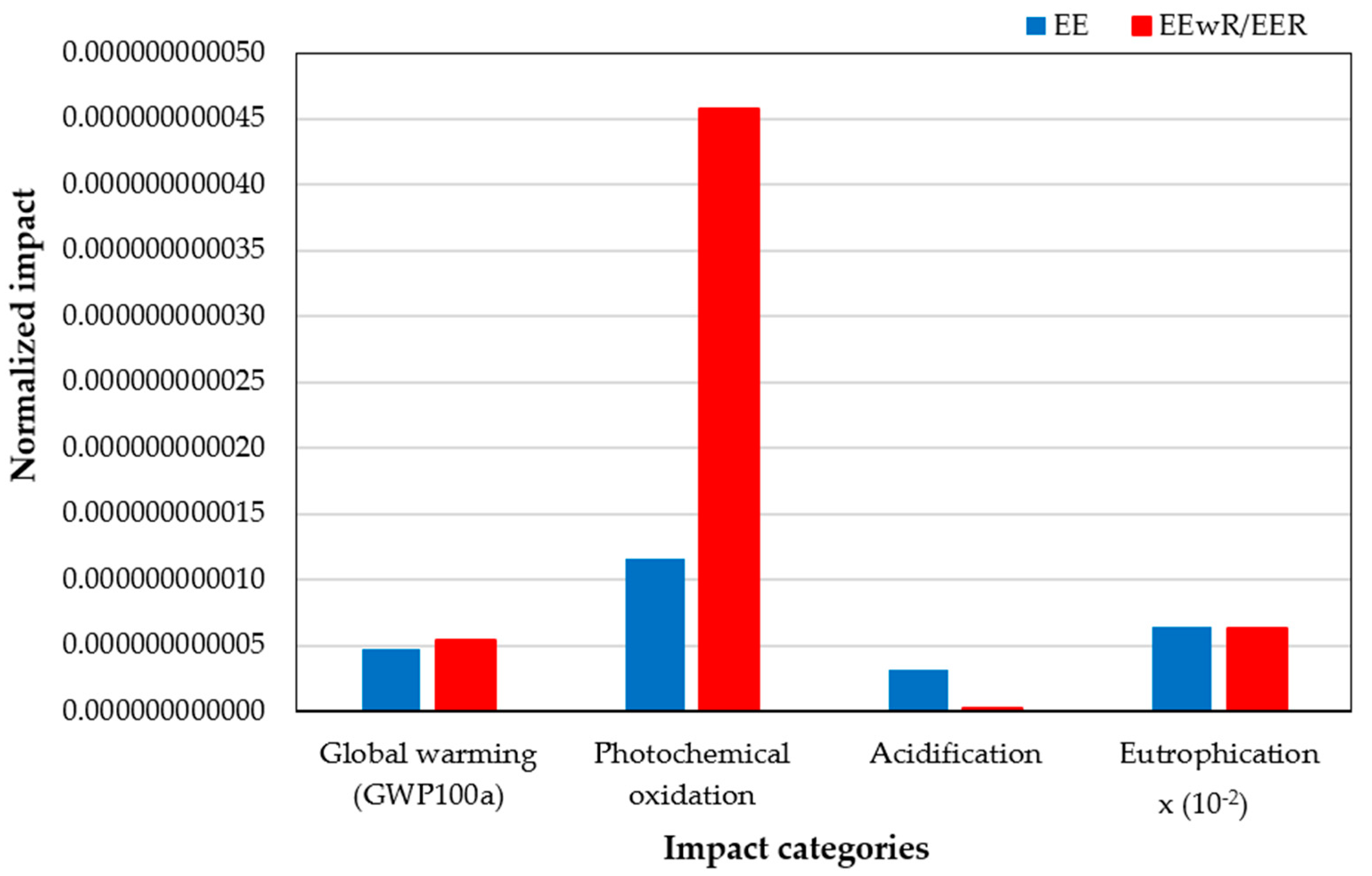

- Both EEwR and EER materials demonstrate the lowest impact on ozone depletion comparable to EE. However, EE exhibits the lowest negative impact on photochemical oxidation, with an impact comparable to EEwR and EER materials.

- The analysis of particular elements of LCA highlights the significant impact of certain stages on environmental profiles, with the detonation process notably affecting eutrophication potential.

