Developing an Active Canopy Sensor-Based Integrated Precision Rice Management System for Improving Grain Yield and Quality, Nitrogen Use Efficiency, and Lodging Resistance

Abstract

:1. Introduction

2. Materials and Methods

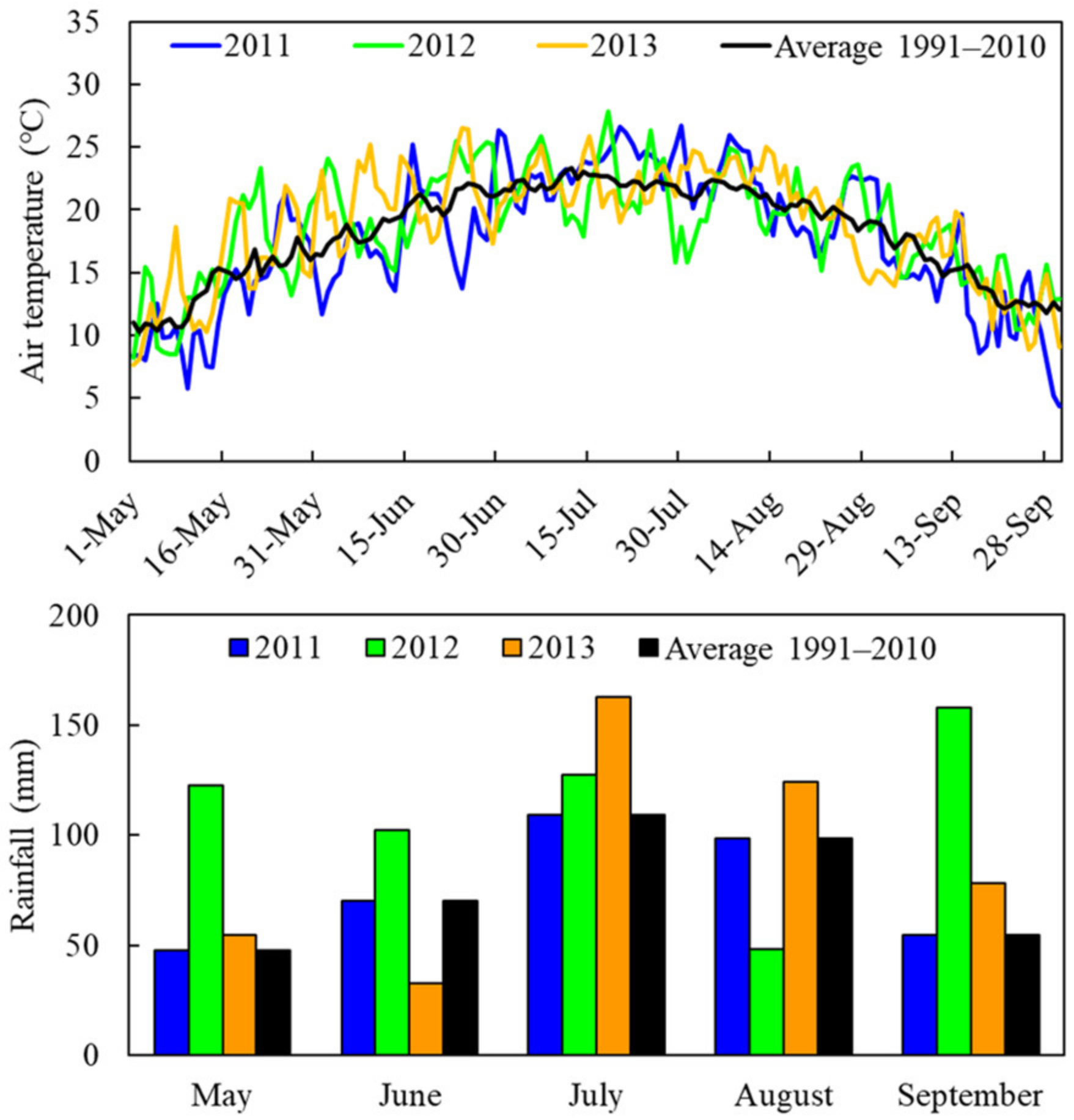

2.1. Study Site

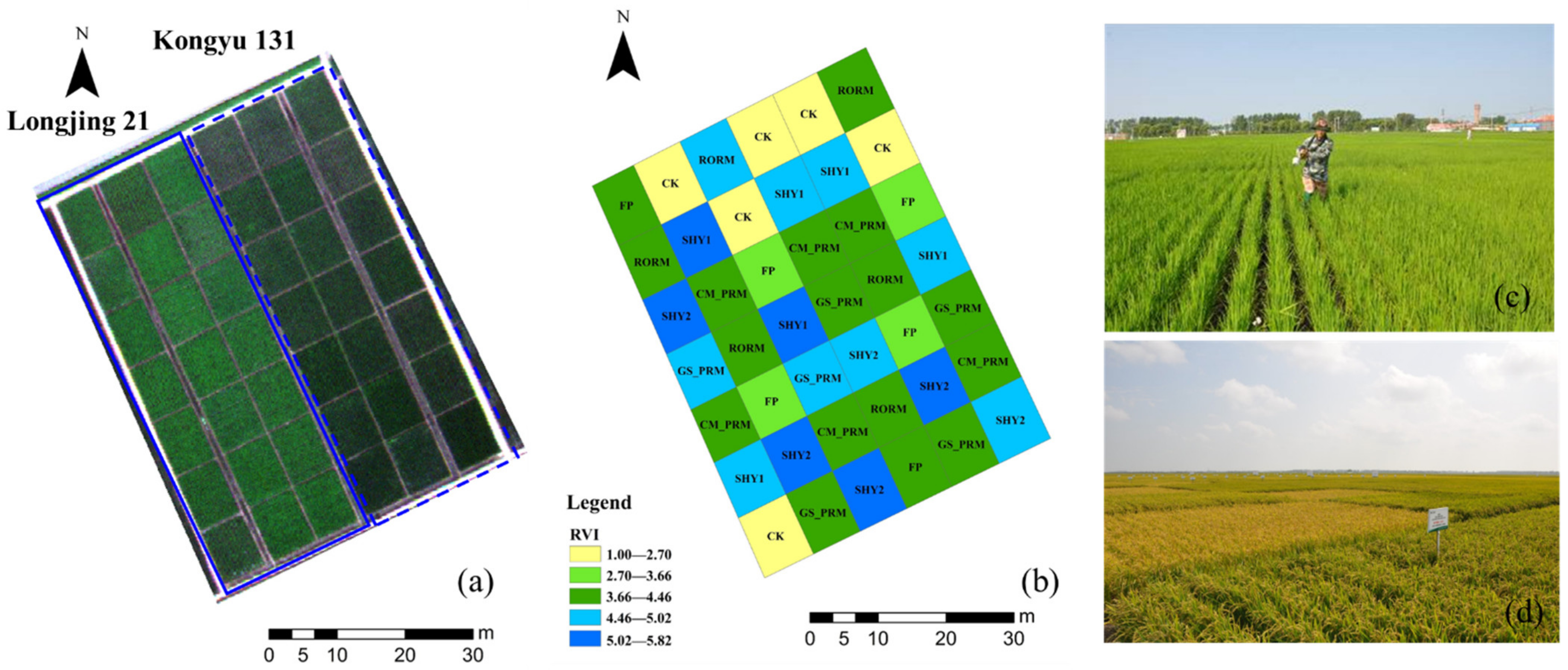

2.2. Experimental Design

- (1)

- Check (CK). No N fertilizer was applied. Transplanting density was 24 hills m−2 for both varieties, with 4 plants hill−1 and 30 cm × 14 cm for row and hill spacing. Water management was carried out with traditional flood irrigation. Rice was continuously irrigated under flooded conditions.

- (2)

- Farmer practice (FP). An excessive farmer’s N application rate is an issue, especially in earlier growth stages, resulting in low NUE. According to a local farmer survey and Zhao et al. (2013) [35], 150 kg N ha−1 as total N rate was used in this treatment, split into 40% applied before planting and 60% at the tillering stage. Transplanting densities and water management were the same as check.

- (3)

- Regional optimum rice management (RORM). The RONR of 110 kg N ha−1 was used as the total N rate, which was applied as 5 splits (basal, tillering, panicle initiation, stem elongation, and heading stage). Transplanting density was increased to 30 cm × 10 cm (30 hills m−2 with 4 plants hill−1) for Kongyu 131, and 30 cm × 12 cm (27 hills m−2 with 6 plants hill−1) for Longjing 21. In addition, the alternate wetting and drying water-saving irrigation management was adopted as reported in [35].

