1. Introduction

Spectrometers are often used by the remote sensing community to characterize

in situ the reflectance of surface features and to perform vicarious calibrations of air- and spaceborne sensors. The spectra measured vary from specific objects and small areas (e.g., leaves, rocks) to composite scenes (e.g., vegetation canopies), and, ultimately, to image pixels [

1–

3]. Mostly, we use a spectrometer to derive the reflectance of an object by comparing the signal reflected from the object to that of a white reference panel, such as Spectralon (compressed polytetrafluoroethylene) or BaSO

4. Measuring radiance rather than reflectance is necessary when performing aerial measurements for which Spectralon calibration is cumbersome [

4]. On this occasion, a pre-flight absolute calibration of the irradiance received at the device’s aperture is needed. In aerial measurements, a fiber optic extension is often used to connect the spectrometer located inside the airplane to the collecting optics located in a pod at the bottom of the aircraft. In this case, the calibration of the spectrometer must be done in the field. While this calibration procedure is usually performed using an integrating sphere (described below) [

5], it is not feasible to move and use this delicate and often large device in the field. The aim of this paper is to describe a simplified procedure suited for in-field absolute calibration of a spectrometer. Section 2 presents the apparatus used to achieve an ideal flat angular response by the spectrometer. Section 3 describes the procedure to calibrate a spectrometer by using an integrating sphere and by a quartz halogen (QH) lamp. In section 4 it is shown how a calibrated QH lamp can be used as a secondary calibration source for an integrating sphere. Section 5 discusses the advantages and shortcomings of the proposed calibration protocol. Section 6 offers concluding remarks.

3. Calibration of a Spectrometer Using an Integrating Sphere and a QH Lamp

An integrating sphere is a hollow spherical cavity with small entrance holes (for calibration lamps) and an exit hole, acting as a uniformly illuminated radiance source. The inner coating of an integrating sphere is a high reflectivity near-Lambertian surface that homogenizes the reflected spectral radiant intensities (W·str

−1·μm

−1) of the calibration lamps [

8]. The spectral radiance at the exit port is accurately measured by the manufacturer and can be used as the US National Institute of Standards and Technology (NIST) traceable standard. This known radiance is used to calibrate spectrometers in the visible (VIS), near-infrared (NIR), and shortwave infrared (SWIR) at the integrating sphere’s aperture. Although transportable integrating spheres [

9] have been used to calibrate remote sensing sensors in the field, these devices are expensive to manufacture and technically complicated to calibrate. In addition, transporting and operating them outside clean laboratory may lead to deterioration of their quality and their traceability to NIST primary standards. Another disadvantage of using common BaSO

4-coated integrating spheres for calibrating a spectrometer is that they may only be calibrated for discrete wavelengths in the VIS-NIR-SWIR regions where there is no absorption of water vapor that is adsorbed to their walls (as discussed later). The use of dry N

2 for purging the integrating sphere during NIST continuous-wavelength calibration will require a similar cumbersome purging during its use in the laboratory calibration. An interpolation made between discrete calibration points will introduce spectral features caused by the water adsorbed to the coating of the sphere [

2]. Therefore, the numeric interpolation approach is inadmissible and a physical-analytical approach is required.

The process of calibrating a spectrometer produces a calibration curve that allows for converting the

DN readout of the spectrometer to irradiance units.

Figure 2B shows the spectral irradiance measurement using an ASD spectrometer fitted with a FOV limiter at a distance

D from an integrating sphere. We used a Labsphere Unisource 1200 integrating sphere (S/N001588). The exact value of

D is insignificant, as will be explained herein. The integration time was set to 132 msec. The solid angle (Ω

aperture) suspended by the FOV limiter is equal to the iris area (A) divided by the square of the distance from the bare fiber end to it (

d2):

The calibrated value of the spectral radiance of the integrating sphere L

sphere (W·str

−1·cm

−2·μm

−1) is divided by the measured signal,

DN, to provide the spectrometer radiance calibration factor K

radiance (W·cm

−2·str

−1·μm

−1·DN

−1):

Figure 3 demonstrates the calibration according to the integrating sphere radiance. Note that the three different detector arrays in the spectrometer (350–985, 986–1,765, and 1,766–2,500 nm) are distinct.

