Abstract

Collegiate sporting venues have been leading efforts toward zero-waste events in pursuit of more sustainable operations. This study audited the landfill-destined waste generated at the University of Missouri (MU) football stadium in 2014 and evaluated the life cycle greenhouse gas (GHG) and energy use associated with waste management options, including options that do and do not comply with zero-waste definitions. An estimated 47.3 metric tons (mt) of waste was generated, the majority (29.6 mt waste) came from off-site, pre-game food preparation activities; of which over 96 percent (%) was pre-consumer and un-sold food waste. The remaining 17.7 mt originated from inside the stadium; recyclable materials accounting for 43%, followed by food waste, 24%. Eleven waste management strategies were evaluated using the Waste Reduction Model (WARM). Results indicate that scenarios achieving zero waste compliance are not necessarily the most effective means of reducing GHG emissions or energy use. The two most effective approaches are eliminating edible food waste and recycling. Source reduction of edible food reduced GHGs by 103.1 mt (carbon dioxide equivalents) CO2e and generated energy savings of 448.5 GJ compared to the baseline. Perfect recycling would result in a reduction of 25.4 mt CO2e and 243.7 GJ compared to the baseline. The primary challenges to achieving these reductions are the difficulties of predicting demand for food and influencing consumer behavior.

Keywords:

zero waste; green events; waste management; sustainability; food waste; compost; athletics 1. Introduction

Sustainability initiatives at athletic venues are on the rise. Many professional and collegiate leagues have adopted energy or water conservation efforts, increased recycling and/or composting rates, purchased or generated renewable energy, constructed Leadership in Energy and Environmental Design (LEED) stadiums or arenas and engaged fans to increase awareness about environmental problems [1,2,3]. Athletic events offer a great opportunity for engaging with a large, diverse audience that may not be familiar with sustainability issues and can generate pro-environmental public relations messaging to a broad audience at relatively low cost [4,5]. Academic research on the greening or sustainability of sporting events has increased over the past decade [4,6,7,8,9,10]. However, details and further work are required to investigate various technical factors associated with “greening” an event, including waste auditing procedures, quantitative evaluations of waste management options, and operational issues associated with the event [11]. Few of these studies exist and even fewer specifically addressed waste. Collins et al. employed Ecological Footprint and environmental input-output life cycle assessment to 2004 FA Cup Final at Cardiff’s Millennium Stadium [12]. Results indicated, similar to Dolf [11], that fan travel to the event contributed the most to the overall carbon footprint. Collins, Jones, and Munday found that the second most significant contribution came from food and drink [12].

Waste diversion from landfills to recycling and composting is one of the more frequently noted efforts toward the greening of sporting events. In some instances, organizations have set zero waste goals. The concept of zero waste is grounded in ecological theory and provides a philosophical target that encourages a complete re-thinking of systems. The concept of zero waste is decades old and challenges humanity to close materials loops such that no waste is generated during the production or consumption of any product or service. This concept is intended to inspire creative design innovations throughout the process [13]. The Zero Waste International Alliance defines zero waste as: “…a goal that is ethical, economical, efficient and visionary, to guide people in changing their lifestyles and practices to emulate sustainable natural cycles, where all discarded materials are designed to become resources for others to use [14]. Zero waste means designing and managing products and processes to systematically avoid and eliminate the volume and toxicity of waste and materials, conserve and recover all resources, and not burn or bury them. Implementing zero waste will eliminate all discharges to land, water or air that are a threat to planetary, human, animal or plant health” [14].

Practically speaking, most organizations translate this goal into the target of recycling or composting 90% of the waste stream, rather than landfill disposal [3]. There is no additional requirement associated with equating this 90% diversion rate to “sustainability.” Rather, it is accepted that recycling and composting of the waste stream is the most sustainable option. While it seems intuitive that landfill diversion is environmentally preferable, it is important to quantitatively evaluate alternative management options against specific metrics associated with achieving greater sustainability, e.g., greenhouse gas (GHG) emissions, ecotoxicity, human toxicity, eutrophication potential. That is, assuming that recycling and composting are the only options or the best options should not be a foregone conclusion, and arguably is not wholly consistent with the original intent of the mission and concept of zero waste, as outlined above.

Achieving 90% waste diversion is a complex task involving alteration of supply chains, staff and/or volunteer coordination, and management and often an investment in waste receptacles and fan education at stadiums and arenas. Some university athletics programs have achieved performance near this level; for example, in 2012 the Ohio State University (OSU) achieved an average diversion rate of 87.2% over the season, with a top diversion rate of 98.2% [3]. The first step toward achieving high rates of waste diversion is to systematically inventory the waste stream generated at a facility or individual event. Given that the waste stream is generated in just a week’s time, and that waste emanating from a stadium with seating for tens of thousands of fans in less than a day, interception and auditing of this waste stream requires a sound sampling approach. This inventory generated from the audit is needed for a number of reasons: (1) to forecast the volumes of waste that would need to be directed to selected waste management options, e.g., recycling or composting, this is particularly important if the desired waste management option is not currently available; (2) to identify any waste streams with the potential for source reduction, e.g., food waste; (3) to estimate the life cycle embodied resources in the waste stream; and, (4) to identify all packaging and food service materials that are not recyclable or compostable so that they may be replaced with materials that are either compostable or recyclable in order to meet the zero waste goals. While there are reports of facilities achieving 90% diversion of waste from the landfill or increasing recycling efforts, few described their waste audit procedure, and/or were focused on small events where it was possible to sort all of the waste generated [15].

The research objectives of this study are fourfold: (1) develop a strategy to quantitatively and qualitatively characterize the waste generated during the food preparation activities prior to game day, in the stadium during game day, and unsold food disposed of following game day destined for landfill disposal over the 2014 Mizzou football season; (2) quantify the life cycle energy and greenhouse gases associated with the current waste management approach (landfill disposal) and alternative waste management scenarios using the Environmental Protection Agency’s (EPA) Waste Reduction Model (WARM) [16]; (3) identify waste management strategies that achieve 90% diversion of waste from the landfill in compliance with definitions of zero waste; and, (4) to identify the scenarios that achieve the largest reductions in greenhouse gas emissions and energy use from a life cycle perspective. The analysis is venue-oriented as the aim was to evaluate waste generation and management for stadium operations in the 2014 season. The results of objectives 3 and 4 will be compared to assess whether 90% diversion of waste to recycling and composting result in the greatest reduction in lifecycle greenhouse gas emissions and energy use.

Hottle et al. [15] recently audited and evaluated alternative waste management scenarios using WARM for baseball games at Arizona State University (ASU) (2015). This study involves much larger volumes of waste and required the development of a sampling strategy due to the infeasibility of sorting all of the waste generated. Hottle et al. [15] found that recycling led to the greatest reductions in GHG emissions and energy use, but that replacing petroleum-based plastic materials with compostable plastic materials would make it easier to achieve a single waste stream that would reduce contamination associated with multiple waste streams, ultimately leading to achieving the goal of zero waste with greater ease.

Over the 2014 football season an audit was performed at the University of Missouri (MU) on the waste stream emanating from Memorial Stadium/Faurot Field. The study design included estimating waste originating from the general stadium seating and box seating locations as well as pre-consumer and unsold food waste generated during preparation for game day; waste associated with tailgating was not included. The information collected by this study includes a quantitative estimation of recyclables (polyethylene terephthalate (PET) and high-density polyethylene (HDPE) plastics, aluminum, glass, cardboard, and paper), compostable organics (separated into food and other, e.g., paper), and materials that do not fit into either category (e.g., polypropylene (PP), polystyrene (PS), low-density polyethylene (LDPE)). Using this information and the WARM model, GHGs and net energy use associated with alternative disposal options were quantified [16]. In addition, recommendations are provided regarding next steps and significant challenges for MU’s Intercollegiate Athletics Department and the City of Columbia’s waste management system.