- (4)

- Chlorophyll meter-based precision rice management (CM_PRM). N fertilizer applied 5 times, similar to RORM, but the second and third topdressing N rates were adjusted by chlorophyll meter-based diagnosis of the rice N status as described by [35]. If the chlorophyll meter reading of the top 2 fully expanded leaves was between 38 and 40, rice N status was optimal. When the meter reading was over 40 or below 38, in-season adjustments of −10 kg N ha−1 or +10 kg N ha−1 were applied based on 15 kg N ha−1 and 20 kg N ha−1 normal rates at the panicle initiation and stem elongation stages, respectively. The remaining nutrient management, transplanting densities, and water management were the same as RORM.

- (5)

- GreenSeeker sensor-based precision rice management (GS_PRM). Transplanting densities and water management were the same as in RORM and CM_PRM. N fertilizer was applied 4 times. The first three applications were the same as RORM. The fourth application at the stem elongation stage was recommended using GreenSeeker sensor based on the algorithm developed by [16]. In this algorithm, the yield potential with no topdressing N rate (YP0) was estimated using in-season estimate of yield (INSEY) calculated with RVI divided by number of days with growing degree days > 0 from transplanting to sensing. The N response index of harvested yield (RIHarvest) was estimated using RVI of the treatment with sufficient N (from the FP plots) divided by the RVI of the GS_PRM treatment at the stem elongation stage. The yield potential with sufficient topdressing N application (YPN) was estimated as the product of RIHarvest and YP0. The N topdressing rate was estimated as the yield increase (YPN-YP0) divided by the average agronomic N efficiency (26.79 kg kg−1) [16].

2.3. Plant Sampling and Measurements

point to the panicle tip (g)/breaking strength × 100.

