Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways

Abstract

:1. Introduction

1.1. Background

1.2. Brief History of Prefab

2. Prefabricated Building Concepts

2.1. Degree of Prefabrication

2.1.1. Components

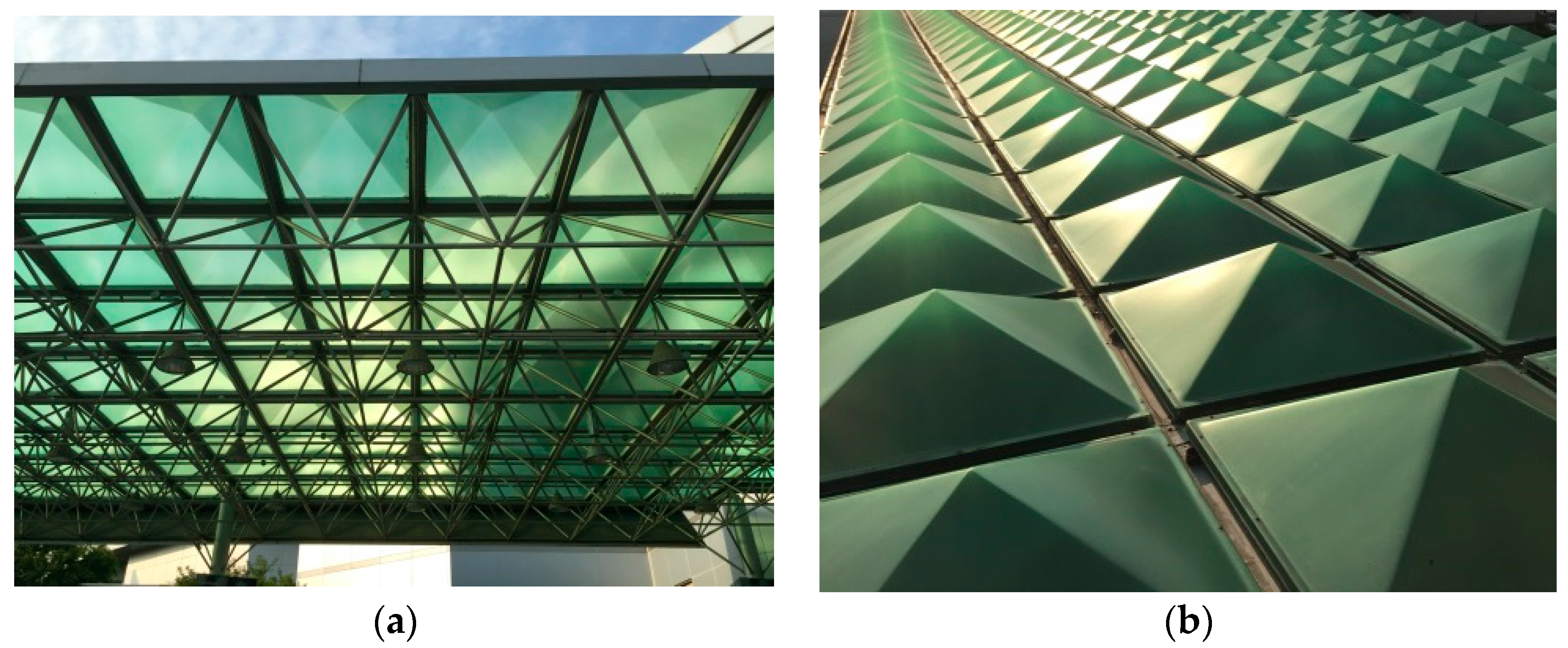

2.1.2. Panelized Structures

2.1.3. Modular Structures

2.1.4. Hybrid Structures

2.1.5. Unitized Whole Buildings

2.2. Load-Bearing Material Classification

2.3. Prefab Methodology

2.3.1. General Approach

2.3.2. On-Site Assembly Case Study

3. Performance of Modular Prefab Cases

3.1. Thermal Behavior

3.2. Acoustic Constraints

3.3. Seismic Resistance

3.4. Energy Consumption

3.5. Life Cycle Analysis

4. Future Pathways

5. Summary and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chairman Zhang’s Flatpack Skyscrapers. Available online: http://www.bbc.com/news/resources/idt-3cca82c0-af80-4c3a-8a79-84fda5015115 (accessed on 21 December 2015).

