Advancing Middle East Construction Sustainability: A Framework for Addressing Logistics Challenges Through Solutions and Critical Success Factors

Abstract

:1. Introduction

2. Literature Review

2.1. The Middle East Construction Industry

2.2. Construction Logistics Challenges

2.3. Sustainability Within Construction Logistics

2.4. Enhancing Sustainability in Construction Logistics

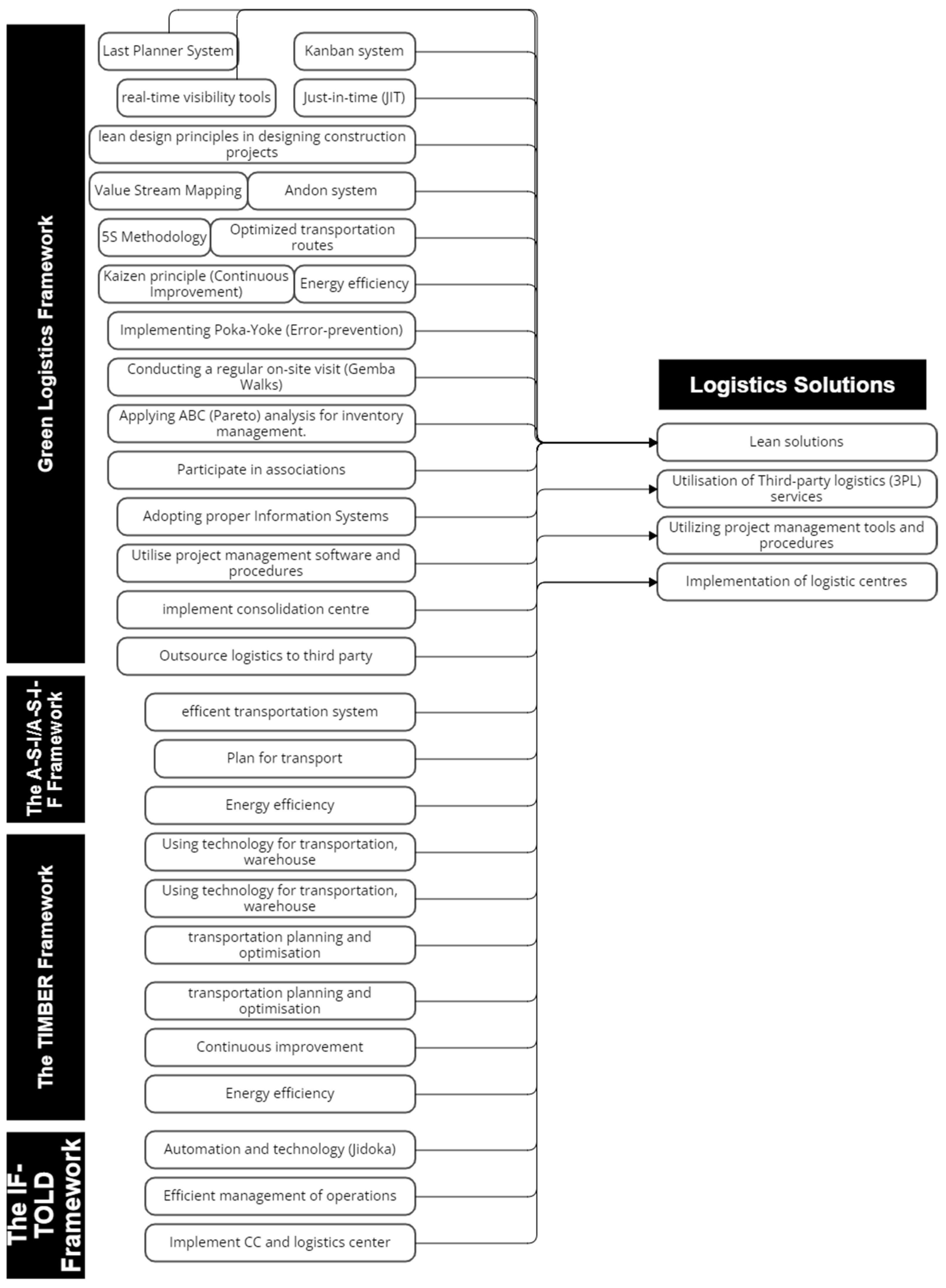

2.4.1. Logistics Solutions

Green Logistics Framework

A-S-I/A-S-I-F Framework

TIMBER Framework

IF-TOLD Framework

Comparative Analysis of Logistics Solutions Frameworks

Green Logistics Framework vs. TIMBER Framework

Green Logistics Framework vs. IF-TOLD Framework

Green Logistics Framework vs. A-S-I/A-S-I-F Framework

Regional Specificity and Uniqueness

- Flexibility: It integrates agile tools like real-time tracking and adaptive scheduling to navigate unpredictable supply chain disruptions caused by political instability.

- Efficiency: Lean methodologies, such as JIT and Kanban, directly tackle high material costs and resource scarcity.

- Scalability: Tools like BIM ensure precise planning and waste reduction for large-scale urban projects.

2.4.2. The Critical Susses Factors (C.S. Fs)

Demand Forecasting and Planning

Proper Information Flow

Compliance with Safety, Environmental and Regulations

Effective Risk Management

Efficient Resource Allocation

Collaborating with Suppliers

Adequate Training and Skill Development

Strong Commitment and Support from Top Management

2.5. The Development of the Conceptual Model

2.5.1. Principal-Agent Theory (PAT)

2.5.2. Transaction Cost Analysis (TCA)

2.5.3. Resource-Based View (RBV)

2.5.4. Network Theory

2.6. Logistics Solutions and Sustainability

2.7. Critical Success Factors (CSFs) and Sustainability

2.8. Logistics Challenges and Sustainability

2.9. Logistics Solutions and Critical Success Factors

2.10. Interaction Between Logistics Solutions and Logistics Challenges

2.11. Interaction Between Critical Success Factors and Logistics Challenges

3. Methodology

3.1. Limitations of the Chosen Methodologies and How They Were Mitigated

3.2. Model Development

3.3. Data Collection

3.4. Pilot Test

3.5. Data Analysis

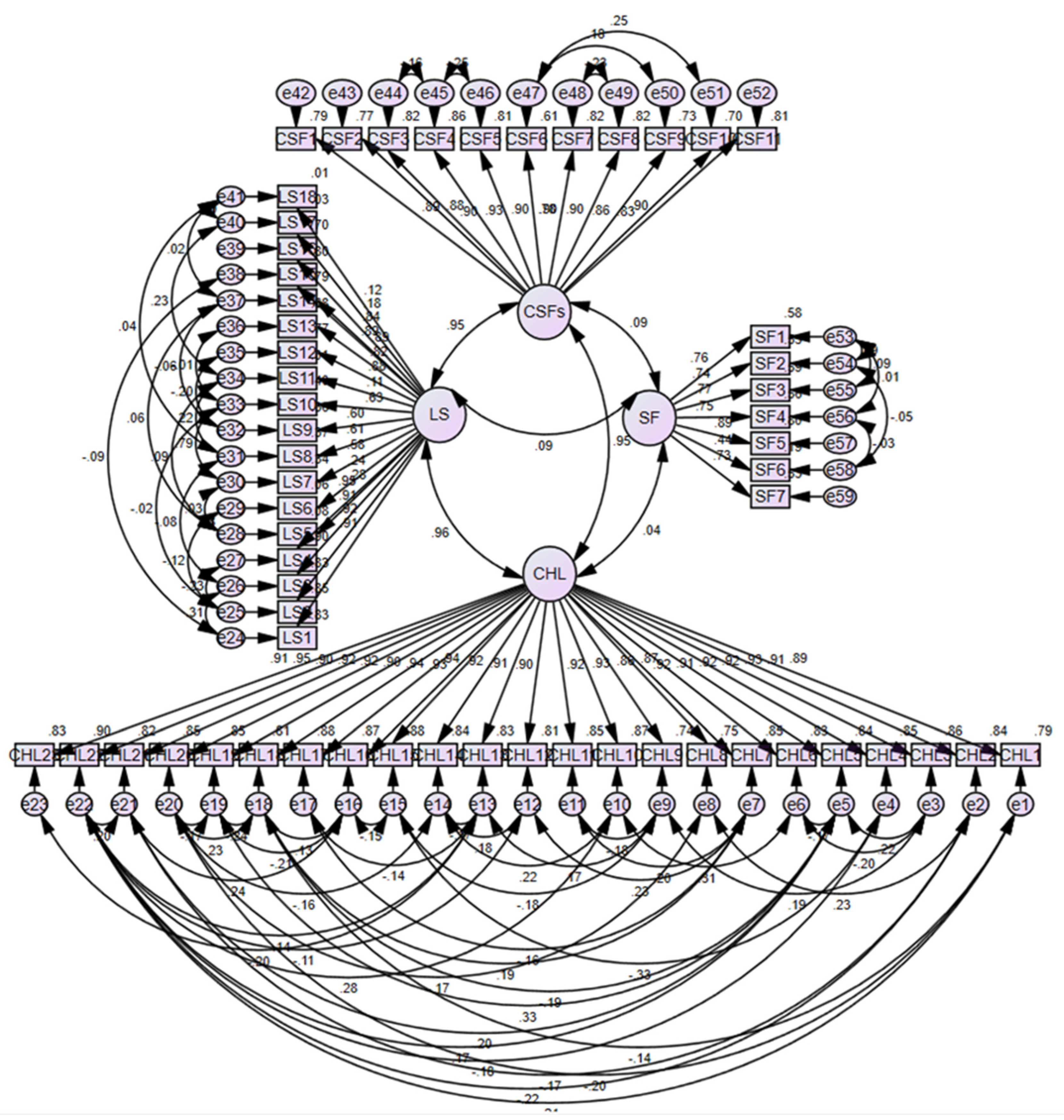

- Structural equation modelling is more appropriate than other statistical techniques when the model includes several exogenous (independent) variables and endogenous (dependent) variables with interconnected relationships [123]. This research includes several variables (construct), including logistics challenges, CSFs, logistics solutions, and sustainability factors. These variables seem to be affected by each other at the same time. The model will undergo simultaneous testing in this situation. When utilising first-generation statistical tools, it would be necessary to conduct multiple analyses.

