Using Fines from Recycled High-Quality Concrete as a Substitute for Cement

Abstract

:1. Introduction

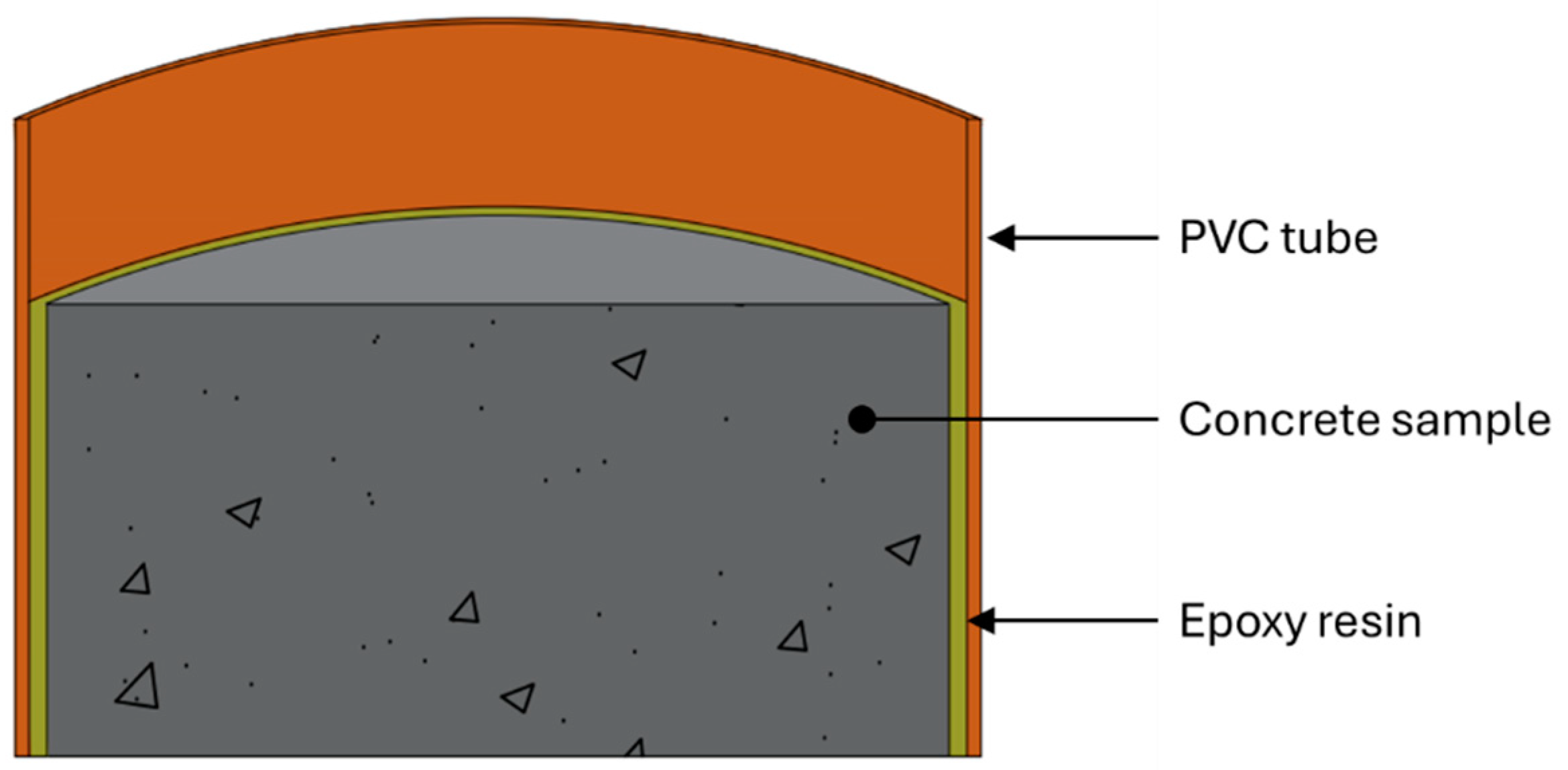

2. Materials

3. Test Methods

3.1. Characterization of the Recycled Fines and Mortar Testing

3.1.1. Particle Size Distribution (PSD)

3.1.2. Particle Shape

3.1.3. Particle Density and Water Absorption

3.1.4. X-Ray Diffraction Analysis

3.1.5. X-Ray Fluorescence

