1. Introduction

There has been a lot of interest in using lidar for wind energy in the recent years, for example to assess the energy yield on a site or to validate a turbine’s power curve. Another very promising application is in the form of lidar-assisted control systems to reduce the loads on turbines during operation. Such systems use a lidar to scan the oncoming wind field to obtain information on the velocity field. Knowing what to expect allows a controller to anticipate any strong perturbations (e.g., gusts), for instance by preventively lowering the thrust on the rotor by pitching the blades. This is different from the conventional feedback controllers used presently, which operate by regulating the generator torque and speed with the big disadvantage that they can only react to past events. Severe gusts, with the potential to trigger extreme loads, can therefore only be dealt with after they have hit the rotor. The potential of lidar-assisted control for the reduction of fatigue and extreme loads is recognized in multiple studies [

1,

2,

3,

4]. A study by Schlipf et al. [

5] showed a 51% reduction in loads resulting from an extreme operating gust as prescribed by the International Electrotechnical Commission (IEC) [

6]. Although the study was performed with a uniform velocity field—not necessarily representative of a real-life event—it shows that lidar-assisted controllers have great potential for gust control when given the proper input.

Although lidars are generally regarded as being suitable tools to assess the mean wind speed, they suffer from some inherent weaknesses that hinder the measurement of gusts. Doppler lidar systems operate by sending out a laser beam and measuring the Doppler shift as the light scatters back from the natural aerosols. Wind speeds are normally averaged along the length of the pulse by range weighting, thereby losing information about the high frequencies. Moreover, lidars are inherently confronted by the so-called

cyclops dilemma [

7], meaning that only the wind speed component along the line of sight can be measured. In addition, nacelle-mounted lidars can be plagued by low data availability, for instance due to the passing of the blades in front of the lens. These issues are addressed in several studies that focus on using lidar measurements to obtain mean wind and turbulence properties [

8,

9,

10,

11] or achieve real-time wind field construction [

12].

However, what a controller ultimately wants to use is one or a set of inputs that have a direct impact on the performance of the entire rotor disk. This is why some authors prefer a rotor-effective or blade-effective wind speed [

13,

14,

15] instead of the full velocity field. Therefore, in order to make any decision on what action to take in response to an oncoming threat, one requires a method to turn a set of (possibly scattered) measurements into useful information. In addition, the inherent weaknesses of the lidar induce some degree of uncertainty, which needs to be taken into account.

In this paper, we propose a method to assess the severity of an oncoming gust. This is done by fitting a homogeneous Gaussian velocity field to a set of scattered point measurements, of which the statistics can be derived analytically. The velocity field allows one to predict the along-wind force acting on the rotor area, which is a measure of the damaging potential of a gust and can be used as control input. Additionally, the uncertainty coming from only knowing the velocity along the lidar beams can be included with the along-wind force in a straightforward fashion. The method is demonstrated by an example of a gust measured in the field by a pulsed lidar system mounted on the nacelle of a 5 MW wind turbine. Furthermore, we validate the outcome by comparing the resulting along-wind force with the rotor-effective wind speed, which is a signal derived from the turbine’s shaft torque and is considered representative for the rotor thrust force.

3. Results

The example shown in this section is based on a 17 m/s velocity peak (

) measured by the center beam at a range of

m on 22 December 2013. During this time, the turbine was not affected by the wake of neighboring turbines or met masts and was operating under a slight yaw misalignment of

(taken as the difference between the turbine’s yaw angle and the wind direction measured at 97 m height by the neighboring met mast). The ten-minute mean hub height wind speed measured at the

m range gate was about 13.3 m/s with a longitudinal turbulence intensity of 5.9% (taken directly from the lidar). Considering that the terrain is flat and homogeneous, a neutral wind shear profile was fitted to the ten-minute mean wind speeds measured along beam positions 0, 1, and 3 (again, at

m):

yielding a roughness length of

m, which is representative of the site [

20]. Furthermore, a spectral tensor

according to [

21], was set up with

m,

m

/s

, and

. The length scale was estimated from the average of 12 ten-minute spectra from the preceding two hours (see

Figure 4). The

parameter was found by scaling the

u-component of the spectral tensor to match the ten-minute longitudinal variance along the center beam:

where again the filtering with

W denotes the effect of range-weighting. The shear parameter, Γ, was taken from [

22] to match neutral atmospheric conditions.

