1. Introduction

Extensive research has been conducted to improve the energy efficiency of domestic and non-domestic buildings in countries with cold or moderate climates where space heating dominates the energy requirements. The attention is gradually shifting towards tropical climates where cooling governs the energy requirements; however, very little has been done on the low-income tropical housing where operational energy for space heating and/or cooling (excluding cooking and hot water) is negligible. Embodied energy, in contrast, is the key factor for improving the energy efficiency of low-income houses in tropical climates. According to Cabeza

et al. [

1], almost all available studies in the area of Life Cycle Assessment (LCA) and embodied energy have been carried out in developed countries, and there are no case studies in African countries. Ramesh

et al. [

2] also mention that most available studies on LCA are from “cold countries” where space heating is the major concern. There is therefore a clear gap in the literature regarding the environmental impacts and embodied energy of construction methods and materials in African countries.

Located in East Africa, Uganda is one of the developing countries with a moderate tropical climate [

3,

4] and a high rate of low-income housing. Around 38% of Uganda’s population live below the international poverty line [

5,

6] and over 60% [

7] of the Ugandan urban population live in slums with poor quality and hygiene conditions. According to the UN-Habitat, 6 million Ugandan households live in 4.5 million residential units, which means an average occupancy density of around 1.3 families per dwelling. The conditions are more critical for slum residents, the majority of whom live in single-room rented properties [

8]. The main fuel sources for cooking and lighting in Uganda are wood fuel and paraffin, respectively. Access to electricity is very limited particularly in rural areas. In 2011, for instance, less than 15% (5.3% in rural areas and 55.4% in urban areas) of the households had access to electricity [

9].

The housing conditions in Uganda have been deteriorating due to the lack of proper building regulations and the absence of authorities to enforce minimum housing standards [

10]. The failure of the country to adopt low-cost building technologies [

10] to deal with low-income housing has also been contributing to the current situation. Introducing new and innovative construction methods and materials which are adapted to local needs and conditions may improve the current conditions. It should be noted, however, that innovation is an evolutionary process, and it is not correct to assume that replacing the current construction methods and materials with new highly efficient, and possibly, more expensive ones would improve the current conditions. The experience has shown that ignoring the current conditions, potentials and limitations of developing countries may result in the failure of an innovation [

11].

Increasing use of low quality, energy intensive, locally produced materials (e.g., burned bricks) and gradual shift from environmentally friendly materials (e.g., adobe; thatched roof) towards environmentally harmful ones (e.g., concrete; iron sheet roof) are the other major issues which have led to an alarming situation that requires urgent attention. The current situation has negatively affected the local environment contributing to issues such as deforestation, desertification, air pollution, excessive agricultural soil extractions, food and fuel crisis, and health issues in the country [

12,

13]. It is obvious that the current situation could lead to social and environmental disasters if no positive action is taken to improve the conditions.

Life cycle assessment is a method of evaluating environmental impacts of buildings during their lifetime from the extraction of raw material though to demolition and disposal [

14,

15]. According to BS EN 15978:2011, the main stages in building life cycle assessment are as follows [

16]:

- (1)

Production stage;

- (2)

Construction;

- (3)

Use stage; and

- (4)

End of life stage.

The production stage consists of three stages of (a) material supply; (b) transport; and (c) manufacturing [

16]. Raw material extraction and its impact on the environment as well as manufacturing and waste are some of the key assessment criteria in LCA. The CO

2 emissions from fossil fuels during extraction and the manufacturing process of construction materials form the majority of the embodied energy/carbon of building products [

14]. The latter is, in fact, the major issue associated with Ugandan low-income housing that suffers from excessive energy and material waste during production and handling processes of construction materials.

Although operating energy accounts for a much higher portion of CO

2 and greenhouse gas emissions during the building lifecycle [

2,

15,

17] (75%–90% operational compared to 10%–25% embodied carbon [

14]), due to the negligible operational energy in Ugandan low-income housing, the embodied energy of building materials is key to evaluating the environmental impacts of the low-income housing sector. To this end, this research intends to evaluate the current conditions of Ugandan low-income housing in order to highlight the environmental damages and embodied energy of construction methods and materials as well as the key areas which should be addressed to improve the conditions and mitigate the environmental impacts of prevailing methods of construction in Uganda.