- Individual process contributions show that ammonium and sodium nitrates significantly impact the overall environmental profile, while recycled nitrocellulose powder diminishes its impact in EEwR and EER materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferreira, C.; Ribeiro, J.; Clift, R.; Freire, F. A Circular Economy Approach to Military Munitions: Valorization of Energetic Material from Ammunition Disposal through Incorporation in Civil Explosives. Sustainability 2019, 11, 255. [Google Scholar] [CrossRef]

- Wilkinson, J.; Watt, D. Review of Demilitarisation and Disposal Techniques for Munitions and Related Materials; Munitions Safety Information Analysis Center: Brussels, Belgium, 2006. [Google Scholar]

- NATO Support and Procurement Organisation. NSPO Regulation No. 4200—Procurement Regulations; NATO Support and Procurement Organisation: Luxembourg, 2024. [Google Scholar]

- Rotter, G. Munitionsentsorgung Aus Der Sicht Des BWB. In Proceedings of the Waste Management of Energetic Materials and Polymers, Karlsruhe, Germany, 30 June–3 July 1992. [Google Scholar]

- Rotter, G. Disposal of Ammunition in the Federal Republic of Germany—An Over View. In Conversion Concepts for Commercial Applications and Disposal Technologies of Energetic Systems; Krause, H.H., Ed.; Springer: Dordrecht, The Netherlands, 1997; pp. 11–15. ISBN 978-94-017-1175-3. [Google Scholar]

- North Atlantic Treaty Organisation. Environmental Impact of Munition and Propellant Disposal; The Research and Technology Organisation (RTO) of NATO: Brussels, Belgium, 2010; p. 86. [Google Scholar]

- Nehring, S.; Ilschner, B. Ostsea-Pipeline-Ein Expolosive Vorhaben Waterkart. Waterkant 2005, 4, 21–25. [Google Scholar]

- MEDEA. Ocean Dumping of Chemical Munitions: Environmental Effects in Arctic Seas; MEDEA: McLean, VA, USA, 1997. [Google Scholar]

- Albright, R.D. Death of the Chesapeake: A History of the Military’s Role in Polluting the Bay; Scrivener Publishing LLC: Salem, MA, USA, 2013; ISBN 978-1-118-75658-4. [Google Scholar]

- Andrulewicz, E. War Gases and Ammunition in the Polish Economic Zone of the Baltic Sea. In Sea-Dumped Chemical Weapons: Aspects, Problems and Solutions; Kaffka, A.V., Ed.; Springer: Dordrecht, The Netherlands, 1996; pp. 9–15. ISBN 978-94-015-8713-6. [Google Scholar]

- Anonymous. Mustard Gas in the Baltic Sea. Mar. Poll Bull 1969, 15, 17–18. [Google Scholar]

- Korotenko, K. Chemical Warfare Munitions Dumped in the Baltic Sea: Modeling of Pollutant Transport Due to Possible Leakage. Oceanology 2003, 43, 16–29. [Google Scholar]

- Bromowicz, J.; Bukowski, M.; Hausner, J.; Kasztelewicz, Z.; Kudłacz, M.; Kulczycka, J.; Piestrzyński, A.; Steinhoff, J.; Wilczyński, M. Polityka Surowcowa Polski; Hausner, J., Ed.; Fundacja Gospodarki i Administracji Publicznej: Cracow, Poland, 2015. [Google Scholar]

- Degórski, M. Studia komitetu przestrzennego zagospodarowania kraju. PAN 2018, 183, 27–35. [Google Scholar]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular Economy as an Essentially Contested Concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Galvão, G.D.A.; De Nadae, J.; Clemente, D.H.; Chinen, G.; De Carvalho, M.M. Circular Economy: Overview of Barriers. Proc. CIRP 2018, 73, 79–85. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the Europeran Economic and Social Committee and the Committee of the Regions. Next Steps for a Sustainable European Future; European Commission: Strasbourg, Germany, 2016. [Google Scholar]

- Rutkowska, M.; Popławski, Ł. Model Zrównoważonej Gospodarki o Obiegu Zamkniętym. Stud. Pr. WNEiZ US 2017, 2, 119–128. [Google Scholar] [CrossRef]

- Foltynowicz, Z.; Stróżyk, K. Europa Bez Odpadów. In Kompleksowe Zarządzanie Gospodarką Odpadami; Manczarski, P., Ed.; Polskie Zrzeszenia Inżynierów i Techników Sanitarnych, Oddział Wielkopolski: Poznan, Poland, 2015; pp. 25–36. ISBN 978-83-89696-87-8. [Google Scholar]

