Abstract

Mass timber buildings are gaining momentum, as they are seen as an environmental alternative to conventional concrete and steel structures, and they are also being used for mid- and high-rise buildings. This study conducted a comparative LCA analysis of 20- and 40-story building structures made with different combinations of steel and mass timber. The results show that, even disregarding the environmental benefits of the sequestered biogenic carbon by using a 0/0 approach, timber-based structures result in a roughly 25% lower Global Warming Potential (GWP) impact than steel- or hybrid-based equivalent solutions. The results show that the contribution of steel does not bring any GWP advantage (an average increase of 20% is reported); however, steel–timber hybrid structures may still be the only viable solution to attain greater heights. This study also evidences that materials with lower GWP in their production phase can present a viable solution even when long transportation is required, highlighting the importance of the production phase to reach environmental targets.

1. Introduction

Greenhouse gas emissions are unanimously considered to be the main driver of climate change [1]. The built environment is responsible for a significant share of manmade greenhouse gases (GHGs), with reports showing that as much as 40% of energy use and 35% of GHG emissions are caused by the construction of buildings, their use, and subsequent demolition [2]. The growth of the world population, longer life expectancy, and increased global wealth will continuously sustain the demand for new buildings in the future [3]. To avoid the depletion of green-fields and to limit urban sprawl, mid- and high-rise buildings are being built more than ever in the past, either with residential, office, or multi-purpose functions [4].

Studies demonstrate that tall buildings can be seen as “carbon spikes” [5], a modification of the term used by Säynäjoki et al. [6], because of their high carbon content and environmental impacts overall. This is due to the exponential growth of lateral forces acting on their load-bearing system as the height of a building increases, as described in the 60s by F. Khan, caused by the premium for height [7]. Also, tall buildings are often characterized by long structural spans that contribute to their material and carbon intensity. In fact, previous research [8] shows that the horizontal structures (beams) can represent up to 70% of the total materials in the above-grade structure of a tall building.

Several studies have quantified the embodied carbon content of tall buildings. A comprehensive list of the most relevant studies can be found in Helal et al. [9].

While tall buildings traditionally featured a steel frame consisting of steel profiles for their vertical (columns), horizontal (beams), and diagonal (braces) structures in the past, reinforced concrete (RC) is now by far the most dominant material in tall building construction, despite many examples of steel frames (usually coupled with a concrete core) or composite structures (concrete-filled steel pipes or concrete-encased steel profiles) still being built [4].

Low-rise buildings and single-family homes, on the contrary, are seeing the substitution of concrete, bricks, and steel with timber at increasing rates. Timber is used either in light-weight solutions, with the evolution of balloon-frame construction techniques especially in North America, or in relatively new mass timber products such as Glue Laminated Timber (GLT) or Cross Laminated Timber (CLT), especially in Europe. While steel and concrete production releases large amounts of CO2, timber-based products like GLT and CLT are notable for their potential for carbon sequestration. Many studies in fact demonstrate the unique environmental features of timber products and, consequently, of timber buildings, thanks to the ability of timber (and other vegetal fibers) to absorb carbon during plant growth and to store it in the product made from it, until its final emission in the atmosphere at the end of the product’s life [10]. Commonly known as “biogenic carbon” [11], this refers to the mechanism whereby trees absorb and retain atmospheric CO2, converting it into carbon stored in wood fibers. This long-term carbon storage contributes to a reduced overall greenhouse gas impact when compared to materials that do not offer similar sequestration benefits [12].

From the life cycle assessment perspective, the biogenic carbon content of timber products becomes relevant at two stages: during the production phases (A1–A3) of timber components, when carbon is “extracted” from the atmosphere, and during the end-of-life stages (C1–C4), when the wood fibers are burnt (or decay in landfills), releasing CO2 back into the atmosphere. The component can also be reused or recycled, but these alternatives still represent, according to EN 15804 [13], a quantity of carbon dioxide leaving the system boundaries of the LCA. Thanks to this property, timber is now celebrated as a sustainable material, and buildings made from timber are promoted as the most sustainable alternative to conventional buildings [3]. It is important to note that, when examining the Environmental Product Declarations (EPDs) of timber products, the most common end-of-life scenario anticipated is incineration, either with or without energy recovery. Reuse and recycling of mass timber products are rarely practiced due to various factors, including a lack of clear responsibility, insufficient recycling infrastructure, and a lack of market demand for claimed structural elements (except for antique beams or columns).

According to research practices, two strategies can be adopted to take into account biogenic carbon in a building LCA. The −1/+1 approach considers the storage of the biogenic carbon, usually showing a negative value for the A phase of the product’s LCA, with the sequestered carbon being released back into the atmosphere during the C phase. On the contrary, the 0/0 approach omits the sequestered carbon content in both phases, which is thus excluded by any calculation when conducting an LCA. Even if credits for the biogenic carbon stored by timber are not used when a 0/0 approach [14] is used in the analysis, timber production still results in lower carbon emissions because it does not involve the same level of fossil fuel combustion as other materials. A more complete analysis of this option is discussed in a later section of this paper. The carbon footprint of the timber needed for buildings, in fact, is considerably smaller due to simpler processing and lower energy needs [15], while concrete and steel require a greater amount of energy and resources [16]. Many LCAs have been conducted in the past to demonstrate the beneficial effects of mass timber buildings [17,18,19].

The tall building industry is not exempt from the de-carbonization efforts asked of the building sector at large, and from here recent interest has been paid to the integration of mass timber products in mid- and high-rise buildings [20]. Several examples have been completed recently, both in Europe—such as the Mjostarnaet tower in Norway and the Sara Kulturhus in Sweden—and in North America, where the Ascent tower in Milwaukee was built, currently holding the title of the tallest mass timber building in the world. These buildings use either CLT, GLT, or a combination of both as a partial substitute of steel and concrete to create the varying parts of the bearing structure of high-rise buildings. This rising trend is driven by environmental considerations, which regard timber as a superior material compared to structural steel or RC [21]. The assessment of these buildings from an environmental perspective has been the focus of some comparative LCA studies [19,22,23,24,25], conducted to demonstrate the beneficial effects of mass timber products to reduce the carbon content of low- and mid-rise buildings built with some timber components. The studies considered differ from each other regarding the building chosen as the case study, but all are comparable in terms of low-to-medium height and for having considered the use of mass timber as a structural material as a variable. Notably, Chen et al. [19] compared the mass timber alternative to a reinforced concrete 8-story residential building built in China. Chen et al. [22] and Liang et al. [24] analyzed the same building constructed in Portland, OR, USA, which is 12 stories tall and serves mixed office–residential purposes; however, they used two different LCA assessment software tools. Meanwhile, Eslami et al. [23] used two single-family 2-story houses built in Luxembourg—one using reinforced concrete and the other featuring mass timber as the structural element—as case studies. This study is interesting because it used the same assessment methodology as this current study, starting from 2D drawings and obtaining the bill of quantities through BIM software. The work of Rinne et al. [25] was analyzed because it assessed all-timber and all-concrete alternatives for a 5-story hybrid timber–concrete building constructed in Helsinki.

The GWP reference values derived from these analyses are shown in Table 1. The studies described above are based on the analysis of individual whole low- and mid-rise buildings used as case studies to inform the LCAs presented. In addition, all of them compared the concrete alternative to the mass timber one. Such case-study-based approaches hinder the possibility of comparing the various results among them and comparing them with other LCAs on more conventional tall building constructive solutions, such as those that consider steel as the structural material.

Table 1.

GWP values for low- and mid-rise buildings, as found in the literature.

This study aims to conduct a systematic analysis of different types of steel-timber hybrid structural solutions, offering a wide range of alternatives in terms of type and extension of mass-timber use in substitution of conventional steel-based construction, filling a significant gap in the knowledge of the environmental implications of high-rise buildings.

1.1. The Use of Mass Timber in Tall Buildings

Sustainability, though, is not the only reason for the increased adoption of mass timber in tall building construction. Other incentives are the high level of prefabrication that this technology offers, the relative simplicity of managing construction sites, and, ultimately, a faster construction sequence [26,27]. Steel, although having a more resource-intensive production stage, shares many of these benefits, such as high prefabrication potential and quicker assembly times. However, concrete, while commonly used in tall building construction, generally lacks the same level of prefabrication efficiency, leading to more complex and time-consuming processes on-site.

From a mechanical point of view, mass timber products (such as GLT and CLT) have a compression resistance capacity comparable and even superior to unreinforced concrete and a weight-to-strength ratio lower than steel in compression and comparable to steel in tension [21]. However, because mass timber is lightweight and flexible compared to other conventional structural materials used in buildings, it is widely recognized that timber, on its own, does not fully meet the height and floor count demands of sustainable, densely populated urban environments. To achieve higher heights, timber needs to be combined with steel or RC in tall buildings. This necessity has driven the development of steel–timber hybrid structures, which offer a balanced solution for such challenges and maintain the ease and benefits of pre-fabricated building solutions offered by mass timber.

1.2. Structure of This Paper

This paper is organized into two main sections, in addition to the current introduction, which describes the research conducted in current design trends for buildings, explaining the interest of the tall building industry in the adoption of mass timber products, notably CLT and GLT. The first section presents the methodology adopted to conduct the research, explains the role of an external panel of structural engineers formed to advise the research team, presents the processes adopted to mimic a professional project, and presents the tools used. It is divided into four subsections, covering the scenario design process with LCA inventory analysis, the quantification of non-structural components, the methodology and implementation of the impact assessment phase, and additional methodological considerations. The second section presents the LCA results for each scenario, emphasizing both the total and phase-specific impacts across the life cycle to facilitate the assessment of the impact of each design decision. Additionally, this section includes a discussion and interpretation of the results to offer further insights into the study’s findings.

2. Methodology

To conduct this study, the LCA methodology (EN 15978 [28]) was applied to different structural frames involving both steel and timber elements, aiming to understand the impacts of choosing one structural solution over another. This research also considers buildings assumed to be built in two different locations: Europe, representing the region where mass timber buildings were largely first popularized thanks to the solid development of the technology [29], and North America, where several advancements have been made to support pilot tall building projects [30].

This research focuses on evaluating the use of timber in conjunction with steel for constructing mid- and high-rise buildings, aiming to assess the carbon balance of different mixes of steel and timber in the creation of the load-bearing structure. All scenarios feature an RC core that is responsible for carrying the lateral loads (wind, seismic forces) acting on the tower, as common practice suggests. Acknowledging the growing interest in sustainable and innovative construction methods, this study investigates whether combining these materials offers environmental advantages. This research thus presents the systematic analysis of eight building scenarios, four with a height of 40 stories and four with a height of 20 stories, each designed with distinct structural frameworks. The 40-story scenario offers an all-steel (with a concrete core) example as a benchmark to evaluate the impact of structural variations containing mass timber elements. The 20-story scenarios present both all-steel and all-timber benchmarks (both with an RC core), as both technologies are suitable for buildings of this size, as well as hybrid models that combine steel and timber elements. These building alternatives are evaluated using a whole-building life cycle assessment (WBLCA) tool, with a reference service life of 50 years. The assessment follows a comprehensive “cradle to grave” methodology, in accordance with the guidelines outlined by the ISO 14044 standard [31]. This approach encompasses the entire life cycle of the building materials, from their extraction and production to their use, maintenance, and eventual disposal or recycling. This current study specifically focuses on evaluating the environmental impacts associated with the production phase (A1–A3), the construction process (A4–A5), and the end-of-life stage (C) of the building’s life cycle. Importantly, the B phase, which pertains to the use and operation of the building, is not included in the assessment. Over the building’s 50-year lifespan, no significant maintenance is anticipated for the structural materials, meaning that the structural components are expected to remain intact without requiring repairs or replacements. However, one potential consideration is the need to periodically verify the cohesion of the fireproofing layer on the steel profiles and to check for the absence of water-related problems (water run-off, leakages, condensation) on the timber elements. Even though such inspections may be necessary to ensure fire safety and structural integrity, their environmental impact is expected to be minimal and will not substantially affect the overall results of the assessment.