2. Methodology

Literature review, and primary data gathered from site visits and photographic surveys are the main methods of data collection for this paper. Relevant documents published by individual researchers, Ugandan Government, UN-Habitat and other research organisations were reviewed. Site visits and photographic surveys were also carried out in two East African countries (Uganda and Tanzania) to collect relevant information on prevailing construction methods and materials and on their environmental impacts in rural areas. Both countries have similar construction methods and the included pictures in this document are from either Uganda or Tanzania. The outcomes of the literature review along with the surveys are used to evaluate the current conditions of low-income housing in rural areas. The embodied energy values of walling methods and materials are also calculated and compared with standard construction methods using the available data in the “Embodied Carbon: The Inventory of Carbon and Energy” [

18]. The key factors for improving energy efficiency and reducing the environmental impacts of the low-income housing sector are highlighted and recommendations are provided as the conclusion of this paper.

3. Construction and Housing Conditions

The construction industry is one of the key sectors of Ugandan economy. Different sources suggest different GDP shares for the construction industry in Uganda. According to Oling

et al. [

19], the share of the construction industry in Uganda increased from 13.4% in 2008 to 14.6% of GDP in 2012. This is while, according to Uganda Bureau of Statistics [

20], the share of the construction industry in 2011 was 13.1% (

Figure 1) showing an increase of 0.8% over 2008 figures. Nevertheless, housing shortages are a major issue facing the Ugandan construction industry. The housing shortages in 2005/6 and 2010 were estimated to be 560,000 [

21] and 612,000 [

10] units, respectively. The housing deficit is estimated to rise to around 885,000 by 2020 and eight million units by 2040, one million of which would be in Kampala [

21].

Figure 1.

Ugandan Economy in 2011 (%). Source of table: [

20].

Figure 1.

Ugandan Economy in 2011 (%). Source of table: [

20].

Housing developers in Uganda follow the market forces rather than the country’s actual requirements in terms of affordability [

22]. The increasing gap between the supply and what people can afford has pushed the prices up and has forced many people out of the housing market resulting in more demand for rental housing. In 2009/10, for instance, 18% of the population were renting their properties. The situation is more critical in urban areas as, for example, around 70% of households in Kampala live in rental properties [

23]. Moreover, incremental self-building by both poor and wealthy people [

8], in addition to the lack of quality controls by the authorities [

10], have resulted in poor housing quality and have made the housing industry less attractive to potential investors [

21]. The situation is more critical in rural areas where the share of good quality housing is much less than in the urban areas [

21].

Figure 2 shows the most common types of housing and tenancy types in Uganda in 2009/2010.

Figure 2.

Types of dwelling and tenure in Uganda (2009/2010). Source of table: [

23].

Figure 2.

Types of dwelling and tenure in Uganda (2009/2010). Source of table: [

23].

Overcrowding is another major issue in Uganda. The average number of occupants in many houses, particularly in urban areas, is more than the international standards of two persons per room [

4]. The national average household size in 2011 was 4.9 [

9] and the average number of occupants per room in 2009/2010 was 2.9 persons [

23]. According to the Uganda National Household Survey 2009/2010, 33% of Ugandan families use two rooms for sleeping and 44% use only one room [

23]. The situation is more critical in Kampala where around 70% of houses use only one room for sleeping.

Figure 3 and

Figure 4 summarise the average number of bedrooms, household size and sleeping occupants in each room in different regions of Uganda in 2009/2010.

Figure 3.

Average number of bedrooms (2009/2010–2011). Source of table: [

9,

23].

Figure 3.

Average number of bedrooms (2009/2010–2011). Source of table: [

9,

23].

Figure 4.

