Agility in the Digital Era: Bridging Transformation and Innovation in Supply Chains

Abstract

1. Introduction

2. Literature Review and Hypothesis Development

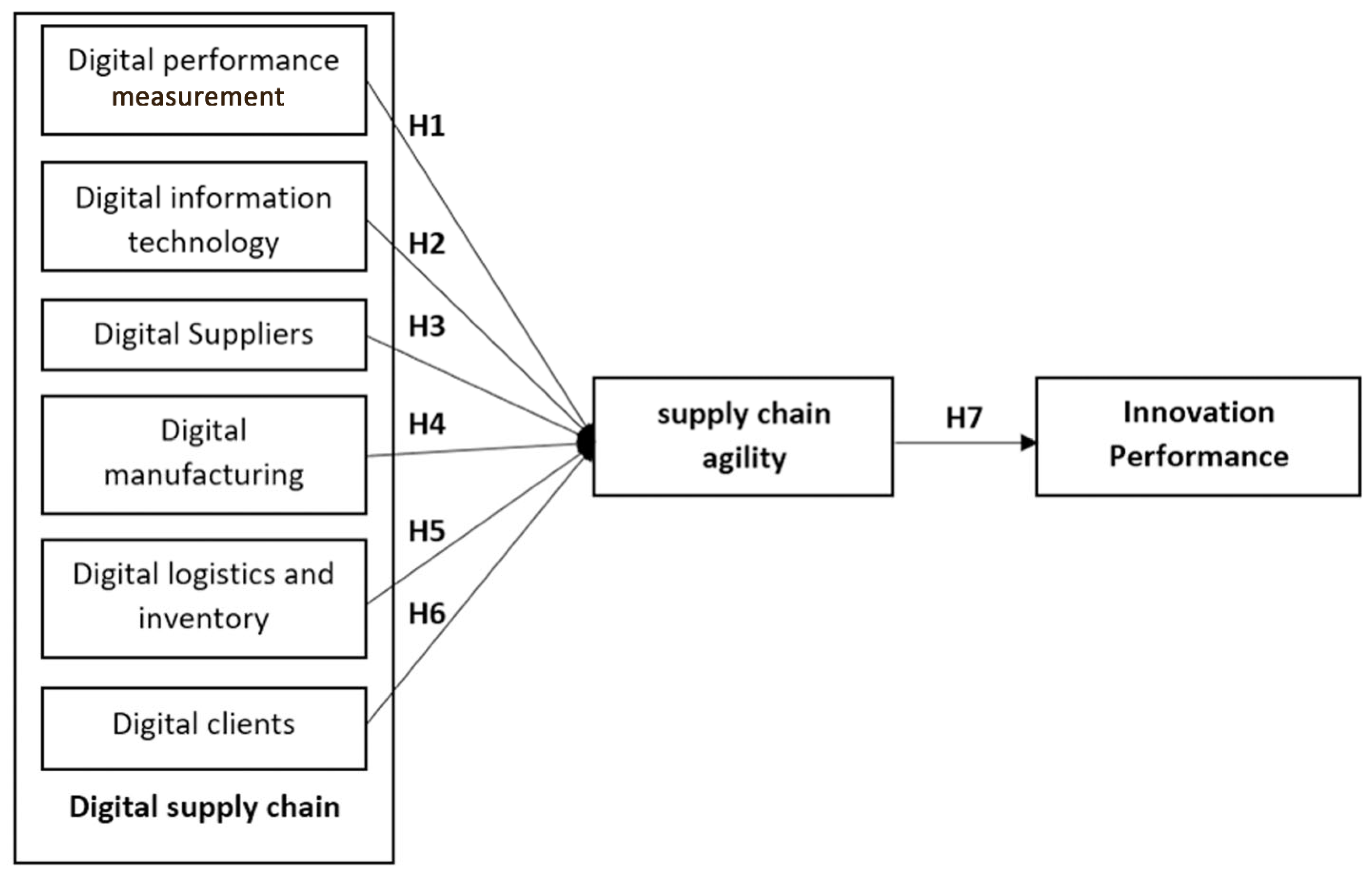

2.1. Conceptual Framework

2.1.1. Digital Supply Chain

2.1.2. Supply Chain Agility

2.1.3. Innovation Performance

2.2. Hypothesis Development

3. Research Methodology

3.1. Research Design

3.2. Sample and Data Collection

3.3. Measurement Instruments

4. Research Results

4.1. Descriptive Statistics

4.2. Assessment of Measurement Model

4.3. Direct Relation Analysis

4.4. Indirect Relation Analysis

5. Research Discussion and Limitation

5.1. Theoretical Implications

5.2. Practical Implications

5.3. Research Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ageron, B.; Bentahar, O.; Gunasekaran, A. Digital Supply Chain: Challenges and Future Directions. Supply Chain Forum Int. J. 2020, 21, 133–138. [Google Scholar] [CrossRef]

- Nowicka, K. Trust in Digital Supply Chain Management. Logist. Transp. 2018, 39, 59–64. [Google Scholar] [CrossRef]

- Alyasein, O.I.Y.; Ojha, D.; Sadeghi, R.K. Supply Chain Digitalization, Innovation Capability, and Organizational Agility: The Moderating Role of Institutionalization and Supply Chain Integration. Ind. Mark. Manag. 2025, 125, 215–225. [Google Scholar] [CrossRef]

- Rana, J.; Daultani, Y.; Goswami, M.; Kumar, S. Exploring the Impact of Supply Chain Digital Transformation on Supply Chain Performance: An Empirical Investigation. Bus. Strategy Environ. 2025, 34, 3497–3521. [Google Scholar] [CrossRef]

- Susitha, E.; Jayarathne, A.; Herath, R. Integrating Agility and Digital Capabilities: A New Paradigm for Competitive Supply Chain Performance in the Apparel Sector. J. Bus. Technol. 2024, 8, 65–98. [Google Scholar] [CrossRef]

