Computational and Experimental Investigation for an Optimal Design of Industrial Windows to Allow Natural Ventilation during Wind-Driven Rain

Abstract

:1. Introduction

2. Experimental Section

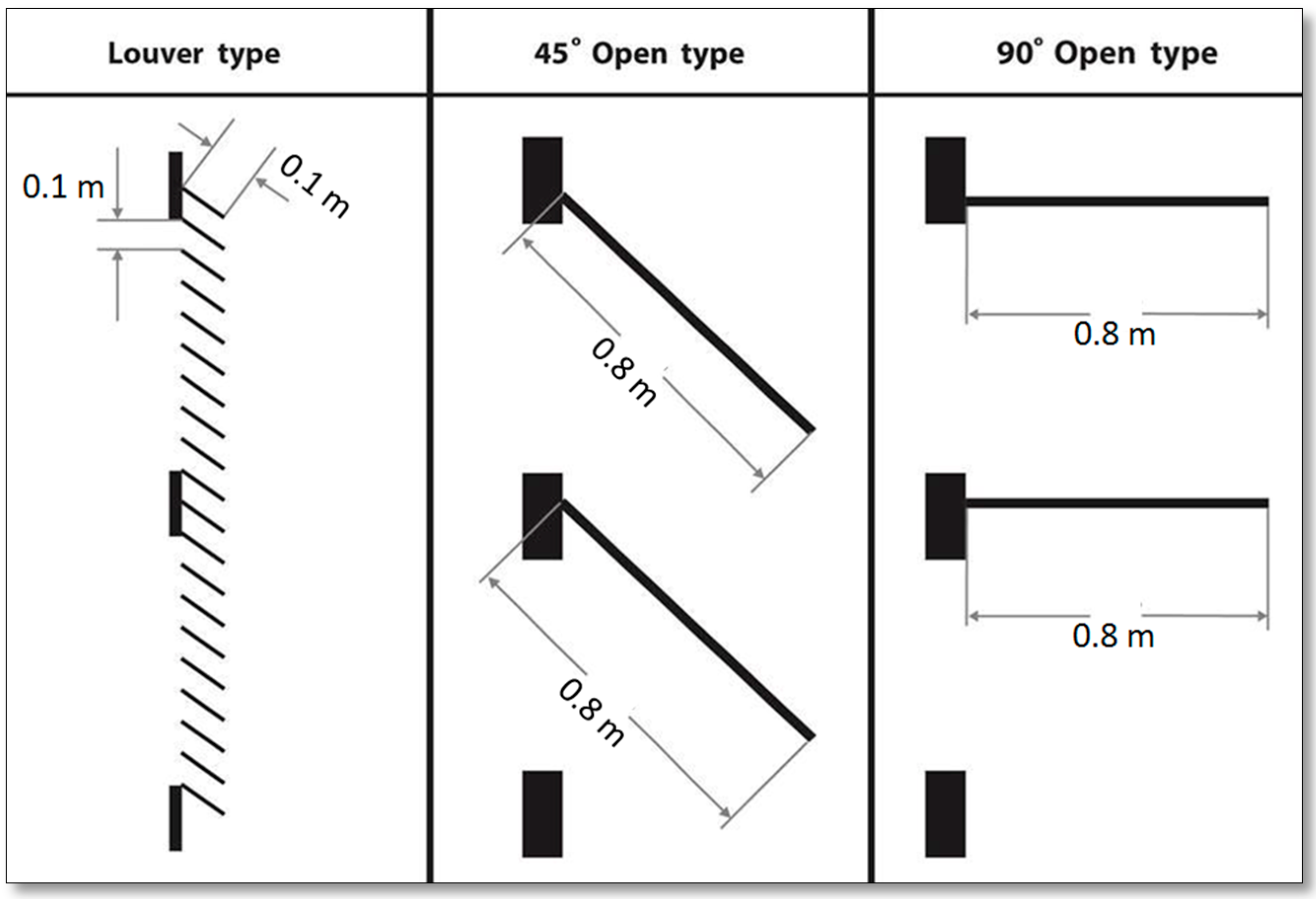

2.1. Preliminary Study: Window Type Selection

2.1.1. Numerical Study

2.1.2. Experimental Study

2.2. Optimization Study: Addition of Supplements for a Selected Window

- R = Flow rate (intensity) of rainwater into each bucket (mm/h),

- M = Total weight of inflow rainwater collected in the buckets (g),

- W = Density of rainwater (g/mm3),

- S = Cross sectional area of each bucket (mm2), and

- H = Measurement time (h).