Average household size and sleeping occupants in each room (2009/2010–2011). Source of table: [

9,

23].

Figure 4.

Average household size and sleeping occupants in each room (2009/2010–2011). Source of table: [

9,

23].

4. Construction Methods and Materials

The major limitations of the construction industries in African countries are high costs and limited access to good quality materials whether imported or produced locally. Moreover, due to the weak transportation infrastructure and limited access to urban factories, particularly in rural areas, material supply cannot cope with the high housing demand [

24]. Using locally available materials seems to be an appropriate solution which has already been considered in many parts of Uganda.

Figure 5 shows the main construction materials in 2009/2010 in Uganda. Brick and mud and poles are the two most common walling materials/methods in Uganda. Brick walling is the most common system in both urban and rural areas; however, mud and poles walls are much more common in rural than in urban areas. The walling methods are explained in more detail in the following sections.

Figure 5.

Main types of construction materials in 2009/2010 (%). Source of table: [

23].

Figure 5.

Main types of construction materials in 2009/2010 (%). Source of table: [

23].

Iron sheets and thatched roofs (

Figure 6) are the most common roofing systems in Uganda. Around 62% of all roofs in Uganda are covered with iron sheets compared to around 37% which are thatched roofs. Iron sheet roofing is much more common in both rural and urban areas. Around 84% of roofs in urban areas are covered with iron sheets compared to 57% in rural areas. This figure for thatched roofs is 43% in rural areas compared to 12% in urban areas. Earth flooring is dominant method/material particularly in rural areas. More than 70% of all floors in Ugandan homes are made out of earth. The share of rural areas is 82% compared to around 25% for urban areas. Cement/concrete flooring is the next most common flooring methods in Uganda. Nearly 30% of all floors in Ugandan homes are made from cement. The share of cement flooring is much higher in urban areas. More than 70% of floors in urban areas are made out of cement/concrete compared to around 17% in rural areas [

23].

Figure 6.

Iron sheet roof (left) and thatched roof (right). Source: The authors.

Figure 6.

Iron sheet roof (left) and thatched roof (right). Source: The authors.

5. Environmental Impacts of Walling Methods and Materials

Many of the prevailing construction methods and materials in Uganda are environmentally harmful. This is because of the inefficient, wasteful and energy intensive production and construction processes. Considering the negligible operational energy of the low-income housing sector in Uganda, embodied energy is the key factor in evaluating the sustainability of low-income housing; however, other issues such as deforestation, air pollution soil extraction, etc. are also important issues in evaluating environmental impacts of construction methods and materials in low-income East African housing. This section intends to assess the adverse environmental impacts of three common walling methods/materials in Uganda as follows: (1) Mud and Poles; (2) Bricks (burned and sun-dried/adobe); and (3) Concrete.

5.1. Mud and Poles

Mud and poles is a very common construction method in Uganda (

Figure 7). In 2010, more than 39% of all dwellings in Uganda were made with mud and poles. This figure was 46% for houses in rural areas compared to 12% in urban areas [

23]. Mud and poles construction consists of wooden structure (poles) and the space/gap between the poles is filled with mud. Thanks to the local availability of its materials, mud and poles is very economical, making it suitable for low-cost housing; however, it is structurally weak and needs constant maintenance as it cracks easily due to the shrinking/swelling of the wood [

25]. Although mud and poles construction can be considered as a sustainable environmentally friendly method of construction (thanks to the application of local unprocessed materials and its negligible embodied energy), it contributes to deforestation due to the use of local wood in its structure [

12]. This makes mud and poles construction less environmentally friendly compared to other methods and materials such as adobe, explained below.

Figure 7.

Cob (left); Mud and Poles (right). Source: The authors.

Figure 7.

Cob (left); Mud and Poles (right). Source: The authors.

5.2. Bricks

Brick walling is the most common construction method in Uganda. Bricks (either burned or adobe/sun-dried bricks) are readily available in both urban and rural areas of Uganda. Nearly 60% of all houses in Uganda have brick walls [

23]; however, it is not clear as to what percentage of walls are made out of burned bricks and/or adobe.