The functional unit defined for this study is solely the structural frame, which includes only the structural columns, beams, floor slabs, and the lateral resisting RC core. Foundations are excluded from this study’s scope. Although they typically have a critical impact on the overall structural, environmental, and cost performance [32], their influence can vary significantly depending on factors such as soil quality, seismic regulations, and specific site stresses [33].

2.1. Scenario Design Process and Inventory Analysis

The goal of this research is to provide information on the environmental impacts, using Global Warming Potential (GWP) as a key indicator, associated with different types of steel–timber hybrid solutions for mid- and high-rise buildings. For this purpose, the scenarios adopted have to be as close as possible to real-world examples while keeping, at the same time, a sufficient level of abstraction to allow for comparison and provide informative results. An overview of the state of the art of steel–timber hybrid buildings was carried out in the first place by looking at several built references that have been analyzed as case studies; the considered examples cover contemporary buildings, all of which have been erected in recent years, intended to be used as a basis from which to extrapolate average structure, layout configurations, and spans for each architectural typology considered. All of the buildings considered have a primary structure composed of steel and timber, with variances in the proportion and the prevalence of one or another of these materials. The buildings were subsequently cataloged in relation to a series of parameters such as height, structural span, number of floors and floor-to-floor height, core dimensions, and typology of the vertical and horizontal framing structure. A panel of prominent structural engineering firms was created to assist with the research, to comment on the case studies selected, and to provide a precise structural design of the resulting scenarios. All the experts of this panel contributed pro bono to the research. Their affiliated companies are mentioned in the Acknowledgments section.

Based on this criterion, three different building typologies emerged from the analysis of the case studies (all steel, hybrid steel–timber, all timber), and these results were consequently extrapolated into the shaping of a series of generic hypothetical modeled scenarios, developed in collaboration with the panel of engineering firms. On this basis, the following aspects have been summed up and analyzed individually for each scenario:

- Vertical and horizontal structures: Both the vertical and horizontal structures have been simplified into a framing structure, omitting any tension rods, load-bearing walls, bracings, finishings, roofing, and any other particularity present in the analyzed case studies. For the purposes of this study, only structural columns and beams will be considered for the design and calculations of the framing structure, while the lateral force system is represented by a reinforced concrete core that is equal for all the variations within each category.

- Floor slab. The floor slab is rendered in two different construction types based on the typization of the identified technologies, either a conventional composite metal deck with concrete topping or a timber floor system with concrete topping for acoustic reasons.

- Floor plan dimensions and configuration: A simple rectangular shape was used for all scenarios with the width-to-depth ratio inspired by the analysis of real-world examples.

- Structural spans representing office and residential typical values were used. Furthermore, size, close columns, and deep window-to-core distance were used to verify the influence of long spans in hybrid solutions.

The following phase of the process involved the design of each of the proposed structural combinations, developed in conjunction with the structural engineering firms engaged in support of the researchers.

All of the eight resulting scenarios have a floor-to-floor height of 4 m and feature a lateral resisting core made of reinforced concrete (RC) with dimensions of 13.33 by 36 m. The core’s thickness decreases every 10 stories, from 0.6 m to 0.3 m for the 40-story scenarios and from 0.3 m to 0.25 m for the 20-story scenarios. The all-timber alternative was considered only for the 20-story category, as a 40-story scenario entirely made of mass timber was deemed unrealistic. The floor area of each scenario was calculated using the IPMS 4.2 standard [34]. This refers to what some specialists call “carpet area”, which is the floor area available after all structural elements, finishes, etc., have been subtracted by the IPMS 1 (gross floor area). By using this precise measurement, this study ensures consistency and accuracy in comparing impact values across the different assessed scenarios.

Table 2 reports a brief description of the different scenarios’ main characteristics. They are further described in more detail in the next paragraphs. The floor areas are slightly different, even within the same height categories, due to the varying sizes of the columns across the scenarios.

Table 2.

Description of scenarios’ features.

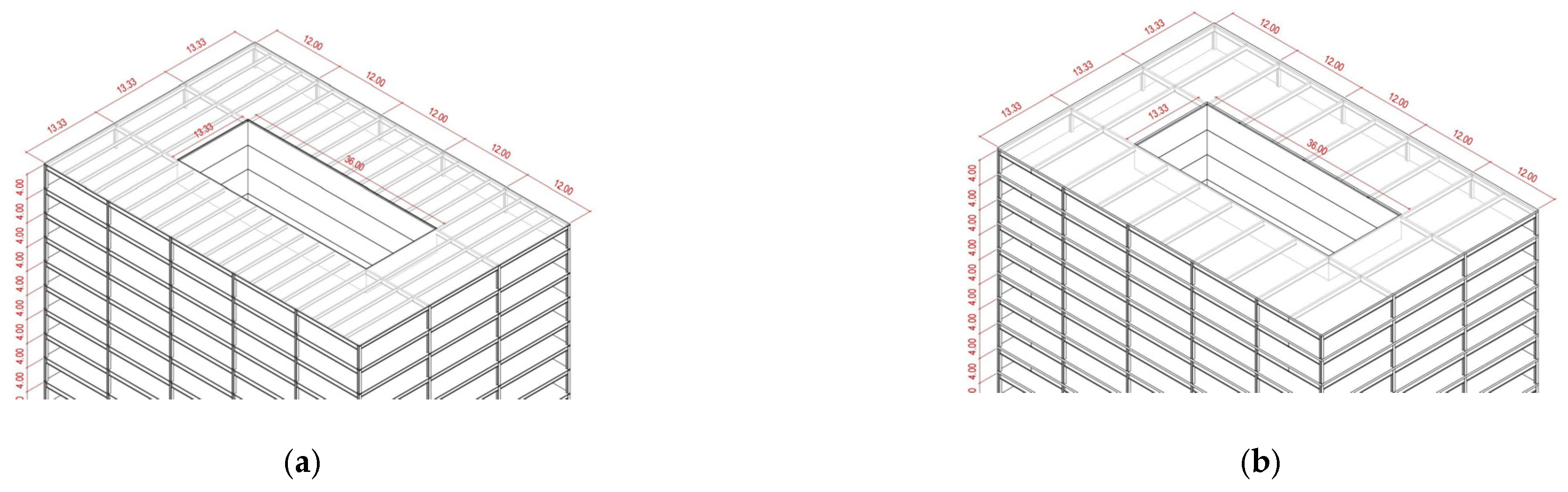

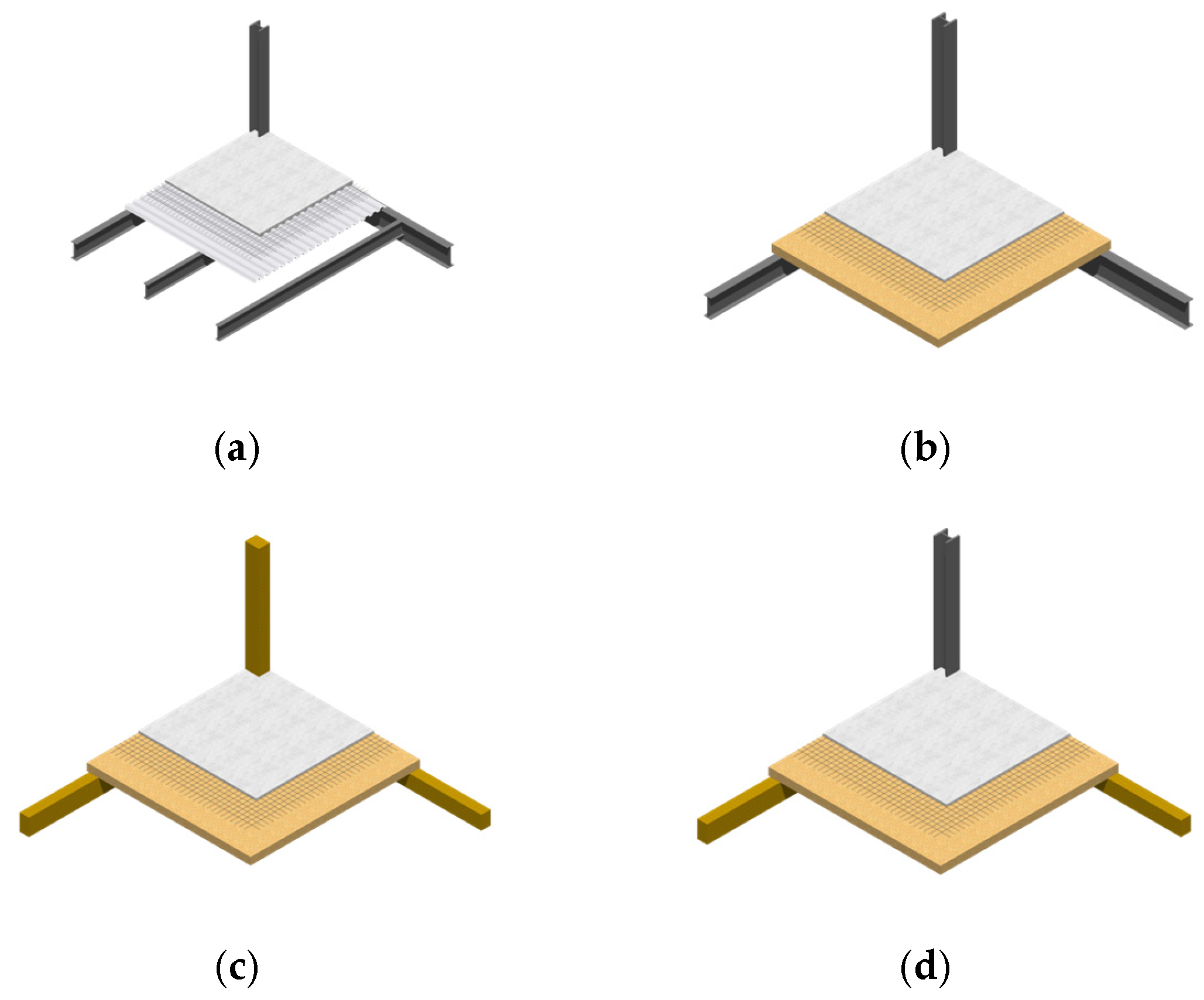

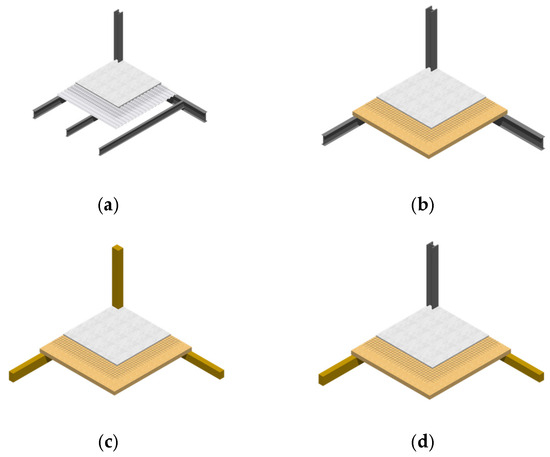

All steel, long spans: The first scenario (named AS20L: all steel, 20 stories, long spans) is represented by a 20-story building with spans of 12 m × 13.33 m and a floor area of 38,373 sqm (Figure 1a). The construction is entirely made of steel; the columns and beams are made with hot-rolled profiles of the W series. The flooring system is created with an 8.3 cm lightweight concrete slab with welded wire mesh as a reinforcement on a 7.6 cm metal deck (Figure 2a). The second scenario (named AS40L: all steel, 40 stories, long spans) is a 40-story version of the first scenario, totaling 76,628 sqm (Figure 1a).

