Automatic Recognition of Common Structural Elements from Point Clouds for Automated Progress Monitoring and Dimensional Quality Control in Reinforced Concrete Construction

Abstract

1. Introduction

2. State of the Art in Semantic Extraction of Structural Components from Point Clouds

- Scan vs. BIM, which is used only when a reliable as-planned 4D BIM exists;

- Supervised learning, which is used when an object template or library of preclassified similar objects exist for training/matching;

- Spatial and contextual relationship, which uses unique a prior knowledge of an object and its relationship to other objects.

2.1. Scan vs. BIM

2.2. Supervised Learning

2.3. Spatial, Geometrical, and Contextual Relationship

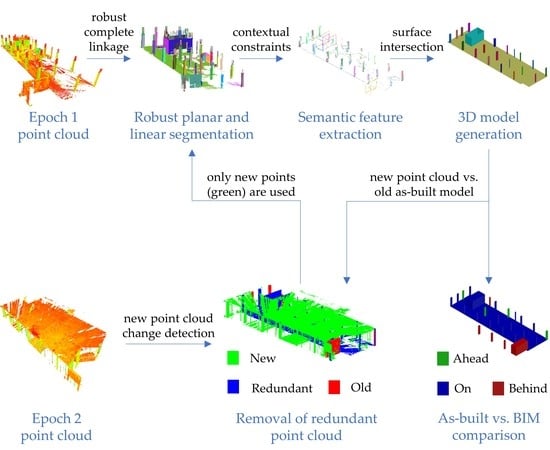

3. Methodology

- Robust extraction of planar and linear features from registered point clouds (Figure 1b);

- Semantic labeling of point clouds into floors, columns, and rebars using contextual and spatial information (Figure 1c);

- Surface intersection and modeling (Figure 1d);

- Identification and visualization of deviations between as-built and planned BIM (Figure 1g); and

3.1. Target-Based Point Cloud Registration

3.2. Robust Planar and Linear Segmentation

3.3. Semantic Object Extraction Using Relationship-Based Reasoning

- Algorithm 1: First, the two main orthogonal orientation directions of planar surfaces, excluding the floor objects, are identified. The planar surfaces whose normal vectors are in the same direction of these two vectors are selected as potential column candidates (i.e., planes whose normal vector follows the direction of the main orthogonal site axes).

- Algorithm 2: The boundaries of the extracted planar candidates are then assessed to determine the presence of floor and/or linear objects in the proximity of their exterior boundaries.

3.3.1. Algorithm 1: Detection of Planes Following the Main Orthogonal Site Axis

- Select the planar surfaces, excluding the floor objects.

- Assign the normal vector associated with the planar surface to each point of that segment.

- For every two identified modes, calculate the allowable standard deviation of the inner product of two modes, , derived by applying the law of variance propagation, using Equation (1):where and are the normal vectors of the ith and jth mode, respectively; is the allowable tolerance of the inner product of vectors and ; is the allowable angular tolerance in radians; are the angles of the normal vector of the ith mode to the x, y and z axes, respectively; and is the inner product of vectors and . In this study, the allowable plumb tolerance () is set to approximately 0.52°, derived from ACI 117 [51,52].

- Select the two modes whose absolute value of the inner product satisfies the orthogonality criteria of Equation (2):The threshold is used to account for approximately 99% confidence.

- For the pair of normal vectors satisfying Equation (2), find the normal vectors of the planar surfaces whose angles are within in each direction.

3.3.2. Algorithm 2: Assessment of Column Boundary Conditions

- Select the planar candidates obtained from Algorithm 1.

- Calculate the first and third quartile of the height of all planar candidates.

- Identify planar surfaces whose minimum height is smaller than the first quartile, and maximum height is larger than the third quartile of height (to ensure removal of shorter clutters).

- Perform connected components region growing (Algorithm 5 of [8]) on the identified boundaries to group together potential columns. Here, the neighborhood size is set to , where is the radius of the neighborhood used for robust PCA classification [22]. This neighborhood size was chosen since the local neighborhood of points within from the edge of two intersecting surfaces are prone to misclassification using classical PCA (see Figure 3b,c). Since robust PCA classifies more planar points closer to the boundaries than classical PCA [22,43], the defined threshold will be large enough to group together surfaces of the same column.

