Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Status Quo of Austrian WWTPs

| Size Category (PE) | Amount of WWTPs with Aerobic Sludge Stabilization | Amount of WWTPs with Anaerobic Sludge Stabilization | Total Amount of WWTPs |

|---|---|---|---|

| 2000–5000 | 246 | 3 | 249 |

| 5001–50,000 | 216 | 104 | 320 |

| 50,001–150,000 | 10 | 37 | 47 |

| >150,000 | 2 | 14 | 16 |

| TOTAL | 474 | 158 | 632 |

2.2. Spatial Contexts of WWTPs

- “continuous urban fabric” is mostly characterized by built structures and transport infrastructure with little coverage of vegetation and bare soils;

- “discontinuous urban fabric” includes both built structures as well as vegetated areas and bare soil with discontinuous, but significant shares on the land coverage;

- “industrial or commercial units” are defined as built environments with a small share of vegetated areas.

- (1)

- WWTPs “within the settlement” are located in a distance of up to 150 m to the nearest spot of at least one of the considered land cover classes, which cover an area of at least 25 hectares within the 1000 m radius around the WWTP.Figure 2. Example of a WWTP in size category 1 within the settlement area.

- (2)

- WWTPs situated “near to settlement” are characterized by an essential share of the circular area covered by at least one of the considered land cover classes with a minimum amount of 25 hectares in a radius between 150 m and 1000 m around the WWTP.Figure 3. Example of a WWTP in size category 3 near to the settlement area.

- (3)

- WWTPs situated “far from the settlement” do not contain significant shares of areas in the considered land cover categories within the 1000 m radius around the WWTP site.Figure 4. Example of a WWTP in size category 2 far from the settlement area.

| Sludge Treatment | Size Category | Spatial Context | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A | within the settlement | B | near to the settlement | C | far from the settlement | Sum | |||

| Aerobic sludge stabilization | 0 | 2000–5000 PE | 77 | 74 | 95 | 246 | |||

| 1 | 5001–50,000 PE | 74 | 74 | 68 | 216 | ||||

| 2 | 50,001–150,000 PE | 3 | 3 | 4 | 10 | ||||

| 3 | >150,000 PE | 2 | 0 | 0 | 2 | ||||

| Sum | 156 | 151 | 167 | 474 | |||||

| Anaerobic sludge stabilization | 0 | 2000–5000 PE | 1 | 0 | 2 | 3 | |||

| 1 | 5001–50,000 PE | 50 | 24 | 30 | 104 | ||||

| 2 | 50,001–150,000 PE | 22 | 5 | 10 | 37 | ||||

| 3 | >150,000 PE | 9 | 2 | 3 | 14 | ||||

| Sum | 82 | 31 | 45 | 158 | |||||

| TOTAL | 238 | 182 | 212 | 632 | |||||

2.3. Classification of WWTP Energy Potentials

- “not suitable” (red): small WWTPs with a large distance to consumers;

- “conditionally suitable” (yellow): small to medium sized WWTPs where a case-by-case examination is needed to survey the potentials in detail;

- “suitable” (green): medium to large sized WWTPs, which very likely can be utilized for district heat supply.

| Size Category | Spatial Context | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | within the settlement | B | near to the settlement | C | far from the settlement | Sum | |||

| Amount of WWTPs | 0 | 2000–5000 PE | 78 | 74 | 97 | 249 | |||

| 1 | 5001–50,000 PE | 124 | 98 | 98 | 320 | ||||

| 2 | 50,001–150,000 PE | 25 | 8 | 14 | 47 | ||||

| 3 | >150,000 PE | 11 | 2 | 3 | 16 | ||||

| Sum | 238 | 182 | 212 | 632 | |||||

| suitable | conditionally suitable | not suitable | |||||||

2.4. Environmental LCIA

3. Results and Discussion

3.1. Thermal Energy Potential Recovered from Wastewater

- The specific thermal capacity of wastewater is calculated with the appropriate value of water (1.16 kWh/m3 × K).

- The average wastewater temperature in the heating period is estimated at 10 °C.

