Green Component Procurement Collaboration for Improving Supply Chain Management in the High Technology Industries: A Case Study from the Systems Perspective

Abstract

:1. Introduction

2. Research Objectives

3. Research Design

3.1. Towards the Environmental Standards and Social Values

3.2. Performance Indices of Economic Feasibility with Green Suppliers

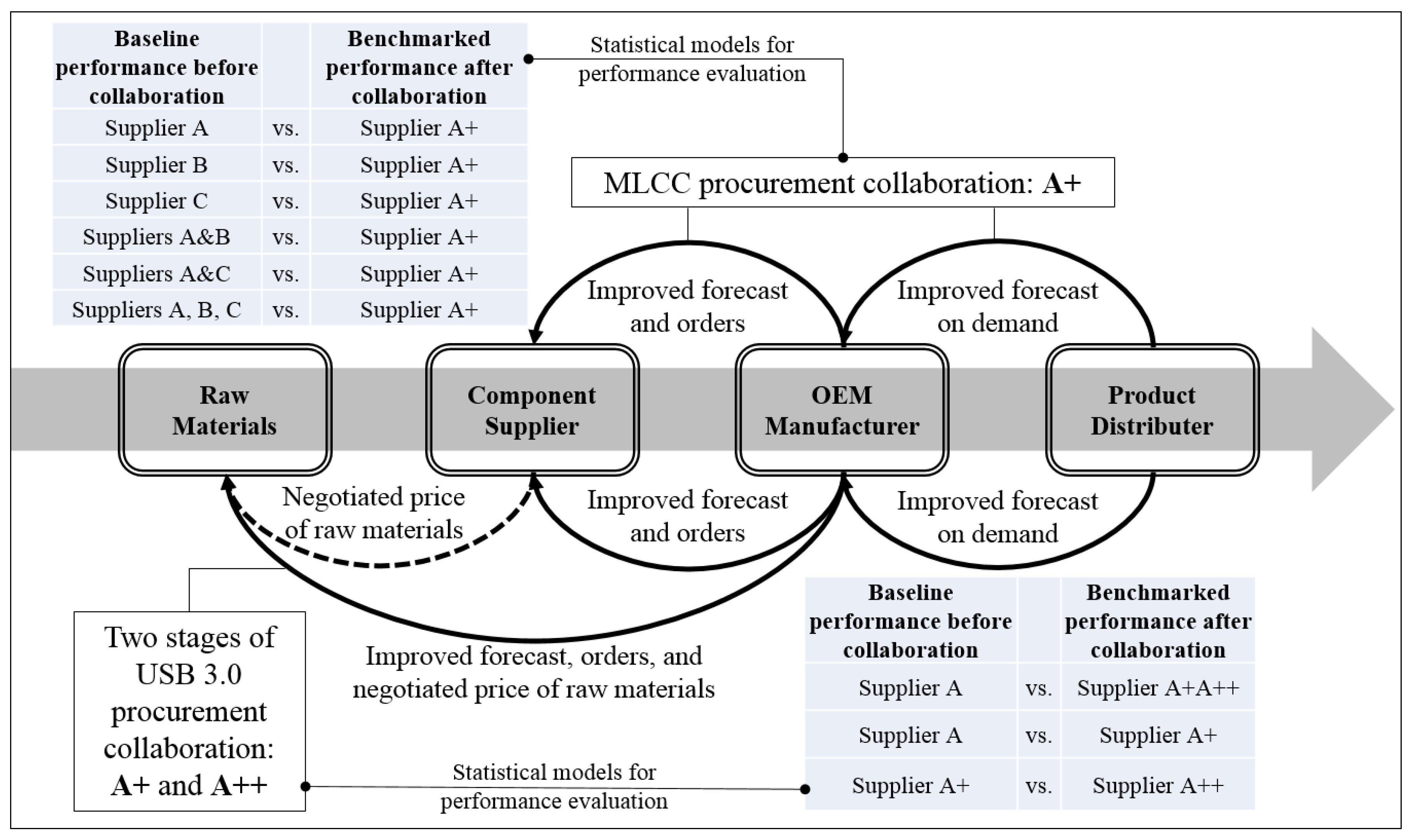

4. Framework for Evaluating the Benchmarked Cases and Systems Analysis

- (1)

- the dependent demand from the OEM company’s procurement strategy, including the forecast of procurement and the real procurement by the OEM company;

- (2)

- the supplier’s capacity planning for meeting the procurement forecast and the delivery time in production and component shipment.