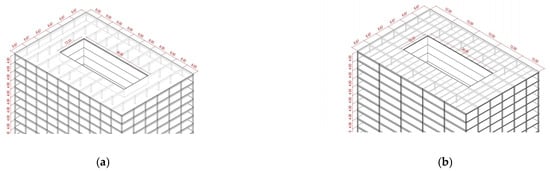

Figure 1.

Axonometric plans: (a) scenarios AS20L and AS40L; (b) scenarios SCB-TD20 and SCB-TD40.

Figure 2.

Architectural nodes and materials used for the eight scenarios: (a) scenarios AS20L, AS40L, AS20S, and AS40S, featuring all-steel elements; (b) scenarios SCB-TD20 and SCB-TD40, made of steel columns and beams and timber floor decks; (c) scenario AT20, featuring all-timber elements; and (d) scenario SC-TBD40, consisting of steel columns and timber beams and floor decks.

Composite, long spans: The third scenario (named SCB-TD20: steel columns and beams, timber decks, 20 stories) entails a 20-story building featuring spans of 12 m × 13.33 m, totaling 38,373 sqm of the carpet area (Figure 1b). The construction utilizes a combination of steel and timber structural elements; the columns and beams are constructed using hot-rolled profiles from the W series, while the flooring system consists of a 7-layer CLT deck with a 6.3 cm concrete topping reinforced with welded wire mesh (Figure 2b). The fourth scenario (named SCB-TD40: steel columns and beams, timber decks, 40 stories) is represented by the 40-story version of the third scenario, featuring a carpet area of 76,628 sqm (Figure 1b).

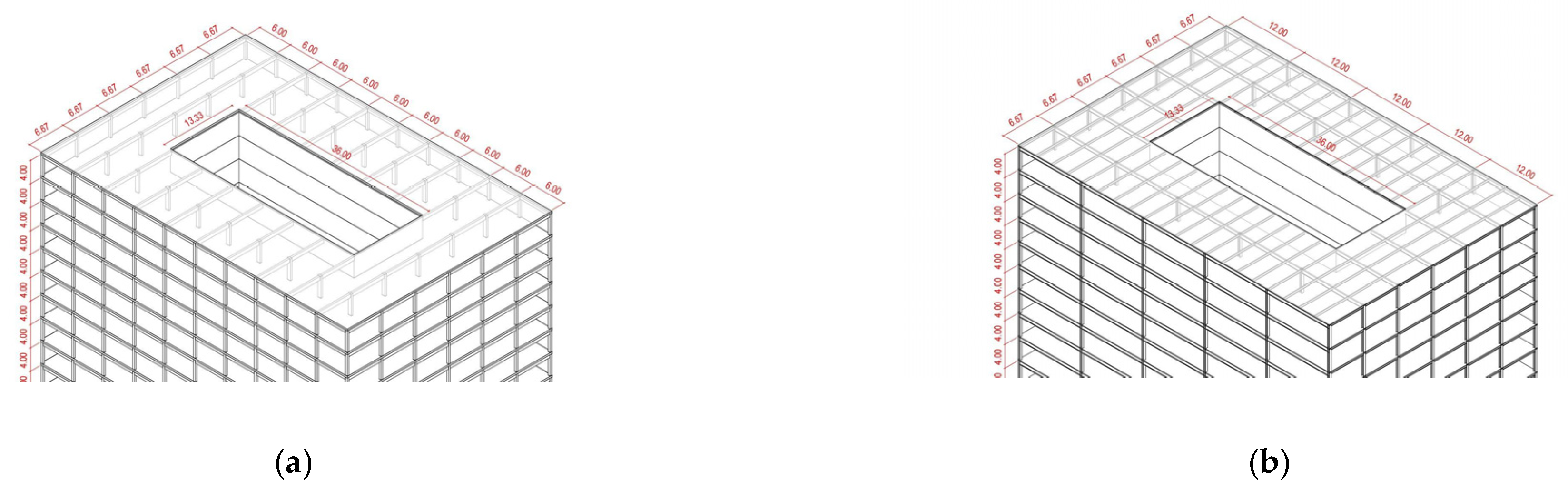

All timber, short spans: The fifth scenario (named AT20: all timber, 20 stories) features a design of a 20-story building with spans of 6 m × 6.66 m and a carpet area amounting to 38,189 sqm (Figure 3a). The construction is made with all-timber structural elements; the columns and beams are crafted in GLT, while the flooring system comprises a 7-layer CLT deck with a 6.3 cm concrete topping reinforced by welded wire mesh (Figure 2c).

Figure 3.

Axonometric plans: (a) scenarios AT20 and SC-TBD40; (b) scenarios AS20L and AS40L.

Composite, short spans: The sixth scenario (named SC-TBD40: steel columns, timber beams and decks, 40 stories) is represented by a 40-story building with spans of 6 m × 6.66 m, with a 76,738 sqm carpet area (Figure 3a). The construction involves a combination of steel and timber structural elements; steel profiles (W series) are used for crafting columns, GLT is employed for beams, and the flooring system consists of a 7-layer CLT deck topped with 6.3 cm concrete, reinforced by welded wire mesh (Figure 2d).

All steel, mid spans: Scenario number 7 (named AS20L: all steel, 20 stories, long spans) is an all-steel 20-story building with spans of 12 m × 6.66 m and totaling 38,382 sqm (Figure 3b). The columns and beams are made with hot-rolled profiles of the W series. The flooring system consists of a metal deck (7.6 cm) with a lightweight concrete slab on top (8.3 cm), reinforced with welded wire mesh (Figure 2a). Scenario number 8 (named AS40L: all steel, 40 stories, long spans) is the 40-story version of number 7, with a total carpet area of 76,744 sqm (Figure 3b).

2.2. Quantification Method of Non-Structural Components

Fire is a much-discussed topic when it comes to steel and, even more, mass timber buildings [35]. The panel of engineers consulted for this research indicated a 2 h fire rating for these structures, in accordance with the provisions of the International Building Code [36] and EN 1991 [37]. To achieve this level of fire protection, various strategies are employed depending on the type of material used in construction. For steel structural members, a common approach involves applying a 5 cm thick layer of sprayed-on plaster finish, which serves as a protective barrier against high temperatures and slows down the rate at which steel heats up during a fire. For timber members, the fire resistance requirements are met by oversized elements, which are designed with additional thickness or larger cross-sectional dimensions to account for potential charring during a fire, ensuring that the core of the wood remains structurally sound for the two-hour period. As for the slabs, which consist of either a CLT deck with a concrete topping (for acoustic reasons) or a composite metal deck; they are engineered with sufficient thickness to inherently meet fire resistance requirements. In these cases, the structural and thermal properties of the materials, in combination with the overall thickness, provide adequate fire protection, eliminating the need for the application of additional sprayed-on fireproofing materials. This design approach ensures compliance with fire safety standards while optimizing the use of materials and construction methods.

This analysis also includes consideration of the steel connectors used in the installation of timber elements, which may be a significant factor in evaluating the overall material requirements and environmental impact of the construction process. The number of steel connectors required is based on recommendations from structural engineers, who determine the necessary quantity to meet safety and performance standards for the specific timber elements used. These recommendations take into account factors such as load distribution, joint strength, and structural stability. Analysis has shown that, on average, 10 kg of steel connectors are needed per cubic meter of CLT elements, and 20 kg are needed per cubic meter of GLT elements.

2.3. Impact Assessment Methodology

Once the inventory analysis has been completed, the next stage is the impact assessment phase. This critical step evaluates the environmental loads of the material inputs used throughout the construction process by examining the resources consumed for their production, as well as the resulting emissions generated over the entire life cycle of these materials. The goal is to understand how the resources used and emissions produced contribute to various environmental concerns [31]. Human activities in construction and material production can lead to significant degradation of the environment, and impact categories help identify which environmental systems are being threatened [38]. In order to quantify and assess these impacts, a variety of indicators, referred to as impact categories, are employed. These categories encompass a wide range of concerns, such as water usage, energy consumption, land use, resource depletion, and emissions of harmful substances like ozone-depleting gases and air pollutants [39]. Each impact category is designed to represent a specific type of environmental stress or risk that human activities may impose on the natural environment. The use of these impact categories facilitates a more comprehensive evaluation of the sustainability of construction practices, ensuring that both resource efficiency and environmental preservation are taken into account [40]. Producers, designers, consumers, and decision makers can better understand the potential environmental risks associated with the materials and processes involved, enabling them to make more informed choices aimed at reducing ecological harm.

Among the various impact categories, when it comes to LCA conducted for buildings, GWP often emerges as the most significant one, especially when against the Paris Agreement targets. GWP measures the impact of greenhouse gas emissions on the atmosphere in kilograms of CO2 equivalents (kg CO2 eq), quantifying how much heat these gases trap over a specific time frame, typically 100 years. This is particularly relevant in the context of building construction and operation, where energy use and material production can result in substantial emissions of carbon dioxide (CO2), methane (CH4), and other GHGs. These emissions are primarily responsible for climate change due to their ability to enhance the greenhouse effect, leading to global temperature increases, shifts in weather patterns, and other related environmental impacts generally labeled as climate change. By centering the analysis on GWP, this study aims to highlight the role that buildings play in global warming and identify opportunities to mitigate their contribution to climate change through more sustainable design and construction practices.

Step-by-Step Methodology

- (1)

- The scenario designs, provided by engineers and including all-steel, all-timber, and composite alternatives, have been subsequently modeled using Building Information Modeling (BIM) software, specifically Autodesk Revit v. 2022. This process aimed to accurately estimate material quantities by considering connections and overlapping layers, such as those between beams and columns or between columns and slabs, for which the software is particularly effective.