- The wastewater in the effluent will be cooled down to 5 °C, so that 5 K can be extracted.

| Size Category | Spatial Context | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | within the settlement | B | near to the settlement | C | far from the settlement | Sum | |||

| Heat power potential from wastewater (MW) (amount of WWTPs) | 0 | 2000–5000 PE | 8 (78) | 7 (74) | 8 (97) | 23 (249) | |||

| 1 | 5001–50,000 PE | 81 (124) | 41 (98) | 51 (98) | 173 (320) | ||||

| 2 | 50,001–150,000 PE | 54 (25) | 22 (8) | 32 (14) | 108 (47) | ||||

| 3 | >150,000 PE | 197 (11) | 12 (2) | 20 (3) | 229 (16) | ||||

| Sum | 340 (238) | 82 (182) | 111 (212) | 533 (632) | |||||

| Thermal energy from wastewater (GWh/a) (amount of WWTPs) | 0 | 2000–5000 PE | 45 (78) | 44 (74) | 48 (97) | 137 (249) | |||

| 1 | 5001–50,000 PE | 489 (124) | 244 (98) | 306 (98) | 1039 (320) | ||||

| 2 | 50,001–150,000 PE | 323 (25) | 134 (8) | 189 (14) | 646 (47) | ||||

| 3 | >150,000 PE | 1180 (11) | 69 (2) | 121 (3) | 1370 (16) | ||||

| Sum | 2037 (238) | 491 (182) | 664 (212) | 3192 (632) | |||||

| suitable | conditionally suitable | not suitable | |||||||

3.2. Thermal Energy Potential Recovered from Digester Gas Production

| Size Category | Spatial Context | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | within the settlement | B | near to the settlement | C | far from the settlement | Sum | |||

| Thermal energy supply from digester gas production (MWh/a) (amount of WWTPs) | 0 | 2000–5000 PE | 96 (1) | 0 (0) | 193 (2) | 289 (3) | |||

| 1 | 5001–50,000 PE | 33,107 (50) | 13,415 (24) | 17,319 (30) | 63,841 (104) | ||||

| 2 | 50,001–150,000 PE | 36,915 (22) | 13,420 (5) | 14,607 (10) | 64,942 (37) | ||||

| 3 | >150,000 PE | 77,409 (9) | 8242 (2) | 16,349 (3) | 102,000 (14) | ||||

| Sum | 147,527 (82) | 35,077 (31) | 48,468 (45) | 231,072 (158) | |||||

| Electric energy supply from digester gas production (MWh/a) (amount of WWTPs) | 0 | 2000–5000 PE | 48 (1) | 0 (0) | 96 (2) | 144 (3) | |||