- The proposed conceptual model is to understand the effect of logistics challenges on sustainability and the promises of the CSFs and logistics solutions in the context of the Middle East which is considered a complex model. So, testing complex modelling requires the use of SEM, which is more valuable than first-generation statistical tools [106].

- The proposed research model, which employs a confirmatory modelling strategy, will be used to test a set of hypothesised relationships within the constructs of this research [99].

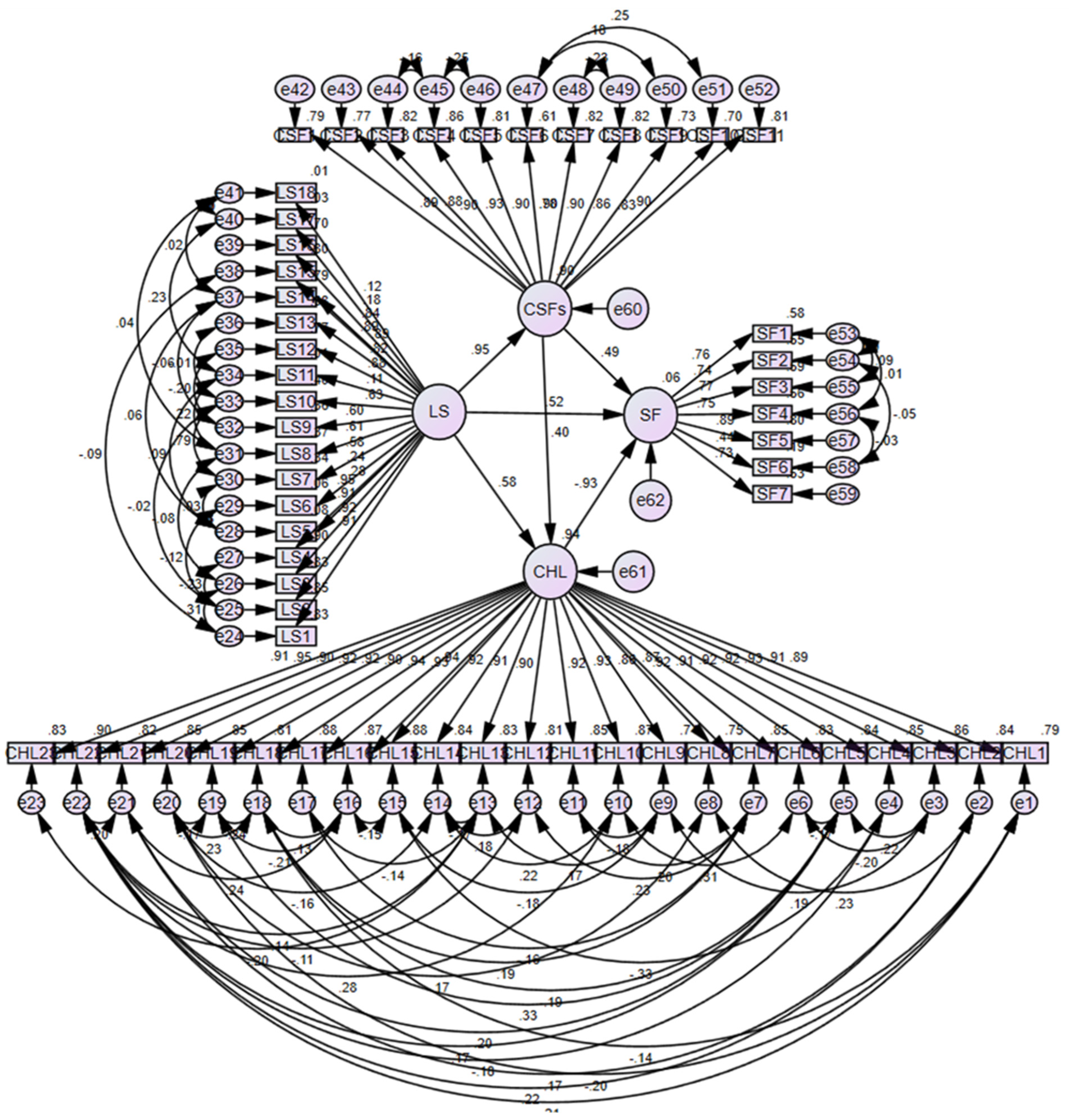

- To evaluate the model fit, this study utilised key indicators, such as CFI (comparative fit index), TLI (Tucker–Lewis index), and RMSEA (root mean square error of approximation). The final model achieved satisfactory fit with CFI = 0.93, TLI = 0.91, and RMSEA = 0.07, meeting commonly accepted thresholds for good model fit.

- Missing data comprised 5% of the dataset and were handled using full information maximum likelihood (FIML), as this method is robust to data missing at random (MAR). Little’s MCAR test confirmed that the missingness did not bias the results (p > 0.05).

- The SEM model included four latent variables: logistics challenges, solutions, success factors, and sustainability factors, measured using a total of 58 observed indicators on a five-point Likert scale. The measurement model was validated through confirmatory factor analysis, achieving significant factor loadings above AVE values above 0.50, indicating convergent validity.