5.2.1. Burned Brick

Burned brick is considered as a durable material; however, it is environmentally harmful due to its low quality, very inefficient production processes and the use of local wood in brick kilns which contribute to deforestation and air pollution [

12,

13] (

Figure 8).

Figure 8.

Inefficient production processes of burned bricks and use of local wood contribute to deforestation. Source: The authors.

Figure 8.

Inefficient production processes of burned bricks and use of local wood contribute to deforestation. Source: The authors.

Excessive use of mortar (

Figure 9) during construction is another major issue associated with burned brick walls. According to Perez [

12], this is due to the uneven sizes of burned bricks; however, considering disproportionate mortar thicknesses of up to 30 mm, it seems that other reasons such as poor construction skills also contribute to this phenomenon. The unpleasant appearance of brick walls also necessitates plastering [

12]. These issues may increase the overall cost of brick walling, making it rather inappropriate for low-cost housing. It is therefore necessary to improve the quality, production and construction processes of burned bricks not only to reduce the overall costs but also to mitigate their environmental impacts.

Figure 9.

Excessive use of mortar increases the environmental damage as well as the overall construction costs. Source: The authors.

Figure 9.

Excessive use of mortar increases the environmental damage as well as the overall construction costs. Source: The authors.

Alternative construction methods and materials such as interlocking blocks/bricks (

Figure 10) have been developed to reduce/eliminate the use of mortar in the construction processes of brick walls. Interlocking bricks, however, are not structurally stable against horizontal and/or earthquake forces. Vertical reinforcement elements may be used to improve their resistance against earthquakes [

25].

Figure 10.

Interlocking bricks can be an alternative for burned bricks. Source: The authors.

Figure 10.

Interlocking bricks can be an alternative for burned bricks. Source: The authors.

Some interlocking soli blocks are cheaper (per square metre) than burned bricks [

12,

13] making them very suitable for low-income housing. However, production of stabilised soli blocks is slower than normal bricks; although their onsite assembly is quicker due to the mortar-less construction. Moreover, they require special pressing equipment which may not be readily available in some rural areas. Stabilised soli blocks also require constant monitoring and supervision [

26] to maintain their quality during production.

5.2.2. Adobe

Thanks to its very low embodied energy, adobe is an environmentally friendly construction material (

Figure 11). Adobe, however, is not as structurally stable and durable compared to burned bricks and requires regular maintenance. The greatest disadvantage of adobe is its vulnerability to water and rain [

24]. Internal/external plastering/rendering may improve the appearance and performance of adobe walls reducing the need for maintenance [

25]. Despite its environmental advantages, adobe is locally regarded as the “material of the poor” [

13], which may restrict its application in Uganda. Educating people about the environmental benefits of adobe and other similar construction materials may help to increase the share of these materials in East African countries. Improving the quality and structural stability of such methods and materials such as mud and poles and adobe to reduce the extent and frequency of maintenance would also improve the public attitudes and encourage the public to consider these methods and materials in their building.

Figure 11.

Adobe is one of the most environmentally friendly construction materials. Source: The authors.

Figure 11.

Adobe is one of the most environmentally friendly construction materials. Source: The authors.

The excessive extraction of fertile agricultural soil is a negative issue associated with bricks and similar construction materials (

Figure 12). Extensive and excessive soil removal may also affect people’s health by creating pools and still water which provides suitable environment for mosquitoes and malaria [

12]. This also applies to other local construction methods and materials such as mud and poles, which heavily rely on the earth as their major source of raw material. However, compared to burned bricks, adobe and mud and poles are less environmentally damaging as they do not need firewood in their production processes.

Figure 12.

Excessive soil extraction damages agriculture and may affect people’s health. Source: The authors.

Figure 12.

Excessive soil extraction damages agriculture and may affect people’s health. Source: The authors.