- Blink and You’ll Miss It 57-Storey Skyscraper Built in 19 Days. Available online: http://www.theurbandeveloper.com/build-skyscraper-19-days/ (accessed on 21 December 2015).

- Broad Sustainable Building. Available online: http://www.61.187.123.140/enbroadcom/uploads/pdf/enhzdj.pdf (accessed on 21 April 2016).

- Smith, R.E. Prefab Architecture: A Guide to Modular Design and Construction; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Permanent Modular Construction. Annual Report. Available online: http://www.modular.org/ (accessed on 20 April 2016).

- Pasquire, C.L.; Conolly, G.E. Leaner construction through off-site manufacturing. In Proceedings of the 10th Annual Conference, International Group for Lean Construction, Gramado, Brazil, 6–8 August 2002.

- Bertelsen, S. Lean construction: Where are we and how to proceed. Lean Constr. J. 2004, 1, 46–69. [Google Scholar]

- Höök, M.; Stehn, L. Applicability of lean principles and practices in industrialized housing production. Constr. Manag. Econ. 2008, 26, 1091–1100. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.; Dainty, A.R. Perspectives of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef] [Green Version]

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef] [Green Version]

- Schoenborn, J.M. A Case Study Approach to Identifying the Constraints and Barriers to Design Innovation for Modular Construction. Master‘s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, Virginia, 27 April 2012. Available online: https://theses.lib.vt.edu/theses/available/etd-05082012-010848/ (acccessed on 14 June 2016). [Google Scholar]

- Velamati, S. Feasibility, Benefits and Challenges of Modular Construction in High Rise Development in the United States: A Developer’s Perspective; Massachusetts Institute of Technology: Cambridge, MA, USA, 2012; Available online: https://dspace.mit.edu/handle/1721.1/77129 (accessed on 14 June 2016).

- Park, M.; Ingawale-Verma, Y.; Kim, W.; Ham, Y. Construction policymaking: With an example of singaporean government’s policy to diffuse prefabrication to private sector. KSCE J. Civ. Eng. 2011, 15, 771–779. [Google Scholar] [CrossRef]

- Delfani, M.; Ibrahim, R.; Raschid, M.Y.M. Towards designing modular of industralized building systems. J. Teknol. 2016. [Google Scholar] [CrossRef]

- Patlakas, P.; Menendez, J.; Hairstans, R. The potential, requirements, and limitations of BIM for offsite timber construction. Int. J. 3-D Inf. Model. 2015, 4, 54–70. [Google Scholar] [CrossRef]

- Ramaji, I.J.; Memari, A.M.; Solnosky, R. Integrated BIM platform for multi-story modular building industry. In Proceedings of the PHRC 2nd Annual Residential Building Design & Construction Conference, State College, PA, USA, 19–20 February 2014.

- Vernikos, V.; Goodier, C.I.; Gibb, A.G. Building Information Modelling and Offsite Construction in Civil Engineering; ARCOM: Loughborough, UK, 2013; Available online: https://dspace.Iboro.ac.uk/dspace-jspui/handle/2134/14483 (accessed on 14 June 2016).

- Nadim, W.; Goulding, J.S. Offsite production in the UK: The way forward? A UK construction industry perspective. Constr. Innov. 2010, 10, 181–202. [Google Scholar] [CrossRef]

- Blismas, N.G.; Pendlebury, M.; Gibb, A.; Pasquire, C. Constraints to the use of off-site production on construction projects. Archit. Eng. Des. Manag. 2005, 1, 153–162. [Google Scholar] [CrossRef] [Green Version]

- UNFCCC COP 31, Adoption of the Paris Agreement. Available online: http://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf (accessed on 21 December 2015).

