The Use of an Innovative Jig to Stimulate Awareness of Sustainable Technologies among Freshman Engineering Students

Abstract

:1. Introduction

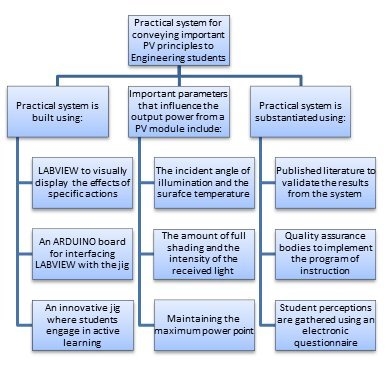

2. Context

| Semester 1 | Semester 2 |

|---|---|

| Digital Literacy | Health and Safety: Principles and Practice |

| Academic Literacy and Communication Studies | Electrical Installation Practice |

| Mathematics I A | Power Generation and Storage |

| Electrical Engineering I | Solar Energy Systems II |

| Applied Physics of Energy Conversion | Small Wind Generation |

| Solar Energy Systems I | Mathematics I B |

3. Innovative Jig for Demonstrating PV Module Operation

- A 10 W PV module mounted on an aluminium structure (F) where its tilt angle can be varied (E);

- A USB connector (G) from an ARDUINO microcontroller located in a watertight box with specific selectable load resistors (D) to enable the sensed data to be viewed and recorded in LabVIEW on a PC;

- A mechanism to adjust the distance of the light source to the PV module (A);

- A switch where the two lights can be switched on or off individually (B); and

- Two 500 W halogen lights (C) which serve as the light source.

- It is an open-source project where the software/hardware is extremely accessible and very adaptable;

- It is flexible and offers a variety of digital and analogue inputs/outputs, serial interface and digital and PWM outputs;

- It is easy to change and update the program as it connects to a PC via USB and communicates using standard serial protocol;

- It is an inexpensive microcontroller for which the software is freely available; and

- It has a large online community with a lot of references, example source codes and libraries to refer to.

| Date | Time ms | Current mA | Temp °C | Angle ° | Voltage V | Light int relative |

|---|---|---|---|---|---|---|

| 26 May 2015 | 4800 | 50.13 | 34.34 | 1.09 | 15.14 | 89.35 |

| 26 May 2015 | 5000 | 50.13 | 34.34 | 1.36 | 15.14 | 89.36 |

| 26 May 2015 | 5200 | 50.13 | 34.36 | 1.36 | 15.14 | 89.36 |

4. Practical Experiments and Their Associated Visual Results

- It provides students with opportunities to develop their problem-solving skills and

- It may serve as a tool for thinking and problem solving.

4.1. Incident Angle of Illumination

4.2. Temperature of the Module

4.3. Shading

4.4. Maximum Power Point of a PV Module

4.5. Light Intensity

5. Student Perceptions

| Module | Solar Energy II |

|---|---|

| The following represents the percentage of students who agreed that the practical experiments: | |

| Were enjoyable | 92% |

| Were relevant to the theory | 83% |

| Helped them to apply their new knowledge | 84% |

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hertzog, P.; Vermaak, H.; Raath, J. Design and implementation of a Higher Certificate in Renewable Energy Technologies at the Central University of Technology (CUT), Free State. Available online: http://www.researchgate.net/publication/271965690_Design_and_implementation_of_a_Higher_Certificate_in_Renewable_Energy_Technologies_at_the_Central_University_of_Technology_%28CUT%29_Free_State (accessed on 8 July 2015).

- Swart, J.; Olwagen, L.; Britz, C.; Luwes, N. Reflecting on the balance between the practical and theoretical success of African engineering students—A case study from the Central University of Technology. In Proceedings of the HELTASA 2014, University of the Free State, Bloemfontein, South Africa, 18–21 November 2014.

- Hertzog, P.; Swart, A. Enhancing freshman engineering student’s experiences of photovoltaic module operation using educational technologies. In Proceedings of the 11th International Conference on Educational Technologies, Dubai, UAE, 22–24 February 2015.

