Stability Analysis of Surrounding Rock in Mining Tunnels Based on Microseismic Monitoring and Numerical Simulation

Abstract

1. Introduction

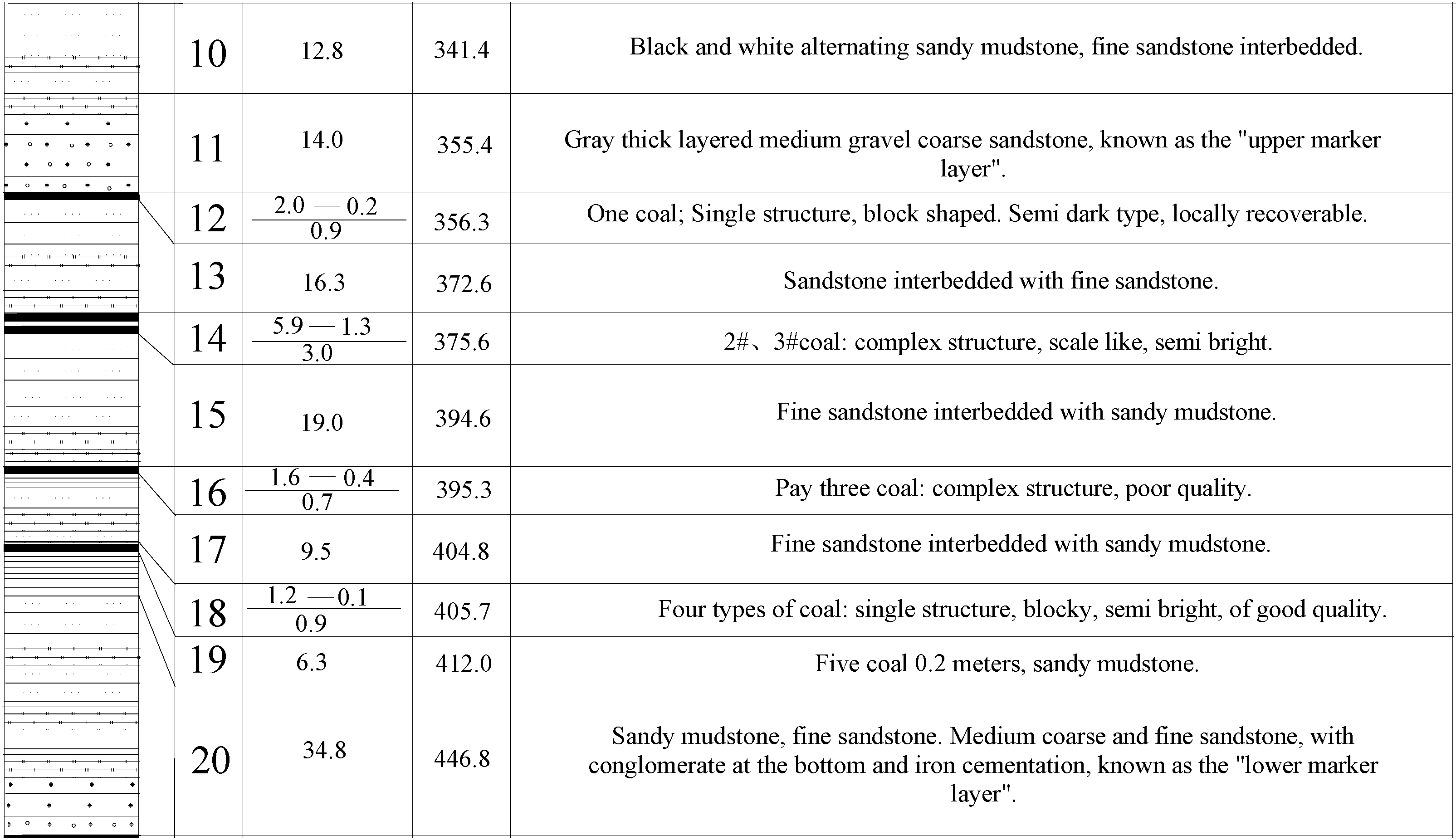

2. Research Background

3. Microseismic Characteristics of the Working Face Under the Influence of Quarrying

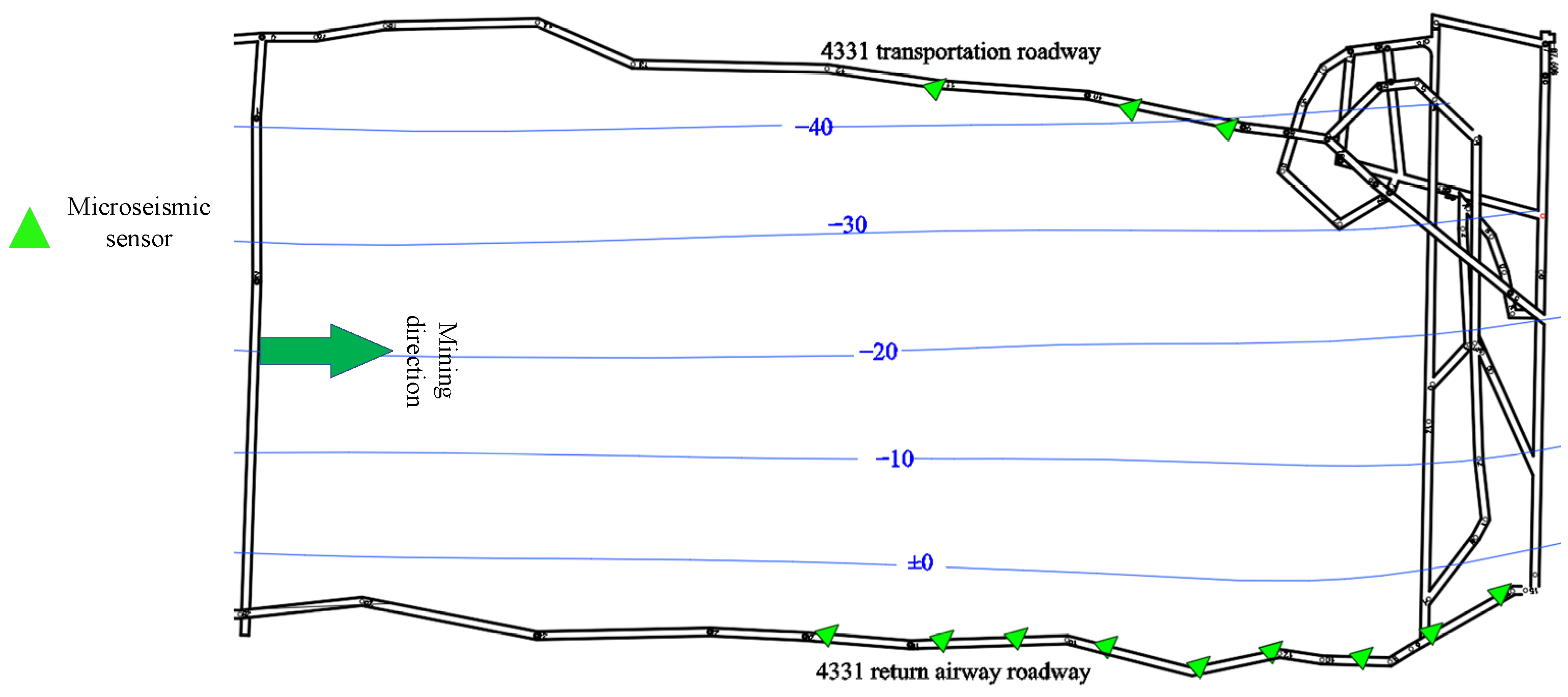

3.1. Introduction to Monitoring System