- Matoski, A.; Ribeiro, R.S. Evaluation of the acoustic performance of a modular construction system: Case study. Appl. Acoust. 2016, 106, 105–112. [Google Scholar] [CrossRef]

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. Archit. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.; Chiang, Y. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Musa, M.F.; Mohammad, M.F.; Mahbub, R.; Yusof, M.R. Enhancing the quality of life by adopting sustainable modular Industrialised Building System (IBS) in the malaysian construction industry. Proced. Soc. Behav. Sci. 2014, 153, 79–89. [Google Scholar] [CrossRef]

- Noguchi, M.; Hernàndez-Velasco, C.R. A mass custom design approach to upgrading conventional housing development in Mexico. Habitat Int. 2005, 29, 325–336. [Google Scholar] [CrossRef]

- Benros, D.; Duarte, J. An integrated system for providing mass customized housing. Autom. Constr. 2009, 18, 310–320. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M.; Zeng, S.; William, C.Y.N. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of modular construction in high-rise buildings. J. Archit. Eng. 2011, 18, 148–154. [Google Scholar] [CrossRef]

- Adekunle, T.; Nikolopoulou, M. Post-occupancy and indoor monitoring surveys to investigate the potential of summertime overheating in UK prefabricated timber houses. In Proceedings of the 8th Windsor Conference, Windsor, UK, 10–14 April 2014.

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Kelly, B. The Prefabrication of Houses; The Technology Press of The Massachusetts Institute of Technology; John Wiley and Sons, Inc.: New York, NY, USA; Chapman & Hall, Ltd.: London, UK, 1951. [Google Scholar]

- Lauren, H. High Speed High Rise: The Earthquake-Proof Skyscrapers Built in 15 Days. Available online: http://www.wired.co.uk/article/high-speed-high-rise (accessed on 21 December 2015).

- WoodWorks, Putting Pieces Together; Technical Report. Available online: http://www.woodworks.org/ (accessed on 20 April 2016).

- The Meridian First Light House. Available online: http://www.firstlightstudio.co.nz/the-meridian-first-light-house/#top (accessed on 20 April 2016).

- US Department of Energy Solar Decathlon. Final Results. Available online: http://www.solardecathlon.gov/past/2011/final_results.html (accessed on 20 April 2015).

- Bell, P. Prefabrication in New Zealand: New Housing Types + Case Studies; Prefab NZ, Presentation Material: Seoul, Korea, 2014; Available online: www.prefabnz.com (accessed on 14 June 2016).

- Falk, R.H.; McKeever, D.B. Recovering Wood for Reuse and Recycling: A United States Perspective. In Proceedings of the European COST E31 Conference : Management of recovered wood recycling bioenergy and other options Construction, Thessaloniki, Greece, 22–24 April 2004; pp. 29–40. Available online: www.treesearch.fs.fed.us/pubs/7100 (accessed on 14 June 2016).

- Lori, Z. Cantilevered Shipping Container Coffee Shop Pops Up in Johannesburg. Available online: http://inhabitat.com/cantilevered-shipping-container-coffee-shop-pops-up-in-johannesburg/ (accessed on 31 May 2016).

- Noguchi, M. The effect of the quality-oriented production approach on the delivery of prefabricated homes in Japan. J. Hous. Built Environ. 2003, 18, 353–364. [Google Scholar] [CrossRef]

- Kurt, M.; Gul, M.S.; Gul, R.; Aydin, A.C.; Kotan, T. The effect of pumice powder on the self-compactability of pumice aggregate lightweight concrete. Constr. Build. Mater. 2016, 103, 36–46. [Google Scholar] [CrossRef]

- Martins, P.F.; de Campos, P.F.; Nunes, S.; Sousa, J.P. Expanding the material possibilities of lightweight prefabrication in concrete through robotic hot-wire cutting-form, texture and composition. In Proceedings of 33rd Annual Conference, eCAADe, Vienna, Austria, 16–18 September 2015.