5.3. Concrete

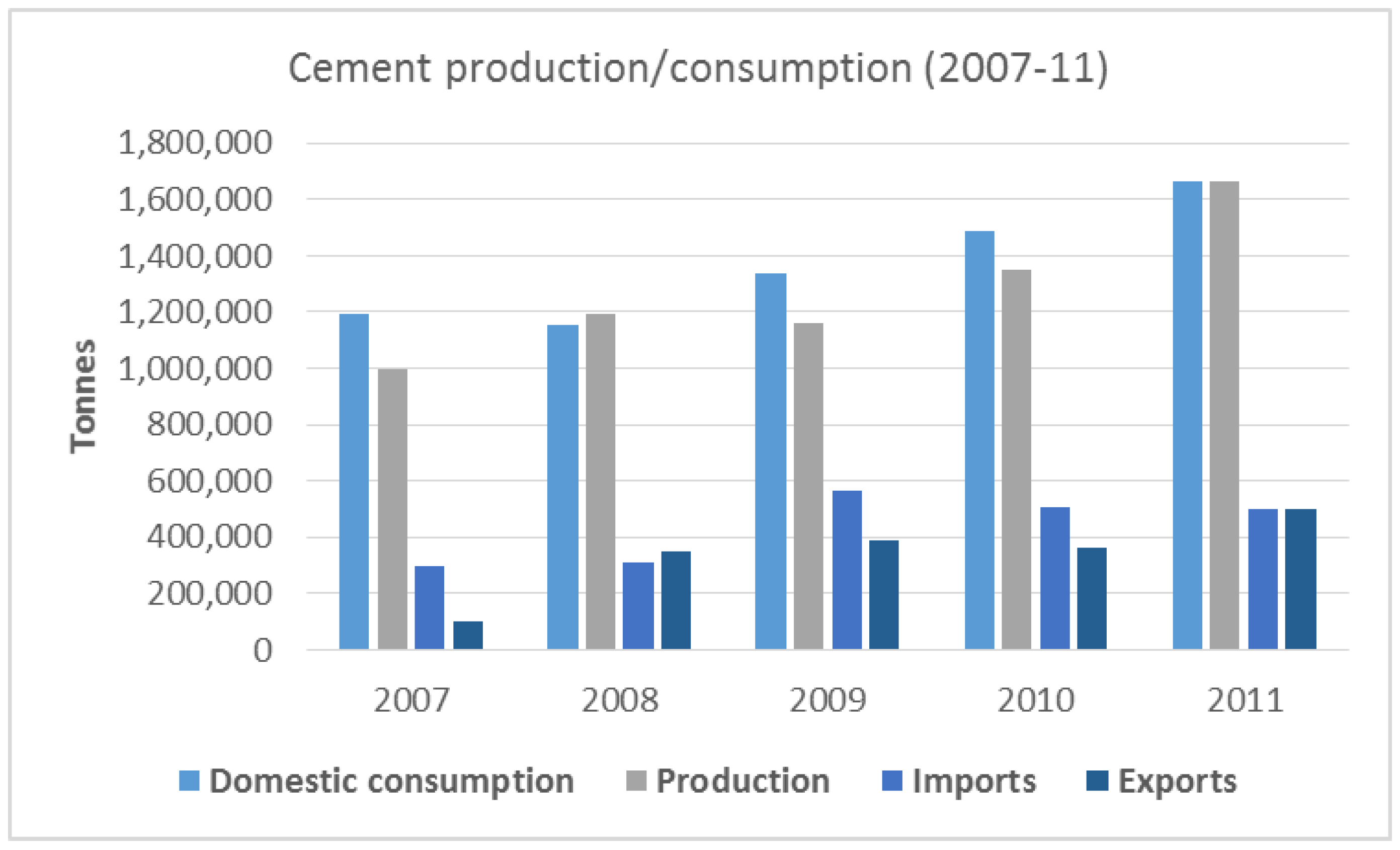

The local production and consumption of cement in Uganda have been increasing during the last decade. The local production of cement and its net domestic supply in 2011 respectively increased by around 12% and 24% compared to 2010 [

20].