2. Methods

2.1. Site Description

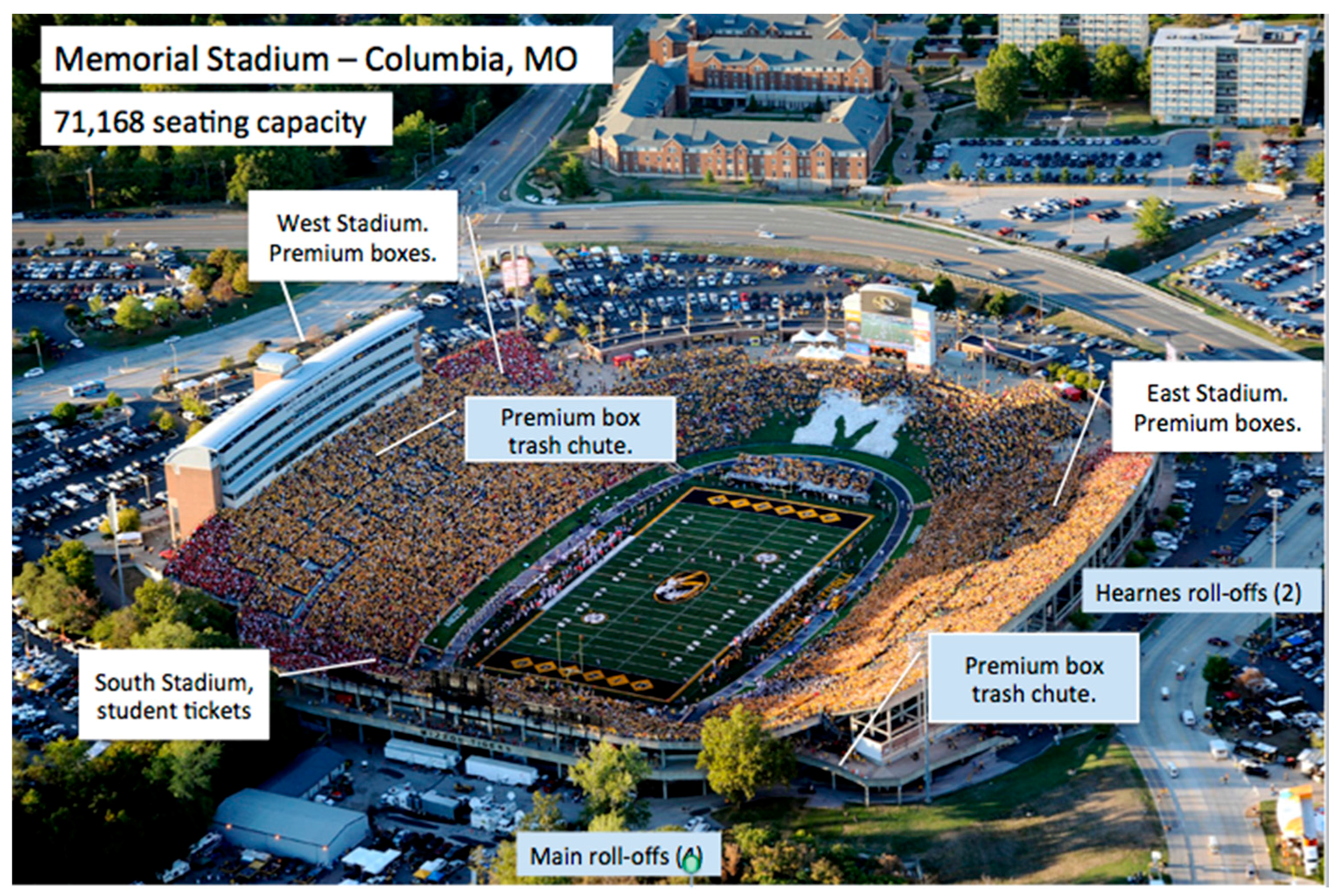

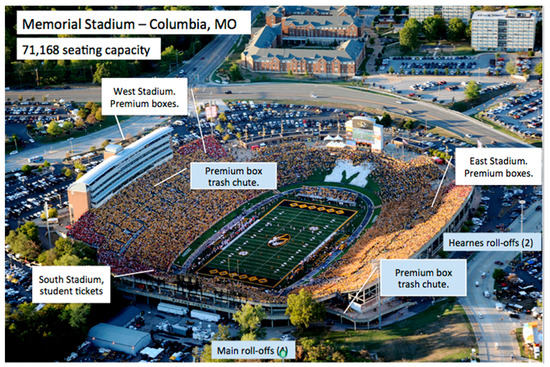

Memorial Stadium/Faurot Field is located on the Columbia, Missouri campus of the University of Missouri. The Stadium was recently expanded to accommodate 71,168 fans and additional seating capacity is expected in the future [17]. There are three major categories of fan seating, each with unique food service options: general stadium seating where fans can purchase food from a host of vendors, all-you-care-to-eat box seating and box seating with à la carte food purchasing options. At the time of this study, the Stadium offered separate receptacles for recyclables. There were no containers for the collection of compostable materials. Landfill and recyclable containers are located throughout the concourse areas, at the time of the study there were not strategic efforts to co-locate them for optimal fan compliance. Recyclables were recovered at the City of Columbia’s Material Recovery Facility and all other materials were disposed of in the City’s landfill; both facilities are located at the same address. The Sustainability Office maintains a presence at games to encourage recycling with an information tent staffed with student volunteers located near the main entrance to the stadium.

Stadium staff transports waste that is collected in trash and recyclable receptacles during the game from the main seating area to 40-cy roll-offs located to the east (Hearnes roll-off) and south (Main roll-off) of the Stadium throughout the game, Figure 1 (there are separate dumpsters and roll-off containers for trash and recyclables). In addition, there are two chutes that service the box seating areas on the east and west sides of the Stadium (the East chute and West chute), as depicted in Figure 1. Each chute has two lines, a recycling line that deposits into a 2-cubic yard (cy) dumpster and a landfill trash line that deposits into a separate 2-cy dumpster. No material collected in recyclables receptacles was audited. Finally, a “Can-do Crew” performs a post-game sweep through the main seating areas, separating the remaining debris into materials destined for recycling and the landfill; these materials were staged in concourse areas prior to being deposited in the Hearnes or Main roll-offs. Additional information regarding Stadium seating and corresponding waste collection are provided below.

Figure 1.

Aerial view of Memorial Stadium/Faurot Field, University of Missouri, Columbia, MO with major seating types and trash collection points noted (photo credit [18]).

2.2. Data Collection Description

2.2.1. Pre-Consumer and Unsold Waste

Food served in the box seating areas is prepared in the kitchen facilities located at the Mizzou Arena the week prior to game day. Prepared and uneaten food is returned to the Mizzou Arena following the game, inventoried, and either reused or disposed of at the Arena. Kitchen staff set aside bags for students to collect and sort on three days occurring prior to the Georgia game (7–9 October 2014) and on one day following the Georgia game (13 October 2014). The waste collected prior to the game represents the waste generated during the food preparation activities prior to game day. Note that we have categorized this waste as “pre-consumer and un-sold waste.” Student workers sorted through collected bags and weighed the waste according to the following Waste Categories: Food Waste (further classified as grains, beef, pork, chicken, dairy, fruits, vegetables, other), Recyclables (further classified into aluminum, PET #1 and HDPE #2, glass), other plastic (polyvinyl chloride (PVC), LDPE, PP, PS; #3-6), nonfood compostable waste (corrugated cardboard, mixed paper) and landfill waste. All of the materials included in the bag were weighed by category and recorded. A qualitative description of the materials in each category was noted. Student workers were provided with a waste audit collection sheet (provided in the Supplementary Materials) and were briefed on how to identify the material for commonly found items in the waste prior to sorting and were supervised throughout by the authors.

The study utilized data that the University received from the City of Columbia regarding the total weight of trash collected from the receptacle at Mizzou Arena. Because this receptacle did not service any other waste streams during the football games in question, all of this waste was included in the study. The waste generated at the Mizzou Arena appear in Table 1, under the column heading “Pre-consumer and un-sold waste.” These total waste values were multiplied by the percentage in each category/sub-category to obtain estimates of the total amount of pre-consumer waste in each category/sub-category for each game.

Table 1.

Total waste estimated corresponding to football game days.

2.2.2. Seating Options and Waste Collection within Memorial Stadium

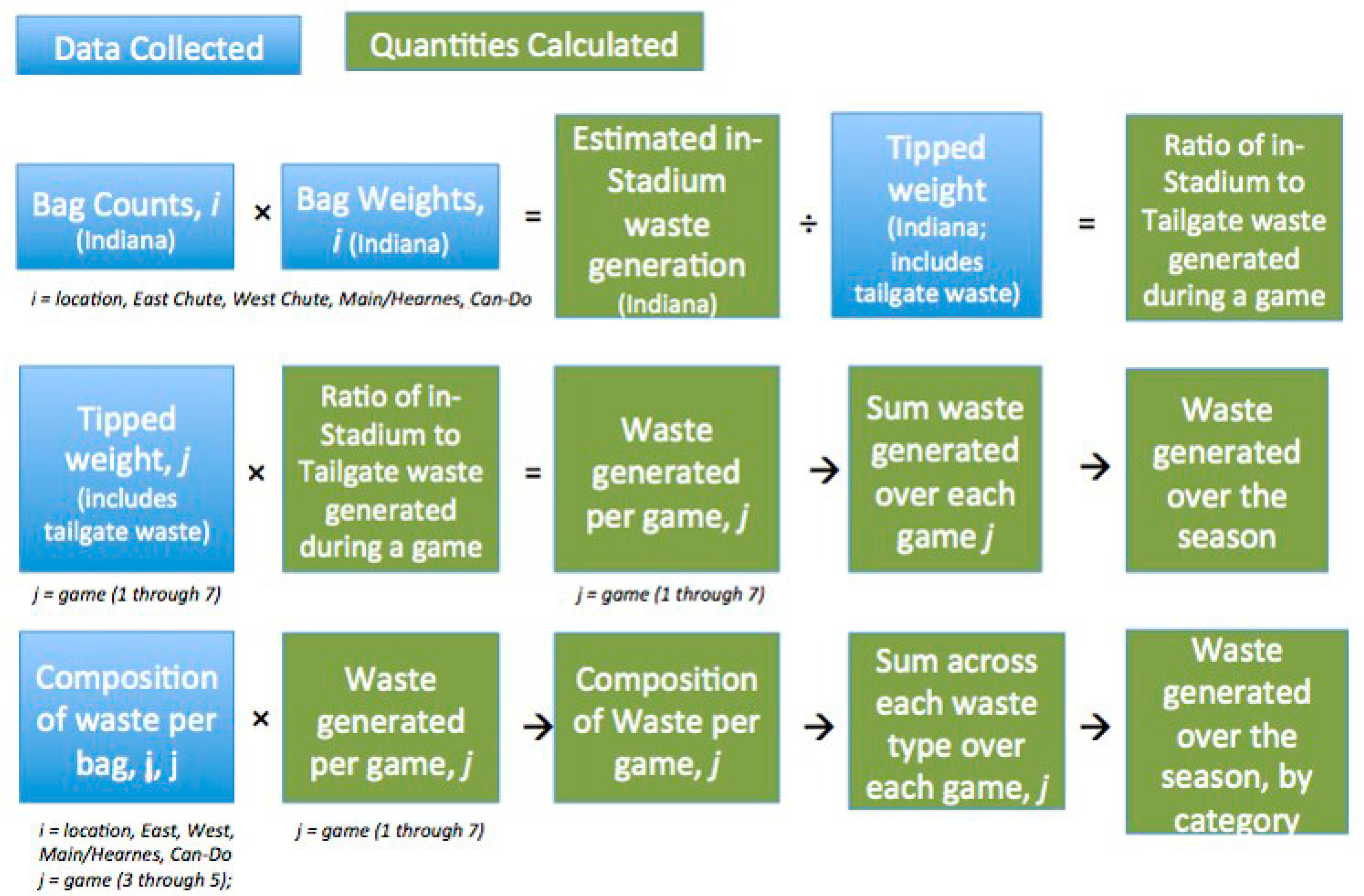

Given the volume of trash emanating from the Stadium, collection and sorting of all of the trash generated was infeasible. Instead, a sampling strategy was devised to collect representative samples from each trash collection point serving the seating options available at the stadium, Figure 2. The first effort was to count the number of bags generated from each major source of trash: East chute, West chute, Main roll-off, Hearnes roll-off, and post-game collections, described below and depicted on Figure 1. This effort occurred on three different occasions, summarized in Table 2. The second effort involved detailed audits of a sample of bags collected over three games, each day was focused on one of the five locations described below:

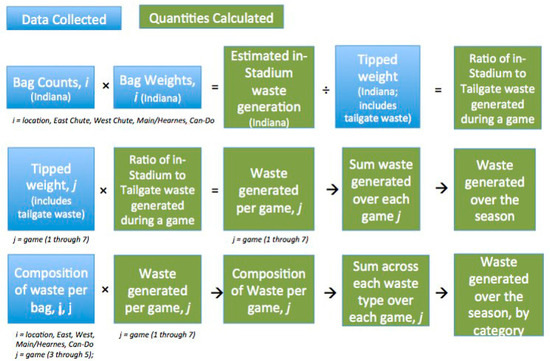

Figure 2.

