Performance Evaluation of Porous Asphalt Mixture Reinforced with Waste Cellulose Acetate Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Asphalt Preparation and Mix Design

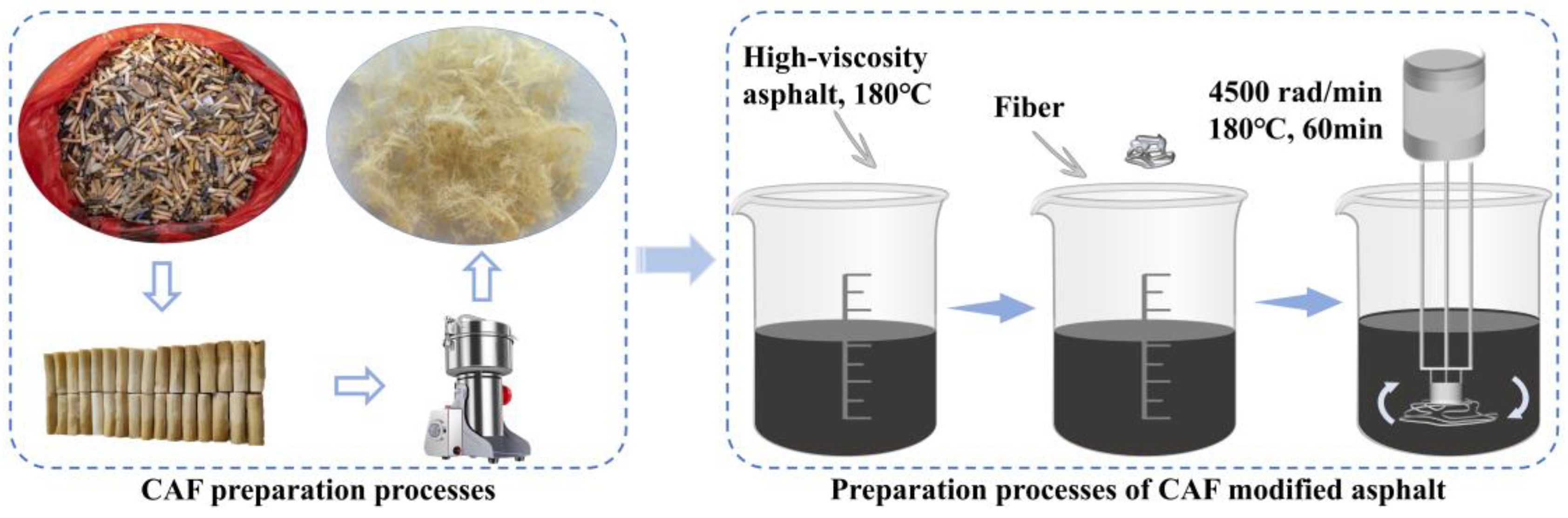

2.2.1. Asphalt Preparation

2.2.2. Mix Design

2.3. Engineering Performance

2.3.1. Asphalt Performance

- (1)

- Dynamic Shear Rheometer (DSR) Test

- (2)

- Bending Beam Rheometer (BBR) Test

- (3)

- Time Sweep Test

2.3.2. PA-13 Mixture Performance

- (1)

- Wheel Tracking Test

- (2)

- Low-temperature Bending Test

- (3)

- Freeze–thaw Splitting Test

- (4)

- Cantabro Test

- (5)

