A Geomatics Approach in Scan to FEM Process Applied to Cultural Heritage Structure: The Case Study of the “Colossus of Barletta”

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Study

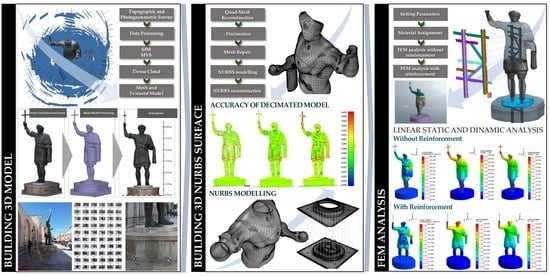

2.2. Methodological Approach

2.2.1. Building the 3D Model

2.2.2. Building the NURBS Model

2.2.3. FEM Analysis

2.3. Scan to FEM Methodology Applied to “Colossus of Barletta”

2.3.1. Topographic and Photogrammetric Survey for 3D Reconstruction

2.3.2. Modelling in Rhino Software

2.4. Finite Element Method

2.4.1. Computations

2.4.2. Unreinforced FEM Analysis

2.4.3. FEM Analysis with Reinforcement

3. Results

3.1. Quality of the 3D Model for FEM Analysis

3.2. FEM Analysis of the Colossus of Barletta

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pieraccini, M.; Guidi, G.; Atzeni, C. 3D Digitizing of Cultural Heritage. J. Cult. Herit. 2001, 2, 63–70. [Google Scholar] [CrossRef]

- Kabadayi, A.; Yunus, K.; Yiğit, A.Y. Comparison of Documentation Cultural Artifacts Using the 3D Model in Different Software. Mersin Photogramm. J. 2020, 2, 51–58. [Google Scholar]

- Patias, P.; Grussenmeyer, P.; Hanke, K. Applications in Cultural Heritage Documentation. In Advances in Photogrammetry, Remote Sensing and Spatial Information Sciences: 2008 ISPRS Congress Book; CRC Press: Beijing, China, 2008; pp. 381–402. [Google Scholar]

- Baik, A. The Use of Interactive Virtual BIM to Boost Virtual Tourism in Heritage Sites, Historic Jeddah. ISPRS Int. J. Geo-Inf. 2021, 10, 577. [Google Scholar] [CrossRef]

- Costantino, D.; Pepe, M.; Restuccia, A.G. Scan-to-HBIM for Conservation and Preservation of Cultural Heritage Building: The Case Study of San Nicola in Montedoro Church (Italy). Appl. Geomat. 2021. [Google Scholar] [CrossRef]

- Petrie, G.; Toth, C.K. Terrestrial Laser Scanners. In Topographic Laser Ranging and Scanning; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Artese, S. The Survey of the San Francesco Bridge by Santiago Calatrava in Cosenza, Italy. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci 2019, 42, 33–37. [Google Scholar] [CrossRef] [Green Version]

- Bertolini-Cestari, C.; Chiabrando, F.; Invernizzi, S.; Marzi, T.; Spanò, A. Terrestrial Laser Scanning and Settled Techniques: A Support to Detect Pathologies and Safety Conditions of Timber Structures. Adv. Mater. Res. 2013, 778, 350–357. [Google Scholar] [CrossRef] [Green Version]

- Virtanen, J.-P.; Hyyppä, H.; Kurkela, M.; Vaaja, M.; Alho, P.; Hyyppä, J. Rapid Prototyping—A Tool for Presenting 3-Dimensional Digital Models Produced by Terrestrial Laser Scanning. ISPRS Int. J. Geo-Inf. 2014, 3, 871–890. [Google Scholar] [CrossRef] [Green Version]

- Khodja, N.A.; Zeghlache, H.; Benali, F.; Guani, O. The Use of New Technologies in the Restoration and Conservation of Built Cultural Heritage/the Case of the Statue of Fouara, Setif, Algeria. Int. Arch. Photog. Remote Sens. Spat. Inf. Sci. 2019, 42, 43–46. [Google Scholar] [CrossRef] [Green Version]

- Schonberger, J.L.; Frahm, J.-M. Structure-from-Motion Revisited. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 4104–4113. [Google Scholar]

- Muzzupappa, M.; Gallo, A.; Spadafora, F.; Manfredi, F.; Bruno, F.; Lamarca, A. 3D Reconstruction of an Outdoor Archaeological Site through a Multi-View Stereo Technique. In Proceedings of the 2013 Digital Heritage International Congress (Digitalheritage), Marseille, France, 28 October–1 November 2013; IEEE: Piscataway, NJ, USA, 2013; Volume 1, pp. 169–176. [Google Scholar]