- Gabbasa, M.; Sopian, K. Potential and Status of the Renewable Energy Technologies for Sustainable Energy Development in Organization of Islamic Conference (OIC) Countries. WSEAS Trans. Environ. Dev. 2013, 9, 254–262. [Google Scholar]

- Uduma, K.; Arciszewski, T. Sustainable Energy Development: The Key to a Stable Nigeria. Sustainability 2010, 2, 1558–1570. [Google Scholar] [CrossRef]

- Yang, Q.; Chen, G.; Liao, S.; Zhao, Y.; Peng, H.; Chen, H. Environmental sustainability of wind power: An emergy analysis of a Chinese wind farm. Renew. Sustain. Energy Rev. 2013, 25, 229–239. [Google Scholar] [CrossRef]

- Garmsiri, S.; Rosen, M.; Smith, G. Integration of Wind Energy, Hydrogen and Natural Gas Pipeline Systems to Meet Community and Transportation Energy Needs: A Parametric Study. Sustainability 2014, 6, 2506–2526. [Google Scholar] [CrossRef]

- Koroneos, C.J.; Piperodos, S.; Tatatzikidis, C.A.; Rovas, D.C. Life cycle assessment of a solar thermal concentrating system. In Proceedings of the Selected Papers from the WSEAS Conferences, Cantabria, Spain, 23–25 September 2008.

- Ferdaus, R.A.; Mohammed, M.A.; Rahman, S.; Salehin, S.; Mannan, M.A. Energy Efficient Hybrid Dual Axis Solar Tracking System. J. Renew. Energy 2014. [CrossRef]

- Asowata, O.; Swart, A.J.; Pienaar, H.C. Optimum tilt and orientation angles for photovoltaic panels in the Vaal Triangle. In Proceedings of the APPEEC 2012, Grand Mercure Baolong Hotel, Shanghai, China, 27–29 March 2012.

- Ozemoya, A.; Swart, J.; Pienaar, C. Poster: Controlling the ambient temperature of a PV panel to maintain high conversion efficiency. In Proceedings of the SATNAC 2012, George, South Africa, 2–5 September 2012.

- Moubayed, N.; El-Ali, A.; Outbib, R. Control of an hybrid solar-wind system with acid battery for storage. WSEAS Trans. Power Syst. 2009, 4, 307–318. [Google Scholar]

- Swart, A.J.; Hertzog, P.E. Quantifying the Effect of Varying Percentages of Full Uniform Shading on the Output Power of a PV Module in a Controlled Environment. In Proceedings of the SATNAC 2014, Boardwalk Conference Centre, Port Elizabeth, South Africa, 31 August–3 September 2014.

- Mathews, S.; Peshek, T.; Hu, Y.; French, R.H. Photovoltaic Degradation Analysis and Simulated Models; Case Western Reserve University: Cleveland, OH, USA, 2014. [Google Scholar]

- Quamruzzaman, M.; Rahman, K. A Modified Perturb and Observe Maximum Power Point Tracking Technique for Single-Stage Grid-Connected Photovoltaic Inverter. WSEAS Trans. Power Syst. 2014, 9, 111–118. [Google Scholar]

- Moradi, M.H.; Reisi, A.R. A hybrid maximum power point tracking method for photovoltaic systems. Sol. Energy 2011, 85, 2965–2976. [Google Scholar] [CrossRef]

- Martins, A.; Lourenço, J.; Patrício, T.; de Alexandria, A. Sensor Kinect in a telepresence application. In Computational Vision and Medical Image Processing IV: VIPIMAGE 2013; CRC Press: Boca Raton, FL, USA, 2013; p. 151. [Google Scholar]

- Woodruff, A.; Görmez, B. Laser Music System: Implemented Using Lasers, Infrared Sensors, Photocells and a Arduino Microcontroller. Bachelor’s Thesis, School of Information Science, Computer and Electrical Engineering, Halmstad University, Halmstad, Sweden, 2012. [Google Scholar]

- Elliott, C.; Vijayakumar, V.; Zink, W.; Hansen, R. National instruments LabVIEW: A programming environment for laboratory automation and measurement. J. Assoc. Lab. Autom. 2007, 12, 17–24. [Google Scholar] [CrossRef]

- Jamaluddin, A.; Sihombing, L.; Supriyanto, A.; Purwanto, A.; Nizam, M. Design real time Battery Monitoring System using LabVIEW Interface for Arduino (LIFA). In Proceedings of the 2013 Joint International Conference on Rural Information & Communication Technology and Electric-Vehicle Technology, Bandung, Indonesia, 26–28 November 2013; pp. 1–4.