2.3. Sensitivity Analysis

3. Results and Discussion

3.1. Preliminary Study: Comparison of Numerical and Experimental Methods for Window Type Selection

| Window Type | CFD Predicted Values | Measured Values | |||||

|---|---|---|---|---|---|---|---|

| Mean age of air (s) | CO2 Concentration (ppm) | CO2 Concentration (ppm) | |||||

| Point 1 (windward side) | Point 2 (leeward side) | Average | Point 1 (windward side) | Point 2 (leeward side) | Average | ||

| 90° open type | 58.0 | 608.8 | 609.0 | 608.9 | 568 | 580 | 574 |

| 45° open type | 62.7 | 622.7 | 644.5 | 633.6 | 583 | 591 | 587 |

| Louver type | 63.1 | 627.0 | 643.1 | 635.1 | 585 | 599 | 592 |

3.2. Optimization Study: Addition of Supplements for 90° Open Windows

3.2.1. Identification of the Rainwater Inflow Path

- Path 1: The small raindrops near the entrance of windows instantly gain horizontal velocity from the wind and enter directly into the room.

- Path 2: The rainwater that fell onto the upper surface of window creates bigger drops at the edge, and when the drops fall, they are carried with the wind. Those drops collide with the bottom window surface, thereby creating a splash and generating small drops that enter through the window opening with the assistance of the wind and the momentum of the bigger drop.

- Path 3: The smaller raindrops relatively far away from the window are unable to enter directly but collide with the bottom window surface, thus producing a similar phenomenon as path 2.

3.2.2. Remedy Methods and Consequences According to the Identified Rainwater Inflow Path

- (1)

- Window angle: As the window angle deviates from 90°, the area of the opening changes accordingly, which results in the increase/decrease of airflow and rain penetration rate through the opening (Figure 6, cases 2–5, 13–20 and 23–24).

- (2)

- Window extension: Extensions of the windows decrease the distance that raindrops can travel to enter through the opening, predominantly intercepting path 1 flows (Figure 6, cases 6–15 and 17–24).

- (3)

- Gutter: A gutter collects and funnels the rainwater that falls on the surface of the window and decreases the amount of rainwater following path 2 (Figure 6, cases 10–15, 17–20 and 22–24).

- (4)

- Bended sheet: A bended sheet directs rainwater on the upper surface of the window towards the gutter to block path 2 flows (Figure 6, cases 10–12 (blue color)).

- (5)

- Cushion: The use of buffer material such as artificial grass to facilitate the soft landing of raindrops on the window surface reduces the entry of water through splashing, thus countering the effect of path 3 flows (Figure 6, cases 21–24).

- (6)

- Screen: A screen allows airflow but obstructs rain penetration because of the presence of small sieves (Figure 6, cases 14–15 and 23). Adjustable screens further aid in manually modifying the orientation of the screen, depending on the rainfall conditions for cases 15 and 23.

Effects Resulting from Changing the Opening Angle (Cases 1–5)

| Case Study | Rain Penetration (mm/h) | Ventilation (m/s) | Rain Penetration (%) | Ventilation (%) | ||