- Wang, M.; Hill, A.; Liu, Y.; Hwang, K.; Lim, M.K. Supply Chain Digitalization and Agility: How Does Firm Innovation Matter in Companies? J. Bus. Logist. 2025, 46, e70007. [Google Scholar] [CrossRef]

- Wang, M.; Prajogo, D. The Effect of Supply Chain Digitalisation on a Firm’s Performance. Ind. Manag. Data Syst. 2024, 124, 1725–1745. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature Review and a Proposed Framework for Future Research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, Maturity and Research Agenda. Supply Chain Manag. Int. J. 2019, 25, 262–282. [Google Scholar] [CrossRef]

- Lisitsa, V.; Mykhaylenko, O.; Rotenberg, O. Digital Supply Chains: Technologies, Trends and Directions of Development. Black Sea Econ. Stud. 2023, 81, 99–106. [Google Scholar] [CrossRef]

- Farahani, P.; Meier, C.; Wilke, J. Digital Supply Chain Management Agenda for the Automotive Supplier Industry. In Shaping the Digital Enterprise: Trends and Use Cases in Digital Innovation and Transformation; Springer: Berlin/Heidelberg, Germany, 2017; pp. 157–172. ISBN 978-3-319-40966-5. [Google Scholar]

- Rahamneh, A.a.A.; Alrawashdeh, S.T.; Bawaneh, A.; Alatyat, Z.; Mohammad, A.; Al-Hawary, S. The Effect of Digital Supply Chain on Lean Manufacturing: A Structural Equation Modelling Approach. Uncertain Supply Chain Manag. 2023, 11, 391–402. [Google Scholar] [CrossRef]

- Fauzi, A.F.; Hendayani, R.; Iskamto, D. The Role of Supply Chain Capability as Mediation Between Digitalization and Digital Connectivity on Operational Performance. J. World Sci. 2023, 2, 1517–1528. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Liu, Q.; Cadden, T. Examining the Effects of Digital Supply Chain Practices on Supply Chain Viability and Operational Performance: A Practice-Based View. IEEE Trans. Eng. Manag. 2024, 71, 10413–10426. [Google Scholar] [CrossRef]