- (2)

- The bill of quantities thus obtained was used for LCA calculation, associating each material with its GWP impact in order to assess the total number of impacts. This analysis was performed using a WBLCA tool, namely One Click LCA v. 0.35, which has been identified as an established tool for LCA analysis among practitioners in the building industry.

- (3)

- This online tool draws information for the inventory analysis straight from BIM, and it thus represents a very intuitive and dynamic tool. Material quantities are then automatically used to calculate the environmental impacts by sourcing data from an internal database built on EPD values or datasets frequently updated by the software company. The great value of this solution lies in the possibility offered to designers to frequently check the impacts of the design solutions being adopted by running an LCA, thus allowing for effective comparisons between alternative solutions. Unfortunately, this is not a “live” system that constantly feeds the user with information while the design is being generated in the BIM environment, as it still needs to pause the design phase and export the data to the LCA tool. Still, the Revit plugin solution offered by One Click LCA is very effective for the constant monitoring of environmental performance while the design itself is being created.

For the purposes of this research, the various building scenarios detailed in the inventory analysis section are regarded as alternative options developed in response to a specific design brief, within each the height category. Each scenario reflects a distinct approach or strategy considered by the design team when formulating the structural solution for a particular building project. The analysis conducted on each scenario thus simulates the process that would typically occur in a design office, where different structural solutions are assessed to determine the most effective and efficient option.

2.4. Considered Aspects

2.4.1. Biogenic Carbon Content of Mass Timber Products

Due to the current lack of uniformity in how biogenic carbon content in timber elements is assessed across EPDs and available databases [41,42], a simplified approach was adopted for this assessment. This approach, commonly referred to as the “0/0” approach, aligns with the methodology outlined in the EN 15804 standard [13], which governs the environmental performance of construction products. For instance, while timber has a natural carbon sequestration capacity, its overall life cycle emissions can vary widely depending on factors such as forest management practices, transportation, and the way timber is processed, used, and disposed of [43]. Additionally, the treatment of biogenic carbon is still a matter of debate in LCA research, as highlighted by studies like Levasseur et al. [44], which emphasize that the timing of carbon release and its potential reabsorption by subsequent plant growth complicate the accuracy of these measurements. By using the “0/0” approach, the assessment avoids the complexities of attributing uncertain carbon benefits to timber materials [14], thereby simplifying calculations while still complying with established standards. However, it also means that the potential long-term benefits of timber’s carbon sequestration capacity during its growth phase are not reflected in the assessment. In some cases, this can lead to an underestimation of the environmental advantages that timber products may offer, especially when compared to non-renewable materials such as steel or concrete, which do not have the same carbon-capturing properties [45]. However, the “0/0” approach remains a practical solution for maintaining consistency and comparability across various life cycle assessments.

A technical service life of 50 years, equivalent to the building’s life, was set for all the materials. If properly designed and constructed, and without the repairs needed after major circumstances such as earthquakes or fires, both steel and timber structures can enjoy a much longer useful life, during which no maintenance, repair, and substitution is needed.

2.4.2. Further Variations in the Considered Scenarios and Transportation Impacts

Three different variations were modeled for each scenario.

- (1)

- A pair of average impact results, defined as “baseline scenarios”, were calculated for the eight scenarios. For each scenario, a set of two results supposed the same building to be built both in Paris for the European variation and in New York for the North American one. The WBLCA tool allows users to choose among different impact data, either from specific EPDs or from embedded average datasets, intended to be used when no specific data for the building location are available. For each construction material referenced by the BoQ, wherever possible, the software-calculated average was used. Thus, for ready-mix concrete, steel, rebars, GLT and CLT element average values were adopted to form the baseline scenario. Given the lack of average data, for steel decks, steel studs, and sprayed-on plaster, specific EPDs were selected instead, equal for all the building scenarios.

- (2)

- For each location (Paris and New York), a “best case” alternative was also assessed for each scenario; the lowest value available was selected for each of the materials used, except for steel decks, steel studs, and sprayed-on plaster, for which the same specific EPDs of baseline cases were used. This alternative represents the solution with the lowest environmental impact, achieved through a meticulous—though potentially unrealistic—selection of material suppliers. By choosing suppliers whose manufacturing processes exhibit the most favorable sustainability metrics, this alternative aims to minimize the overall ecological footprint of the construction project. However, it is important to note that this approach might not reflect practical constraints and real-world challenges faced in procurement and supply chain management, where factors such as availability, cost, and logistical considerations can influence material selection. Thus, while this alternative provides an idealized benchmark for environmental performance, its feasibility in practical application may be limited.

- (3)

- If significant deviations were observed between the total environmental impacts for the two locations, an additional alternative was assessed—the “best with imported materials” scenario. This alternative involved a sensitivity analysis where structural materials—steel and timber—intended to be used in one location were assessed using the environmental performance data from the other location, incorporating the impacts of transportation. It was based on the condition that the EPD of a product available in one market showed a GWP at least 10% lower than its equivalent in the other. The analysis explored the potential benefits of sourcing materials with superior environmental performance, balancing these against the environmental costs of transportation. This included evaluating whether importing materials, despite associated trade-offs, might yield a more favorable environmental outcome than relying exclusively on local production, considering specific impact profiles and logistical factors.

The default mean values suggested by the WBLCA software (One Click LCA v. 0.35) used were adopted for several parameters, including the transportation distance (as detailed in Table 3) for the various materials, their means of transport, and their payload and fuel efficiency.

Table 3.

Mean transportation distances (km) for each material and location, as provided by the software One Click LCA.

Among the available options for the end of life, the most common scenarios were selected for each material, based on industry best practices: recycling with downcycling for concrete, full recycling for steel, and incineration with heat recovery for wood. As plaster is considered an inert material, it is more likely to be landfilled.

The diversity introduced by the various scenarios allows for a range of comparative analyses. By examining different scenarios, it becomes possible to identify and understand potential discrepancies in the environmental impacts of various construction options. Specifically, the comparison focuses on two locations, three distinct building frame types, two height alternatives, and three span dimensions for a total of 32 results. This approach allows for a more nuanced understanding of how different design choices can influence the sustainability of a construction project.

2.4.3. Discussion on the Comparability of the Various Results

The comparison of the results is grounded in a hypothetical comparability between the EPDs produced in the two locations, where two alternative impact assessment methods are used: the TRACI (Tool for the Reduction and Assessment of Chemical and other environmental Impacts) and the CML (Centre of Environmental Science at Leiden University) impact calculation methodologies, on which ISO 21930 [46] and EN 15804 [13] are respectively based [47,48]. The validity of this assumption is supported by the observation that these methods, while showing differences in evaluating various parameters, exhibit minimal discrepancies in the assessment of GWP values, as documented in recent studies [49,50]. Both TRACI and CML employ a global base for the characterization of GWP factors, ensuring that their assessments are comparable. As detailed by Santero and Hendry [51], this global approach allows for a standardized evaluation of GWP across different regions and methodologies. Consequently, the assumption of comparability between EPDs from the two locations holds, provided that the impact assessment methods used are aligned, thus enabling a meaningful comparison of environmental impacts based on the GWP values derived from these methodologies.

An additional layer of analysis was incorporated to ensure the homogeneity of the results, focusing on the comparability of the various materials available in the two geographic regions, and of the information included in their EPDs. This is, for instance, the case with steel products. Unlike European EPDs, which follow scheme A1 for raw material extraction, scheme A2 for transportation to the production site, and scheme A3 for profile production (as dictated by the EN 15804 standard), the EPDs of North American steel products typically aggregate the extraction of raw materials and production stages in the A1 module, while A2 represents transportation to a workshop, and A3 encompasses only the final fabrication step for the steel profiles to be directly installed in buildings (e.g., cutting, punching, drilling, bending, welding). To enhance comparability between structural steel products of the two reference markets, a “fabrication factor” was added to the European ones in calculations. Based on the EPDs for structural steel collected from the North American market, this factor was determined as the straight average of the A3 modules reported in those EPDs. The resulting factor amounted to 81.22 kg CO2 eq per ton of structural steel profiles.