| 1 | 5001–50,000 PE | 16,554 (50) | 6708 (24) | 8660 (30) | 31,922 (104) | ||||

| 2 | 50,001–150,000 PE | 18,458 (22) | 6710 (5) | 7303 (10) | 32,471 (37) | ||||

| 3 | >150,000 PE | 38,705 (9) | 4121 (2) | 8175 (3) | 51,001 (14) | ||||

| Sum | 73,765 (82) | 17,539 (31) | 24,234 (45) | 115,538 (158) | |||||

| suitable | conditionally suitable | not suitable | |||||||

3.3. Summary of the Thermal Energy Resource Potentials

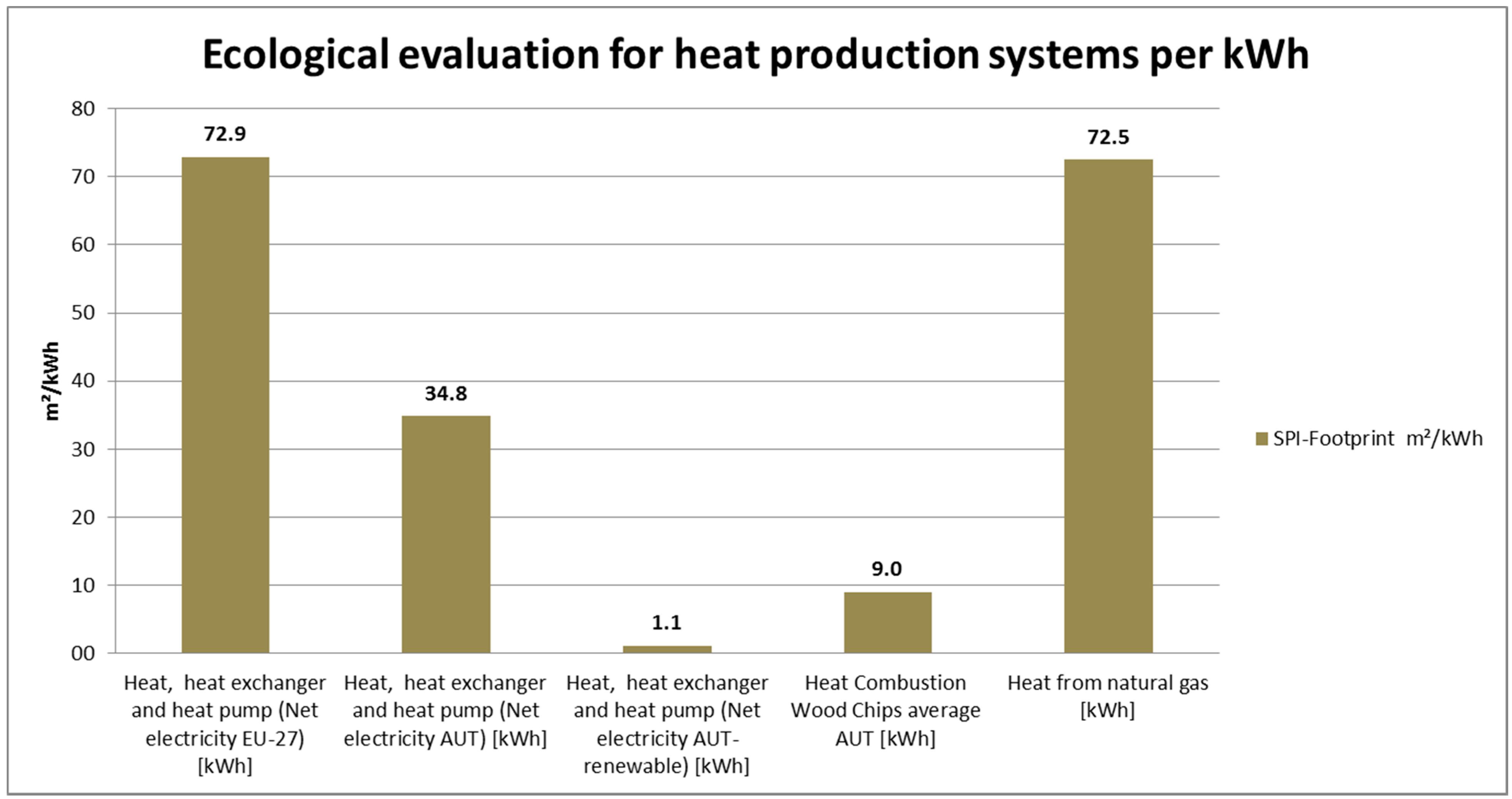

3.4. Environmental Evaluation of Wastewater Heat Recovery

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Culha, O.; Gunerhan, H.; Biyik, E.; Ekren, O.; Hepbasli, A. Heat exchanger applications in wastewater source heat pumps for buildings: A key review. Energy Build. 2015, 104, 215–232. [Google Scholar] [CrossRef]

- Mo, W.; Zhang, Q. Energy-nutrients-water nexus: Integrated resource recovery in municipal wastewater treatment plants. J. Environ. Manag. 2013, 127, 255–267. [Google Scholar] [CrossRef] [PubMed]

- Funamizu, N.; Iida, M.; Sakakura, Y.; Takakuwa, T. Reuse of heat energy in wastewater: Implementation examples in Japan. Water Sci. Technol. 2001, 43, 277–285. [Google Scholar] [PubMed]

