Eco-Efficiency of Concrete Sandwich Panels with Different Insulation Core Materials

Abstract

1. Introduction

2. Materials and Methods

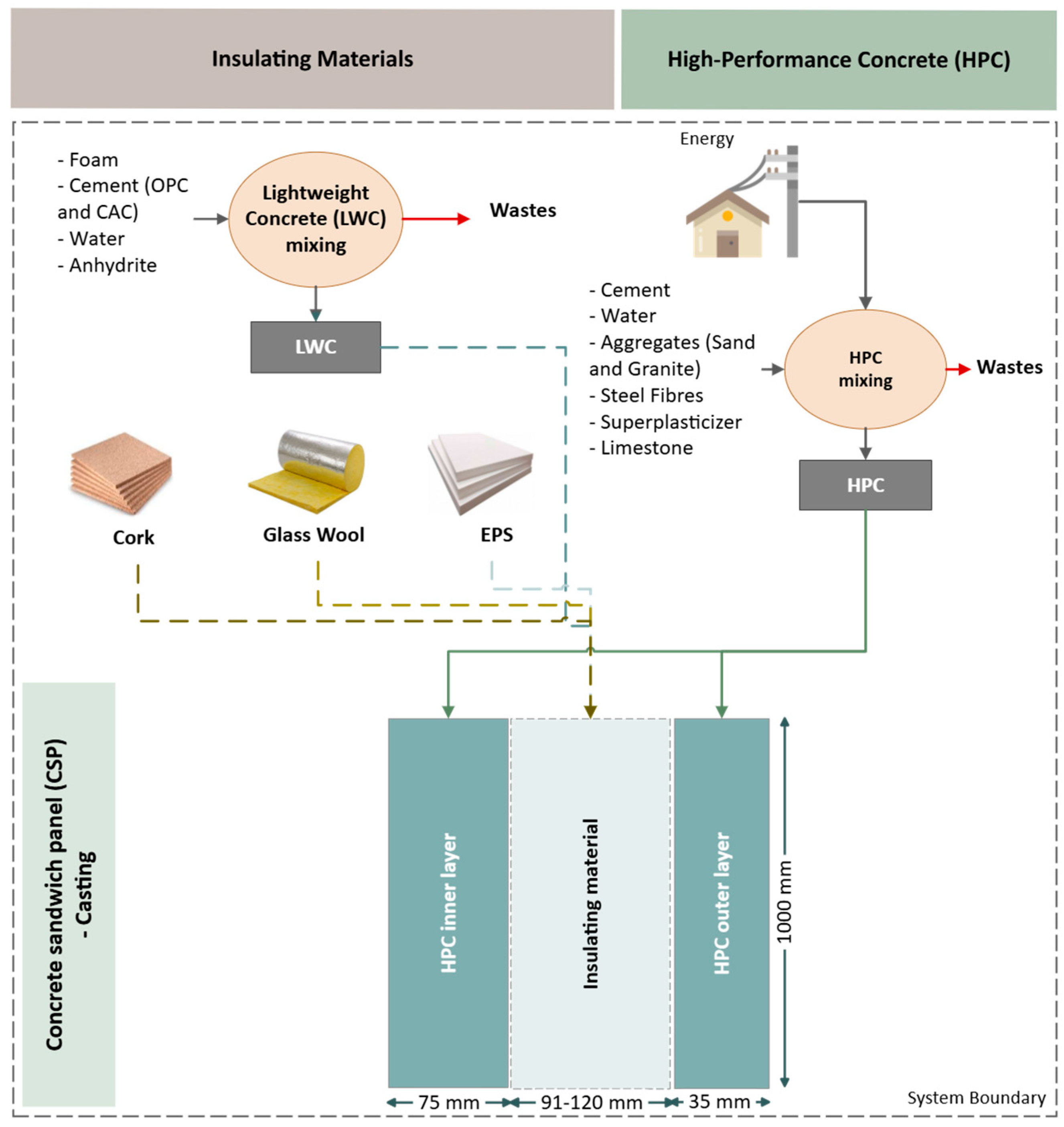

2.1. Case Study and System Boundary Definition

2.2. Life Cycle Assessment

2.2.1. Goal and Scope Definition

2.2.2. Life Cycle Inventory (LCI)

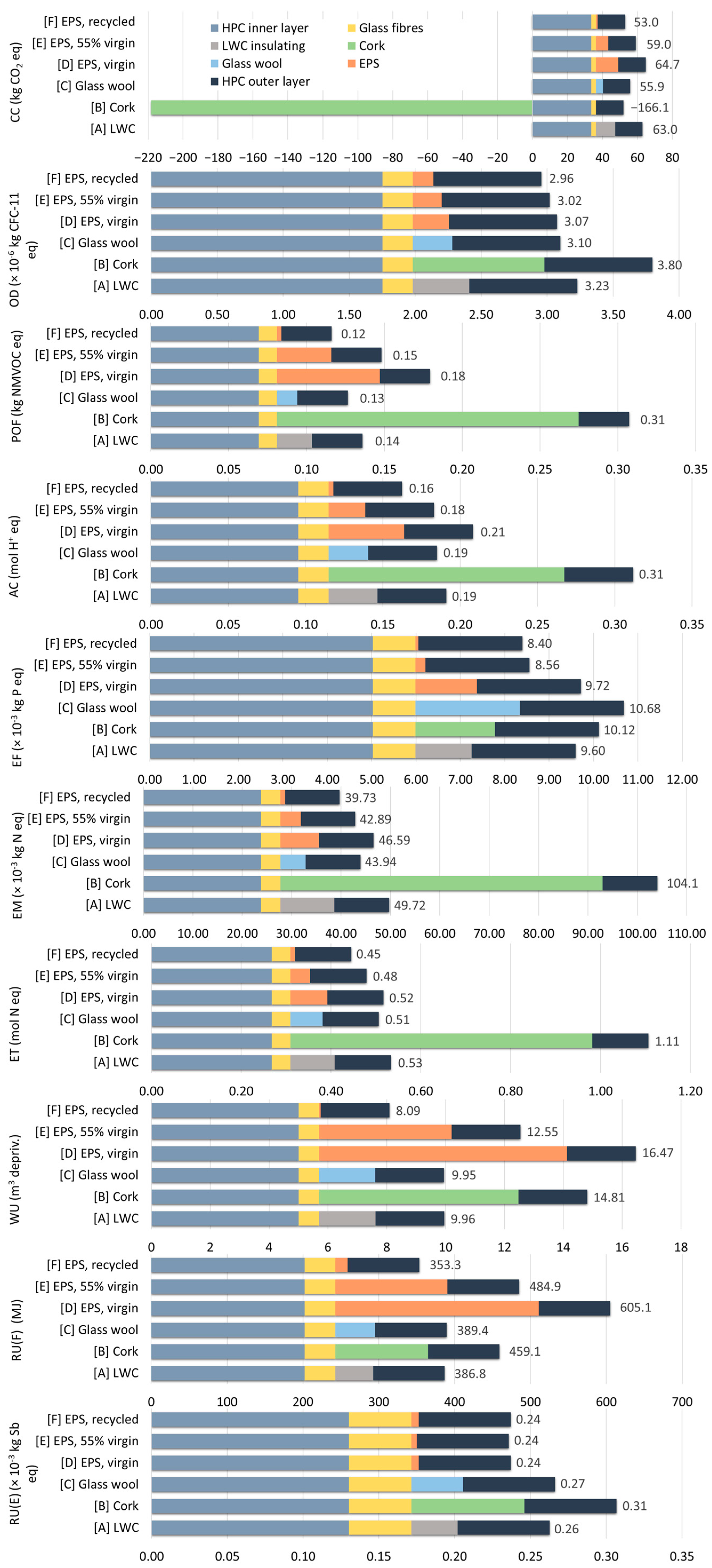

2.2.3. Life Cycle Impact Assessment (LCIA)

2.3. Life Cycle Costing

2.3.1. Flow Model and Material Balance

2.3.2. Monetary Value Attribution

2.4. Eco-Efficiency Analysis

3. Results and Discussion

3.1. LCA Results

3.2. LCC Results

3.3. Eco-Efficiency Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yılmaz, E.; Aykanat, B.; Çomak, B. Environmental life cycle assessment of rockwool filled aluminum sandwich facade panels in Turkey. J. Build. Eng. 2022, 50, 104234. [Google Scholar] [CrossRef]