|---|---|---|---|---|---|---|

| Measurement | CFD | Measurement | CFD | |||

| 1 | 3.70 | 1.96 | 1.89 | 100.0 | 100.0 | 100.0 |

| 2 | 1.20 | 1.85 | 1.72 | 32.4 | 94.4 | 91.0 |

| 3 | 0.20 | 1.81 | 1.83 | 5.4 | 92.3 | 96.8 |

| 4 | 0.09 | 1.61 | 1.54 | 2.4 | 82.1 | 81.5 |

| 5 | 0.00 | 1.21 | 1.14 | 0.0 | 61.7 | 60.3 |

| 6 | 3.31 | 1.95 | 1.88 | 89.5 | 99.5 | 99.5 |

| 7 | 2.02 | 1.94 | 1.89 | 54.6 | 99.0 | 100.0 |

| 8 | 0.97 | 1.90 | 1.87 | 26.2 | 96.9 | 98.9 |

| 9 | 0.82 | 1.92 | 1.86 | 22.2 | 98.0 | 98.4 |

| 10 | 0.21 | 1.89 | 1.85 | 5.7 | 96.4 | 97.9 |

| 11 | 0.15 | 1.69 | 1.82 | 4.1 | 86.2 | 96.3 |

| 12 | 0.10 | 1.88 | 1.85 | 2.7 | 95.9 | 97.9 |

| 13 | 0.24 | 2.03 | 1.96 | 6.5 | 103.6 | 103.7 |

| 14 | 0.04 | 1.34 | - | 1.1 | 68.4 | - |

| 15 | 0.05 | 1.79 | - | 1.4 | 91.3 | - |

| 16 | 2.21 | 1.89 | 1.72 | 59.7 | 96.4 | 91.0 |

| 17 | 1.54 | 1.34 | 1.25 | 41.6 | 68.4 | 66.1 |

| 18 | 1.03 | 1.45 | 1.38 | 27.8 | 74.0 | 73.0 |

| 19 | 0.06 | 1.78 | 1.63 | 1.6 | 90.8 | 86.2 |

| 20 | 0.03 | 1.59 | 1.45 | 0.8 | 81.1 | 76.7 |

| 21 | 0.89 | 1.90 * | - | 24.1 | 96.9 | - |

| 22 | 0.06 | 1.88 * | - | 1.6 | 95.9 | - |

| 23 | 0.04 | 1.79 * | - | 1.1 | 91.3 | - |

| 24 | 0.02 | 1.59 * | - | 0.5 | 81.1 | - |

| 25 | 0.16 | 2.03 ** | - | 4.3 | 103.6 | - |

| 26 | 0.20 | 2.03 ** | - | 5.4 | 103.6 | - |

| 27 | 0.23 | 2.03 ** | - | 6.2 | 103.6 | - |

| 28 | 0.14 | 2.03 ** | - | 3.8 | 103.6 | - |

| 29 | 0.23 | 2.03 ** | - | 6.2 | 103.6 | - |

Effects Resulting from Changing the Windowpane Length (Cases 6–9)

Effects Resulting from the Addition of a Bended Sheet and Gutter (Cases 10–12)

Effects Resulting from the Addition of a Gutter and a Screen Plus a Change in the Angle (Cases 13–15)

Effects Resulting from the Addition of a Gutter and the Length Plus a Change in the Angle (Cases 16–20)

Effects Resulting from the Addition of a Cushion (Buffer Material Code JN 108: Table S2) (Cases 21–24)

Effects Resulting from the Use of Different Cushions (Cases 25–29)

3.2.3. Sensitivity Analysis and Correlation Coefficient

4. Conclusions

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bangalee, M.Z.I.; Lin, S.Y.; Miau, J.J. Wind driven natural ventilation through multiple windows of a building: A computational approach. Energy Build. 2012, 45, 317–325. [Google Scholar] [CrossRef]

- Evola, G.; Popov, V. Computational analysis of wind driven natural ventilation in buildings. Energy Build. 2006, 38, 491–501. [Google Scholar] [CrossRef]

- Homod, R.Z.; Sahari, K.S.M.; Almurib, H.A.F. Energy saving by integrated control of natural ventilation and HVAC systems using model guide for comparison. Renew. Energy 2014, 71, 639–650. [Google Scholar] [CrossRef]

- Stavrakakis, G.M.; Zervas, P.L.; Sarimveis, H.; Markatos, N.C. Optimization of window-openings design for thermal comfort in naturally ventilated buildings. Appl. Math. Model. 2012, 36, 193–211. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, F.Y.; Kuckelkorn, J.; Liu, D.; Liu, J.; Zhang, J.L. Classroom energy efficiency and air environment with displacement natural ventilation in a passive public school building. Energy Build. 2014, 70, 258–270. [Google Scholar] [CrossRef]

- Yang, D.; Li, P. Natural ventilation of lower-level floors assisted by the mechanical ventilation of upper-level floors via a stack. Energy Build. 2015, 92, 296–305. [Google Scholar] [CrossRef]

