Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain

Abstract

:1. Introduction

2. Literature Review

2.1. Monitoring System in Food Supply Chain

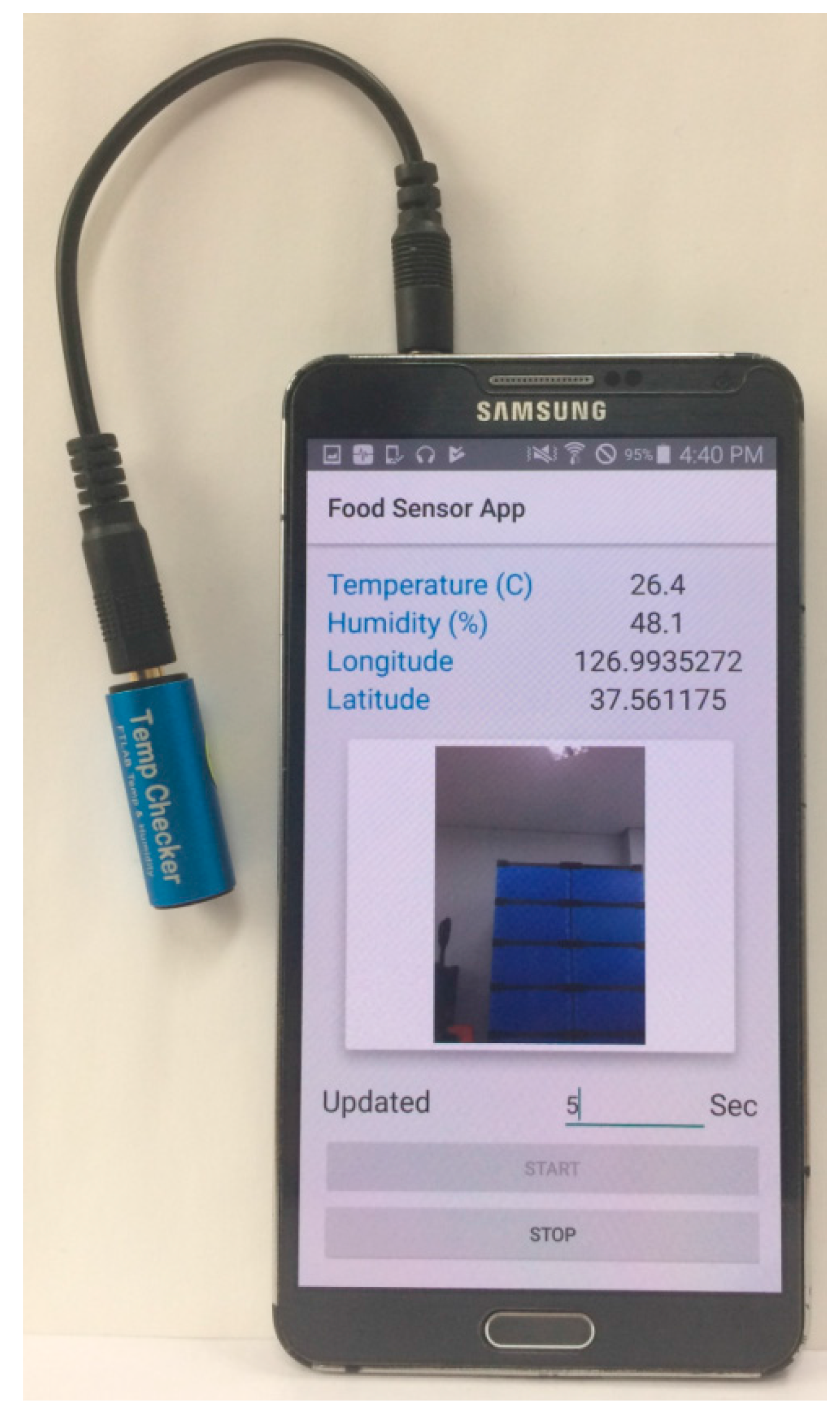

2.2. Smartphone-Based Sensors

2.3. NoSQL for Big Data

2.4. Outlier Detection

2.4.1. Statistical-Based Approach

2.4.2. Clustering-Based Approach

- For each point unvisited in D, mark as visited and find that the ϵ-neighborhood of contains at least MinPts objects.