- Bagnéris, M.; Cherblanc, F.; Bromblet, P.; Gattet, E.; Gügi, L.; Nony, N.; Mercurio, V.; Pamart, A. A Complete Methodology for the Mechanical Diagnosis of Statue Provided by Innovative Uses of 3D Model. Application to the Imperial Marble Statue of Alba-La-Romaine (France). J. Cult. Herit. 2017, 28, 109–116. [Google Scholar] [CrossRef] [Green Version]

- Adamopoulos, E.; Rinaudo, F. Documenting the State of Preservation of Historical Stone Sculptures in Three Dimensions with Digital Tools. In Proceedings of the Pattern Recognition. ICPR International Workshops and Challenges, Proceedings, Part III, Virtual Event. online, 10–15 January 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 666–673. [Google Scholar]

- El-Hakim, S.F.; Beraldin, J.-A.; Picard, M.; Vettore, A. Effective 3D Modeling of Heritage Sites. In Proceedings of the Fourth International Conference on 3-D Digital Imaging and Modeling, Banff, AB, Canada, 6–10 October 2003; IEEE: Piscataway, NJ, USA, 2003; pp. 302–309. [Google Scholar]

- Scianna, A.; Gaglio, G.F.; La Guardia, M. Digital Photogrammetry, TLS Survey and 3D Modelling for VR and AR Applications in CH. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2020, 43, 901–909. [Google Scholar] [CrossRef]

- Barone, S.; Paoli, A.; Razionale, A.V. 3D Reconstruction and Restoration Monitoring of Sculptural Artworks by a Multi-Sensor Framework. Sensors 2012, 12, 16785–16801. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pepe, M.; Costantino, D. Techniques, Tools, Platforms and Algorithms in Close Range Photogrammetry in Building 3D Model and 2D Representation of Objects and Complex Architectures. Comput.-Aided Des. Appl. 2020, 18, 42–65. [Google Scholar] [CrossRef]

- Barazzetti, L.; Banfi, F.; Brumana, R.; Oreni, D.; Previtali, M.; Roncoroni, F.; Gusmeroli, G.; Schiantarelli, G. BIM from Laser Clouds and Finite Element Analysis: Combining Structural Analysis and Geometric Complexity. In Proceedings of the International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, 3D Virtual Reconstruction and Visualization of Complex Architectures, Avila, Spain, 25–27 February 2015; 2015; Volume XL-5/W4, pp. 345–350. [Google Scholar]

- Guarnieri, A.; Fissore, F.; Masiero, A.; Di Donna, A.; Coppa, U.; Vettore, A. From survey to FEM analysis for documentation of built heritage: The case study of Villa Revedin-Bolasco. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 527–533. [Google Scholar] [CrossRef] [Green Version]

- Pfeuffer, C.; Rahrig, M.; Snethlage, R.; Drewello, R. 3D Mapping as a Tool for the Planning of Preservation Measures on Sculptures Made of Natural Stone. Environ. Earth Sci. 2018, 77, 312. [Google Scholar] [CrossRef]

- Pepe, M.; Costantino, D.; Restuccia Garofalo, A. An Efficient Pipeline to Obtain 3D Model for HBIM and Structural Analysis Purposes from 3D Point Clouds. Appl. Sci. 2020, 10, 1235. [Google Scholar] [CrossRef] [Green Version]

- Santini, S.; Baggio, C.; Sabbatini, V.; Sebastiani, C. Setup Optimization of Experimental Measures on a Historical Building: The Octagonal Hall of the Diocletian’s Bath. Heritage 2021, 4, 2205–2223. [Google Scholar] [CrossRef]

- Funari, M.F.; Hajjat, A.E.; Masciotta, M.G.; Oliveira, D.V.; Lourenço, P.B. A Parametric Scan-to-FEM Framework for the Digital Twin Generation of Historic Masonry Structures. Sustainability 2021, 13, 11088. [Google Scholar] [CrossRef]

- Valenti, M.C.; Parronchi, A.; Giovannini, P.; Paolucci, A.; Luchinat, C.A.; D’Adda, S.B.; Matteini, M. Exploring David: Diagnostic Tests and State of Conservation; Giunti: Firenze, Italy, 2004. [Google Scholar]

- Borri, A.; Grazini, A. Diagnostic Analysis of the Lesions and Stability of Michelangelo’s David. J. Cult. Herit. 2006, 7, 273–285. [Google Scholar] [CrossRef]

- Visintini, D.; Spangher, A. Il Contributo Della Geomatica per l’analisi Strutturale Dei Beni Culturali: L’esempio Di Una Statua Romana Lesionata. In Proceedings of the Atti 18a Conferenza Nazionale ASITA, Firenze, Italy, 14–16 October 2014; pp. 1229–1236. [Google Scholar]