- Kim, T.; Lee, D.H.; Ahn, K.; Ha, H.; Park, H.; Piao, C.X.; Li, X.; Seo, J. Characteristics of rain penetration through a gravity ventilator used for natural ventilation. Ann. Occup. Hyg. 2008, 52, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Von Grabe, J.; Svoboda, P.; Bäumler, A. Window ventilation efficiency in the case of buoyancy ventilation. Energy Build. 2014, 72, 203–211. [Google Scholar] [CrossRef]

- Stavridou, A.D.; Prinos, P.E. Natural ventilation of buildings due to buoyancy assisted by wind: Investigating cross ventilation with computational and laboratory simulation. Build. Environ. 2013, 66, 104–119. [Google Scholar] [CrossRef]

- Redlich, C.A.; Sparer, J.; Cullen, M.R. Sick-building syndrome. Lancet 1997, 349, 1013–1016. [Google Scholar] [CrossRef]

- Santamouris, M. Natural Ventilation in Buildings: A Design Handbook, 1st ed.; James & James (Science Publishers) Ltd.: London, UK, 1998; pp. 2–3. [Google Scholar]

- Fontanini, A.; Vaidya, U.; Ganapathysubramanian, B. A stochastic approach to modeling the dynamics of natural ventilation systems. Energy Build. 2013, 63, 87–97. [Google Scholar] [CrossRef]

- Kleiven, T. Natural Ventilation in Buildings Architectural Concepts, Consequences and Possibilities. DoktorIngeniør Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2003. [Google Scholar]

- Heiselberg, P.; Svidt, K.; Nielsen, P.V. Characteristics of airflow from open windows. Build. Environ. 2001, 36, 859–869. [Google Scholar] [CrossRef]

- Van Hooff, T.; Blocken, B. CFD evaluation of natural ventilation of indoor environments by the concentration decay method: CO2 gas dispersion from a semi-enclosed stadium. Build. Environ. 2013, 61, 1–17. [Google Scholar] [CrossRef]

- Van Hooff, T.; Blocken, B. Full-scale measurements of indoor environmental conditions and natural ventilation in a large semi-enclosed stadium: Possibilities and limitations for CFD validation. J. Wind Eng. Ind. Aerodyn. 2012, 104–106, 330–341. [Google Scholar] [CrossRef]

- Gao, C.F.; Lee, W.L. Influence of window types on natural ventilation of residential buildings in Hong Kong. Available online: http://docs.lib.purdue.edu/ihpbc/16 (accessed on 1 April 2015).

- Fracastoro, G.V.; Mutani, G.; Perino, M. Experimental and theoretical analysis of natural ventilation by windows opening. Energy Build. 2002, 34, 817–827. [Google Scholar] [CrossRef]

- Walker, C.; Tan, G.; Glicksman, L. Reduced-scale building model and numerical investigations to buoyancy-driven natural ventilation. Energy Build. 2011, 43, 2404–2413. [Google Scholar] [CrossRef]

- Teppner, R.; Langensteiner, B.; Meile, W.; Brenn, G.; Kerschbaumer, S. Air change rates driven by the flow around and through a building storey with fully open or tilted windows: An experimental and numerical study. Energy Build. 2014, 76, 640–653. [Google Scholar] [CrossRef]

- Shetabivash, H. Investigation of opening position and shape on the natural cross ventilation. Energy Build. 2015, 93, 1–15. [Google Scholar] [CrossRef]

- Kang, J.H.; Lee, S.J. Improvement of natural ventilation in a large factory building using a louver ventilator. Build. Environ. 2008, 43, 2132–2141. [Google Scholar] [CrossRef]

- Cruz-Salas, M.V.; Castillo, J.A.; Huelsz, G. Experimental study on natural ventilation of a room with a windward window and different windexchangers. Energy Build. 2014, 84, 458–465. [Google Scholar] [CrossRef]

- Yin, W.; Zhang, G.; Yang, W.; Wang, X. Natural ventilation potential model considering solution multiplicity, window opening percentage, air velocity and humidity in China. Build. Environ. 2010, 45, 338–344. [Google Scholar] [CrossRef]

- Blocken, B.; Carmeliet, J. A review of wind-driven rain research in building science. J. Wind Eng. Ind. Aerodyn. 2004, 92, 1079–1130. [Google Scholar] [CrossRef]

