Conditioning Biomass for Biogas Plants: Innovative Pre-Treatment and Digestate Valorization Techniques to Enhance Soil Health and Fertility

Abstract

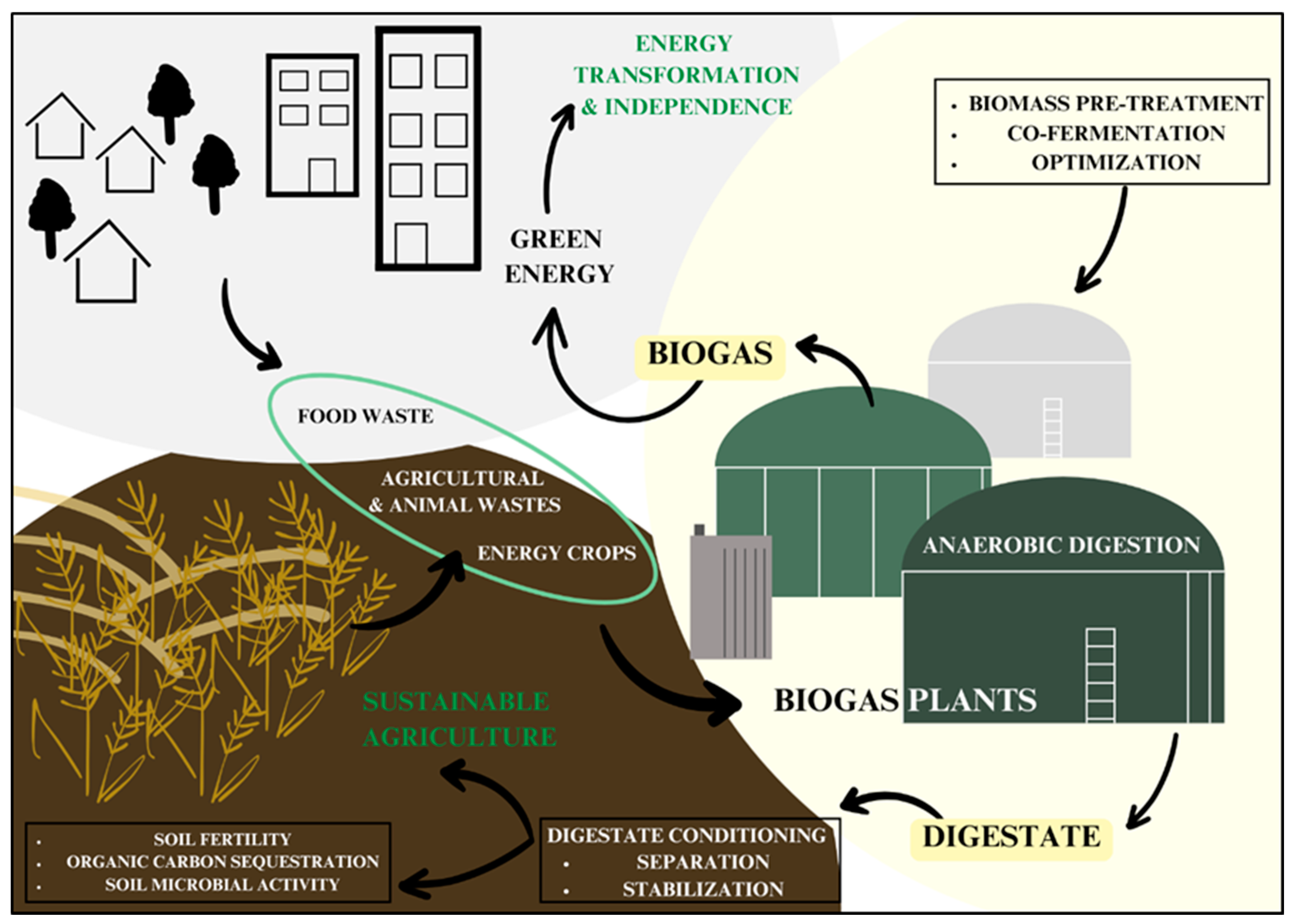

:1. Introduction

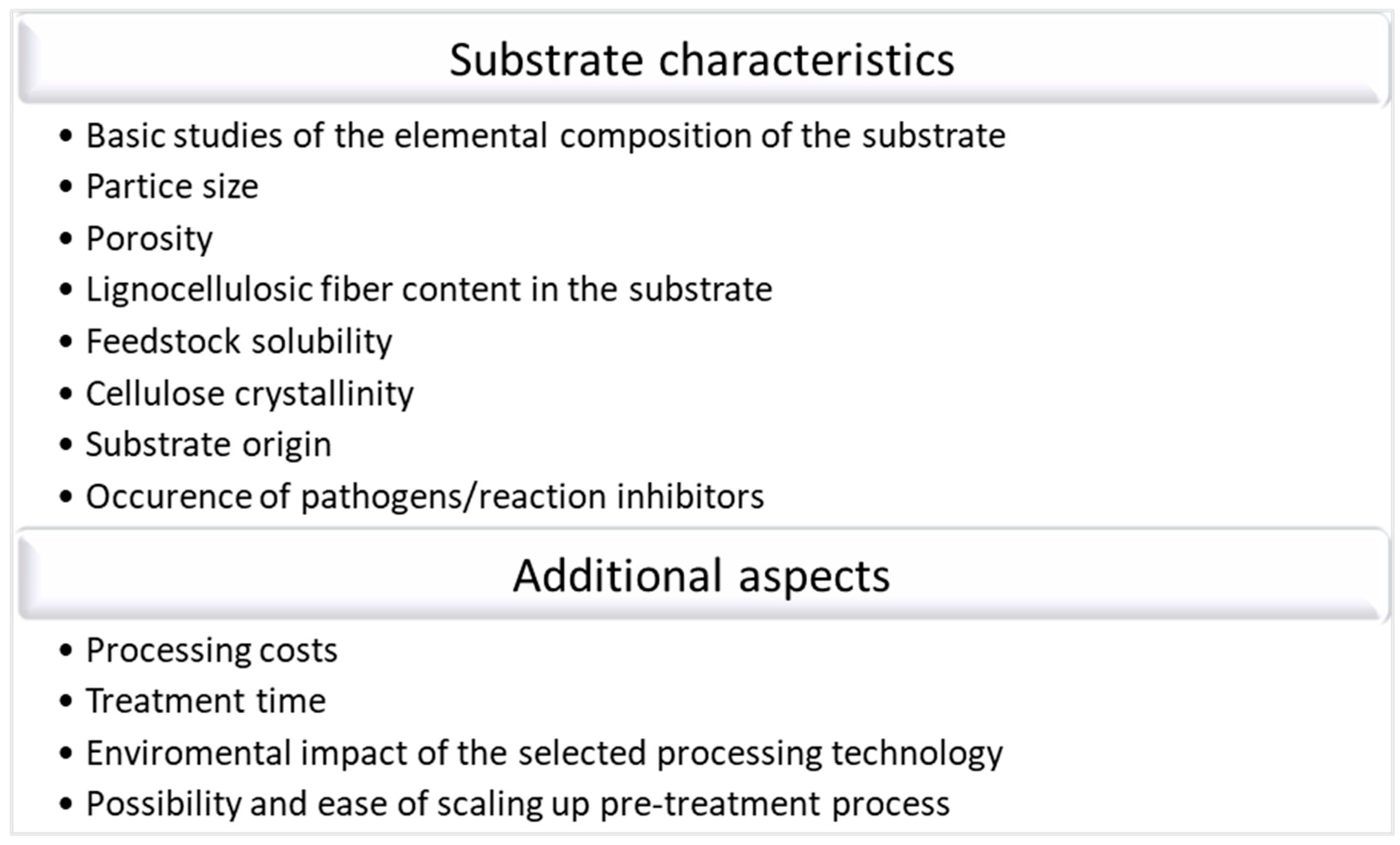

2. Methods of Conditioning Plant Biomass

2.1. Mechanical Pre-Treatment

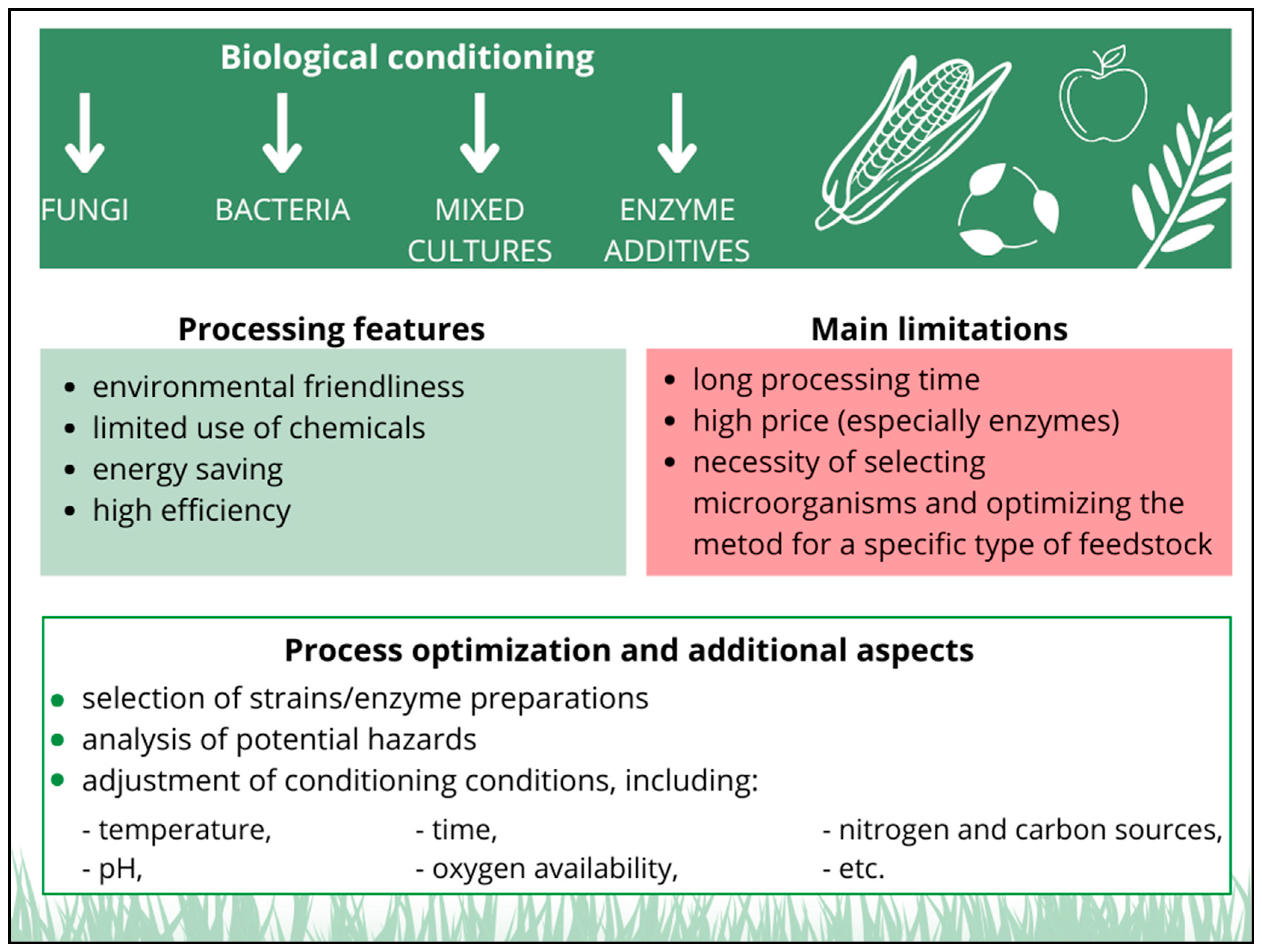

2.2. Biological Modification of Biomass

- Improvement of the activity of methane digestion microorganisms;

- Increase in biogas yields;

- Acceleration of hydrolysis, the bottleneck of the substrate processing during anaerobic digestion;

2.3. Thermal, Chemical, and Hybrid Methods

2.4. Optimization of Anaerobic Digestion

2.5. Increasing the Efficiency of Biogas Production Through Co-Digestion and Conditioning Methods

2.6. Reducing the Retention Time of Substrates in the Reactor

- (1)

- Hydraulic retention time

- (2)