- If is not already assigned to a cluster, create a new cluster C. Add the objects in the ϵ-neighborhood of to a candidate set N. Add any objects in N (that do not belong to any cluster) to C .

- For each object p in N, mark p as visited and find that the ϵ-neighborhood of contains at least MinPts objects. Those objects in the ϵ-neighborhood of are then added to the candidate set N and assigned to cluster C.

- Iterate through the remaining objects in N and the unvisited points in the data set D.

3. Methodology

3.1. System Design

3.2. System Implementation

4. Results and Discussion

4.1. Performance of MongoDB-Based Real-Time Monitoring System

4.2. The Performance of the Smartphone-Based Sensor Monitoring System

4.3. Outlier Detection Methods for Sensor Data

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sethi, P.; Sarangi, S.R. Internet of Things: Architectures, Protocols, and Applications. J. Electr. Comput. Eng. 2017. [Google Scholar] [CrossRef]

- Aloi, G.; Caliciuri, G.; Fortino, G.; Gravina, R.; Pace, P.; Russo, W.; Savaglio, C. Enabling IoT interoperability through opportunistic smartphone-based mobile gateways. J. Netw. Comput. Appl. 2017, 81, 74–84. [Google Scholar] [CrossRef]

- Lane, N.D.; Miluzzo, E.; Lu, H.; Peebles, D.; Choudhury, T.; Campbell, A.T. A survey of mobile phone sensing. IEEE Commun. Mag. 2010, 48, 140–150. [Google Scholar] [CrossRef]

- Morón, M.J.; Luque, R.; Casilari, E. On the Capability of Smartphones to Perform as Communication Gateways in Medical Wireless Personal Area Networks. Sensors 2014, 14, 575–594. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Gerla, M. Personal Gateway in Mobile Health Monitoring. In Proceedings of the 2011 IEEE International Conference on Pervasive Computing and Communications Workshops (PERCOM Workshops), Seattle, WA, USA, 21–25 March 2011; pp. 636–641. [Google Scholar]

- Pongnumkul, S.; Chaovalit, P.; Surasvadi, N. Applications of Smartphone-Based Sensors in Agriculture: A Systematic Review of Research. J. Sens. 2015, 195308. [Google Scholar] [CrossRef]

- Thiagarajan, A.; Ravindranath, L.; LaCurts, K.; Madden, S.; Balakrishnan, H.; Toledo, S.; Eriksson, J. VTrack: Accurate, Energy-Aware Traffic Delay Estimation Using Mobile Phones. In Proceedings of the 7th ACM Conference on Embedded Networked Sensor Systems, Berkeley, CA, USA, 4–6 November 2009. [Google Scholar]

- Trieneken, J.; Zuurbier, P. Quality and Safety Standards in the food industry, developments and challenges. Int. J. Prod. Econ. 2008, 113, 107–122. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Temperature management for the quality assurance of a perishable food supply chain. Food Control 2014, 40, 198–207. [Google Scholar] [CrossRef]

- Thakur, M.; Foras, E. EPCIS based online temperature monitoring and traceability in a cold meat chain. Comput. Electron. Agric. 2015, 117, 22–30. [Google Scholar] [CrossRef]

- Ko, D.; Kwak, Y.; Song, S. Real Time Traceability and Monitoring System for Agricultural Products Based on Wireless Sensor Network. Int. J. Distrib. Sens. Netw. 2014. [Google Scholar] [CrossRef]

- Jagyasi, B.G.; Pande, A.K.; Jain, R. Event based experiential computing in agro-advisory system for rural farmers. In Proceedings of the IEEE 7th International Conference on Wireless and Mobile Computing, Networking and Communications (WiMob’11), Washington, DC, USA, 10–12 October 2011; pp. 439–444. [Google Scholar]

- Gómez-Robledo, L.; López-Ruiz, N.; Melgosa, M.; Palma, A.J.; Capitán-Vallvey, L.F.; Sánchez-Marañón, M. Using the mobile phone as munsell soil-colour sensor: An experiment under controlled illumination conditions. Comput. Electron. Agric. 2013, 99, 200–208. [Google Scholar] [CrossRef]