Data flow diagram describing the relationship between data collected and calculations performed to estimate the total waste and composition of waste over the home games of the 2014 season.

Table 2.

Dates and description of waste audit activities completed at home games over the season.

- East Chute serves a premium seating area for 1204 fans and includes waste from an all-you-care-to-eat food service operation; recycling is bagged separately and is disposed of in a separate chute so minimal recycling content in the sorted bags is anticipated. The food is included in the ticket price and is served buffet style, the foods are more consistent with whole meals (rather than snack foods or sandwiches), and fans are able to take as much as they care to over the course of the game.

- West Chute serves a premium seating area for 1556 fans and includes trash from an á la carte food service operation; recycling is bagged separately and is disposed of in a separate chute so here also minimal recycling content in the sorted bags is anticipated. The foods prepared for this area are similar to those in the east box seating area, but are sold á la carte, or by the item, rather than buffet style.

- The roll-offs at Main and Hearnes include trash from the general seating area, which has seating for 67,206 fans. Fans place waste into bins located throughout the Stadium; although there are separate bins for trash and recyclables, consumers do not strictly adhere to use of the proper receptacle types. Foods served in this area are more typical of fast foods and snacks, e.g., nachos, popcorn, hamburgers, and hot dogs. These roll-offs also receive trash from tailgating, however the majority of tailgate trash is deposited the day after the game (personal communication Anthony Wirkus, Director of Event Management and Sustainability Coordinator of Intercollegiate Athletics), and thus it is assumed that no tailgate trash appears in our counts. Note that we did not attempt to count or audit any of the trash associated with tailgating.

- Post-game collection consists of trash left in the stands after the game; the Can-Do crew separates recycling from other materials so again minimal recycling content in the sorted bags is anticipated.

The East and West premium seating areas are provided with food from the catering operation located in the Mizzou Arena. The general seating area food vendors operate under independent contracts and, as noted above, include primarily fast foods and snacks.

Bag counts from all locations were performed during the Missouri vs. Indiana game on 20 September 2014. Students were stationed at each location approximately 30 min before kick-off, and these stations were monitored continuously through the end of the game. Students used an app called “Tally Counter,” [19] which provided a time stamp for each bag counted. Bags fall from the East and West Chutes more uniformly over the course of the game than bags from the main concourse destined for the Main and Hearnes roll-offs. It should be noted that bags exiting stadium bathrooms were counted as they were disposed of at the Main and Hearnes roll-offs, but were not audited if found due to health concerns. Counting was also performed during the post-game clean up as Can-do Crew volunteers carried the bags down from the stands to a collection point on the concourse. Bags counts conducted on 20 September 2014 (denoted Bi for location i) appear in Table 3. The majority of the trash was collected from the main stadium seating area.

Table 3.

Bag count data from 20 September 2014, Missouri vs. Indiana.

The sorting and auditing of waste was carried out over three games: Missouri vs. Georgia, Vanderbilt, and Kentucky, Table 2. Students were placed at the dumpster or roll-off and collected bags throughout the game. A sticker was placed on each bag collected noting the location and time of collection. Since it was not possible (with our level of resources) to sort all bags, we sorted a sample from each location: 13 bags from East chute, 10 bags from West chute, 15 bags from the roll-offs at Main and Hearnes, and 17 bags from post-game clean-up in the main seating areas executed by the Can-do Crew.

The contents of each bag selected for the detailed waste audit were sorted by eight student workers into the categories described above for the pre-consumer waste with one exception being that pork and chicken were inventoried as one category, “other meats.” This information was utilized to obtain an average bag weight (denoted Wi and appearing in Table 4) and percentage of bag weight associated with each waste category (denoted Pik for location i and waste category k) for each of the locations. Next, an overall percentage of waste in each category (denoted Qk and appearing in Tables 7–9) was computed as follows, Figure 2:

Table 4.

Average bag weight at each trash collection location.

Total waste generated for each of the seven home games was estimated in two steps utilizing the detailed Indiana data and tipping weights for all waste containers from the City associated with game day: (1) total stadium waste for the Indiana game was calculated using the bag counts, Table 3, and the average bag weights, Table 4, and (2) the total weight reported from the City for each game was converted to a percent difference relative to the total weight collected from the Indiana game to estimate the weight of the materials collected from within the Stadium on other (i.e., not Indiana) game days, Figure 2. These per-game factors were applied to the estimated total weight from the Indiana game to approximate total waste generated from within the Stadium from other home games. This is necessary because the reported total trash weights include the trash collected from tailgating occurring outside of the Stadium. As part of its waste management contract with the City of Columbia, the University received data stating the total weight of trash collected from each location for each football game weekend. Next, the proportions of waste from each category audited over the three games noted above were applied to total waste estimates for all games to provide material-specific weights for each game.

Note the following assumptions: (a) the proportion of bags from each location in the Indiana game is representative of the proportions across all other games; and, (b) the samples used to estimate the average bag weights and percentage of bag weight associated with each Waste Category were representative samples. The vendors were consistent over the season, thus the types of concessions available did not change over the season. There were no statistically significant differences in the observed composition of the waste found in bags across the four location and three collection days.

2.3. GHG and Energy Use Evaluation of Alternative Waste Management Scenarios

The EPA developed the WARM model to calculate life cycle GHG emissions and energy for baseline and alternative waste management scenarios [16]. The WARM model takes a life cycle approach and includes the following options for waste management scenarios: source reduction, recycling, combustion, composting and landfilling. There is no existing incineration facility in Columbia, MO and this option was not considered in our analysis. The WARM model includes GHG and energy estimations for raw material extraction, manufacture, transportation and disposal. Transportation estimates are inclusive of raw materials to the manufacturing facility, from the manufacturing facility to a retail location, and from the origin of the waste to the landfill. The use phase and any corresponding transportation are not included in the model as it is not relevant to materials and waste management decisions. Avoided virgin materials associated with recycling are accounted for, and in the case of paper there are carbon storage credits applied based on the assumption that recycling reduces the amount of trees that are harvested. Avoided GHG emissions and energy use are estimated using industry average recycling rates. Source reduction is estimated by assuming that a specified amount of waste is not produced, thus avoiding GHG emissions and energy use associated with producing the material. Biogenic sources of CO2, i.e., released during decomposition in composting are not included in GHG emissions estimates within WARM. For landfills with landfill gas (LFG) recovery, flaring results in no CH4 emissions and the CO2 emissions are not included, as they are considered biogenic. When the LFG is combusted to produce electricity, it is assumed that GHG emissions based on the typical production mix in the specified region are avoided and are credited to the waste management option. The model is constructed to report the relative difference between the baseline scenario and the alternative scenario. The GHG emissions and energy use for each individual set of management assumptions are reported in the Supplementary Materials.

The WARM model includes the ability to customize the electricity mix and landfill characteristics for the location of study, in this case Columbia, Missouri. The landfill in Columbia has an LFG recovery system and the collected biogas is utilized to generate electricity; both of these features are accounted for by WARM. For the model’s assumptions about the LFG collection efficiency the “aggressive operation” was assumed and moisture conditions were modeled after the “wet” option, selected based on personal communication with the City’s landfill manager Cynthia Mitchell (21 January 2016). WARM allows the user to specify transportation distances from the collection location to the waste management facility. Using Google Maps, we estimated the distance between the Stadium and the Material Recovery Facility, where the bioreactor landfill, composting operation and recycling collection and sorting take place, to be between 8.8 and 10.2 miles, for this analysis a distance of 10 miles was entered. Note that the separated recyclables are transported outside of the City of Columbia for recycling, and this additional transportation is approximated within WARM.

Due to mismatches between our inventory and categories within WARM the following changes to the inventory categories were made:

- Fruits and vegetables are one category in WARM and thus these totals are added.

- PET and HDPE plastics were not separated during the audit and are modeled as “Mixed Plastics,” which in WARM is a mix of 39% HDPE and 61% PET.

- Plastics numbered 3–6 were weighed as one category during the audit and are evenly allocated to three plastics (LDPE, PP, PS), it was assumed that there was no PVC present. WARM does not allow for the recycling of plastics #3–6, moreover circa 2014 the City of Columbia did not offer recycling for these materials.

- The WARM model does not allow for composting of paper or cardboard, similar to Hottle et al. (2015) [15] the weight of these materials was modeled as “Mixed Organics,” based on guidance from the EPA in scenarios where composting was maximized.

- Pork is not included in the WARM model and typically results in higher GHG emissions and energy use than chicken and less than beef [20,21]. Therefore, manual edits to the weights of chicken and beef input to the WARM model to better simulate the amount of wasted pork in the model. To accomplish this life cycle GHG and energy estimates for these foods from existing literature were used to modify the GHG and energy values for chicken and beef in WARM. The WARM model includes an estimate of 2.47 carbon dioxide equivalents (CO2e)/kg chicken and 30.05 kg CO2e/kg beef [16]. González et al. [21] estimate that chicken results in 4.7 kg of carbon dioxide equivalents (100-year basis) (CO2e)/kg chicken, 8.2 kg CO2e/kg pork, and 29 CO2e/kg beef; and, 27 MJ/kg chicken, 28 MJ/kg pork, and 47 MJ/kg beef (2011). A review of many food LCAs [20] report life cycle GHG and energy estimates per unit of chicken, pork, and beef overlap with values reported by González [21], which lends confidence to the choice to use the values from González. To represent the GHG and energy requirements for pork more accurately the values for chicken and beef were applied to a portion of the pork weight to result in 8.2 kg CO2e/kg pork, specifically (0.208 * pork weight * 30.05 kg CO2e/kg beef] + [0.792 * chicken weight * 2.47 kg CO2e/kg chicken).