- Solid retention time

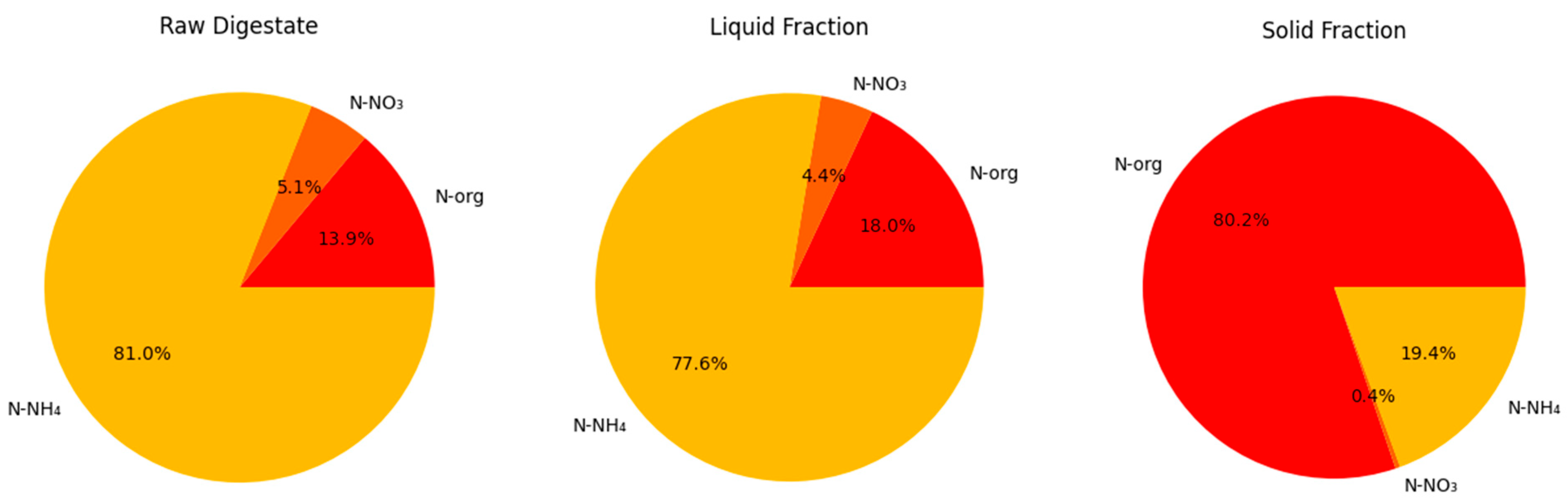

3. Digestate Conditioning

3.1. Solid–Liquid Separation Techniques

3.1.1. Filtration

3.1.2. Centrifugation

3.1.3. Sedimentation

3.1.4. Ultrasounds

3.1.5. Osmosis and Nanofiltration

3.2. Addition of Biochar and Mineral Additives for Nutrient Enrichment

3.3. Stabilization of Digestate to Reduce Odor and Greenhouse Gases (GHGs) Emissions

4. The Impact of Digestate on Soils

4.1. Regeneration of Degraded Soils

4.2. Increase in Humus Content and Improvement of Soil Structure

4.3. Sustainable Supply of Micro and Trace Elements

4.4. Importance for Circular Agriculture, Closing the Nutrient Cycle—Digestate as an Ecological Alternative to Mineral Fertilizers

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HTPT | High-temperature pre-treatment |

| ORL | Organic loading rate |

| HRT | Hydraulic retention time |

| SRT | Solid retention time |

| AnMBR | Anaerobic membrane reactors |

| PVDF | Polyvinylidene |

| GADR | Gradient anaerobic digestion reactor |

| MAP | Magnesium ammonium phosphate |

| SDGs | Sustainable Development Goals |

| SOM | Soil organic matter |

| SOC | Soil organic carbon |

| OM | Organic matter |

| MAOM | Mineral-associated organic matter |

| EOM | Exogenous organic matter |

| POM | Particulate organic matter |

| LD | Liquid digestate |

| SD | Solid digestate |

References

- Brémond, U.; Bertrandias, A.; de Buyer, R.; Latrille, E.; Jimenez, J.; Escudié, R.; Stryer, J.-P.; Bernet, N.; Carrere, H. Recirculation of solid digestate to enhance energy efficiency of biogas plants: Strategies, conditions and impacts. Energy Convers. Manag. 2021, 231, 113759. [Google Scholar]

- Kim, D.; Kim, J. Predicting biogas production from organic waste through anaerobic co-digestion. J. Clean. Prod. 2025, 496, 145122. [Google Scholar]

- Ngabala, F.J.; Emmanuel, J.K. ; Potential substrates for biogas production through anaerobic digestion-an alternative energy source. Helion 2024, 10, e40632. [Google Scholar] [CrossRef]

- Urbanowska, A.; Kotas, P.; Kabsch-Korbutowicz, M. Charakterystyka i metody zagospodarowania masy pofermentacyjnej powstającej w biogazowniach. Ochr. Sr. 2019, 41, 39–45. [Google Scholar]

- Chojnacka, K.; Moustakas, K. Anaerobic digestate management for carbon neutrality and fertilizer use: A review of current practices and future opportunities. Biomass Bioenergy 2024, 180, 106991. [Google Scholar]

- Kowalczyk-Juśko, A.; Szymańska, M.A. Poferment Nawozem dla Rolnictwa; Fundacja na rzecz Rozwoju Polskiego Rolnictwa: Warszawa, Poland, 2015; pp. 1–64. [Google Scholar]

- Koszel, M.; Lorencowicz, E. Agricultural use of biogas digestate as a replacement fertilizers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar]

- Bolzonella, D.; Fatone, F.; Gottardo, M.; Frison, N. Nutrients recovery from anaerobic digestate of agro-waste: Techno-economic assessment of full-scale applications. J. Environ. Manag. 2018, 216, 111–119. [Google Scholar]

- Carraro, G.; Tonderski, K.; Enrich-Prast, A. Solid-liquid separation of digestate from biogas plants: A systematic review of the techniques’ performance. J. Environ. Manag. 2024, 356, 120585. [Google Scholar]

- Brémond, U.; Bertrandias, A.; Steyer, J.P.; Bernet, N.; Carrere, H. A vision of European biogas sector development towards 2030: Trends and challenges. J. Clean. Prod. 2021, 287, 125065. [Google Scholar]