3.1.6. Isothermal Calorimetry

3.1.7. Flexural and Compressive Strength of Mortars

3.2. Tests for Strength and Durability on Concrete

3.2.1. Compressive Strength of Concrete

3.2.2. Water Absorption Under Vacuum

3.2.3. Carbonation

3.2.4. Shrinkage

3.2.5. Freeze–Thaw Resistance

4. Results and Discussion

4.1. Characterization of the Recycled Fines and Mortar Testing

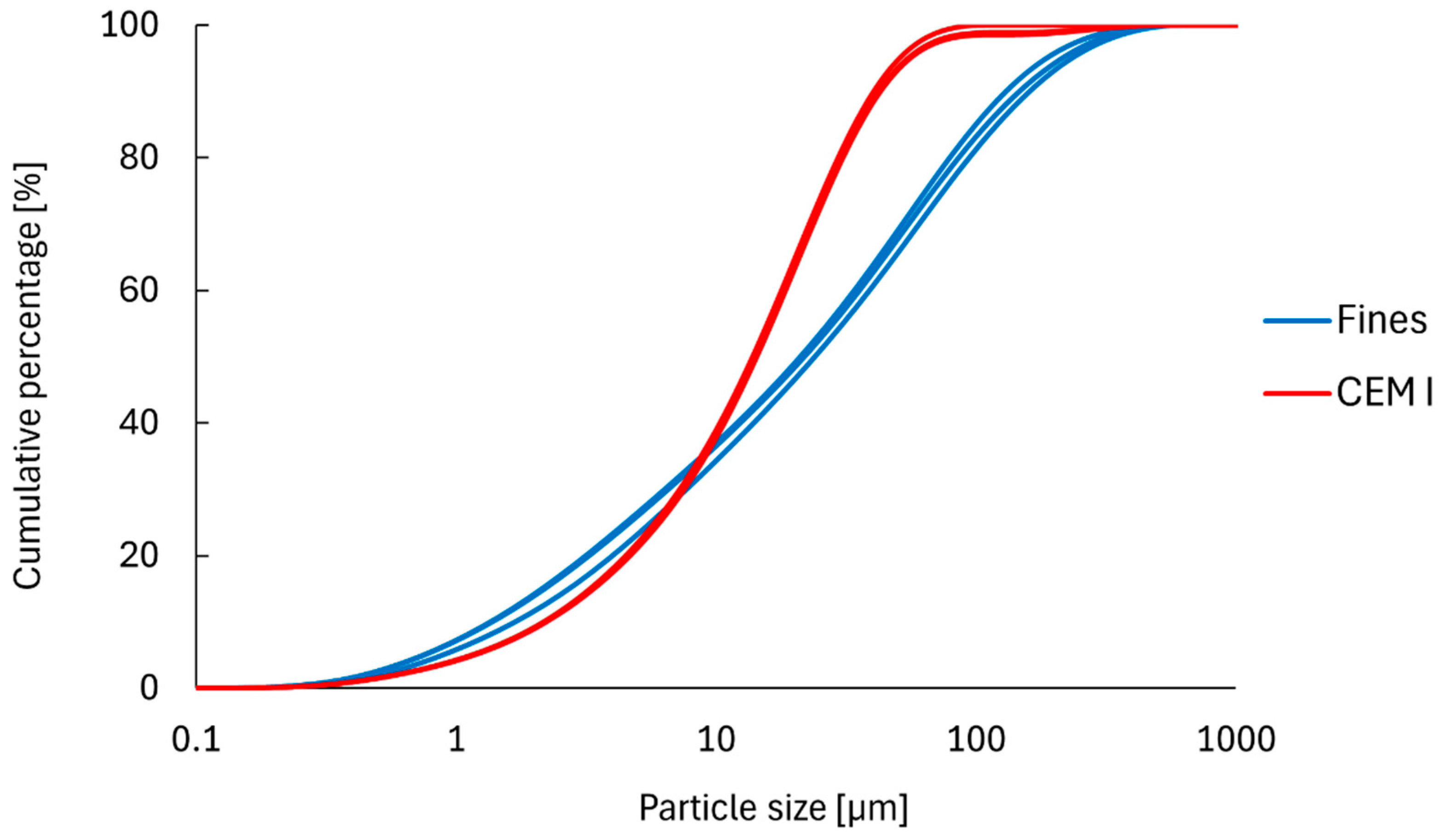