2.4. Statistical Analysis

3. Results

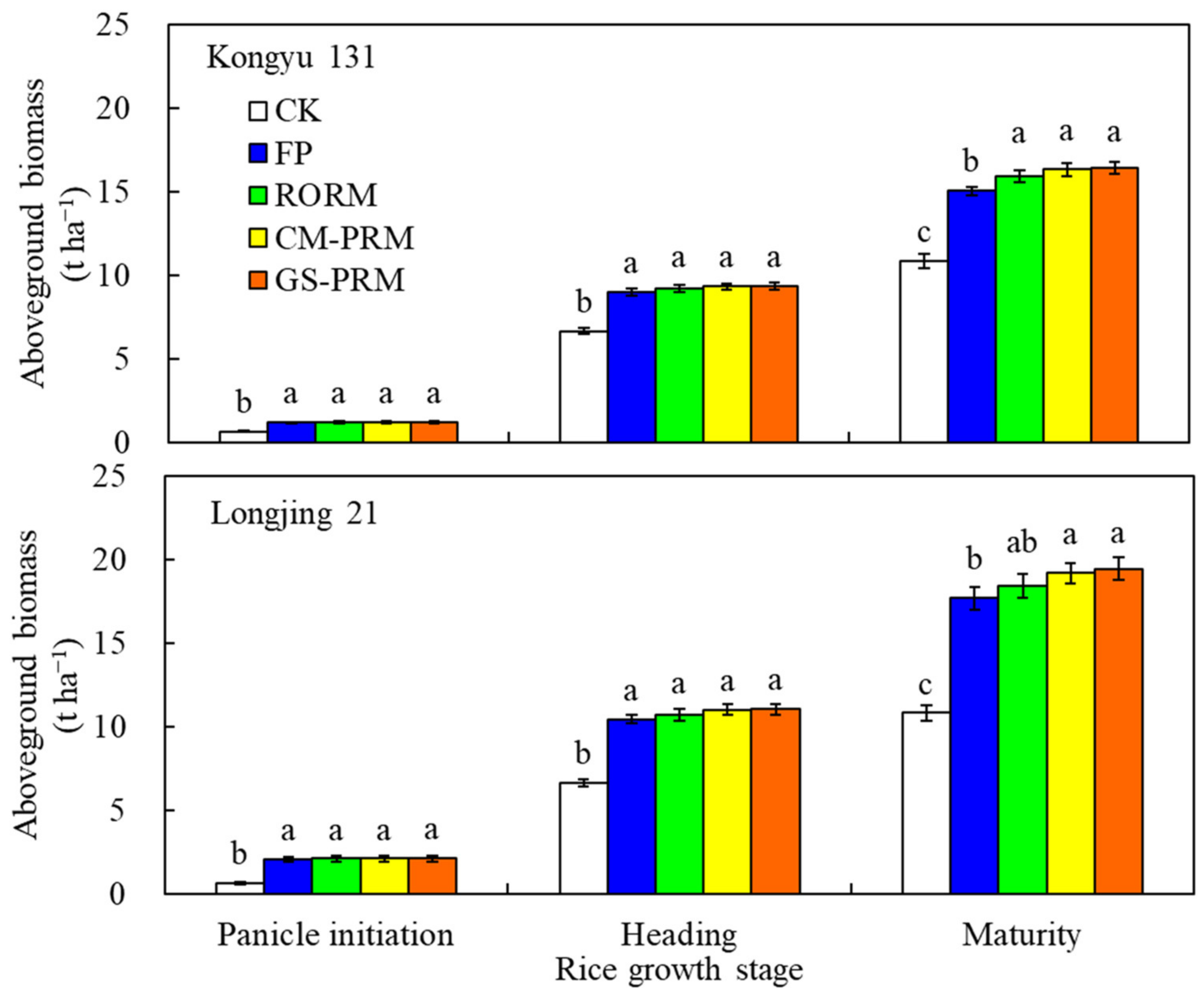

3.1. Aboveground Biomass and Plant Nitrogen Accumulation

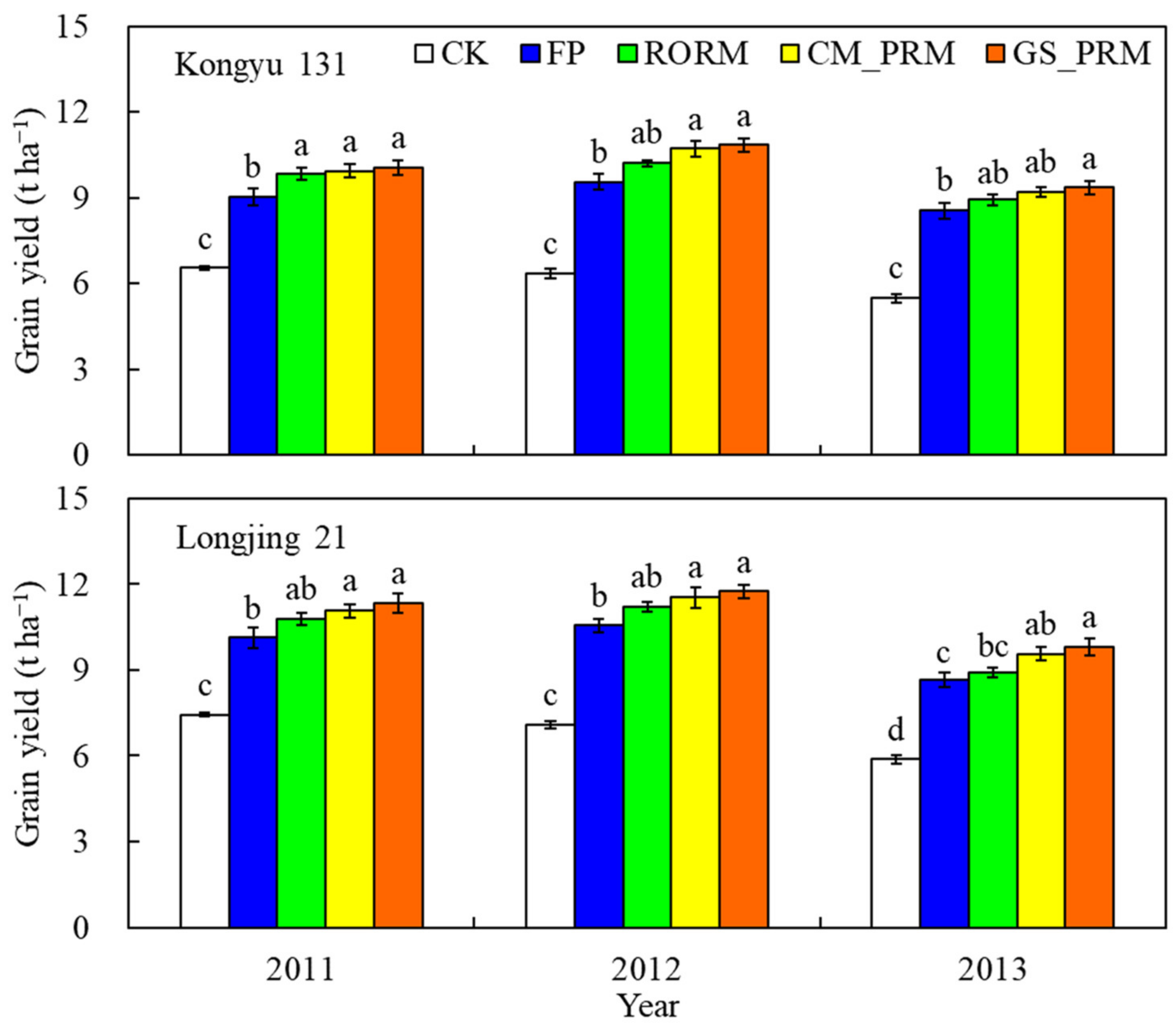

3.2. Grain Yield and Yield Components

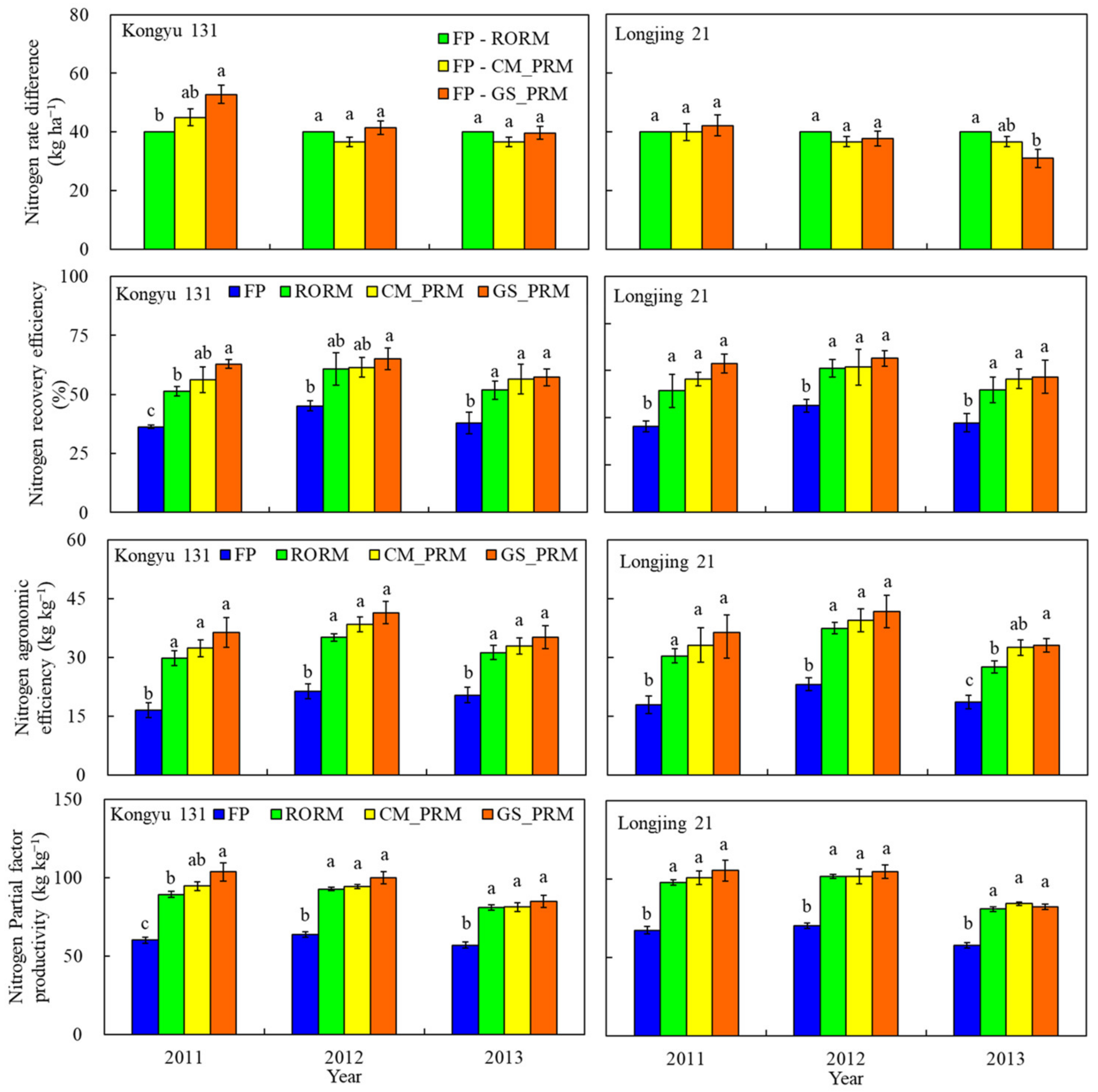

3.3. Nitrogen Use Efficiency

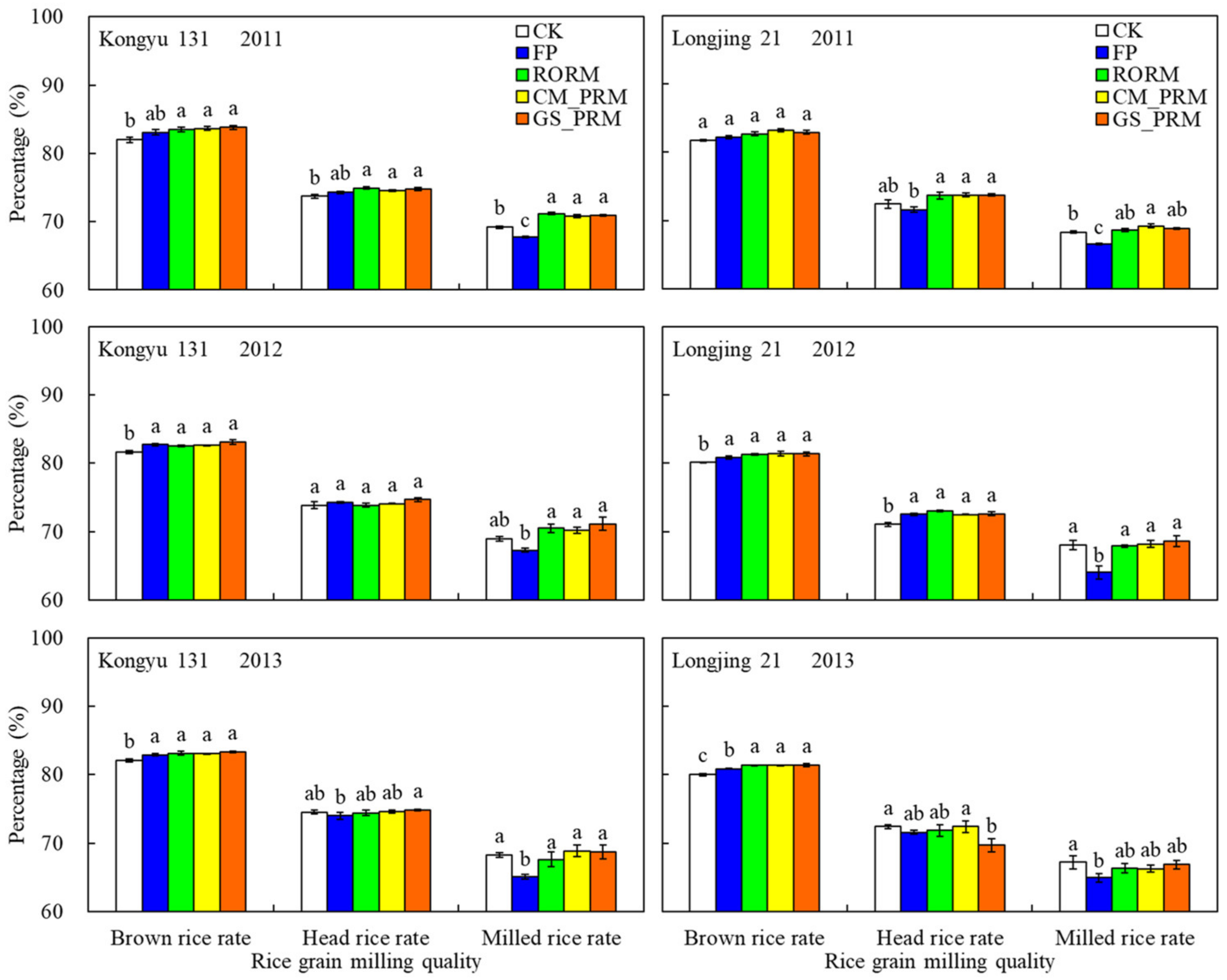

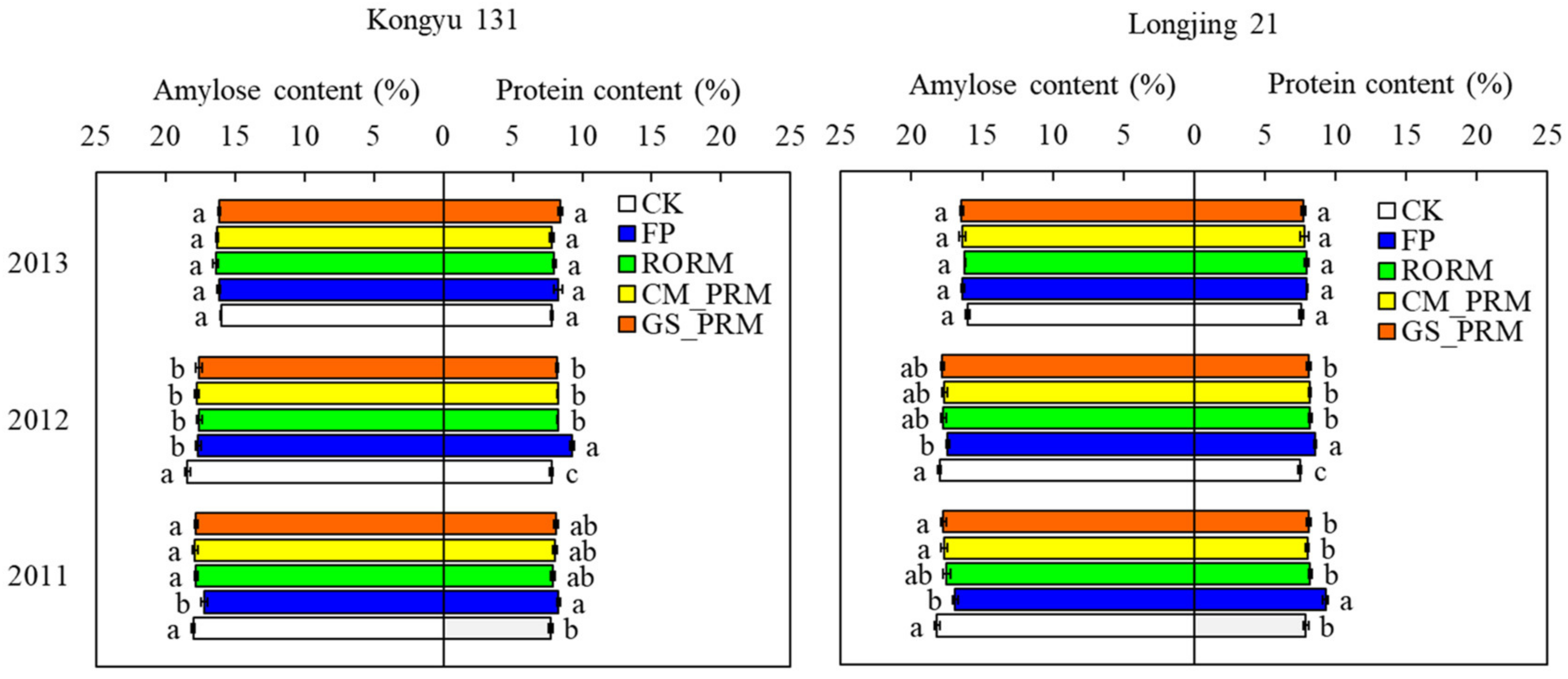

3.4. Rice Grain Quality

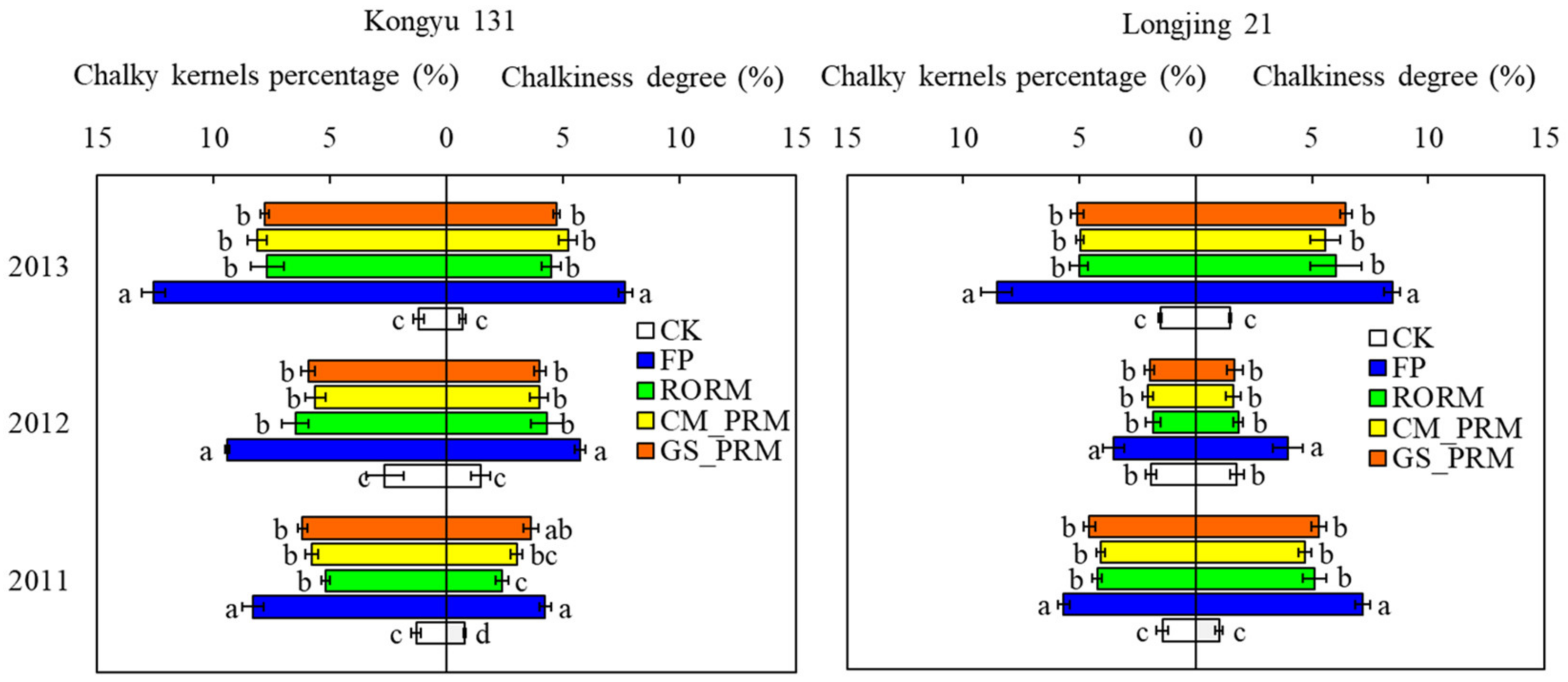

3.5. Lodging Resistance

4. Discussion

4.1. Yield Increase by Optimizing the Transplanting Density and Water Management

4.2. Improving Nitrogen Use Efficiency Based on Precision Nitrogen Management

4.3. Rice Grain Quality Improvement in Integrated Rice Management Systems

4.4. Lodging Resistance Increase in Integrated Rice Management Systems

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Treatment | Basal N | 1st Topdressing | 2nd Topdressing | 3rd Topdressing | 4th Topdressing | Total N | Total P2O5 | Total K2O | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage | N Rate | Stage | N Rate | Stage | N Rate | Stage | N Rate | |||||

| CK | - | - | - | - | - | - | - | - | - | 0 | 30 | 60 |

| FP | 60 | Tillering | 90 | - | - | - | - | - | - | 150 | 60 | 50 |

| RORM | 45 | Tillering | 20 | Panicle initiation | 15 | Stem elongation | 20 | Heading | 10 | 110 | 50 | 105 |

| CM_PRM | 45 | Tillering | 20 | Panicle initiation | 15 * | Stem elongation | 20 * | Heading | 10 | 110 ** | 50 | 105 |

| GS_PRM | 45 | Tillering | 20 | Panicle initiation | 15 | Stem elongation | 30 ** | Heading | - | 110 ** | 50 | 105 |

References

- Yin, Y.; Zhao, R.; Yang, Y.; Meng, Q.; Ying, H.; Cassman, K.G.; Cong, W.; Tian, X.; He, K.; Wang, Y.; et al. A steady-state N balance approach for sustainable smallholder farming. Proc. Natl. Acad. Sci. USA 2021, 118, e2106576118. [Google Scholar] [CrossRef] [PubMed]