5. Data Collection and Sampling Method for Empirical Study

- (1)

- The selected samples must have the same specifications or the same enterprise characteristics to allow in-depth comparison on the same basis.

- (2)

- Comparable samples from the same supplier are required. Collaboration must occur in the procurement processes of samples for the evaluation of effectiveness differences before and after the collaboration was implemented.

- (3)

- The manufacturing processes of selected samples must remain unchanged before and after the collaboration was implemented.

5.1. MLCC Component Sample Data

| Supplier | Shipping Records before Collaboration | Shipping Records after Collaboration | Total Shipping Records | Total Ordered Quantity (Rolls) | Accuracy of Forecasted Procurement Quantity |

|---|---|---|---|---|---|

| A | 135 | 342 | 477 | 84,782 | 42% |

| B | 197 | N/A | 197 | 57,100 | 29% |

| C | 228 | N/A | 228 | 40,650 | 20% |

5.2. USB 3.0 Cable Component Sample Data

6. Evaluation of Cost Effectiveness for Procurement Collaborations

6.1. Cost Effectiveness of MLCC Procurement Collaboration

| Comparison for Cooperative and Non-Cooperative Suppliers | N | Price Means (US$) | Mean Standard Error (US$) | Cost Effectiveness (Measured by Price Reduction) | Significance (One-Tailed) of t-Test for the Equality of Two Means |

|---|---|---|---|---|---|

| A vs. A+ | 28 | 8.9071 | 0.0130 | 21.60% | *** |

| 70 | 6.9800 | 0.0553 | |||

| B vs. A+ | 42 | 8.8095 | 0.4762 | 20.80% | *** |

| 70 | 6.9800 | 0.0553 | |||

| C vs. A+ | 66 | 9.6136 | 0.0887 | 27.40% | *** |

| 70 | 6.9800 | 0.0553 | |||

| AB vs. A+ | 70 | 8.8486 | 0.2844 | 21.10% | *** |

| 70 | 6.9800 | 0.0553 | |||

| AC vs. A+ | 94 | 9.4032 | 0.0707 | 25.80% | *** |

| 70 | 6.9800 | 0.0553 | |||

| ABC vs. A+ | 136 | 9.2199 | 0.1556 | 24.30% | *** |

| 70 | 6.9800 | 0.0553 |

6.2. Cost Effectiveness of USB 3.0 Cable Procurement Collaboration

| Comparison for Cooperative and Non-Cooperative Suppliers | N | Price Means (US$) | Mean Standard Error (US$) | Cost Effectiveness (Measured by Price Reduction) | Significance (One-Tailed) of t-Test for the Equality of Two Means |

|---|---|---|---|---|---|

| A vs. A+A++ | 77 | 1.2571 | 0.0017 | 8.00% | *** |

| 75 | 1.1556 | 0.0053 | |||

| A vs. A+ | 77 | 1.2571 | 0.0017 | 4.20% | *** |

| 29 | 1.2045 | 0.0009 | |||

| A+ vs. A++ | 29 | 1.2045 | 0.0009 | 6.60% | *** |

| 46 | 1.1248 | 0.0044 |

7. Evaluation of Shipping Time Efficiency under Procurement Collaboration

7.1. Shipping Time Efficiency of MLCC Procurement Collaboration

| Comparison for Cooperative and Non-Cooperative Suppliers | N | Mean Delayed Shipment (Days) | Mean Standard Error (Days) | Shipping Time Efficiency (Measured by Delay Reduction) | Significance (One-Tailed) of t-Test for the Equality of Two Means |