3.6. Bias Minimising

4. Results and Discussion

4.1. The Survey Instrument’s Reliability

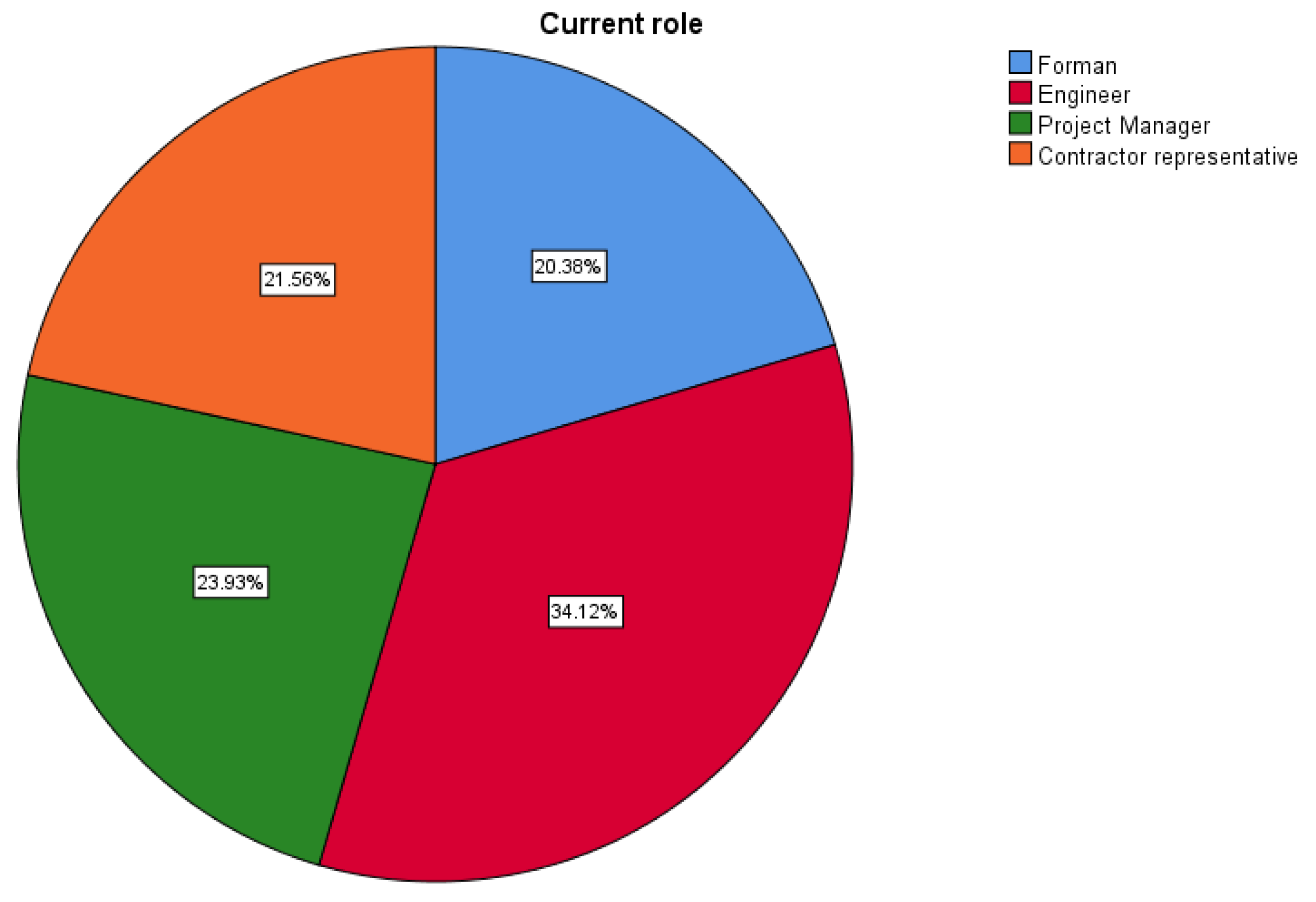

4.2. Respondents Background

4.3. Years of Experience

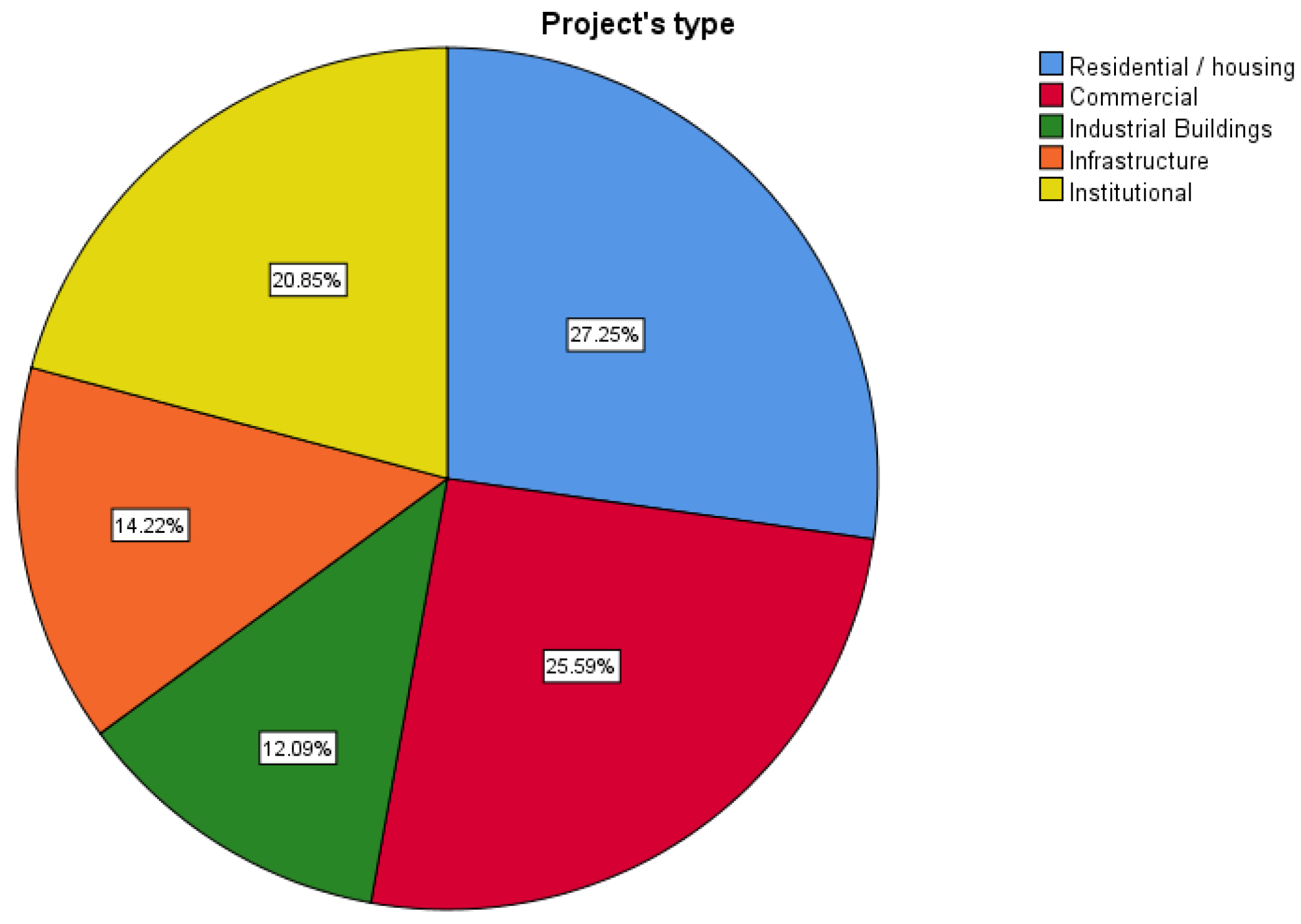

4.4. Construction’s Project Category

4.5. Experience Field

4.6. Descriptive Statistics for Challenges Affecting Construction Logistics

4.7. Descriptive Statistics for Logistics Critical Success Factors (CSFs)

4.8. Descriptive Statistics for Logistics Solutions

4.9. Descriptive Statistics for Sustainable Factors

4.10. The Validity of the Survey Instrument

4.11. Results of Confirmatory Factor Analysis (CFA)

4.11.1. Results of One-Dimensionality, Convergent Validity, and Discriminant Validity of Research Concept

4.11.2. Results of Composite Reliability and Average Variance Extracted of Research Concepts

4.12. Results of Model Research Hypotheses Testing

4.12.1. Results for Testing of the Research Hypotheses

4.12.2. How to Utilise Logistics Solutions to Address Logistics Challenges

4.12.3. How CSFs Mitigate Logistics Challenges

5. Conclusions and Recommendations

- Enterprise Managers: Prioritise implementing logistics solutions, such as real-time visualisation tools, lean construction principles, and just-in-time systems, to improve coordination, resource allocation, and material flow. Focus on achieving CSFs like proper information flow and effective risk management to address logistical inefficiencies.

- Policy Makers: Design policies that promote the adoption of green logistics technologies, such as tax incentives for firms adopting eco-friendly practices, and establish regulatory frameworks mandating sustainability reporting in construction projects. Support industry-wide adoption of frameworks like Green Logistics and TIMBER through funding and public-private collaborations.

- Industry Associations: Facilitate knowledge sharing and capacity building by organising workshops, certification programs, and forums to disseminate best practices in logistics management. Advocate for the integration of advanced technologies, such as building information modelling (BIM), to enable real-time collaboration among stakeholders.

- Researchers: Build on this framework to develop phased implementation strategies and test the feasibility of solutions in diverse operational contexts across the Middle East.

5.1. Contribution

- This research fills a gap in the literature by comprehensively presenting logistics challenges affecting the construction industry along with the logistics functions to enhance sustainability.

- To the best of our knowledge, this research is the first research to examine the role of logistics solutions and CSFs on addressing logistics challenges to enhance the sustainability of construction logistics.

- This research integrates existing logistics frameworks and theories to introduce new practical frameworks that link logistics challenges, logistics solutions, and CSFs with sustainability in the construction industry. This research proposes a new way of evaluating sustainability for the built environment considering logistics aspects.

- This research demonstrates the successful implementation of sustainable logistics solutions and CSFs in construction projects. Consequently, it identifies and documents best practices and guidelines for implementing sustainable logistics in construction, which can be adopted by industry practitioners.

- Construction stakeholders will gain further guidance and perceptions on understanding, identifying, and then assessing their construction logistics process within the Middle East construction industry.

- By using the contribution of this research as a benchmark for Middle East construction, academics will have a significant opportunity to increase their research in this field, which is still undervalued by most developing countries.

- By extending their research in logistics solutions and CSFs within construction fields, developing countries can assess and develop their current situation, as this research encourages.

5.2. Limitations

Directions for Future Research

- Inclusion of Governmental Perspectives: Future studies should seek to include data from governmental sectors to provide a more comprehensive understanding of logistics challenges and solutions. Collaborating with public agencies or leveraging official datasets could help bridge this gap, offering insights into how public-private partnerships influence construction logistics and sustainability.

- Broader Stakeholder Engagement: While this study focused on contractors, future research could include perspectives from consultants, clients, suppliers, and other stakeholders involved in construction projects. This multi-stakeholder approach would offer a more holistic view of the challenges and opportunities in achieving sustainable logistics.

- Expanded Geographic Scope: To enhance the generalisability of findings, future research should incorporate data from additional Middle Eastern countries, especially those currently excluded due to instability (e.g., Syria, Lebanon). Comparative studies between stable and unstable regions could provide valuable insights into how political and economic conditions influence logistics practices.

- Longitudinal Studies: A longitudinal approach could examine how the adoption of proposed logistics solutions evolves over time and their long-term impact on sustainability. This could provide a deeper understanding of the dynamic nature of logistics challenges and the effectiveness of solutions in diverse contexts.

- Integration of Advanced Technologies: Future research could explore the role of emerging technologies, such as artificial intelligence (AI), blockchain, and the Internet of things (IoT), in optimising construction logistics. Investigating the barriers to technology adoption, such as cost and technical expertise, could help design actionable strategies for implementation.