To validate the calibration curve, we used a Gilway L9390 QH lamp (12 V, 100 W) operated by a stabilized current source (Oriel 68735 regulated power supply, 110/220 V, 450 W. The power unit weighs 7.85 kg, and it can be operated in the field by a small portable generator or a 1 kW DC/AC converter) as a gray body [

10] (

Figure 2C). The spectrometer readout (

DN) was multiplied by the calibration curve, thus yielding the spectral radiance of the lamp. However, there is a distinct difference between the two calibration methods: while the aperture of the integrating sphere fills the entire FOV limiter, the filament of the QH lamp is only a point source in it. Therefore, the calibration of the spectrometer should be performed with regard to the spectral irradiance of the aperture of the integrating sphere as measured at the FOV limiter plane E

sphere (W·cm

−2·μm

−1), yielding the irradiance calibration factor: K

irradiance (W·cm

−2·μm

−1·DN

−1). This is done by multiplying the values of the spectral radiance of the integrating sphere (L

sphere) by the area of the sphere aperture that is subtended by the FOV limiter (Ω

aperture·D

2), and by the solid angle of 1 cm

2 at the FOV limiter plane, subtended in relation to the sphere aperture:

It is evident from

Equation (3) that the irradiance does not depend on the distance

D between the iris of the FOV limiter and the aperture of the integrating sphere.

Figure 4 shows the spectral irradiance calibration curve.

When using the spectrometer to measure the irradiance of the lamp (

Figure 2C), the irradiance value E

lamp is dependent on the distance to the fiber aperture and not to the iris (D

lamp) because the filament of the lamp is a point source. As a result, the lamp spectral radiant intensity (I

lamp (W·str

−1·μm

−1)) is obtained by multiplying the signal measured by the spectrometer (

DN) by the irradiance calibration factor (K

irradiance) and dividing the product by the solid angle that 1 cm

2 at the fiber aperture plane subtends in relation to the lamp. This angle is equal to

.