3. Results of the LCA and Discussion

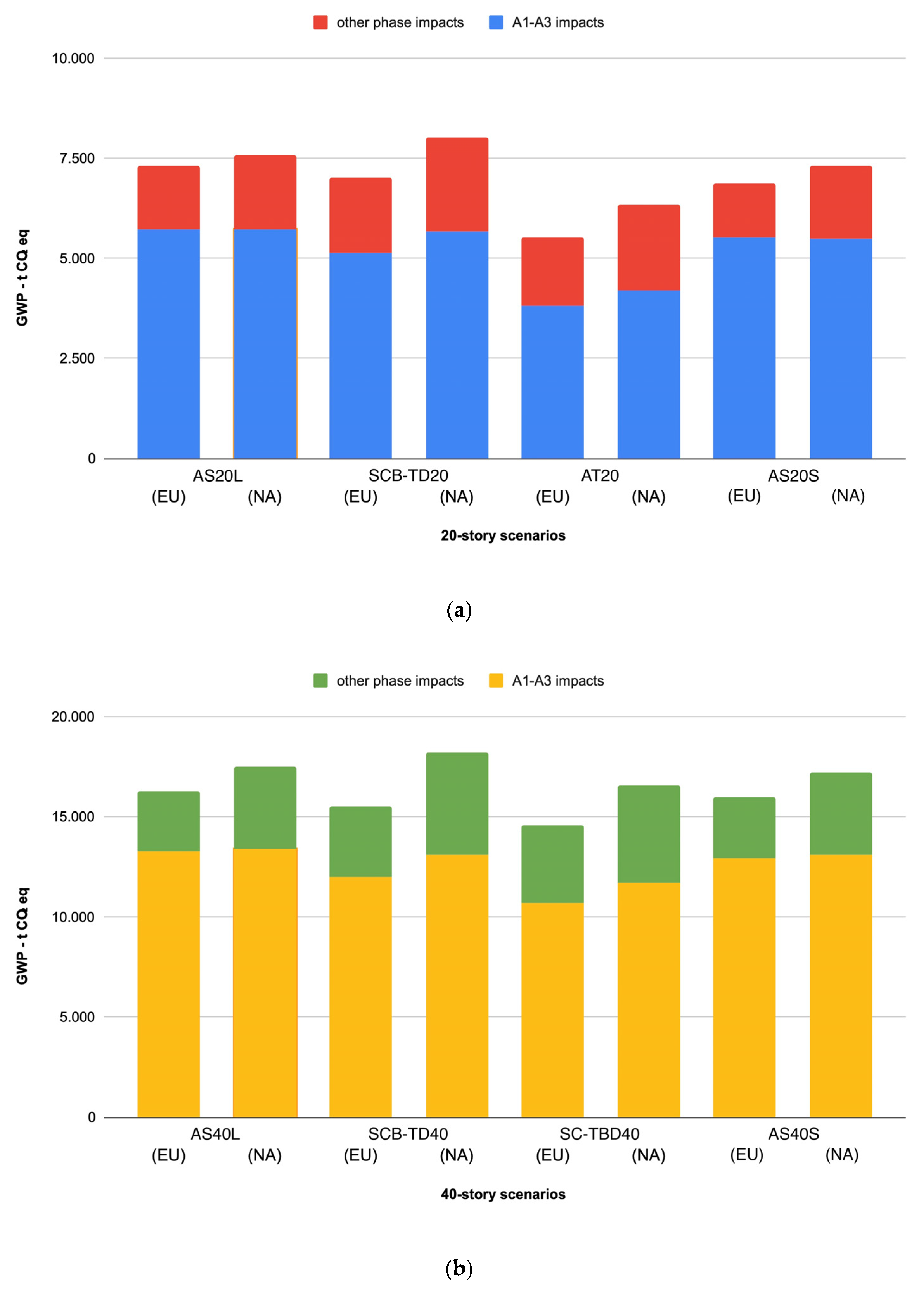

The results of the total impacts for the baseline scenarios designed to be built in Europe and North America are shown in Table 4. It is interesting to note that the production phase (A1–A3) accounts for, on average, nearly 77% of the total impacts for the European alternatives and nearly 73% for the North American ones. This is explained by the different relevance of the transportation phase (A4), which is consistently less impactful for the European scenarios, whereas the North American transportation phases are between 2.6 and 3.6 times higher. The largest discrepancies are found in scenarios where timber is featured; CLT and GLT structural elements, in fact, even if lighter, require a larger volume to achieve the same strength grade as their steel counterparts, leading to a need for more transportation activities for the timber. Europe typically shows shorter traveling distances, both for materials and end-of-life demolition debris. Additionally, European trucks are generally smaller and more fuel-efficient compared to those commonly used in North America. This difference in vehicle characteristics is due in part to varying regulations, road infrastructure, and operational practices across regions [52,53].

Table 4.

Summary of GWP impacts for the baseline case scenarios for both locations (kg CO2 eq. per square meters of carpet area).

By contrast, the other phases of the LCA—such as construction, operation, and end of life—show largely similar environmental impacts between the two locations. These phases generally involve comparable processes and technologies, leading to similar environmental outcomes regardless of regional differences in transportation practices.

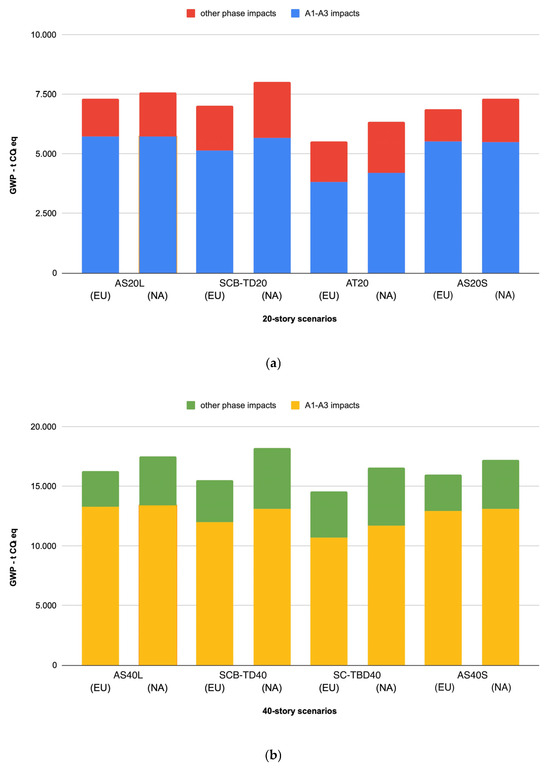

As shown by Figure 4a, for both locations, the all-timber scenario (scenario AT20) reports a lower total impact compared to the other 20-story scenarios (scenarios AS20L, SCB-TD20, and AS20S), each of which includes at least one steel structural element. Similarly, scenario SC-TBD40 has the lowest impact among the 40-story scenarios, as it incorporates a greater proportion of timber elements than the others (Figure 4b). These results confirm that timber alternatives have a significantly lower impact during the production stage, due to the reduced emissions associated with timber-based products, even without accounting for the environmental benefit of carbon sequestration during tree growth.

Figure 4.

(a) Share of the production stage in total impacts for Europe (left bars) and North America (right bars), across 20-story scenarios. (b) Share of the production stage in total impacts for Europe (left bars) and North America (right bars), across 40-story scenarios.

Comparing the two scenarios featuring 20 stories and all-steel structural elements, scenario SCB-TD20, with a shorter span (12 m × 6.66 m), reports a lower impact than scenario AS20L, which features a larger span (12 m × 13.33 m). The same result is reported for the corresponding 40-story scenarios (AS40L and AS40S). The key factor contributing to the lower impact in scenario SCB-TD20 is the use of smaller steel profiles for both columns and beams, which are required for shorter spans as the structural demands are reduced. Even though this means having a larger number of elements, the smaller size of each profile results in less material and energy to produce, leading to reduced emissions and resource consumption, compared to the larger profiles used in scenario AS20L. Additionally, smaller profiles are easier to transport, further reducing transportation-related impacts [54]. This pattern of reduced impact with shorter spans and smaller profiles is consistent across the two locations. The findings highlight the importance of span dimensions and material choices in reducing environmental impacts. Smaller spans and the efficient use of materials can lead to significant reductions in the production and transportation impacts of steel structures.

Among the 40-story scenarios, scenario SC-TBD40, featuring steel columns and timber beams and floor decks, consistently reports the lowest total environmental impact across both locations. This outcome is primarily due to the unique choice of construction materials used in this scenario (timber beams and decks).