- Bischofberger, T.; Lendi, B.; Thöny, A.; Bühler, H.; Dettli, R.; Bättig, M. Arbeitshilfe zur Erstellung einer Richtplanung Energie für Gemeinden des Kantons Graubünden (Guideline for the Elaboration of an Energy Structure Plan for Municipalities of the Canton Graubünden); Amt für Raumentwicklung Graubünden, Amt für Energie und Verkehr Graubünden: Chur, Switzerland, 2009; pp. 1–12. (In German) [Google Scholar]

- Hausladen, G.; Hamacher, T. Leitfaden Energienutzungsplan (Guideline Energy Use Plan); Bayerisches Staatsministerium für Umwelt und Gesundheit, Bayerisches Staatsministerium für Wirtschaft, Infrastruktur, Verkehr und Technologie, Oberste Baubehörde im Bayerischen Staatsministerium des Inneren: München, Germany, 2011. (In German) [Google Scholar]

- Bundesgesetz über die Steigerung der Energieeffizienz bei Unternehmen und dem Bund (Bundes-Energieeffizienzgesetz—EEffG), BGBl. I Nr. 72/2014 (Austrian Federal Law on the Increase of Energy Efficiency). Available online: http://www.ris.bka.gv.at/GeltendeFassung.wxe?Abfrage=Bundesnormen&Gesetzesnummer=20008914 (accessed on 14 May 2015).

- Frijns, J.; Hofman, J.; Nederlof, M. The potential of (waste) water as energy carrier. Energy Convers. Manag. 2013, 6, 357–363. [Google Scholar] [CrossRef]

- Meggers, F.; Leibundgut, H. The potential of wastewater heat and exergy: Decentralized high-temperature recovery with a heat pump. Energy Build. 2011, 43, 879–886. [Google Scholar] [CrossRef]

- Baber, C. Tapping into waste heat. Water Environ. Technol. 2010, 22, 40–45. [Google Scholar]

- Chae, K.-J.; Kang, J. Estimating the energy independence of a municipal wastewater treatment plant incorporating green energy resources. Energy Convers. Manag. 2013, 75, 664–672. [Google Scholar] [CrossRef]

- Wanner, O.; Panagiotidis, V.; Clavadetscher, P.; Siegrist, H. Effect of heat recovery from raw wastewater on nitrification and nitrogen removal in activated sludge plants. Water Res. 2005, 39, 4725–4734. [Google Scholar] [CrossRef] [PubMed]

- Dürrenmatt, D.; Wanner, O. A mathematical model to predict the effect of heat recovery on the wastewater temperature in sewers. Water Res. 2014, 48, 548–558. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Aal, M.; Mohamed, M.; Smits, R.; Abdel-Aal, R.E.; de Gussem, K.; Schellart, A.; Tait, S. Predicting wastewater temperatures in sewer pipes using abductive network models. Water Sci. Technol. 2015, 71, 89–96. [Google Scholar] [CrossRef]

- Koch, M.; Nietlisbach, A.; Känel, B.; Calderoni, M.; Wille, B.; Müller, R.; Bretscher, P.; Wanner, O.; Siegrist, H.; Peter, A.; et al. Heizen und Kühlen mit Abwasser—Leitfaden für die Planung, Bewilligung und Realisierung von Anlagen zur Abwasserenergienutzung (Heating and Cooling with Wastewater—Guideline for Planning, Permission and Realisation of Wastewater Energy Recovery Systems); Baudirektion Kanton Zürich, Amt für Abfall, Wasser, Energie und Luft des Kantons Zürich: Zürich, Switzerland, 2010. (In German) [Google Scholar]

- Haberkern, B.; Maier, W.; Schneider, U. Steigerung der Energieeffizienz auf Kommunalen Kläranlagen (Enhanced Energy Efficiency in Waste Water Treatment Plants); Federal Environmental Agency: Dessau-Roßlau, Germany, 2008; pp. 196–202. (In German)