- Select the connected segments that contain a floor object within from its minimum height ( is used for the same reasons given in step 5 and Figure 3c).

- From the remaining connected segments satisfying step 6, a connected segment is labeled a column if one of the following two criteria is satisfied:

- Select the column segments from Algorithm 2 that satisfy the condition of step 7b.

- For each column segment, identify all linear segments whose minimum height is larger than the column’s height.

- Project all identified linear segments onto the x−y plane.

- The linear segments whose boundaries in the x−y plane are enclosed by the boundaries of the columns are considered as rebars.

3.4. Parametric Surface Representation

- Floors: every floor is represented by a normal vector (estimated through robust PCA), and a point on the plane (robust center of the points) [22]. The boundary of the floors is identified using the modified convex hull algorithm and boundary regularization presented in [56] to define the extents of the floor planes.

- Rebars: each rebar is represented by a point (e.g., robust center of the segmented rebar), length of the rebar, cylinder’s axis, and radius. The radius and cylinder’s axis are estimated through Algorithms 1 through 3 of [8] to provide an accurate and robust estimation. To define the length of the cylinder, rotate the cylinder’s axis to the z direction using Rodrigues rotational formulation. The length of the rebar is then the difference between the maximum and minimum heights of the rotated rebar.

- Columns: the extents of the rectangular columns are defined by the eight vertices of the rectangular prism (Figure 2b). Each planar façade of the column is represented by the four plane parameters (see floor objects above). The bottom vertices are estimated through the intersection of planar surfaces and the floor object on the bottom. The process is identical in cases where a floor object also exists on the top (i.e., ceiling; see Figure 2b). In cases where only rebars exist on top, a virtual plane parallel to the bottom floor plane with distance of the maximum height of the column segment from the bottom floor is generated. The top four vertices are calculated accordingly through planar intersection.

3.5. Planned vs. As-Built Comparison

3.6. Redundant Point Removal of Prospective Scans

- For every new scan point, , calculate the covariance matrix, using Equation (5).

- Calculate the eigenvalues ( and eigenvectors () of the covariance matrix ().

- Construct error ellipsoid using Equation (6):where is the vector of coordinates of point in the object space and is a chi-squared probability with 95% confidence and 3 degrees of freedom ().

- Find all planar and cylindrical (rebars are modeled as cylinders; see Section 3.4) objects from Algorithms 1–3 that intersect the error ellipsoid.

- If more than one surface meets the conditions of step 4, the point is assigned to the closest surface. The point is then semantically labeled to the corresponding object represented by the segmented surface.

3.6.1. Algorithm 5: Intersection of an Ellipsoid and Plane

- Calculate the distance of the point to the planar segments ( of Figure 5a).

- Identify all surfaces where is smaller than , the semimajor axis.

- Calculate the linear transformation matrix that transforms the error ellipsoid of Equation (6) into a sphere with radius . This transformation reduces the problem to finding the intersection between a sphere and a plane, since planes are affine equivariant.

- Calculate the distance of point from each transformed planar segment ().

- Identify all surfaces whose distances () are smaller than .

- Project the transformed error sphere onto the surfaces satisfying condition 5 to construct an error circle with the point’s projection as the center and radius (Pythagorean theorem).

- The point is assigned to the surface if and only if its projected circle intersects with the boundary of that surface.

3.6.2. Algorithm 6: Intersection of an Ellipsoid and Cylinder

- Calculate the distance of the point to the axis of the cylindrical segments .

- Identify all cylinders where is smaller than , where is the radius of the cylindrical segment.

- Find the rotation matrix, , that orients the cylinder’s axis parallel to the z-axis following Rodrigues rotation formula.

- Rotate the error ellipsoid (Equation 6) and the cylindrical segment using .

- Project the rotated ellipsoid and cylinder onto the x−y plane. This reduced the problem to finding the intersection between a circle and an ellipse in a 2D plane. To this end, we first identify the closest point, , from the center of the circle () to the ellipse using the following steps.

- Calculate the transformation matrix of the newly rotated error ellipse.

- Transform the error ellipse into an error circle with radius and center, .