2.4. Waste Management Scenario Descriptions

Scenarios were developed to evaluate research objectives 2–4, that is, to estimate life cycle GHG emissions and energy use for waste management options, including those that achieve 90% diversion of waste to recycling and composting. First, a base case scenario was modeled in WARM representing the actual fate of the materials collected during the audit, i.e., all audited materials are disposed of in the landfill. Eleven scenarios were created to consider a range of waste management options ranging from relatively simple to fairly complex in terms of implementation. Scenarios were developed to explore combinations of recycling, composting, source reduction of food waste, and materials replacement of materials that were not recyclable or compostable in the observed waste stream. The scenarios allow for a clear understanding of the benefits of recycling and composting, individually, and in combination. As well as options that are more complex and require greater effort such as food waste reduction and materials replacement. Total waste weights are provided in Table 1. Table 5 indicates the distribution of the total weight by material and waste management option for each Scenario.

Table 5.

Summary of waste management scenarios, represented by percent weight of materials generated over the 2014 football season. The total estimated weight of waste is provided in Table 1.

Scenario 1 (in Table 5) represented the potential GHG and energy use associated with recycling of all of the recyclable materials, (i.e., aluminum, glass, PET, HDPE, corrugated cardboard and mixed paper) found in the waste stream. This scenario is currently achievable if all recyclables were disposed of in the appropriate receptacles. In Scenario 2a recyclables (including paper and cardboard) are recycled as in Scenario 1, and food waste is composted, while the remaining materials, i.e., plastics #3–6, are landfilled. In Scenario 2b aluminum, glass, PET, HDPE are recycled while food waste, cardboard, and mixed paper are composted and plastics #3–6 are landfilled. The differentiation in Scenarios 2a and 2b enable the comparison of recycling versus composting paper and cardboard. In Scenario 3, all recyclables are recycled and food waste is composted as in 2a and the non-recyclable plastics are replaced with polylactic acid (PLA) plastic and assumed to be composted. It was assumed that PLA replaced these plastics with equal weight, similar to Hottle et al. [15]. In Scenario 4 all non-food materials are replaced on a weight-per-weight basis with PLA, again as was done in Hottle et al. [15], and all materials are composted. Scenarios 3 and 4 represent scenarios that represent waste streams that would technically be 100% eligible for diversion to recycling and compost.

The last five scenarios all include source reduction of the edible portion of food waste observed in the waste stream in combination with recycling, composting, and materials replacement. This assumption demonstrates an ideal scenario in which there is no post-consumer waste, no over-preparation of edible food and no food (produce in particular) is rejected due to imperfections or lost to spoilage. Inedible food waste was only observed in the fruit and vegetable category. Some portion of the inedible fraction would also be avoided due to a corresponding avoidance of peels, cores, etc. associated with the avoided edible portion. Due to data limitations, specifically a lack of detailed information regarding the total amount of food entering the facility, it was not possible to approximate what portion of the inedible food waste would be avoided due to avoiding the edible fraction. In the results section we have estimated the GHG emissions and energy associated with assuming that all inedible Food Waste (FW) is source reduced to bound this assumption.

In Scenario 5a, all materials, including inedible food materials, are landfilled to demonstrate the potential GHG and energy savings of reducing edible food waste only. In Scenario 5b, recyclable materials are recycled, the inedible fraction of food waste is composted, and non-recyclable materials are landfilled, similar to 2a. Scenario 5c assumes that cardboard and mixed paper are composted as Mixed Organics, recyclables are recycled, non-recyclables are landfilled, similar to Scenario 2b. In Scenario 5d, inedible food materials are composted, plastics #3–6 are replaced with PLA, similar to Scenario 3. Finally, in Scenario 5e, all non-food materials are replaced with PLA and composted, and the inedible food waste is composted.

3. Results

3.1. Waste Audit Results

3.1.1. Pre-Consumer and Unsold Waste

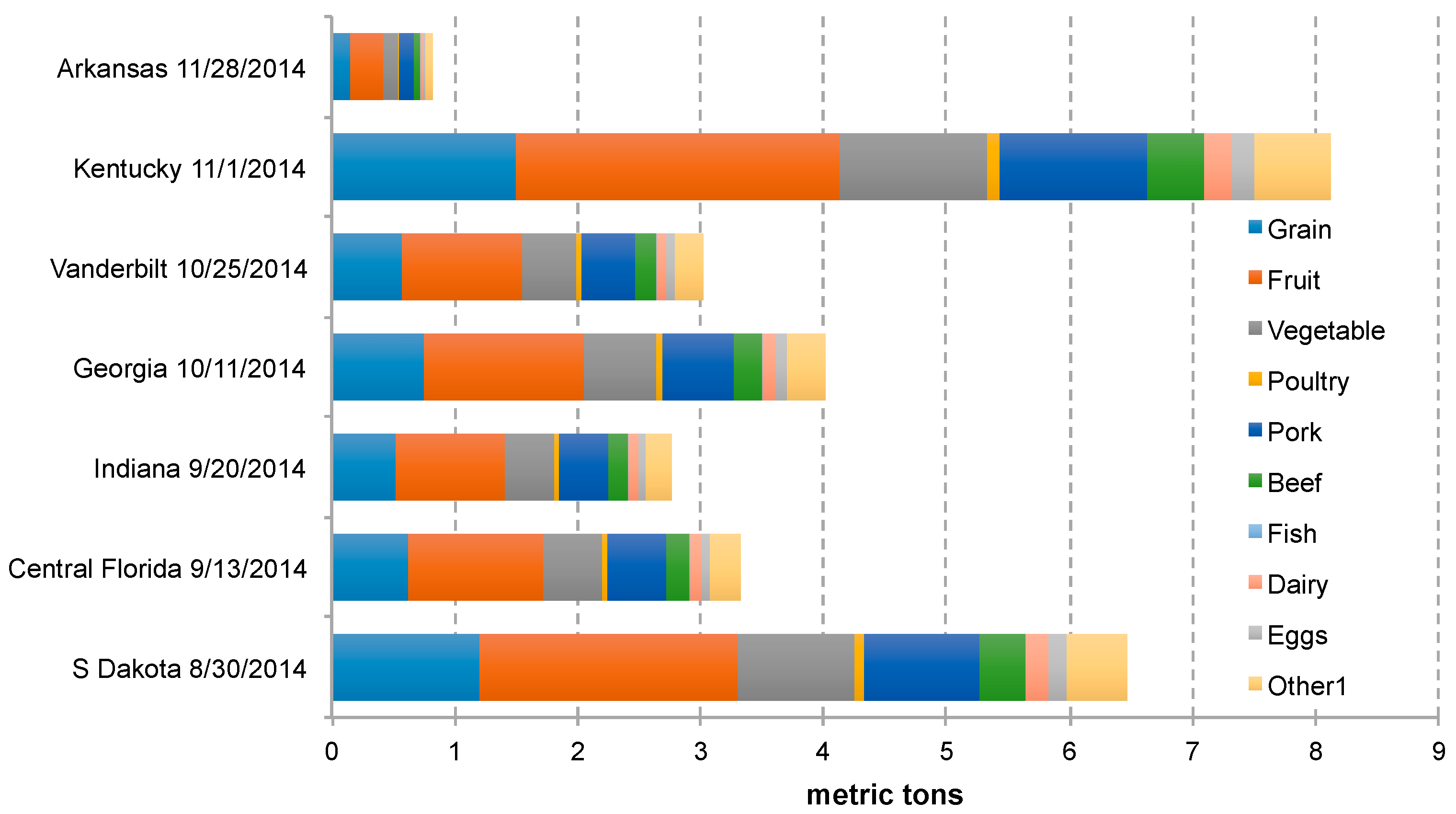

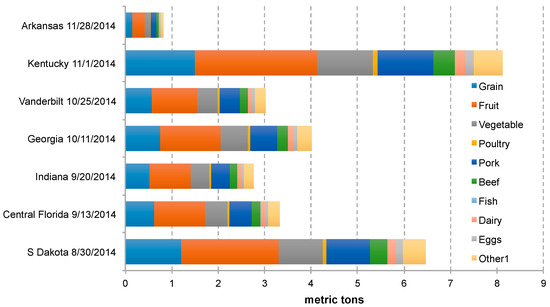

The audit results for pre-consumer and unsold waste are show in Table 6. A total of 29.64 mt of waste was estimated to be generated over the season in the pre-consumer waste category, Table 1, using the audit data collected in conjunction with the City of Columbia’s data on the total weight of the trash removed from the facility. Ninety-six percent of this audited waste was food waste, 71.2% was edible and 25% was inedible food waste. Fruit food waste and grain-based products were the two largest categories of food waste observed, Figure 3, followed by vegetables and pork estimated at 4.17 and 4.14 mt, respectively. Beef is the next largest category by weight at 1.63 mt. The recyclables were not weighed individually and the total weight was allocated to aluminum (one-third) and mixed plastics (two-thirds).

Table 6.

Pre-consumer and un-sold food waste audited from Mizzou Arena.

Figure 3.

Food waste, by type, from pre-consumer and un-sold food waste audit. (1) The foods in the “other” category were primarily gravy and barbeque sauce. (2) Numerical values are provided in the Supplementary Materials.