- Lindtner, S. Leitfaden für die Erstellung Eines Energiekonzeptes Kommunaler Kläranlagen (Guideline for the Development of an Energy Concept for Municipal Wastewater Treatment Plants); Austrian Federal Ministry of Agriculture and Forestry, Environment and Water Management: Vienna, Austria, 2008; pp. 11–23. (In German)

- Kollmann, R.; Maier, S.; Shahzad, K.; Kretschmer, F.; Neugebauer, G.; Stoeglehner, G.; Ertl, T.; Narodoslawsky, M. Waste Water Treatment Plants as Regional Energy Cells—Evaluation of Economic and Ecologic Potentials in Austria. Chem. Eng. Trans. 2014, 39, 607–612. [Google Scholar]

- Kretschmer, F.; Neugebauer, G.; Kollmann, R.; Eder, M.; Zach, F.; Zottl, A.; Narodoslawsky, M.; Stoeglehner, G.; Ertl, T. Resource Recovery from Wastewater in Austria—Wastewater Treatment Plants as Regional Energy Cells. In Proceedings of the IWA World Water Congress and Exhibition, Lisbon, Portugal, 21–26 September 2014.

- Nowak, O.; Enderle, P.; Varbanov, P. Ways to optimize the energy balance of municipal wastewater systems: Lessons learned from Austrian applications. J. Clean. Prod. 2015, 88, 125–131. [Google Scholar] [CrossRef]

- Batstone, D.J.; Hülsen, T.; Mehta, C.M.; Keller, J. Platforms for energy and nutrient recovery from domestic wastewater: A review. Chemosphere 2015, 140, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Stillwell, A.; Hoppock, D.C.; Webber, M.E. Energy Recovery from Wastewater Treatment Plants in the United States: A Case Study of the Energy-Water Nexus. Sustainability 2010, 2, 945–962. [Google Scholar] [CrossRef]

- Kretschmer, F.; Weissenbacher, N.; Ertl, T. Integration of Wastewater Treatment Plants into Regional Energy Supply Concepts. Sustain. Sanit. Pract. 2015, 22, 4–9. [Google Scholar]

- Narodoslawsky, M.; Niederl-Schmidinger, A.; Halasz, L. Utilising renewable resources economically: New challenges and chances for process development. J. Clean. Prod. 2008, 16, 164–170. [Google Scholar] [CrossRef]

- Neugebauer, G.; Stoeglehner, G. Realising energy potentials from wastewater by integrating spatial and energy planning. Sustain. Sanit. Pract. 2015, 22, 15–21. [Google Scholar]

- Ochsner, K.; Adelberger, G.; Ertl, T.; Kretschmer, F.; Müller, E.A.; Penthor, A.; Zach, F. Energie aus Abwasser. Abwasser-Wärme- und Kältenutzung Mittels Hocheffizienter Großwärmepumpen (Energy from Wastewater. Heat and Cold Extraction from Wastewater Using High Efficiency Heat Pumps). Available online: https://www.klimafonds.gv.at/assets/Uploads/Blue-Globe-Reports/Erneuerbare-Energien/2012-2013/BGR0022013EEneueEnergien2020.pdf (accessed on 21 September 2015). (In German)

- Kind, E.; Levy, G.A. Energieeffizienz und Energieproduktion auf ARA (Energy Efficiency and Energy Generation at WWTP); Swiss Federal Office of the Environment: Bern, Switzerland, 2012. (In German) [Google Scholar]

- Müller, E.; Schmid, F.; Kobel, B.; Stadtmeister, W. Heizen und Kühlen mit Abwasser—Ratgeber für Bauträger und Kommunen (Heating and Cooling with Wastewater—Guideline for Building Project Organisers and Communities); Deutsche Bundesstiftung Umwelt, Bundesverband Wärmepumpen e.V., Institut für Energie in Infrastrukturanlagen: Osnabrück, Germany, 2009. [Google Scholar]

- Venkatesh, C.; Brattebø, H. Energy consumption, costs and environmental impacts for urban water cycle services: Case study of Oslo (Norway). Energy 2011, 36, 792–800. [Google Scholar] [CrossRef]