- Sharma, S.; Raval, J.; Jagyasi, B. Mobile sensing for agriculture activities detection. In Proceedings of the 3rd IEEE Global Humanitarian Technology Conference (GHTC 2013), San Jose/Silicon Valley, CA, USA, 20–23 October 2013; pp. 337–342. [Google Scholar]

- Liu, B.; Koc, A.B. Safe Driving: A mobile application for tractor rollover detection and emergency reporting. Comput. Electron. Agric. 2013, 98, 117–120. [Google Scholar] [CrossRef]

- Veen, J.S.; Waaij, B.; Meijer, R.J. Sensor data storage performance: SQL or NoSQL, Physical or Virtual. In Proceedings of the IEEE 5th International Conference on Cloud Computing (CLOUD), Honolulu, HI, USA, 24–29 June 2012; pp. 431–438. [Google Scholar]

- Zhuang, Y.; Chen, L. In-network Outlier Cleaning for Data Collection in Sensor Networks. In Proceedings of the CleanDB, Workshop VLDB, Seoul, Korea, 11 September 2006. [Google Scholar]

- Wang, L.; Kwok, S.K.; Ip, W.H. A radio frequency identification and sensor-based system for the transportation of food. J. Food Eng. 2010, 101, 120–129. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and Quality perspective. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Dabbene, F.; Gay, P.; Tortia, C. Traceability issues in food supply chain management: A review. Biosyst. Eng. 2014, 120, 65–80. [Google Scholar] [CrossRef]

- Manzini, R.; Accorsi, R. The new conceptual framework for food supply chain assessment. J. Food Eng. 2013, 115, 251–263. [Google Scholar] [CrossRef]

- Pizzuti, T.; Mirabelli, G. The Global Track & Trace System for food: General framework and functioning principles. J. Food Eng. 2015, 159, 16–35. [Google Scholar]

- Bosona, B.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- European Commission—Agriculture Directorate-General. A Framework for Indicators for the Economic and Social Dimensions of Sustainable Agriculture and Rural Development. Available online: http://ec.europa.eu/agriculture/publi/reports/sustain/index_en.pdf (accessed on 3 November 2017).

- Wognum, P.M.N.; Bremmers, H.; Trienekens, J.H.; van der Vorst, J.G.A.J.; Bloemhof, J.M. Systems for sustainability and transparency of food supply chains–Current status and challenges. Adv. Eng. Inform. 2011, 25, 65–76. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.J.M.; Rialland, A. Virtualization of food supply chains with the internet of things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef] [Green Version]

- Accorsi, R.; Bortolini, M.; Baruffaldi, G.; Pilati, F.; Ferrari, E. Internet-of-things Paradigm in Food Supply Chains Control and Management. Procedia Manuf. 2017, 11, 889–895. [Google Scholar] [CrossRef]

- Copeland, R. MongoDB Applied Design Patterns; O‘Reilly Media, Inc.: Sebastopol, CA, USA, 2013. [Google Scholar]

- Chodorow, K. MongoDB: The Definitive Guide; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2013. [Google Scholar]

- Nyati, S.S.; Pawar, S.; Ingle, R. Performance evaluation of unstructured NoSQL data over distributed framework. In Proceedings of the 2013 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Mysore, India, 22–25 August 2013; pp. 1623–1627. [Google Scholar]

- Kang, Y.S.; Park, I.H.; Rhee, J.; Lee, Y.H. MongoDB-based repository design for IoT-generated RFID/sensor big data. IEEE Sens. J. 2015, 16, 485–497. [Google Scholar] [CrossRef]

- Kumar, K.B.S.; Srividya; Mohanavalli, S. A performance comparison of document oriented NoSQL databases. In Proceedings of the International Conference on Computer, Communication and Signal Processing (ICCCSP), Chennai, India, 10–11 January 2017. [Google Scholar] [CrossRef]