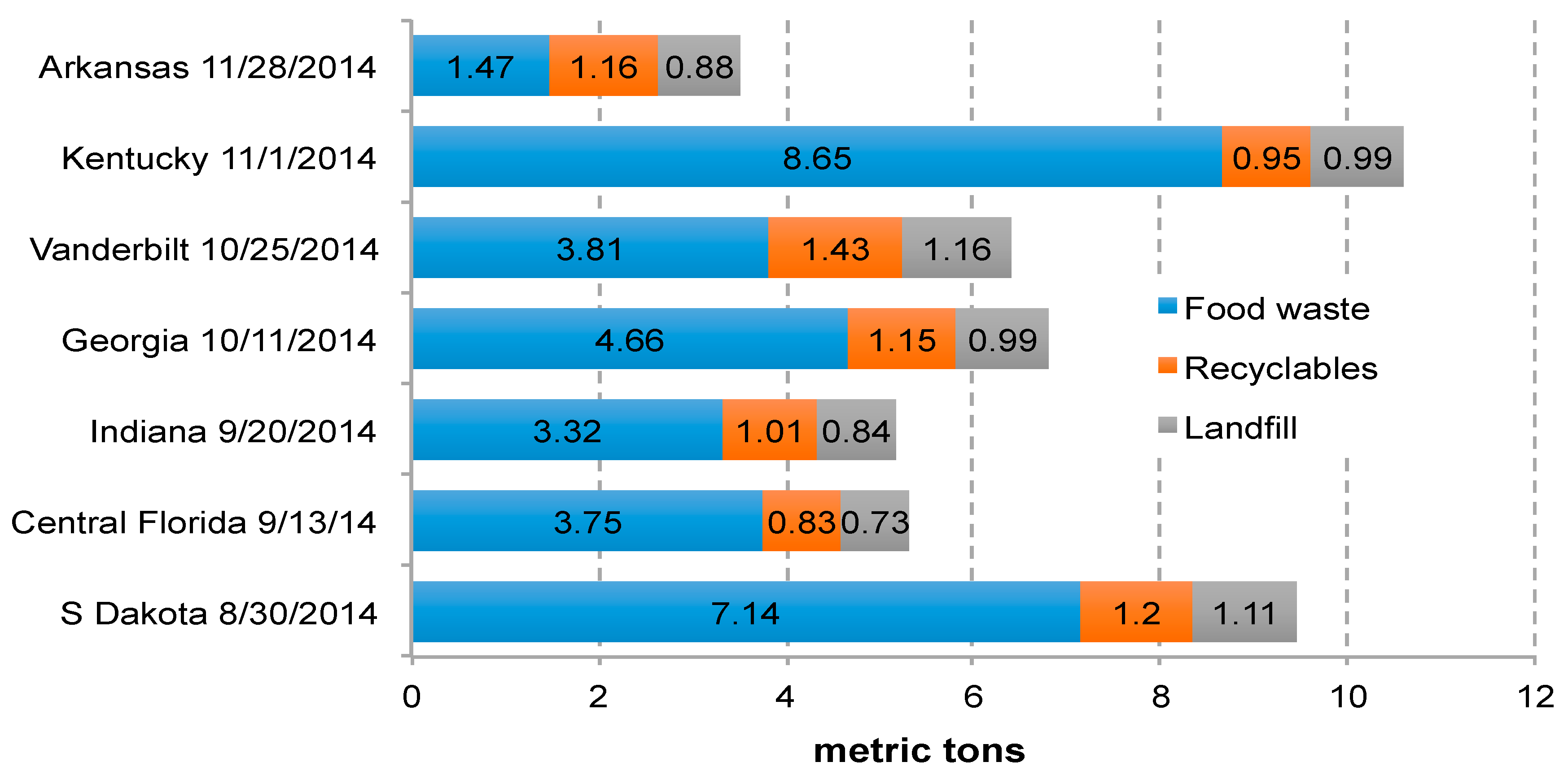

3.1.2. Waste Collection within Memorial Stadium/Faurot Field

This section describes the observed weights of waste categories from the waste stream generated within the stadium, or the Post-consumer waste, estimated for the 2014 season. In total, separation and auditing was performed on 55 bags. For each bag that was separated and audited, the source location and time of collection was recorded. Given the kickoff times for each game (which varied), the elapsed time (in minutes) from kickoff to bag collection time was calculated. For each bag that was separated and audited, we computed the percentage of the total bag weight in each of four categories: Food Waste, Recyclables, #3 through #6 Plastic, Landfill.

A statistical analyses was performed to examine the impact of collection time on the bag weight percentages by category as follows. This analysis, performed using the STATA software package [22], found that there was no statistically significant difference (at the 5% level) between the mean percentages of bag weight by category when contrasting bags collected before halftime with those collected after halftime. The next statistical analyses was to examine the impact of location on the percent contribution of each waste type to the total bag weight percentages, again using STATA, to perform a pairwise means comparison with unequal variances, using Tamhane’s T2 test to determine p-values. This analysis found that there was no statistically significant difference (at the 5% level) between the mean percentages of bag weight by category across the different locations. Then the overall percentages of waste by category were computed as follows.

Using the values in Table 3 and Table 4, we computed the percentage of overall estimated weight from the Indiana game emanating from each location. We then applied these percentages to the aggregated percentages of waste by category emanating from each location, to compute the values appearing in Table 7, which present the percentage of waste in each major aggregate waste category recorded during the audit over all locations. Recyclable materials constituted the largest category (43.2%) of waste observed by weight, the majority of this recyclable material was corrugated cardboard and paper (26.6%), Table 8. Food waste is the second largest category by weight accounting for 24.2% of the total. Landfill waste, excluding #3–6 plastic, is the third largest category at 23.3%. The overall percentage in each Food Waste sub-category appears in Table 9. Dairy (6.9% of total waste weight) and grain-based foods (5.6% of total waste weight), e.g., breads, were the largest categories of food waste observed by weight, followed by fruits (3.2%), “other meats” (3.1%) and vegetables (3.0%).

Table 7.

Percentage of waste by category observed in post-consumer waste collected at Memorial Stadium over the season.

Table 8.

Percentage of the total weight observed by recyclable subcategories in post-consumer waste collected at Memorial Stadium over the season.

Table 9.

Percentage of the total weight observed by food subcategories in post-consumer waste collected at Memorial Stadium over the season.

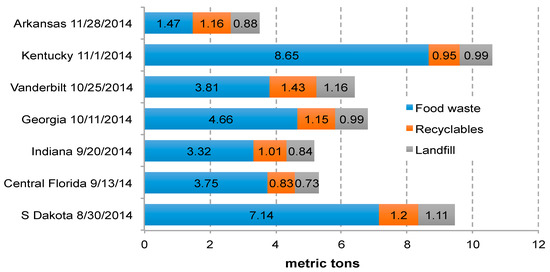

3.1.3. Total Waste

The largest waste category over both the Arena (pre-consumer and unsold waste) and the Stadium (post-consumer) by weight was food waste, at 69% of the total weight over both locations, as shown in Figure 4. Of the 32.8 mt of food waste generated, approximately 7.2 mt was inedible food waste associated with preparation activities and the remainder was edible. All of the food waste leaving the Stadium can be considered edible.

Figure 4.

Approximate weights by major category of pre-consumer, un-sold and post-consumer food waste.

3.2. WARM Scenario Analysis Results

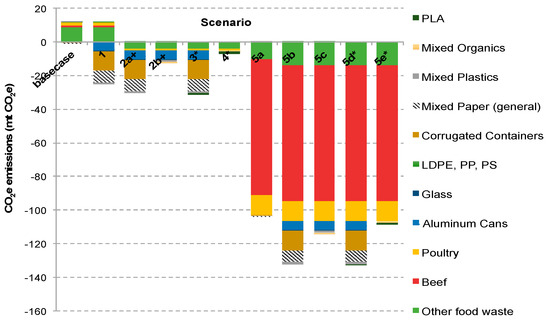

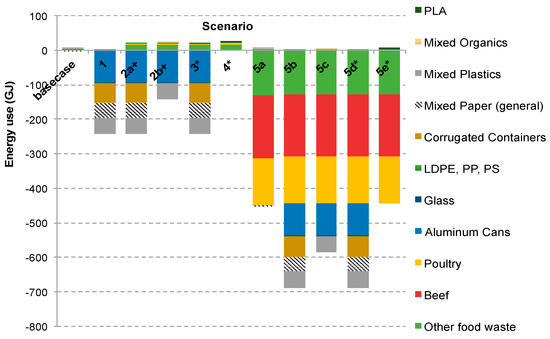

WARM model results for the eleven scenarios described in Section 2.4 are shown on Figure 5 and Figure 6, negative values indicate reductions compared to the base case, i.e., landfilling of all materials. The base case represents current conditions, in which all of the audited waste is disposed of at the Columbia bioreactor landfill, Figure 5 and Figure 6. Disposal of the waste in the bioreactor landfill results in 11.1 metric tons of CO2e and 3.45 gigajoules (GJ) of net energy as estimated using WARM. If the landfill did not have the capacity to generate electricity and flared the collected gas instead, which is more typical, the GHG emission estimate would be higher (21.5 mt of CO2e) and require more energy (25.3 GJ) to manage this waste. Finally, if the landfill did not collect LFG, and instead released methane directly to the atmosphere the GHG emissions would be 60.2 mt CO2e, with the same energy use as the flare scenario. Note that it is no longer legal to construct landfills without LFG capture systems, but some landfills have been exempted from this rule. This information is provided for context about the variability in emissions and energy use associated with possible landfill designs across different locations.