- Briggen, P.M.; Blocken, B.; Schellen, H.L. Wind-driven rain on the facade of a monumental tower: Numerical simulation, full-scale validation and sensitivity analysis. Build. Environ. 2009, 44, 1675–1690. [Google Scholar] [CrossRef]

- World Health Organization (WHO). WHO Guidelines for Indoor Air Quality: Dampness and Mould; WHO Regional Office of Europe: Copenhagen, Denmark, 2009; pp. 36–77. Available online: https://books.google.co.kr/books?hl=en&lr=&id=PxB8UUHihWgC&oi=fnd&pg=PR7&dq=WHO+Guidelines+for+Indoor+Air+Quality:+Dampness+and+Mould.&ots=9zJXOYO4FO&sig=DiQf8RL7jiY_VDGZQL0oARBRBS0&redir_esc=y#v=onepage&q&f=false (accessed on 19 April 2019).

- Blocken, B.; Carmeliet, J. Spatial and temporal distribution of driving rain on a low-rise building. Wind Struct. 2002, 5, 441–462. [Google Scholar] [CrossRef]

- Lopez, C.; Masters, F.J.; Bolton, S. Water penetration resistance of residential window and wall systems subjected to steady and unsteady wind loading. Build. Environ. 2011, 46, 1329–1342. [Google Scholar] [CrossRef]

- Lacasse, M.A.; Rousseau, M.Z.; Cornick, S.M.; Manning, M.M.; Ganapathy, G.; Nicholls, M.; Williams, M.F. Laboratory tests of water penetration through wall-window interfaces based on U.S. residential window installation practice. J. ASTM Int. 2009, 6, 1–35. [Google Scholar] [CrossRef]

- Salzano, C.T.; Masters, F.J.; Katsaros, J.D. Water penetration resistance of residential window installation options for hurricane-prone areas. Build. Environ. 2010, 45, 1373–1388. [Google Scholar] [CrossRef]

- Blocken, B.; Derome, D.; Carmeliet, J. Rainwater runoff from building facades: A review. Build. Environ. 2013, 60, 339–361. [Google Scholar] [CrossRef]

- Coutu, S.; Wyrsch, V.; Rossi, L.; Emery, P.; Golay, F.; Carneiro, C. Modelling wind-driven rain on buildings in urbanized area using 3-D GIS and LiDAR datasets. Build. Environ. 2013, 59, 528–535. [Google Scholar] [CrossRef]

- MohaddesForoushani, S.S.; Ge, H.; Naylor, D. Effects of roof overhangs on wind-driven rain wetting of a low-rise cubic building: A numerical study. J. Wind Eng. Ind. Aerodyn. 2014, 125, 38–51. [Google Scholar] [CrossRef]

- Pérez-Bella, J.M.; Domínguez-Hernández, J.; Rodríguez-Soria, B.; del Coz-Díaz, J.J.; Cano-Suñén, E. Combined use of wind-driven rain and wind pressure to define water penetration risk into building façades: The Spanish case. Build. Environ. 2013, 64, 46–56. [Google Scholar] [CrossRef]

- Blocken, B.; Carmeliet, J. Impact, runoff and drying of wind-driven rain on a window glass surface: Numerical modelling based on experimental validation. Build. Environ. 2015, 84, 170–180. [Google Scholar] [CrossRef]

- Blocken, B.; Stathopoulos, T.; Carmeliet, J.; Hensen, J. Application of CFD in building performance simulation for the outdoor environment. In Proceedings of the Building Simulation. Eleventh International IBPSA Conference, Glasgow, UK, 27–30 July 2009; pp. 489–496.

- Weather Underground (WU)—History, Monthly Summary. Available online: http://www.webcitation.org/6YYSJgbl1 (accessed on 16 May 2015).

- Shin, K.B. Ageing of composites in transport applications. In Ageing of Composites; Martin, R., Ed.; Woodhead Publishing Limited: Great Abington, UK, 2008; Chapter 10; p. 294. [Google Scholar]

- Homepage of Steve Horstmeyer—Typical raindrop sizes. Available online: http://www.webcitation.org/6Ybwgtqi0 (accessed on 18 May 2015).