- Khan, K.U.; Atlas, F.; Ali, W.; Ghani, U.; Khan, F. The Nexus Between IT Capabilities and Firm Innovation Performance: The Mediating Effect of Supply Chain Agility. Sci. Technol. Soc. 2023, 28, 561–581. [Google Scholar] [CrossRef]

- Faturrahman, M.A.; Nursyamsiah, S. The Influence of Supply Chain Integration, Agility, and Innovation on Company Performance. Asian. J. Econ. Bus. Account. 2024, 24, 382–399. [Google Scholar] [CrossRef]

- Sunil, K. Supply Chain Innovation: The Core Capabilities Required and Expected Outcomes. J. Inf. Technol. Softw. Eng. 2019, 9, 256. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, S.; Fan, X.; Wang, S.; Shao, D. Green Supply Chain Integration, Supply Chain Agility and Green Innovation Performance: Evidence from Chinese Manufacturing Enterprises. Front. Environ. Sci. 2022, 10, 1045414. [Google Scholar] [CrossRef]

- Klaus, P. Towards Practical Relevance—Delivering Superior Firm Performance through Digital Customer Experience Strategies. Direct 2014, 15, 306–316. [Google Scholar] [CrossRef]

- Mihardjo, L.; Sasmoko, S.; Alamsjah, F. The Influence of Digital Customer Experience and Electronic Word of Mouth on Brand Image and Supply Chain Sustainable Performance. Uncertain Supply Chain Manag. 2019, 7, 691–702. [Google Scholar] [CrossRef]

- Agarwal, A.; Shankar, R.; Tiwari, M.K. Modeling Agility of Supply Chain. Ind. Mark. Manag. 2007, 36, 443–457. [Google Scholar] [CrossRef]

- Alzamendi-Ramirez, A.; Yoshida-Chiney, J.; Ramos-Palomino, E.; Mesia, R. Supply Chain Agility in Manufacturing Companies: A Literature Review. In Proceedings of the 2019 7th International Engineering, Sciences and Technology Conference (IESTEC), Panama, Panama, 9–11 October 2019; pp. 467–472. [Google Scholar] [CrossRef]

- Juneho, U. The Impact of Supply Chain Agility on Business Performance in a High Level Customization Environment. Oper. Manag. Res. 2017, 10, 10–19. [Google Scholar] [CrossRef]

- Chan, F.; Qi, H. An Innovative Performance Measurement Method for Supply Chain Management. Supply Chain Manag. 2003, 8, 209–223. [Google Scholar] [CrossRef]

- Barmuta, K.; Ivanova, E.; Orekhova, L.L. Measuring the Performance of Supply Chain Innovations. E3S Web Conf. 2022, 363, 01051. [Google Scholar] [CrossRef]

- Arabshahi, H.; Fazlollahtabar, H. Supply Chain Innovation Performance Evaluation Based on the Cross-Efficiency Concept: Case Study of Supply Chain Innovation Award’s Winners, Runner-Ups and Finalists. Int. J. Logist. Syst. Manag. 2020, 36, 343–369. [Google Scholar] [CrossRef]

- Chatterjee, S.; Mariani, M.; Ferraris, A. Digitalization of Supply Chain and Its Impact on Cost, Firm Performance, and Resilience: Technology Turbulence and Top Management Commitment as Moderator. IEEE Trans. Eng. Manag. 2024, 71, 10469–10484. [Google Scholar] [CrossRef]

- Ehie, I.; Ferreira, L.M.D.F. Conceptual Development of Supply Chain Digitalization Framework. IFAC-PapersOnLine 2019, 52, 2338–2342. [Google Scholar] [CrossRef]

- Ramos, E.; Patrucco, A.S.; Chavez, M. Dynamic Capabilities in the “New Normal”: A Study of Organizational Flexibility, Integration and Agility in the Peruvian Coffee Supply Chain. Supply Chain Manag. Int. J. 2023, 28, 55–73. [Google Scholar] [CrossRef]

- Roh, T.; Xiao, S. Extending the Research Agenda for Supply Chain Management in the Age of Disruption: The Multifaceted Role and Implications of Dynamic Capabilities. J. Gen. Manag. 2024, 50, 5–15. [Google Scholar] [CrossRef]