- Skrzypczak, D.; Trzaska, K.; Mikula, K.; Gil, F.; Izydorczyk, G.; Mironiuk, M.; Polomska, X.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Conversion of anaerobic digestates from biogas plants: Laboratory fertilizer formulation, scale-up and demonstration of applicative properties on plants. Renew. Energy 2023, 203, 506–517. [Google Scholar]

- Jurgutis, L.; Šlepetienė, A.; Amalevičiūtė-Volungė, K.; Volungevičius, J.; Šlepetys, J. The effect of digestate fertilisation on grass biogas yield and soil properties in field-biomass-biogas-field renewable energy production approach in Lithuania. Biomass Bioenergy 2021, 153, 106211. [Google Scholar]

- Rao, M.; Zou, X.; Huang, Z.; Ye, J.; Huang, C.; Zhang, M.; Chen, C.; Kuang, C.; Song, Y.; Xin, K.; et al. Purification of anaerobic fermentation digestate of dairy manure by Arthrospira biomass cultivated with biogas-CO2 fixation. Biochem. Eng. J. 2024, 203, 109178. [Google Scholar]

- Prasad, R.K.; Sharma, A.; Mazumder, P.B.; Dhussa, A. A comprehensive pre-treatment strategy evaluation of ligno-hemicellulosic biomass to enhance biogas potential in the anaerobic digestion process. Sustainability 2024, 2, 2444–2467. [Google Scholar] [CrossRef]

- Carrere, H.; Antonopoulou, G.; Affes, R.; Passos, F.; Battimelli, A.; Lyberatos, G.; Ferrer, I. Review of feedstock pretreatment strategies for improved anaerobic digestion: From lab-scale research to full-scale application. Bioresour. Technol. 2016, 199, 386–397. [Google Scholar]

- Samadamaeng, N.; Sawatdeenarunat, C.; Charnnok, B. Enhancing biogas production from cattle manure: A circular economy approach with solar thermal pretreatment and soil conditioning. J. Environ. Manag. 2024, 368, 122086. [Google Scholar]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies. Environ. Int. 2020, 137, 105522. [Google Scholar]

- Bharadwaj, A.S.; Dev, S.; Zhuang, J.; Wang, Y.; Yoo, C.G.; Jeon, B.H.; Aggarwal, S.; Park, S.H.; Kim, T.H. Review of chemical pretreatment of lignocellulosic biomass using low-liquid and low-chemical catalysts for effective bioconversion. Bioresour. Technol. 2023, 368, 128339. [Google Scholar]

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in biogas production: Pretreatment and codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509. [Google Scholar]

- Kovács, E.; Szűcs, C.; Farkas, A.; Szuhaj, M.; Maróti, G.; Bagi, Z.; Rákhely, G.; Kovács, K.L. Pretreatment of lignocellulosic biogas substrates by filamentous fungi. J. Biotechnol. 2022, 360, 160–170. [Google Scholar]

- Eswari, A.P.; Kavitha, S.; Kannah, R.Y.; Kumar, G.; Bhatia, S.K.; Park, J.H.; Banu, J.R. Dispersion assisted pretreatment for enhanced anaerobic biodegradability and biogas recovery-strategies and applications. Bioresour. Technol. 2022, 361, 127634. [Google Scholar]

- Olatunji, K.O.; Ahmed, N.A.; Ogunkunle, O. Optimization of biogas yield from lignocellulosic materials with different pretreatment methods: A review. Biotechnol. Biofuels 2021, 14, 159. [Google Scholar] [CrossRef] [PubMed]

- Arce, C.; Kratky, L. Mechanical pretreatment of lignocellulosic biomass toward enzymatic/fermentative valorization. IScience 2022, 25, 104610. [Google Scholar] [CrossRef] [PubMed]

- Al Afif, R.; Pfeifer, C. Enhancement of methane yield from cotton stalks by mechanical pre-treatment. Carbon Resour. Convers. 2021, 4, 164–168. [Google Scholar] [CrossRef]

- Heller, R.; Brandhorst, C.; Hülsemann, B.; Lemmer, A.; Oechsner, H. Comparison of different mechanical pretreatment methods for the anaerobic digestion of landscape management grass. Energies 2023, 16, 8091. [Google Scholar] [CrossRef]

- Moretti, P.; de Oliveira, M.M.; Bayard, R.; Buffiere, P.; de Araujo, J.M.; de Castilhos, A.B.; Gourdon, R. Mechanical pretreatment of municipal biowaste to produce an aqueous slurry dedicated to anaerobic digestion. Environ. Sci. Pollut. Res. 2021, 28, 20586–20597. [Google Scholar] [CrossRef]

- Di Mario, J.; Montegiove, N.; Gambelli, A.M.; Brienza, M.; Zadra, C.; Gigliotti, G. Waste Biomass Pretreatments for Biogas Yield Optimization and for the Extraction of Valuable High-Added-Value Products: Possible Combinations of the Two Processes toward a Biorefinery Purpose. Biomass 2024, 4, 865–885. [Google Scholar] [CrossRef]

- Donkor, K.O.; Gottumukkala, L.D.; Lin, R.; Murphy, J.D. A perspective on the combination of alkali pre-treatment with bioaugmentation to improve biogas production from lignocellulose biomass. Bioresour. Technol. 2022, 351, 126950. [Google Scholar] [CrossRef]

- Tamilselvan, R.; Selwynraj, A.I. Enhancing biogas generation from lignocellulosic biomass through biological pretreatment: Exploring the role of ruminant microbes and anaerobic fungi. Anaerobe 2024, 85, 102815. [Google Scholar] [CrossRef]

- Gao, Z.; Alshehri, K.; Li, Y.; Qian, H.; Sapsford, D.; Cleall, P.; Harbottle, M. Advances in biological techniques for sustainable lignocellulosic waste utilization in biogas production. Renew. Sustain. Energy Rev. 2022, 170, 112995. [Google Scholar] [CrossRef]