- Janikowski, R. Zarządzanie Ekologiczne; Akademicka Oficyna Wydawnicza PLJ: Warsaw, Poland, 1999; ISBN 83-7101-420-1. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the Europeran Economic and Social Committee and the Committee of the Regions. Towards a Circular Economy: A Zero Waste Programme for Europe; European Commission: Strasbourg, Germany, 2014. [Google Scholar]

- Gaustad, G.; Krystofik, M.; Bustamante, M.; Badami, K. Circular Economy Strategies for Mitigating Critical Material Supply Issues. Resour. Conserv. Recycl. 2018, 135, 24–33. [Google Scholar] [CrossRef]

- Harris, S.; Staffas, L.; Rydberg, T.; Eriksson, E. Renewable Materials in the Circular Economy; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2018; p. 25. [Google Scholar]

- Maranda, A. Utylizacja Materiałów Wybuchowych Pozyskiwanych z Wycofanej Amunicji. Ochr. Powietrza I Probl. Odpad. 2002, 36, 75–80. [Google Scholar]

- Grasso, V.B. Rare Earth Elements in National Defense: Background, Oversight Issues, and Options for Congress; Congressional Research Service: Washington, DC, USA, 2013; p. 43.

- Lozano-Gomez, R. The Application of Circular Economy in the Defense Sector; Opinion Paper; IEEE, Instituto Español de Estudios Estratégicos: Madrid, Spain, 2022. [Google Scholar]

- Janikowski, R. Transformation towards a Circular Economy in the Polish Armed Forces. Econ. Environ. 2020, 73, 9. [Google Scholar]

- Maranda, A.; Nowaczewski, J. Zastosowanie Materiału Wybuchowego z Deelaboracji Amunicji. In Proceedings of the Military Arms, Gdynia, Poland, 1996; Volume 2, pp. 291–302. [Google Scholar]

- Maranda, A.; Nowaczewski, J.; Statuch, J. Badania Nad Zastosowaniem Paliw Bezdymnych Trotylu i Heksogenu w Górnictwie. Pr. Nauk. Głównego Inst. Górnictwa 1999, 58, 193–202. [Google Scholar]

- Maranda, A.; Nowaczewski, J.O. Niektórych Problemach Utylizacji Materiałów Wybuchowych Pochodzących z Wyrobów Wojskowych; Wojskowa Akademia Techniczna: Warszawa, Poland, 2000; p. 33. [Google Scholar]

- Ribeiro, J.B.; Mendes, R.; Tavares, B.; Louro, C. Features of the Incorporation of Single and Double Based Powders within Emulsion Explosives. J. Phys. Conf. Ser. 2014, 500, 192017. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable Supply Chain Management and the Transition towards a Circular Economy: Evidence and Some Applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Zeman, S.; Tamchyna, V. Application of Demilitarized Energetic Materials in Blasting Techniques. Sci. Pap. Univ. Pardubice. Ser. A Fac. Chem. Technol. 2005, 10, 271–277. [Google Scholar]

- Marchard, R.C.; Isbell, J.R. The Design Permitting a Construction of an Explosives Waste Incineration. In Proceedings of the Waste Managing of Energetic Materials and Polymers, Karlsruhe, Germany, 30 June–3 July 1992. [Google Scholar]

- Ferreira, C.; Ribeiro, J.; Mendes, R.; Freire, F. Life-Cycle Assessment of Ammunition Demilitarization in a Static Kiln. Propellants Explos. Pyrotech. 2013, 38, 296–302. [Google Scholar] [CrossRef]

- Scola, R.; Santos, J.S. Fluidized Bed Incinerator for Disposal of Propellants and Explosives; Technical Report ARL CD-TR-78032; US Army Armament Research and Development Center: Picatinny, NJ, USA, 1978; p. 128.