- Analysis of Implementation Challenges: While this study proposed logistics solutions, future research could focus on identifying and addressing practical implementation challenges, such as cost constraints, technical capability gaps, and organisational resistance. Developing phased implementation strategies tailored to the Middle Eastern context would enhance the feasibility of these solutions.

- Cross-Industry Comparisons: Future studies could compare logistics practices in the construction industry with those in other sectors, such as manufacturing or retail, to identify transferable strategies and innovations that could improve construction logistics.

- Policy Framework Development: Research could investigate the role of policy interventions in promoting sustainable logistics. This includes evaluating the effectiveness of existing regulations and identifying new policies to incentivise the adoption of green logistics practices across the region.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fredriksson, A.; Janne, M.; Rudberg, M. Characterizing third-party logistics setups in the context of construction. Int. J. Phys. Distrib. Logist. Manag. 2012, 51, 325–349. [Google Scholar] [CrossRef]

- Stefansson, G. Collaborative logistics management and the role of third-party service providers. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 76–92. [Google Scholar] [CrossRef]

- Shemov, G.; Garcia, B.; Alkhzaimi, H. Blockchain applied to the construction supply chain: A case study with a threat model. Front. Eng. Manag. 2020, 1, 20–29. [Google Scholar] [CrossRef]

- Department for Business Innovation and Skills. Supply Chain Analysis into the Construction Industry—A Report for the Construction Industrial Strategy; Department for Business Innovation and Skills [BIS]: London, UK, 2019.

- Miemczyk, J.; Johnsen, T.; Macquet, M. Sustainable purchasing and supply management: A structured literature review of definitions and measures at dyad, chain and network levels. Supply Chain Manag. Int. J. 2012, 17, 478–496. [Google Scholar] [CrossRef]

- Shigute, A.; Nasirian, A. The Future of Construction Logistics—Consolidation Centres in Construction. Master’s Thesis, Chalmers University, Gothenburg, Sweden, 2014. [Google Scholar]

- Zalaghi, H.; Khazaei, M. The Role of Deductive and Inductive Reasoning in Accounting Research and Standard Setting. Asian J. Financ. Account. 2016, 8, 23–37. [Google Scholar] [CrossRef]

- Tashakkori, A.; Teddlie, C. Handbook of Mixed Methods in Social and Behavioural Research; Sage: Thousand Oaks, CA, USA, 2003. [Google Scholar]

- Vrijhoef, R. Improving efficiency and environmental impact applying JIT logistics and transport consolidation in urban construction projects. In Proceedings of the Creative Construction Conference, Ljubljana, Slovenia, 30 June–3 July 2018. [Google Scholar]

- Manuj, L.; Dittmann, P.; Gaudenzi, B. Global Supply Chain Management; Sage: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Bahga, A.; Madisetti, V.K. Blockchain Applications: A Hands-On Approach; White Falcon Publishing: Ajitgarh, India, 2017. [Google Scholar]

- Thunberg, M.; Persson, F. Using the SCOR models performance measurements to improve construction logistics. Prod. Plan. Control. J. 2014, 25, 1065–1078. [Google Scholar] [CrossRef]

- Johnston, A.; Clark, G. Service Operations Management: Improving Service Delivery, 2nd ed.; Pearson Education Limited: New York, NY, USA, 2005. [Google Scholar]

- Kowalkowski, C.; Gebauer, H.; Kamp, B.; Parry, G. Servitization and deservitization: Overview, concepts, and definitions. Ind. Mark. Manag. 2017, 60, 4–10. [Google Scholar] [CrossRef]

- Dubois, A.; Kajsa, H.; Sundquist, V. Organising Logistics and Transport Activities in Construction. Int. J. Logist. Manag. 2019, 30, 620–640. [Google Scholar] [CrossRef]

- Treiblmaier, H. The impact of the blockchain on the supply chain: A theory-based research framework and a call for action. Supply Chain Manag. 2018, 23, 545–559. [Google Scholar] [CrossRef]

- Ying, F.; Tookey, J.; Roberti, J. Addressing effective construction logistics through the lens of vehicle movements. Eng. Constr. Archit. Manag. 2018, 21, 261–275. [Google Scholar] [CrossRef]

- Larossa, R.; Bennett, A. Ethical dilemmas in qualitative family research. In The Psychosocial Interior of the Family; Routledge: London, UK, 2018; pp. 139–156. [Google Scholar]

- Grant, D.; Teller, C.; Kotzab, H. Qualitative Research in Logistics: Theory and Practice. J. Supply Chain Manag. Res. Pract. 2010, 4, 1–23. [Google Scholar]

- Harriss, D.; Atkinson, G. Ethical Standards in Sport and Exercise Science Research: 2016 Update. Int. J. Sports Med. 2015, 36, 1121–1124. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjya, J.; Ellison, A.; Tripathi, S. An exploration of logistics-related customer service provision on Twitter. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 659–680. [Google Scholar] [CrossRef]

- Gebauer, H.; Paiola, M.; Saccani, N. Characterizing service networks for moving from products to solutions. Ind. Mark. Manag. 2013, 42, 31–46. [Google Scholar] [CrossRef]

- Gosman, L.; Kohlbeck, J. Effects of the existence and identity of major customers on supplier profitability: Is Wal-Mart different. J. Manag. Account. Res. 2009, 21, 179–201. [Google Scholar] [CrossRef]

- Hilletofth, P.; Hilmola, O. Role of logistics outsourcing on supply chain strategy and management. Strateg. Outsourc. Int. J. 2010, 3, 46–61. [Google Scholar] [CrossRef]

- Bourlakis, M.; Melewar, T. Marketing Perspectives of Logistics Service Providers: Present and Future Research Directions. Eur. J. Mark. 2011, 45, 300–310. [Google Scholar] [CrossRef]

- Ekeskar, A. Exploring Third-Party Logistics and Partnering in Construction: A Supply Chain Management Perspective. Ph.D. Thesis, Linkoping University, Linköping, Sweden, 2016. Available online: http://liu.diva-portal.org/smash/record.jsf?pid=diva2%3A932215&dswid=4274 (accessed on 1 August 2021).

- Selviaridis, K.; Norrman, A. Performance-based contracting for advanced logistics services: Challenges in its adoption, design and management. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 592–617. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using IBM SPSS Statistics; Sage: London, UK, 2013. [Google Scholar]

- Brintrup, A.; Kito, T.; New, S.; Reed-Tsochas, F. From transaction cost economics to food webs: A multidisciplinary discussion on the length of supply chains. In Proceedings of the 18th EurOMA Conference, Cambridge, UK, 3–6 July 2011; University of Cambridge: Cambridge, UK, 2011; pp. 125–139. [Google Scholar]

- Wang, P.; Gong, M. How Third-Party Logistics Providers Manage Relationship with Customers—A Multiple Case Study. Master’s Thesis, University of Gavle, Gävle, Sweden, 2014. [Google Scholar]

- Bragg, S.M. Inventory Best Practices; John Wiley and Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Halldorsson, A.; Vural, A. Servitization and logistics: Building a service-based typology. In Proceedings of the 26th Annual EurOMA Conference: Operations Adding Value to Society, Helsinki, Finland, 17–19 June 2019; Aalto University Business School: Helsinki, Finland; pp. 325–349. [Google Scholar]

- Bovet, D.; Martha, J. Value Nets—Breaking the Supply Chain to Unlock Hidden Profits; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Henric, J.; Rudberg, M. KPIs for measuring performance of production systems for residential building: A production strategy perspective. Constr. Innov. Inf. Process Manag. 2017, 17, 381–403. [Google Scholar]

- Ghanem, M.; Hamzeh, F.; Seppanen, O.; Zankoul, E. A new perspective of construction logistics and production control: An exploratory study. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 16–22 July 2018; International Group for Lean Construction: Chennai, India, 2018; pp. 992–1001. [Google Scholar]

- Ekeskar, A.; Rudberg, M. Third-party logistics in construction: Perspectives from suppliers and transport service providers. Prod. Plan. Control 2020, 32, 875–974. [Google Scholar] [CrossRef]

- Guerlain, C.; Renault, S.; Ferrero, F. Understanding Construction Logistics in Urban Areas and Lowering its Environmental Impact: A Focus on Construction Consolidation Centres. Sustainability 2019, 11, 6118. [Google Scholar] [CrossRef]

- Neuman, W. Social Research Methods: Qualitative and Quantitative Approaches, 4th ed.; Pearson Education: Boston, MA, USA, 2000. [Google Scholar]

- Gosling, J.; Denis, R.; Mohamed, N.; Andrew, D. Principles for the Design and Operation of Engineer-to-Order Supply Chains in the Construction Sector. Prod. Plan. Control J. 2015, 26, 203–218. [Google Scholar] [CrossRef]

- Bruggeman, J. Social Networks: An Introduction; Routledge: London, UK, 2008. [Google Scholar]

- Handfield, R.; Nichols, E. Supply Chain Redesign: Transforming Supply Chains into Integrated Value Systems; Financial Times Prentice-Hall: Englewood, NJ, USA, 2002. [Google Scholar]