- Saputra, N. Bolstering Effect of Digital Capability on Firm Performance by Fostering Alliance Capability and Supply Chain Agility. In Proceedings of the 2024 International Conference on Information Management and Technology (ICIMTech), Bali, Indonesia, 28–29 August 2024; IEEE: New York, NY, USA; pp. 25–30. [Google Scholar]

- Garcia, F.; Grabot, B.; Paché, G. Creating and Sharing Interorganizational Knowledge Through a Supply Chain 4.0 Project: A Case Study. J. Glob. Inf. Manag. 2023, 31, 1–19. [Google Scholar] [CrossRef]

- Ma, C.; Gao, X.; Zhang, L.; Kang, W. Optimizing Timber Supply Chains: Exploring the Potential of Digital Collaboration. Sustainability 2024, 17, 15. [Google Scholar] [CrossRef]

- Danese, P.; Romano, P.; Formentini, M. The Impact of Supply Chain Integration on Responsiveness: The Moderating Effect of Using an International Supplier Network. Transp. Res. Part E Logist. Transp. Rev. 2013, 49, 125–140. [Google Scholar] [CrossRef]

- Landel, R. Coordination Module: Managing Supply Chains. SSRN Electron. J. 2017, 1–2. [Google Scholar] [CrossRef]

- Tazvivinga, K.; Samuels, A. Digital Transformation and Its Role in FMCG Supply Chain Resilience. Int. J. Bus. Ecosyst. Strategy 2687-2293 2024, 6, 23–38. [Google Scholar] [CrossRef]

- Jiang, F.; Isa, F.M.; Ng, S.P.; Bhatti, M. The Impact of Supply Chain Integration to Supply Chain Responsiveness in Chinese Electronics Manufacturing Companies. Sage Open 2023, 13, 21582440231219070. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, Y.; You, L. Research on the Impact of Supply Chain Integration on Supply Chain Resilience in NEV Manufacturing Enterprises. Sustainability 2024, 16, 8546. [Google Scholar] [CrossRef]

- He, Y.; Zheng, S.; Yuan, L. Dynamics of Fractional-Order Digital Manufacturing Supply Chain System and Its Control and Synchronization. Fractal Fract. 2021, 5, 128. [Google Scholar] [CrossRef]

- Lin, D.; Li, M.; Zhan, Q.; Song, X.; Yang, Y.; Li, H. Application of Intelligent Logistics Inventory Optimization Algorithm Based on Digital Supply Chain. Int. J. Emerg. Electr. Power Syst. 2023, 24, 61–72. [Google Scholar] [CrossRef]

- Khastoo, M.; Dori, B.; Raad, A. Impact of Agility Capabilities in the Supply Chain Network. Int. J. Sci. Study 2017, 5, 47–56. [Google Scholar]

- Hassani, Y.; Ceauşu, I.; Iordache, A. Lean and Agile Model Implementation for Managing the Supply Chain. Proc. Int. Conf. Bus. Excell. 2020, 14, 847–858. [Google Scholar] [CrossRef]

- Pasupuleti, V.; Thuraka, B.; Kodete, C.S.; Malisetty, S. Enhancing Supply Chain Agility and Sustainability through Machine Learning: Optimization Techniques for Logistics and Inventory Management. Logistics 2024, 8, 73. [Google Scholar] [CrossRef]

- Chen, Y.; Li, B.; Huo, B. Building Operational Resilience through Digitalization: The Roles of Supply Chain Network Position. Technol. Forecast. Soc. Change 2025, 211, 123918. [Google Scholar] [CrossRef]

- Sharma, A. Role of Digitalization in Improving Supply Chain Management: A Quantitative Investigation. Inf. Technol. Ind. 2018, 6, 57–61. [Google Scholar] [CrossRef]

- Mohaghegh, M.; Blasi, S.; Russo, I.; Baldi, B. Digital Transformation and Sustainable Performance: The Mediating Role of Triple-A Supply Chain Capabilities. J. Bus. Ind. Mark. 2024, 1–15. [Google Scholar] [CrossRef]