- Transform the center of the circle, , into using the same transformation matrix as step 6. This transformation further reduces the problem to identifying the closest point between the newly transformed point () and error circle of step 7.

- Calculate the point of intersection, , between the line segment and the error circle.

- Identify by transforming the point of intersection, , back to the correct coordinate system (i.e., before the affine transformation of step 6).

- Identify all segments where the distance between and is smaller than the radius, (the condition for the intersection of the ellipse and circle).

- Project the rotated error ellipsoid of step 4 onto the axis. Identify the maximum and minimum height of the projected ellipsoid. The point is assigned to the surface if and only if its projected height intersects with the height of the cylindrical segment.

3.7. Method of Validation of Results

4. Experimental Results

4.1. Experiment Description

4.2. Extraction of Columns from Segmented Planar and Linear Features

4.3. Results of Redundant Surface Removal

4.4. As-Built vs. Planned BIM Comparison

4.4.1. Progress Monitoring through EVM

4.4.2. Dimensional Compliance Control

5. Summary of Findings and Discussion

6. Conclusions

- Examination of the methods proposed in this manuscript for progress monitoring and dimensional conformity control of rebars in reinforced concrete projects where a detailed planned BIM, containing the complete details of the rebars, exists.

- The simultaneous application of scan vs. BIM, supervised learning, and the methods proposed in our study for the extraction of structural components with complex geometries. Additionally, the application of novel methods used to reduce the dependency of semantic labeling on new training data, such as those presented in [61], for TLS acquired from construction sites is an interesting research topic for future investigations.

- The extraction of temporary objects, such as scaffolds and formwork, from TLS acquired from construction sites using validated methods applied to photogrammetric point clouds, such as those proposed in [62].

- Evaluations of methods proposed by [63] for surface flatness assessment to generate a standardized surface flatness metric.

- Development of a fuzzy logic-based uncertainty model for the estimation of the location of structures, similar to the method proposed by [64] for the prediction of the locations of utility data.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Josephson, P.E.; Larsson, B.; Li, H. Illustrative Benchmarking Rework and Rework Costs in Swedish Construction Industry. J. Manag. Eng. 2002, 18, 76–83. [Google Scholar] [CrossRef]

- Oko, J.A.; Itodo, E.D. Professionals’ Views of Material Wastage on Construction Sites and Cost Overruns. Organ. Technol. Manag. Constr. Int. J. 2013, 5, 747–757. [Google Scholar] [CrossRef]

- Kultermann, E.; Spence, W.P. Construction Materials, Methods and Techniques, 4th ed.; Cengage Learning: Boston, MA, USA, 2016; ISBN 978-1-3050-8627-2. [Google Scholar]

- Geng, Y.; Wang, Z.; Shen, L.; Zhao, J. Calculating of CO2 Emission Factors for Chinese Cement Production Based on Inorganic Carbon and Organic Carbon. J. Clean. Prod. 2019, 217, 503–509. [Google Scholar] [CrossRef]

- Miami Herald: Feds Fine Contractors Behind Deadly FIU Bridge Collapse for ‘Serious’ Safety Violations. Available online: https://www.miamiherald.com/news/local/community/miami-dade/article218594530.html (accessed on 11 April 2019).

- Shalabi, F.; Turkan, Y. IFC BIM-Based Facility Management Approach to Optimize Data Collection for Corrective Maintenance. J. Perform. Constr. Facil. 2017, 31, 04016081. [Google Scholar] [CrossRef]

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life Cycle Environmental Impact Assessment to Manage and Optimize Construction Waste Using Building Information Modeling (BIM). Int. J. Constr. Manag. 2019, 1–18. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Walker, R.; Bhavnani, A.; Ruwanpura, J.Y. Extraction of Pipes and Flanges from Point Clouds for Automated Verification of PreFabricated Modules in Oil and Gas Refinery Projects. Autom. Constr. 2019, 103, 150–167. [Google Scholar] [CrossRef]

- Tang, P.; Huber, D.; Akinci, B.; Lipman, R.; Lytle, A. Automatic Reconstruction of As-Built Building Information Models from Laser-Scanned Point Clouds: A Review of Related Techniques. Autom. Constr. 2010, 19, 829–843. [Google Scholar] [CrossRef]