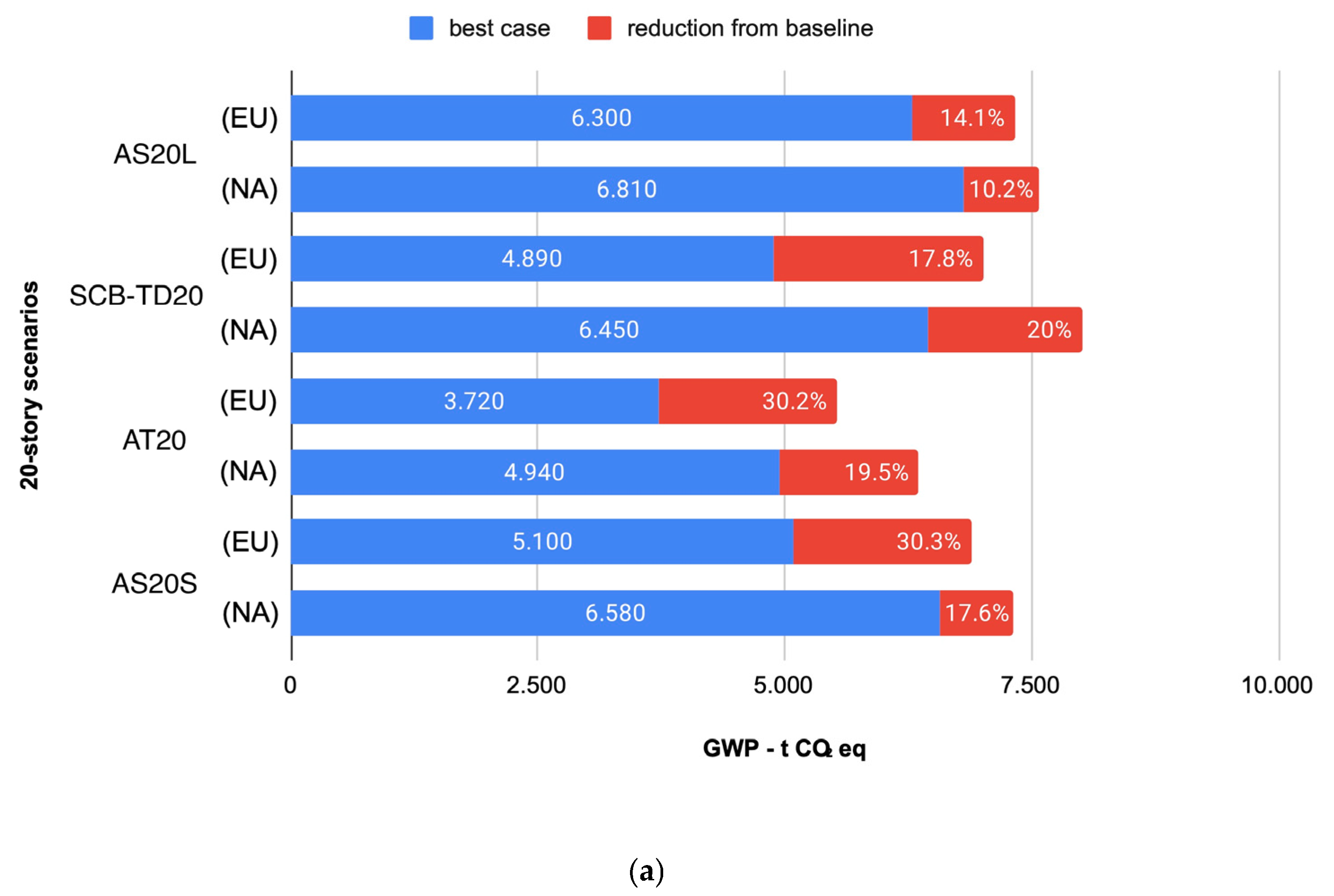

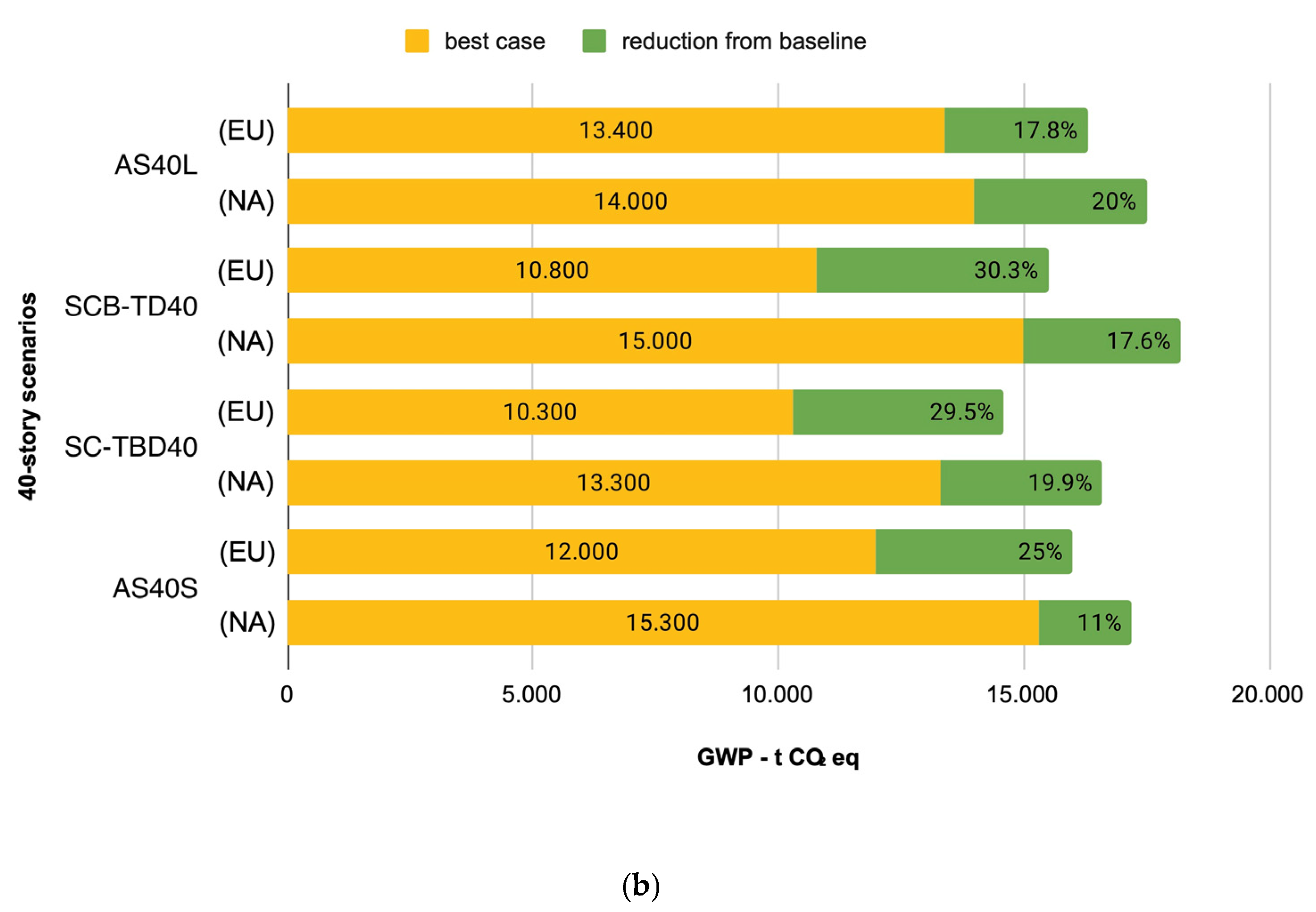

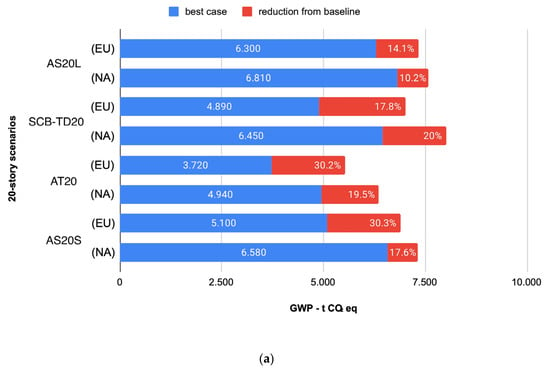

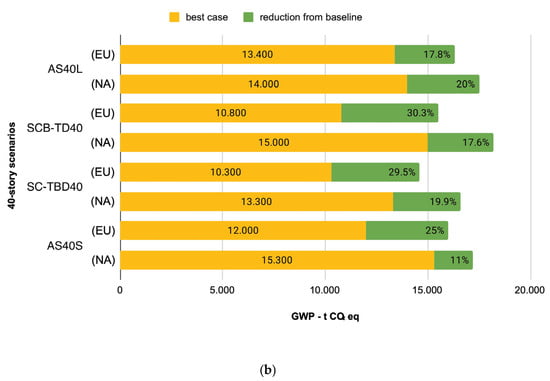

The results for the best-case scenarios (those where materials are selected based on the smaller GWP indicator reported in their EPDs) for both European and North American cases are shown in Table 5. Looking at the total impacts, the reductions from the baseline cases are, on average, 25.7% for Europe and 16.3% for North America, as shown in Figure 5a,b. These figures indicate that products with lower environmental impacts are more readily available in the European market compared to North America. This disparity could be attributed to varying regulations, market demands, and the availability of sustainable materials in the respective regions. Among all scenarios, the all-timber scenario (AT20) demonstrates the most substantial reductions in environmental impacts. For Europe, this scenario achieves a notable reduction of 48.7%, while in North America, the reduction is 28.7%. The higher-impact reductions in the former could be due to the more advanced or widespread use of sustainable timber products and practices.

Table 5.

Summary of GWP impacts for the best-case scenarios for both locations (kg CO2 eq. per square meters of carpet area).

Figure 5.

(a) Total impacts of best-case alternatives and reductions from baseline cases for 20-story scenarios, shown for Europe (top bar) and North America (bottom bar). (b) Total impacts of best-case alternatives and reductions from baseline cases for 40-story scenarios, shown for Europe (top bar) and North America (bottom bar).

The all-steel scenarios (AS20L, AS20S, AS40L, and AS40S) exhibit smaller variations in environmental impact reductions. For Europe, these reductions range from 16.3% to 35.1%, while for North America they range from 11.3% to 25%.

The relatively small differences observed can be attributed to the fact that the baseline cases are based on steel products that already have relatively low impacts compared to other building products. This contrasts sharply with the timber elements, which exhibit more pronounced differences in environmental impact due to varying material properties and processing methods. The steel products used in the baseline cases are made from a significant proportion of recycled material. Specifically, the steel used for structural profiles contains 90% scrap metal, while the chosen rebars are made from 97% scrap metal. The high percentage of recycled content in these steel products reduces their overall environmental impact, as recycling steel requires less energy and generates fewer emissions compared to producing new steel from raw materials [55]. Consequently, the difference between these baseline products and the lowest-impact steel profiles and rebars—used in the best case, both of which use 100% scrap metal—is minimal. Given that the baseline products are already optimized for low environmental impact, the benefits of further reducing impacts are less pronounced.

When comparing the environmental impacts of building scenarios between Europe and North America, it is evident that European scenarios generally exhibit lower environmental impacts compared to their North American counterparts, both for baseline and best-case scenarios. The EPDs available in Europe typically report lower GWP impacts compared to those available in North America. This discrepancy can be attributed to differences in manufacturing practices, energy sources, and environmental standards between the two regions. European EPDs often benefit from more rigorous sustainability practices and higher proportions of recycled materials, which contribute to their lower reported impacts [55].

Sensitivity Analysis

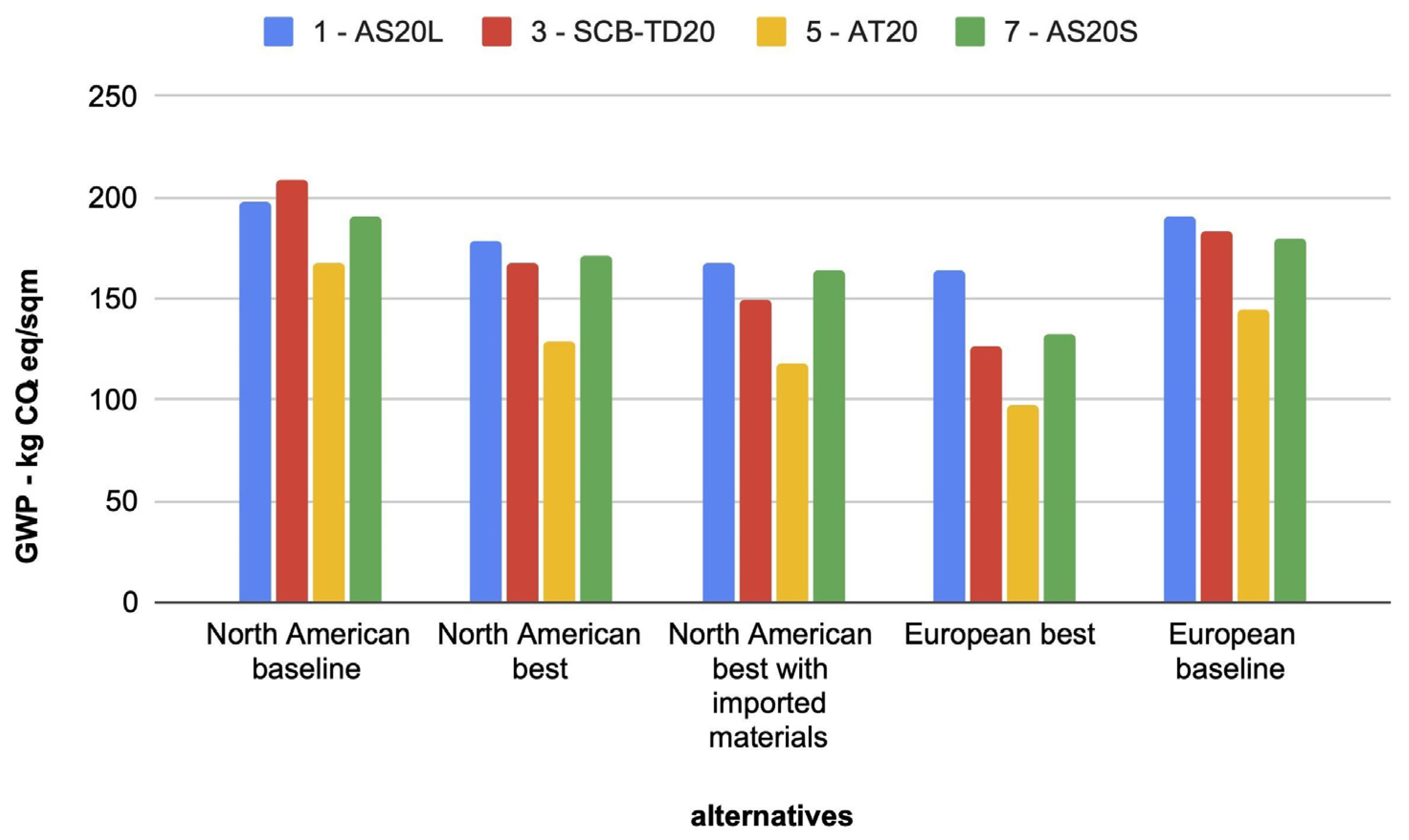

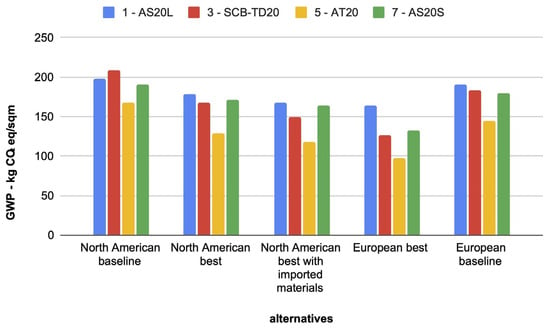

The initial condition for the “best with imported materials” alternative was met for both structural steel and timber, with European products demonstrating a more than 10% lower environmental impact compared to their North American equivalents. This alternative thus assumes the use of the most efficient European products in a North American building project (Figure 6).

Figure 6.

Total impacts per square meter of carpet area for all the assessed alternatives in the 20-story scenarios.