- Indirect Tensile Fatigue Test

3. Results and Discussion

3.1. Performance Evaluation of Modified Asphalt Binder

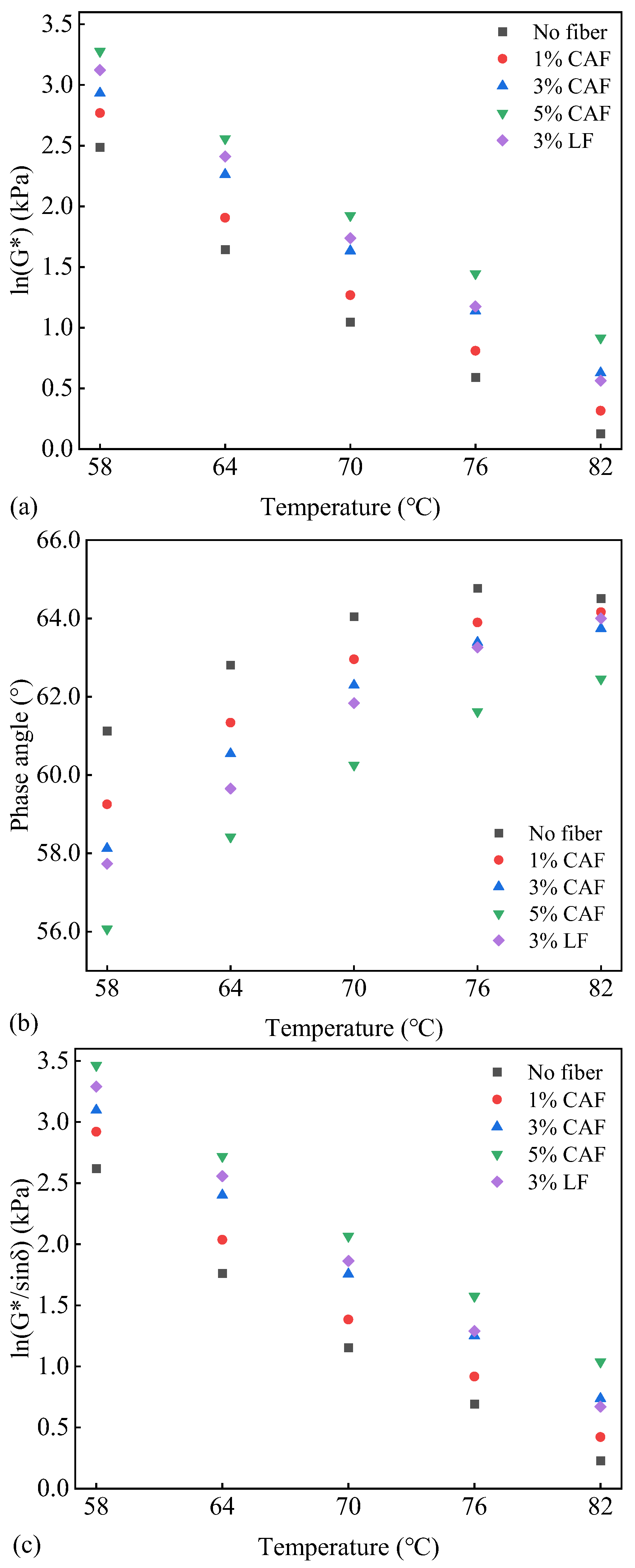

3.1.1. High-Temperature Rheological Property

3.1.2. Low-Temperature Rheological Property

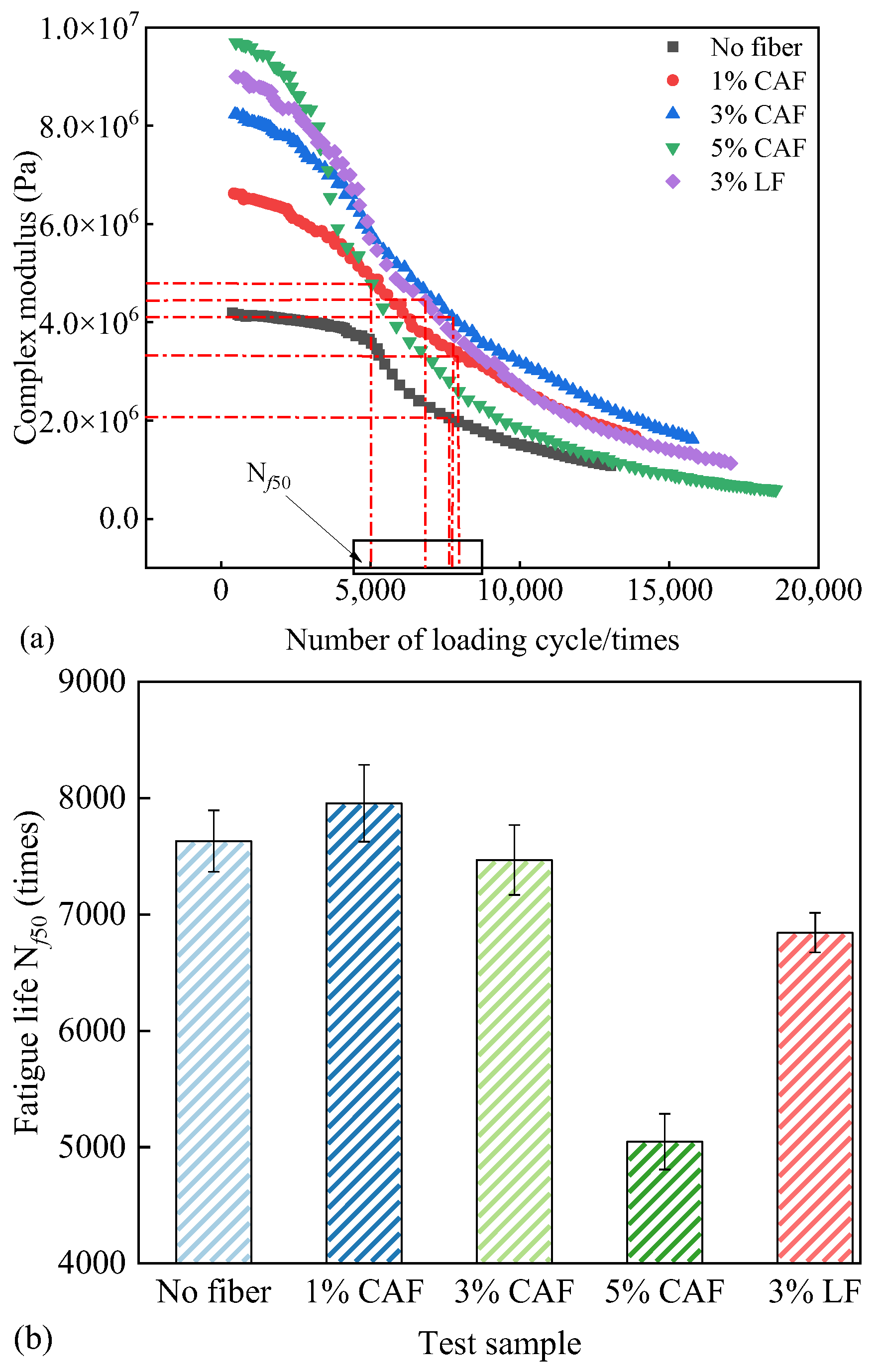

3.1.3. Fatigue Property

3.2. Performance Evaluation of PA-13 Mixture

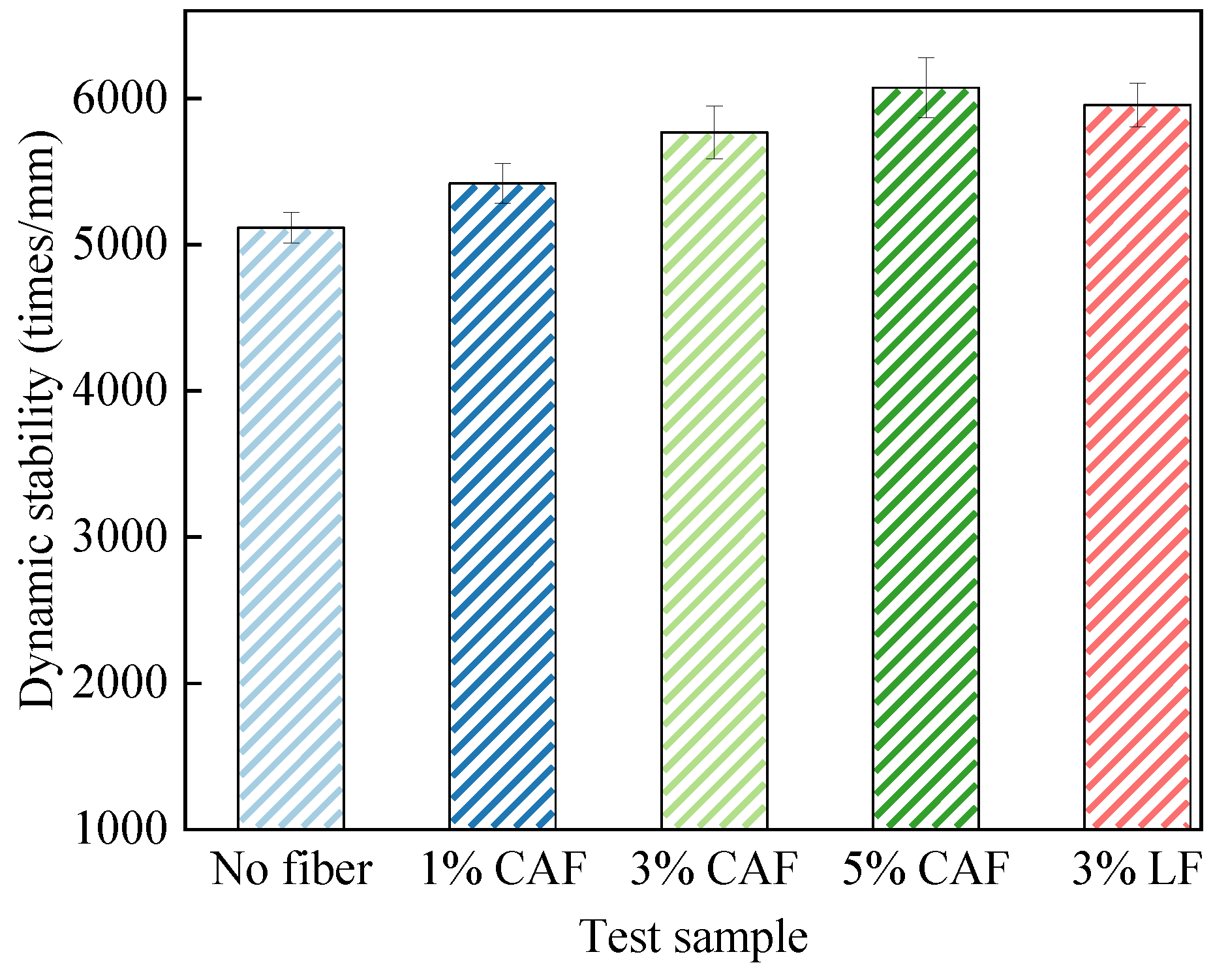

3.2.1. Influence of CAF on Rutting Resistance