Figure 13 shows the cement production, consumption, imports and exports during 2007–2011. Living in concrete homes represents a higher social status in Uganda (

Figure 14); however, there are concerns over the thermal comfort of the occupants living in concrete homes due to its weak thermal resistance (

Table 1) [

12]. This requires more investigation to evaluate the effects of different construction methods and materials on the thermal comfort conditions. Moreover, relatively higher costs of concrete [

12] may raise questions over its suitability for low-income housing.

Figure 13.

Cement production/consumption during 2007–2011. Source of table: [

20].

Figure 13.

Cement production/consumption during 2007–2011. Source of table: [

20].

Although concrete is strong and durable, it is considered as an environmentally harmful material due to high-energy consumption during the production of cement. Nevertheless, compared with burned bricks, concrete may be regarded as a more sustainable material considering the inefficient and energy wasteful production processes of burned brick, which makes it rather more environmentally damaging. Moreover, durability and longer lifespan of concrete compensate for its embodied energy when considering the overall lifecycle of buildings. Therefore, it could be argued that increased use of concrete is not necessarily a negative issue in Uganda. The next sections explain the embodied energy of brick and concrete walling in more detail.

Table 1.

Physical properties of typical construction materials in Uganda. Source: [

12].

Table 1.

Physical properties of typical construction materials in Uganda. Source: [12].

| Material | Interlocking Stabilised Soil Block | Sun-dried Mud Block | Burned Clay Brick | Stabilised Soil Block | Concrete Blocks |

|---|

| Dimension: L × W × H (mm) | 265 × 140 × 100 | 250 × 150 × 70 to 400 × 200 × 150 | 200 × 100 × 100 | 290 × 140 × 115 | 400 × 200 × 200 |

| Thermal conductivity (W/m.K) | 0.8–1.4 | 0.4–0.8 | 0.7–1.3 | 0.8–1.7 | 1–1.7 |

| Density (Kg/m3) | 1700–200 | 1200–1700 | 1400–2400 | 1700–2200 | 1700–2200 |

Figure 14.

The share of concrete construction is increasing rapidly. Source: The authors.

Figure 14.

The share of concrete construction is increasing rapidly. Source: The authors.

6. Embodied Energy of Burned/Fired Bricks

Artisan producers, small-scale and medium-scale manufacturers are the three major brick suppliers in Uganda [

27]. According to the World Bank [

27], an average of 0.5 m

3 of Eucalyptus wood is required to produce one tonne of artisan clamp fired bricks. Assuming a lower heating value of 17 MJ/kg [

28] and a density of 0.56 g/cm

3 [

29] for Eucalyptus wood, an average of 4760 MJ (0.5 × 560 × 17 = 4760) is required to produce one tonne of artisan bricks.

For the small-scale brick manufacturers, the firing period is considerably longer resulting in much higher consumption of wood. The average wood consumption for small-scale manufactures is 1.8 m

3 [

27] which means a massive embodied energy of 17,136 MJ per tonne of bricks (1.8 × 560 × 17 = 17,136). The wood consumption for medium-scale brick manufacturers considerably reduces to around 0.2–0.3 m

3 per tonne of bricks [

27] meaning an embodied energy of around 1900–2850 MJ/tonne, which is six to nine times less than the small-scale brick manufacturers.

According to the Inventory of Carbon and Energy, the embodied energy of “General Clay Bricks” is 3000 MJ/tonne [

18]. Therefore, the energy consumptions by artisans and small-scale brick producers are respectively 1.6 and 5.7 times more than the average energy required for brick production in developed countries. It should be noted that the 5.7 times energy consumption may be a better representative of the actual conditions in East African countries. This is because artisans keep the firing period and temperature low to save as much fuel as possible, which in turn results in low quality bricks up to 45% of the entire production. Improving moulding, kiln construction and production processes could save up to 75% in energy consumptions during brick manufacturing [

27].