- Teece, D.; Peteraf, M.A.; Leih, S. Dynamic Capabilities and Organizational Agility: Risk, Uncertainty and Entrepreneurial Management in the Innovation Economy. SSRN Electron. J. 2016, 58, 13–35. [Google Scholar] [CrossRef]

- Benitez, J.; Arenas, A.; Castillo, A.; Esteves, J. Impact of Digital Leadership Capability on Innovation Performance: The Role of Platform Digitization Capability. Inf. Manag. 2022, 59, 103590. [Google Scholar] [CrossRef]

- Usai, A.; Fiano, F.; Messeni Petruzzelli, A.; Paoloni, P.; Farina Briamonte, M.; Orlando, B. Unveiling the Impact of the Adoption of Digital Technologies on Firms’ Innovation Performance. J. Bus. Res. 2021, 133, 327–336. [Google Scholar] [CrossRef]

- Wong, K. Partial Least Squares Structural Equation Modeling (PLS-SEM) Techniques Using SmartPLS. Mark. Bull. 2013, 24, 1–32. [Google Scholar]

- Najmi, A.; Makui, A. A Conceptual Model for Measuring Supply Chain’s Performance. Prod. Plan. Control 2012, 23, 694–706. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital Supply Chain Model in Industry 4.0. J. Manuf. Technol. Manag. 2019, 31, 887–933. [Google Scholar] [CrossRef]

- Zou, P.; Zhang, H. A Measurement Model for Collaboration between Suppliers and Manufacturers. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011; IEEE: New York, NY, USA; pp. 529–533. [Google Scholar]

- Ahmad Amouei, M.; Valmohammadi, C.; Fathi, K. Developing and Validating an Instrument to Measure the Impact of Digital Supply Chain Activities on Sustainable Performance. J. Enterp. Inf. Manag. 2023, 36, 925–951. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R. Logistics Capabilities Measurement in the Fractal Supply Network. Int. J. Logist. Syst. Manag. 2020, 36, 251. [Google Scholar] [CrossRef]

- Faisal, M.N.; Banwet, D.K.; Shankar, R. An Approach to Measure Supply Chain Agility. Int. J. Ind. Syst. Eng. 2007, 2, 79. [Google Scholar] [CrossRef]

- Li, X.; Goldsby, T.J.; Holsapple, C.W. Supply Chain Agility: Scale Development. Int. J. Logist. Manag. 2009, 20, 408–424. [Google Scholar] [CrossRef]

- Maharaja, R.; Devadasan, S.R.; Sakthivel, M.; Murugesh, R. Performance Measurement of the Leagile Supply Chain. Int. J. Serv. Oper. Manag. 2018, 31, 396. [Google Scholar] [CrossRef]

- Das, D. Development and Validation of a Scale for Measuring Sustainable Supply Chain Management Practices and Performance. J. Clean. Prod. 2017, 164, 1344–1362. [Google Scholar] [CrossRef]

- Abourokbah, S.H.; Mashat, R.M.; Salam, M.A. Role of Absorptive Capacity, Digital Capability, Agility, and Resilience in Supply Chain Innovation Performance. Sustainability 2023, 15, 3636. [Google Scholar] [CrossRef]

- Zhou, F.; Xu, S. How Digitalization and Information Technology Adoption Affect Firms’ Innovation Performance: Evidence from Chinese Automotive Firms. Eur. J. Innov. Manag. 2024. [Google Scholar] [CrossRef]

- Jermsittiparsert, K.; Rungsrisawat, S. Impact Strategic Sourcing, Supplier Innovativeness, and Information Sharing on Supply Chain Agility. Humanit. Soc. Sci. Rev. 2019, 7, 132–140. [Google Scholar] [CrossRef]

- Kim, M.; Chai, S. The Impact of Supplier Innovativeness, Information Sharing and Strategic Sourcing on Improving Supply Chain Agility: Global Supply Chain Perspective. Int. J. Prod. Econ. 2017, 187, 42–52. [Google Scholar] [CrossRef]