4.1.1. Particle Size Distribution (PSD)

4.1.2. Particle Shape

4.1.3. Particle Density and Water Absorption

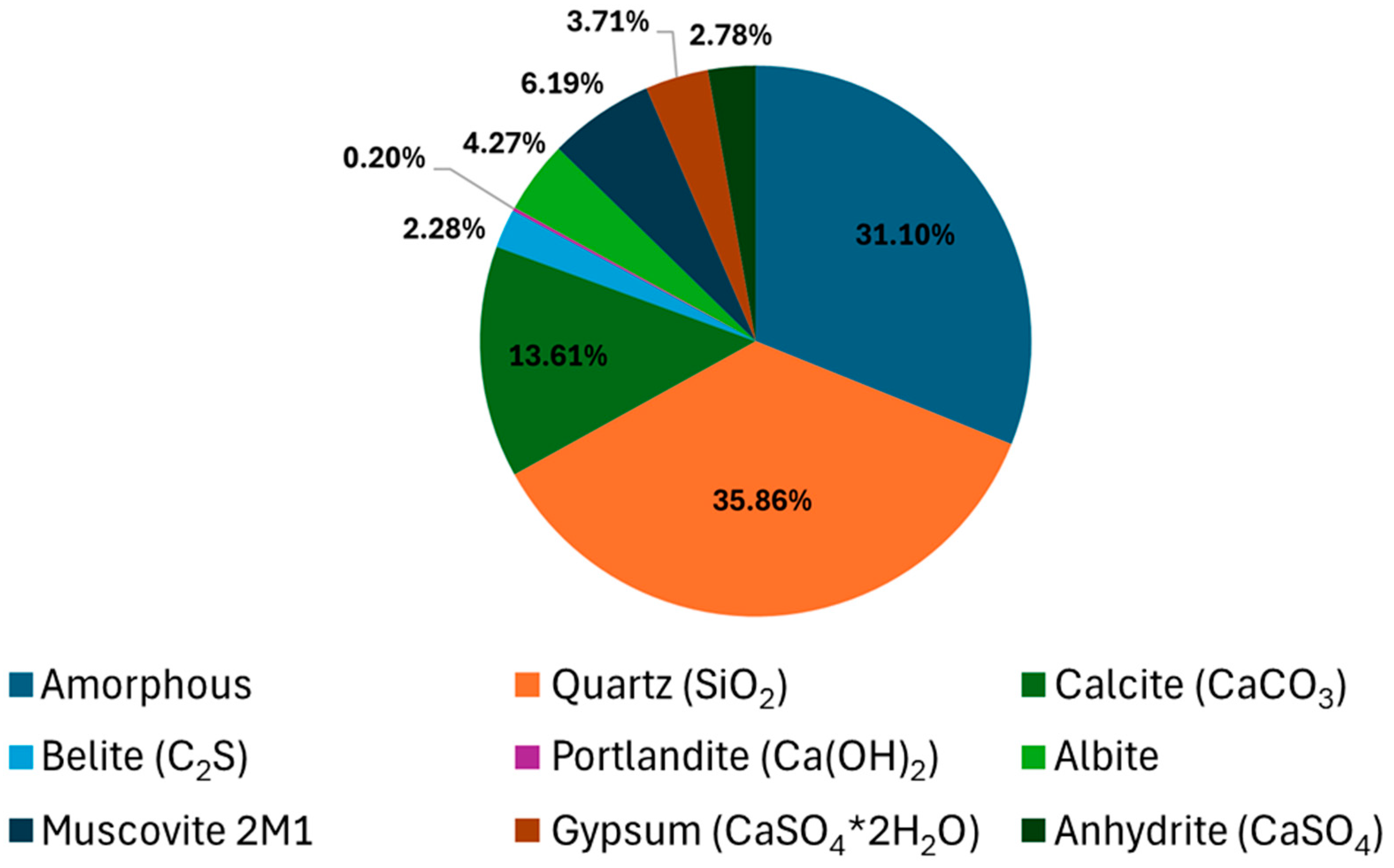

4.1.4. X-Ray Diffraction Analysis

4.1.5. X-Ray Fluorescence

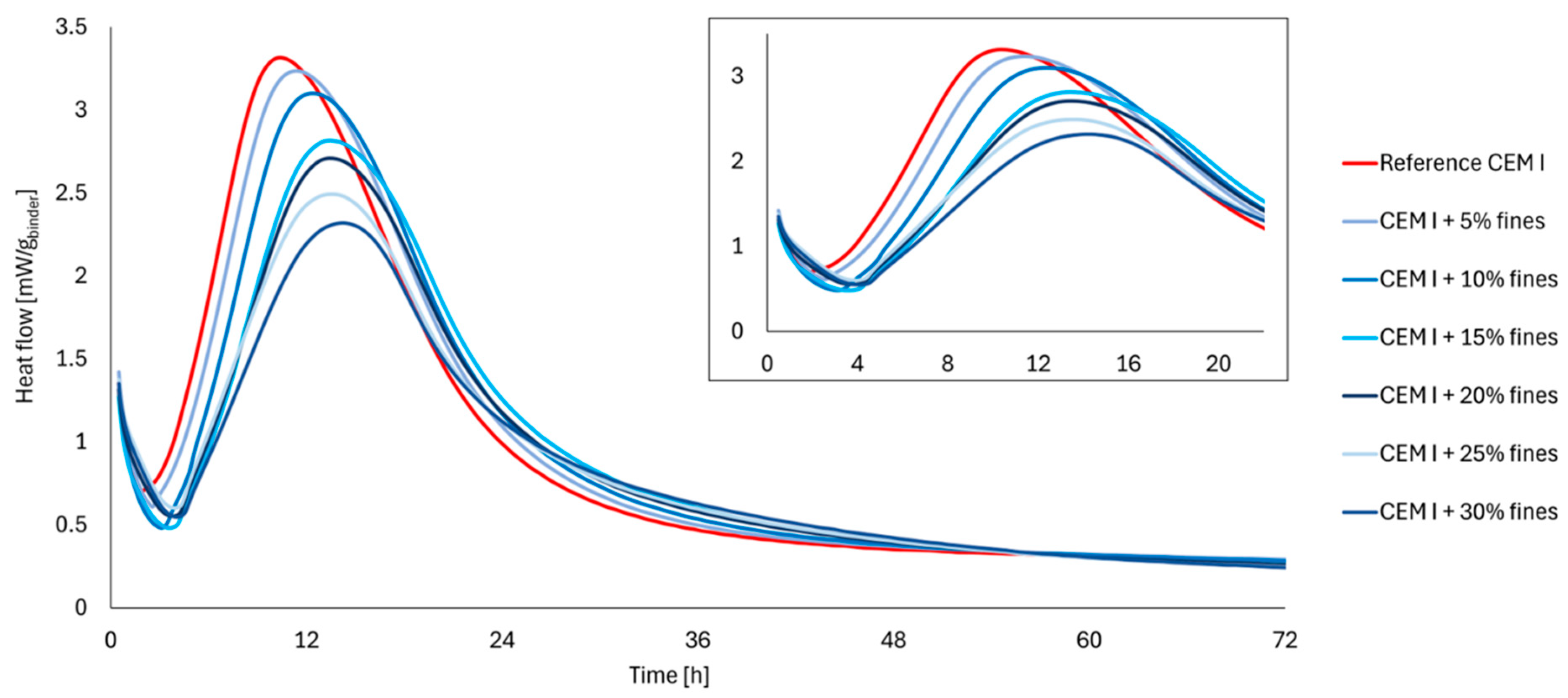

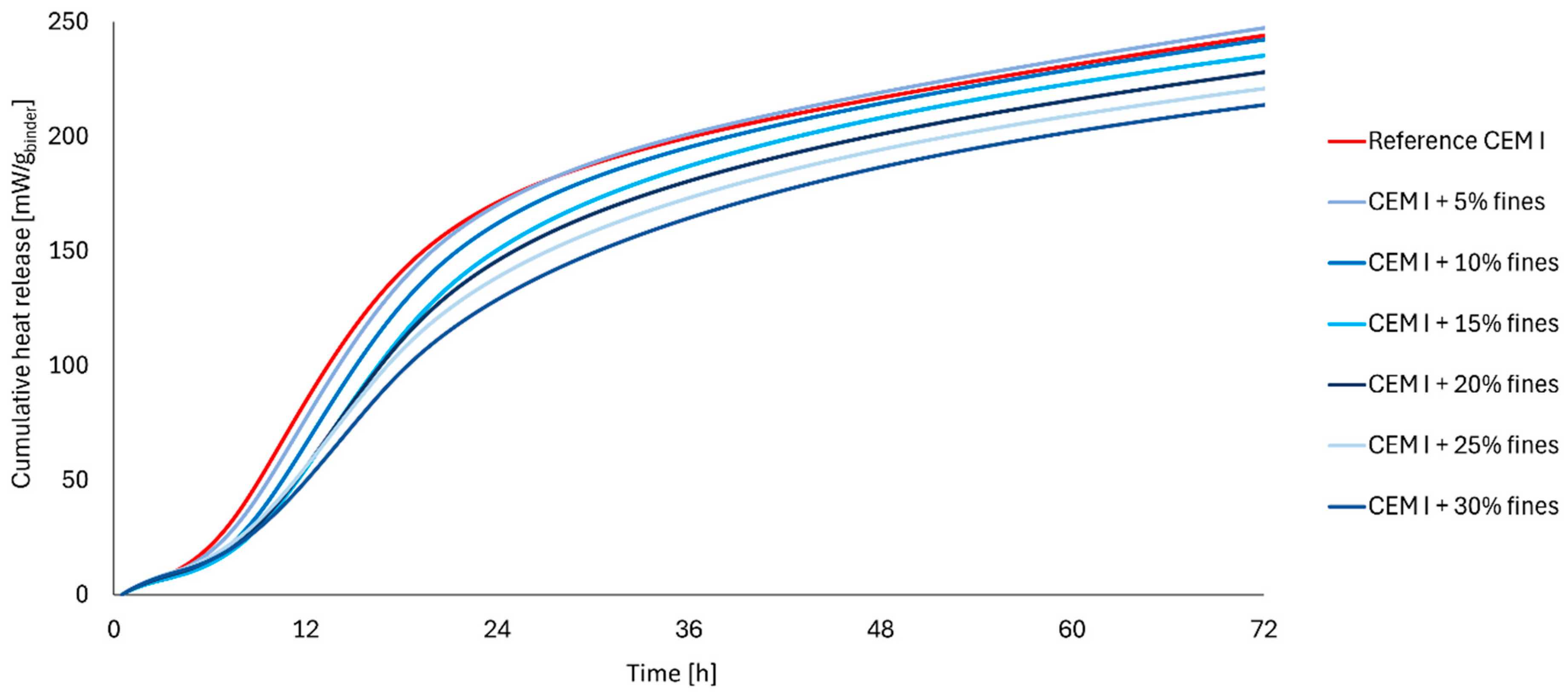

4.1.6. Isothermal Calorimetry

4.1.7. Flexural and Compressive Strength of Mortars

4.2. Tests for Strength and Durability on Concrete