- Laborde, D.; Martin, W.; Swinnen, J.; Vos, R. COVID-19 risks to global food security. Science 2020, 369, 500–502. [Google Scholar] [CrossRef] [PubMed]

- Sishodia, R.P.; Ray, R.L.; Singh, S.K. Applications of remote sensing in precision agriculture: A review. Remote Sens. 2020, 12, 3136. [Google Scholar] [CrossRef]

- Singh, J.; Singh, V.; Kaur, S. Precision nitrogen management improves grain yield, nitrogen use efficiency and reduces nitrous oxide emission from soil in spring maize. J. Plant Nutr. 2020, 43, 2311–2321. [Google Scholar] [CrossRef]

- Lu, J.; Miao, Y.; Shi, W.; Li, J.; Hu, X.; Chen, Z.; Wang, X.; Kusnierek, K. Developing a proximal active canopy sensor-based precision nitrogen management strategy for high-yielding rice. Remote Sens. 2020, 12, 1440. [Google Scholar] [CrossRef]

- Neupane, J.; Guo, W.X. Agronomic basis and strategies for precision water management: A review. Agronomy 2019, 9, 87. [Google Scholar] [CrossRef] [Green Version]

- Song, T.; Xu, F.; Yuan, W.; Chen, M.; Hu, Q.; Tian, Y.; Zhang, J.; Xu, W. Combining alternate wetting and drying irrigation with reduced phosphorus fertilizer application reduces water use and promotes phosphorus use efficiency without yield loss in rice plants. Agric. Water Manag. 2019, 223, 105686. [Google Scholar] [CrossRef]

- Behmann, J.; Mahlein, A.-K.; Rumpf, T.; Roemer, C.; Pluemer, L. A review of advanced machine learning methods for the detection of biotic stress in precision crop protection. Precis. Agric. 2015, 16, 239–260. [Google Scholar] [CrossRef]

- Iost Filho, F.H.; Heldens, W.B.; Kong, Z.; de Lange, E.S. Drones: Innovative technology for use in precision pest management. J. Econ. Entomol. 2020, 113, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Shamal, S.A.M.; Alhwaimel, S.A.; Mouazen, A.M. Application of an on-line sensor to map soil packing density for site specific cultivation. Soil Tillage Res. 2016, 162, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, F.; Maleki, M.R.; Khodaei, J. Control of variable rate system of a rotary tiller based on real-time measurement of soil surface roughness. Soil Tillage Res. 2022, 215, 105216. [Google Scholar] [CrossRef]

- Trevisan, R.G.; Bullock, D.S.; Martin, N.F. Spatial variability of crop responses to agronomic inputs in on-farm precision experimentation. Precis. Agric. 2020, 22, 342–363. [Google Scholar] [CrossRef]

- Kerry, R.; Escolà, A. Sensing Approaches for Precision Agriculture; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Heffer, P. Assessment of Fertilizer Use by Crop at the Global Level: 2010–2010/11; International Fertilizer Industry Association: Paris, France, 2013. [Google Scholar]

- Peng, S.; Buresh, R.J.; Huang, J.; Zhong, X.; Zou, Y.; Yang, J.; Wang, G.; Liu, Y.; Hu, R.; Tang, Q.; et al. Improving nitrogen fertilization in rice by site-specific N management. A review. Agron. Sustain. Dev. 2010, 30, 649–656. [Google Scholar] [CrossRef]

- Yao, Y.; Miao, Y.; Huang, S.; Gao, L.; Ma, X.; Zhao, G.; Jiang, R.; Chen, X.; Zhang, F.; Yu, K.; et al. Active canopy sensor-based precision N management strategy for rice. Agron. Sustain. Dev. 2012, 32, 925–933. [Google Scholar] [CrossRef] [Green Version]

- Miao, Y.; Mulla, D.J.; Randall, G.W.; Vetsch, J.A.; Vintila, R. Combining chlorophyll meter readings and high spatial resolution remote sensing images for in-season site-specific nitrogen management of corn. Precis. Agric. 2009, 10, 45–62. [Google Scholar] [CrossRef]

- Raun, W.R.; Solie, J.B.; Johnson, G.V.; Stone, M.L.; Mullen, R.W.; Freeman, K.W.; Thomason, W.E.; Lukina, E.V. Improving nitrogen use efficiency in cereal grain production with optical sensing and variable rate application. Agron. J. 2002, 94, 815–820. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Miao, Y.; Zhang, F.; Cui, Z.; Li, R.; Chen, X.; Zhang, H.; Schroder, J.; Raun, W.R.; Jia, L. In-season optical sensing improves nitrogen-use efficiency for winter wheat. Soil Sci. Soc. Am. J. 2009, 73, 1566–1574. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Sharma, R.K.; Kaur, J.; Jat, M.L.; Martin, K.L.; Singh, Y.; Singh, V.; Chandna, P.; Choudhary, O.P.; Gupta, R.K.; et al. Assessment of the nitrogen management strategy using an optical sensor for irrigated wheat. Agron. Sustain. Dev. 2011, 31, 589–603. [Google Scholar] [CrossRef] [Green Version]

- Cao, Q.; Miao, Y.; Li, F.; Gao, X.; Liu, B.; Lu, D.; Chen, X. Developing a new Crop Circle active canopy sensor-based precision nitrogen management strategy for winter wheat in North China Plain. Precis. Agric. 2017, 18, 2–18. [Google Scholar] [CrossRef]

- Shaver, T.M.; Khosla, R.; Westfall, D.G. Evaluation of two crop canopy sensors for nitrogen variability determination in irrigated maize. Precis. Agric. 2011, 12, 892–904. [Google Scholar] [CrossRef]

- Wang, X.; Miao, Y.; Dong, R.; Chen, Z.; Guan, Y.; Yue, X.; Fang, Z.; Mulla, D.J. Developing active canopy sensor-based precision nitrogen management strategies for maize in Northeast China. Sustainability 2019, 11, 706. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Miao, Y.; Dong, R.; Zha, H.; Xia, T.; Chen, Z.; Kusnierek, K.; Mi, G.; Sun, H.; Li, M. Machine learning-based in-season nitrogen status diagnosis and sidedress nitrogen recommendation for corn. Eur. J. Agron. 2021, 123, 126193. [Google Scholar] [CrossRef]

- Xue, L.; Li, G.; Qin, X.; Yang, L.; Zhang, H. Topdressing nitrogen recommendation for early rice with an active sensor in south China. Precis. Agric. 2014, 15, 95–110. [Google Scholar] [CrossRef]

- Cao, Q.; Miao, Y.; Feng, G.; Gao, X.; Li, F.; Liu, B.; Yue, S.; Cheng, S.; Ustin, S.L.; Khosla, R. Active canopy sensing of winter wheat nitrogen status: An evaluation of two sensor systems. Comput. Electron. Agric. 2015, 112, 54–67. [Google Scholar] [CrossRef]

- Singh, B.; Singh, V.; Purba, J.; Sharma, R.K.; Jat, M.L.; Singh, Y.; Thind, H.S.; Gupta, R.K.; Chaudhary, O.P.; Chandna, P.; et al. Site-specific fertilizer nitrogen management in irrigated transplanted rice (Oryza sativa) using an optical sensor. Precis. Agric. 2015, 16, 455–475. [Google Scholar] [CrossRef]

- Cao, Y.; Yin, B. Effects of integrated high-efficiency practice versus conventional practice on rice yield and N fate. Agric. Ecosyst. Environ. 2015, 202, 1–7. [Google Scholar] [CrossRef]

- Miao, Y.; Stewart, B.A.; Zhang, F.S. Long-term experiments for sustaiable nutrient management in China. A review. Agron. Sustain. Dev. 2011, 31, 397–414. [Google Scholar] [CrossRef] [Green Version]

- Cao, Q.; Miao, Y.; Guohui, F.; Gao, X.; Liu, B.; Liu, Y.; Li, F.; Khosla, R.; Mulla, D.; Zhang, F. Improving nitrogen use efficiency with minimal environmental risks using an active canopy sensor in a wheat-maize cropping system. Field Crop. Res. 2017, 214, 365–372. [Google Scholar] [CrossRef]

- Jat, H.S.; Choudhary, M.; Kakraliya, S.K.; Gora, M.K.; Kakraliya, M.; Kumar, V.; Priyanka; Poonia, T.; McDonald, A.J.; Jat, M.L.; et al. A decade of climate-smart agriculture in major agri-food systems: Earthworm abundance and soil physico-biochemical properties. Agronomy 2022, 12, 658. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, L.; Luo, S.; Peng, X.; Li, J. Effects of integrated nutrient management on lodging resistance of rice in cold area. Sci. Agric. Sin. 2010, 43, 4536–4542. (In Chinese) [Google Scholar]