This alternative also takes into account the environmental impact of transporting these European materials from their production sites in Europe to the North American construction site. Although using European EPDs could theoretically reduce the environmental impacts due to their lower GWP values, the transportation of materials across the Atlantic and for the mainland legs of the journey (port handling operations are excluded) introduces additional impacts. The primary objective is to compare the environmental impacts of using high-efficiency, low-impact materials from overseas against locally produced materials within North America. The results of this exploration are combined with the results of the total impacts of all the scenarios and alternatives in Table 6, which reports GWP values expressed in kg CO2 eq normalized by square meters of carpet area. The analysis confirms that even when accounting for the significant environmental impact of transporting steel and timber elements over nearly 6000 km of ocean, the “best with imported materials” alternatives still result in a lower overall environmental impact compared to the best North American case (Figure 6). Specifically, these imported alternatives exhibit an average reduction in environmental impact of approximately 7.7%. The use of this alternative reveals varying degrees of environmental impact reductions across different scenarios, with the most substantial decreases observed in scenarios incorporating timber elements (from 9% to 11%), while scenarios featuring only steel elements show smaller reductions (from 4% to 6%). Additionally, all “best with imported materials” alternatives exhibit higher impacts compared to the European best cases (15% on average), primarily due to the environmental burden of transportation and the contribution of North American-produced materials.

Table 6.

Summary of A1–C4 impacts for different scenarios and alternatives (kg CO2 eq. per square meters of carpet area).

In Table 7, a comprehensive breakdown of the environmental impacts associated with each phase of the LCA for scenario AT20 is presented. This scenario, which reported the lowest GWP impact among the various 20-story scenarios, serves as a benchmark for evaluating and comparing the relative impacts of different construction alternatives. When examining the total environmental impacts, a notable disparity is observed between the North American and European baseline cases. The North American baseline scenario demonstrates a 15% higher environmental impact compared to its European counterpart. This difference reflects variations in material production processes, environmental regulations, and overall sustainability practices between the two regions. When the least impactful materials are applied, the European best-case scenario achieves a total reduction of 33% in environmental impact compared to its baseline case. By contrast, the North American best-case scenario shows a reduction of 23% from its baseline case. Although this is a notable improvement, it is less significant than the reduction achieved in the European best case, and it reflects the relative limitations in available low-impact materials and practices in North America, as well as potentially less efficient production processes compared to Europe. The North American alternative scenario that incorporates materials imported from Europe results in a 9% reduction from the North American best case.

Table 7.

GWP impacts of each LCA phase for all alternatives and for both locations, scenario AT20 (kg CO2 eq.). Legend: A1–A3, production stage; A4, transportation module; A5, construction module; C1–C4, end-of-life stage; D, loads and benefits beyond the system boundary.

In the detailed examination of LCA phases, significant variations are observed between European and North American scenarios. For the production stage (A1–A3), the European best case shows a notable 42% reduction in environmental impact compared to the baseline. By contrast, the North American best case achieves a 31% reduction, reflecting improvements in material efficiency and production practices, although not as pronounced as in Europe. When North American scenarios incorporate European materials, the reduction is 18% compared to the North American best case. However, this benefit is somewhat diminished by the impacts of transportation. The transportation phase (A4) reveals the most significant difference, with the North American baseline having environmental impacts nearly 3.6 times higher than those of the European baseline. This disparity arises from longer transport distances and less efficient logistics in North America.

- The “best with imported materials” scenario reveals a 34% higher environmental impact in the transportation phase (A4) compared to the North American best case. This increase is primarily due to the transoceanic transportation required to bring European materials to North America, which adds significant environmental burdens. While the proportions of impacts related to site operations and waste handling remain consistent between the two locations, the construction phase (A5) in the North American baseline exhibits a 7.5% higher impact relative to the European baseline.

- The “best cases” for both European and North American scenarios demonstrate a substantial reduction in environmental impacts related to construction waste. Specifically, the European best case shows a 17% decrease, while the North American best case shows a 13% reduction. This significant reduction underscores the fact that using less impactful materials leads to lower environmental impacts associated with construction waste. In terms of the end-of-life phase, the variations among different alternatives are minimal. Notably, the best cases exhibit improvements in the waste transport (C2) and waste processing (C3) phases. For both Europe and North America, these phases are less impactful compared to the baseline scenarios. This reduction is attributed to the use of more efficient materials, which simplifies and streamlines waste management processes, resulting in lower overall environmental impacts.

4. Conclusions

This study aimed to evaluate whether combining steel and timber as structural materials for tall buildings offers environmental advantages while also examining how differences between the European and North American markets influence these outcomes. By systematically analyzing eight building scenarios, this research sought to provide valuable insights into leveraging the synergy between steel and timber in high-rise construction to achieve sustainability goals and engineering efficiency.

The main findings of this study, which aim to offer valuable insights for optimizing material choices in future high-rise construction projects, are as follows:

- Timber-based scenario alternatives have significantly lower production-stage impacts due to reduced emissions associated with timber-based products, even without considering the carbon sequestration benefits of tree growth, adopting a conservative 0/0 approach (as discussed in Section 2.4) to account for biogenic carbon. If a 1/1 approach is used instead, the timber-based scenarios present a negative GWP impact until the building reaches its end of life.

- Span dimensions and material efficiency play a crucial role in reducing the environmental impacts of steel structures; smaller spans and efficient material use, such as optimizing the design to minimize waste and selecting high-strength materials to reduce the quantity needed, can significantly lower production and transportation impacts.

- Low-GWP products are more readily available in Europe compared to North America, likely due to differences in regulations, market demand, and the availability of sustainable materials.

This study’s findings reveal that the total environmental impacts of the North American best-case scenarios range from 129 to 200 kg CO2 equivalent per square meter, measured using the IPMS 4.2 standard. In comparison, the European best-case scenarios exhibit lower total impacts, ranging from 97 to 173 kg CO2 equivalent per square meter. These figures reflect the impact of the above-grade structural systems alone, excluding foundations. These results are obviously lower when compared to the references used in the literature review (see Section 1, Introduction), as they were assessed with a different scope—the entire building. Interestingly, the study conducted by Eslami et al. [23] reported a lower total for the timber alternative than that reported by this current study; this difference can be attributed to the fewer number of stories—only two.

When comparing these results with other benchmarks, such as those from similar studies focusing solely on the structure, both discrepancies and similarities can be found. Eaton and Amato [56] also conducted a pioneering study on the embodied carbon of various office buildings, built with different structural materials (steel, composite, reinforced and precast concrete), with a number of stories comparable to those in the current research scenarios. The results for the structure alone range from a mean of 200 kg CO2 equivalent per square meter for the concrete buildings to a mean of 350 kg CO2 equivalent per square meter for the steel ones, which are significantly higher than those found in this current research. A recent study by Szalay [57] establishes 3.75 kg CO2 equivalent per square meter per year as the average GWP reference for the superstructure of multi-family houses. When this value is extended across the standard reference service life of 50 years, the cumulative GWP impact reaches 187.5 kg CO2 equivalent per square meter. This result is notably similar to the findings of this study, suggesting consistent alignment in the environmental impact assessments of structural systems.

Another crucial finding emerges from the results of the “best with imported material” analysis, which shows that, despite the environmental costs associated with transportation, using more sustainable and efficient materials from overseas can result in a net reduction in overall environmental impact. The results highlight a significant consideration for decision makers when evaluating material sourcing options. This analysis supports the idea that adopting best practices and materials from international markets can contribute to enhanced sustainability in construction, provided that transportation impacts are managed effectively. Despite the relatively minor impact of transportation on the overall LCA of a building, the efficiency of transport logistics plays a role in the environmental footprint of construction activities. Studies have shown that improvements in fuel efficiency can lead to notable reductions in greenhouse gas emissions and energy consumption [58]. Thus, the North American construction industry could benefit from enhancing the fuel efficiency of its vehicles, aligning with practices seen in Europe, where innovative technologies, such as Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPFs) [59], and stringent regulations, such as the Euro VI standards [60], have led to notable improvements in reducing the environmental impact of transport logistics. This market comparison analysis can thus influence strategies for sourcing building materials, potentially encouraging the use of more sustainable products from international markets if they offer a net environmental benefit.

This study does not identify an environmental advantage of the combination of timber and steel, as mass timber buildings remain less environmentally impactful, at least when GWP is considered. However, the inclusion of steel is crucial to ensure the necessary elasticity of mass timber buildings. Apart from this, the emergence of the steel–timber hybrid model is particularly significant as global urbanization continues, and the need for sustainable construction solutions becomes increasingly urgent. Such composite structures may soon provide an optimal balance between structural performance, environmental responsibility, and architectural innovation, positioning them as a key player in the future of high-rise building design.

This research focused on LCA applied to 20- and 40-story buildings, which are currently being considered in the construction sector for hybrid structures. Future studies could explore smaller buildings, such as 8-story residential buildings, or even structures like sports centers, warehouses, and data centers, which make up a significant portion of the current construction landscape.

This study, like most LCA studies conducted for buildings, focused solely on Global Warming Potential (GWP) among the various environmental impact categories, as GWP emissions are the leading contributors to climate change and the main focus of current regulations. While this focus provides valuable insights into the climate-related impacts of building materials, other important environmental aspects, such as energy consumption, resource depletion, and ecosystem quality, could also be examined. By considering these additional parameters, further study could offer a more comprehensive assessment of the sustainability and long-term environmental consequences of construction practices.

Limitations of This Study

This study is based on an analysis of buildings with two different heights and eight scenarios in total. Future research should explore buildings with a broader range of story numbers and consider various combinations of structural elements.

In terms of LCA indicators, this study focused exclusively on the Global Warming Potential (GWP) parameter. A comprehensive LCA should be conducted to include additional critical factors such as toxicity, resource depletion, and other environmental impacts.

In this study, the fire performance of the structural elements was assessed for each material individually rather than for the combination of the two. Fire performance can pose a limitation for hybrid steel–timber structures, as the two materials exhibit distinct behaviors in the event of a fire. Additionally, the connections between the materials can be a weak point, further complicating fire safety. Additionally, building codes often have strict fire resistance requirements for both materials, and hybrid structures must comply with these standards, which can sometimes be a challenge. However, ongoing research on connections [61] and advancements in fire-resistant technologies [62] are helping to overcome these limitations, making hybrid structures more feasible for fire safety.

Author Contributions

Conceptualization, D.T.; methodology, D.T.; software, G.P.; validation, D.T. and G.P.; investigation, D.T. and G.P.; data curation, G.P.; writing—original draft preparation, G.P.; writing—review and editing, D.T.; visualization, G.P.; supervision, D.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors wish to acknowledge the insights and technical expertise provided by numerous teams and individuals from globally recognized structural engineering firms who participated in the design and verification of the hypothetical designed scenarios—Magnusson Klemencic Associates, Fast + Epp, Glotman Simpson Consulting Engineers, Buro Happold, Thornton Tomasetti, DCI Engineers, Ramboll, Mott MacDonald, and Taylor Thomson Whitting. The authors also thank Claudia Cabrero Aparicio and Alberto Balzan for their essential contributions to the 3D modeling of the scenarios and the consequent extraction of the bill of quantities.

Conflicts of Interest

The authors declare no conflicts of interest.

List of Abbreviations and Glossary of Terms

BIM = Building Information Modeling. Digital process for creating, managing, and sharing 3D models of a building or infrastructure project throughout its lifecycle.