3.2. Layout of Microseismic Monitoring System

3.3. Evolutionary Pattern of Microseismic Event Distribution During the Extraction Process

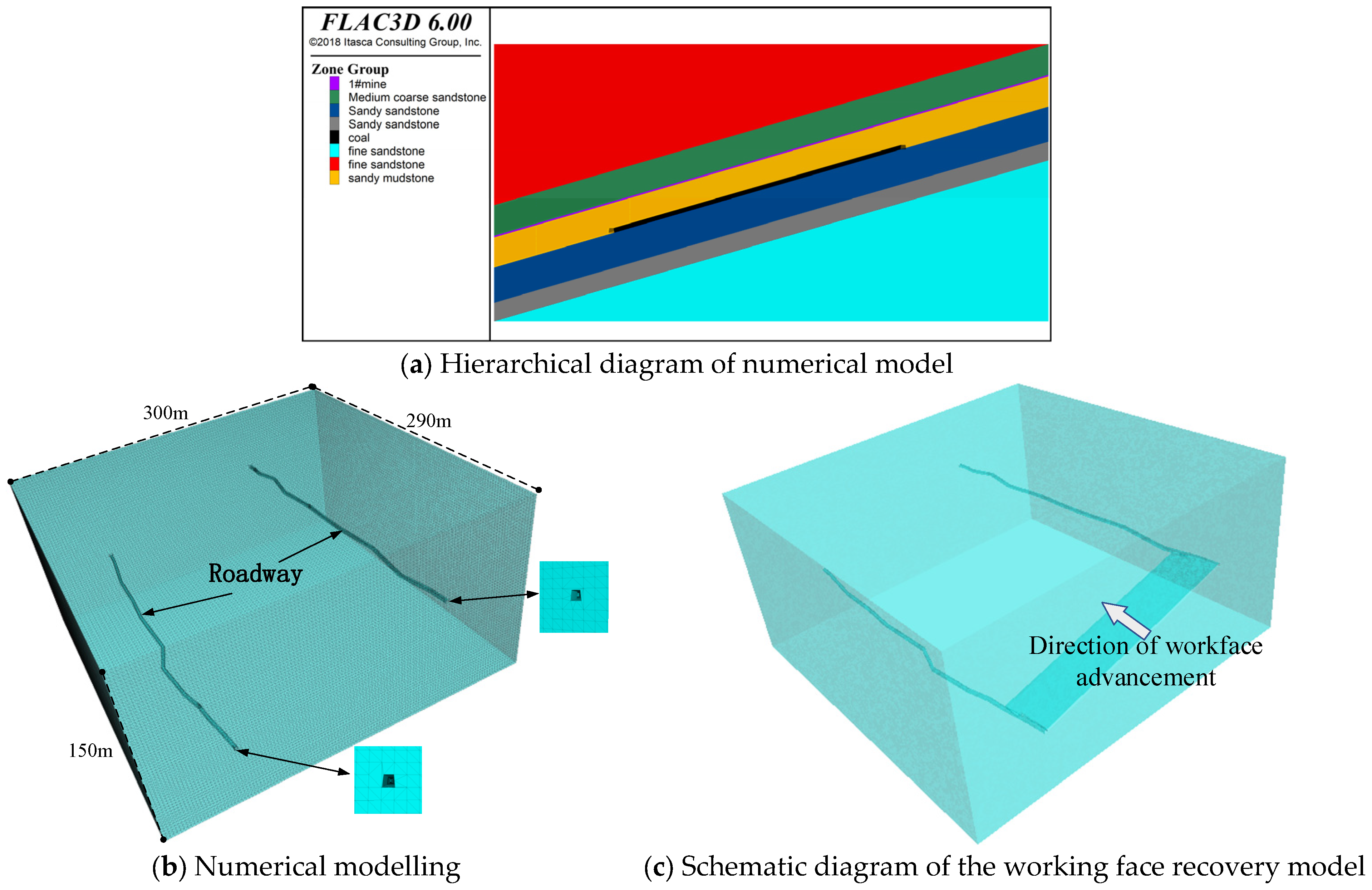

4. Numerical Simulation of the Stability of the Perimeter Rock of the Mining Tunnel

4.1. Numerical Model Establishment

4.2. Sensitivity Analysis of Model Grid

4.3. Analysis of Displacement Evolution of Mining Face