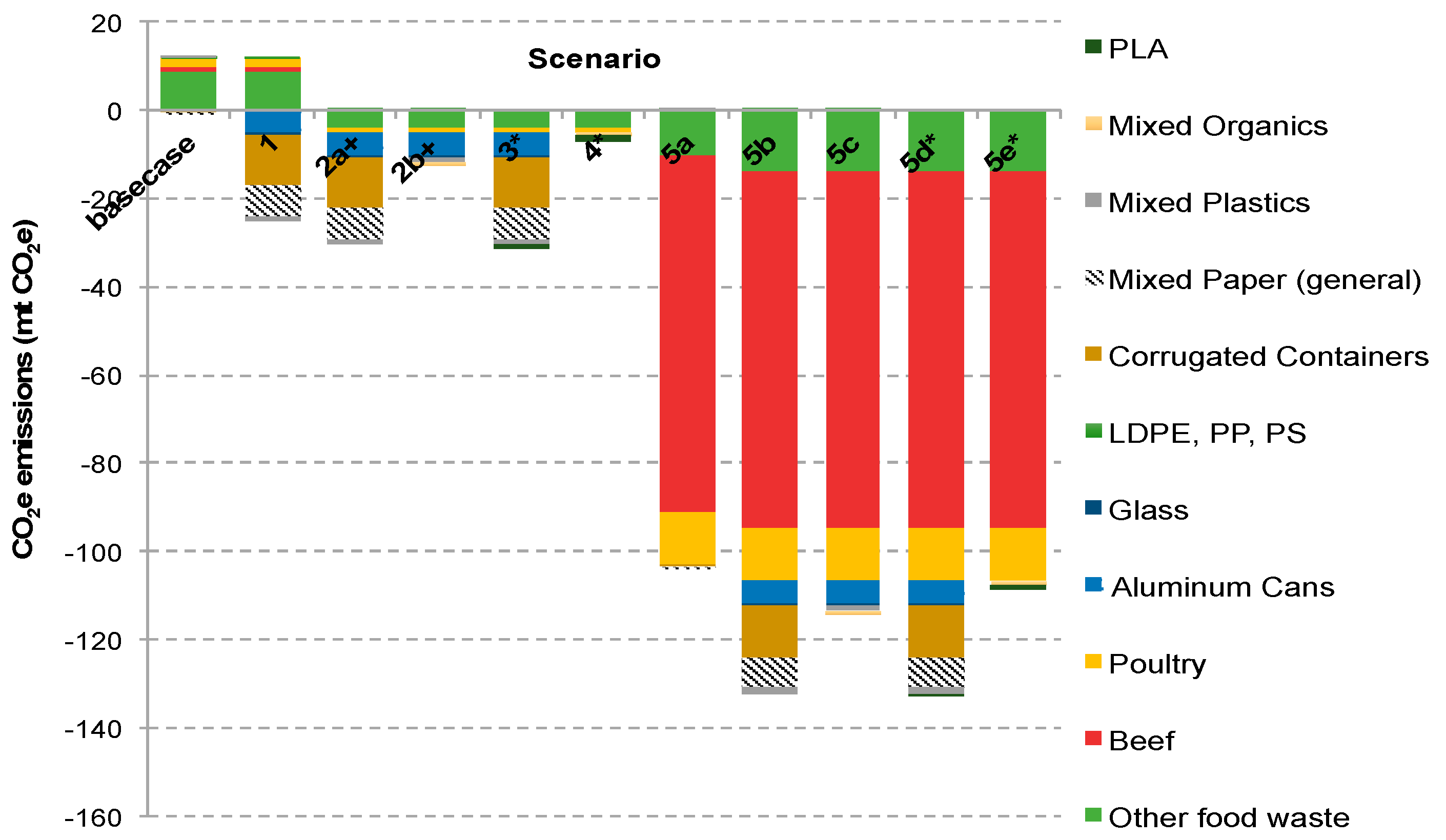

Figure 5.

Greenhouse gas emissions estimated for each waste management scenario modeled in Waste Reduction Model (WARM). Note that if all of the inedible food waste was also assumed to be source reduced WARM estimates an additional greenhouse gas (GHG) reduction of 5 mt CO2e. “+” Indicates 88% waste diversion from the landfill and “*” Indicates 100% waste diversion from the landfill.

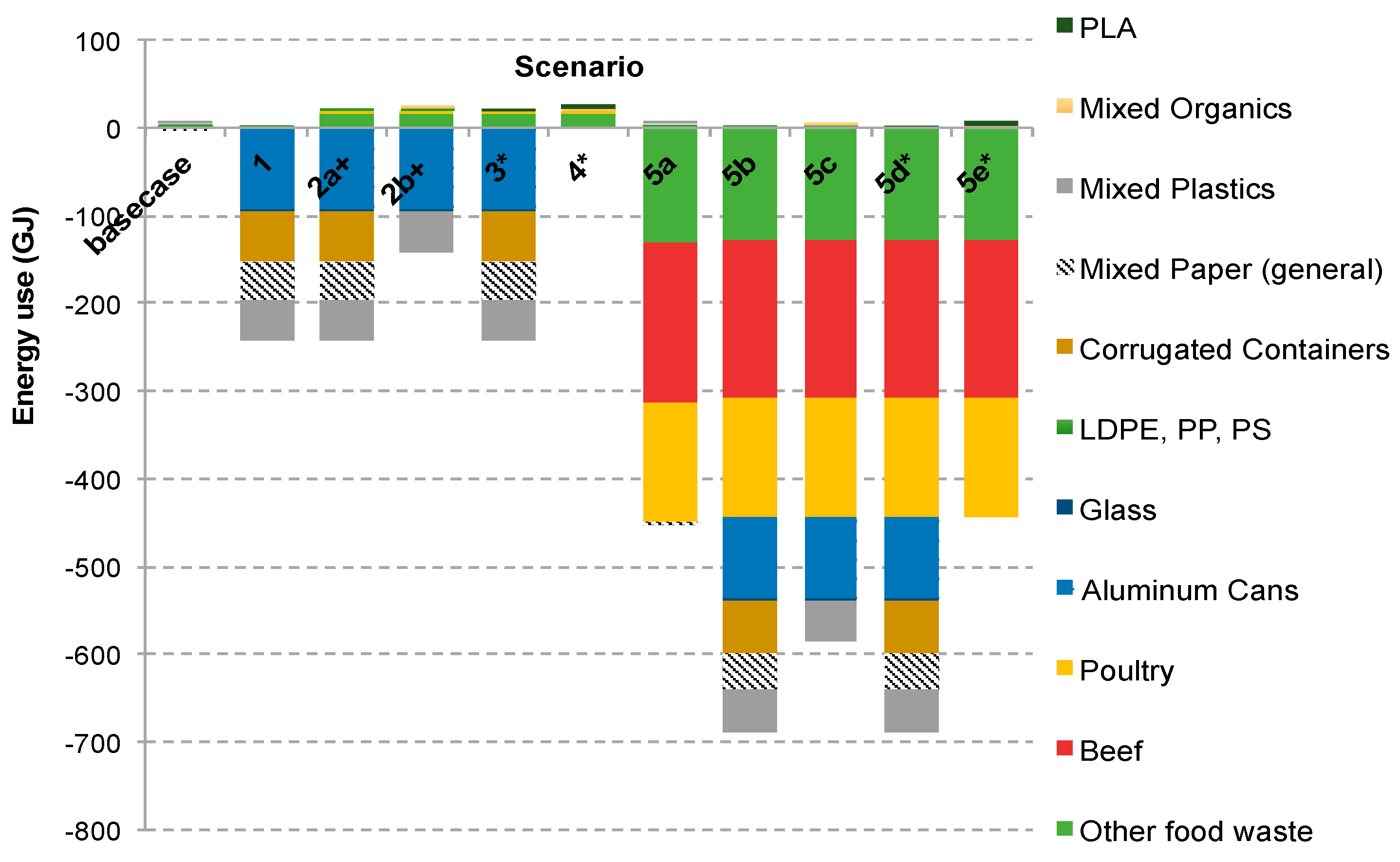

Figure 6.

Energy use estimated for each waste management scenario. Note that if all of the inedible food waste was also assumed to be source reduced WARM estimates an additional energy savings of 77.4 GJ. “+” Indicates 88% waste diversion from the landfill and “*” Indicates 100% waste diversion from the landfill.

Overall, the two most effective approaches for reducing GHG emissions and energy use are recycling and source reduction of food waste. Recycling corrugated cardboard and mixed paper contributes the largest GHG savings in the recycling category, given the mix of recyclable waste found at the Stadium. Recycling achieves GHGs reductions of 25.4 mt GHGs and energy savings of 243.7 GJ. WARM estimates that GHG emissions are reduced by 3.45 mt CO2e/mt of recycled corrugated cardboard and 3.91 mt CO2e/mt for mixed paper; the majority of the savings are attributed to forest carbon storage [16]. Recycling of aluminum results in the third largest GHG emissions reduction reflecting aluminum’s relatively large GHG reduction per unit of material, at 10.1 mt CO2e per mt of aluminum. Source reduction of edible food waste results in a reduction of 103.1 mt of GHG emissions and 448.5 GJ of energy use or the largest opportunity for GHG reduction and energy savings over all scenarios. Note that edible beef food waste is responsible for the majority, 80%, of the CO2e reductions associated with source reduction because beef is estimated to cause 30.05 mt CO2e/mt beef in the WARM model, one to two orders of magnitude larger than any other food included in the model [16]. Beef and poultry (which includes pork as described in the methods) result in 41% and 31%, respectively, of the overall energy use reductions associated with source reduction. Note that if all of the inedible food waste was also assumed to be source reduced WARM estimates an additional GHG reduction of 5 mt CO2e and additional energy savings of 77.4 GJ. Scenario 5a represents the case where all edible food waste is avoided, “source reduction,” and the remaining materials are landfilled as in the base case, resulting in −114.8 mt CO2e, as compared to the base case. Net energy in Scenario 5a is −448.8 GJ, as compared to the base case. These savings indicate the potential benefits of targeting only food waste reduction.

Scenario 1, recycling of all recyclable materials found in the waste stream currently destined for the landfill, would result in a reduction of 24.7 mt CO2e and 243.8 GJ, as compared to the baseline, shown in Figure 5 and Figure 6. The largest reduction in GHG emissions is due to recycling corrugated cardboard (11.6 mt CO2e), followed by mixed paper (7.1 mt CO2e) and aluminum (5.2 mt CO2e). The largest source of energy reduction is associated with the recycling of aluminum (91.5 GJ), followed by corrugated cardboard (59.1 GJ), mixed plastics (46.8 GJ) and mixed paper (43.3 GJ). Scenario 1 requires no significant investment in waste management infrastructure and no replacement of materials. The major hurdle with regard to realizing Scenario 1 is the improvement of fan compliance with regard to sorting landfill waste and recyclables and placing them into the correct receptacles, this may require improvements in Stadium signage and receptacle type and placement.

In Scenario 2a, recyclables are recycled and all food waste is composted, the GHG emissions are further reduced from the baseline to a net reduction of 41.4 mt CO2e. The additional reductions occur because the CO2e associated with the food waste switches from a positive estimate to a negative estimate per unit when switching from landfilling to composting. The net energy associated with this scenario is also negative, as in Scenario 1, but slightly less so at −224.5 GJ, as compared to the baseline as the WARM model includes more energy use associated with operating an industrial compost operation than if the food waste were placed in the bioreactor landfill where methane generated due to anaerobic decomposition are used to generate electricity. Scenario 5b is the same as Scenario 2a, except that the edible fraction of the food waste is avoided, resulting in additional GHG and energy use savings for a total reduction of 143 mt CO2e and 688 GJ compared to the base case scenario.