- Torres-rivas, A.; Pozo, C.; Palumbo, M.; Ewertowska, A.; Jiménez, L.; Boer, D. Systematic combination of insulation biomaterials to enhance energy and environmental efficiency in buildings. Constr. Build. Mater. 2021, 267, 120973. [Google Scholar] [CrossRef]

- Sahmenko, G.; Sinka, M.; Namsone, E.; Korjakins, A.; Bajare, D. Sustainable Wall Solutions Using Foam Concrete and Hemp Composites. Environ. Clim. Technol. 2021, 25, 917–930. [Google Scholar] [CrossRef]

- Monteiro, H.; Cruz, P.L.; Oliveira, M.C.; Iten, M. Technical and economical assessment of waste heat recovery on a ceramic industry. In Wastes: Solutions, Treatments and Opportunities III; CRC Press: Boca Raton, FL, USA, 2019; pp. 524–530. [Google Scholar] [CrossRef]

- Monteiro, H.; Soares, N. Integrated life cycle assessment of a southern European house addressing different design, construction solutions, operational patterns, and heating systems. Energy Rep. 2022, 8, 526–532. [Google Scholar] [CrossRef]

- Losch, E.D.; Hynes, P.W.; Andrews Jr, R.; Browning, R.; Cardone, P.; Devalapura, R.; Donahey, R.; Freedman, S.; Gleich, H.A.; Goettsche, G.; et al. State of the Art of Precast/Prestressed Concrete Sandwich Wall Panels. PCI J. 2011, 56, 131–176. [Google Scholar]

- Resende, P.; May, M.; Hallak, T.; Hiermaier, S. Bio-based/green sandwich structures: A review. Thin-Walled Struct. 2022, 177, 109426. [Google Scholar] [CrossRef]

- Monteiro, H.; Moura, B.; Soares, N. Advancements in nano-enabled cement and concrete: Innovative properties and environmental implications. J. Build. Eng. 2022, 56, 104736. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, D.; Chen, D.; Chen, Z.; Zhou, W.; Zhu, B. A Material Flow Analysis (MFA)-based potential analysis of eco-efficiency indicators of China’s cement and cement-based materials industry. J. Clean. Prod. 2016, 112, 787–796. [Google Scholar] [CrossRef]

- de Souza, A.M.; de Lima, G.E.S.; Nalon, G.H.; Lopes, M.M.S.; Júnior, A.L.d.O.; Lopes, G.J.R.; Olivier, M.J.d.A.; Pedroti, L.G.; Ribeiro, J.C.L.; de Carvalho, J.M.F. Application of the desirability function for the development of new composite eco-efficiency indicators for concrete. J. Build. Eng. 2021, 40, 102374. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Monteiro, H.; Freire, F. Life-cycle assessment of a house with alternative exterior walls: Comparison of three impact assessment methods. Energy Build. 2012, 47, 572–583. [Google Scholar] [CrossRef]

- Monteiro, H.; Freire, F.; Soares, N. Life cycle assessment of a south European house addressing building design options for orientation, window sizing and building shape. J. Build. Eng. 2021, 39, 102276. [Google Scholar] [CrossRef]

- Demertzi, M.; Silvestre, J.D.; Durão, V. Life cycle assessment of the production of composite sandwich panels for structural floor’s rehabilitation. Eng. Struct. 2020, 221, 111060. [Google Scholar] [CrossRef]