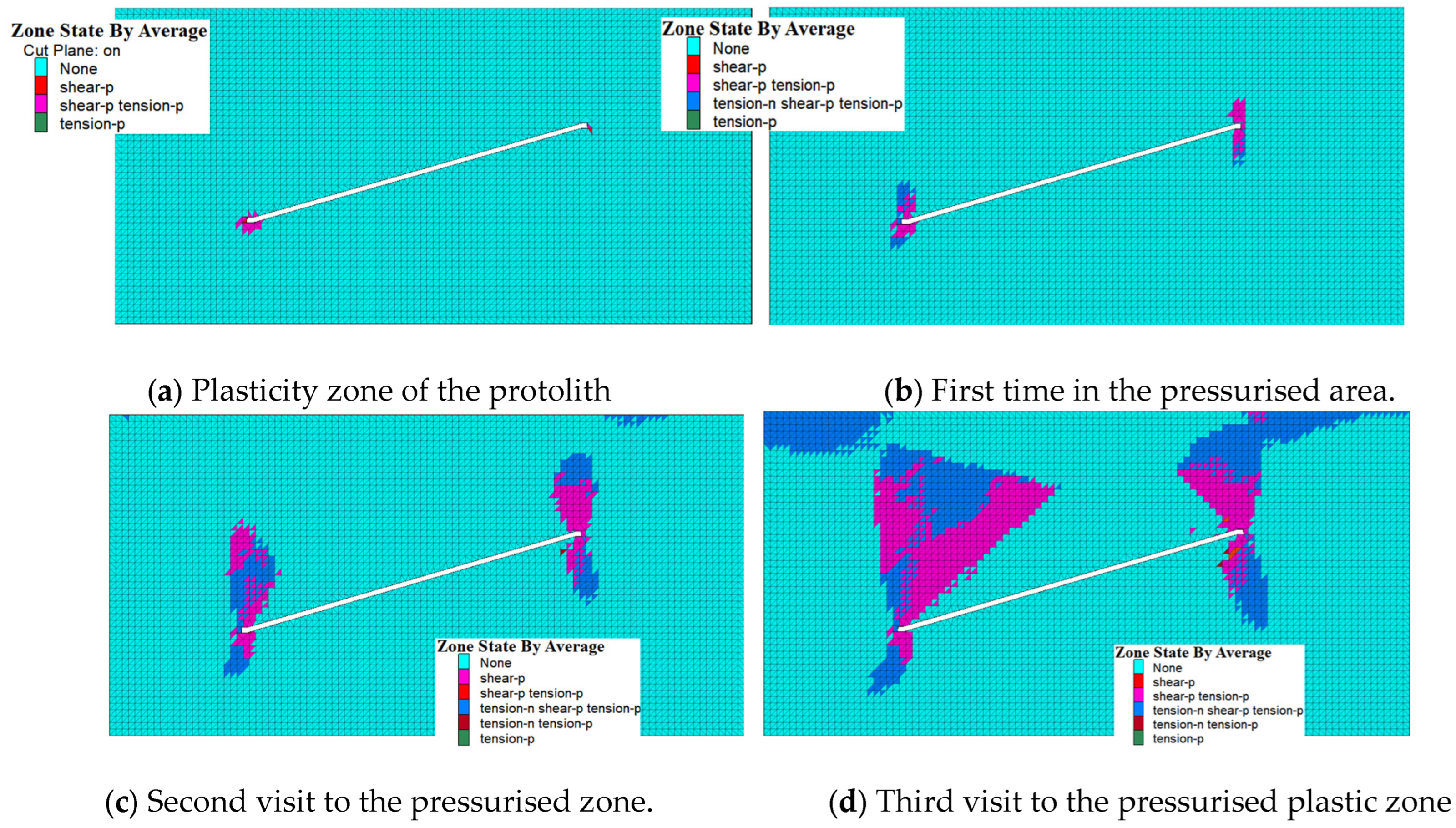

4.4. Analysis of the Development of Plastic Zones in the Peripheral Rock of the Mining Tunnel

4.5. Comparison of Numerical Simulation and Field Monitoring Results

4.5.1. Feasibility of Simulating Microseismicity in FLAC3D

4.5.2. Comparison and Verification of Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, H.J.; Wang, G.F.; Li, M.Z.; Zhang, J.H.; Li, Y.P. Research status of support technology and equipment for ultra high mining height fully mechanized mining face. Coal Mine Saf. 2024, 55, 213–221. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Su, Y.H.; Luo, B.; Yang, Z.W.; Chen, B. Principles and Methods of Tunnel Surrounding Rock Stability Analysis Based on Limit States. J. Railw. Sci. Eng. 2024, 21, 1–13. [Google Scholar] [CrossRef]