- Bryman, B.; Bell, E. Business Research Methods, 3rd ed.; Oxford University Press: Oxford, UK, 2011. [Google Scholar]

- Yao, Y.; Dresner, M.; Palmer, W. Impact of Boundary-Spanning information technology and position in the chain on firm performance. J. Supply Chain Manag. 2009, 45, 3–16. [Google Scholar] [CrossRef]

- Kim, Y.; Choi, Y.; Yan, T.; Dooley, K. Structural investigation of supply networks: A social network analysis approach. J. Oper. Manag. 2011, 29, 194–211. [Google Scholar] [CrossRef]

- Bygballe, L.; Marianne, J.; Anna, S. Partnering Relationships in Construction: A Literature Review. J. Purch. Supply Manag. 2010, 16, 239–253. [Google Scholar] [CrossRef]

- Wincel, J. Lean Supply Chain Management; Routledge: London, UK; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Cohen, L.; Manion, L.; Morrison, K. Research Methods in Education; Routledge: New York, NY, USA, 2007. [Google Scholar]

- Luong, L.; Jarroudi, I.; Dao, T.; Chaabane, A. Integrated construction supply chain: An optimal decision-making model with third-party logistics partnership. Constr. Manag. Econ. 2021, 39, 133–155. [Google Scholar]

- Carnovale, S.; Yeniyurt, S. The role of ego networks in manufacturing joint venture formations. J. Supply Chain Manag. 2014, 50, 1–17. [Google Scholar] [CrossRef]

- Creswell, J. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches, 4th ed.; Sage: London, UK, 2014. [Google Scholar]

- Hedlund, R.; Telese, G. Outsourcing Construction Logistics. Master’s Thesis, Chalmers University, Gothenburg, Sweden, 2019. [Google Scholar]

- Tavakol, M.; Dennick, R. Making Sense of Cronbach’s Alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef]

- Dubois, A.; Gadde, L. Supply strategy and network effects—Purchasing behaviour in the construction industry. Eur. J. Purch. Supply Manag. 2000, 6, 207–215. [Google Scholar] [CrossRef]

- Naslund, D. Logistics needs qualitative research—Especially action research. Int. J. Phys. Distrib. Logist. Manag. 2002, 32, 321–338. [Google Scholar] [CrossRef]

- Shapiro, P. Agency theory. Annu. Rev. Sociol. 2005, 31, 263–284. [Google Scholar] [CrossRef]

- Manuj, I.; Mentzer, T. Global supply chain risk management strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 192–223. [Google Scholar] [CrossRef]

- Rahman, M. The Advantages and Disadvantages of Using Qualitative and Quantitative Approaches and Methods in Language “Testing and Assessment” Research: A Literature Review. J. Educ. Learn. 2017, 6, 211–230. [Google Scholar] [CrossRef]

- Seth, D.; Krishna, N.; Pokharel, S.; Al Sayed, A. Impact of Competitive Conditions on Supplier Evaluation: A Construction Supply Chain Case Study. Prod. Plan. Control J. 2018, 29, 217–235. [Google Scholar] [CrossRef]

- Janne, M.; Fredriksson, A. Construction Logistics Governing Guidelines in Urban Development Projects. Constr. Innov. J. 2019, 19, 89–109. [Google Scholar] [CrossRef]

- Kaal, A. Blockchain solutions for agency problems in corporate governance. In Proceedings of the 1st Annual Toronto FinTech Conference, Toronto, ON, Canada, 20–21 October 2017; The University of St-Thomas: Toronto, ON, Canada; pp. 545–559. [Google Scholar]

- Linden, S.; Josephson, P.E. In-housing or out-sourcing on-site materials handling in housing. J. Eng. Des. Technol. 2013, 11, 90–106. [Google Scholar] [CrossRef]

- Wilson, J. Essentials of Business Research: A Guide to Doing Your Research Project; Sage Publications: Thousand Oaks, CA, USA, 2010. [Google Scholar]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 6th ed.; Pearson Education Limited: London, UK, 2012. [Google Scholar]

- Yang, L.; Li, F.; Li, L.; Jin, C.; Wang, R.; Wang, H. A 3PL supplier selection model based on fuzzy sets. Comput. Oper. Res. 2022, 39, 1879–1884. [Google Scholar]

- Hearnshaw, E.J.; Wilson, M.M. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469. [Google Scholar] [CrossRef]

- Miemczyk, J.; Howard, M.; Johnsen, T.E. Dynamic development and execution of Closed-Loop supply chains: A natural Resource-Based view. Supply Chain Manag. Int. J. 2016, 21, 453–469. [Google Scholar] [CrossRef]

- Segerstedt, A.; Olofsson, T. Supply chains in the construction industry. Supply Chain Manag. Int. J. 2010, 15, 347–353. [Google Scholar] [CrossRef]

- Santos, J.; Wysk, R.; Torres, J. Improving Production with Lean Thinking; John Wiley and Sons Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Bobko, P. Correlation and Regression: Applications for Industrial Organizational Psychology and Management; Sage Publications: London, UK, 2001. [Google Scholar]

- El-Sawalhi, N. A construction material management system for Gaza building contractors. In Proceedings of the 4th International Engineering Conference—Towards Engineering of 21st Century, Gaza, Palestine, 15–16 October 2012. [Google Scholar]

- Ellinger, A.E.; Chapman, K. Benchmarking leading supply chain management and logistics strategy journals. Int. J. Logist. Manag. 2011, 22, 403–419. [Google Scholar] [CrossRef]

- Fadiya, O.; Chinyio, E.; Nwagboso, C.; Georgakis, P. Decision-making framework for selecting ICT-based construction logistics systems. J. Eng. Des. Technol. 2015, 13, 260–281. [Google Scholar] [CrossRef]

- Frodell, M.; Josephson, P.E.; Lindahl, G. Swedish Construction Clients’ Views on Project Success and Measuring Performance. J. Eng. 2008, 6, 21–32. [Google Scholar] [CrossRef]

- Josephoson, P.E.; Saukkoriipi, L. Waste in construction projects: Call for a new approach. J. Purch. Supply Manag. 2007, 6, 159–168. [Google Scholar]

- Wanga, J.; Yuanb, H.; Kangc, X.; Lud, W. Critical success factors for on-site sorting of construction waste: A China study. Resour. Conserv. Recycl. 2010, 54, 931–936. [Google Scholar] [CrossRef]

- Scarsi, R.; Spinelli, R. An analysis of strategic groups in the Third-Party Logistics industry. Int. J. Logist. Syst. Manag. 2017, 27, 466–486. [Google Scholar] [CrossRef]

- Halldorsson, A.; Hsuan, J.; Kotzab, H. Complementary theories to supply chain management revisited—From borrowing theories to theorizing. Supply Chain Manag. Int. J. 2015, 6, 574–586. [Google Scholar] [CrossRef]

- Jang, H.; Russell, J.; Yi, J.S. A project manager’s level of satisfaction in construction logistics. Can. J. Civ. Eng. 2003, 30, 1133–1142. [Google Scholar] [CrossRef]

- Johansen, J.; Riis, J.O. The interactive firm—Towards a new paradigm. Int. J. Oper. Prod. Manag. 2005, 25, 202–216. [Google Scholar] [CrossRef]

- Kotzab, H.; Christoph, T.; David, B.; Anders, F. Supply Chain Management Resources, Capabilities and Execution. Prod. Plan. Control J. 2015, 26, 525–542. [Google Scholar] [CrossRef]

- Janne, M.; Rudberg, M. Effects of employing third party logistics arrangements in construction projects. Prod. Plan. Control. J. 2020, 33, 71–83. [Google Scholar] [CrossRef]

- Picot, A.; Reichwald, R.; Wigand, R. Die Greenhouse Undernimming. Information, Organisation and Management, 4th ed.; Gabler: Wiesbaden, Germany, 2001. [Google Scholar]

- Davis, E.; Spekman, E. The Extended Enterprise: Gaining Competitive Advantage Through Collaborative Supply Chains; FT Prentice-Hall: Englewood, NJ, USA, 2004. [Google Scholar]

- Hertz, S.; Alfredsson, M. Strategic development of third-party logistics providers. Ind. Mark. Manag. 2003, 32, 139–149. [Google Scholar] [CrossRef]

- Thunberg, M. Towards a Framework for Process Mapping and Performance Measurement in Construction Supply Chains. Master’s Thesis, Linkoping University, Linköping, Sweden, 2013. [Google Scholar]

- Chen, D.; Jia, S.; Sun, M. Engineering construction project site logistics management. J. Chem. Pharm. Res. 2014, 6, 353–360. [Google Scholar]

- Field, A. Discovering Statistics Using SPSS, 3rd ed.; Sage: London, UK, 2009. [Google Scholar]

- Kwak, D. Risk Management in International Container Logistics Operations: Risk Analysis and Mitigating Strategies. Ph.D. Thesis, University of Cardiff, Cardiff, UK, 2014. [Google Scholar]

- Kasim, N.B. Improving Materials Management on the Construction Project. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2008. [Google Scholar]