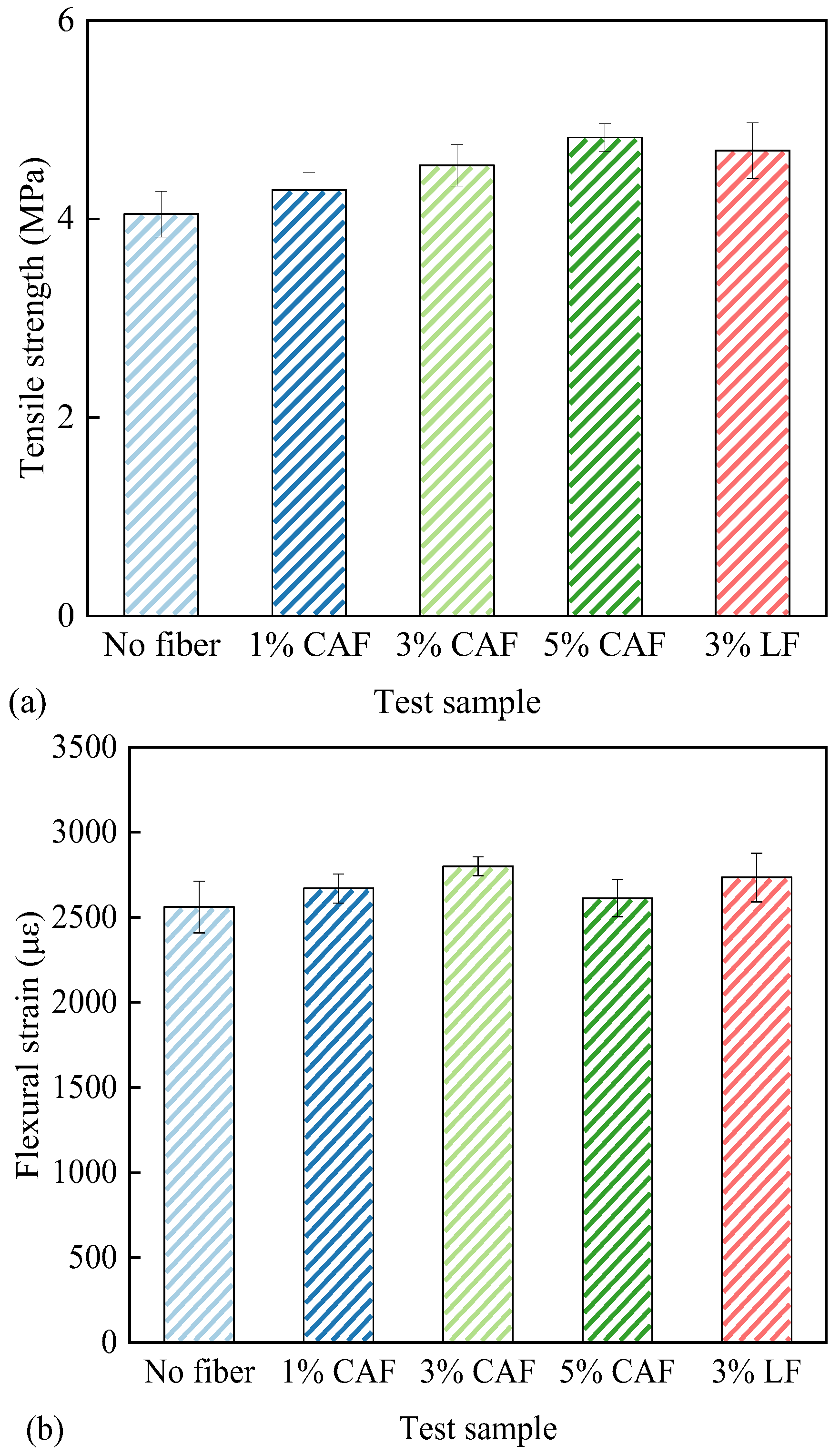

3.2.2. Influence of CAF on Low-Temperature Cracking Resistance

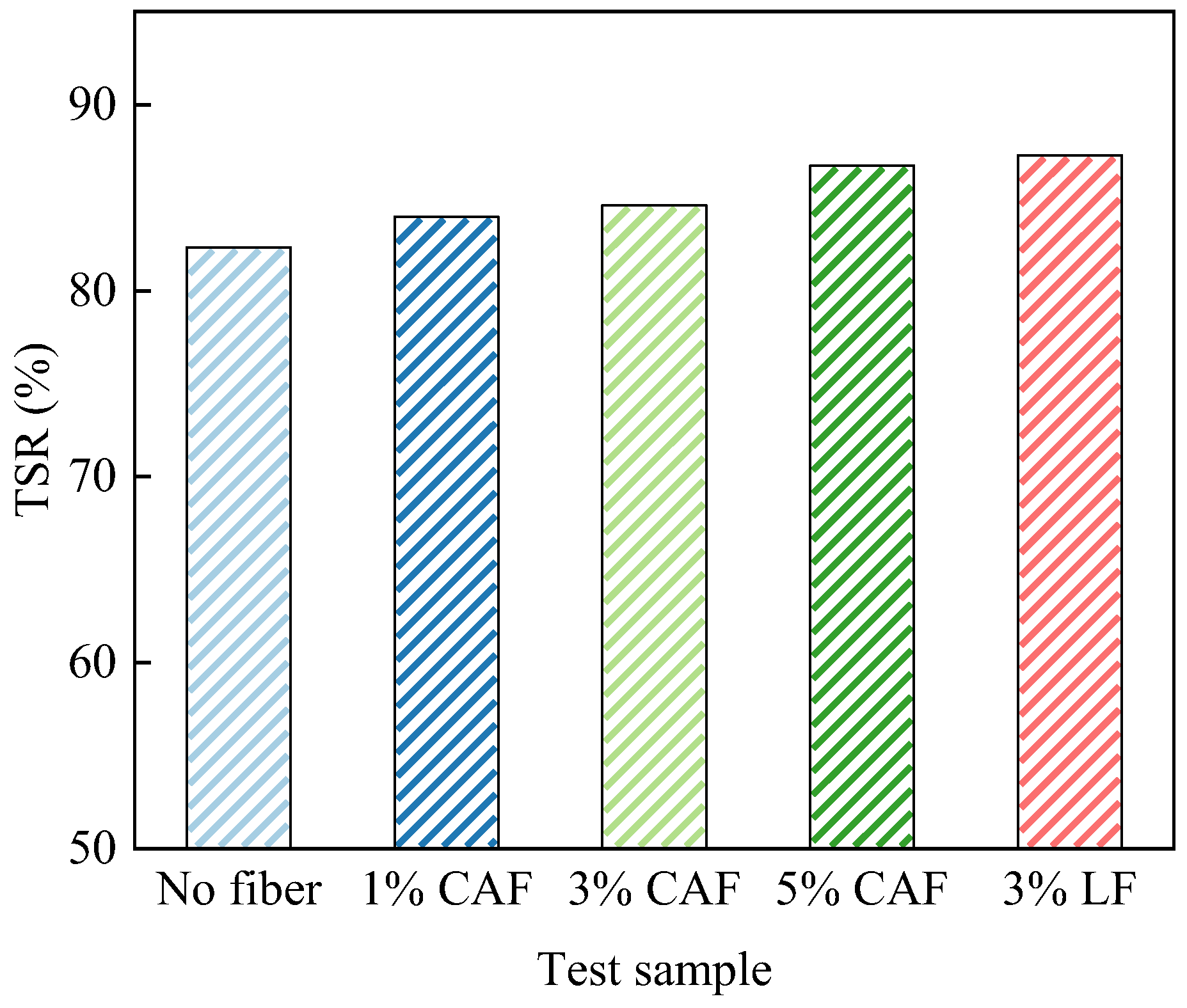

3.2.3. Influence of CAF on Moisture Resistance

3.2.4. Influence of CAF on Stripping Resistance

3.2.5. Influence of CAF on Fatigue Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shahnewaz, S.M.; Masri, K.A.; Ahmad Abdul Ghani, N.A.; Putra Jaya, R.; Siew Choo, C.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Petrounias, P. Porous asphalt mixtures enriched with bamboo fibers as a new approach for future sustainable construction. Constr. Build. Mater. 2023, 407, 133456. [Google Scholar] [CrossRef]

- Nazmey, K.G.; Eisa, M.S.; Morsi, A.G.M.; Debaiky, A.S. Enhancement of porous asphalt mixtures modified with various fibers and ethylene–vinyl acetate polymer. Sci. Rep. 2024, 14, 15599. [Google Scholar] [CrossRef]

- Gupta, A.; Castro-Fresno, D.; Lastra-Gonzalez, P.; Rodriguez-Hernandez, J. Selection of fibers to improve porous asphalt mixtures using multi-criteria analysis. Constr. Build. Mater. 2021, 266, 121198. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; He, L.; Guo, R.; Li, X.; Chen, Y.; Muhammad, Y.; Liu, Y. Research progresses of fibers in asphalt and cement materials: A review. J. Road Eng. 2023, 3, 35–70. [Google Scholar] [CrossRef]