4.2.1. Compressive Strength

4.2.2. Water Absorption Under Vacuum

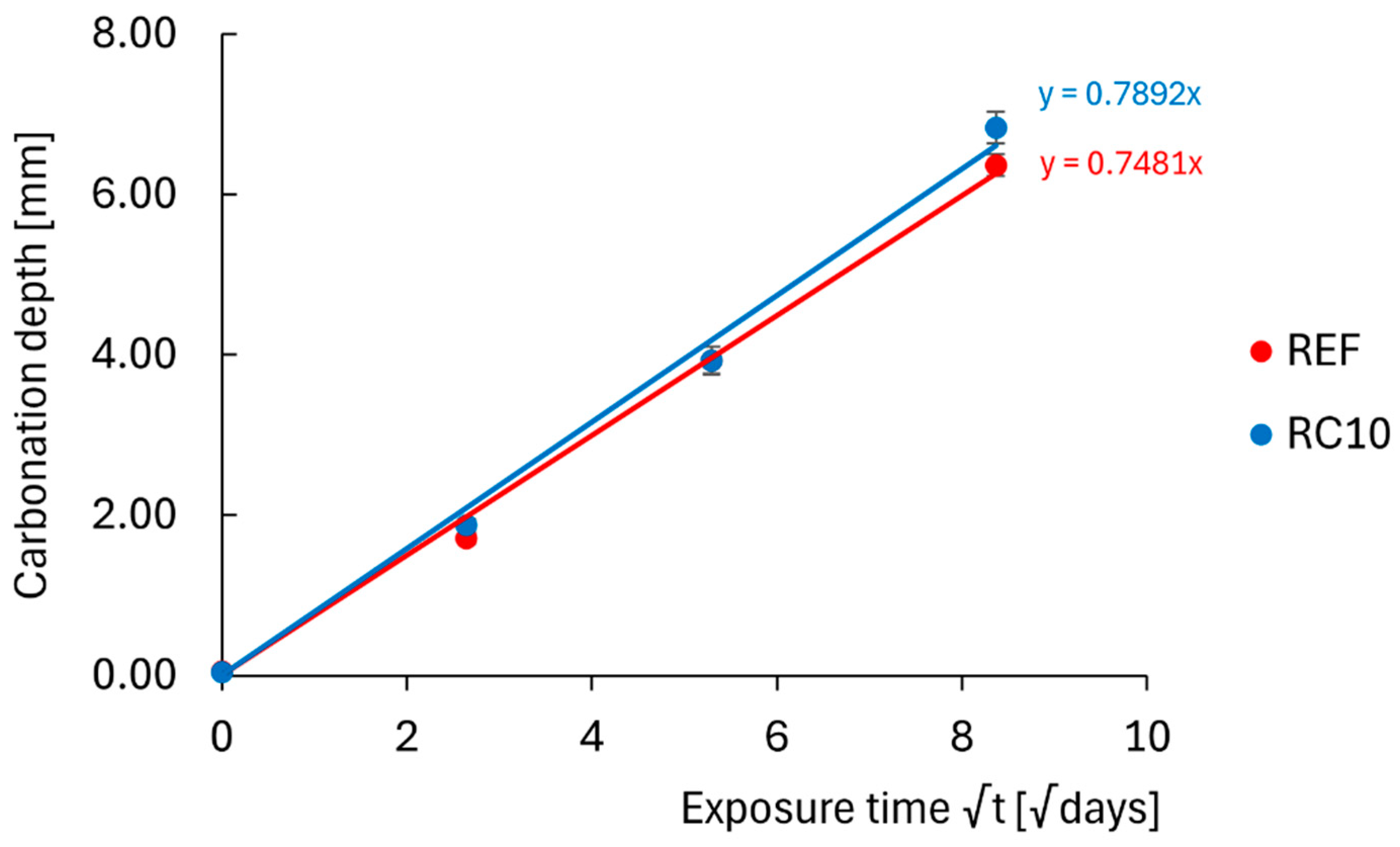

4.2.3. Carbonation

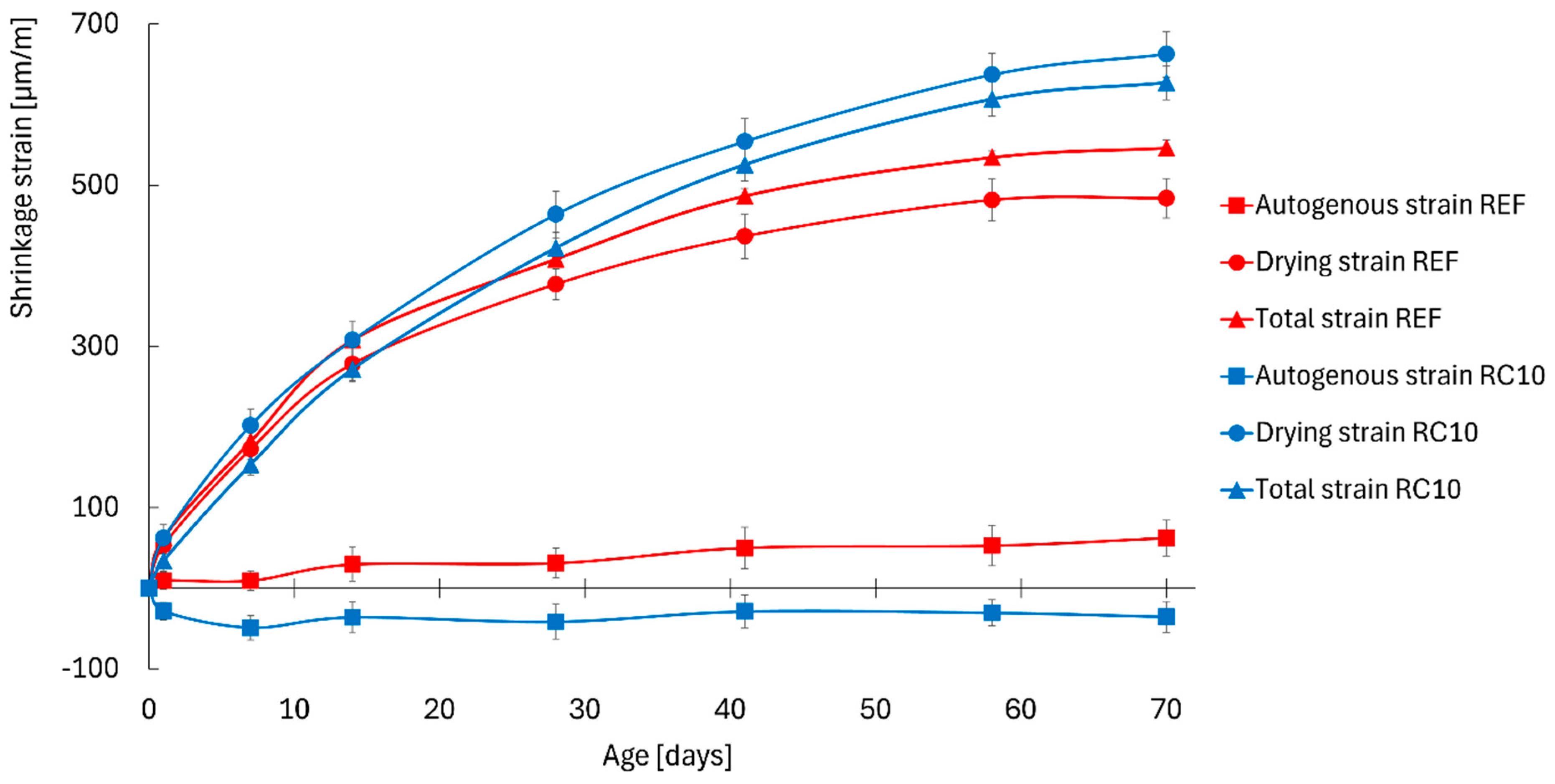

4.2.4. Shrinkage

4.2.5. Freeze–Thaw Resistance

5. Conclusions

- It is possible to conclude that the recycled fines are less homogeneous in size than cement, likely caused by a milling procedure that is not optimized.

- For replacement rates up to 10%, the total heat production during hydration after 72 h was comparable to a CEM I, and the strength reduction in mortars containing up to 10% recycled fines is restricted.

- When compared to a reference concrete that has natural aggregates and no fines, the recycled concrete with 10% fines and partly recycled aggregates had a positive impact on autogenous shrinkage. This can be explained by the recycled aggregates’ capacity to retain water, which allows them to act as a water reservoir during hydration.

- After 56 days, the compressive strength had decreased by just 4.2% for a concrete mix with (partially) recycled fine and coarse aggregates and 10% cement replacement by recycled fines.

- The inclusion of 10% recycled fines and recycled aggregates only had a limited negative impact on the carbonation resistance of concrete.