- Zhang, D.M.; Sun, G.Y.; Li, G. Stability analysis and maintenance scheme design of coal seam roadway under double mining influence. J. Eng. Geol. 2021, 29, 1028–1036. [Google Scholar] [CrossRef]

- Qiu, H.; Qiu, R.; Luo, G.; Ayasrah, M.M.; Wang, Z. Study on the Mechanical Behavior of Fluid–Solid Coupling in Shallow Buried Tunnels under Different Biased Terrain. Symmetry 2022, 14, 1339. [Google Scholar] [CrossRef]

- Yin, Y.; Yang, S.; He, Y.; Pan, J.; Guo, Z.; Fan, J.; Wang, Z. Stability assessment of surrounding rock in downward mining route supported by slab-wall backfill structure. Sci. Rep. 2024, 14, 13706. [Google Scholar] [CrossRef]

- Qin, Z.Z.; Liu, Y.T.; Wang, S.C.; Cai, H.; Wang, B.B. Research on the overlying rock movement law of deep buried “two hard” fully mechanized caving face based on microseismic monitoring. J. Min. Saf. Eng. 2017, 34, 74–78+102. [Google Scholar]

- Zhu, Q.; Li, Q.; Zhang, E.; Zhang, J.; Heng, X. Study on microseismic characteristics of geological anomalies in outburst coal seams under mining influence. Coal Sci. Technol. 2019, 47, 39–46. [Google Scholar]

- Zhang, D.Y.; Gai, Q.K.; Huang, L.; Li, Y.B.; Shen, X.Y.; Zhao, L.S.; Peng, Z.X. The spatiotemporal evolution mechanism and risk zoning of microseismic activity on the roof of abandoned roadway in working face. J. Coal Sci. 2021, 46, 3805–3818. [Google Scholar]

- Zhang, P.H.; Yang, T.H.; Zheng, C.; Yu, Q.L.; Liu, H.L.; Wang, P.T. Rock mass stability analysis based on mining induced stress field and microseismic activity. J. Coal Min. 2013, 38, 183–188. [Google Scholar]

- Wang, C.; Liu, X.; Yao, W.; Wang, E.; Hu, N.; Huang, Z.; Sun, Y. Study on rock stability and structural response of shield-driven twin tunnels crossing fault fracture zone based on 3d numerical simulation. Bull. Eng. Geol. Environ. 2024, 83, 287. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, W.; Zhou, P.; Zhu, Z.; Zhao, J.; Gao, P. Research on Coal Mine Goaf Restoration Based on Stability of Overlying Rocks and Numerical Simulation Analysis: A Case Study of Jingmen Garden Expo Park. Sustainability 2023, 15, 1464. [Google Scholar] [CrossRef]

- Dong, H.L.; Gao, Q.C.; Zhang, Z.; Chen, R.; Liu, N. An approximate solution and numerical simulation of the plastic zone of the surrounding rock of a two-way unequal pressure roadway. J. Coal Sci. 2019, 44, 3360–3368. [Google Scholar]

- Lu, A.; Song, D.; Li, Z.; He, X.; Zhou, C.; Qiu, L. Numerical Simulation Study on Microseismic Characteristics and Rockburst Hazard Prediction in Deep Mining of Steeply Inclined Coal Seams. Rock Mech. Rock Eng. 2024, prepublish. 1–22. [Google Scholar] [CrossRef]

- Song, J.F.; Lu, C.P. Stress distribution characteristics and microseismic activity patterns in coal seam gangue occurrence areas. J. Min. Strat. Control. Eng. 2021, 3, 043518. [Google Scholar] [CrossRef]

- Jiang, F.X.; Chen, Y.; Li, D.; Wang, C.W.; Gai, D.C.; Zhu, S.T. Exploration of the Mechanism of Initial Mining induced Impact in Island Filling Working Face. J. Coal Ind. 2019, 44, 151–159. [Google Scholar] [CrossRef]

- Jiang, F.X.; Liu, Y.; Liu, J.; Zhang, M.; Du, J.P.; Sum, W.S.; Zhang, W.P. Research on the decompression mechanism of local protective layer mining in coal seams under impact ground pressure. J. Geotech. Eng. 2019, 41, 368–375. [Google Scholar]