- Kou, C.; Chen, Z.; Kang, A.; Zhang, M.; Wang, R. Rheological behaviors of asphalt binders reinforced by various fibers. Constr. Build. Mater. 2022, 323, 126626. [Google Scholar] [CrossRef]

- Chen, C.; Li, C.; Zhang, S.; Liu, W.; Lin, H.; Zhang, H. Performance Evaluation on Open-Graded Friction Course Reinforced by Double-Adding Fibers Technology. Processes 2024, 12, 428. [Google Scholar] [CrossRef]

- Pang, Y.; Li, H.; Han, Z.; Wu, P.; Lin, H. Performance evaluation of asphalt mixture reinforced by lignin and ceramic fiber. J. Eng. Res. 2023. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, J.; Lyu, L.; Li, Y.; Tan, X.; Li, Z.; Pei, J. Durable and Environmental Asphalt Pavement with Plant Fiber: A State-of-the-Art Review. J. Mater. Civ. Eng. 2024, 36, 03123003. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, Z.; Jiang, C.; Yang, Y.; Sun, Z.; Yuang, J.; Xiao, F. Recent development and application of natural fiber in asphalt pavement. J. Clean. Prod. 2024, 449, 141832. [Google Scholar] [CrossRef]

- Alnadish, A.M.; Singh, N.S.; Alawag, A.M. Applications of Synthetic, Natural, and Waste Fibers in Asphalt Mixtures: A Citation-Based Review. Polymers 2023, 15, 1004. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Yang, F.; He, S.; Jing, H.; Zou, X.; Li, Z.; Sheng, Y. Review of utilization of bamboo fiber in asphalt modification: Insights into preparation, performance, reinforcement, and challenges. J. Clean. Prod. 2024, 468, 143010. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Y.; Zhou, J.; Sun, S.; Liu, J.; Li, Z.; Wang, Q. Performance and Mechanism Analysis of Corn Straw Fiber Asphalt Mixture for Road Use. China J. Highw. Transp. 2019, 32, 47–58. [Google Scholar] [CrossRef]

- Meneses João, P.C.; Lutif Teixeira Jamilla Emi, S.; Alvarez Allex, E.; Aragão Francisco Thiago, S.; Fritzen Marcos, A. Exploratory Study on the Addition of Sugarcane Bagasse Fibers to Permeable Friction Course Mixtures. J. Mater. Civ. Eng. 2021, 33, 04021241. [Google Scholar] [CrossRef]

- Singh, S.; Khairandish, M.I.; Razahi, M.M.; Kumar, R.; Chohan, J.S.; Tiwary, A.; Sharma, S.; Li, C.; Ilyas, R.A.; Asyraf, M.R.M.; et al. Preference Index of Sustainable Natural Fibers in Stone Matrix Asphalt Mixture Using Waste Marble. Materials 2022, 15, 2729. [Google Scholar] [CrossRef]

- Ye, X.; Xiao, Z.; He, C.; Li, W.; Lin, P.; Meng, Y.; Hu, C. Roles of waste carbon fibers on the efficiency of multiple induction heating healing behavior in asphalt mixture for sustainable infrastructure. J. Clean. Prod. 2023, 423, 138694. [Google Scholar] [CrossRef]

- Jin, D.; Mohammadi, S.; Xin, K.; Yin, L.; You, Z. Laboratory performance and field demonstration of asphalt overlay with recycled rubber and tire fabric fiber. Constr. Build. Mater. 2024, 438, 136941. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, Y.; He, X.; Su, Y.; Liu, Q.; Chen, W.; Wang, Y.; Zhang, H.; Wang, W.; Fan, J.; et al. Properties of recycled facemask fiber modified asphalt binder: Comparative analysis of surface modification and composite modification method. Constr. Build. Mater. 2023, 406, 133466. [Google Scholar] [CrossRef]

- Nciri, N.; Kim, N. Infrastructure in the Age of Pandemics: Utilizing Polypropylene-Based Mask Waste for Durable and Sustainable Road Pavements. Polymers 2023, 15, 4624. [Google Scholar] [CrossRef]

- Yalcin, E.; Munir Ozdemir, A.; Vural Kok, B.; Yilmaz, M.; Yilmaz, B. Influence of pandemic waste face mask on rheological, physical and chemical properties of bitumen. Constr. Build. Mater. 2022, 337, 127576. [Google Scholar] [CrossRef]

- Goli, A.; Sadeghi, P. Evaluation on the use of COVID-19 single-use face masks to improve the properties of hot mix asphalt. Road Mater. Pavement Des. 2023, 24, 1371–1388. [Google Scholar] [CrossRef]