- Pandis Iveroth, S.; Vernay, A.L.; Mulder, K.F.; Brandt, N. Implications of systems integration at the urban level: The case of Hammarby Sjöstad, Stockholm. J. Clean. Prod. 2013, 48, 220–231. [Google Scholar] [CrossRef]

- Müller, E.; Kobel, B.; Graf, E.; Roth, Y.; Müller, K.; Billmaier, K.; Lambauer, J.; Makowezki, V.; Blesl, M.; Fahl, U. Untersuchungen der Voraussetzungen für Projekte zur Wärmerückgewinnung aus dem Abwasser (Investigations on the Conditions for Projects Using Heat Recovery from Wastewater); Institut Energie Infrastrukturanlagen: Winterthur, Switzerland, 2010. [Google Scholar]

- Müller, E.A.; Butz, J. Abwasserwärmenutzung in Deutschland: Aktueller Stand und Ausblick (Wastewater heat recovery in Germany: Current status and future prospects). KA Korresp. Abwasser Abfall 2010, 57, 437–442. (In German) [Google Scholar]

- Knüsel, P. Räumliche Energieplanung (Spatial energy planning). Raum Umw. 2011, 3, 1–24. (In German) [Google Scholar]

- Stoeglehner, G.; Niemetz, N.; Kettl, K.-H. Spatial dimensions of sustainable energy systems: New visions for integrated spatial and energy planning. Energy Sustain. Soc. 2011, 1. [Google Scholar] [CrossRef]

- Stoeglehner, G.; Baaske, W.; Mitter, H.; Niemetz, N.; Kettl, K.-H.; Weiss, M.; Lancaster, B.; Neugebauer, G. Sustainability appraisal of residential energy demand and supply—A life cycle approach including heating, electricity, embodied energy and mobility. Energy Sustain. Soc. 2014, 4. [Google Scholar] [CrossRef]

- Überreiter, E.; Stork, C.; Windhofer, G.; Zieritz, I. Kommunales Abwasser. Österreichischer Bericht 2014 (Communal Wastewater. Austrian Report 2014); Austrian Federal Ministry of Agriculture and Forestry, Environment and Water Management: Vienna, Austria, 2014. (In German)

- EmRegV-OW—Verordnung des Bundesministers für Land-und Forstwirtschaft, Umwelt und Wasserwirtschaft über ein elektronisches Register zur Erfassung aller wesentlichen Belastungen von Oberflächenwasserkörpern durch Emissionen von Stoffen aus Punktquellen (Regulation of the Federal Minister for Agriculture and Forestry, Environment and Water Management on a Electronic Register for Recording All Significant Surface Water Pollutions through Emissions of Substances from Point Sources), BGBL II 29/2009. Available online: http://www.ris.bka.gv.at/Dokumente/BgblAuth/BGBLA_2009_II_29/BGBLA_2009_II_29.html (accessed on 14 May 2015).

- BMLFUW, UBA—Austrian Federal Ministry of Agriculture and Forestry, Environment and Water Management, Environment Agency Austria. Position Coordinates, Treatment Capacities and Annual Runoff of Austrian Wastewater Treatment Plants, Data Status Council Directive 91/271/EEC Concerning Urban Wastewater Treatment—Austrian Report 2014. 2015; unpublished work. [Google Scholar]

- AEV für kommunales Abwasser—Verordnung des Bundesministers für Land-und Forstwirtschaft über die Begrenzung von Abwasseremissionen aus Abwasserreinigungsanlagen für Siedlungsgebiete (Order of the Federal Minister for Agriculture and Forestry on the limitation of wastewater emissions from wastewater treatment plants for settlement areas), BGBl. 210/1996. Available online: http://www.ris.bka.gv.at/GeltendeFassung.wxe?Abfrage=Bundesnormen&Gesetzesnummer=10010980 (accessed on 14 May 2015).