- Cao, Q.; Cui, Z.; Chen, X.; Khosla, R.; Dao, T.H.; Miao, Y. Quantifying spatial variability of indigeous nitrogen supply for precision nitrogen management in small scale farming. Precis. Agric. 2012, 13, 45–61. [Google Scholar] [CrossRef]

- Xue, Y.; Duan, H.; Liu, L.; Wang, Z.; Yang, J.; Zhang, J. An improved crop management increases grain yield and nitrogen and water use efficiency in rice. Crop Sci. 2013, 53, 271–284. [Google Scholar] [CrossRef]

- Zhao, G.; Miao, Y.; Wang, H.; Su, M.; Fan, M.; Zhang, F.; Jiang, R.; Zhang, Z.; Liu, C.; Liu, P. A preliminary precision rice management system for increasing both grain yield and nitrogen use efficiency. Field Crop. Res. 2013, 154, 23–30. [Google Scholar] [CrossRef]

- Drinkwater, L.E. Cropping systems research: Reconsidering agricultural experimental approaches. Horttechnology 2002, 12, 355–361. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.S.; Peng, S.; Visperas, R.M.; Ereful, N.; Bhuiya, M.S.U.; Julfiquar, A.W. Lodging-related morphological traits of hybrid rice in a tropical irrigated ecosystem. Field Crop. Res. 2007, 101, 240–248. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Sasaki, H.; Ishimaru, K. Factors responsible for decreasing sturdiness of the lower part in lodging of rice (Oryza sativa L.). Plant Prod. Sci. 2005, 8, 166–172. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, L.; Wu, X.; Ding, Y.; Li, G.; Li, J.; Weng, F.; Liu, Z.; Tang, S.; Ding, C. Lodging resistance of Japonica rice (Oryza Sativa L.): Morphological and anatomical traits due to top-dressing nitrogen application rates. Rice 2016, 9, 31. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Huang, J.; Cui, K.; Nie, L.; Wang, Q.; Yang, F.; Shah, F.; Yao, F.; Peng, S. Sheath blight reduces stem breaking resistance and increases lodging susceptibility of rice plants. Field Crop. Res. 2012, 128, 101–108. [Google Scholar] [CrossRef]

- Zhu, G.; Li, G.; Wang, D.; Yuan, S.; Wang, F. Changes in the lodging-related traits along with rice genetic improvement in China. PLoS ONE 2016, 11, e0160104. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Dong, G.; Gu, H.; Huang, J.; Zhu, J.; Yang, H.; Liu, G.; Han, Y. The impact of free-air CO2 enrichment (FACE) and nitrogen supply on grain quality of rice. Field Crop. Res. 2007, 102, 128–140. [Google Scholar] [CrossRef]

- Wei, H.; Zhu, Y.; Qiu, S.; Han, C.; Hu, L.; Xu, D.; Zhou, N.; Xing, Z.; Hu, Y.; Cui, P.; et al. Combined effect of shading time and nitrogen level on grain filling and grain quality in japonica super rice. J. Integr. Agric. 2018, 17, 2405–2417. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; He, P.; Zhao, S.; Qiu, S.; Johnston, A.M.; Zhou, W. Quantification of yield gap and nutrient use efficiency of irrigated rice in China. Field Crop. Res. 2016, 186, 58–65. [Google Scholar] [CrossRef]

- Peng, X.; Yang, Y.; Yu, C.; Chen, L.; Zhang, M.; Liu, Z.; Sun, Y.; Luo, S.; Liu, Y. Crop management for increasing rice yield and nitrogen use efficiency in northeast China. Agron. J. 2015, 107, 1682–1690. [Google Scholar] [CrossRef]

- Norton, G.J.; Shafaei, M.; Travis, A.J.; Deacon, C.M.; Danku, J.; Pond, D.; Cochrane, N.; Lockhart, K.; Salt, D.; Zhang, H.; et al. Impact of alternate wetting and drying on rice physiology, grain production, and grain quality. Field Crop. Res. 2017, 205, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Carrijo, D.R.; Lundy, M.E.; Linquist, B.A. Rice yields and water use under alternate wetting and drying irrigation: A meta-analysis. Field Crop. Res. 2017, 203, 173–180. [Google Scholar] [CrossRef]

- Zhang, Z.; Chu, G.; Liu, L.; Wang, Z.; Wang, X.; Zhang, H.; Yang, J.; Zhang, J. Mid-season nitrogen application strategies for rice varieties differing in panicle size. Field Crop. Res. 2013, 150, 9–18. [Google Scholar] [CrossRef]

- Dobermann, A.; Witt, C.; Dawe, D.; Abdulrachman, S.; Gines, H.C.; Nagarajan, R.; Satawathananont, S.; Son, T.T.; Tan, P.S.; Wang, G.H.; et al. Site-specific nutrient management for intensive rice cropping systems in Asia. Field Crop. Res. 2002, 74, 37–66. [Google Scholar] [CrossRef]

- De Datta, S.; Gomez, K. Changes in Phosphorus and Potassium Responses in Wetland Rice Soils in South-East Asia. In Phosphorus and Potassium in the Tropics; Malaysian Society of Soil Science: Kuala Lumpur, Malaysia, 1982. [Google Scholar]

- Tian, Y.; Feng, L.; Zou, H.; Zhang, Z.; Zhu, H.; Miao, Y. Effects of water and nitrogen on growth, development and yield of rice in cold area of Northeast China. Acta Ecol. Sin. 2014, 34, 6864–6871. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, J.; Miao, Y.; Batchelor, W.; Lu, J.; Wang, H.; Kang, S. Improving high-latitude rice nitrogen management with the CERES-rice crop model. Agronomy 2018, 8, 263. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Hou, D.; Peng, X.; Ma, B.; Shao, S.; Jing, W.; Gu, J.; Liu, L.; Wang, Z.; Liu, Y.; et al. Optimizing integrative cultivation management improves grain quality while increasing yield and nitrogen use efficiency in rice. J. Integr. Agric. 2019, 18, 2716–2731. [Google Scholar] [CrossRef]

- Nangju, D.; Datta, S.K.D. Effect of time of harvest and nitrogen level on yield and grain breakage in transplanted rice. Agron. J. 1970, 62, 468–474. [Google Scholar] [CrossRef]

- Perez, C.M.; Juliano, B.O.; Liboon, S.P.; Alcantara, J.M.; Cassman, K.G. Effects of late nitrogen fertilizer application on head rice yield, protein content, and grain quality of rice. Cereal Chem. 1996, 73, 556–560. [Google Scholar] [CrossRef]

- Wopereis-Pura, M.; Watanabe, H.; Moreira, J.; Wopereis, M.C.S. Effect of late nitrogen application on rice yield, grain quality and profitability in the Senegal River valley. Eur. J. Agron. 2002, 17, 191–198. [Google Scholar] [CrossRef]

- Atapattu, A.J.; Prasantha, B.D.R.; Amaratunga, K.S.P.; Marambe, B. Increased rate of potassium fertilizer at the time of heading enhances the quality of direct seeded rice. Chem. Biol. Technol. Agric. 2018, 5, 22. [Google Scholar] [CrossRef]

- Valojai, S.T.S.; Niknejad, Y.; Amoli, H.F.; Tari, D.B. Response of rice yield and quality to nano-fertilizers in comparison with conventional fertilizers. J. Plant Nutr. 2021, 44, 1971–1981. [Google Scholar] [CrossRef]

- Lal, B.; Gautam, P.; Mohanty, S.; Raja, R.; Tripathi, R.; Shahid, M.; Panda, B.B.; Baig, M.J.; Rath, L.; Bhattacharyya, P.; et al. Combined application of silica and nitrogen alleviates the damage of flooding stress in rice. Crop Pasture Sci. 2015, 66, 679–688. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, H.; Zhang, S.; Wang, Z.; Yang, J. Effects of soil moisture and irrigation patterns during grain filling on grain yield and quality of rice and their physiological mechanism. Acta Agron. Sin. 2008, 34, 268–276. (In Chinese) [Google Scholar] [CrossRef]

- Pan, S.; Cao, C.; Cai, M.; Wang, J.; Wang, R.; Zhai, J.; Huang, S. Effects of irrigation regime and nitrogen management on grain yield, quality and water productivity in rice. J. Food Agric. Environ. 2009, 7, 559–564. [Google Scholar] [CrossRef]