- Lin, H.; Sun, M.; Du, X.; Zhang, H. Sustainable Use of COVID-19 Face Masks in Asphalt Binder and Asphalt Mixture. J. Mater. Civ. Eng. 2023, 35, 05023003. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Saberian, M.; Rahat, M.H.H.; Massarra, C.; Buckhalter, C.; Farrington, J.; Collins, T.; Johnson, J. Use of COVID-19 single-use face masks to improve the rutting resistance of asphalt pavement. Sci. Total Environ. 2022, 826, 154118. [Google Scholar] [CrossRef]

- Zhu, J.; Saberian, M.; Li, J.; Yaghoubi, E.; Rahman, M.T. Sustainable use of COVID-19 discarded face masks to improve the performance of stone mastic asphalt. Constr. Build. Mater. 2023, 398, 132524. [Google Scholar] [CrossRef]

- World Health Organization. WHO Report on the Global Tobacco Epidemic, 2021: Addressing New and Emerging Products; World Health Organization: New York, NY, USA, 2021. [Google Scholar]

- Tareq Rahman, M.; Mohajerani, A. Recycling Waste Cigarette Butts in Dense Graded Asphalt. J. Mater. Civ. Eng. 2021, 33, 04021313. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Possible Recycling of Cigarette Butts as Fiber Modifier in Bitumen for Asphalt Concrete. Materials 2020, 13, 734. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Possible use of cigarette butt fiber modified bitumen in stone mastic asphalt. Constr. Build. Mater. 2020, 263, 120134. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mohajerani, A. Thermal conductivity and environmental aspects of cigarette butt modified asphalt. Case Stud. Constr. Mater. 2021, 15, e00569. [Google Scholar] [CrossRef]

- Hu, X.; Chen, X.; Yu, J.; Cheng, G.; Yuan, Y.; Zhang, L. Physical Properties and Rheological Characteristics of Cigarette Butt-Modified Asphalt Binders. Coatings 2025, 15, 170. [Google Scholar] [CrossRef]

- Li, C.; Deng, Q.; Gan, Y.; Yu, T.; Xiao, Y.; Wang, W. Research on Water Stability and Crack Resistance of Waste Cellulose Acetate–Reinforced Asphalt Mixtures Based on Response-Surface Methodology. J. Mater. Civ. Eng. 2023, 35, 04023270. [Google Scholar] [CrossRef]

- Al-Ameri, N.A.H.; Ramadhansyah, P.J. Performance of Asphalt Mixture Incorporated Encapsulated Cigarette Butts as Bitumen Modifier. Construction 2022, 2, 10–21. [Google Scholar] [CrossRef]

- Ahlawat, Y.; Bhardawaj, A.; Bhardwaj, R. An experimental study on the stability and flow characteristics of mastic asphalt mix using cigarette butt additive. Mater. Today Proc. 2022, 65, 651–661. [Google Scholar] [CrossRef]

- Guo, Y.; Tataranni, P.; Tarsi, G.; Balzano, F.; Dai, J.; Sangiorgi, C. Recycling of waste E-cigarette butts as engineered pelletized fibres for sustainable stone mastic asphalt. J. Road Eng. 2024, 4, 468–477. [Google Scholar] [CrossRef]

- Tataranni, P.; Sangiorgi, C. A Preliminary Laboratory Evaluation on the Use of Shredded Cigarette Filters as Stabilizing Fibers for Stone Mastic Asphalts. Appl. Sci. 2021, 11, 5674. [Google Scholar] [CrossRef]

- JTG/T 3350-03-2020; Technical Specifications for Design and Construction of Porous Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- JTG F40-2004; Technical Standards of the Chinese Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- AASHTO T315; Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2012.

- Li, M.; Yuan, J.; Jin, T.; Wang, W.; Sun, Y.; Cheng, H. Investigation of performance evolution in recycled asphalt mixtures: The impact of virgin and RAP binder blending. Constr. Build. Mater. 2025, 469, 140519. [Google Scholar] [CrossRef]

- Xing, X.; Chen, S.; Li, Y.; Pei, J.; Zhang, J.; Wen, Y.; Li, R.; Cui, S. Effect of different fibers on the properties of asphalt mastics. Constr. Build. Mater. 2020, 262, 120005. [Google Scholar] [CrossRef]

- Cai, C.; Lou, K.; Qian, F.; Xiao, P. Influence of Basalt Fiber Morphology on the Properties of Asphalt Binders and Mixtures. Materials 2024, 17, 5358. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, Y.; Guo, P.; Underwood, S.; Chen, H.; Kim, Y.R.; Li, Y.; Ma, Q. Effect of synthetic fibers on the mechanical performance of asphalt mixture: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 331–348. [Google Scholar] [CrossRef]

