1. Introduction

ZiYuan3-02 (ZY3-02) is the first remote sensing satellite for the development of China’s civil space infrastructure (CCSI) and the second satellite of the ZiYuan3 series. The ZY3-02 satellite was launched successfully on 30 May 2016, aboard the CZ-4B rocket at the Taiyuan Satellite Launch Center (TSLC) in China [

1]. Phased 180° apart in the same orbit, the ZY3-02 and ZiYuan3-01 [

2] (ZY3-01, China’s first domestic civil high-resolution stereo mapping satellite launched in January 2012) genuine constellation, beyond increasing the in-orbit data acquisition efficiency, will now enhance the acquisition of space geographic information as well as support mapping services and data collections for land resource surveys and monitoring. These satellites are of great significance in efforts to speed up the construction of China’s space geographic information data infrastructure and promote the development of geographical information industries.

The ZY3-02 satellite carries core payloads including a triple linear array camera (TLC) and multi-spectral camera. The TLC is comprised of a nadir (NAD) and forward (FWD) and backward (BWD) optical linear sensors, where the FWD and BWD sensors are arranged at an inclination of ±22° from NAD to realize a base-to-height (B/H) ratio of 0.88. Compared with the ZY3-01 satellite, the number of charge-coupled devices (CCDs) in the FWD/BWD focal plane of ZY3-02 was changed from four units to three units and the size was changed from 10 μm to 7 μm, which improved the ground sample distance (GSD) from 3.5 m to 2.7 m. Each sensor (NAD, BWD, and FWD) in the TLC of ZY3-02 adopts the optical butting system to realize multi-CCD splicing. As is shown in

Figure 1, after the incident light is reflected by the half transparent and half reflecting prism, the incident light is imaged on the transmitting and reflection areas, respectively, thereby realizing CCD splicing. Each raw focal plane is composed of three units of a CCD with 8192 pixels; overlapping pixels between the adjacent CCDs amount to about 30 pixels. The design and specification information for ZY3-02 are listed in

Table 1.

Geometric quality is crucial for the performance and potential of satellite imagery and has a bearing on the mapping precision and subsequent applications. Therefore, many optical remote sensing satellites, both domestically and internationally, have been the subject of geometric calibrations and evaluations after being launched, with the goal of improving and assessing the geometric performance of the satellite imagery. The National Centre for Space Studies (CNES) Image Quality Team performed calibration operations with imagery from Pleiades-HR 1A&1B in the commissioning phase to assess and improve the geometric quality of the images [

3,

4]. Poli et al. [

5] addressed the radiometric and geometric evaluations of the GeoEye-1, WorldView-2, and Pleiades-1A stereo images included in the Trento testfield and their potential for three-dimensional (3D) information extraction. Languille et al. [

6] detailed calibration sites and methods to be used for geometrical parameter calibrations, and then, they presented a geolocation performance assessment for Sentinel-2A. Seo et al. [

7] presented geometric calibration and validation work and checked the planimetric accuracy by bundle adjustment with ground control points (GCPs) for Kompsat-3A. Tadono et al. [

8,

9] described the results of calibration and validation, including the absolute accuracy, during stability evaluations over the course of one and half years for PRISM (Panchromatic Remote-sensing Instrument for Stereo Mapping) onboard ALOS (Advanced Land Observing Satellite). Wang et al. [

10] described imaging error sources and introduced a calibration model for the GF4 satellite, and then, they performed a geometric quality assessment. Zhang et al. [

11,

12,

13] introduced a geometric calibration model and validated the geometric calibration accuracy for ZY3-01. Thanks to these efforts, the geometric quality of imagery can be checked easily and the calibration procedures can be further refined by the corresponding accuracy results.