- van Ham, N.H.A. Munitions Disposal as a Total Concept. In Conversion Concepts for Commercial Applications and Disposal Technologies of Energetic Systems; Krause, H.H., Ed.; Springer: Dordrecht, The Netherlands, 1997; pp. 47–54. ISBN 978-94-017-1175-3. [Google Scholar]

- Dahn, A. Chemical and Biological Processes for Decomposition of Nitrocellulose-Based Propellants. In Conversion Concepts for Commercial Applications and Disposal Technologies of Energetic Systems; Krause, H.H., Ed.; Springer: Dordrecht, The Netherlands, 1997; pp. 191–212. ISBN 978-94-017-1175-3. [Google Scholar]

- Karwowska, E. Materiały Wybuchowe w Środowisku; Oficyna Wydawnicza Politechniki Warszawskiej: Warsaw, Poland, 2016; ISBN 978-83-7814-529-5. [Google Scholar]

- Wanniger, P. Conversion of High Explosives. Int. J. Energ. Mater. Chem. Propuls. 1997, 4, 155–166. [Google Scholar] [CrossRef]

- Krause, H.H. Advanced Disposal and Recycling Technologies of Energetic Materials. In Conversion Concepts for Commercial Applications and Disposal Technologies of Energetic Systems; Krause, H.H., Ed.; Springer: Dordrecht, The Netherlands, 1997; pp. 91–97. ISBN 978-94-017-1175-3. [Google Scholar]

- Brogle, R.; Rys, P.; Rochat, E.; Heller, W. Recycling of Explosives from Obsolete Medium Caliber Ammunition; Sichuan Publishing House of Science and Technology: Chengdu, China, 1999. [Google Scholar]

- Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards; Bruijn, H., Duin, R., Huijbregts, M.A.J., Guinee, J.B., Gorree, M., Heijungs, R., Huppes, G., Kleijn, R., Koning, A., Oers, L., et al., Eds.; Eco-Efficiency in Industry and Science; Springer: Dordrecht, The Netherlands, 2006; ISBN 978-0-306-48055-3. [Google Scholar]

- Becker, M.; Ziemińska-Stolarska, A.; Markowska, D.; Lütz, S.; Rosenthal, K. Comparative Life Cycle Assessment of Chemical and Biocatalytic 2′3′-Cyclic GMP-AMP Synthesis. ChemSusChem, 2022; early view. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical Appraisal of the Circular Economy Standard BS 8001:2017 and a Dashboard of Quantitative System Indicators for Its Implementation in Organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Sleeswijk, A.W.; van Oers, L.F.C.M.; Guinée, J.B.; Struijs, J.; Huijbregts, M.A.J. Normalisation in Product Life Cycle Assessment: An LCA of the Global and European Economic Systems in the Year 2000. Sci. Total. Environ. 2008, 390, 227–240. [Google Scholar] [CrossRef] [PubMed]

- Acquaye, A.A.; Barratt, P.; Topi, C.; Glew, D.; Kuylenstierna, J.; Koh, L.; Barrett, J.; McQueen-Mason, S. Green Supply Chain Management: The Development of Supply Chain Carbon Maps. Int. J. Eng. Manag. Econ. 2012, 3, 175–192. [Google Scholar] [CrossRef]

- Ferreira, C.; Freire, F.; Ribeiro, J. Life-Cycle Assessment of a Civil Explosive. J. Clean. Prod. 2015, 89, 159–164. [Google Scholar] [CrossRef]

- Hertwich, E.G. Increased Carbon Footprint of Materials Production Driven by Rise in Investments. Nat. Geosci. 2021, 14, 151–155. [Google Scholar] [CrossRef]

- Fried, E. CHEETAH 1.39–User’s Manual 1996; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1996.

- Dowbysz, A.; Kukfisz, B.; Samsonowicz, M.; Markowska, D.; Jankowski, P. Life Cycle Assessment of Glass/Polyester Laminates Used in the Shipbuilding Industry and Its Fire Behavior. Econ. Environ. 2023, 85, 236–254. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- BS 8001:2017; Framework for Implementing the Principles of the Circular Economy in Organizations. Guide. BSI: London, UK, 2017.