- After 56 freeze–thaw cycles, both the reference mix and the recycled concrete lacked sufficient freeze–thaw resistance. For the recycled concrete, the scaling increased by 77.8%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef] [PubMed]

- Vrijders, J.; De Bock, L. Het Gebruik van Gerecycleerde Betongranulaten in Beton; Wetenschappelijk en Technisch Centrum voor het Bouwbedrijf: Brussel, Belgium, 2019. [Google Scholar]

- NBN EN 206; Specification, Performance, Production and Conformity. Belgian Standards: Brussel, Belgium, 2014.

- Villagrán-Zaccardi, Y.A.; Marsh, A.T.M.; Sosa, M.E.; Zega, C.J.; De Belie, N.; Bernal, S.A. Complete re-utilization of waste concretes–Valorisation pathways and research needs. Resour. Conserv. Recycl. 2022, 177, 105955. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Kang, X.; Fan, Y. Study on Recycled Concrete Powders as Mineral Admixture in Recycled Concrete. IOP Conf. Ser. Earth Environ. Sci. 2019, 330, 022113. [Google Scholar] [CrossRef]

- Lidmila, M.; Tesárek, P.; Plachy, T.; Rácová, Z.; Padevět, P.; Nežerka, V.; Zobal, O. Utilization of recycled fine-ground concrete from railway sleepers for production of cement-based binder. Appl. Mech. Mater. 2014, 486, 323–326. [Google Scholar] [CrossRef]

- Šeps, K.; Broukalová, I. Properties of cement based composite with fine ground recycled concrete. Adv. Mater. Res. 2014, 1000, 110–113. [Google Scholar] [CrossRef]

- Topič, J.; Prošek, Z. Properties and microstructure of cement paste including recycled concrete powder. Acta Polytech. 2017, 57, 49–57. [Google Scholar] [CrossRef]

- Shui, Z.; Xuan, D.; Wan, H.; Cao, B. Rehydration reactivity of recycled mortar from concrete waste experienced to thermal treatment. Constr. Build. Mater. 2008, 22, 1723–1729. [Google Scholar] [CrossRef]

- Shui, Z.; Xuan, D.; Chen, W.; Yu, R.; Zhang, R. Cementitious characteristics of hydrated cement paste subjected to various dehydration temperatures. Constr. Build. Mater. 2009, 23, 531–537. [Google Scholar] [CrossRef]

- Schoon, J.; De Buysser, K.; Van Driessche, I.; De Belie, N. Fines extracted from recycled concrete as alternative raw material for Portland cement clinker production. Cem. Concr. Compos. 2015, 58, 70–80. [Google Scholar] [CrossRef]

- Costa, F.N.; Ribeiro, D.V. Reduction in CO2 emissions during production of cement, with partial replacement of traditional raw materials by civil construction waste (CCW). J. Clean. Prod. 2020, 276, 123302. [Google Scholar] [CrossRef]

- Kwon, E.; Ahn, J.; Cho, B.; Park, D. A study on development of recycled cement made from waste cementitious powder. Constr. Build. Mater. 2015, 83, 174–180. [Google Scholar] [CrossRef]

- De Brabandere, L.; Grigorjev, V.; Van den Heede, P.; Nachtergaele, H.; Degezelle, K.; De Belie, N. Use of the Fine Fraction from High-Quality Concrete Recycling as an Alternative Cement Substitute. In The 1st International Conference on Net-Zero Built Environment; Kioumarsi, M., Shafei, B., Eds.; Springer: Cham, Switzserland, 2025; pp. 183–194. [Google Scholar]

- EN 12620; Aggregates for Concrete. B. f. Standardisation: London, UK, 2008.

- NBN EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. B. f. Standardisation: London, UK, 2022.

- NBN EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. B. f. Standardisation: London, UK, 2016.

- NBN EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. B. f. Standardisation: London, UK, 2019.

- NBN B 24-213; Masonry Units Testing—Water Absorption Under Vacuum. B. f. Standardisation: London, UK, 1976.

- NBN EN 12390-12; Testing Hardened Concrete—Part 12: Determination of the Carbonation Resistance of Concrete—Accelerated Carbonation Method. B. f. Standardisation: London, UK, 2020.

- NBN EN 12390-16; Testing Hardened Concrete—Part 16: Determination of the Shrinkage of Concrete. B. f. Standardisation: England, UK, 2019.

- CEN/TS 12390-9; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance with De-Icing Salts—Scaling. Belgian Standards: Brussel, Belgium, 2016.