Table 2 summarises the fuel consumption, embodied energy and potential energy saving rates of bricks produced by artisans, small- and medium-scale manufacturers.

Table 2.

Embodied energy of burned/fired bricks.

Table 2.

Embodied energy of burned/fired bricks.

| Production Scale | Required fuel (m3 of equivalent fuelwood/tonne) * | Energy Consumption (MJ/tonne) | Energy Consumption Compared to General Clay Bricks | Potential Savings in Energy through Different Measures * |

|---|

| Artisans | 0.5 | 4760 | 159% | 35% |

| Small-scale | 1.8 | 17,136 | 570% | 75% |

| Medium-scale | 0.3 | 2856 | −5% | 30% |

7. Embodied Energy of Walls

Various sizes have been suggested for burned bricks in East African countries. According to World Bank [

27], the length, width and height of artisan clamp fired bricks and blocks may vary greatly (220–295 mm (length); 100–150 mm (width); and 65–130 mm height). The weight of bricks may also vary between 2.5 and 7.6 Kg. The embodied energy of clamp fired brick walls for lower and higher size ranges are calculated in

Table 3. An average of 20 mm, 1:4 cement mortar with an embodied energy of 1.1 MJ/Kg [

18] is assumed for both artisan and small-scale brick and block walls. As described above, excessive mortar thicknesses of up to 30 mm is normal in Uganda.

Table 3.

Embodied energy (EE) of brick and concrete walls.

Table 3.

Embodied energy (EE) of brick and concrete walls.

| Product | Brick/Block Size: L × W × H (mm) | External Wall Thickness (mm) | EE of Material (MJ/Kg) | Mass per item/littre (Kg) | EE of Wall (MJ/m2) | EE of Wall (MJ/m3) |

|---|

| Artisan Burned Brick/Block | 300 × 150 × 130 | 150 | 4.76 | 7.6 | 810 | 5398 |

| 20 mm mortar | 1.11 | 1.65 |

| 220 × 110 × 65 | 220 | 4.76 | 2 | 1067 | 4849 |

| 20 mm mortar | 1.11 | 1.65 |

| Small-Scale Brick | 220 × 110 × 65 | 220 | 17.136 | 2 | 3542 | 16,100 |

| 20 mm mortar | 1.11 | 1.65 |

| General Clay Brick | 215 × 102.5 × 65 | 215 | 3 | 2 | 791 | 3677 |

| 10 mm mortar | 1.11 | 1.65 |

| Cement Stabilised Soil Blocks | 290 × 140 × 115 | 140 | 0.68 | 8 | 176 | 1257 |

| 10 mm mortar | 1.11 | 1.65 |

| Hollow Concrete Block * | 400 × 200 × 200 | 200 | 0.59 | 14 | 127 | 636 |

| 20 mm mortar | 1.11 | 1.65 |

According to the results, the embodied energy of 150 mm and 220 mm artisan brick walls are 810 and 1067 MJ/m

2, respectively. This is while the embodied energy values of 200 mm hollow concrete block and 140 mm cement stabilised soil block walls (with an embodied energy of 0.59 MJ/Kg and 0.68 MJ/Kg [

18]) are 127 MJ/m

2 and 176 MJ/m

2, respectively. Therefore, the embodied energy of artisan clamp fired brick walls is in order around 8.4 and 4.6 times more than concrete and cement stabilised soil block walls with similar wall thickness.

Obviously these figures are much higher for small-scale manufactured fired bricks with an embodied energy of 17.136 MJ/Kg, which is 3.6 times higher than the bricks produced by artisans. Assuming the same brick density, dimensions and mortar thickness, the embodied energy of one square metre of small-scale burned brick wall would be 3542 MJ/m2. This is 3.3 times more than artisan brick walls and around 28 times more than hollow concrete block walls. Moreover, the embodied energy of a 215 mm solid wall built with General Clay Bricks is 791 MJ/m2, which is around 26% and 78% less than a 220 mm artisan and small-scale brick wall, respectively.