|---|---|---|---|---|---|

| A vs. A+ | 135 | 57.2100 | 7.7610 | 79.13% | *** |

| 342 | 11.9400 | 0.7930 | |||

| B vs. A+ | 197 | 5.0600 | 0.4150 | −135.97% | *** |

| 342 | 11.9400 | 0.7930 | |||

| C vs. A+ | 228 | 8.6000 | 1.7340 | −38.84% | * |

| 342 | 11.9400 | 0.7930 | |||

| AB vs. A+ | 332 | 26.2700 | 3.4580 | 54.55% | *** |

| 342 | 11.9400 | 0.7930 | |||

| AC vs. A+ | 363 | 26.6800 | 3.3170 | 55.25% | *** |

| 342 | 11.9400 | 0.7930 | |||

| ABC vs. A+ | 560 | 19.0700 | 2.1980 | 37.39% | ** |

| 342 | 11.9400 | 0.7930 |

7.2. Shipping Time Efficiency of USB 3.0 Cable Procurement Collaboration

| Comparison for Cooperative and Non-Cooperative Suppliers | N | Mean Delayed Shipment (Days) | Mean Standard Error (Days) | Shipping Time Efficiency (Measured by Delay Reduction) | Significance (One-Tailed) of t-Test for the Equality of Two Means |

|---|---|---|---|---|---|

| A vs. A+A++ | 77 | 9.2078 | 1.6219 | 45.55% | ** |

| 75 | 5.0133 | 0.9338 | |||

| A vs. A+ | 77 | 9.2078 | 1.6219 | 56.18% | ** |

| 29 | 4.0345 | 1.7345 | |||

| A+ vs. A++ | 29 | 4.0345 | 1.7345 | −39.56% | p > 0.1 (insignificant) |

| 46 | 5.6304 | 1.0657 |

8. Conclusions

- (1)

- It systematically investigates the possibility of green component procurement collaboration and illustrates improved performance for the triple objectives of sustainable development. Through green component procurement collaboration, supply chain performance could be enhanced not just from a single operational activity but to a sustainable corporate strategy. If high technology manufacturing companies could develop their organization-wide awareness and sustainable corporate strategy, they would have better alternatives to developing the capability toward SSCM and leading industrial competitiveness with collaborative green suppliers. The risks shared by the commitment to stable procurement collaboration with green suppliers translate into the benefit in cost savings and improved time efficiency that demonstrate the economic feasibility and competitiveness of green supply chain collaboration.

- (2)

- It is hoped this paper will encourage interested groups and parties to acquire information and to participate in the supply chain collaboration process of planning, decision making, and implementation. Green suppliers are able to lower their cost of market development and inventory management, while manufacturers are better equipped to achieve the triple values with defined components and reliable logistics at reasonable cost. Therefore, developing mutual trust relationship through the supply line and contractual arrangement for supply chain collaboration are critical for mutual benefits between the buyer and supplier. The mutual benefits could be further encouraged by governmental policies for industrial development, such as the relevant regulations and/or standards for green materials and manufacturing processes, public-funded incentives for supply chain collaborations, consistent promotions and establishments of consumers’ awareness for sustainability, etc.

- (3)

- In addition to statistically testing the hypothesis with empirical data, this study have added a systems thinking model and computer simulation analysis as a complimentary model to validate the rationale of green component procurement collaboration and its mutual benefits among supply chain partners. Accordingly, it is suggested that a company’s procurement strategy should not only consider the purchasing cost but also the total benefit among the collaborative supply chain partners as a system. The systems thinking and the practices of green component procurement collaboration would help to lower the risk in production, inventory, and delivery process and eventually the purchasing cost for green components.