- Son, H.; Bosché, F.; Kim, C. As-Built Data Acquisition and Its Use in Production Monitoring and Automated Layout of Civil Infrastructure: A Survey. Adv. Eng. Inform. 2015, 29, 172–183. [Google Scholar] [CrossRef]

- Pătrăucean, V.; Armeni, I.; Nahangi, M.; Yeung, J.; Brilakis, I.; Haas, C. State of Research in Automatic As-Built Modelling. Adv. Eng. Inform. 2015, 29, 162–171. [Google Scholar] [CrossRef]

- Lehtola, V.V.; Kaartinen, H.; Nüchter, A.; Kaijaluoto, R.; Kukko, A.; Litkey, P.; Honkavaara, E.; Rosnell, T.; Vaaja, M.T.; Virtanen, J.-P.; et al. Comparison of the Selected State-Of-The-Art 3D Indoor Scanning and Point Cloud Generation Methods. Remote Sens. 2017, 9, 796. [Google Scholar] [CrossRef]

- Wang, R.; Peethambaran, J.; Chen, D. LiDAR Point Clouds to 3-D Urban Models: A Review. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2018, 11, 606–627. [Google Scholar] [CrossRef]

- Wang, Q.; Tan, Y.; Mei, Z. Computational Methods of Acquisition and Processing of 3D Point Cloud Data for Construction Applications. Arch. Comput. Methods Eng. 2019. [Google Scholar] [CrossRef]

- Bosche, F.; Haas, C.T. Automated Retrieval of 3D CAD Model Objects in Construction Range Images. Autom. Constr. 2008, 17, 499–512. [Google Scholar] [CrossRef]

- Bosché, F. Automated Recognition of 3D CAD Model Objects in Laser Scans and Calculation of As-Built Dimensions for Dimensional Compliance Control in Construction. Adv. Eng. Inform. 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Bosché, F.; Guillemet, A.; Turkan, Y.; Haas, C.T.; Haas, R. Tracking the Built Status of MEP Works: Assessing the Value of a Scan-vs-BIM System. J. Comput. Civ. Eng. 2014, 28, 05014004. [Google Scholar] [CrossRef]

- Turkan, Y.; Bosche, F.; Haas, C.T.; Haas, R. Automated Progress Tracking Using 4D Schedule and 3D Sensing Technologies. Autom. Constr. 2012, 22, 414–421. [Google Scholar] [CrossRef]

- Kim, C.; Son, H.; Kim, C. Automated Construction Progress Measurement Using a 4D Building Information Model and 3D Data. Autom. Constr. 2013, 31, 75–82. [Google Scholar] [CrossRef]

- Turkan, Y.; Bosché, F.; Haas, C.T.; Haas, R. Tracking of Secondary and Temporary Objects in Structural Concrete Work. Constr. Innov. 2014, 14, 145–167. [Google Scholar] [CrossRef]

- Zhang, C.; Arditi, D. Automated Progress Control Using Laser Scanning Technology. Autom. Constr. 2013, 36, 108–116. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Robust Segmentation of Planar and Linear Features of Terrestrial Laser Scanner Point Clouds Acquired from Construction Sites. Sensors 2018, 18, 819. [Google Scholar] [CrossRef]

- Yang, J.; Shi, Z.-K.; Wu, Z.-Y. Towards Automatic Generation of As-Built BIM: 3D Building Facade Modeling and Material Recognition from Images. Int. J. Autom. Comput. 2016, 13, 338–349. [Google Scholar] [CrossRef]

- Kim, H.; Kim, K.; Kim, H. Data-Driven Scene Parsing Method for Recognizing Construction Site Objects in the Whole Image. Autom. Constr. 2016, 71, 271–282. [Google Scholar] [CrossRef]

- Verity—Clear Edge 3D. Available online: http://www.clearedge3d.com/products/verity/ (accessed on 11 April 2019).