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Kim, T.; Tae, S.; Roh, S. Assessment of the CO2 emission and cost reduction performance of a low-carbon-emission concrete mix design using an optimal mix design system. Renew. Sustain. Energy Rev. 2013, 25, 729–741. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M.; Ostertag, C.P. Greenhouse gas emissions from concrete can be reduced by using mix proportions, geometric aspects, and age as design factors. Environ. Res. Lett. 2015, 10, 114–017. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Lee, W.-H.; Kim, K.-W.; Lim, S.-H. Improvement of floor impact sound on modular housing for sustainable building. Renew. Sustain. Energy Rev. 2014, 29, 263–275. [Google Scholar] [CrossRef]

- Newton, C. Prefabrication Perspectives from Australia; Presentation Material: Seoul, Korea, 2014. [Google Scholar]

- Inside One9: The Six Star, Prefab Apartments in Moonee Ponds. Available online: http://www.theurbandeveloper.com/inside-one9-the-six-star-prefab-apartments-in-moonee-ponds/ (accessed on 21 December 2015).

- Meng, X.; Wang, C.; Liang, W.; Wang, S.; Li, P.; Long, E. Thermal performance improvement of prefab houses by covering retro-reflective materials. Proced. Eng. 2015, 121, 1001–1007. [Google Scholar] [CrossRef]

- Chen, H.; Long, E.; Huang, L.; Wang, T. Discussion of the indoor thermal environment of prefab house in winter of Chengdu. Refrig. Air Cond. 2011, 121, 1628–1634. [Google Scholar]

- Synnefa, A.; Santamouris, M.; Livada, I. A study of the thermal performance of reflective coatings for the urban environment. Solar Energy 2006, 80, 968–981. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gasper, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Meng, X.; Wang, M.; Long, E. Research on indoor thermal environment improvement of lightweight building integrated with phase change material under different climate conditions. Proced. Eng. 2015, 121, 1628–1634. [Google Scholar] [CrossRef]

- Annan, C.; Youssef, M.; el Naggar, M. Seismic overstrength in braced frames of modular steel buildings. J. Earthq. Eng. 2008, 13, 1–21. [Google Scholar] [CrossRef]

- Annan, C.; Youssef, M.; el Naggar, M. Analytical investigation of semi-rigid floor beams connection in modular steel structures. In Proceedings of the 33rd Annual General Conference of the Canadian Society for Civil Engineering, Toronto, ON, Canada, 2–4 June 2005.

- Annan, C.; Youssef, M.; el Naggar, M. Seismic performance of modular steel braced frames. In Proceedings of the Ninth Canadian Conference on Earthquake Engineering, Ottawa, ON, Canada, 26–29 June 2007.

- Annan, C.; Youssef, M.; el Naggar, M. Experimental evaluation of the seismic performance of modular steel-braced frames. Eng. Struct. 2009, 31, 1435–1446. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Papadopoulos, A.M. Cost-optimal insulation thickness in dry and mesothermal climates: Existing models and their improvement. Energy Build. 2014, 68, 203–212. [Google Scholar] [CrossRef]

- Zhang, Y.; He, C.-Q.; Tang, B.-J. China’s energy consumption in the building sector: A life cycle approach. Energy Build. 2015, 94, 240–251. [Google Scholar] [CrossRef]

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast), Official Journal of the European Union, 153 (2010) 13–35. Available online: http://www.eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:EN:PDF (accessed on 20 April 2016).

- Institute, M.B. Modular Advantage. Available online: http://www.modular.org/HtmlPage.aspx?name=Modular_Passive_House_Dorm_MA (accessed on 31 May 2016).

- Adalberth, K. Energy use during the life cycle of single-unit dwellings: Examples. Build. Environ. 1997, 32, 321–329. [Google Scholar] [CrossRef]

- Scheuer, C.; Keoleian, G.A.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Keoleian, G.A.; Blanchard, S.; Reppe, P. Life-cycle energy, costs, and strategies for improving a single-family house. J. Ind. Ecol. 2000, 4, 135–156. [Google Scholar] [CrossRef]

- Cole, R.J.; Kernan, P.C. Life-cycle energy use in office buildings. Build. Environ. 1996, 31, 307–317. [Google Scholar] [CrossRef]