- Spangher, A.; Visintini, D.; Tucci, G.; Bonora, V. Geomatic 3D modeling of a statue (also) for structural analysis and risk evaluation: The example of San Giovannino Martelli in Florence. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Riccardelli, C.; Morris, M.; Wheeler, G.; Soultanian, J.; Becker, L.; Street, R. The Treatment of Tullio Lombardo’s Adam: A New Approach to the Conservation of Monumental Marble Sculpture. Metrop. Mus. J. 2014, 49, 48–116. [Google Scholar] [CrossRef]

- Bici, M.; Campana, F.; Colacicchi, O.; D’Ercoli, G. CAD-CAE Methods to Support Restoration and Museum Exhibition of Bronze Statues: The “Principe Ellenistico”. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Florence, Italy, 16–18 May 2018; IOP Publishing: Bristol, UK, 2018; Volume 364, p. 012014. [Google Scholar]

- Stefania, V.; Pintucchi, B.; Tommaso, R.; Tanganelli, M. The Seismic Analysis of Cerere at the Museum of Bargello. Bull. Earthq. Eng. 2020, 18, 2635–2656. [Google Scholar]

- Kiilerich, B. The Barletta Colossus Revisited: The Methodological Challenges of an Enigmatic Statue. Acta Archaeol. Artivm Hist. Pertin. 2015, 28, 55–72. [Google Scholar]

- Buccolieri, G.; Nassisi, V.; Delle Side, D.; Giuffreda, E.; Marabelli, M.; Buccolieri, A.; Iacobellis, V.N.; Paladini, F.; Vona, F.; Castellano, A. The Restoration of the Colosso Di Barletta: EDXRF Analysis. In Proceedings of the 4th Workshop-Plasmi, Sorgenti, Biofisica ed Applicazioni, Lecce, Italy, 17-18 October 2014; Volume 2014, pp. 7–10. [Google Scholar]

- Berger, M.; Tagliasacchi, A.; Seversky, L.; Alliez, P.; Levine, J.; Sharf, A.; Silva, C. State of the Art in Surface Reconstruction from Point Clouds. In Proceedings of the Eurographics 2014-State of the Art Reports, Strasbourg, France, 7–11 April 2014; Volume 1, pp. 161–185. [Google Scholar]

- Coaker, L.H. Reflector-Less Total Station Measurements and Their Accuracy, Precision and Reliability. Bachelor’s Thesis, University of Southern Queensland, Toowoomba, Australia, October 2009. [Google Scholar]

- Bommes, D.; Lévy, B.; Pietroni, N.; Puppo, E.; Silva, C.; Tarini, M.; Zorin, D. Quad-Mesh Generation and Processing: A Survey. Comput. Graph. Forum 2013, 32, 51–76. [Google Scholar] [CrossRef]

- Shepherd, J.F.; Johnson, C.R. Hexahedral Mesh Generation Constraints. Eng. Comput. 2008, 24, 195–213. [Google Scholar] [CrossRef]

- Girardeau-Montaut, D. CloudCompare; EDF R&D Telecom ParisTech: Paris, France, 2016. [Google Scholar]

- Pepe, M.; Costantino, D.; Alfio, V.S.; Restuccia, A.G.; Papalino, N.M. Scan to BIM for the Digital Management and Representation in 3D GIS Environment of Cultural Heritage Site. J. Cult. Herit. 2021, 50, 115–125. [Google Scholar] [CrossRef]

- Piegl, L. On NURBS: A Survey. IEEE Comput. Graph. Appl. 1991, 11, 55–71. [Google Scholar] [CrossRef]

- Ji, S.; Lei, L.; Zhao, J.; Lu, X.; Gao, H. An Adaptive Real-Time NURBS Curve Interpolation for 4-Axis Polishing Machine Tool. Robot. Comput.-Integr. Manuf. 2021, 67, 102025. [Google Scholar] [CrossRef]

- MIDASoft North America. Available online: https://www.midasoft.com (accessed on 2 December 2021).

- NTC2018-D.M.; Ministero Delle Infrastrutture e dei Trasporti Aggiornamento delle «Norme Tecniche per le Costruzioni». Il ministero delle infrastrutture e dei trasporti: Rome, Italy, 17 January 2018. (In Italian)

- De Canio, G. New anti seismic basements for high vulnerable statues in Italy. In Proceedings of the 14th World Conference on Seismic Isolation, Energy Dissipation and Active Vibration Control of Structures, San Diego, CA, USA, 9–11 September 2015. [Google Scholar]