- Demertzi, M.; Silvestre, J.; Garrido, M.; Correia, J.R.; Durão, V.; Proença, M. Life cycle assessment of alternative building floor rehabilitation systems. Structures 2020, 26, 237–246. [Google Scholar] [CrossRef]

- Santos, P.; Correia, J.R.; Godinho, L.; Dias, A.M.P.G.; Dias, A. Life cycle analysis of cross-insulated timber panels. Structures 2021, 31, 1311–1324. [Google Scholar] [CrossRef]

- Tighnavard, A.; Sher, W.; Yeoh, D.; Koushfar, K. LCA & LCC analysis of hybrid glued laminated Timber—Concrete composite floor slab system. J. Build. Eng. 2022, 49, 104005. [Google Scholar] [CrossRef]

- França, W.T.; Barros, M.V.; Salvador, R.; de Francisco, A.C.; Moreira, M.T.; Piekarski, C.M. Integrating life cycle assessment and life cycle cost: A review of environmental-economic studies. Int. J. Life Cycle Assess. 2021, 26, 244–274. [Google Scholar] [CrossRef]

- Schaltegger, S.; Synnestvedt, T. The link between “green” and economic success: Environmental management as the crucial trigger between environmental and economic performance. J. Environ. Manag. 2002, 65, 339–346. [Google Scholar] [CrossRef]

- UN.ESCAP. Eco-efficiency Indicators: Measuring Resource-use Efficiency and the Impact of Economic Activities on the Environment. Green. Econ. Growth Ser. 2009. Available online: https://hdl.handle.net/20.500.12870/1598 (accessed on 13 February 2025).

- Shanmugam, K.; Jansson, S.; Gadhamshetty, V.; Matsakas, L.; Rova, U.; Tysklind, M.; Christakopoulos, P.; Upadhyayula, V.K.K. Ecoefficiency of Thermal Insulation Sandwich Panels Based on Fly Ash Modified with Colloidal Mesoporous Silica. ACS Sustain. Chem. Eng. 2019, 7, 20000–20012. [Google Scholar] [CrossRef]

- Pérez-García, A.; Víllora, A.G.; Pérez, G.G. Building’s eco-efficiency improvements based on reinforced concretemultilayer structural panels. Energy Build. 2014, 85, 1–11. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O. Review of precast concrete sandwich panels and their innovations. Constr. Build. Mater. 2020, 233, 117145. [Google Scholar] [CrossRef]

- Fonseca, T.J.F.; Parresol, B.R. A new model for cork weight estimation in Northern Portugal with methodology for construction of confidence intervals. For. Ecol. Manag. 2001, 152, 131–139. [Google Scholar] [CrossRef]

- Lakreb, N.; Şen, U.; Toussaint, E.; Amziane, S.; Djakab, E.; Pereira, H. Physical properties and thermal conductivity of cork-based sandwich panels for building insulation. Constr. Build. Mater. 2023, 368, 130420. [Google Scholar] [CrossRef]

- Lameiras, R.; Barros, J.; Valente, I.B.; Azenha, M. Development of sandwich panels combining fibre reinforced concrete layers and fibre reinforced polymer connectors. Part I: Conception and pull-out tests. Compos. Struct. 2013, 105, 446–459. [Google Scholar] [CrossRef]

- Lameiras, R.; Barros, J.; Azenha, M.; Valente, I.B. Development of sandwich panels combining fibre reinforced concrete layers and fibre reinforced polymer connectors. Part II: Evaluation of mechanical behaviour. Compos. Struct. 2013, 105, 460–470. [Google Scholar] [CrossRef]

- Fenollera, M.; Míguez, J.L.; Goicoechea, I.; Lorenzo, J. Experimental Study on Thermal Conductivity of Self-Compacting Concrete with Recycled Aggregate. Materials 2015, 8, 4457–4478. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006/Amd 1:2020; Environmental management–Life cycle assessment–Principles and framework–Amendment 1. ISO: Geneva, Switzerland, 2020.