- CO2 Now.org—What the World Needs to Watch, Earth’s CO2 Home Page. Available online: http://www.webcitation.org/6YZbg68tj (accessed on 17 May 2015).

- Buratti, C.; Mariani, R.; Moretti, E. Mean age of air in a naturally ventilated office: Experimental data and simulations. Energy Build. 2011, 43, 2021–2027. [Google Scholar] [CrossRef]

- Chanteloup, V.; Mirade, P.S. Computational fluid dynamics (CFD) modelling of local mean age of air distribution in forced-ventilation food plants. J. Food Eng. 2009, 90, 90–103. [Google Scholar] [CrossRef]

- Tian, L.; Lin, Z.; Liu, J.; Yao, T.; Wang, Q. The impact of temperature on mean local air age and thermal comfort in a stratum ventilated office. Build. Environ. 2011, 46, 501–510. [Google Scholar] [CrossRef]

- Krpan, R. Wind-driven Rain on Buildings in Metro Vancouver: Parameters for Rain Penetration Testing of Window Assemblies. Master’s Thesis, Concordia University, Montreal, QC, Canada, 2013. [Google Scholar]

- Perén, J.I.; van Hooff, T.; Leite, B.C.C.; Blocken, B. CFD analysis of cross-ventilation of a generic isolated building with asymmetric opening positions: Impact of roof angle and opening location. Build. Environ. 2015, 85, 263–276. [Google Scholar] [CrossRef]

- Perén, J.I.; van Hooff, T.; Leite, B.C.C.; Blocken, B. Impact of eaves on cross-ventilation of a generic isolated leeward sawtooth roof building: Windward eaves, leeward eaves and eaves inclination. Build. Environ. 2015, 92, 578–590. [Google Scholar] [CrossRef]

- Abohela, I.; Hamza, N.; Dudek, S. Effect of roof shape, wind direction, building height and urban configuration on the energy yield and positioning of roof mounted wind turbines. Renew. Energy 2013, 50, 1106–1118. [Google Scholar] [CrossRef]

- Krishnan, A.; Paraschivoiu, M. 3D analysis of building mounted VAWT with diffuser shaped shroud. Sustain. Cities Soc. 2015. [Google Scholar] [CrossRef]

- Zhang, Y.; Habashi, W.G.; Khurram, R.A. Predicting wind-induced vibrations of high-rise buildings using unsteady CFD and modal analysis. J. Wind Eng. Ind. Aerodyn. 2015, 136, 165–179. [Google Scholar] [CrossRef]

- Liu, J.; Srebric, J.; Yu, N. Numerical simulation of convective heat transfer coefficients at the external surfaces of building arrays immersed in a turbulent boundary layer. Int. J. Heat Mass Transfer 2013, 61, 209–225. [Google Scholar] [CrossRef]

- Singwang Mat—Product Information. Available online: http://www.webcitation.org/6Ycw7U6na (accessed on 19 May 2015). (In Korean)

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prueksakorn, K.; Piao, C.-X.; Ha, H.; Kim, T. Computational and Experimental Investigation for an Optimal Design of Industrial Windows to Allow Natural Ventilation during Wind-Driven Rain. Sustainability 2015, 7, 10499-10520. https://doi.org/10.3390/su70810499

Prueksakorn K, Piao C-X, Ha H, Kim T. Computational and Experimental Investigation for an Optimal Design of Industrial Windows to Allow Natural Ventilation during Wind-Driven Rain. Sustainability. 2015; 7(8):10499-10520. https://doi.org/10.3390/su70810499

Chicago/Turabian StylePrueksakorn, Kritana, Cheng-Xu Piao, Hyunchul Ha, and Taehyeung Kim. 2015. "Computational and Experimental Investigation for an Optimal Design of Industrial Windows to Allow Natural Ventilation during Wind-Driven Rain" Sustainability 7, no. 8: 10499-10520. https://doi.org/10.3390/su70810499

APA StylePrueksakorn, K., Piao, C.-X., Ha, H., & Kim, T. (2015). Computational and Experimental Investigation for an Optimal Design of Industrial Windows to Allow Natural Ventilation during Wind-Driven Rain. Sustainability, 7(8), 10499-10520. https://doi.org/10.3390/su70810499