- Poddar, B.J.; Khardenavis, A.A. Genomic characterization of bacteria reveals their bioaugmentation and pre-treatment potential for improved hydrolysis and biomethanation of protein-rich substrates. Biomass Conver. Biorefin. 2024, 1–16. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J.; Li, Y.; Li, Q.; Li, P.; Luo, L.; Zgen, F.; Zheng, G.; Sun, Y. Low-temperature pretreatment of biomass for enhancing biogas production: A Review. Fermentation 2022, 8, 562. [Google Scholar] [CrossRef]

- Andlar, M.; Belskaya, H.; Morzak, G.; Ivančić Šantek, M.; Rezić, T.; Petravić Tominac, V.; Šantek, B. Biogas production systems and upgrading technologies: A review. Food Technol. Biotechnol. 2021, 59, 387–412. [Google Scholar] [CrossRef]

- Rajput, A.A.; Hassan, M. Enhancing biogas production through co-digestion and thermal pretreatment of wheat straw and sunflower meal. Renew. Energy 2021, 168, 1–10. [Google Scholar]

- Scherzinger, M.; Kaltschmitt, M. Thermal pre-treatment options to enhance anaerobic digestibility—A review. Renew. Sustain. Energy Rev. 2021, 137, 110627. [Google Scholar]

- Pirozzi, A.; Ferrari, G.; Donsì, F. Cellulose isolation from tomato pomace pretreated by high-pressure homogenization. Foods 2022, 11, 266. [Google Scholar] [CrossRef]

- Akbay, H.E.G.; Dizge, N.; Kumbur, H. Enhancing biogas production of anaerobic co-digestion of industrial waste and municipal sewage sludge with mechanical, chemical, thermal, and hybrid pretreatment. Bioresour. Technol. 2021, 340, 125688. [Google Scholar]

- Di Costanzo, N.; Di Capua, F.; Cesaro, A.; Carraturo, F.; Salamone, M.; Mascolo, M.C.; Carpentieri, A.; Esposito, G. Low-intensity magnetization pretreatment to enhance biomethane generation and the abundance of key microorganisms for anaerobic digestion of sewage sludge. Bioresour. Technol. 2024, 413, 131534. [Google Scholar] [CrossRef]

- Show, B.K.; Shivakumaran, G.; Koley, A.; Ghosh, A.; Chaudhury, S.; Hazra, A.K.; Balachandran, S. Effect of thermal and NaOH pretreatment on water hyacinth to enhance the biogas production. Environ. Sci. Pollut. Res. 2023, 30, 120984–120993. [Google Scholar]

- Rocha-Meneses, L.; Zannerni, R.; Inayat, A.; Abdallah, M.; Shanableh, A.; Ghenai, C.; Kamil, M.; Kikas, T. Current progress in anaerobic digestion reactors and parameters optimization. Biomass Conver. Biorefin. 2022, 1–24. [Google Scholar] [CrossRef]

- Tian, P.; Gong, B.; Bi, K.; Liu, Y.; Ma, J.; Wang, X.; Ouyang, Z.; Cui, X. Anaerobic co-digestion of pig manure and rice straw: Optimization of process parameters for enhancing biogas production and system stability. Int. J. Environ. Res. Public Health 2023, 20, 804. [Google Scholar] [CrossRef] [PubMed]

- Dębowski, M.; Kazimierowicz, J.; Zieliński, M.; Bartkowska, I. Co-Fermentation of microalgae biomass and miscanthus× giganteus silage—Assessment of the substrate, biogas production and digestate characteristics. Appl. Sci. 2022, 12, 7291. [Google Scholar] [CrossRef]

- El Gnaoui, Y.; Frimane, A.; Lahboubi, N.; Herrmann, C.; Barz, M.; Bari, H.E. Biological pre-hydrolysis and thermal pretreatment applied for anaerobic digestion improvement: Kinetic study and statistical variable selection. Clean. Waste Syst. 2022, 2, 100005. [Google Scholar] [CrossRef]

- Nava-Valente, N.; Del Ángel-Coronel, O.A.; Atenodoro-Alonso, J.; López-Escobar, L.A. Effect of thermal and acid pre-treatment on increasing organic loading rate of anaerobic digestion of coffee pulp for biogas production. Biomass Convers. Biorefin. 2023, 13, 4817–4830. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Bair, R.; Ozcan, O.; Ravishankar, H.; Esposito, G.; Lens, P.N.; Yeh, D.H. Performance of AnMBR in treatment of post-consumer food waste: Effect of hydraulic retention time and organic loading rate on biogas production and membrane fouling. Front. Bioeng. Biotechnol. 2021, 8, 594936. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Liu, W.; Zhao, Y.; He, H.; Ma, J.; Cui, Z.; Yuan, X. Optimization of semi-continuous dry anaerobic digestion process and biogas yield of dry yellow corn straw: Based on “gradient anaerobic digestion reactor”. Bioresour. Technol. 2023, 389, 129804. [Google Scholar] [CrossRef]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid–liquid separation of animal slurry in theory and practice. Sustain. Agric. 2011, 2, 30153–30180. [Google Scholar]

- Uppuluri, N.S.T.; Ran, X.; Müller, J.; Guo, J.; Oechsner, H. Effects of additives on shifting phosphorus to solid phase during Solid-Liquid separation of digestate in full-scale biogas plant. Bioresour. Technol. 2025, 416, 131804. [Google Scholar]

- Bauer, A.; Mayr, H.; Hopfner-Sixt, K.; Amon, T. Detailed monitoring of two biogas plants and mechanical solid-liquid separation of fermentation residues. J. Biotechnol. 2009, 142, 56–63. [Google Scholar] [CrossRef]

- Cathcart, A.; Smyth, B.M.; Lyons, G.; Murray, S.T.; Rooney, D.; Johnston, C.R. Optimising mechanical separation of anaerobic digestate for total solids and nutrient removal. J. Environ. Manag. 2023, 345, 118449. [Google Scholar] [CrossRef]

- Tambone, F.; Orzi, V.; D’Imporzano, G.; Adani, F. Solid and liquid fractionation of digestate: Mass balance, chemical characterization, and agronomic and environmental value. Bioresour. Technol. 2017, 243, 1251–1256. [Google Scholar] [CrossRef]

- Moller, H.B.; Hansen, J.D.; Sorensen, C.A.G. Nutrient recovery by solid-liquid separation and methane productivity of solids. Trans. ASABE 2007, 50, 193–200. [Google Scholar]