It should be noted that despite much lower embodied energy of concrete blocks compared to burned bricks, the cost of hollow concrete block walls per square metre is around 36% more than artisan clamp fired brick walls [

12]. Therefore, it is necessary to reduce the overall costs of concrete construction in order to encourage using concrete blocks in low-income housing. Cement stabilised soil blocks, in contrast, are around 18% cheaper [

12] while their embodied energy is considerably lower than burned bricks. Cement stabilised soil blocks are therefore an appropriate environmentally friendly option for low-income housing.

8. Conclusions

This paper briefly discussed the current housing conditions and prevailing methods of construction in Uganda. Unacceptable housing conditions and low quality, energy-intensive construction methods and materials were highlighted as the major issues of the low-income housing sector. Excessive energy waste during the production processes of building materials such as burned bricks, which also contributes to deforestation, air pollution and other environmental issues, is the major concern which should be addressed. Reducing the embodied energy of locally produced materials is therefore key to mitigating the environmental damages of East African low-income housing.

In fact, some of the locally produced construction methods are much more environmentally damaging than, for example, concrete, which is broadly regarded as an energy intensive and environmentally harmful material in the developed world. According to the results, the embodied energy values of burned bricks produced by artisan and small-scale manufactures are 4760 MJ/Kg and 17,136 MJ/Kg which are 1.6 and 5.7 times higher than generic fired clay bricks, respectively. Moreover, the per square metre embodied energy rates of brick walls built with artisans’ and small-scale manufactures’ fired bricks are in order 1.35 and 4.5 times more than generic brick walls with similar thicknesses. Furthermore, the per square metre embodied energy of hollow concrete block walls is around 88% and 96% less than brick walls built with artisans’ and small-scale manufacturers’ bricks, respectively. This, in addition to the higher quality and durability, make concrete a much more environmentally friendly material/method of construction compared with brick walling in Uganda.

Hence, it could be argued that the current increasing trend in the production/consumption of concrete is not necessarily a negative phenomenon. However, considerably higher costs of concrete blocks compared to artisan burned bricks is a major barrier for broader application of concrete in low-income housing. Cement stabilised soil blocks, in contrast, have a much lower embodied energy and a comparable cost with burned bricks making them an appropriate option for low-income housing.

Nevertheless, it should be noted that the local construction industry provides employment to many people in East Africa. Therefore, despite its environmental benefits, replacing the current materials with more energy efficient, factory produced materials may have some negative social outcomes. Refining the existing production and construction methods to improve the quality and reduce the wastes and embodied energy of buildings and materials would therefore be a better strategy to address both environmental and social concerns. In this respect, providing alternative and more sustainable fuels for brick kilns (to reduce deforestation and air pollution), improving moulding systems and energy efficiency during production and construction processes as well as providing dedicated areas for local brick production (to avoid excessive widespread soil extractions) and increasing access to renewable energy sources, particularly in rural areas, are some of the solutions which may be considered to improve the current conditions.

Raising public awareness on environmental issues and educating the stakeholders including local manufacturers, builders and artisans to reduce material waste, replanting trees, and adopting more energy efficient production methods would also help to reduce the environmental impacts of prevailing construction methods and materials in Uganda. Moreover, considering national programmes to change the negative public attitude towards sustainable materials such as adobe would help to increase the share of such materials in the housing industry. Simultaneously, improving construction quality and aesthetics of sustainable methods and materials would make them more appealing to the public and encourage the society to reconsider them as stylish materials which could replace environmentally harmful materials such as burned bricks. National building codes and minimum standards should also be implemented to gradually improve the quality of housing stock in Uganda.

Furthermore, alternative innovative methods and materials which are adapted to local needs and conditions should be developed and introduced to the construction industry. However, it should be noted that innovation is an evolutionary and long-term process and a hasty replacement of the current construction methods and materials with new highly efficient and possibly more expensive ones would probably deteriorate the current conditions. The most effective approach is therefore to improve the production and construction processes of prevailing methods and materials while new and more efficient ones are gradually introduced to the construction industry.