- ISO 14044:2006/Amd 2:2020; Environmental management–Life cycle assessment–Requirements and guidelines–Amendment 2. ISO: Geneva, Switzerland, 2020.

- Thomas, A.; Anya, V.; Johannes, H.; Linda, H.; Sigrid, B.-C. Ultra-lightweight foamed concrete for an automated facade application. Mag. Concr. Res. 2018, 71, 424–436. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 9, 1218–1230. [Google Scholar] [CrossRef]

- PRé Sustainability, B.V. Simapro Database Manual—Methods Library. 2020. Available online: https://simapro.com/wp-content/uploads/2022/07/DatabaseManualMethods.pdf (accessed on 13 February 2025).

- EPD EN 15804+A2/ISO 14025/ISO 21930; Expanded Insulation Corkboard (ICB). Amorim Cork Insulation: Mozelos, Portugal, 2023.

- EPD-IES-0003101:002; Recycled Aggregate Products. Argent Materials Inc.: Oakland, CA, USA, 2021.

- EN 15804:2012+A2:2019; Sustainability of construction works—Environmental product declarations—Core rules for the product category of construction products. CEN: Brussels, Belgium, 2019.

- European Comission. European Platform on LCA|EPLCA—EN15804. Available online: https://eplca.jrc.ec.europa.eu/LCDN/EN15804.html (accessed on 13 December 2024).

- Kloepffer, W. Life cycle Sustainability Assessment of Products (with Comments by Helias A. Udo de Haes, p. 95). Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Swarr, T.E.; Hunkeler, D.; Klöpffer, W.; Pesonen, H.-L.; Ciroth, A.; Brent, A.C.; Pagan, R. Environmental life-cycle costing: A code of practice. Int. J. Life Cycle Assess. 2011, 16, 389–391. [Google Scholar] [CrossRef]

- ISO 14051:2011; Environmental management—Material flow cost accounting—General framework. ISO: Geneva, Switzerland, 2011.

- Bierer, A.; Götze, U.; Meynerts, L.; Sygulla, R. Integrating life cycle costing and life cycle assessment using extended material flow cost accounting. J. Clean. Prod. 2015, 108, 1289–1301. [Google Scholar] [CrossRef]

- ISO 14051; Manual on Material Flow Cost Accounting. Asian Productivity Organization: Tokyo, Japan, 2014.

- EDP Comercial. Tarifários de Eletricidade e Gás Natural para Particulares. Available online: https://www.edp.pt/particulares/energia/tarifarios/ (accessed on 12 August 2022).

- Agere. TARIFÁRIO 2023. Available online: https://agere.pt/wp-content/uploads/2023/01/TARIFARIO-AGERE-2023.pdf (accessed on 13 February 2025).

- Haufler Composites GmbH & Co. KG, Haufler Composites—Online Store. Available online: https://www.compositeshop.de/xoshop/ (accessed on 12 August 2022).

- Obras360 by Sotecnisol. Obras360 by Sotecnisol|Loja de Materiais de Construção e Energia. Available online: https://www.obras360.pt/ (accessed on 12 August 2022).

- Coelho, A.; De Brito, J. Economic viability analysis of a construction and demolition waste recycling plant in Portugal—Part I: Location, materials, technology and economic analysis. J. Clean. Prod. 2013, 39, 338–352. [Google Scholar] [CrossRef]

- Master Ferro. Master Ferro–Comércio de Produtos Siderúrgicos. Available online: https://www.masterferro.pt/pt (accessed on 12 August 2022).

- Aercrete Technology AB. Aercrete FG-6TM—Aercrete. Available online: https://www.aercrete.se/en/aercrete-fg-6-2/ (accessed on 12 September 2022).

- Chave Vertical—Máquinas & Ferramentas Profissionais. Betoneira Hidráulica Brh1200 Eléctrica C/PÁ SIRL’. Available online: https://chavevertical.com/produto/betoneira-hidraulica-brh1200-electrica-c-pa-sirl/ (accessed on 12 August 2022).