- Li, M.; Han, Z.; Chen, H.; Yang, R.; Yuan, J.; Jin, T. Low-temperature Performance Improvement Strategies for High RAP content Recycled Asphalt Mixtures: Focus on RAP Gradation Variability and Mixing Process. Fuel 2025, 387, 134362. [Google Scholar] [CrossRef]

- Mashaan, N.; Karim, M.; Khodary, F.; Saboo, N.; Milad, A. Bituminous Pavement Reinforcement with Fiber: A Review. Civil. Eng. 2021, 2, 599–611. [Google Scholar] [CrossRef]

- Mohajerani, A.; Tanriverdi, Y.; Nguyen, B.T.; Wong, K.K.; Dissanayake, H.N.; Johnson, L.; Whitfield, D.; Thomson, G.; Alqattan, E.; Rezaei, A. Physico-mechanical properties of asphalt concrete incorporated with encapsulated cigarette butts. Constr. Build. Mater. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Phan, T.M.; Nguyen, S.N.; Seo, C.-B.; Park, D.-W. Effect of treated fibers on performance of asphalt mixture. Constr. Build. Mater. 2021, 274, 122051. [Google Scholar] [CrossRef]

- Guo, Y.; Tataranni, P.; Tarsi, G.; Sangiorgi, C. Recycling shredded waste cigarette butts as stabilising fibres in stone mastic asphalt concretes. Int. J. Pavement Eng. 2023, 24, 2229477. [Google Scholar] [CrossRef]

| Index | 60 °C Viscosity (Pa·s) | Softening Point (°C) | 5 °C Ductility (cm) | 25 °C Penetration (0.1 mm) |

|---|---|---|---|---|

| Test value | 100,280 | 81.5 | 35 | 52 |

| Standards | ≥50,000 | ≥80 | ≥30 | ≥40 |

| Group ID | No Fiber | 3% LF | 1% CAF | 3% CAF | 5% CAF |

|---|---|---|---|---|---|

| OAC (%) | 4.68% | 5.00% | 4.75% | 4.83% | 4.95% |

| Group ID | No Fiber | 1% CAF | 3% CAF | 5% CAF | 3% LF |

|---|---|---|---|---|---|

| Splitting strength (MPa) | 0.81 | 0.89 | 0.95 | 1.04 | 0.98 |

| Type Sample | The Fatigue Lives (N) Corresponding to Stress Ratio (S) | |||

|---|---|---|---|---|

| 0.3 | 0.4 | 0.5 | 0.6 | |

| No fiber | 8409 | 2570 | 1469 | 656 |

| 8969 | 2867 | 1586 | 730 | |

| 7928 | 2491 | 1658 | 699 | |

| 1% CAF | 7360 | 2905 | 1807 | 803 |

| 8109 | 2709 | 1527 | 722 | |

| 11,958 | 2821 | 1669 | 775 | |

| 3% CAF | 9614 | 3302 | 1780 | 780 |

| 11,146 | 2918 | 1696 | 819 | |

| 9284 | 3096 | 1715 | 855 | |

| 5% CAF | 9585 | 3235 | 1623 | 736 |

| 8455 | 3039 | 1578 | 791 | |

| 11,064 | 2864 | 1331 | 637 | |

| 3% LF | 12,056 | 2900 | 1507 | 726 |

| 9923 | 3376 | 1846 | 684 | |

| 10,620 | 3493 | 1456 | 735 | |

| Type Sample | a | b | R² |

|---|---|---|---|

| No fiber | 2.091 | 3.480 | 0.989 |

| 1% CAF | 2.129 | 3.464 | 0.989 |

| 3% CAF | 2.138 | 3.526 | 0.993 |

| 5% CAF | 2.043 | 3.695 | 0.998 |

| 3% LF | 2.011 | 3.855 | 0.997 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Du, X.; Lin, H. Performance Evaluation of Porous Asphalt Mixture Reinforced with Waste Cellulose Acetate Fibers. Sustainability 2025, 17, 3447. https://doi.org/10.3390/su17083447

Yan J, Du X, Lin H. Performance Evaluation of Porous Asphalt Mixture Reinforced with Waste Cellulose Acetate Fibers. Sustainability. 2025; 17(8):3447. https://doi.org/10.3390/su17083447

Chicago/Turabian StyleYan, Jing, Xiaobo Du, and Hongwei Lin. 2025. "Performance Evaluation of Porous Asphalt Mixture Reinforced with Waste Cellulose Acetate Fibers" Sustainability 17, no. 8: 3447. https://doi.org/10.3390/su17083447

APA StyleYan, J., Du, X., & Lin, H. (2025). Performance Evaluation of Porous Asphalt Mixture Reinforced with Waste Cellulose Acetate Fibers. Sustainability, 17(8), 3447. https://doi.org/10.3390/su17083447