- Kaur, J.; Mahal, S.S.; Kaur, A. Yield and quality evaluation of direct seeded basmati rice (Oryza sativa L.) under different irrigation and nitrogen regimes. Cereal Res. Commun. 2016, 44, 330–340. [Google Scholar] [CrossRef] [Green Version]

- Mahajan, G.; Chauhan, B.S.; Timsina, J.; Singh, P.P.; Singh, K. Crop performance and water- and nitrogen-use efficiencies in dry-seeded rice in response to irrigation and fertilizer amounts in northwest India. Field Crop. Res. 2012, 134, 59–70. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, M.; Saiz, G.; Dannenmann, M.; Guo, L.; Tao, Y.; Shi, J.; Zuo, Q.; Butterbach-Bahl, K.; Li, G.; et al. Enhancement of root systems improves productivity and sustainability in water saving ground cover rice production system. Field Crop. Res. 2017, 213, 186–193. [Google Scholar] [CrossRef]

- Zhang, J.; Li, G.; Song, Y.; Liu, Z.; Yang, C.; Tang, S.; Zheng, C.; Wang, S.; Ding, Y. Lodging resistance characteristics of high-yielding rice populations. Field Crop. Res. 2014, 161, 64–74. [Google Scholar] [CrossRef]

- Zaman, U.; Ahmad, Z.; Farooq, M.; Saeed, S.; Ahmad, M.; Wakeel, A. Potassium fertilization may improve stem strength and yield of basmati rice grown on nitrogen-fertilized soils. Pak. J. Agric. Sci. 2015, 52, 439–445. [Google Scholar]

- Cao, Q.; Miao, Y.; Shen, J.; Yu, W.; Yuan, F.; Cheng, S.; Huang, S.; Wang, H.; Yang, W.; Liu, F. Improving in-season estimation of rice yield potential and responsiveness to topdressing nitrogen application with Crop Circle active crop canopy sensor. Precis. Agric. 2016, 17, 136–154. [Google Scholar] [CrossRef]

- Lu, J.; Miao, Y.; Shi, W.; Li, J.; Yuan, F. Evaluating different approaches to non-destructive nitrogen status diagnosis of rice using portable RapidSCAN active canopy sensor. Sci. Rep. 2017, 7, 14073. [Google Scholar] [CrossRef]

- Huang, S.; Miao, Y.; Yuan, F.; Gnyp, M.; Yao, Y.; Cao, Q.; Wang, H.; Lenzwiedemann, V.; Bareth, G. Potential of RapidEye and WorldView-2 satellite data for improving rice nitrogen status monitoring at different growth stages. Remote Sens. 2017, 9, 227. [Google Scholar] [CrossRef] [Green Version]

- Zha, H.; Miao, Y.; Wang, T.; Li, Y.; Zhang, J.; Sun, W.; Feng, Z.; Kusnierek, K. Improving unmanned aerial vehicle remote sensing-based rice nitrogen nutrition index prediction with machine learning. Remote Sens. 2020, 12, 215. [Google Scholar] [CrossRef] [Green Version]

| Year | Treatment | Panicle Number (m−2) | Grains/Panicle | Filled Grains (%) | 1000-Grain Weight (g) | Harvest Index (%) |

|---|---|---|---|---|---|---|

| 2011 | CK | 513 ± 6.2 c | 58.1 ± 0.45 b | 96.1 ± 0.57 a | 27.6 ± 0.10 a | 48.3 ± 2.30 a |

| FP | 606 ± 16.3 b | 68.6 ± 0.72 a | 89.9 ± 0.86 b | 26.5 ± 0.15 b | 51.0 ± 2.34 a | |

| RORM | 661 ± 12.7 a | 70.2 ± 0.98 a | 92.9 ± 1.14 ab | 26.6 ± 0.15 b | 52.3 ± 0.92 a | |

| CM_PRM | 671 ± 16.3 a | 70.0 ± 0.87 a | 91.0 ± 1.06 b | 26.6 ± 0.12 b | 52.2 ± 2.00 a | |

| GS_PRM | 680 ± 23.0 a | 69.7 ± 1.11 a | 91.6 ± 1.69 b | 26.7 ± 0.19 b | 53.0 ± 1.35 a | |

| 2012 | CK | 510 ± 9.0 c | 56.6 ± 0.41 b | 94.0 ± 0.16 a | 27.7 ± 0.12 a | 48.5 ± 1.41 a |

| FP | 614 ± 18.5 b | 74.0 ± 0.49 a | 85.8 ± 1.03 c | 26.5 ± 0.31 b | 52.7 ± 1.53 a | |

| RORM | 677 ± 21.7 a | 76.5 ± 0.67 a | 90.9 ± 0.99 ab | 26.7 ± 0.27 b | 51.9 ± 1.29 a | |

| CM_PRM | 687 ± 19.1 a | 76.0 ± 1.26 a | 88.8 ± 0.91 bc | 26.8 ± 0.18 b | 53.3 ± 1.87 a | |

| GS_PRM | 694 ± 14.2 a | 76.2 ± 1.24 a | 88.0 ± 0.98 bc | 26.8 ± 0.28 b | 53.4 ± 1.87 a | |

| 2013 | CK | 507 ± 6.2 c | 50.3 ± 0.30 c | 93.1 ± 0.17 a | 27.2 ± 0.13 a | 49.6 ± 0.69 a |

| FP | 608 ± 16.0 b | 67.3 ± 0.72 b | 85.0 ± 0.81 b | 25.5 ± 0.27 c | 51.4 ± 3.30 a | |

| RORM | 650 ± 15.3 a | 71.3 ± 0.45 a | 86.7 ± 0.72 b | 25.9 ± 0.16 b | 52.2 ± 0.94 a | |

| CM_PRM | 665 ± 13.2 a | 70.7 ± 0.37 a | 87.3 ± 0.91 b | 25.8 ± 0.10 bc | 52.0 ± 2.46 a | |

| GS_PRM | 672 ± 16.0 a | 71.3 ± 0.97 a | 86.6 ± 0.82 b | 25.7 ± 0.12 bc | 52.0 ± 2.75 a | |

| Analysis of variance (F) | Treatment | *** | *** | *** | *** | NS |

| Year | NS | *** | *** | *** | NS | |

| Treatment × Year | NS | *** | NS | NS | NS |

| Year | Treatment | Panicle Number (m−2) | Grains/Panicle | Filled Grains (%) | 1000-Grain Weight (g) | Harvest Index (%) |

|---|---|---|---|---|---|---|

| 2011 | CK | 399 ± 16.8 c | 66.7 ± 0.39 b | 96.8 ± 0.66 a | 28.4 ± 0.08 a | 46.0 ± 1.03 a |

| FP | 493 ± 17.9 b | 82.0 ± 0.91 a | 89.4 ± 1.01 b | 26.4 ± 0.16 c | 45.9 ± 0.49 a | |

| RORM | 545 ± 11.9 ab | 83.7 ± 0.57 a | 90.9 ± 0.68 b | 26.9 ± 0.19 b | 46.5 ± 1.14 a | |

| CM_PRM | 549 ± 23.8 ab | 82.8 ± 0.95 a | 91.7 ± 1.10 b | 26.9 ± 0.19 bc | 46.9 ± 2.32 a | |

| GS_PRM | 563 ± 19.6 a | 83.8 ± 0.77 a | 92.1 ± 1.02 b | 26.5 ± 0.16 bc | 46.9 ± 1.64 a | |

| 2012 | CK | 405 ± 10.9 c | 67.7 ± 0.50 b | 94.7 ± 0.48 a | 28.4 ± 0.06 a | 46.8 ± 0.93 a |

| FP | 501 ± 14.2 b | 86.6 ± 0.71 a | 86.5 ± 1.06 b | 26.4 ± 0.27 b | 47.1 ± 2.43 a | |

| RORM | 537 ± 13.1 ab | 90.2 ± 1.24 a | 89.4 ± 0.93 b | 26.5 ± 0.12 b | 47.6 ± 0.51 a | |

| CM_PRM | 566 ± 14.1 a | 89.9 ± 0.86 a | 88.5 ± 1.40 b | 26.4 ± 0.21 b | 47.6 ± 2.16 a | |

| GS_PRM | 558 ± 18.1 a | 88.2 ± 1.55 a | 87.1 ± 1.06 b | 26.5 ± 0.10 b | 48.0 ± 0.78 a | |

| 2013 | CK | 415 ± 6.3 d | 61.3 ± 0.19 b | 92.6 ± 0.31 a | 27.9 ± 0.10 a | 48.3 ± 0.30 a |