- Davidnunuo. CHAPA PILAR 2500X500. Available online: https://www.davidnuno.com/(S(bshhtbtq5axggx4bf2ml0113))/artigo.aspx?code=19030305 (accessed on 12 August 2022).

- Portugal, S. 2022–TABELA DE PREÇOS–CONSTRUÇÃO. Available online: https://www.almacla.pt/wp-content/uploads/2021/10/tabela-precos-sika.pdf (accessed on 12 August 2022).

- Backstein Engineering GmbH. Moertelshop Online store. Available online: https://www.moertelshop.eu/ (accessed on 12 August 2022).

- Armazéns Reis. Armazéns Reis—Online Store. Available online: https://www.armazensreis.pt/pt/ (accessed on 12 August 2022).

- Maria Granel. Maria Granel—Online store. Available online: https://www.mariagranel.com/ (accessed on 12 August 2022).

- CYPE Ingenieros, S.A. Gerador de preços para construção civil—Portugal. Available online: http://www.geradordeprecos.info (accessed on 12 August 2022).

- Gabinete de Estratégia e Planeamento do Ministério do Trabalho Solidariedade e Segurança Social Estatísticas de Salários por Profissão na Construção—Janeiro 2021. 2021. Available online: www.gep.mtsss.gov.pt (accessed on 16 June 2022).

- ISO 14045; Environmental management—Eco-efficiency assessment of product systems—Principles, requirements and guidelines. ISO: Geneva, Switzerland, 2012.

- Burul, D.; Algesten, D. Battery Electric Vs Diesel Driven, SCINIA: Södertälje, Sweden, 2021.

- Demertzi, M.; Sierra-Pérez, J.; Paulo, J.A.; Arroja, L.; Dias, A.C. Environmental performance of expanded cork slab and granules through life cycle assessment. J. Clean. Prod. 2017, 145, 294–302. [Google Scholar] [CrossRef]

- Demertzi, M.; Paulo, J.A.; Arroja, L.; Dias, A.C. A carbon footprint simulation model for the cork oak sector. Sci. Total Environ. 2016, 566–567, 499–511. [Google Scholar] [CrossRef] [PubMed]

- Silvestre, J.D.; Pargana, N.; De Brito, J.; Pinheiro, M.D.; Durão, V. Insulation Cork Boards—Environmental Life Cycle Assessment of an Organic Construction Material. Materials 2016, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Rodrigo-Bravo, A.; Calderón, V.; Cuenca-Romero, L.A.; Arroyo, R.; Gutiérrez-González, S. Eco-efficiency and economic assessment of gypsum-based precast with polymeric waste: A case study. Case Stud. Constr. Mater. 2024, 20, e03052. [Google Scholar] [CrossRef]

- Lévesque, J.; Perreault, V.; Mikhaylin, S. Eco-efficiency as a prioritization tool in the reduction of food waste in restaurants. Sci. Total Environ. 2024, 927, 171515. [Google Scholar] [CrossRef] [PubMed]

| Scenario | Insulation Core Material/External Layers | Density [kg/m3] | Thermal Conductivity [W/m·K] | Thickness [mm] |