- Kruse, K.; Keil, J. Technology-Based Training—The Art and Science of Design, Development, and Delivery; Jossey-Bass Pfeiffer: San Francisco, CA, USA, 2000. [Google Scholar]

- Swart, A.J. Enhancing students’ perception of single-sideband suppressed-carrier principles by using cooperative and computer-based learning. CAEE Comput. Appl. Eng. Educ. 2012, 20, 332–338. [Google Scholar] [CrossRef]

- McCown, R.; Driscoll, M.; Roop, P.G. Educational Psychology A Learning-centered Approach to Classroom Practice, 2nd ed.; Allyn & Bacon: Boston, MA, USA, 1996. [Google Scholar]

- Pelland, S.; Galanis, G.; Kallos, G. Solar and photovoltaic forecasting through post-processing of the Global Environmental Multiscale numerical weather prediction model. Prog. Photovolt. Res. Appl. 2013, 21, 284–296. [Google Scholar] [CrossRef]

- Janjal, C.S.; Khanchandani, K. Design and Development Model of Solar Grid Tied Photovoltaic Power Inverter for Nagpur. Int. J. Adv. Res. Comput. Sci. Electron. Eng. (IJARCSEE) 2012, 1, 146–148. [Google Scholar]

- Heywood, H. Operating experiences with solar water heating. J. Install. Heat Vent. Energy 1971, 39, 63–69. [Google Scholar]

- Chinnery, D.N.W. Solar heating in South Africa. In Pretoria CSIR-Research Report 248; National Building Research Institute: Roorkee, India, 1981. [Google Scholar]

- Hertzog, P.; Swart, A. Determining the optimum tilt angles for PV modules in a semi-arid region of South Africa for the summer season. In Proceedings of the Southern Africa Telecommunication Networks and Applications Conference (SATNAC) 2015 Kogelberg Biosphere Reserve near Hermanus, Western Cape, South Africa, 6–9 September 2015.

- Ma, T.; Yang, H.; Lu, L. Performance evaluation of a stand-alone photovoltaic system on an isolated island in Hong Kong. Appl. Energy 2013, 112, 663–667. [Google Scholar] [CrossRef]

- Makrides, G.; Zinsser, B.; Phinikarides, A.; Schubert, M.; Georghiou, G.E. Temperature and thermal annealing effects on different photovoltaic technologies. Renew. Energy 2012, 43, 407–417. [Google Scholar] [CrossRef]

- Bataineh, K.; Hamzeh, A. Efficient maximum power point tracking algorithm for photovoltaic cells. In Proceedings of the 1st WSEAS International Conference on Industrial and Manufacturing Technologies, Athens, Greece, 14–16 May 2013.

- Hertzog, P.; Swart, A. Quantifying the effect of varying percentages of full uniform shading on the output power of a PV module in a controlled environment. In Proceedings of the SATNAC 2014, Port Elizabeth, South Africa, 31 August–3 September 2014.

- Yau, H.-T.; Wu, C.-H. Comparison of Extremum-Seeking Control Techniques for Maximum Power Point Tracking in Photovoltaic Systems. Energies 2011, 4, 2180–2195. [Google Scholar] [CrossRef]

- Kharb, R.K.; Shimi, S.; Chatterji, S.; Ansari, M.F. Modeling of solar PV module and maximum power point tracking using ANFIS. Renew. Sustain. Energy Rev. 2014, 33, 602–612. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L. A feasibility study of a stand-alone hybrid solar–wind–battery system for a remote island. Appl. Energy 2014, 121, 149–158. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L. Feasibility study and economic analysis of pumped hydro storage and battery storage for a renewable energy powered island. Energy Convers. Manag. 2014, 79, 387–397. [Google Scholar] [CrossRef]

- Swart, A.J.; de Jager, H. Utilizing computer aided equipment in conveying Amplitude Modulation principles to senior engineering students. In Proceedings of the ARCEE 2006, African Regional Conference on Engineering Education, University of Pretoria, Pretoria, South Africa, 26–29 September 2006.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hertzog, P.; Swart, A.J. The Use of an Innovative Jig to Stimulate Awareness of Sustainable Technologies among Freshman Engineering Students. Sustainability 2015, 7, 9100-9117. https://doi.org/10.3390/su7079100

Hertzog P, Swart AJ. The Use of an Innovative Jig to Stimulate Awareness of Sustainable Technologies among Freshman Engineering Students. Sustainability. 2015; 7(7):9100-9117. https://doi.org/10.3390/su7079100

Chicago/Turabian StyleHertzog, Pierre, and Arthur James Swart. 2015. "The Use of an Innovative Jig to Stimulate Awareness of Sustainable Technologies among Freshman Engineering Students" Sustainability 7, no. 7: 9100-9117. https://doi.org/10.3390/su7079100

APA StyleHertzog, P., & Swart, A. J. (2015). The Use of an Innovative Jig to Stimulate Awareness of Sustainable Technologies among Freshman Engineering Students. Sustainability, 7(7), 9100-9117. https://doi.org/10.3390/su7079100