- Cole, R.J. Energy and greenhouse gas emissions associated with the construction of alternative structural systems. Build. Environ. 1998, 34, 335–348. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Itard, L.; Klunder, G. Comparing environmental impacts of renovated housing stock with new construction. Build. Res. Inf. 2007, 35, 252–267. [Google Scholar] [CrossRef]

- Kim, D. Preliminary Life Cycle Analysis of Modular and Conventioinal Housing in Benton Harbor, Michigan; University of Michigan: Ann Arbor, MI, USA, 2008. [Google Scholar]

- Ramaji, I.J.; Memari, A.M. Product architecture model for multistory modular buildings. J. Constr. Eng. Manag. 2016. [Google Scholar] [CrossRef]

- Kamar, A.M.; Hamid, Z.A.; Azman, N.A. Industrialized Building System (IBS): Revisiting issues of definition and classification. Int. J. Emerg. Sci. 2011, 1, 120–132. [Google Scholar]

- Zavala, G.R.; Nebro, A.J.; Luna, F.; Coello, C.A. A survey of multi-objective metaheuristics applied to structural optimization. Struct. Multidiscip. Opt. 2014, 49, 537–558. [Google Scholar] [CrossRef]

- Dodier, R.H.; Henze, G.P. Statistical analysis of neural networks as applied to building energy prediction. J. Solar Energy Eng. 2004, 126, 592–600. [Google Scholar] [CrossRef]

| Climate Zone | City | Season | Tout | Tin1 | Tin2 | ΔTday | ΔTnight |

|---|---|---|---|---|---|---|---|

| Severe cold | Harbin | Winter | −25.1–11.0 | −26.9–11.0 | −18.7–14.7 | 5.7 | 8.7 |

| Transition | 13.2–24.2 | 12.4–32.3 | 22–25.2 | 7.7 | 10.0 | ||

| Summer | 14.4–28.4 | 14.8–35.9 | 25.0–29.5 | 7.4 | 9.9 | ||

| Cold | Beijing | Winter | −7.3–8.4 | −8.3–15.4 | −0.5–5.1 | 11.5 | 8.4 |

| Transition | 11.8–29.4 | 11.9–38.5 | 24.2–29.6 | 9.7 | 13.9 | ||

| Summer | 27.2–34.8 | 27.2–42.0 | 33.6–37.4 | 4.9 | 7.5 | ||

| Hot summer and cold winter | Shanghai | Winter | 0.9–14.9 | 0.5–21.6 | 7.7–12.6 | 9.8 | 7.4 |

| Transition | 17.4–20.7 | 16.2–27.6 | 23.7–25.3 | 2.7 | 8.1 | ||

| Summer | 27.2–32.8 | 26.1–41.3 | 31.5–36.6 | 7.3 | 6.7 | ||

| Hot summer and hot winter | Guangzhou | Winter | 6.0–14.9 | 4.4–31.5 | 15.4–21.18 | 11.0 | 11.6 |

| Transition | 13.8–25.8 | 12.7–36.3 | 22.1–27.9 | 9.7 | 9.8 | ||

| Summer | 27.1–35.6 | 27.1–43.6 | 35.4–38.8 | 5.2 | 9.4 | ||

| Temperate | Kunming | Winter | 1.9–17.8 | 1.7–28.6 | 12.5–18.5 | 11.2 | 11.6 |

| Transition | 13.3–23.7 | 12.0–32.5 | 21.2–25.3 | 8.1 | 9.8 | ||

| Summer | 13.9–25.8 | 13.8–36.1 | 24.4–36.1 | 7.7 | 10.3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boafo, F.E.; Kim, J.-H.; Kim, J.-T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. https://doi.org/10.3390/su8060558

Boafo FE, Kim J-H, Kim J-T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability. 2016; 8(6):558. https://doi.org/10.3390/su8060558

Chicago/Turabian StyleBoafo, Fred Edmond, Jin-Hee Kim, and Jun-Tae Kim. 2016. "Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways" Sustainability 8, no. 6: 558. https://doi.org/10.3390/su8060558

APA StyleBoafo, F. E., Kim, J.-H., & Kim, J.-T. (2016). Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability, 8(6), 558. https://doi.org/10.3390/su8060558