- (4)

- Compared with the traditional benchmark approach, the proposed green component procurement collaboration model comprises a balanced triple objectives and companies are suggested to consider the multiple objectives as the co-values of SSCM instead of constraints from the market environment and social pressure. With a continuous practice towards SSCM, companies will be able to improve the cost and economic feasibility and demonstrate diverse values to stakeholders and the society. Therefore, the environmental and social standards could be embedded in the multi-criteria decision making process for improving supply chain management so that the sustainable co-values could be encouraged.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yan, M.R.; Chien, K.M. Evaluating the economic performance of high-technology industry and energy efficiency: A case study of science parks in taiwan. Energies 2013, 6, 973–987. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Seuring, S.; Muller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Product. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Brindley, C.; Oxborrow, L. Aligning the sustainable supply chain to green marketing needs: A case study. Ind. Mark. Manag. 2014, 43, 45–55. [Google Scholar] [CrossRef]

- Gaussin, M.; Hu, G.; Abolghasem, S.; Basu, S.; Shankar, M.R.; Bidanda, B. Assessing the environmental footprint of manufactured products: A survey of current literature. Int. J. Prod. Econ. 2013, 146, 515–523. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Mosgaard, M.; Riisgaard, H.; Huulgaard, R.D. Greening non-product-related procurement—When policy meets reality. J. Clean. Product. 2013, 39, 137–145. [Google Scholar] [CrossRef]

- Ozkir, V.; Basligil, H. Modelling product-recovery processes in closed-loop supply-chain network design. Int. J. Prod. Res. 2012, 50, 2218–2233. [Google Scholar] [CrossRef]

- Abbasi, M.; Nilsson, F. Themes and challenges in making supply chains environmentally sustainable. Supply Chain Manag. 2012, 17, 517–530. [Google Scholar]

- Gimenez, C.; Tachizawa, E.M. Extending sustainability to suppliers: A systematic literature review. Supply Chain Manag. 2012, 17, 531–543. [Google Scholar]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Wittstruck, D.; Teuteberg, F. Understanding the success factors of sustainable supply chain management: Empirical evidence from the electrics and electronics industry. Corp. Soc. Responsib. Environ. Manag. 2012, 19, 141–158. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.H.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Barari, S.; Agarwal, G.; Zhang, W.J.; Mahanty, B.; Tiwari, M.K. A decision framework for the analysis of green supply chain contracts: An evolutionary game approach. Expert Syst. Appl. 2012, 39, 2965–2976. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study approach. Transp. Res. E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Bonilla, D.; Keller, H.; Schmiele, J. Climate policy and solutions for green supply chains: Europe’s predicament. Supply Chain Manag. 2015, 20, 249–263. [Google Scholar]

- Jabbour, A.; Azevedo, F.D.; Arantes, A.F.; Jabbour, C.J.C. Green supply chain management in local and multinational high-tech companies located in brazil. Int. J. Adv. Manuf. Technol. 2013, 68, 807–815. [Google Scholar] [CrossRef]

- Yan, R.L.; Wang, K.Y. Franchisor-franchisee supply chain cooperation: Sharing of demand forecast information in high-tech industries. Ind. Mark. Manage. 2012, 41, 1164–1173. [Google Scholar] [CrossRef]

- Chuang, C.H.; Wang, C.X.; Zhao, Y.B. Closed-loop supply chain models for a high-tech product under alternative reverse channel and collection cost structures. Int. J. Prod. Econ. 2014, 156, 108–123. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hu, A.H. Green supply chain management in the electronic industry. Int. J. Environ. Sci. Technol. 2008, 5, 205–216. [Google Scholar] [CrossRef]

- Sheu, J.B. Green supply chain collaboration for fashionable consumer electronics products under third-party power intervention-a resource dependence perspective. Sustainability 2014, 6, 2832–2875. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Product. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and resilient supply chain network design under disruption risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef]

- Chen, R.J.C. An integrated sustainable business and development system: Thoughts and opinions. Sustainability 2014, 6, 6862–6871. [Google Scholar] [CrossRef]

- Devika, K.; Jafarian, A.; Nourbakhsh, V. Designing a sustainable closed-loop supply chain network based on triple bottom line approach: A comparison of metaheuristics hybridization techniques. Eur. J. Oper. Res. 2014, 235, 594–615. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lim, M.; Wong, W.P. Sustainable supply chain management: A closed-loop network hierachical approach. Ind. Manag. Data Syst. 2015, 115, 436–461. [Google Scholar] [CrossRef]

- Wu, K.J.; Liao, C.J.; Tseng, M.L.; Chiu, S.F. Exploring decisive factors in green supply chain practices under uncertainty. Int. J. Product. Econ. 2015, 159, 147–157. [Google Scholar] [CrossRef]