- Tavares, A.T.; Oliveira, M.I.S.; Lóscio, B.F. Data producer catalogs for the web of things: A study on NoSQL solutions. In Proceedings of the 31st Annual ACM Symposium on Applied Computing (SAC ’16), Pisa, Italy, 4–8 April 2016. [Google Scholar] [CrossRef]

- Li, Y.; Manoharan, S. A performance comparison of SQL and NoSQL databases. In Proceedings of the IEEE Pacific Rim Conference on Communications, Computers and Signal Processing (PACRIM), Victoria, BC, Canada, 27–29 August 2013. [Google Scholar] [CrossRef]

- Pereira, D.A.; de Morais, W.O.; de Freitas, E.P. NoSQL real-time database performance comparison. Int. J. Parallel, Emerg. Distrib. Syst. 2017. [Google Scholar] [CrossRef]

- Han, J.; Kamber, M.; Pei, J. Data Mining: Concepts and Techniques, 3rd ed.; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2011. [Google Scholar]

- Zhao, Y.; Lehman, B.; Ball, R.; Mosesian, J.; de Palma, J.F. Outlier detection rules for fault detection in solar photovoltaic arrays. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 2913–2920. [Google Scholar]

- Ester, M.; Kriegel, H.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the KDD’96 Proceedings of the Second International Conference on Knowledge Discovery and Data Mining, Portland, OR, USA, 2–4 August 1996. [Google Scholar]

- Park, K.Y.; Jeong, J.K.; Lee, Y.E.; Daily, J.W., III. Health Benefits of Kimchi (Korean Fermented Vegetables) as a Probiotic Food. J. Med. Food 2014, 17, 6–20. [Google Scholar] [CrossRef] [PubMed]

- Eom, K.; Lee, C.H.; Park, S.Y.; Kim, J.W. Fermentation Food Monitoring System using the Smart RFID Sensor Tag. Int. J. Multimed. Ubiquitous Eng. 2013, 8, 55–66. [Google Scholar] [CrossRef]

- Smart Temp Checker. Available online: http://allsmartlab.com/eng/smart-temp-checker-ftc-001/ (accessed on 26 September 2017).

- Cluster Module. Available online: https://nodejs.org/api/cluster.html (accessed on 26 September 2017).

- Lee, G.I.; Lee, H.M.; Lee, C.H. Food safety issues in industrialization of traditional Korean foods. Food Control 2012, 24, 1–5. [Google Scholar] [CrossRef]

- Thang, T.M.; Kim, J. The Anomaly Detection by Using DBSCAN Clustering with Multiple Parameters. In Proceedings of the 2011 International Conference on Information Science and Applications, Jeju Island, Korea, 23 May 2011; pp. 1–5. [Google Scholar]

- Chen, Z.; Li, Y.F. Anomaly Detection Based on Enhanced DBScan Algorithm. Procedia Eng. 2011, 15, 178–182. [Google Scholar] [CrossRef]

| Server | Client | ||

|---|---|---|---|

| Hardware | CPU | 4.20 GHz × 8 cores | 2.53 GHz × 8 cores |

| RAM | 16 GB | 16 GB | |

| HDD | 500 GB | SSD 250 GB | |

| Software | OS | Ubuntu Server 14.04 | Windows 10 Pro 64-bit |

| Node.js | 8.4.0 | - | |

| Express | 4.15.4 | - | |

| Socket.IO | 1.7.4 | - | |

| MongoDB | 3.4.7 | - | |

| JDK | - | 1.8.0_144 | |

| Eclipse | - | 4.7.0 | |

| HttpClient | - | 4.5.3 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfian, G.; Syafrudin, M.; Rhee, J. Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain. Sustainability 2017, 9, 2073. https://doi.org/10.3390/su9112073

Alfian G, Syafrudin M, Rhee J. Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain. Sustainability. 2017; 9(11):2073. https://doi.org/10.3390/su9112073

Chicago/Turabian StyleAlfian, Ganjar, Muhammad Syafrudin, and Jongtae Rhee. 2017. "Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain" Sustainability 9, no. 11: 2073. https://doi.org/10.3390/su9112073

APA StyleAlfian, G., Syafrudin, M., & Rhee, J. (2017). Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain. Sustainability, 9(11), 2073. https://doi.org/10.3390/su9112073