Scenario 2b, in which paper and cardboard are composted (rather than recycled) along with food waste, using the proxy of Mixed Organics in WARM, and the remaining recyclables are recycled, is estimated to achieve a reduction of 23.5 mt CO2e compared to the base case. The net energy balance for Scenario 2b is considerably less than the 3.45 GJ in the base case with a value of −256.7 GJ. Scenario 5c is similar to Scenario 2b, except that the edible fraction of food waste is avoided, resulting in a large reduction in GHGs and energy use compared to the base case, −125.3 mt CO2e and −582.6 GJ, respectively, highlighting the benefits of reducing the wastage of food. Scenario 5c assumes that paper materials are composted rather than recycled, which results in less GHG and energy savings, largely due to carbon credits attributed to avoiding the logging of trees.

Scenario 3, in which recyclables are recycled, food waste is composted and non-recyclable materials are replaced with compostable PLA materials, GHGs are reduced 42.4 mt CO2e and energy use is reduced to −224.2 GJ compared to the base case. Scenario 5d, which is the same as Scenario 3 except for source reduction of edible food waste, results in the largest reduction of GHG emissions over all scenarios at 144.1 mt CO2e and the second largest reduction in net energy, at 688.0 GJ compared to the base case due to recycling and the source reduction of food waste. Scenario 5b has the most negative net energy at −688.3 GJ, but is effectively the same as Scenario 5d, the difference occurs between the net energy estimated to landfill plastics #3–6 in Scenario 5b compared to composting PLA in Scenario 5d.

In Scenario 4, all non-compostable materials are replaced with PLA and all materials are composted), this results in a GHG emissions value of −18.1 mt CO2e and net energy use of −24.7 GJ, as compared to the baseline. Scenario 5e is identical to Scenario 4 except that edible food waste is avoided. Replacing recyclables with PLA, as in Scenarios 4 and 5e, results in less net GHG and energy reductions than recycling of recyclable materials due to the large savings associated with recycling aluminum and paper products. The source reduction of edible food waste results in −101.3 mt CO2e savings and an overall reduction in net energy usage of 444.2 GJ.

Scenarios 3, 4, 5d and 5e would all achieve zero waste goals as all materials would either be composted or recycled, if not avoided altogether as with the source reduction of edible food waste in Scenarios 5d and 5e. Based on the weights observed in this study, Scenarios 2a and 2b would achieve 88% materials diversion from the landfill based on weight, or only 2% short of meeting the requirement to be considered zero waste. While Scenario 5b would result in a considerable reduction in the total volume of waste sent to the landfill, 21.6 mt compared to 47.2 mt, the diversion rate would only be 74%.

4. Discussion

This work suggests that it would be prudent for managers to consider waste mitigation strategies within sustainability or zero waste strategies. In this work, source reduction of food waste would have the greatest benefit in terms of minimizing GHG emissions and energy consumption, followed by proper sorting of recyclables into the recycling waste management stream. Hamilton et al. [23] also found that preventing food waste was more ecologically beneficial than producing biogas from food waste. These findings suggest that waste management practices are not likely to overcome the losses associated with embodied resources in a wasted food item.

Reducing the wastage of animal based foods, beef in particular, could have significant impacts with regard to reducing GHG emissions and energy use. Conversations with management involved in event planning revealed that there is a strong aversion to the risk of running out of food particularly in the East box with its all-you-care-to-eat food service operation. This aversion coupled with great difficulty in forecasting demand for food due to high variability in conditions across games, (e.g., time of day, weather, team performance on any given game day) make it very challenging to develop solutions that would reduce waste without risking customer satisfaction. The Chef responsible for preparing food for the games mentioned that the time of the game (morning, afternoon or early evening) as well as the success of the home team during the game were relevant variables associated with the amount of food consumed, i.e., fans may consume less if the game is later in the day allowing for a longer tailgate time period, or many fans might leave the Stadium before the end of the game if Missouri (the home team) was losing the game (personal communication with Travis Taylor, Executive Chef). Careful documentation of all of these variables in relation to food consumed versus food prepared may provide useful insights, but was beyond the scope of this paper. Improving the predictability of food demand could also reduce expenditures, which may be the most successful strategy for motivating stakeholders toward more sustainable practices [24]. Given the Intercollegiate Athletics Department’s aversion to disappointing fans in premium seating due to running out of food items, some amount of production in excess of the expected demand is likely unavoidable. Additional research to survey fans about these issues and exploration of possible benefits of marketing or educational campaigns highlighting sustainability efforts may lead to creative solutions. Another possibility with regard to reducing the life cycle GHG and energy use associated with food waste would be to replace high-impact foods with lower impact foods.

Beef is the most GHG- and energy-intensive food and contributes to the majority of the savings in the Source Reduction scenarios (i.e., scenarios starting with the number 5). In order to test the robustness of the overall conclusion of this work, i.e., that GHG and energy savings may be greater in waste management scenarios that do not achieve zero waste goals of 90% diversion to recycling and composting, the full weight of the estimated beef food waste was instead modeled as chicken and pork. In this case, the GHG reductions associated with source reduction of food waste change from 103.1 to 31.9 and the energy use savings changes from 448.5 to 342.4. However, this “loss” of savings due to wasting a less GHG-intensive is not sufficient to change the rank order of waste management alternatives.

Interestingly, given the definition of zero waste, three of the five scenarios that included source reduction of edible food would not achieve the goal of a zero waste event. This finding suggests that it may be appropriate to observe overall reductions in waste in addition to waste diversion in pursuit of setting sustainability goals for venue-based events. As noted throughout, avoiding overproduction of food is complex and not well understood.

Removing recyclables from the landfill stream is the second most effective approach for reducing GHG emissions and net energy consumption. The largest limitation to achieving increased recycling of materials is engaging fans to properly dispose of recyclable materials. To improve the recovery of recyclables while minimizing contamination of the recycling waste stream Intercollegiate Athletics may consider deploying bin guards to direct fans to dispose of waste in the correct bin in real-time throughout the game as well as during egress following the game. A coordinated public relations campaign to educate fans about the benefits of properly sorting may also be a useful tactic for increasing enthusiasm on behalf of the fans. This was found to be a successful strategy in Hottle et al. (2015) [11]. Improving proper sorting of recyclable materials would reduce GHGs and energy use considerably. Another strategy that would reduce the complexity of the waste stream may be to replace all packaging materials with PLA, e.g., Scenarios 4 and 5e; however, given the limitations of the City of Columbia’s composting facility additional investment in compost management would be required.

The weight of successfully diverted recyclables was not included in calculations of overall waste diverted from the landfill. Inclusion of these recyclables would increase the total diversion rate. Particularly for the scenarios that were close to 90%, i.e., Scenarios 2a and 2b, inclusion of these diverted recyclables might result in achieving Zero Waste.

Many of the items that were not compostable or recyclable were novelty items such as commemorative cups or pom-poms. These objects were either made from #7 plastic, typically not recyclable, or multi-material objects, i.e., pom-poms, consisting of plastics and paper, which are also difficult to recycling due to the need to separate these materials before recycling. Re-design of these items could be very useful with regard to streamlining the waste stream for maximum recyclability or composting. A more progressive option, and one that is more in line with the initial conception of zero waste, would be to question whether these items are necessary at all, though this loss of revenue is unlikely to be considered a favorable possibility. Creative marketing and hospitality professionals may be able to identify possible solutions to maintaining revenue and fan satisfaction without the generation of waste.

Another challenge to all efforts to control the waste stream for optimal sustainability or to achieve complete diversion to recycling or composting is the introduction of outside materials by fans. During the waste audit the team observed materials that were smuggled into the Stadium, e.g., fast food packaging, small liquor bottles, etc. These materials present a challenge to managers since they may not comply with a 100% compostable waste stream and/or may not be recyclable. Aside from thorough searches of fans entering the stadium, which is likely to be both infeasible and a potential privacy violation, the best hope is that fans will be sufficiently aware of the waste management goals that they will properly sort the trash or take it with them when they leave. Technical options might include human or mechanized screening of waste streams; however, this is likely to be financially infeasible in many municipalities.

Every effort was taken to validate our sampling approach and extrapolation of observations to the total waste stream. With any sampling strategy there is the potential that waste estimates for any particular waste category are not perfect, which would impact the GHG and energy use estimations. To provide some sense of the potential for imperfect estimation to impact the results of this study consideration of imperfect weight estimation of rigid materials used primarily for beverage service, i.e., aluminum, mixed plastics, and glass as well as the estimated weight of beef wasted is discussed here. The most beneficial material to recycle is aluminum, every metric ton of aluminum recycled in estimated to save 9.1 mt CO2e and 16.1 GJ. The least savings for recycling of these three materials is glass with an estimated savings of 0.21 mt CO2e and 2.21 GJ per metric ton recycled. If all of the estimated weight over these three categories, 3.02 mt over the season, were aluminum the GHG savings associated with recycling would be estimated to save an additional 21 mt CO2e and 345 GJ of energy over the mix of aluminum, mixed plastics and glass, estimated in this analysis. The GHG benefits of avoided food waste would still be much larger at 103.1 mt CO2e than recycling; however, the energy savings would be greater, 486 GJ, than avoiding food waste, 448.5 GJ, given that recycling of aluminum saves a significant amount of energy compared to the use of primary aluminum. Since we observed mixed plastics and glass in the waste stream there is no chance than this example is possible, however, this exercise provides a sense of the sensitivity of results to estimated weights of these materials.

Improvements to our audit approach could be made by employing more people to increase the number of bags sampled and to count bags from all points of egress at every game. If food and merchandise purveyors could provide detailed inventory and sales data that would be allow a materials flow analysis to track all materials entering the stadium through to final disposal. This would also make it possible to bound the possible weights for all materials to provide greater certainty of the estimated weight for each material.