CLT = Cross Laminated Timber. An engineered wood product made by gluing layers of solid-sawn lumber in alternating directions.

EN = European norms. Standards developed by European Standardization Organizations, such as the CEN (European Committee for Standardization).

EPD = Environmental Product Declaration. A standardized document that provides transparent and verified information about the environmental impacts of a product throughout its life cycle.

GLT = Glue Laminated Timber. An engineered wood product made by bonding multiple layers of solid timber with adhesives.

GHGs = Greenhouse Gases. Gases such as carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) that trap heat and contribute to global warming and climate change.

GWP = Global Warming Potential. A metric used to compare the impact of different greenhouse gases on global warming, measured in kilograms of carbon dioxide equivalent (kg CO2 e).

IPMS = International Property Measurement Standards. Global standards for measuring and reporting the size and area of buildings, developed by the IPMS Coalition to create consistency and transparency in the real estate industry.

ISO = International standards. These refer to the set of internationally recognized guidelines and specifications established by the International Organization for Standardization (ISO).

LCA = life cycle assessment. A systematic method for evaluating the environmental impacts of a product, process, or service throughout its entire life cycle, from raw material extraction to disposal.

RC = reinforced concrete. A construction material made by combining concrete with steel reinforcement (rebar) to improve its tensile strength and durability.

WBLCA = whole-building life cycle assessment. A comprehensive assessment that evaluates the environmental impacts of an entire building over its life cycle.

References

- IPCC—Intergovernmental Panel on Climate Change. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar] [CrossRef]

- EEA—European Energy Agency. Addressing the Environmental and Climate Footprint of Buildings, EEA Report 09/2024; Luxembourg: Publications Office of the European Union: Luxembourg, 2024. [Google Scholar] [CrossRef]

- UNEP—United Nations Environment Programme & Yale Center for Ecosystems + Architecture. Building Materials and the Climate: Constructing a New Future. Available online: https://wedocs.unep.org/20.500.11822/43293 (accessed on 11 October 2024).

- CTBUH. CTBUH Data Handbook 2023; CTBUH: Chicago, IL, USA, 2023. [Google Scholar]

- Helal, J.; Stephan, A.; Crawford, R.H. The influence of structural design methods on the embodied greenhouse gas emissions of structural systems for tall buildings. Structures 2020, 24, 650–665. [Google Scholar] [CrossRef]

- Säynäjoki, A.; Heinonen, J.; Junnila, S. A scenario analysis of the life cycle greenhouse gas emissions of a new residential area. Environ. Res. Lett. 2012, 7, 034037. [Google Scholar] [CrossRef]

- Khan, F.R. Current Trends in Concrete High-Rise Buildings. In Tall Buildings. The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures; Coull, A., Stafford Smith, B., Eds.; Pergamon: Oxford, UK, 1967; pp. 571–590. [Google Scholar]

- Trabucco, D.; Wood, A.; Vassart, O.; Popa, N.; Davies, D. Life Cycle Assessment of Tall Building Structural Systems; CTBUH: Chicago, IL, USA, 2015. [Google Scholar]

- Helal, J.; Trabucco, D.; Savovic, D. Embodied carbon premium for vanity height: A case for the exclusion of decorative spires in the design of tall buildings. J. Clean. Prod. 2024, 456, 142334. [Google Scholar] [CrossRef]

- Howard, C.; Dymon, C.; Griess, V.; Tolkien-Spur, D.; van Kooten, C. Wood product carbon substitution benefits: A critical review of assumptions. Carbon Balance Manag. 2021, 16, 9. [Google Scholar] [CrossRef]

- Nepal, P.; Prestemon, J.P.; Ganguly, I.; Kumar, V.; Bergman, R.; Poudial, N. The potential use of mass timber in mid-to high-rise construction and the associated carbon benefits in the United States. PLoS ONE 2024, 19, e0298379. [Google Scholar] [CrossRef]

- Sathre, R.; O’Connor, J. Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ. Sci. Policy 2010, 13, 104–114. [Google Scholar] [CrossRef]

- EN 15804+A1:2014; CEN—European Committee for Standardization. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN: Brussels, Belgium, 2014.

- Hoxha, E.; Passer, A.; Ruschi Mendes Saade, M.; Trigaux, D.; Shuttleworth, A.; Pittau, F.; Allacker, K.; Habert, G. Biogenic carbon in buildings: A critical overview of LCA methods. Build. Cities 2020, 1, 504–524. [Google Scholar] [CrossRef]

- Gustavsson, L.; Madlener, R.; Hoen, H.F.; Jungmeier, G.; Karjalainen, T.; KlÖhn, S.; Mahapatra, K.; Pohjola, J.; Solberg, B.; Spelter, H. The role of wood material for greenhouse gas mitigation. Mitig. Adapt. Strateg. Glob. Change 2006, 11, 1097–1127. [Google Scholar] [CrossRef]

- EPA—U.S. Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2013; U.S. Environmental Protection Agency: Boston, MA, USA, 2015.

- Duan, Z.; Huang, Q.; Zhang, Q. Life cycle assessment of mass timber construction: A review. Build. Environ. 2022, 221, 109320. [Google Scholar] [CrossRef]

- Hemmati, M.; Messadi, T.; Gu, H. Life Cycle Assessment of the Construction Process in a Mass Timber Structure. Sustainability 2024, 16, 262. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Jones, S.; Maples, I.; Gong, Y.; Ganguly, I. Comparative Life Cycle Assessment of Mass Timber and Concrete Residential Buildings: A Case Study in China. Sustainability 2022, 14, 144. [Google Scholar] [CrossRef]

- Tupenaite, L.; Zilenaite, V.; Kanapeckiene, L.; Gecys, T.; Geipele, I. Sustainability Assessment of Modern High-Rise Timber Buildings. Sustainability 2022, 13, 8719. [Google Scholar] [CrossRef]

- Quintana Gallo, P.; Carradine, D.M.; Bazaez, R. State of the art and practice of seismic-resistant hybrid timber structures. Eur. J. Wood Wood Prod. 2021, 79, 5–28. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative Life-Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Eslami, H.; Yaghma, A.; Jayasinghe, L.B.; Waldmann, D. Comparative life cycle assessment of light frame timber and reinforced concrete masonry structural systems for single-family houses in Luxembourg. Heliyon 2024, 10, e26083. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R. Environmental Life-Cycle Assessment and Life-Cycle Cost Analysis of a High-Rise Mass Timber Building: A Case Study in Pacific Northwestern United States. Sustainability 2021, 13, 7831. [Google Scholar] [CrossRef]

- Rinne, R.; Emre Ilgin, H.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef]

- Abed, J.; Rayburg, S.; Rodwell, J.; Neave, M. A review of the performance and benefits of mass timber as an alternative to concrete and steel for improving the sustainability of structures. Sustainability 2022, 14, 5570. [Google Scholar] [CrossRef]

- Gutierrez, N.; Negrao, J.; Dias, A.; Guindos, P. Bibliometric review of prefabricated and modular timber construction from 1990 to 2023: Evolution, trends, and current challenges. Sustainability 2024, 16, 2134. [Google Scholar] [CrossRef]

- EN 15978:2011; CEN—European Committee for Standardization. Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. CEN: Brussels, Belgium, 2011.

- Žegarac Leskovar, V.; Premrov, M. A Review of Architectural and Structural Design Typologies of Multi-Storey Timber Buildings in Europe. Forests 2021, 12, 757. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Mass timber building material in the U.S. construction industry: Determining the existing awareness level, construction-related challenges, and recommendations to increase its current acceptance level. J. Clean. Eng. Technol. 2020, 1, 100007. [Google Scholar] [CrossRef]

- ISO 14044:2006; ISO—International Organization for Standardization. Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Mercader-Moyano, P.; Roldan-Porras, J. Evaluating environmental impact in foundations and structures through disaggregated models: Towards the decarbonisation of the construction sector. Sustainability 2020, 12, 5150. [Google Scholar] [CrossRef]

- Pujadas-Gispert, E.; Sanjuan-Delmas, D.; de la Fuente, A.; Moonen, S.P.G.; Josa, A. Environmental analysis of concrete deep foundations: Influence of prefabrication, concrete strength, and design codes. J. Clean. Prod. 2020, 244, 118751. [Google Scholar] [CrossRef]

- IPMS—International Property Measurement Standards Coalition. International Property Measurement Standards: All Buildings; IPMS: Melbourne, Australia, 2023. [Google Scholar]

- Barber, D. Fire Safety of Mass Timber Buildings with CLT in USA. Wood Fiber Sci. 2018, 50, 83–95. [Google Scholar] [CrossRef]

- International Code Council. International Building Code (IBC) 2018 Edition. Chapter 7: Fire-Resistance-Rated Construction; ICC: Washington, DC, USA, 2018. [Google Scholar]

- EN 1991-1-2:2002; CEN—European Committee for Standardization. Eurocode 1: Actions on Structures—Part 1-2: General Actions—Actions on Structures Exposed to Fire. CEN: Brussels, Belgium, 2002.

- Hertwich, E.G.; Peters, G.P. Carbon Footprint of Nations: A Global, Trade-Linked Analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Irving Olsen, S. Life Cycle Assessment: Theory and Practice; Springer: New York, NY, USA, 2011. [Google Scholar]

- Andersen, C.E.; Rasmussen, F.N.; Habert, G.; Birgisdottir, H. Embodied GHG emissions of wooden buildings. Challenges of biogenic carbon accounting in current LCA methods. Front. Built Environ. 2021, 7, 729096. [Google Scholar] [CrossRef]

- Linkosalmi, L.; Schwarzschachner, H.; Valtonen, T. Harmonisation of the environmental product declarations for wood products. In Proceedings of the World Conference on Timber Engineering, Oslo, Norway, 19–22 June 2023. [Google Scholar]

- Guest, G.; Cherubini, F.; Strømman, A.H. The role of forest residues in the accounting for the global warming impact of bioenergy. GCB Bioenergy 2013, 5, 459–466. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic carbon and temporary storage addressed with dynamic life cycle assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- Petersen, A.K.; Solberg, B. Environmental and economic impacts of substitution between wood products and alternative materials: A review of micro-level analyses from Norway and Sweden. For. Policy Econ. 2005, 7, 249–259. [Google Scholar] [CrossRef]

- ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. ISO: Geneva, Switzerland, 2017.

- Bare, J. TRACI: The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts. J. Ind. Ecol. 2002, 6, 49–78. [Google Scholar] [CrossRef]

- Guinée, J.B. (Ed.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Alphen can den Rijn, The Netherlands, 2002. [Google Scholar]

- Dong, Y.; Hossain, M.H.; Li, H.; Liu, P. Developing Conversion Factors of LCIA Methods for Comparison of LCA Results in the Construction Sector. Sustainability 2021, 13, 9016. [Google Scholar] [CrossRef]

- Koch, D.; Friedl, A.; Mihalyi, B. Influence of different LCIA methods on an exemplary scenario analysis from a process development LCA case study. Environ. Dev. Sustain. 2023, 25, 6269–6293. [Google Scholar] [CrossRef]