- Chai, J.; Chi, H.-L.; Wang, X.; Wu, C.; Jung, K.H.; Lee, J.M. Automatic As-Built Modeling for Concurrent Progress Tracking of Plant Construction Based on Laser Scanning. Concurr. Eng. 2016, 24, 369–380. [Google Scholar] [CrossRef]

- Son, H.; Kim, C. Semantic As-Built 3D Modeling of Structural Elements of Buildings Based on Local Concavity and Convexity. Adv. Eng. Inform. 2017, 34, 114–124. [Google Scholar] [CrossRef]

- Xiong, X.; Adan, A.; Akinci, B.; Huber, D. Automatic Creation of Semantically Rich 3D Building Models from Laser Scanner Data. Autom. Constr. 2013, 31, 325–337. [Google Scholar] [CrossRef]

- Rabbani, T.; van den Heuvel, F.A.; Vosselman, G. Segmentation of Point Clouds Using Smoothness Constraints. In ISPRS 2006: Proceedings of the ISPRS Commission V Symposium Vol. 35, Part 6: Image Engineering and Vision Metrology, Dresden, Germany, 25–27 September 2006; International Society for Photogrammetry and Remote Sensing (ISPRS): Dresden, Germany, 2006; pp. 248–253. Available online: https://www.isprs.org/proceedings/XXXVI/part5/paper/RABB_639.pdf (accessed on 8 May 2019).

- Wolpert, D.H. Stacked Generalization. Neural Netw. 1992, 5, 241–259. [Google Scholar] [CrossRef]

- Czerniawski, T.; Sankaran, B.; Nahangi, M.; Haas, C.; Leite, F. 6D DBSCAN-Based Segmentation of Building Point Clouds for Planar Object Classification. Autom. Constr. 2018, 88, 44–58. [Google Scholar] [CrossRef]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for Point-Cloud Shape Detection. Comput. Graph. Forum 2007, 26, 214–226. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.-P.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery and Data Mining, KDD’96, Portland, OR, USA, 2–4 August 1996; pp. 226–231. [Google Scholar]

- Son, H.; Kim, C.; Hwang, N.; Kim, C.; Kang, Y. Classification of Major Construction Materials in Construction Environments Using Ensemble Classifiers. Adv. Eng. Inform. 2014, 28, 1–10. [Google Scholar] [CrossRef]

- Ma, L.; Sacks, R.; Kattel, U.; Bloch, T. 3D Object Classification Using Geometric Features and Pairwise Relationships. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 152–164. [Google Scholar] [CrossRef]

- Shi, W.; Ahmed, W.; Li, N.; Fan, W.; Xiang, H.; Wang, M. Semantic Geometric Modelling of Unstructured Indoor Point Cloud. ISPRS Int. J. Geo-Inf. 2019, 8, 9. [Google Scholar] [CrossRef]

- Macher, H.; Landes, T.; Grussenmeyer, P. From Point Clouds to Building Information Models: 3D Semi-Automatic Reconstruction of Indoors of Existing Buildings. Appl. Sci. 2017, 7, 1030. [Google Scholar] [CrossRef]

- Pu, S.; Vosselman, G. Knowledge Based Reconstruction of Building Models from Terrestrial Laser Scanning Data. ISPRS J. Photogramm. Remote Sens. 2009, 64, 575–584. [Google Scholar] [CrossRef]

- Vosselman, G.; Gorte, B.G.H.; Sithole, G.; Rabbani, T. Recognising Structure in Laser Scanning Point Clouds. In Proceedings of the ISPRS Working Group VIII/2: Laser Scanning for Forest and Landscape Assessment, ISPRS 2004, Freiburg, Germany, 3–6 October 2004; University of Freiburg: Freiburg, Germany, 2004; pp. 33–38. [Google Scholar]

- Wang, Q.; Yan, L.; Zhang, L.; Ai, H.; Lin, X. A Semantic Modelling Framework-Based Method for Building Reconstruction from Point Clouds. Remote Sens. 2016, 8, 737. [Google Scholar] [CrossRef]

- Hong, S.; Jung, J.; Kim, S.; Cho, H.; Lee, J.; Heo, J. Semi-Automated Approach to Indoor Mapping for 3D as-Built Building Information Modeling. Comput. Environ. Urban Syst. 2015, 51, 34–46. [Google Scholar] [CrossRef]