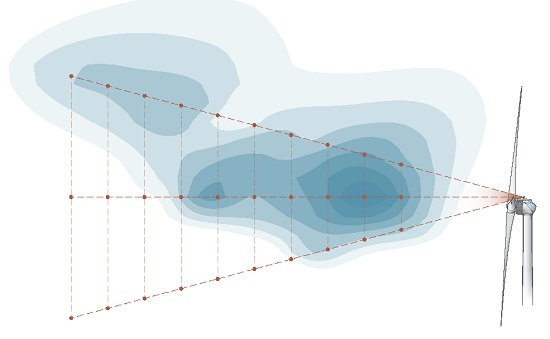

Figure 5 shows slices of the velocity field fitted to one full measurement cycle (10 ranges × 5 beam locations:

), at a time where all five beams were available.

Figure 5a,c shows a slice of the wind field at a distance

m.

Figure 5b,d shows the

-plane through

.

Figure 5a,b show that it is possible, even with a collection of scattered points, to make an educated guess of the size of an upcoming gust structure. At the same time,

Figure 5c,d are able to show approximately how reliable these estimates are. A variance of

implies that the velocity is known for certain, whereas a variance of

implies that there is no knowledge about the field but the ten-minute statistics. Of course, the uncertainty is the lowest along the direction of the beam, although it never reaches zero because of range weighting and beam pointing.

Figure 5c also shows that the range gate at

m is a convenient one to rely on, since it provides good coverage of the rotor disk (although all 50 points are used to estimate

).

Figure 6 shows how the estimated along-wind force,

, through the disk at

m is constructed from the individual beam signals. First,

Figure 6a shows the expectation plus 1–3 standard deviations, corresponding to an exceedance probability of 15.9%, 2.3%, and 0.1%, respectively. The highest peak of the signal, at

, approximately matches the peaks in the velocity signals, which is what one would expect. The fact that the velocity peaks stay above the mean for a relatively long period (10–20 s) is already an indication that the gust structure is large and contains a lot of momentum. At the same time, very localized peaks, such as

at

s, hardly have an effect on the total along-wind force.

Shown in

Figure 6b is the variance associated with

, which is a direct result of the data availability. The lidar can only supply a set of point measurements along several beams and all the space in between is translated into uncertainty. This uncertainty not only includes the probability that a certain measured peak is very local, but also the possibility of another, higher velocity peak being hidden between the beams. It also means that, if the flow is strongly correlated with itself, the quality of the forecast would naturally increase because one point measurement is more representative of its surroundings. Another source of uncertainty is that not all five lidar beams are available every full cycle, which is why the variance fluctuates over time. This is due to the rotor blades passing in front of the beam and the overall technical availability of the lidar system.

As a validation check, the expected along-wind force,

, is compared to the rotor-effective wind speed, which is a pseudo signal derived from the shaft torque,

Q, and should be representative of the loads. Using this as an input for feed-forward control has shown to improve the turbine behavior in the case of severe wind gusts [

13,

23] and has been used extensively by ECN for research and operation. The rotor-effective wind speed,

, follows from

where

D is the rotor diameter and

is a dimensionless torque coefficient that depends on the blade pitch angle,

θ, and tip speed ratio,

λ. A comparison of

with the predicted along-wind force, shown in

Figure 7, confirms that the method is able to capture the most important trends well (i.e., the low-frequency up- and downcrossings). The signals cannot be expected to match perfectly, however, since

is affected by any actions taken by the controller and also contains a lot of high-frequency noise coming from structural vibrations.