- Chiumenti, A.; da Borso, F.; Teri, F.; Chiumenti, R.; Piaia, B. Pełnoskalowy system filtracji membranowej do obróbki pofermentu z zakładu współfermentacji. Appl. Eng. Agric. 2013, 29, 985–990. [Google Scholar]

- Vaneeckhaute, C.; Darveau, O.; Meers, E. Fate of micronutrients and heavy metals in digestate processing using vibrating reversed osmosis as resource recovery technology. Sep. Purif. Technol. 2019, 223, 81–87. [Google Scholar] [CrossRef]

- Chen, L.; Sun, S.; Yao, B.; Peng, Y.; Gao, C.; Qin, T.; Zhou, Y.; Sun, C.; Quan, W. Effects of straw return and straw biochar on soil properties and crop growth: A review. Front. Plant Sci. 2022, 13, 986763. [Google Scholar]

- Pang, Y.; Zhen, F.; Wang, D.; Luo, Z.; Huang, J.; Zhang, Y. Effects of biochar combined with MgO desulfurization waste residue on nitrogen conversion and odor emission in chicken manure composting. Environ. Technol. 2024, 45, 4779–4790. [Google Scholar]

- Burato, A.; Džomba, E.; Čengić-Džomba, S.; Chrysargyris, A.; Kallikazarou, N.; Melito, S.; Marceddu, D.; González-Orenga, S.; Giannini, V.; Antoniou, M.G.; et al. Effects of organo-mineral fertilizers containing struvite from liquid digestate on the growth of baby-leaf lettuce and radish. Ital. J. Agron. 2025, 20, 100030. [Google Scholar]

- Skrzypczak, D.; Trzaska, K.; Gil, F.; Chawla, Y.; Mikula, K.; Izydorczyk, G.; Samoraj, M.; Tkacz, K.; Turkiewicz, I.; Moustakas, K.; et al. Towards anaerobic digestate calorization to recover fertilizer nutrients: Elaboration of technology and profitability analysis. Biomass Bioenergy 2023, 178, 106967. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour nuisance at municipal waste biogas plants and the effect of feedstock modification on the circular economy—A review. Energies 2021, 14, 6470. [Google Scholar] [CrossRef]

- Zilio, M.; Pigoli, A.; Rizzi, B.; Geromel, G.; Meers, E.; Schoumans, O.; Giordano, A.; Adani, F. Measuring ammonia and odours emissions during full field digestate use in agriculture. Sci. Total Environ. 2021, 782, 146882. [Google Scholar]

- Korba, J.; Šařec, P.; Novák, V.; Brož, P.; Dolan, A.; Dědina, M. Digestate Application Methods and Rates with Regard to Greenhouse Gas Emissions and Crop Conditions. Agronomy 2024, 14, 336. [Google Scholar] [CrossRef]

- Kovačić, Đ.; Lončarić, Z.; Jović, J.; Samac, D.; Popović, B.; Tišma, M. Digestate management and processing practices: A review. Appl. Sci. 2022, 12, 9216. [Google Scholar] [CrossRef]

- Romio, C.; Ward, A.J.; Møller, H.B. Characterization and valorization of biogas digestate and derived organic fertilizer products from separation processes. Front. Sustain. Food Syst. 2024, 8, 1415508. [Google Scholar] [CrossRef]

- Weldon, S.; Rivier, P.A.; Joner, E.J.; Coutris, C.; Budai, A. Co-composting of digestate and garden waste with biochar: Effect on greenhouse gas production and fertilizer value of the matured compost. Environ. Technol. 2023, 44, 4261–4271. [Google Scholar]

- Cheng, J.; Gao, X.; Yan, Z.; Li, G.; Luo, W.; Xu, Z. Intermittent aeration to reduce gaseous emission and advance humification in food waste digestate composting: Performance and mechanisms. Bioresour. Technol. 2023, 371, 128644. [Google Scholar]

- Lal, R.; Bouma, J.; Brevik, E.; Dawson, L.; Field, D.J.; Glaser, B.; Hatano, R.; Hartemink, A.E.; Kosaki, T.; Lascelles, B.; et al. Soils and sustainable development goals of the United Nations: An International Union of Soil Sciences perspective. Geoderma Reg. 2021, 25, e00398. [Google Scholar]

- Grobelak, A.; Placek, A.; Grosser, A.; Singh, B.R.; Almås, Å.R.; Napora, A.; Kacprzak, M. Effects of single sewage sludge application on soil phytoremediation. J. Clean. Prod. 2017, 155, 189–197. [Google Scholar] [CrossRef]

- Wołejko, E.; Jabłońska-Trypuć, A.; Wydro, U.; Butarewicz, A.; Łozowicka, B. Soil biological activity as an indicator of soil pollution with pesticides—A review. Appl. Soil Ecol. 2020, 147, 103356. [Google Scholar]

- FAO; ITPS; GSBI; SCBD; EC. State of Knowledge of Soil Biodiversity—Status, Challenges and Potentialities, Summary for Policy Makers; FAO: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Willett, W.; Rockström, J.; Loken, B.; Springmann, M.; Lang, T.; Vermeulen, S.; Garnett, T.; Tilman, D.; DeClerck, F.; Wood, A.; et al. Food in the Anthropocene: The EAT–Lancet Commission on healthy diets from sustainable food systems. Lancet 2019, 393, 447–492. [Google Scholar]

- Paradelo, R.; Navarro-Pedreño, J.; Glaser, B.; Grobelak, A.; Kowalska, A.; Singh, B.R. Potential and constraints of use of organic amendments from agricultural residues for improvement of soil properties. Sustainability 2023, 16, 158. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAOSTAT: Emissions from Drained Organic Soils. 2025. Available online: https://www.fao.org/faostat/en/#data/GV/visualize (accessed on 10 March 2025).