- Panichakarn, B.; Pochan, J.; Shafiq, M.; Saleem, I.; Wang, Y.; Nazeer, S. The Interplay of Digital Transformation, Agility, Environmental Volatility, and Innovation to Spur Enterprise Performance: Evidence from Chinese Electric Vehicle Firms. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100408. [Google Scholar] [CrossRef]

- DeGroote, S.E.; Marx, T.G. The Impact of IT on Supply Chain Agility and Firm Performance: An Empirical Investigation. Int. J. Inf. Manag. 2013, 33, 909–916. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N. Achieving Supply Chain Agility through IT Integration and Flexibility. Int. J. Prod. Econ. 2008, 116, 288–297. [Google Scholar] [CrossRef]

- Tuominen, T.; Kitaygorodskaya, N.; Helo, P. Achieving Agility in Supply Chains with the Help of IT. Int. J. Electron. Cust. Relatsh. Manag. 2008, 1, 374. [Google Scholar] [CrossRef]

- Aninda, N.; Karyani, E. Supply Chain Digitalization and Operational Performance. Int. J. Asian Bus. Inf. Manag. 2022, 13, 1–16. [Google Scholar] [CrossRef]

- Ivanov, D.; Das, A.; Choi, T.-M. New Flexibility Drivers for Manufacturing, Supply Chain and Service Operations. Int. J. Prod. Res. 2018, 56, 3359–3368. [Google Scholar] [CrossRef]

- Najat, T.; Alaa Eddine, E.M. Digitalization and Business Automation for an Effective Supply Chain Integration: A Literature Review. In Proceedings of the 2024 IEEE 15th International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Sousse, Tunisia, 2–4 May 2024; IEEE: New York, NY, USA; pp. 1–7. [Google Scholar]

- Martinez-Sanchez, A.; Lahoz-Leo, F. Supply Chain Agility: A Mediator for Absorptive Capacity. Balt. J. Manag. 2018, 13, 264–278. [Google Scholar] [CrossRef]

| Research Constructs | References for Measurement Items Development | |

|---|---|---|

| Digital supply chain | Digital performance measurement | [7,8,45,51] |

| Digital information technology | [7,8,52] | |

| Digital suppliers | [7,8,53] | |

| Digital manufacturing | [8,47,54] | |

| Digital logistics and inventory | [7,8,55] | |

| Digital clients | [7,8] | |

| Supply chain agility | [56,57,58] | |

| Innovation performance | [26,27,59] | |

| Attributes | Characteristics | Number of Responses | Percentage |

|---|---|---|---|

| Respondent characteristics | Male | 366 | 57.73% |

| Female | 268 | 42.27% | |

| Total | 634 | 100% | |

| Age | 25–35 years | 200 | 31.55 |

| 35–45 years | 230 | 36.28 | |

| 45–55 years | 150 | 23.66 | |

| >55 years | 54 | 8.52 | |

| Total | 634 | 100% | |

| Sector | Agri-food sector | 211 | 33.28 |

| Textile | 169 | 26.66 | |

| Automotive industry | 150 | 23.66 | |

| Aerospace industry | 36 | 5.68 | |

| Other | 68 | 10.73 | |

| Total | 634 | 100% |

| Constructs | Loadings | CA | CR | AVE | Constructs | Loadings | CA | CR | AVE |

|---|---|---|---|---|---|---|---|---|---|

| Digital clients | 0.823 | 0.859 | 0.648 | Digital manufacturing | 0.867 | 0.895 | 0.716 | ||

| DC1 | 0.815 | DM1 | 0.871 | ||||||

| DC2 | 0.893 | DM2 | 0.725 | ||||||

| DC3 | 0.716 | DM3 | 0.893 | ||||||

| DC4 | 0.786 | DM4 | 0.883 | ||||||

| Digital information technology | 0.802 | 0.900 | 0.716 | Digital performance measurement | 0.863 | 0.866 | 0.785 | ||

| DIT1 | 0.939 | DPM1 | 0.888 | ||||||

| DIT2 | 0.765 | DPM2 | 0.869 | ||||||

| DIT3 | 0.824 | DPM3 | 0.901 | ||||||

| Digital logistics and inventory | 0.716 | 0.774 | 0.635 | Digital suppliers | 0.874 | 0.892 | 0.726 | ||