4. Discussion

The expected along-wind force at a certain upwind distance,

, together with its variance, is a single signal that can be easily compared to some threshold value, making it possible to devise a control strategy based on avoiding risk. For example, if a designer accepts a 0.1% probability of

F exceeding 3.0 MN, the controller would need to take action if

MN. Avoiding high loads is then done by collectively pitching the blades to decrease the rotor thrust. Modern-day multi-megawatt turbines can pitch at a rate of

deg/s, which should be fast enough to handle a gust measured 140 m upwind (especially when considering that the highest loads are generally found around rated wind speeds in the order of 10–12 m/s). Distilling the lidar measurements into a single force also helps to put individual velocity peaks into perspective. This is needed to avoid unnecessary control actions that could lead to power fluctuations, additional loading, and wear in the actuators. Alternatively, if the integral in Equation (

27) is carried out per rotor annulus, it could provide a set of signals to a smart rotor (i.e., a machine with flaps distributed along its blades).

How well the statistics of

F match with reality will depend on how close

is to a stationary homogeneous Gaussian velocity field. Stationarity will not be the case during a storm or at the outflow boundary of a downdraft. Homogeneity is usually a questionable assumption for large vertical separations or under stable conditions. For example, the velocity variances,

,

, and

, usually decrease with height [

24]. This would mean that the severity of gusts will likely be underpredicted in the bottom half of the rotor plane (where the turbulence intensity is actually higher than what is predicted at hub height) and overpredicted in the upper half. Due to the shape of the variance profile, this will likely lead to a conservative estimate for

F. It is possible to use an alternative shape of the spectral tensor to account for the vertical inhomogeneity (e.g.,

), but that requires more information of the flow than lidars currently can provide. Furthermore, Gaussianity is a property that is violated on a smaller scale [

25]. However, this should not have a major impact on the quality of the forecast, since most of the momentum is carried by the large-scale flow structures. In any case, some future work will have to be done on validating the correlation of the predicted along-wind force with the loads acting on the turbine, preferably using longer time series.

One of the strengths of this method is the ability to deal with missing measurements. This is needed when the lidar is mounted on the top of the nacelle with blades passing in front of the lens. Any serious gaps in the data will raise the uncertainty and therefore the risk associated with an oncoming gust, which can be included in the control strategy. In addition, since the method can handle any set of scattered velocity measurements, it should be compatible with any scanning pattern the lidar might have (e.g., see [

26]).

A final remark has to be made on the evolution of wind traveling towards the turbine. Depending on the mean wind speed and which slice of the flow field is used to derive the along-wind force, the lidar can grant somewhere between 5 and 30 s of look-ahead time. During this time, the wind field would have inevitably changed. The statistics of such an evolving wind field are perhaps best predicted by considering the evolution of the Fourier modes, yielding an expression in the shape of

where the Fourier modes are a function of time and an initial state at a time

. For example, the effect of the diffusion on the total uncertainty can be modeled by a wave number-dependent decay function where the state of the field slowly decorrelates from an initial state (e.g., see [

27]). In addition, there is the effect of the induction field in front of the turbine. As the flow expands, the wave numbers are stretched and the variances of the velocity components will change. Such effects could be included in the spectral tensor, most notably in its decomposition matrix,

, with a linear transformation:

This would lead to solutions similar to those resulting from rapid distortion theory (e.g., see [

17,

28]), used to predict the properties of turbulence after moving through wind tunnel contractions. However, this would require some more validation and will be the subject of future study.

5. Conclusions

The goal of this paper was to present a method to turn lidar measurements of an oncoming gust into useful control input. This method works by fitting a homogeneous Gaussian velocity field to a set of scattered measurement points. From this field, an along-wind force can be derived by integrating the dynamic pressure over the rotor plane, which acts as a measure for the damaging potential of an upwind velocity peak.

The assumption of a homogeneous Gaussian velocity field allows one to analytically compute the uncertainty associated with some inherent weaknesses of the lidar system (i.e., range weighting, cyclops dilemma, and missing measurements). These uncertainties can then be included in the prediction of the along-wind force. A controller can use this to make a probablistic forecast of an oncoming gust and take preventive action based on avoiding risk.

A real-life example of the method illustrated that this is able to put individual velocity peaks, measured by several lidar beams, into perspective by computing their contribution to the total along-wind force. Furthermore, the important low-frequency up- and downcrossings found in the predicted along-wind force agree with those found in the rotor-effective wind speed employed by Van der Hooft [

23]. This rotor-effective wind speed has been proven to improve turbine performance under gust loading when used as an input for feed-forward control.