|---|---|---|---|---|

| A | LWC | 137 | 0.045 | 120 |

| B | Cork | 115 | 0.040 | 107 |

| C | Glass Wool | 40 | 0.034 | 91 |

| D | EPS, virgin | 30 | 0.035 | 93 |

| E | EPS, 55% virgin | 30 | 0.035 | 93 |

| F | EPS, recycled | 30 | 0.035 | 93 |

| All | HPC | 2357 | 0.707 | 35–75 |

| Layer | Scenario | Element | Amount [kg/m2] |

|---|---|---|---|

| Inner | A to F | HPC | 180.0 |

| Insulation | A | LWC | 30.0 |

| B | Cork | 12.3 | |

| C | Glass wool | 1.4 | |

| D | EPS, virgin | 2.8 | |

| E | EPS, 55% virgin | 2.8 | |

| F | EPS, recycled | 2.8 | |

| Outer | A to F | HPC | 84.0 |

| A to F | Glass fibres | 1.2 |

| Impact Category | Abbreviation | Unit |

|---|---|---|

| Climate change | CC | kg CO2-eq |

| Ozone depletion | OD | kg CFC-11-eq |

| Photochemical ozone formation | POF | kg NMVOC-eq |

| Acidification | AC | mol H+ -eq |

| Eutrophication, freshwater | EF | kg P-eq |

| Eutrophication, marine | EM | kg N-eq |

| Eutrophication, terrestrial | ET | mol N-eq |

| Water use | WU | m3 depriv. |

| Resource use, fossils | RU(F) | MJ |

| Resource use, minerals, and metals | RU(E) | kg Sb-eq |

| Category | Description | Example |

|---|---|---|

| Material Costs | Cost of the materials used in production. | Water, cement, aggregates, etc. |

| Energy Costs | Costs with all energy inputs. | Electricity, fuel, etc. |

| System Costs | Expenses associated with the production processes that do not fit into the other categories. | Labour and equipment costs. |

| Waste Management Costs | Costs of handling and disposing of the process wastes. | Labour for waste handling, recycling, and cleaning. |