- Ochmann, S.; Vock, R.; Klein, R. Automatic Reconstruction of Fully Volumetric 3D Building Models from Oriented Point Clouds. ISPRS J. Photogramm. Remote Sens. 2019, 151, 251–262. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Ruwanpura, J. Robust Classification and Segmentation of Planar and Linear Features for Construction Site Progress Monitoring and Structural Dimension Compliance Control. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, 3, 129–136. [Google Scholar] [CrossRef]

- Li, L.; Su, F.; Yang, F.; Zhu, H.; Li, D.; Zuo, X.; Li, F.; Liu, Y.; Ying, S. Reconstruction of Three-Dimensional (3D) Indoor Interiors with Multiple Stories via Comprehensive Segmentation. Remote Sens. 2018, 10, 1281. [Google Scholar] [CrossRef]

- Díaz-Vilariño, L.; Conde, B.; Lagüela, S.; Lorenzo, H. Automatic Detection and Segmentation of Columns in As-Built Buildings from Point Clouds. Remote Sens. 2015, 7, 15651–15667. [Google Scholar] [CrossRef]

- Steadman, P. Why Are Most Buildings Rectangular? ARQ Archit. Res. Q. 2006, 10, 119–130. [Google Scholar] [CrossRef]

- Nunnally, S.W. Construction Methods and Management, 8th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2010; pp. 517–518. [Google Scholar]

- Zalka, K.A. Structural Analysis of Regular Multi-Storey Buildings, 1st ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Fukunaga, K.; Hostetler, L. The Estimation of the Gradient of a Density Function, with Applications in Pattern Recognition. IEEE Trans. Inf. Theory 1975, 21, 32–40. [Google Scholar] [CrossRef]

- Shimazaki, H.; Shinomoto, S. Kernel Bandwidth Optimization in Spike Rate Estimation. J. Comput. Neurosci. 2010, 29, 171–182. [Google Scholar] [CrossRef]

- ACI Committee 117. Specification for Tolerances for Concrete Construction and Materials (Reapproved 2015); American Concrete Institute: Farmington Hills, MI, USA, 2010. [Google Scholar]

- Ballast, D.K. Handbook of Construction Tolerances, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Edelsbrunner, H.; Kirkpatrick, D.; Seidel, R. On the Shape of a Set of Points in the Plane. IEEE Trans. Inf. Theory 1983, 29, 551–559. [Google Scholar] [CrossRef]

- Fayed, M.; Mouftah, H.T. Localised Alpha-Shape Computations for Boundary Recognition in Sensor Networks. Ad Hoc Netw. 2009, 7, 1259–1269. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Sampath, A.; Shan, J. Building Boundary Tracing and Regularization from Airborne Lidar Point Clouds. Photogramm. Eng. Remote Sens. 2007, 73, 805–812. [Google Scholar] [CrossRef]

- Olsen, D.L.; Denlen, D. Advanced Data Mining Techniques; Springer: New York, NY, USA, 2008; p. 138. [Google Scholar]

- Maalek, R.; Sadeghpour, F. Accuracy Assessment of Ultra-Wide Band Technology in Tracking Static Resources in Indoor Construction Scenarios. Autom. Constr. 2013, 30, 170–183. [Google Scholar] [CrossRef]

- Leica HDS6100 TLS Datasheet and Key Performance Specifications. Available online: http://w3.leicageosystems.com/downloads123/hds/hds/HDS6100/brochures/Leica_HDS6100_brochure_us.pdf (accessed on 29 April 2019).

- Maalek, R.; Ruwanpura, J.; Ranaweera, K. Evaluation of the State-of-the-Art Automated Construction Progress Monitoring and Control Systems. In Construction Research Congress 2014; American Society of Civil Engineers: Atlanta, GA, USA, 2014; pp. 1023–1032. [Google Scholar] [CrossRef]

- Wu, J.; Yao, W.; Zhang, J.; Li, Y. 3D Semantic Labeling of ALS Data Based on Domain Adaption by Transferring and Fusing Random Forest Models. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII-3, 1883–1887. [Google Scholar] [CrossRef]

- Xu, Y.; Tuttas, S.; Hoegner, L.; Stilla, U. Reconstruction of Scaffolds from a Photogrammetric Point Cloud of Construction Sites Using a Novel 3D Local Feature Descriptor. Autom. Constr. 2018, 85, 76–95. [Google Scholar] [CrossRef]