- Zheng, C. Research on the Characterization Method of Mining Rock Mass Strength Parameters Based on Microseismic Monitoring Data. Ph.D. Thesis, Northeastern University, Shenyang, China, 2013. [Google Scholar]

- Xu, N.W.; Liang, Z.Z.; Tang, C.A.; Dai, F.; Zhou, Z.; Sha, C. Three dimensional feedback analysis of rock slope stability based on microseismic monitoring. J. Rock Mech. Eng. 2014, 33 (Suppl. S1), 3093–3104. [Google Scholar]

- Yang, Y.; Sun, Y.D.; Zhang, G.Y. Study on microseismic response characteristics and support of surrounding rock in tunnels under dynamic loads. China Saf. Prod. Sci. Technol. 2020, 16, 73–79. [Google Scholar]

- Li, Z.H.; Xu, N.W.; Sun, Z.Q.; Liu, J.; Li, B.; Sun, Y.P.; Zhu, J.L. Analysis of Large Deformation Characteristics of High Stress Soft Rock Tunnel Surrounding Rock Based on Microseismic Monitoring and Numerical Simulation. J. Rock Mech. Eng. 2024, 43, 2725–2737. [Google Scholar] [CrossRef]

- Yuan, G.; Zhang, M.; Wang, J.; Wei, J.; Yang, K. Numerical simulation study on the evolution characteristics of microseismic zoning in mining overlying strata. Coal Sci. Technol. 2023, 51, 36–46. [Google Scholar] [CrossRef]

- Li, A.; Dai, F.; Xu, N.; Gu, G.; Hu, Z. Analysis of a Complex Flexural Toppling Failure of Large Underground Caverns in Layered Rock Masses. Rock Mech. Rock Eng. 2019, 52, 3157–3181. [Google Scholar] [CrossRef]

- Li, A.; Liu, Y.; Dai, F.; Liu, K.; Wang, K. Deformation mechanisms of sidewall in layered rock strata dipping steeply against the inner space of large underground powerhouse cavern. Tunn. Undergr. Space Technol. 2022, 120, 104305. [Google Scholar] [CrossRef]

- Ma, C.C.; Li, T.B.; Zhang, H.; Wang, J.F. Rockburst warning method and discussion based on EMS microseismic parameters. Geotech. Mech. 2018, 39, 765–774. [Google Scholar]

- Wang, J.Q.; Zhu, Q.J.; Zhang, E.H. Research on Energy Expression Method and Application of Mine Microseismic Source. Coal Eng. 2020, 52, 86–91. [Google Scholar]

- Qin, S.Q.; Xu, X.W.; Hu, P.; Wang, Y.Y.; Huang, X.; Pan, X.H. Exploration of the multi locking segment brittle fracture mechanism of seismogenic faults and new methods for earthquake prediction. J. Geophys. 2010, 53, 1001–1014. [Google Scholar]

- Liu, H.Y.; Meng, F.L. Roof fracture and dynamic evolution law of energy field in thick coal seam working face. Coal Mine Saf. 2023, 54, 153–160. [Google Scholar]

- Zhang, Y.; Deng, X.Y.; Li, X.H.; Chen, X.M.; Qu, H.L. Research on rock burst hazard prediction based on elastic strain energy characteristics. J. Undergr. Space Eng. 2022, 18 (Suppl. S1), 305–311. [Google Scholar]

- Xing, S.; Pei, X.; Mei, J.; Dong, P.; Zhen, C.; Li, X.; Lu, F.; Liu, P. A novel elastic strain energy density approach for fatigue evaluation of welded components. Eng. Fract. Mech. 2023, 293, 109713. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, L. Study on Rock Failure Criterion Based on Elastic Strain Energy Density. Appl. Sci. 2023, 13, 8435. [Google Scholar] [CrossRef]

- Kang, G.; Kim, M.; Yang, H.; Shin, J.; Sim, J.; Ahn, H.; Jang, M.; Kim, Y.; Min, H.S.; Jung, H. Latch Applicator for Efficient Delivery of Dissolving Microneedles Based on Rapid Release of Elastic Strain Energy by Thumb Force. Adv. Funct. Mater. 2023, 33, 2210805. [Google Scholar] [CrossRef]