- Spatzierer, G. Nachbarschafts-und Kläranlagenliste (List of wastewater treatment plants and neighborhoods). In Kanal-und Kläranlagennachbarschaften; Folge 22; Austrian Water and Waste Management Association: Vienna, Austria, 2014. (In German) [Google Scholar]

- Communal Wastewater Treatment Plants. Available online: http://wisa.bmlfuw.gv.at/wasserkarten/sonstige_themen/kommunale_klaeranlagen.html (accessed on 28 May 2015).

- CORINE land cover 2012 for Austria. Available online: http://www.umweltbundesamt.at/umweltsituation/umweltinfo/opendata/oed_landbedeckung/ (accessed on 28 May 2015).

- European Commission Directorate General Joint Research Center; European Environment Agency. CORINE Land Cover Technical Guide; European Environment Agency: Copenhagen, Denmark, 1999. [Google Scholar]

- Buri, R.; Kobel, B. Energie aus Kanalabwasser. Leitfaden für Ingenieure und Planer. (Energy from Wastewater. Guideline for Engineers and Planners); Deutsche Bundesstiftung Umwelt: Osnabrück, Germany, 2005. (In German) [Google Scholar]

- Otter, P.; Raber, W.; Wichmann, K. Heizwerk Abwasser-Abwärme. Fachinformation für Aufbau und Betrieb des Heizwerks Abwasser-Abwärme. (Heating Plant Wastewater-Wasteheat. Subject Information for Developing and Operating the Heating Plant Wastewater-Wasteheat); Forschungsverbund, RePro—Ressourcen vom Land: Berlin, Germany, 2013. (In German) [Google Scholar]

- Bucar, G.; Schweyer, K.; Fink, C.; Riva, R.; Neuhäuser, M.; Meissner, E.; Streicher, W.; Halmdienst, C. Dezentrale erneuerbare Energie für bestehende Fernwärmenetze. Berichte Energy Umweltforsch. 2006, 78, 1–156. (In German) [Google Scholar]

- Wien Energie Blog. Unsere Kräftigsten Teil 3: Kraftwerk Donaustadt. Available online: http://blog.wienenergie.at/2013/04/15/unsere-kraftigsten-teil-3-kraftwerk-donaustadt/ (accessed on 1 April 2015).

- Bühler, R.; Gabathuler, H.R.; Mayer, H. Situationserfassung mit EXCEL-Tabelle. Qualitätsmanagement Holzheizwerke, Manual, Version 18.1. Available online: http://www.qmholzheizwerke.at/fileadmin/sites/qm/files/04_Situationserfassung/Situationserfassung_Manual_de.pdf (accessed on 14 May 2015).

- Narodoslawsky, M.; Stoeglehner, G. Planning for Local and Regional Energy Strategies with the Ecological Footprint. J. Environ. Policy Plan. 2010, 12, 363–379. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Sandin, G.; Clancy, G.; Heimersson, S.; Peters, G.M.; Svanström, M.; Ten Hoeve, M. Making the most of LCA in technical inter-organizational R&D projects. J. Clean. Prod. 2014, 70, 97–104. [Google Scholar]

- Narodoslawsky, M. From processes to life cycles to technology networks—New challenges for LCA in chemical engineering. Curr. Opin. Chem. Eng. 2013, 2, 282–285. [Google Scholar] [CrossRef]

- Cuček, L.; Klemes, J.J.; Kravanja, Z. A Review of Footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- ISO. ISO-Norm, Environmental Management—Life Cycle Assessment—Principles and Framework ISO 14040:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Kettl, K.-H. Evaluation of Energy Technology Systems Based on Renewable Resources. Ph.D. Thesis, Institute for Process and Particle Engineering, Graz University of Technology, Graz, Austria, 2012. [Google Scholar]

- Kettl, K.-H. SPIonWeb Advanced Sustainable Process Index, Calculation Software, Manual and Software Structure; Version 1.1; Graz University of Technology: Graz, Austria, 2013; pp. 1–30. Available online: http://spionweb.tugraz.at/SPIonWeb_Manual_eng.pdf (accessed on 28 May 2015).

- SPIonWeb (Sustainable Process Index on Web). Available online: http://spionweb.tugraz.at (accessed on 14 May 2015).