- Kowalska, A.; Grobelak, A.; Almås, Å.R.; Singh, B.R. Effect of biowastes on soil remediation, plant productivity and soil organic carbon sequestration: A review. Energies 2020, 13, 5813. [Google Scholar] [CrossRef]

- Otlewska, A.; Migliore, M.; Dybka-Stępień, K.; Manfredini, A.; Struszczyk-Świta, K.; Napoli, R.; Białkowska, A.; Canfora, L.; Pinzari, F. When salt meddles between plant, soil, and microorganisms. Front. Plant Sci. 2020, 11, 553087. [Google Scholar]

- Siebielec, S.; Siebielec, G.; Woźniak, M. Potential of using digestate to regenerate soil and stimulate its biological life. Polish J. Agron. 2023, 52, 157–170. [Google Scholar]

- Mockeviciene, I.; Repsiene, R.; Amaleviciute-Volunge, K.; Karcauskiene, D.; Slepetiene, A.; Lepane, V. Effect of long-term application of organic fertilizers on improving organic matter quality in acid soil. Arch. Agron. Soil Sci. 2022, 68, 1192–1204. [Google Scholar]

- Slepetiene, A.; Kochiieru, M.; Jurgutis, L.; Mankeviciene, A.; Skersiene, A.; Belova, O. The effect of anaerobic digestate on the soil organic carbon and humified carbon fractions in different land-use systems in lithuania. Land 2022, 11, 133. [Google Scholar] [CrossRef]

- Grobelak, A.; Całus-Makowska, K.; Jasińska, A.; Klimasz, M.; Wypart-Pawul, A.; Augustajtys, D.; Baor, E.; Sławczyk, D.; Kowalska, A. Environmental Impacts and Contaminants Management in Sewage Sludge-to-Energy and Fertilizer Technologies: Current Trends and Future Directions. Energies 2024, 17, 4983. [Google Scholar] [CrossRef]

- Häfner, F.; Hartung, J.; Möller, K. Digestate composition affecting N fertiliser value and C mineralisation. Waste Biomass Valorization 2022, 13, 3445–3462. [Google Scholar]

- Jasińska, A.; Grosser, A.; Meers, E.; Aguilar, A.R. Energy recovery from poultry manure in the process of semi-continuous anaerobic co-digestion with sewage sludge. Energy Rep. 2024, 12, 3969–3981. [Google Scholar]

- Greenberg, I.; Kaiser, M.; Gunina, A.; Ledesma, P.; Polifka, S.; Wiedner, K.; Mueller, C.W.; Glaser, B.; Ludwig, B. Substitution of mineral fertilizers with biogas digestate plus biochar increases physically stabilized soil carbon but not crop biomass in a field trial. Sci. Total Environ. 2019, 680, 181–189. [Google Scholar] [CrossRef]

- Koch, S.; Liu, H.; Lenz, C.; Eichler-Löbermann, B.; Vogel, H.J.; Lennartz, B. Soil structure and solute transport pathways in biogas digestate-amended soils. Soil Tillage Res. 2024, 240, 106074. [Google Scholar]

- Olayemi, O.P.; Kallenbach, C.M.; Wallenstein, M.D. Distribution of soil organic matter fractions are altered with soil priming. Soil Biol. Biochem. 2022, 164, 108494. [Google Scholar]

- Sinatra, M.; Giannetta, B.; Plaza, C.; Galluzzi, G.; Squartini, A.; Zaccone, C. Anaerobic digestate influences the carbon distribution in soil organic matter pools after six months from its application. Soil Tillage Res. 2024, 239, 106049. [Google Scholar]

- Czekała, W. Digestate as a Source of Nutrients: Nitrogen and Its Fractions. Water 2022, 14, 4067. [Google Scholar] [CrossRef]

- Makádi, M.; Tomócsik, A.; Orosz, V. Digestate: A new nutrient source–review. Biogas 2012, 14, 295–312. [Google Scholar]

- Mayerová, M.; Šimon, T.; Stehlík, M.; Madaras, M.; Koubová, M.; Smatanová, M. Long-term application of biogas digestate improves soil physical properties. Soil Tillage Res. 2023, 231, 105715. [Google Scholar]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar]

- Rolka, E.; Wyszkowski, M.; Żołnowski, A.C.; Skorwider-Namiotko, A.; Szostek, R.; Wyżlic, K.; Borowski, M. Digestate from an Agricultural Biogas Plant as a Factor Shaping Soil Properties. Agronomy 2024, 14, 1528. [Google Scholar] [CrossRef]

- Council of the European Union. Council Directive 91/676/EEC of 12 December 1991 concerning the protection of waters against pollution caused by nitrates from agricultural sources. Off. J. Eur. Communities 1991, 375, 1–8. [Google Scholar]

- Zhang, W.; Wu, S.; Liu, J. Anaerobic digestion performance and microbial community structure of corn stover in combination with dairy manure in a two-phase solid-state system. Bioresour. Technol. 2019, 274, 171–179. [Google Scholar]

- Rodino, S.; Pop, R.; Sterie, C.; Giuca, A.; Dumitru, E. Developing an Evaluation Framework for Circular Agriculture: A Pathway to Sustainable Farming. Agriculture 2023, 13, 2047. [Google Scholar] [CrossRef]

- Yu, L.; Qiao, X.; Duan, H.; Zhang, Z.; Gong, L.; Li, X.; Lu, J.; Li, X. Life cycle assessment of liquid digestate application strategies for rice agri-food chain in “Zero-waste City”. Biomass Convers. Biorefinery 2022, 12, 4389–4401. [Google Scholar]

- Risberg, K.; Cederlund, H.; Pell, M.; Arthurson, V.; Schnürer, A. Comparative characterization of digestate versus pig slurry and cow manure—Chemical composition and effects on soil microbial activity. Waste Manag. 2017, 61, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Tuszynska, A.; Wilinska, A.; Czerwionka, K. Phosphorus and nitrogen forms in liquid fraction of digestates from agricultural biogas plants. Environ. Technol. 2021, 42, 3942–3954. [Google Scholar] [CrossRef] [PubMed]