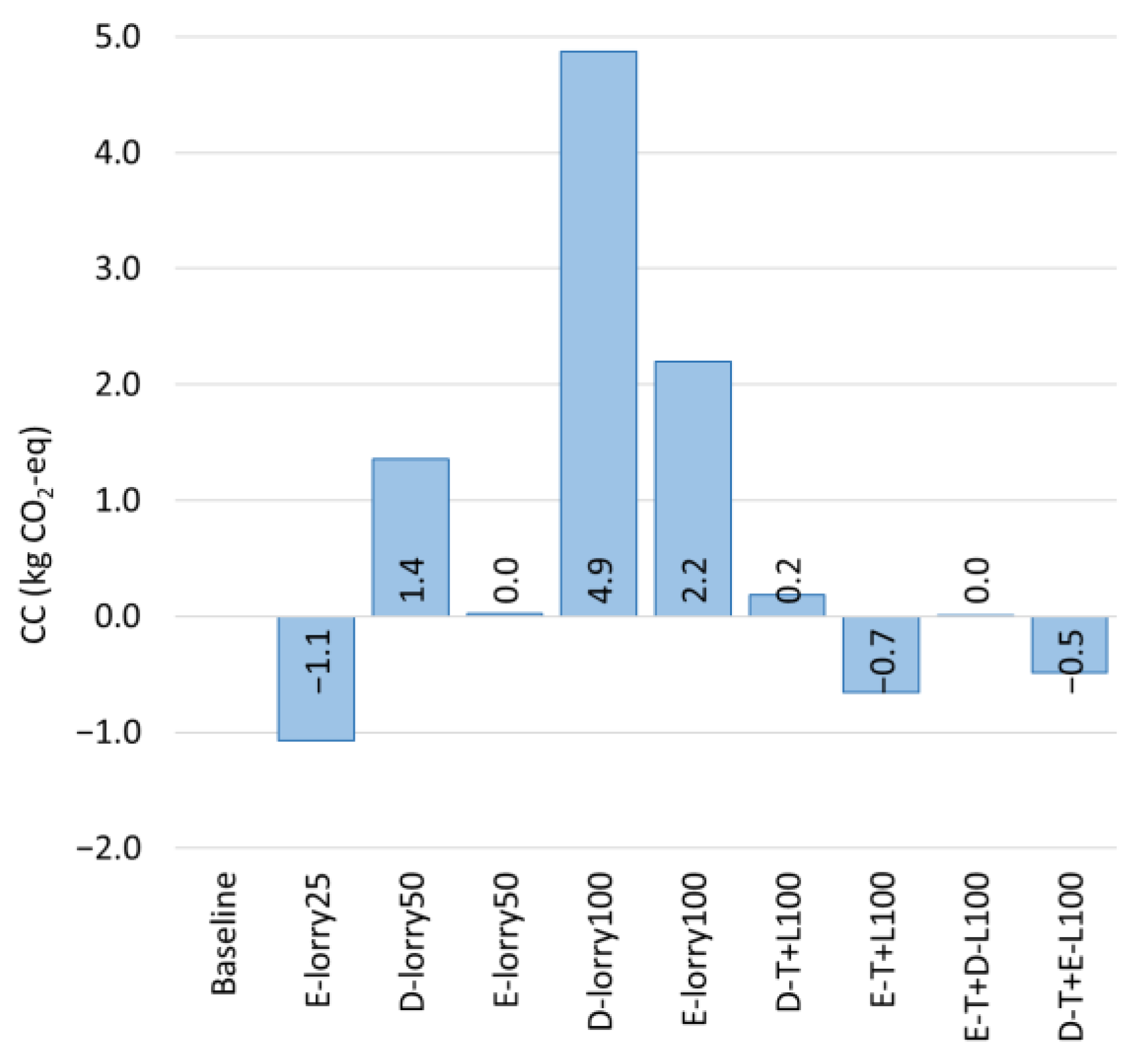

| Transport Distance [km] | Scenario | Mean of Transport Used |

|---|---|---|

| 25 | Baseline | Lorry powered by diesel |

| E-lorry25 | Electrical lorry | |

| 50 | D-lorry50 | Lorry powered by diesel |

| E-lorry50 | Electrical lorry | |

| 100 (or 75 km by train and 25 km by lorry) | D-lorry100 | Lorry powered by diesel |

| E-lorry100 | Electrical lorry | |

| E-T + L100 | Electrical train and lorry | |

| D-T + L100 | Train and lorry powered by diesel | |

| E-T + D-L100 | Electrical train and lorry powered by diesel | |

| D-T + E-L100 | Train powered by diesel and electrical lorry |

| Scenario | Insulation Material | EV [€/m2] | CC [kg CO2-eq] | POF [kg NMVOC-eq] | RU(F) [MJ] | EI—CC | EI—POF | EI—RU(F) |

|---|---|---|---|---|---|---|---|---|

| A | LWC | 59.80 | 62.97 | 0.14 | 386.82 | 0.95 | 439.97 | 0.15 |

| B | Cork | 31.16 | −166.14 | 0.31 | 459.14 | −0.19 | 101.43 | 0.07 |

| C | Glass wool | 59.60 | 55.92 | 0.13 | 389.38 | 1.07 | 470.88 | 0.15 |

| D | EPS, virgin | 54.42 | 64.74 | 0.18 | 605.12 | 0.84 | 303.32 | 0.09 |

| E | EPS, 55% virgin | 58.98 | 59.03 | 0.15 | 484.87 | 1.00 | 397.88 | 0.12 |

| F | EPS, recycled | 64.54 | 52.99 | 0.12 | 353.33 | 1.22 | 555.21 | 0.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moura, B.; Ramos da Silva, T.; Soares, N.; Monteiro, H. Eco-Efficiency of Concrete Sandwich Panels with Different Insulation Core Materials. Sustainability 2025, 17, 1687. https://doi.org/10.3390/su17041687

Moura B, Ramos da Silva T, Soares N, Monteiro H. Eco-Efficiency of Concrete Sandwich Panels with Different Insulation Core Materials. Sustainability. 2025; 17(4):1687. https://doi.org/10.3390/su17041687

Chicago/Turabian StyleMoura, Bruna, Tiago Ramos da Silva, Nelson Soares, and Helena Monteiro. 2025. "Eco-Efficiency of Concrete Sandwich Panels with Different Insulation Core Materials" Sustainability 17, no. 4: 1687. https://doi.org/10.3390/su17041687

APA StyleMoura, B., Ramos da Silva, T., Soares, N., & Monteiro, H. (2025). Eco-Efficiency of Concrete Sandwich Panels with Different Insulation Core Materials. Sustainability, 17(4), 1687. https://doi.org/10.3390/su17041687