- Cruz-Matías, I.; Ayala, D.; Hiller, D.; Gutsch, S.; Zacharias, M.; Estradé, S.; Peiró, F. Sphericity and roundness computation for particles using the extreme vertices model. J. Comput. Sci. 2019, 30, 28–40. [Google Scholar] [CrossRef]

- Lotfi, S.; Rem, P. Recycling of end of life concrete fines into hardened cement and clean sand. J. Environ. Prot. 2016, 7, 934–950. [Google Scholar] [CrossRef]

- Florea, M.; Brouwers, H. Properties of various size fractions of crushed concrete related to process conditions and re-use. Cem. Concr. Res. 2013, 52, 11–21. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Valverde-Palacios, I.; Cuenca-Moyano, G.; Sánchez-Roldán, Z. Quality control of recycled aggregates (RAs) from construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Elsevier: Amsterdam, The Netherlands, 2013; pp. 270–303. [Google Scholar]

- Nedeljković, M.; Visser, J.; Nijland, T.G.; Valcke, S.; Schlangen, E. Physical, chemical and mineralogical characterization of Dutch fine recycled concrete aggregates: A comparative study. Constr. Build. Mater. 2021, 270, 121475. [Google Scholar] [CrossRef]

- Kulisch, D.; Katz, A.; Zhutovsky, S. Quantification of residual unhydrated cement content in cement pastes as a potential for recovery. Sustainability 2022, 15, 263. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, Á.A. Use of recycled fine aggregate in concretes with durable requirements. Waste Manag. 2011, 31, 2336–2340. [Google Scholar] [CrossRef] [PubMed]

- Revilla-Cuesta, V.; Evangelista, L.; de Brito, J.; Skaf, M.; Ortega-López, V. Mechanical performance and autogenous and drying shrinkage of MgO-based recycled aggregate high-performance concrete. Constr. Build. Mater. 2022, 314, 125726. [Google Scholar] [CrossRef]

- Ma, Z.; Li, W.; Wu, H.; Cao, C. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar]

- Gruyaert, E.; De Belie, N.p. Effect van Hoogovenslak Als Cementvervanging op de Hydratatie, Microstructuur, Sterkte en Duurzaamheid van Beton; Ghent University: Ghent, Belgium, 2011; Available online: http://lib.ugent.be/catalog/rug01:001471218 (accessed on 16 January 2024).

| Materials | Reference | RC10 |

|---|---|---|

| CEM I 52.5 N | 310 | 280 |

| Recycled fines | - | 30 |

| Limestone 4/20 | 1030 | - |

| Recycled coarse aggregate 4/20 | - | 802 |

| Sea sand 0/2 | 345 | - |

| Sand 0/4 | 515 | - |

| River sand 0/7 | - | 660 |

| Recycled sand 0/6 | - | 262 |

| Water | 179 | 224 |

| TechniFlow 92 | 1.5 | - |

| PowerFlow EVO503 | - | 7 |

| Recycled Fines | CEM I | |

|---|---|---|

| d10 [µm] | 1.6 | 2.5 |

| d50 [µm] | 24 | 16 |

| d90 [µm] | 159 | 48 |

| Compound | Quantity [%] |

|---|---|

| SiO2 | 36.30 ± 1.37 |

| CaO | 46.22 ± 1.10 |

| Al2O3 | 5.91 ± 0.11 |

| MgO | 2.17 ± 0.05 |

| Na2O | 1.35 ± 0.14 |

| P2O5 | 0.02 ± 0.01 |

| S | 2.01 ± 0.09 |

| K2O | 0.50 ± 0.06 |

| TiO2 | 2.21 ± 0.13 |

| Fe2O3 | 3.25 ± 0.07 |

| Mn2O3 | 0.06 ± 0.00 |

| 2 Days | 7 Days | 28 Days | 56 Days | 90 Days | |

|---|---|---|---|---|---|

| REF | 31.9 ± 1.4 | 45.8 ± 2.0 | 57.0 ± 0.3 | 61.5 ± 0.6 | 62.3 ± 0.7 |

| RC10 | 31.2 ± 0.8 | 44.1 ± 0.6 | 55.4 ± 1.1 | 58.9 ± 2.3 | 59.8 ± 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Brabandere, L.; Grigorjev, V.; Van den Heede, P.; Nachtergaele, H.; Degezelle, K.; De Belie, N. Using Fines from Recycled High-Quality Concrete as a Substitute for Cement. Sustainability 2025, 17, 1506. https://doi.org/10.3390/su17041506

De Brabandere L, Grigorjev V, Van den Heede P, Nachtergaele H, Degezelle K, De Belie N. Using Fines from Recycled High-Quality Concrete as a Substitute for Cement. Sustainability. 2025; 17(4):1506. https://doi.org/10.3390/su17041506

Chicago/Turabian StyleDe Brabandere, Laurena, Vadim Grigorjev, Philip Van den Heede, Hannah Nachtergaele, Krist Degezelle, and Nele De Belie. 2025. "Using Fines from Recycled High-Quality Concrete as a Substitute for Cement" Sustainability 17, no. 4: 1506. https://doi.org/10.3390/su17041506

APA StyleDe Brabandere, L., Grigorjev, V., Van den Heede, P., Nachtergaele, H., Degezelle, K., & De Belie, N. (2025). Using Fines from Recycled High-Quality Concrete as a Substitute for Cement. Sustainability, 17(4), 1506. https://doi.org/10.3390/su17041506