| Stage | Assembly | Ecoinvent Database | Quantity | ||

|---|---|---|---|---|---|

| EE | EEwR | EER | |||

| A1 | Ammonium nitrate [kg] | Ammonium nitrate, market for ammonium nitrate | 600 | 560 | 560 |

| Sodium nitrate, technical grade [kg] | Sodium nitrate, market for | 200 | 170 | 170 | |

| Water [kg] | Water, decarbonized, market for water | 130 | 100 | 100 | |

| Mineral oil [kg] | White mineral oil, at plant | 50 | 50 | 50 | |

| Nitrocellulose powder [kg] | Market for cellulose, nitric acid production, market for sulfuric acid; water, decarbonized, market for water | - | 100 | 100 | |

| Polycarboxylate [kg] | Polycarboxylates, market for | 20 | 20 | 20 | |

| A2 | In-house transport [tkm] | Transport, freight, lorry, all sizes, unregulated to generic market for transport, freight, lorry, unspecified | 1 | 1 | 1 |

| A3 | Electricity [kWh] | Electricity, medium voltage, market group for | 140.67 | 195.67 | 195.67 |

| Steam [GJ] | Steam production, in chemical industry | - | 4.5 | 4.5 | |

| B1 | Transport [tkm] | Transport, freight, lorry, all sizes, unregulated to generic market for transport, freight, lorry, unspecified | 100 | 100 | 100 |

| B2 | Loading [kWh] | Electricity, medium voltage, market group for | 2 | 2 | 2 |

| Stage | Assembly | Quantity [g/1000 kg of Explosive] | Ecoinvent Database | |

|---|---|---|---|---|

| EE | EEwR/EER | |||

| C1 | H2O (g) | 454,320 | 431,460 | Water |

| N2 (g) | 242,340 | 236,040 | Nitrogen | |

| CO2 (g) | 195,756 | 226,072 | Carbon dioxide | |

| O2 (g) | 33,056 | 0 | Oxygen | |

| NO (g) | 1000 | 2 | Nitrogen monoxide | |

| CO (g) | 5 | 43,400 | Carbon monoxide | |

| H2 (g) | 0 | 47 | Hydrogen | |

| CH2O2 (g) | 0 | 244 | Formic acid | |

| NH3 (g) | 0 | 36 | Ammonia | |

| CH2O (g) | 0 | 1 | Formaldehyde | |

| CH3OH (g) | 0 | 4 | Methanol | |

| CH4 (g) | 0 | 84 | Methane | |

| C2H4 (g) | 0 | 1 | Ethylene | |

| Na2O (l) | 72,912 | 62,000 | Sodium oxide | |

| Impact Category | Unit | Definition |

|---|---|---|

| Abiotic depletion | kg Sb eq | Depletion of non-renewable resources, such as metals and minerals, measured in antimony equivalents (Sb) |

| Abiotic depletion (fossil fuels) | MJ | Depletion of fossil fuels as an energy source, measured in megajoules (MJ) |

| Global warming (GWP100a) | kg CO2 eq | Potential for global warming due to greenhouse gas emissions, measured in CO2 equivalents |

| Ozone layer depletion (ODP) | kg CFC-11 eq | Impact on ozone layer degradation, measured in CFC-11 equivalents |

| Human toxicity | kg 1,4-DB eq | Negative effects of emissions on human health, measured in 1,4-dichlorobenzene (1,4-DB) equivalents |

| Fresh water aquatic ecotoxicity | kg 1,4-DB eq | Toxicity of emissions to freshwater aquatic organisms, measured in 1,4-DB equivalents |

| Marine aquatic ecotoxicity | kg 1,4-DB eq | Toxicity of emissions to marine aquatic organisms, measured in 1,4-DB equivalents |

| Terrestrial ecotoxicity | kg 1,4-DB eq | Toxicity of emissions to terrestrial organisms, measured in 1,4-DB equivalents |

| Photochemical oxidation | kg C2H4 eq | Formation of ground-level ozone (photochemical smog), measured in ethylene (C2H4) equivalents |

| Acidification | kg SO2 eq | Potential for environmental acidification (soil, water), measured in sulfur dioxide (SO2) equivalents |

| Eutrophication | kg PO43− eq | Enrichment of aquatic ecosystems with nutrients, leading to overgrowth of algae, measured in phosphate (PO43−) equivalents |

| Impact Category | Unit | EE | EEwR | EER |

|---|---|---|---|---|

| Abiotic depletion | kg Sb eq | 0.03 | 0.04 | 0.03 |

| Abiotic depletion (fossil fuels) | MJ | 24,208.13 | 33,073.60 | 30,932.71 |

| Global warming (GWP100a) | kg CO2 eq | 2274.26 | 2587.38 | 2297.77 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 0.00015 | 0.00015 | 0.00014 |