| FP | 488 ± 19.2 c | 83.3 ± 0.82 a | 83.2 ± 0.74 b | 25.7 ± 0.22 b | 50.8 ± 3.50 a | |

| RORM | 505 ± 13.5 bc | 84.7 ± 0.60 a | 85.0 ± 0.84 b | 25.8 ± 0.17 b | 50.6 ± 1.58 a | |

| CM_PRM | 534 ± 21.3 ab | 84.7 ± 0.73 a | 85.1 ± 0.83 b | 25.8 ± 0.21 b | 50.3 ± 1.38 a | |

| GS_PRM | 543 ± 6.9 a | 85.3 ± 0.96 a | 84.3 ± 0.56 b | 25.8 ± 0.23 b | 51.2 ± 1.64 a | |

| Analysis of variance (F) | Treatment | *** | *** | *** | *** | NS |

| Year | NS | *** | *** | *** | NS | |

| Treatment × Year | NS | ** | NS | NS | NS |

| Year | Treatment | N4 Internode Length (cm) | Plant Height (cm) | Fresh Weight per Plant (g) | Breaking Strength (g cm) | Lodging Index (%) |

|---|---|---|---|---|---|---|

| 2011 | CK | 10.3 ± 0.15 d | 70.1 ± 0.30 d | 4.83 ± 0.21 b | 774 ± 19.48 a | 43.8 ± 1.97 d |

| FP | 18.2 ± 0.20 a | 88.2 ± 0.10 a | 7.13 ± 0.21 a | 489 ± 4.10 d | 128.6 ± 2.89 a | |

| RORM | 16.7 ± 0.17 c | 84.3 ± 0.40 c | 6.90 ± 0.20 a | 614 ± 3.21 b | 94.8 ± 3.69 c | |

| CM_PRM | 16.8 ± 0.10 bc | 84.9 ± 0.20 b | 7.13 ± 0.15 a | 609 ± 8.96 bc | 99.4 ± 2.78 b | |

| GS_PRM | 16.9 ± 0.17 b | 84.7 ± 0.32 bc | 7.03 ± 0.21 a | 593 ± 10.31 c | 100.5 ± 2.23 b | |

| 2012 | CK | 9.7 ± 0.20 c | 68.8 ± 0.50 d | 4.80 ± 0.20 c | 797 ± 8.93 a | 41.5 ± 2.02 d |

| FP | 18.3 ± 0.20 a | 89.1 ± 0.51 a | 6.80 ± 0.30 a | 492 ± 9.96 c | 123.1 ± 2.70 a | |

| RORM | 16.8 ± 0.30 b | 84.7 ± 0.31 c | 6.20 ± 0.30 b | 563 ± 7.02 b | 93.2 ± 3.58 c | |

| CM_PRM | 16.9 ± 0.26 b | 86.5 ± 0.25 b | 6.30 ± 0.30 ab | 554 ± 9.05 b | 98.5 ± 5.98 bc | |

| GS_PRM | 17.1 ± 0.26 b | 87.0 ± 0.35 b | 6.40 ± 0.17 ab | 548 ± 7.97 b | 101.6 ± 2.24 b | |

| 2013 | CK | 9.4 ± 0.11 c | 67.6 ± 0.82 d | 4.50 ± 0.17 b | 811 ± 7.10 a | 37.5 ± 0.74 c |

| FP | 17.8 ± 0.46 a | 87.5 ± 0.72 a | 6.80 ± 0.17 a | 502 ± 18.59 c | 118.6 ± 3.66 a | |

| RORM | 16.2 ± 0.36 b | 83.6 ± 0.93 c | 6.50 ± 0.20 a | 614 ± 12.39 b | 88.5 ± 3.51 b | |

| CM_PRM | 16.5 ± 0.36 b | 85.3 ± 1.11 b | 6.70 ± 0.26 a | 610 ± 11.34 b | 93.7 ± 3.09 b | |

| GS_PRM | 16.3 ± 0.26 b | 84.7 ± 0.97 bc | 6.60 ± 0.26 a | 619 ± 11.50 b | 90.4 ± 3.96 b | |

| Analysis of variance (F) | Treatment | *** | *** | *** | *** | *** |

| Year | *** | *** | *** | *** | *** | |

| Treatment × Year | NS | *** | NS | *** | NS |

| Year | Treatment | N4 Internode Length (cm) | Plant Height (cm) | Fresh Weight per Plant (g) | Breaking Strength (g cm) | Lodging Index (%) |

|---|---|---|---|---|---|---|

| 2011 | CK | 14.0 ± 0.30 c | 75.2 ± 0.40 d | 6.23 ± 0.25 b | 896 ± 12.12 a | 52.4 ± 3.10 d |

| FP | 22.2 ± 0.30 a | 96.5 ± 0.66 a | 9.03 ± 0.15 a | 670 ± 6.55 c | 130.1 ± 2.24 a | |

| RORM | 20.3 ± 0.20 b | 92.1 ± 1.89 c | 9.03 ± 0.25 a | 887 ± 6.55 ab | 93.9 ± 3.83 c | |

| CM_PRM | 20.4 ± 0.25 b | 93.8 ± 0.26 bc | 9.10 ± 0.26 a | 883 ± 6.75 b | 96.7 ± 2.34 bc | |

| GS_PRM | 20.3 ± 0.21 b | 94.2 ± 0.46 b | 9.20 ± 0.20 a | 878 ± 8.36 b | 98.7 ± 0.77 b | |

| 2012 | CK | 12.6 ± 0.26 d | 75.4 ± 0.96 d | 6.50 ± 0.30 b | 926 ± 7.10 a | 52.9 ± 2.94 c |

| FP | 22.0 ± 0.20 a | 97.7 ± 0.59 a | 9.00 ± 0.35 a | 685 ± 5.85 d | 128.4 ± 4.67 a | |

| RORM | 19.6 ± 0.30 c | 93.2 ± 0.87 c | 8.90 ± 0.26 a | 842 ± 25.51 c | 98.6 ± 4.59 b | |

| CM_PRM | 20.2 ± 0.36 b | 94.2 ± 0.62 bc | 9.00 ± 0.20 a | 858 ± 9.40 bc | 98.8 ± 1.65 b | |

| GS_PRM | 19.8 ± 0.36 bc | 95.0 ± 1.32 b | 9.20 ± 0.26 a | 861 ± 13.09 b | 101.5 ± 3.61 b | |

| 2013 | CK | 12.4 ± 0.30 c | 73.4 ± 0.78 d | 5.60 ± 0.26 b | 948 ± 14.03 a | 43.4 ± 1.75 c |

| FP | 21.4 ± 0.62 a | 95.6 ± 0.80 a | 8.70 ± 0.30 a | 692 ± 10.31 c | 120.3 ± 5.95 a | |

| RORM | 19.7 ± 0.26 b | 92.3 ± 0.67 c | 8.50 ± 0.26 a | 901 ± 9.66 b | 87.1 ± 3.38 b | |

| CM_PRM | 20.0 ± 0.53 b | 93.5 ± 1.15 bc | 8.60 ± 0.30 a | 910 ± 11.85 b | 88.4 ± 3.37 b | |

| GS_PRM | 20.1 ± 0.30 b | 94.1 ± 0.89 b | 8.70 ± 0.26 a | 907 ± 11.48 b | 90.3 ± 2.45 b | |

| Analysis of variance (F) | Treatment | *** | *** | *** | *** | *** |

| Year | *** | *** | *** | *** | *** | |

| Treatment × Year | * | NS | NS | *** | NS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Wang, H.; Miao, Y.; Zhao, L.; Zhao, G.; Cao, Q.; Kusnierek, K. Developing an Active Canopy Sensor-Based Integrated Precision Rice Management System for Improving Grain Yield and Quality, Nitrogen Use Efficiency, and Lodging Resistance. Remote Sens. 2022, 14, 2440. https://doi.org/10.3390/rs14102440

Lu J, Wang H, Miao Y, Zhao L, Zhao G, Cao Q, Kusnierek K. Developing an Active Canopy Sensor-Based Integrated Precision Rice Management System for Improving Grain Yield and Quality, Nitrogen Use Efficiency, and Lodging Resistance. Remote Sensing. 2022; 14(10):2440. https://doi.org/10.3390/rs14102440

Chicago/Turabian StyleLu, Junjun, Hongye Wang, Yuxin Miao, Liqin Zhao, Guangming Zhao, Qiang Cao, and Krzysztof Kusnierek. 2022. "Developing an Active Canopy Sensor-Based Integrated Precision Rice Management System for Improving Grain Yield and Quality, Nitrogen Use Efficiency, and Lodging Resistance" Remote Sensing 14, no. 10: 2440. https://doi.org/10.3390/rs14102440