If the conception of “Sustainability” in waste management practices were expanded to include life-cycle GHG emissions or energy use embodied in materials rather than limiting consideration of these materials to waste management options there may be motivation from management or fans to explore different possibilities with regard to greening events. Similarly, if there were policy or economic structures that valued GHG emissions, e.g., a carbon tax, such that the cost of materials reflected the relative GHG emissions perhaps managers would select materials that were less GHG and energy-intensive based on costs alone. In all cases, it is recommended that venue managers expand their understanding of waste beyond simply how to manage it once it is generated to upstream options to avoid generating it in the first place.

5. Conclusions

This work details a sampling approach for auditing the waste stream emanating from a large football venue, over a seven-game season. Given that each game entails a large volume of waste generated over a short time duration, capturing information about the entire waste stream is challenging; a full audit is not practical and sampling approaches are necessary. Given the lack of prior studies detailing an approach for separating and measuring the waste for such large (>70,000-person) events, the sampling approach discussed herein describes a means for event managers to obtain detailed waste stream composition information.

The most-important findings from this paper are not solely the estimates of the composition of the waste stream by category (in Table 7, Table 8 and Table 9), although the sampling and estimation techniques utilized here do provide an important initial examination into this topic that can be expanded by future collection research efforts. Rather, what we emphasize is that for these estimates of the waste stream composition, source reduction of food waste, even with some amount of landfill waste (Scenarios 5a, 5b, 5c), can achieve dramatically greater reductions in life cycle GHG emissions and energy use than can zero waste strategies achieving 100% diversion of recyclables and compostable materials (Scenarios 3 and 4). We strengthen this finding (and address potential shortcomings in our sampling procedure) by performing sensitivity analyses, in which we vary the values in Table 7, Table 8 and Table 9 for recycling materials as well as substituting beef (which has very large GHG and energy impacts) with lower GHG- and energy-intensive poultry. Based on this sensitivity analysis, we find that that even if these estimates of waste material composition were incorrect, the findings regarding the benefits of source reduction exceeding those of zero waste remain valid.

With respect to maximizing GHG emissions and energy use savings, this analysis found the best options to be source reduction of food waste and improving fan sorting of recyclables . It should be noted that achieving zero waste through diversion of waste to recycling and composting does not always correspond to the largest reductions in two common metrics used for assessing “sustainability”, i.e., life cycle GHG emissions and energy use. It is important that event managers also consider the life cycle impacts of materials, including the potential for avoiding waste generation in the first place, when assessing the sustainability of their waste management practices.

The results of this study also lead to the conclusion that recycling is more environmentally friendly than composting biodegradable polymers. The decision to exclusively utilize PLA for packaging, as in Scenarios 4 and 5e, would lead to a single waste stream, and 100% diversion, negating the need for fans to sort properly. However, the City of Columbia, as is the case in many small cities, currently does not accept biopolymers due to inadequate composting facilities to degrade PLA materials, thus realizing this scenario would require an investment into composting capabilities.

These insights should lead to a more nuanced understanding of sustainability and sporting events, moving beyond earlier studies, which simply stated that recycling and composting is aligned with achieving sustainability. This work demonstrates that expanding this view to include the possibility of waste reduction, in particular food waste reduction, could result in greater life cycle GHG and energy savings than any other available waste management options. Moving beyond source reduction, additional gains could be achieved by modifying the food offerings at such events to favor less GHG- or energy-intensive foods, e.g., preparing chicken rather than beef and/or offering meat-substitute options at buffets.

Additional research is needed to extend these efforts in order to develop the tools and understanding necessary for event managers to achieve these potential GHG and energy savings. Replication of these data collection efforts will help to reduce the uncertainties regarding waste stream composition. Given these estimates of waste stream composition, additional modeling should be performed to develop a decision support tool for event managers, allowing for a more user-friendly interface and automated data collection, to identify the amounts of waste (in particular, food waste), GHG, and energy savings associated with changes in event operations (e.g., substituting beef menu items with meat-substitute items at buffets). Such a decision support tool should be accompanied by operations guidelines, capturing best-practices from other sporting events managers. Successful completion of these additional efforts will require integration and collaboration with a variety of disciplines, including not only environmental engineering and management science, but also strategic communications, human-computer interaction, and organizational psychology, to ensure successful implementation.

Supplementary Materials

The following are available online at www.mdpi.com/2071-1050/9/7/1236/s1, Tables S1–S13 and the Data Collection form.

Acknowledgments

The authors would like to thank the four anonymous reviewers for the suggestions, which have improved the manuscript considerably. The authors would like to thank the University of Missouri’s Intercollegiate Athletics Department, in particular Anthony Wirkus, for their interest and cooperation throughout this project. We also extend many thanks to the MU Sustainability Office for their support. And finally, many thanks to the undergraduate and graduate workers who assisted with sorting through the waste collected at the Stadium. This work was supported by The Mizzou Advantage.

Author Contributions

Christine Costello and Ronald G. McGarvey conceived and designed the collection strategy based on interviews with Stadium personnel and food service providers, and supervised collection activities. Ronald G. McGarvey and Esma Birisci completed the statistical analysis to estimate the proportion of waste in the total waste stream using data collected during the study. Christine Costello generated waste management scenarios and performed the analysis of greenhouse gas emission sand energy use using the WARM model. All authors contributed to the manuscript via drafting text for their respective contributions and editing the overall document.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- NRDC. Game Changer: How the Sports Industry Is Saving the Environment; R:12-08-A; NRDC: New York, NY, USA, 2012. [Google Scholar]

- Trendafilova, S.; Kellison, T.B.; Spearman, L. Environmental Sustainability in Sport Facilities in East Tennessee. J. Facil. Plan. Des. Manag. 2014, 2, 1–11. [Google Scholar]

- NRDC. Collegiate Game Changers: How Campus Sport Is Going Green; R:13-08-A; NRDC: New York, NY, USA, 2013. [Google Scholar]

- Casper, J.M.; Pfahl, M.; McCullough, B. Intercollegiate Sport and the Environment: Examining Fan Engagement Based on Athletics Department Sustainability Efforts. J. Issues Intercoll. Athl. 2014, 7, 65–71. [Google Scholar]

- Kellison, T.B.; Kim, Y.K. Marketing Pro-Environmental Venues in Professional Sport: Planting Seeds of Change among Existing and Prospective Consumers. J. Sport Manag. 2014, 28, 34–48. [Google Scholar] [CrossRef]

- Agins, J.; Dyson, C.; Meyer, R.; Zimmerman, L. Zero Waste at the Big House: Minimizing Waste at 32 Michigan Stadium. Available online: http://erblegacy.snre.umich.edu/Research/InstituteReports/11-12/Zero-Waste-Big%20House-Final%20Report.pdf (accessed on 13 July 2017).

- Pelham, F. Will sustainability change the business model of the event industry? Worldw. Hosp. Tour. Themes 2011, 3, 187–192. [Google Scholar] [CrossRef]

- Laing, J.; Frost, W. How green was my festival: Exploring challenges and opportunities associated with staging green events. Int. J. Hosp. Manag. 2010, 29, 261–267. [Google Scholar] [CrossRef]

- Mallen, C.; Stevens, J.; Adams, L.J. A Content Analysis of Environmental Sustainability Research in a Sport-Related Journal Sample. J. Sport Manag. 2011, 25, 240–256. [Google Scholar] [CrossRef]

- McCullough, B.P. Identifying the influences on sport spectator recycling behaviours using the theory of planned behaviour. Int. J. Sport Manag. Market. 2013, 14, 146–168. [Google Scholar] [CrossRef]

- Dolf, M.; Teehan, P. Reducing the carbon footprint of spectator and team travel at the University of British Columbia’s varsity sports events. Sport Manag. Rev. 2015, 18, 244–255. [Google Scholar] [CrossRef]

- Collins, A.; Jones, C.; Munday, M. Assessing the environmental impacts of mega sporting events: Two options? Tour. Manag. 2009, 30, 828–837. [Google Scholar] [CrossRef]

- Zaman, A.U. A comprehensive review of the development of zero waste management: Lessons learned and guidelines. J. Clean. Prod. 2015, 91, 12–25. [Google Scholar] [CrossRef]

- ZWIA. Zero Waste International Alliance. ZW Definition. Available online: http://zwia.org/standards/zw-definition/ (accessed on 18 July 2016).

- Hottle, T.A.; Bilec, M.M.; Brown, N.R.; Landis, A.E. Toward zero waste: Composting and recycling for sustainable venue based events. Waste Manag. 2015, 38, 86–94. [Google Scholar] [CrossRef] [PubMed]

- EPA. Documentation for Greenhouse Gas Emissions and Energy Factors Used in the Waste Reduction Model (WARM); Version 13; EPA: Washington, DC, USA, 2015. [Google Scholar]

- Mizzou2sec. Available online: http://mizzou2sec.com/stadium_expansion.php (accessed on 18 July 2016).

- Dak Dillon Photograhy. Available online: http://www.dakdillonphotography.com/2012/an-overhead-view-of-mizzous-sec-kickoff/ (accessed on 18 July 2016).

- Tally Counter by Pixel Research Labs. Available online: https://itunes.apple.com/us/app/tally-counter/id288732372?mt=8 (accessed on 29 April 2017).

- De Vries, M.; de Boer, I.J.M. Comparing environmental impacts for livestock products: A review of life cycle assessments. Livest. Sci. 2010, 128, 1–11. [Google Scholar] [CrossRef]

- González, A.D.; Frostell, B.; Carlsson-Kanyama, A. Protein efficiency per unit energy and per unit greenhouse gas emissions:Potential contribution of diet choices to climate change mitigation. Food Policy 2011, 36, 562–570. [Google Scholar] [CrossRef]

- STATA. Data Analysis and Statistical Software. Available online: http://www.stata.com/ (accessed on 13 June 2017).

- Hamilton, H.A.; Peverill, M.S.; Müller, D.B.; Brattebø, H. Assessment of Food Waste Prevention and Recycling Strategies Using a Multilayer Systems Approach. Environ. Sci. Technol. 2015, 49, 13937–13945. [Google Scholar] [CrossRef] [PubMed]

- Uecker-Mercado, H.; Walker, M. The Value of Environmental Social Responsibility to Facility Managers: Revealing the Perceptions and Motives for Adopting ESR. J. Bus. Ethics 2012, 110, 269–284. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).