- Bosché, F.; Guenet, E. Automating Surface Flatness Control Using Terrestrial Laser Scanning and Building Information Models. Autom. Constr. 2014, 44, 212–226. [Google Scholar] [CrossRef]

- Olde Scholtenhuis, L.L.; den Duijn, X.; Zlatanova, S. Representing Geographical Uncertainties of Utility Location Data in 3D. Autom. Constr. 2018, 96, 483–493. [Google Scholar] [CrossRef]

| Epoch | No. of Scan Stations | Total No. of Points (millions) | Registration Precision (mm) |

|---|---|---|---|

| 1 | 3 | 37 | 1.5 |

| 2 | 3 | 153 | 1.4 |

| 3 | 4 | 201 | 2.2 |

| 4 | 3 | 115 | 1.5 |

| 5 | 5 | 358 | 1.8 |

| Epoch | Precision | Recall | Accuracy |

|---|---|---|---|

| 1 | 95.45 | 100.00 | 96.30 |

| 2 | 100.00 | 100.00 | 100.00 |

| 3 | 100.00 | 100.00 | 100.00 |

| 4 | 100.00 | 100.00 | 100.00 |

| 5 | 100.00 | 100.00 | 100.00 |

| Overall | 99.24 | 100.00 | 99.31 |

| Epochs | Precision | Recall | Accuracy |

|---|---|---|---|

| 1–2 | 97.44 | 98.70 | 98.04 |

| 2–3 | 95.71 | 97.10 | 99.38 |

| 3–4 | 97.16 | 97.71 | 96.09 |

| 4–5 | 96.70 | 97.78 | 99.65 |

| Overall | 97.09 | 98.04 | 98.79 |

| Epochs | BCWS 1 (Units of Cost) | BCWP 2 (Units of Cost) | SPI 3 | Schedule Performance of Project |

|---|---|---|---|---|

| 1 | 1.73 | 1.29 | 0.74 | Behind |

| 2 | 2.56 | 2.56 | 1.00 | On |

| 3 | 3.62 | 3.35 | 0.93 | Behind |

| 4 | 4.18 | 4.18 | 1.00 | On |

| 5 | 4.90 | 5.57 | 1.14 | Ahead |

| Epochs | DRMS 1 Compared to Planned (mm) | DRMS Compared to Ground Truth (mm) | Columns within Tolerance (%) |

|---|---|---|---|

| 1 | 9 | 2 | 90.48 |

| 2 | 6 | 1 | 100.00 |

| 3 | 8 | 2 | 96.15 |

| 4 | 6 | 2 | 100.00 |

| 5 | 8 | 1 | 93.10 |

| Overall | 7 | 1 | 96.21 |

| Floors | Estimated Slab Thickness (mm) | Absolute Difference from Plan (mm) | Absolute Difference from Ground Truth (mm) |

|---|---|---|---|

| 2 | 173 | 2 | 0 |

| 3 | 179 | 4 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Automatic Recognition of Common Structural Elements from Point Clouds for Automated Progress Monitoring and Dimensional Quality Control in Reinforced Concrete Construction. Remote Sens. 2019, 11, 1102. https://doi.org/10.3390/rs11091102

Maalek R, Lichti DD, Ruwanpura JY. Automatic Recognition of Common Structural Elements from Point Clouds for Automated Progress Monitoring and Dimensional Quality Control in Reinforced Concrete Construction. Remote Sensing. 2019; 11(9):1102. https://doi.org/10.3390/rs11091102

Chicago/Turabian StyleMaalek, Reza, Derek D. Lichti, and Janaka Y. Ruwanpura. 2019. "Automatic Recognition of Common Structural Elements from Point Clouds for Automated Progress Monitoring and Dimensional Quality Control in Reinforced Concrete Construction" Remote Sensing 11, no. 9: 1102. https://doi.org/10.3390/rs11091102

APA StyleMaalek, R., Lichti, D. D., & Ruwanpura, J. Y. (2019). Automatic Recognition of Common Structural Elements from Point Clouds for Automated Progress Monitoring and Dimensional Quality Control in Reinforced Concrete Construction. Remote Sensing, 11(9), 1102. https://doi.org/10.3390/rs11091102