- Deutz, P.; Ioppolo, G. From theory to practice: Enhancing the potential policy impact of industrial ecology. Sustainability 2015, 7, 2259–2273. [Google Scholar] [CrossRef]

- Ioppolo, G.; Cucurachi, S.; Salomone, R.; Saija, G.; Ciraolo, L. Industrial ecology and environmental lean management: Lights and shadows. Sustainability 2014, 6, 6362–6376. [Google Scholar] [CrossRef]

- Kou, T.C.; Lee, B.C.Y. The influence of supply chain architecture on new product launch and performance in the high-tech industry. J. Bus. Ind. Mark. 2015, 30, 677–687. [Google Scholar] [CrossRef]

- Liu, C.C.; Yu, Y.H.; Wernick, I.K.; Chang, C.Y. Using the electronic industry code of conduct to evaluate green supply chain management: An empirical study of Taiwan’s computer industry. Sustainability 2015, 7, 2787–2803. [Google Scholar] [CrossRef]

- Lo, S.M. Effects of supply chain position on the motivation and practices of firms going green. Int. J. Oper. Prod. Manag. 2014, 34, 93–114. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Wu, W.W.; Lee, Y.T.; Tseng, M.L.; Chiang, Y.H. Data mining for exploring hidden patterns between KM and its performance. Knowl.-Based Syst. 2010, 23, 397–401. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P. Being “green and competitive”: The impact of environmental actions and collaborations on firm performance. Bus. Strateg. Environ. 2013, 24, 413–430. [Google Scholar] [CrossRef]

- National Council for Sustainable Development. 2013 Sustainable Development Indicator Report; National Council for Sustainable Development Network: Taipei, Taiwan, 2014. [Google Scholar]

- Levi, D.S.; Kaminsky, P.; Levi, E.S. Designing and Managing the Supply Chain: Concepts, Strategies, and Case Studies; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Ramanathan, U. Supply chain collaboration for improved forecast accuracy of promotional sales. Int. J. Oper. Prod. Manag. 2012, 32, 676–695. [Google Scholar] [CrossRef]

- Behzad, G.; Dragan, B.; Andrew, J. Product support improvement by considering system operating environment: A case study on spare parts procurement. Int. J. Qual. Reliab. Manag. 2012, 29, 436–450. [Google Scholar]

- Philip, M.K.L.; Cesar, R.-G. In search of differentiation and the creation of value: The quest of the scottish pig supply chainnull. Br. Food J. 2013, 115, 1487–1504. [Google Scholar]

- Yan, M.R. Project-based market competition and policy implications for sustainable developments in building and construction sectors. Sustainability 2015, 7, 15423–15448. [Google Scholar] [CrossRef]

- Sterman, J. Business Dynamics: Systems Thinking and Modeling for a Complex World; HAR/CDR, Ed.; McGraw-Hill Education: Columbus, OH, USA, 2000. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.-R.; Chien, K.-M.; Yang, T.-N. Green Component Procurement Collaboration for Improving Supply Chain Management in the High Technology Industries: A Case Study from the Systems Perspective. Sustainability 2016, 8, 105. https://doi.org/10.3390/su8020105

Yan M-R, Chien K-M, Yang T-N. Green Component Procurement Collaboration for Improving Supply Chain Management in the High Technology Industries: A Case Study from the Systems Perspective. Sustainability. 2016; 8(2):105. https://doi.org/10.3390/su8020105

Chicago/Turabian StyleYan, Min-Ren, Kuo-Ming Chien, and Tai-Ning Yang. 2016. "Green Component Procurement Collaboration for Improving Supply Chain Management in the High Technology Industries: A Case Study from the Systems Perspective" Sustainability 8, no. 2: 105. https://doi.org/10.3390/su8020105

APA StyleYan, M.-R., Chien, K.-M., & Yang, T.-N. (2016). Green Component Procurement Collaboration for Improving Supply Chain Management in the High Technology Industries: A Case Study from the Systems Perspective. Sustainability, 8(2), 105. https://doi.org/10.3390/su8020105