| DLI1 | 0.896 | DS1 | 0.891 | ||||||

| DLI2 | 0.727 | DS2 | 0.789 | ||||||

| DLI3 | 0.757 | DS3 | 0.884 | ||||||

| DS4 | 0.840 | ||||||||

| Innovation performance | 0.874 | 0.914 | 0.731 | Supply chain agility | 0.941 | 0.943 | 0.811 | ||

| IP1 | 0.939 | SCA1 | 0.890 | ||||||

| IP2 | 0.673 | SCA2 | 0.909 | ||||||

| IP3 | 0.894 | SCA3 | 0.866 | ||||||

| IP4 | 0.888 | SCA4 | 0.933 | ||||||

| SCA5 | 0.903 |

| DC | DIT | DLI | DM | DPM | DS | IP | SCA | |

| Digital Clients | ||||||||

| Digital Information Technology | 0.494 | |||||||

| Digital Logistics and Inventory | 0.498 | 0.213 | ||||||

| Digital Manufacturing | 0.880 | 0.553 | 0.493 | |||||

| Digital Performance Measurement | 0.379 | 0.873 | 0.161 | 0.411 | ||||

| Digital Suppliers | 0.822 | 0.512 | 0.441 | 0.842 | 0.373 | |||

| Innovation Performance | 0.266 | 0.832 | 0.072 | 0.254 | 0.806 | 0.242 | ||

| Supply Chain Agility | 0.236 | 0.650 | 0.181 | 0.234 | 0.715 | 0.248 | 0.648 |

| Hypotheses | Relationships | Findings | Results | Adjusted R2 |

|---|---|---|---|---|

| H1 | DC → SCA | p > 0.05, β = 0.013 | Not supported | - |

| H2 | DIT → SCA | p < 0.05, β = 0.199 | Supported | - |

| H3 | DLI → SCA | p < 0.05, β = 0.087 | Supported | - |

| H4 | DM → SCA | p < 0.05, β = −0.122 | Supported | - |

| H5 | DPM → SCA | p < 0.05, β = 0.499 | Supported | - |

| H6 | DS → SCA | p > 0.05, β = 0.025 | Not supported | 0.430 |

| H7 | SCA → IP | p < 0.05, β = 0.600 | Supported | 0.359 |

| Hypotheses | Independent Variable | Mediator | Dependent Variable | Std. Beta | T-Value | p-Value | Decision |

|---|---|---|---|---|---|---|---|

| H7 | DC | Supply chain agility | IP | 0.008 | 0.263 | p > 0.05 | Not supported |

| H7 | DIT | Supply chain agility | IP | 0.119 | 3.226 | p < 0.05 | Supported |

| H7 | DLI | Supply chain agility | IP | 0.052 | 2.765 | p < 0.05 | Supported |

| H7 | DM | Supply chain agility | IP | −0.073 | 2.351 | p < 0.05 | Supported |

| H7 | DPM | Supply chain agility | IP | 0.299 | 8.041 | p < 0.05 | Supported |

| H7 | DS | Supply chain agility | IP | 0.015 | 0.532 | p > 0.05 | Not supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmouhib, S.; Idrissi, Z.Y. Agility in the Digital Era: Bridging Transformation and Innovation in Supply Chains. Sustainability 2025, 17, 3462. https://doi.org/10.3390/su17083462

Elmouhib S, Idrissi ZY. Agility in the Digital Era: Bridging Transformation and Innovation in Supply Chains. Sustainability. 2025; 17(8):3462. https://doi.org/10.3390/su17083462

Chicago/Turabian StyleElmouhib, Soufiane, and Zineb Youbi Idrissi. 2025. "Agility in the Digital Era: Bridging Transformation and Innovation in Supply Chains" Sustainability 17, no. 8: 3462. https://doi.org/10.3390/su17083462

APA StyleElmouhib, S., & Idrissi, Z. Y. (2025). Agility in the Digital Era: Bridging Transformation and Innovation in Supply Chains. Sustainability, 17(8), 3462. https://doi.org/10.3390/su17083462