| Parameter (Unit) | Solid Fraction | Liquid Fraction |

|---|---|---|

| Dry matter, % | 22.00–27.0 | 2.70–4.30 |

| Organic dry matter, % | 89.00–94.5 | 58.00–62.00 |

| Total nitrogen, % | 0.40–0.80 | 0.29–0.75 |

| Ammonium nitrogen, % | 0.08–0.52 | 0.28–0.38 |

| Phosphorus, % | 0.10–0.28 | 0.03–0.05 |

| Potassium, % | 0.12–0.69 | 0.50–0.62 |

| Calcium, % | 0.22–0.43 | 0.05–0.07 |

| Magnesium, % | 0.06–0.17 | 0.01–0.02 |

| Cadmium, mg Cd/kg | 0.25–0.50 | 0.55–0.71 |

| Chromium, mg Cr/kg | 1.15–4.55 | 4.52–6.73 |

| Nickel, mg Ni/kg | 1.07–9.45 | 11.60–18.50 |

| Lead, mg Pb/kg | 0.50–2.16 | 4.12–6.01 |

| Zinc, mg Zn/kg | 27.8–105.0 | 9.40–11.5 |

| Copper, mg Cu/kg | 7.90–27.90 | 1.50–1.74 |

| Temperature Conditions | Thermophilic Pre-Treatment | Mesophilic Pre-Treatment |

|---|---|---|

| Temperature range | 49 °C–70 °C | 30 °C–35 °C |

| Advantages of the process |

|

|

| Disadvantages of the process |

|

|

| Scale of application | <10% of fermentation reactors worldwide | >90% of fermentation reactors worldwide |

| Soil Parameter | Effect of Digestate Soil Application | Type of Digestate-Feedstock | Reference |

|---|---|---|---|

| Organic matter content | Topsoil (0–0.3 m): control 0.76 ± 0.08%, digestate: 1.00 ± 0.07% SD caused a significant displacement effect—the share of organic in POM (particulate organic matter) increased at the expense of MAOM (mineral-associated organic matter). | digested slurry, digestate corn and poultry, manure, solid SD, and liquid LD | [82,84] |

| Soil organic carbon (SOC) | Digestate I (Ctot) 1.13%, digestate II 1.17%, compared to control 1.09%. Slight increase in SOC (2–5% increase compared to unfertilized soil). | (digestate I) corn silage, cattle slurry, (digestate II) corn silage, pig slurry, farmyard manure, and hay; digestates from maize (M), clover and grass (CG), poultry manure (PM), cattle slurry (CS) | [87,88] |

| Soil pH | Digestate I: pH 6.95, digestate II: pH 7.05, control 6.80. | (digestate I) corn silage, cattle slurry, (digestate II) corn silage, pig slurry, farmyard manure, and hay | [87] |

| Total nitrogen content | LD increased the N content; this effect was more pronounced than in the case of SD. Digestates used as liquid fraction—have a high share of mineral nitrogen (NH4+ constitutes 35–81% of total N). Their application increases the availability of N in the soil, although the total TN content changes only slightly (differences in the order of several point percentages compared to the control). | digestate from corn silage, straw, chicken manure, pig slurry, corn-based distiller’s grain, cattle slurry; digestates from maize (M), clover and grass (CG), poultry manure (PM), cattle slurry (CS) | [88,89] |

| Available phosphorus | (PDL—double lactate-extractable P) in topsoil: control 3.99 ± 0.51 mg/kg, digestate: 5.24 ± 1.91 mg/kg increase; effects are dependent on the type of digestate: digestates from food waste and manure (e.g., PM, CS) show higher P values, while those from plant silage (M, CG) may be slightly lower; changes in the range of 10–30% compared to the initial values. | digested slurry digestates from maize (M), clover and grass (CG), poultry manure (PM), cattle slurry (CS) | [82,88] |

| Microbial activity | Food waste digestate with very high OM mineralization (Cm ≈ 60.9%, CO2 production—1900 mgCO2-C kg−1 of soil), the remaining digestates had Cm in the range of 16–22% (corresponding to mineralization, about 720 mgCO2-C kg−1 of soil. | Seven digestates: maize silage (M), clover and grass silage (CG), grass silage (G), food waste (FW), source-separated organic household waste (OW), poultry manure (PM), and cattle slurry (CS) | [79] |

| Soil structure | Soil aggregates stability (SAS); digestate I: 32.35%, digestate II: 36.47%, control—26.22%. Porosity of macropores (>36 mm3,), control 4.02 ± 0.90 vol%, digestate 6.16 ± 2.78 vol%. | (digestate I) corn silage, cattle slurry, (digestate II) corn silage, pig slurry, farmyard manure, and hay; digested slurry | [82,87] |

| Soil salinity | Electrical conductivity (EC) increase; control 181 μS/cm, solid digestate 215 μS/cm, liquid digestate 327–386 μS/cm. | digestate corn and poultry, manure, solid SD and liquid LD | [84] |

| Trace elements | Digestates may contain elevated concentrations of microelements, such as Cu, Zn, or Mn (e.g., PM, CS), and accumulation may occur with repeated use—typical concentrations of Cu and Zn may be 20–50% higher than in soils fertilized with traditional manures. LD, at higher doses, increased the available forms of Fe, Mn, Cu, and Pb (e.g., at the highest dose, an increase in available Fe by 6.9%, Mn by 12.4%, Cu by 21.9%, and Pb by 20% compared to the control). | digestates from maize (M), clover and grass (CG), poultry manure (PM), cattle slurry (CS) digestate from corn silage, straw, chicken manure, pig slurry, corn-based distiller’s grain, cattle slurry | [88,89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grobelak, A.; Bień, B.; Sławczyk, D.; Bień, J. Conditioning Biomass for Biogas Plants: Innovative Pre-Treatment and Digestate Valorization Techniques to Enhance Soil Health and Fertility. Sustainability 2025, 17, 3289. https://doi.org/10.3390/su17083289

Grobelak A, Bień B, Sławczyk D, Bień J. Conditioning Biomass for Biogas Plants: Innovative Pre-Treatment and Digestate Valorization Techniques to Enhance Soil Health and Fertility. Sustainability. 2025; 17(8):3289. https://doi.org/10.3390/su17083289

Chicago/Turabian StyleGrobelak, Anna, Beata Bień, Daria Sławczyk, and Jurand Bień. 2025. "Conditioning Biomass for Biogas Plants: Innovative Pre-Treatment and Digestate Valorization Techniques to Enhance Soil Health and Fertility" Sustainability 17, no. 8: 3289. https://doi.org/10.3390/su17083289

APA StyleGrobelak, A., Bień, B., Sławczyk, D., & Bień, J. (2025). Conditioning Biomass for Biogas Plants: Innovative Pre-Treatment and Digestate Valorization Techniques to Enhance Soil Health and Fertility. Sustainability, 17(8), 3289. https://doi.org/10.3390/su17083289