- Cigada, A.; Sabbioni, E.; Siami, A.; Zappa, E. Modeling and Testing of the Anti-Vibration Base for Michelangelo’s Pietà Rondanini. In Special Topics in Structural Dynamics; Springer: Berlin/Heidelberg, Germany, 2016; Volume 6, pp. 11–21. [Google Scholar]

| Spatial Position | ID | Type | Error [m] | Error [pix] |

|---|---|---|---|---|

| 10 | GCP | 0.0008 | 0.846 |

| 12 | GCP | 0.0007 | 0.898 | |

| 19 | GCP | 0.0003 | 0.831 | |

| 21 | GCP | 0.0006 | 2.102 | |

| 1001 | GCP | 0.0034 | 2.129 | |

| 1002 | GCP | 0.0007 | 2.000 | |

| 1003 | GCP | 0.0039 | 1.636 | |

| Total error | 0.0020 | 1.607 | ||

| C1-2 | CP | 0.00001 | ||

| C3-4 | CP | −0.00003 | ||

| C5-6 | CP | 0.00046 | ||

| Total error | 0.00027 |

| Process | Setting | Description | Values | Processing Times |

|---|---|---|---|---|

| Alignment | Highest | Highest accuracy setting upscales the image by factor of 4 | 1,932,377 (tie points) | 36 m 44 s |

| Dense cloud | Medium | Medium setting causes image downscaling by factor of 16 | 5,644,260 (vertices) | 1 d 20 h |

| Mesh | Medium | Medium setting causes image downscaling by factor of 16 | 10,775,553 (triangles) | 3 m 20 s |

| Decimation | C2M Distance [m] | Histogram | C2M Image | ||

|---|---|---|---|---|---|

| Average | StD | Max | |||

| 90 (10%) | 0.001 | 0.009 | 0.029 |  |  |

| 60 (40%) | 0.001 | 0.011 | 0.031 |  |  |

| 30 (70%) | 0.003 | 0.019 | 0.037 |  |  |

| Material | Properties | Value |

|---|---|---|

| bronze alloy | E | 11,000 KN/cm2 |

| v | 0.35 | |

| γ | 9200 Kg/m3 | |

| concrete | E | 3057 KN/cm2 |

| v | 0.20 | |

| γ | 2400 Kg/m3 | |

| steel | E | 21,000 KN/cm2 |

| v | 0.30 | |

| γ | 7859 Kg/m3 |

| Dataset | Images [#] | Dense Cloud [n. of Points] | Mesh [n. of Mesh] | Quad Mesh | C2M Distances | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Decimation | Faces [#] | Memory OBJ Format [KB] | Average Distances [m] | StD [m] | Max Distances [m] | |||||

| A |  | 32 | 59,630 | 133,311 | 90 (10%) | 6683 | 1142 | 0.001 | 0.001 | 0.024 |

| 70 (30%) | 4932 | 842 | 0.002 | 0.001 | 0.025 | |||||

| 30 (70%) | 2828 | 479 | 0.003 | 0.003 | 0.047 | |||||

| B |  | 101 | 341,712 | 800,956 | 90 (10%) | 13,857 | 2409 | 0.001 | 0.002 | 0.023 |

| 70 (30%) | 9437 | 1618 | 0.002 | 0.002 | 0.034 | |||||

| 30 (70%) | 3869 | 660 | 0.003 | 0.004 | 0.048 | |||||

| C |  | - | 2,369,663 | 149,820 | 90 (10%) | 11,932 | 2053 | 0.002 | 0.010 | 0.032 |

| 70 (30%) | 8173 | 1394 | 0.003 | 0.011 | 0.050 | |||||

| 30 (70%) | 3543 | 601 | 0.004 | 0.012 | 0.060 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfio, V.S.; Costantino, D.; Pepe, M.; Restuccia Garofalo, A. A Geomatics Approach in Scan to FEM Process Applied to Cultural Heritage Structure: The Case Study of the “Colossus of Barletta”. Remote Sens. 2022, 14, 664. https://doi.org/10.3390/rs14030664

Alfio VS, Costantino D, Pepe M, Restuccia Garofalo A. A Geomatics Approach in Scan to FEM Process Applied to Cultural Heritage Structure: The Case Study of the “Colossus of Barletta”. Remote Sensing. 2022; 14(3):664. https://doi.org/10.3390/rs14030664

Chicago/Turabian StyleAlfio, Vincenzo Saverio, Domenica Costantino, Massimiliano Pepe, and Alfredo Restuccia Garofalo. 2022. "A Geomatics Approach in Scan to FEM Process Applied to Cultural Heritage Structure: The Case Study of the “Colossus of Barletta”" Remote Sensing 14, no. 3: 664. https://doi.org/10.3390/rs14030664

APA StyleAlfio, V. S., Costantino, D., Pepe, M., & Restuccia Garofalo, A. (2022). A Geomatics Approach in Scan to FEM Process Applied to Cultural Heritage Structure: The Case Study of the “Colossus of Barletta”. Remote Sensing, 14(3), 664. https://doi.org/10.3390/rs14030664