- Lundesjo, G. Using Construction Consolidation Centres to Reduce Construction Waste and Carbon Emissions; Wrap: London, UK, 2015. [Google Scholar]

- Sundquist, V.; Gadde, L.; Hulthen, K. Reorganizing construction logistics for improved performance. Constr. Manag. Econ. 2018, 36, 49–65. [Google Scholar] [CrossRef]

- Halldorsson, A.; Kotzab, H.; Mikkola, J.H.; Skjott-Larsen, T. Complementary theories to supply chain management. Supply Chain Manag. Int. J. 2007, 12, 284–296. [Google Scholar] [CrossRef]

- Heaslip, G.; Kovacs, G. Examination of service triads in humanitarian logistics. Int. J. Logist. Manag. 2019, 30, 595–619. [Google Scholar] [CrossRef]

- Fellows, R.; Liu, A. Managing organizational interfaces in engineering construction projects: Addressing fragmentation and boundary issues across multiple interfaces. Constr. Manag. Econ. 2012, 30, 653–671. [Google Scholar] [CrossRef]

- Hosie, P.; Sundarakani, B.; Tan, A.W.K.; Kozlak, A. Determinants of fifth party logistics [5PL]: Service providers for supply chain management. Int. J. Logist. Syst. Manag. 2012, 13, 287–316. [Google Scholar] [CrossRef]

- Huo, B.; Flynn, B.; Zhao, X. Supply Chain Power Configurations and Their Relationship with Performance. J. Supply Chain Manag. 2017, 53, 88–111. [Google Scholar] [CrossRef]

- Allen, J.; Browne, M.; Woodburn, A.; Leonardi, J. A review of urban consolidation centres in the supply chain based on a case study approach. Supply Chain Forum Int. J. 2021, 15, 100–112. [Google Scholar] [CrossRef]

- Aguezzoul, A. Third-party logistics selection problem: A literature review on criteria and methods. Omega 2014, 49, 69–78. [Google Scholar] [CrossRef]

- Kotonen, U.; Lahtinen, H.; Savonen, L.; Suomaki, A.; Tuominen, U. Process and Methods of Competence Management and Development: Competence Development of Logistics Centres. Master’s Thesis, Lahti University of Applied Sciences, Lahti, Finland, 2012. [Google Scholar]

- Yin, R.K. Case Study Research Design and Methods, 77th ed.; Sage Publication: London, UK, 2014. [Google Scholar]

- Kagioglou, K.; Cooper, R.; Aouad, G.; Sexton, M. Rethinking Construction: Mie Generic Design and Construction Process. Eng. Constr. Archit. Manag. 2000, 7, 141–153. [Google Scholar] [CrossRef]

- Khan, S.; Singh, R.; Haleem, A.; Dsilva, J.; Ali, S.S. Exploration of Critical Success Factors of Logistics 4.0: A DEMATEL Approach. Logistics 2022, 6, 13. [Google Scholar] [CrossRef]

- Halldorsson, A.; Skjqtt-Larsen, T.; Andersson, D.; Dreyer, H.; Virum, H.; Ojala, L. Third party logistics—A Nordic approach. Int. J. Value Chain Manag. 2006, 1, 190–204. [Google Scholar]

- Easterby-Smith, M.; Thorpe, R.; Jackson, P.; Lowe, A. Management Research; Sage: London, UK, 2008. [Google Scholar]

- Karatas-Cetin, C.; Denktas-Sakar, G. Logistics Research Beyond 2000: Theory, Method and Relevance. Asian J. Shipp. Logist. 2013, 29, 125–144. [Google Scholar] [CrossRef]

- Sukamolson, S. Fundamentals of quantitative research. E J. Res. Teach. 2005, 2, 15–28. [Google Scholar]

- Palestine Government. The Vision of the Technology and Services. Available online: http://www.palestinecabinet.gov.ps/portal/home/indexen (accessed on 25 July 2021).

- Lee, N.; Lings, I. Doing Business Research: A Guide to Theory and Practice; Sage: London, UK, 2008. [Google Scholar]

- Lundesjo, G. Supply Chain Management and Logistics in Construction: Delivering Tomorrow’s Environment; Kogan Page Publishers: London, UK, 2015. [Google Scholar]

- Rowley, J. Designing and using research questionnaires. Manag. Res. Rev. 2014, 37, 308–330. [Google Scholar] [CrossRef]

- Piplani, R.; Fu, Y. A coordination framework for supply chain inventory alignment. J. Manuf. Technol. Manag. 2005, 16, 598–614. [Google Scholar] [CrossRef]

- Marasco, A. Third-party logistics: A literature review. Int. J. Prod. Econ. 2008, 113, 127–147. [Google Scholar] [CrossRef]

- Nguyen, L.D.; Oguniana, S.O.; Xuan Lan, D.T. A study on project success factors in large construction projects in Vietnam. Eng. Constr. Archit. Manag. 2004, 11, 404–413. [Google Scholar] [CrossRef]

- Blumberg, B.; Cooper, D.R.; Schindler, P.S. Business Research Methods; McGraw Hill Education: Berkshire, UK, 2005. [Google Scholar]

- Patel, K.V.; Vyas, C.M. Construction materials management on project sites. In Proceedings of the National Conference on Recent Trends in Engineering and Technology, Gujarat, India, 13–14 May 2011. [Google Scholar]

- Katsaliaki, K.; Galetsi, P.; Kumar, S. Supply chain disruptions and resilience: A major review and future research agenda. Annu. Oper. Res. J. 2021, 319, 965–1002. [Google Scholar] [CrossRef] [PubMed]

- Rudberg, M.; Olhager, J. Manufacturing networks and supply chains: An operations strategy perspective. Omega 2003, 31, 29–39. [Google Scholar] [CrossRef]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 8th ed.; Financial Times Prentice Hall: Harlow, UK, 2019. [Google Scholar]

- Hair, J.; Black, W.; Babin, B.; Anderson, R. Multivariate Data Analysis; Prentice Hall: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Schmoltzi, C.; Wallenburg, C. Operational Governance in Horizontal Cooperations of Logistics Service Providers: Performance Effects and the Moderating Role of Cooperation Complexity. J. Supply Chain Manag. 2012, 48, 53–74. [Google Scholar] [CrossRef]

- Selviaridis, K.; Spring, M. Third Party Logistics: A Literature Review and Research Agenda. Int. J. Logist. Manag. 2007, 18, 125–150. [Google Scholar] [CrossRef]

- Bryman, A. Social Research Methods, 2nd ed.; Oxford University Press: Oxford, UK, 2004. [Google Scholar]

- Rushton, A.; Walker, S. International Logistic and Supply Chain Outsourcing: From Local to Global; Kogan Page Publisher: London, UK, 2007. [Google Scholar]

- Baker, M.J.; Foy, A. Business and Management Research: How to Complete Your Research Project Successfully, 2nd ed.; West Burn Publishers: Helensburgh, UK, 2008. [Google Scholar]

- Strategic Forum for Construction Logistics Group. Improving Construction Logistics, Report of the Strategic Forum for Construction Logistics Group; Construction Production Association: London, UK, 2015. [Google Scholar]

- Strandberg, J.; Josephson, P.-E. What do construction workers do? Observations in housing projects. In Proceedings of the 11th Joint CIB International Symposium Combining Forces, Helsinki, Finland, 13–16 June 2016; pp. 184–193. [Google Scholar]

- Wood, M.; Welch, C. Are Qualitative and Quantitative Useful Terms for Describing Research? Methodol. Innov. Online J. 2010, 5, 56–71. [Google Scholar] [CrossRef]

- Choi, T.; Linton, Y. Don’t Let Your Supply Chain Control Your Business; Harvard Business Review: Brighton, MA, USA, 2011; Volume 89. [Google Scholar]

- Brax, A.; Bask, A.; Hsuan, J.; Voss, C. Service modularity and architecture—An overview and research agenda. Int. J. Oper. Prod. Manag. 2017, 37, 686–702. [Google Scholar] [CrossRef]

| Factors | [49,50,51,52] | [1,53,54,55] | [56,57,58] | [59,60,61,62] | [36,63,64] | [48,65,66,67] | [7,39,68] | [44,69,70,71] |

|---|---|---|---|---|---|---|---|---|

| Enhance labour productivity | x | x | x | x | x | |||

| Minimise greenhouse gas emissions | x | x | x | |||||

| Reduce the total cost of completing a project | x | x | x | |||||

| Improve resource efficiency | x | x | x | x | ||||

| Reduce waste | x | x | x | x | ||||

| Increase well-being | x | x | x | x | x | |||

| Enhance technology adoption | x | x | x | x |

| # | Code | Role of Interviewees | Experience |

|---|---|---|---|

| 1 | A | Contractor’s representative | More than 15 years |

| 2 | B | Project manager | 12 years |

| 3 | C | Senior Site engineer | 15 years |

| 4 | D | Logistics manager | 12 years |

| 5 | E | Logistics manager | 15 years |

| 6 | F | Project manager | 21 years |

| 7 | G | Contractor’s representative | 18 years |

| 8 | H | Project engineer | 10 years |

| 9 | I | Senior office engineer | 10 years |

| 10 | J | Project manager | 20 years |

| 11 | K | Construction manager | More than 15 years |

| 12 | L | Contractor’s representative | 13 years |

| 13 | M | Project manager | 10 years |

| 14 | N | Senior Site engineer | 18 years |

| 15 | O | Logistics manager | 8 years |

| 16 | P | Logistics manager | 11 years |

| 17 | Q | Project manager | 17 years |

| 18 | R | Contractor’s representative | 8 years |

| 19 | S | Supplier of construction material and previous owner of a construction owner | 20 years |