| Human toxicity | kg 1,4-DB eq | 1650.62 | 1612.60 | 1504.90 |

| Fresh water aquatic ecotox. | kg 1,4-DB eq | 965.57 | 951.46 | 881.01 |

| Marine aquatic ecotoxicity | kg 1,4-DB eq | 1,711,885.21 | 1,792,395.48 | 1,617,389.47 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 2.53 | 2.69 | 2.46 |

| Photochemical oxidation | kg C2H4 eq | −0.14 | 2.05 | 2.01 |

| Acidification | kg SO2 eq | 9.65 | 9.72 | 9.15 |

| Eutrophication | kg PO43− eq | 105.82 | 102.95 | 102.65 |

| Impact Category | EE | EEwR | EER |

|---|---|---|---|

| Abiotic depletion | 1.59 × 10−10 | 1.83 × 10−10 | 1.42 × 10−10 |

| Abiotic depletion (fossil fuels) | 6.37 × 10−11 | 8.70 × 10−11 | 8.14 × 10−11 |

| Global warming (GWP100a) | 5.44 × 10−11 | 6.18 × 10−11 | 5.50 × 10−11 |

| Ozone layer depletion (ODP) | 6.54 × 10−13 | 6.48 × 10−13 | 6.34 × 10−13 |

| Human toxicity | 6.40 × 10−10 | 6.26 × 10−10 | 5.84 × 10−10 |

| Fresh water aquatic ecotox. | 4.08 × 10−10 | 4.03 × 10−10 | 3.73 × 10−10 |

| Marine aquatic ecotoxicity | 8.83 × 10−9 | 9.25 × 10−9 | 8.35 × 10−9 |

| Terrestrial ecotoxicity | 2.32 × 10−12 | 2.47 × 10−12 | 2.26× 10−12 |

| Photochemical oxidation | −3.68 × 10−12 | 5.59 × 10−11 | 5.49 × 10−11 |

| Acidification | 4.05 × 10−11 | 4.07 × 10−11 | 3.84 × 10−11 |

| Eutrophication | 6.69 ×10−10 | 6.51 × 10−10 | 6.49 × 10−10 |

| Impact Category | EE | EEwR/EER |

|---|---|---|

| Abiotic depletion | 0 | 0 |

| Abiotic depletion (fossil fuels) | 0 | 0 |

| Global warming (GWP100a) | 4.68 × 10−12 | 5.46 × 10−12 |

| Ozone layer depletion (ODP) | 0 | 0 |

| Human toxicity | 0 | 1.72 × 10−15 |

| Fresh water aquatic ecotox. | 0 | 3.49 × 10−15 |

| Marine aquatic ecotoxicity | 0 | 8.41 × 10−18 |

| Terrestrial ecotoxicity | 0 | 8.6 × 10−16 |

| Photochemical oxidation | 1.2 × 10−11 | 4.58 × 10−11 |

| Acidification | 3.18 × 10−12 | 2.48 × 10−13 |

| Eutrophication | 6.45 × 10−10 | 6.27 × 10−10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maranda, A.; Wachowski, L.; Kukfisz, B.; Markowska, D.; Paszula, J. Valorization of Energetic Materials from Obsolete Military Ammunition Through Life Cycle Assessment (LCA): A Circular Economy Approach to Environmental Impact Reduction. Sustainability 2025, 17, 346. https://doi.org/10.3390/su17010346

Maranda A, Wachowski L, Kukfisz B, Markowska D, Paszula J. Valorization of Energetic Materials from Obsolete Military Ammunition Through Life Cycle Assessment (LCA): A Circular Economy Approach to Environmental Impact Reduction. Sustainability. 2025; 17(1):346. https://doi.org/10.3390/su17010346

Chicago/Turabian StyleMaranda, Andrzej, Leszek Wachowski, Bożena Kukfisz, Dorota Markowska, and Józef Paszula. 2025. "Valorization of Energetic Materials from Obsolete Military Ammunition Through Life Cycle Assessment (LCA): A Circular Economy Approach to Environmental Impact Reduction" Sustainability 17, no. 1: 346. https://doi.org/10.3390/su17010346

APA StyleMaranda, A., Wachowski, L., Kukfisz, B., Markowska, D., & Paszula, J. (2025). Valorization of Energetic Materials from Obsolete Military Ammunition Through Life Cycle Assessment (LCA): A Circular Economy Approach to Environmental Impact Reduction. Sustainability, 17(1), 346. https://doi.org/10.3390/su17010346