- Wang, J.; Poh, L.H.; Guo, X. Localizing gradient damage model based on a decomposition of elastic strain energy density. Eng. Fract. Mech. 2023, 279, 109032. [Google Scholar] [CrossRef]

- Chang, D.; Yang, X.; Liu, R.; Huang, Z.; Peng, H.; Zuo, H. Experimental investigation on the correlation between critical storage of elastic strain energy and crack extension in elastic–plastic materials. Fatigue Fract. Eng. Mater. Struct. 2022, 46, 1007–1021. [Google Scholar] [CrossRef]

- Huang, B.; Xie, P.; Wu, Y.; Lin, W.; Luo, S.; Wang, S.; Wen, Z.; Chen, J. The effect of overlying rock fracture and stress path evolution in steeply dipping and large mining height stope. Géoméch. Geophys. Geo-Energy Geo-Resources 2024, 10, 95. [Google Scholar] [CrossRef]

- Huang, B.; Xie, P.; Lin, W.; Wu, Y.; Luo, S.; Ye, X.; Nan, C.; Zhao, W. Study on the evolution mechanism of gangue filling and overlying rock spatial structure in steeply dipping stope. Eng. Fail. Anal. 2024, 166, 108884. [Google Scholar] [CrossRef]

| Recording Unit | Operating and Analyzing Software Technical Parameters | ||

|---|---|---|---|

| Receiver Port | 12 | Data acquisition | Sampling interval: 31.25 μs 62.5 μs,125 μs Record length: minimum 451.1 ms, maximum 1808.5 ms |

| Record the number of tracks | 12 Microseismic sensors | ||

| Sampling interval | 31.25 μs, 62.5 μs, 125 μs, 250 μs | Microseismic data processing | Number of lanes: 1–12 Processing procedure: 1. Data length setting 2. Bandpass filtering 3. Initial pickup 4. Pick up and process 5. Separation of P and S waves 6. Speed analysis 7. Microseismic data localization |

| Record bandwidth | 10,000 Hz, 5000 Hz | ||

| Analog-to-digital conversion | 24 bit | ||

| Record length | 2048 sample points | ||

| Maximum input signal | ±10 Vpp | ||

| Dynamic range | 120 dB | ||

| Microseismic sensitivity | 1000 mV/g ± 5% | ||

| Frequency range | 0.5~15,000 Hz | ||

| Response frequency | 20 kHz | ||

| Transverse sensitivity | >1% | ||

| Operation temperature | 0 °C~+65 °C | ||

| Nature of the Formation | Bulk Modulus (GPa) | Shear Modulus (GPa) | Cohesion (MPa) | Friction Angle (°) | Density (kN/m3) | |

|---|---|---|---|---|---|---|

| 1# | sandy mudstone | 8.85 | 5.93 | 2.71 | 32 | 2600 |

| 2# | three coals | 3.8 | 4.21 | 4.21 | 32 | 1400 |

| 3# | siltstone | 2.0 | 1.3 | 1.6 | 34 | 2700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Li, Q.; Zhu, C.; Tang, P. Stability Analysis of Surrounding Rock in Mining Tunnels Based on Microseismic Monitoring and Numerical Simulation. Sustainability 2025, 17, 630. https://doi.org/10.3390/su17020630

Wu H, Li Q, Zhu C, Tang P. Stability Analysis of Surrounding Rock in Mining Tunnels Based on Microseismic Monitoring and Numerical Simulation. Sustainability. 2025; 17(2):630. https://doi.org/10.3390/su17020630

Chicago/Turabian StyleWu, Hao, Qingfeng Li, Chuanqu Zhu, and Pei Tang. 2025. "Stability Analysis of Surrounding Rock in Mining Tunnels Based on Microseismic Monitoring and Numerical Simulation" Sustainability 17, no. 2: 630. https://doi.org/10.3390/su17020630

APA StyleWu, H., Li, Q., Zhu, C., & Tang, P. (2025). Stability Analysis of Surrounding Rock in Mining Tunnels Based on Microseismic Monitoring and Numerical Simulation. Sustainability, 17(2), 630. https://doi.org/10.3390/su17020630