- BMWFW—Austrian Federal Ministry of Science, Research and Economy. Energiestatus Österreich 2014 (Energy Status Quo Austria 2014); BMWFW: Vienna, Austria, 2014. Available online: http://www.bmwfw.gv.at/EnergieUndBergbau/Energieeffizienz/PublishingImages/Energiestatus%20%C3%96sterreich%202014_HP-Version.pdf (accessed on 28 May 2015).

- Wett, B.; Bucher, K.; Fimml, C. Energy self-sufficiency as a feasible concept for wastewater treatment systems. Asian Water 2007, 9, 22–25. [Google Scholar]

- Olsen, P.K.; Lambertsen, H.; Hummelshøj, R.; Bøhm, B.; Christiansen, C.H.; Svendsen, S.; Larsen, C.T.; Worm, J. A New Low-Temperature District Heating System for Low-Energy Buildings. In Proceedings of the 11th International Symposium on District Heating and Cooling, Reykjavik, Iceland, 31 August–2 September 2008.

- Bucar, G.; Schinnerl, D. Technisches und Wirtschaftliches Marktpotenzial der Wärmeenergienutzung aus dem Abwasser in Österreich—Gesamtanalyze für Österreich und Spezifische Analyze Fuer zwei Unterschiedliche Gemeinden (Technical and Economic Market Potential of Heat Extraction from Wastewater in Austria—Overall Analysis for Austria and Specific Analysis for Two Different Communities); Grazer Energieagentur GmbH: Graz, Austria, 2007. [Google Scholar]

- Dehoust, G.; Mehlhardt, G.; Vogt, R.; Otter, P. Ausgewählte Klimaschutzpotenziale der Abwasserwirtschaft. Wärmepotenzial aus Abwasser. Potenzial der Faulgasnutzung (Selected Climate Protection Potentials of the Wastewater Management Industry. Heat Potential from Wastewater. Potential of Digester Gas Utilization); Institut für angewandte Ökologie: Darmstadt, Germany; Institut für Energie-und Umweltforschung: Heidelberg, Germany, 2010. [Google Scholar]

- Anderl, M.; Bednar, W.; Gössl, M.; Haider, S.; Heller, C.; Jobstmann, H.; Lampert, C.; Moosmann, L.; Pazdernik, K.; Poupa, S.; et al. Klimaschutzbericht 2014 (Climate Protection Report 2014); Environment Agency Austria: Vienna, Austria, 2014.

- Ergebnisse Industriegaspreise (Industrial Gas Prices). Available online: http://www.e-control.at/de/industrie/gas/gaspreis/industriegaspreise/energiepreis (accessed on 29 May 2015).

- Biermayr, P. Erneuerbare Energie in Zahlen. Die Entwicklung Erneuerbarer Energie in Österreich im Jahr 2013. (Renewable Energy in Figures. Development of Renewable Energy in Austria in 2013); Bundesministerium für Land- und Forstwirtschaft, Umwelt und Wasserwirtschaft: Vienna, Austria, 2014. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neugebauer, G.; Kretschmer, F.; Kollmann, R.; Narodoslawsky, M.; Ertl, T.; Stoeglehner, G. Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants. Sustainability 2015, 7, 12988-13010. https://doi.org/10.3390/su71012988

Neugebauer G, Kretschmer F, Kollmann R, Narodoslawsky M, Ertl T, Stoeglehner G. Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants. Sustainability. 2015; 7(10):12988-13010. https://doi.org/10.3390/su71012988

Chicago/Turabian StyleNeugebauer, Georg, Florian Kretschmer, René Kollmann, Michael Narodoslawsky, Thomas Ertl, and Gernot Stoeglehner. 2015. "Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants" Sustainability 7, no. 10: 12988-13010. https://doi.org/10.3390/su71012988

APA StyleNeugebauer, G., Kretschmer, F., Kollmann, R., Narodoslawsky, M., Ertl, T., & Stoeglehner, G. (2015). Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants. Sustainability, 7(10), 12988-13010. https://doi.org/10.3390/su71012988