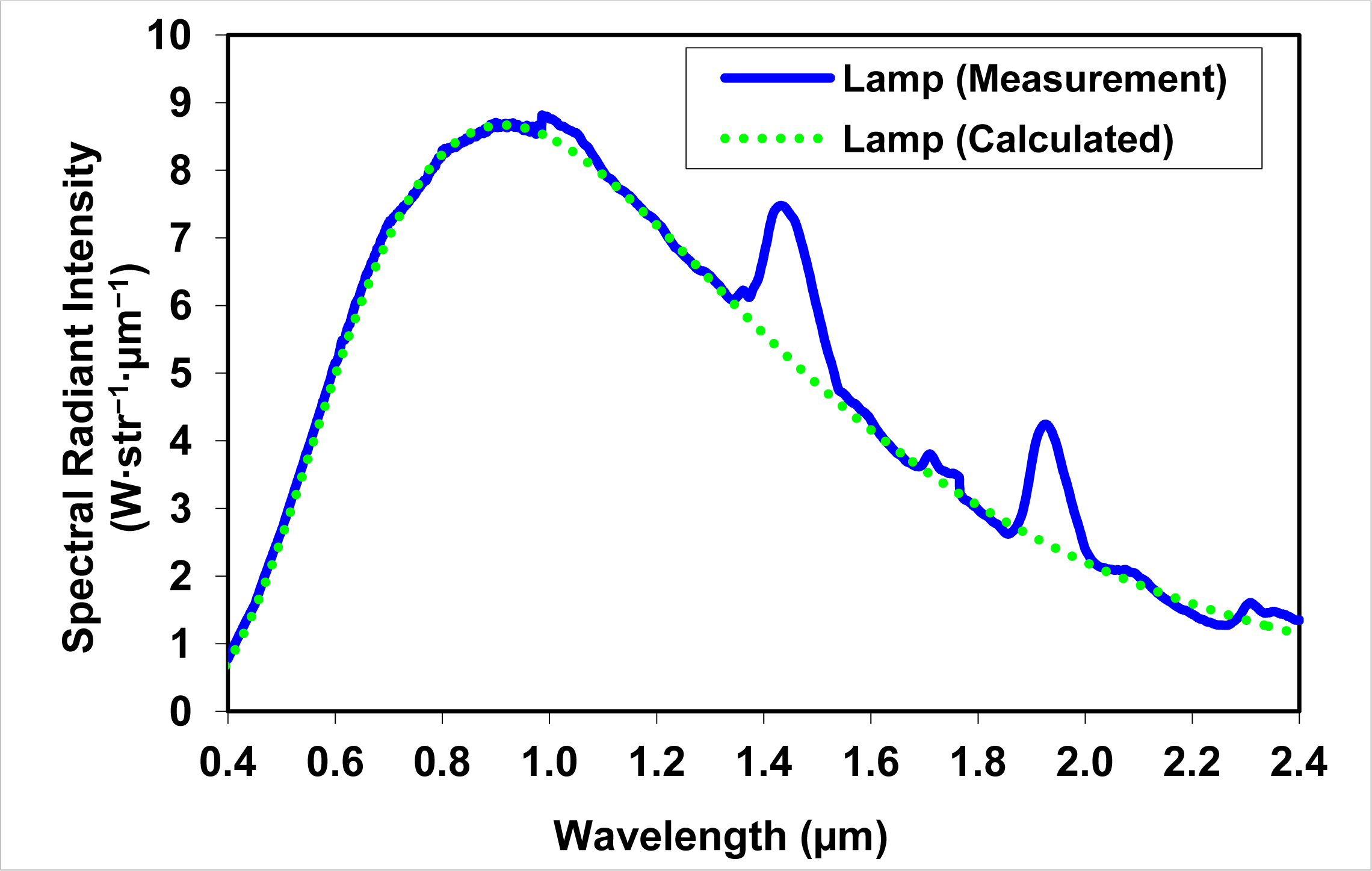

Following this equation, the measured spectral radiant intensity of the lamp (dotted line in

Figure 5) does not seem to be a gray body and has a strange wavelength dependence. This can be explained by the visual comparison between the lamp spectral radiant intensity and the spectral radiance of the integrating sphere as shown in

Figure 6. From this figure, it is evident that the radiant intensity of the lamp shows spectral offsets from a black (or gray) body curve at those wavelengths where there are no calibration values for the sphere radiance (probably due to the water absorption by the sphere’s BaSO

4 coating). This absorption is intensified by multiple reflections of light inside the integrating sphere. By ignoring these artifacts (caused by water absorption bands), we could compare the measured spectral behavior of the lamp with a theoretical gray body according to Planck’s law. As the tungsten filament is not a perfect gray body emitter, we assumed that its emissivity is wavelength dependent. From this, we concluded that for a filament area of 3 × 5 mm (according to the data sheet of this lamp), the spectral radiant intensity of the lamp matches that of a source with a temperature of 3,000 K (

Figure 7). Consequently, the wavelength-dependent emissivity (ε

λ) is defined as:

where

λ is the wavelength in μm. Without this emissivity correction, there would be a mismatch between the calculated and measured values of the spectral radiant intensity of the lamp [

11].

5. Discussion

We have demonstrated a procedure for the calibration of an ASD spectrometer at absolute irradiance units. This procedure is especially useful when the measurement procedure requires that the spectrometer will be calibrated before or after each measurement. The basis of our method relies on the calibration of a QH lamp prior to going into the field. This part is implemented in the laboratory using a calibrated integrating sphere. The advantage of using the lamp, as opposed to the integrating sphere, is twofold: (1) the QH lamp and the stabilized current source are easily transported to the field, while the integrating sphere is not easily taken out of the laboratory environment; and (2) the QH lamp provides a continuous calibration curve, while in most cases, the integrating sphere is calibrated for discrete wavelengths.

By using a calibrated lamp, the calibration of a spectrometer, in field conditions and on-board an aircraft, is easily performed. One obvious shortcoming of using a QH lamp that is calibrated by us is that we remove ourselves from the NIST standard (according to which the integrating sphere is calibrated), and adding some error to our calibrations. However, this application allows for the calibration to be conducted under similar conditions to those under which the measurements are to be made [

12] and in spectral regions where the integrating sphere is not calibrated, thereby reducing another source of error.

It has also been demonstrated that the calibrated lamp could be used for a secondary calibration of an integrating sphere, in cases when the sphere calibration is unknown. Though expensive NIST-traceable calibrated FEL lamps are used as a standard, we chose to demonstrate the application of inexpensive and fairly available QH lamps. We have shown that a relatively accurate calibration can be achieved for the VIS-NIR-SWIR region using these lamps. Currently, several groups in the remote sensing community lack the resources to maintain expensive measurement equipment, which has led to the establishment of an “equipment pool.” One of these is the Field Spectroscopy Facility (FSF) of the UK Natural Environment Research Council (NERC) [

13]. Such equipment is often considered infallible despite its calibration not having been maintained since its purchase [

2]. The presented method, using standard QH lamps, could contribute to the generation of better quality and more uniform data across research groups. Only one visit to a laboratory with an integrating sphere is required to calibrate several QH lamps. Caution should be taken when using any lamp after transport, as changes in spectral radiance (> 1%) have been documented to occur in one of three FEL lamps during transportation [

14,

15]. Therefore, it is good practice to calibrate several lamps and compare them from time to time to make sure no great changes to the calibration lamp radiance have occurred. It is advised that no lamp be used for over 100 hours without recalibrating its radiance, even without transport.