| 20 | T | Supplier of construction material and owner of block factory | 25 years |

| 21 | J | Construction manager | 12 years |

| 22 | V | Logistics manager | 12 years |

| 23 | W | Logistics manager | 15 years |

| 24 | X | Project manager | 12 years |

| 25 | Y | Contractor’s representative | More than 18 years |

| 26 | Z | Project engineer | 21 years |

| 27 | AA | Senior office engineer | 18 years |

| 28 | BB | Project manager | 8 years |

| 29 | CC | PhD in construction logistics | 6 years |

| Logistics Challenges |

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| Logistics Critical Success Factors |

|

| |

| |

| |

| |

| |

| |

| |

| Logistics Solutions |

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

| Construct | # of Variables | Cronbach’s Alpha Coefficient |

|---|---|---|

| 23 | 0.99 |

| 18 | 0.94 |

| 11 | 0.97 |

| 7 | 0.88 |

| Challenges | Min | Max | Sum | Mean | Std. | Variance |

|---|---|---|---|---|---|---|

| CHL17: Accuracy of goods (orders) received from suppliers | 1.00 | 5.00 | 1831.00 | 4.3389 | 1.21 | 1.47 |

| CHL11: Delays in decision-making by the consultant engineer | 1.00 | 5.00 | 1828.00 | 4.3318 | 1.19 | 1.43 |

| CHL4: Inadequate alignment between construction schedules and logistics practices | 1.00 | 5.00 | 1816.00 | 4.3033 | 1.23 | 1.51 |

| CHL14: Lack of coordination and integration with suppliers | 1.00 | 5.00 | 1810.00 | 4.2891 | 1.18 | 1.39 |

| CHL10: Ambiguity in logistics responsibilities for the construction team | 1.00 | 5.00 | 1806.00 | 4.2796 | 1.30 | 1.71 |

| CHL20: The use of inappropriate types of vehicles in transportation | 1.00 | 5.00 | 1803.00 | 4.27 | 1.19 | 1.43 |

| CHL22: (Temporary) Closures resulting from unstable political conditions | 1.00 | 5.00 | 1802.00 | 4.27 | 1.27 | 1.61 |

| CHL18: Waste of materials due to inefficient material handling | 1.00 | 5.00 | 1796.00 | 4.2 | 1.16 | 1.35 |

| CHL8: Inadequate communication among internal parties | 1.00 | 5.00 | 1793.00 | 4.24 | 1.18 | 1.40 |

| CHL1: Inadequate planning for logistics processes, including resource management | 1.00 | 5.00 | 1791.00 | 4.24 | 1.20 | 1.44 |

| CHL7: Ineffective coordination among internal parties | 1.00 | 5.00 | 1784.00 | 4.2 | 1.19 | 1.43 |

| CHL2: A lack of expertise (or knowledge) in construction logistics | 1.00 | 5.00 | 1780.00 | 4.21 | 1.187 | 1.41 |

| CHL23: The sudden labour shortage | 1.00 | 5.00 | 1777.00 | 4.2 | 1.28 | 1. |

| CHL5: Inefficient site layout | 1.00 | 5.00 | 1775.00 | 4.20 | 1.20 | 1.46 |

| CHL16: Poor material identification and estimation | 1.00 | 5.00 | 1774.00 | 4.20 | 1.31 | 1.73 |

| CHL6: Management’s insufficient commitment to on-site logistics operations | 1.00 | 5.00 | 1770.00 | 4.19 | 1.213 | 1.47 |

| CHL12: Duplication and errors caused by excessive paperwork | 1.00 | 5.00 | 1767.00 | 4.18 | 1.18 | 1.40 |

| CHL15: Neglecting the understanding of quality in purchasing processes | 1.00 | 5.00 | 1760.00 | 4.17 | 1.25 | 1.56 |

| CHL3: Ineffective monitoring and control of logistics activities | 1.00 | 5.00 | 1755.00 | 4.15 | 1.28 | 1.66 |

| CHL21: Inefficient management of the return process for purchased materials | 1.00 | 5.00 | 1754.00 | 4.15 | 1.2 | 1.59 |

| CHL19: Inaccurate inventory records | 1.00 | 5.00 | 1750.00 | 4.14 | 1.18 | 1.40 |

| CHL13: The fluctuating prices of construction materials and components | 1.00 | 5.00 | 1741.00 | 4.1256 | 1.28054 | 1.640 |

| CHL9: Lack of real-time tracking of fleet and equipment used in construction logistics | 1.00 | 5.00 | 1721.00 | 4.0782 | 1.33153 | 1.773 |

| CSFs | Min | Max | Sum | Mean | Std | Variance |

|---|---|---|---|---|---|---|

| CSF6: Effective risk management | 1.00 | 5.00 | 1831.00 | 4.33 | 0.053 | 1.21 |

| CSF9: Collaborating with suppliers | 1.00 | 5.00 | 1808.00 | 4.28 | 0.060 | 1.52 |

| CSF10: Adequate training and skill development | 1.00 | 5.00 | 1796.00 | 4.25 | 0.057 | 1.40 |

| CSF7: Integration of technology | 1.00 | 5.00 | 1782.00 | 4.2 | 0.058 | 1.44 |

| CSF5: Compliance with safety, environmental and regulations | 1.00 | 5.00 | 1780.00 | 4.21 | 0.059 | 1.50 |

| CSF2: Efficient transportation and delivery management | 1.00 | 5.00 | 1760.00 | 4.17 | 0.06 | 1.59 |

| CSF4: Proper information flow | 1.00 | 5.00 | 1759.00 | 4.16 | 0.064 | 1.74 |

| CSF8: Efficient resource allocation | 1.00 | 5.00 | 1751.00 | 4.14 | 0.062 | 1.64 |

| CSF3: Effective inventory management | 1.00 | 5.00 | 1748.00 | 4.14 | 0.064 | 1.73 |

| CSF1: Accurate demand forecasting and planning | 1.00 | 5.00 | 1738.00 | 4.1 | 0.06 | 1.77 |

| CSF11: Strong commitment and support from top management | 1.00 | 5.00 | 1736.00 | 4.1 | 0.060 | 1.56 |

| Logistics Solutions | Mean | Min | Max | Std. | Variance |

|---|---|---|---|---|---|

| LS17: Participate in associations, non-profit activities, and events | 4.73 | 1.00 | 5.00 | 0.58 | 0.34 |

| LS6: Implementation of logistic centres | 4.72 | 2.00 | 5.00 | 0.59 | 0.35 |

| LS5: Utilisation of third-party logistics (3PL) services | 4.71 | 1.00 | 5.00 | 0.60 | 0.36 |

| LS11: Implementing Poka-Yoke (Error-prevention) | 4.6 | 1.00 | 5.00 | 0.65 | 0.43 |

| LS18: Use of Information Systems and Modelling Tools, such as BIM and 3D | 4.69 | 3.00 | 5.00 | 0.52 | 0.27 |

| LS4: The utilisation of Real-time visibility tools | 4.33 | 1.00 | 5.00 | 1.30 | 1.70 |

| LS10: Applying the Kaizen principle (Continuous Improvement) | 4.31 | 1.00 | 5.00 | 1.31 | 1.71 |

| LS2: Implementing the Last Planner System (LPS) | 4.31 | 1.00 | 5.00 | 1.29 | 1.68 |

| LS8: Utilising project management tools and procedures | 4.29 | 1.00 | 5.00 | 1.30 | 1.71 |

| LS14: Applying the 5S Methodology | 4.28 | 1.00 | 5.00 | 1.26 | 1.60 |

| LS1: Implementing the Kanban system | 4.27 | 1.00 | 5.00 | 1.26 | 1.59 |

| LS7: Applying lean design principles in designing construction projects | 4.25 | 1.00 | 5.00 | 1.27 | 1.61 |

| LS3: Implementing just-in-time (JIT) | 4.24 | 1.00 | 5.00 | 1.328 | 1.76 |

| LS15: Applying ABC (Pareto) analysis for inventory management. | 4.23 | 1.00 | 5.00 | 1.29 | 1.68 |

| LS9: Using value-stream mapping to assist in identifying and eliminating non-value-added activities | 4.21 | 1.00 | 5.00 | 1.35 | 1.83 |

| LS12: Optimised transportation routes | 4.2 | 1.00 | 5.00 | 1.26 | 1.60 |

| LS16: Implementing the Andon system | 4.1 | 1.00 | 5.00 | 1.32 | 1.75 |

| LS13: Conducting a regular on-site visit (Gemba Walks) | 4.11 | 1.00 | 5.00 | 1.25 | 1.58 |

| Factors | Min | Max | Mean | Std | Variance |

|---|---|---|---|---|---|

| SF6: Employee well-being | 1.00 | 5.00 | 4.63 | 0.74 | 0.55 |

| SF5: Waste reduction | 1.00 | 5.00 | 4.61 | 0.66 | 0.43 |

| SF7: Enhancing technology adoption | 1.00 | 5.00 | 4.57 | 0.74 | 0.55 |

| SF2: Greenhouse gas emissions | 2.00 | 5.00 | 4.55 | 0.68 | 0.47 |

| SF3: Total cost of completing a project | 1.00 | 5.00 | 4.53 | 0.70 | 0.49 |

| SF4: Resource efficiency | 2.00 | 5.00 | 4.52 | 0.68 | 0.46 |

| SF1: Labour productivity | 1.00 | 5.00 | 4.50 | 0.69 | 0.48 |

| Item | Construct | Estimate | S.E. | C.R. | |

|---|---|---|---|---|---|

| CHL1 | ← | CHL | 1.000 | ||

| CHL1 | ← | CHL | 0.888 | 0.034 | 30.005 |

| CHL2 | ← | CHL | 0.915 | 0.036 | 31.187 |

| CHL3 | ← | CHL | 0.928 | 0.035 | 30.492 |

| CHL4 | ← | CHL | 0.921 | 0.034 | 30.245 |

| CHL5 | ← | CHL | 0.917 | 0.035 | 29.712 |

| CHL6 | ← | CHL | 0.911 | 0.034 | 30.480 |

| CHL7 | ← | CHL | 0.921 | 0.036 | 26.462 |

| CHL8 | ← | CHL | 0.868 | 0.041 | 26.024 |

| CHL9 | ← | CHL | 0.862 | 0.036 | 31.524 |

| CHL10 | ← | CHL | 0.932 | 0.034 | 30.636 |

| CHL11 | ← | CHL | 0.922 | 0.035 | 28.673 |

| CHL12 | ← | CHL | 0.899 | 0.037 | 29.765 |

| CHL13 | ← | CHL | 0.912 | 0.034 | 30.330 |

| CHL14 | ← | CHL | 0.919 | 0.034 | 32.321 |

| CHL15 | ← | CHL | 0.940 | 0.037 | 31.441 |

| CHL16 | ← | CHL | 0.931 | 0.033 | 32.180 |

| CHL17 | ← | CHL | 0.939 | 0.036 | 27.085 |

| CHL18 | ← | CHL | 0.901 | 0.033 | 30.835 |

| CHL19 | ← | CHL | 0.924 | 0.037 | 28.079 |

| CHL20 | ← | CHL | 0.923 | 0.037 | 29.043 |

| CHL21 | ← | CHL | 0.903 | 0.030 | 36.929 |

| CHL22 | ← | CHL | 0.948 | 0.037 | 29.825 |

| LS1 | ← | LS | 1.000 | ||

| LS1 | ← | LS | 0.909 | 0.032 | 32.528 |

| LS2 | ← | LS | 0.921 | 0.028 | 37.965 |

| LS3 | ← | LS | 0.912 | 0.030 | 35.666 |

| LS4 | ← | LS | 0.948 | 0.025 | 5.922 |

| LS5 | ← | LS | 0.282 | 0.025 | 4.905 |

| LS6 | ← | LS | 0.236 | 0.047 | 13.871 |

| LS7 | ← | LS | 0.585 | 0.047 | 14.792 |

| LS8 | ← | LS | 0.612 | 0.049 | 14.285 |

| LS9 | ← | LS | 0.598 | 0.047 | 15.564 |

| LS10 | ← | LS | 0.635 | 0.028 | 2.281 |

| LS11 | ← | LS | 0.112 | 0.034 | 28.467 |

| LS12 | ← | LS | 0.878 | 0.037 | 24.598 |

| LS13 | ← | LS | 0.824 | 0.033 | 29.407 |

| LS14 | ← | LS | 0.890 | 0.036 | 28.430 |

| LS15 | ← | LS | 0.893 | 0.038 | 25.506 |

| LS16 | ← | LS | 0.839 | 0.025 | 3.661 |

| LS17 | ← | LS | 0.178 | 0.023 | 2.377 |

| CSF1 | ← | CSFs | 0.890 | ||

| CSF2 | ← | CSFs | 0.879 | 0.034 | 27.275 |

| CSF3 | ← | CSFs | 0.904 | 0.035 | 29.089 |

| CSF4 | ← | CSFs | 0.926 | 0.033 | 30.887 |

| CSF5 | ← | CSFs | 0.903 | 0.032 | 28.964 |

| CSF6 | ← | CSFs | 0.782 | 0.034 | 21.468 |

| CSF7 | ← | CSFs | 0.903 | 0.032 | 29.024 |

| CSF8 | ← | CSFs | 0.905 | 0.034 | 29.154 |

| CSF9 | ← | CSFs | 0.857 | 0.035 | 25.757 |

| CSF10 | ← | CSFs | 0.834 | 0.034 | 24.318 |

| CSF11 | ← | CSFs | 0.899 | 0.033 | 28.724 |

| SF1 | ← | SF | 1.000 | ||

| SF1 | ← | SF | 0.762 | 0.060 | 15.975 |

| SF2 | ← | SF | 0.742 | 0.061 | 16.767 |

| SF3 | ← | SF | 0.771 | 0.062 | 15.491 |

| SF4 | ← | SF | 0.749 | 0.061 | 18.071 |

| SF5 | ← | SF | 0.893 | 0.071 | 8.620 |

| SF6 | ← | SF | 0.439 | 0.069 | 14.955 |

| Research Concepts | Code | # of Observed Variables | Composite Reliability | Convergent Validity (AVE) to Be 0.5 and Greater |

|---|---|---|---|---|

| Logistics Challenges | CHL | 23 | 0.9 | 0.83 |

| Logistics solutions | LS | 18 | 0.8 | 0.51 |

| Critical success factors | CSFs | 11 | 0.9 | 0.77 |

| Sustainable factors | SF | 7 | 0.82 | 0.54 |

| The Hypotheses | Effect | p | Decision |

|---|---|---|---|

| H1.Logistics solutions have a direct positive effect on sustainability in the construction industry. (LS → SF) H1 0. Logistics solutions do not have a direct positive effect on sustainability in the construction industry (Null hypothesis) | 0.516 | 0.034 | Supported, and the null hypothesis rejected |

| H2.Critical success factors positively influence sustainability in the construction industry. (CSF → SF) H2 0. There is no influence of the critical success factors on sustainability in the construction industry (Null hypothesis). | 0.487 | 0.02 | Supported, and the null hypothesis rejected |

| H3.Logistics challenges adversely affect sustainability in the construction industry. H3 0.Logistics challenges do not affect sustainability in the construction industry (Null hypothesis). | −0.926 | xxx | Supported, and the null hypothesis rejected |

| Interactions: | |||

| H4.There is an interaction between logistics solutions and critical success factors in the construction industry. H4 0.There is no interaction between logistics solutions and critical success factors in the construction industry (Null hypothesis). | 0.948 | xxx | Supported, and the null hypothesis rejected |

| H5.There is an interaction between logistics solutions and logistics challenges in the construction industry. H5 0. There is no interaction between logistics solutions and logistics challenges in the construction industry (Null hypothesis). | 0.58 | xxx | Supported, and the null hypothesis rejected |

| H6.There is an interaction between critical success factors and logistics challenges in the construction industry. H6 0.There is no interaction between critical success factors and logistics challenges in the construction industry (Null hypothesis). | 0.404 | xxx | Supported, and the null hypothesis rejected |

| Estimate | S.E. | C.R. | Label | |||

|---|---|---|---|---|---|---|

| CSFs | ← | LS | 0.948 | 0.037 | 26.477 | par_129 |

| CHL | ← | LS | 0.580 | 0.050 | 10.800 | par_130 |

| CHL | ← | CSFs | 0.404 | 0.047 | 7.778 | par_132 |

| SF | ← | LS | 0.516 | 0.113 | 2.122 | par_127 |

| SF | ← | CSFs | 0.487 | 0.094 | 2.326 | par_128 |

| SF | ← | CHL | −0.926 | 0.124 | −3.733 | par_131 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruzieh, A.S. Advancing Middle East Construction Sustainability: A Framework for Addressing Logistics Challenges Through Solutions and Critical Success Factors. Sustainability 2025, 17, 533. https://doi.org/10.3390/su17020533

Ruzieh AS. Advancing Middle East Construction Sustainability: A Framework for Addressing Logistics Challenges Through Solutions and Critical Success Factors. Sustainability. 2025; 17(2):533. https://doi.org/10.3390/su17020533

Chicago/Turabian StyleRuzieh, Abdulla Subhi. 2025. "Advancing Middle East Construction Sustainability: A Framework for Addressing Logistics Challenges Through Solutions and Critical Success Factors" Sustainability 17, no. 2: 533. https://doi.org/10.3390/su17020533

APA StyleRuzieh, A. S. (2025). Advancing Middle East Construction Sustainability: A Framework for Addressing Logistics Challenges Through Solutions and Critical Success Factors. Sustainability, 17(2), 533. https://doi.org/10.3390/su17020533