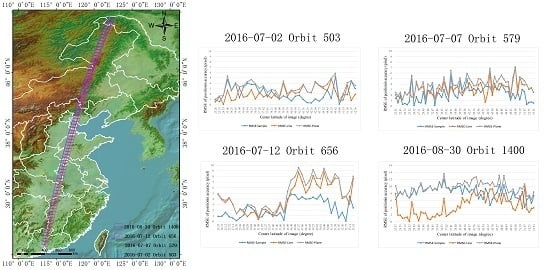

For the TLC camera of ZY3-02, similarly, it is essential to make a full assessment of its geometric potential. Therefore, a comprehensive evaluation of the geometric potential of ZY3-02 TLC imagery is performed in this paper. First, an on-orbit geometric calibration approach for ZY3-02 is presented to finely characterize the geometric model, and then, a model for sensor corrected products that can serve as basic products distributed to users is introduced. Furthermore, a thorough geometric quality evaluation, which includes the geometric calibration accuracy, absolute positioning accuracy, internal accuracy, stereoscopic measurements, and the derived digital surface model (DSM) accuracy, is made on a set of images covering reference sites. The experimental results demonstrate that the direct location performance is increased enormously and internal distortion is well-compensated after calibration. The geometric performance will however, vary with the geographical location and imaging time changes resulting from variations such as those due to thermal environment changes that alter the camera’s installation angle. In general, the TLC imagery of ZY3-02 can be used for 1:50,000 stereo mapping without GCPs and updates of larger-scale basic geographical information products are possible.

2. Methods

The rigorous geometric imaging model is a basic model used for satellite image geometric processing, and it also serves as the basis for the satellite sensor in-orbit geometric calibration [

14,

15,

16,

17]. According to observation data obtained by ZY3-02, the geometric model of the TLC was established as follows:

where

are the coordinates of a pixel in the camera’s coordinate system,

are the coordinates in the World Geodetic System 1984 (WGS84) corresponding to the pixel,

stands for the NAD/BWD/FWD sensor,

is the number of CCDs,

is the scanning time of an image line,

are the coordinates of the Global Positioning System (GPS) antenna phase center, which are measured by a dual-frequency GPS receiver on the satellite in WGS84 at

,

is a scale factor,

and

are the rotation matrix from the satellite’s body-fixed coordinate system in relation to WGS84 and the rotation matrix from the camera’s coordinate system in relation to the satellite’s body-fixed coordinate system, respectively, and

are the coordinates of the eccentric vector from the sensor’s projection center to the GPS antenna phase center in the satellite’s body-fixed coordinate system, which are prelaunch calibrated in the laboratory.

2.1. Geometric Calibration of the TLC Camera

According to Equation (1), the location performance for the geometric model of the ZY3-02 TLC is subject to bias from the camera installation angle , bias from the GPS antenna phase, time measurement errors, attitude measurement errors, orbit measurement errors, and pixel errors induced by the camera’s internal distortion, including ones from the optical distortion of the camera lens, and other ones from CCD translation, scale, rotation, and changes of the principle distance. Owing to the fact that the ZY3-02 satellite adopts the use of 1 pps in the GPS to improve the precision of synchronization, the timing accuracy reaches 30 μs and the errors induced by time measurement errors are negligible.

The measurement errors of attitude and orbit are considered as constant errors within one standard scene, but a degree of random deviation occurs between several scenes imaged at different times [

18]. Meanwhile, the external angle element and line element are strongly correlated in affecting the positioning accuracy, so the orbit measurement error can be treated as part of the attitude measurement error [

19]. Additionally, the errors caused by biases of the camera installation angle and GPS antenna phase, as well as the camera distortion are systematic errors and vary little over time; they directly impact the location accuracy, which characterizes the deviation between the real position of any pixel on an image and its estimated positioning using the geometric model, so it is essential to build a corresponding calibration model to compensate for these errors.

In this paper, geometric parameters are divided into static interior parameters and dynamic exterior parameters. The dynamic exterior parameters

are used for assessing the main bias of location, compensating for the biases of instruments, and determining the attitude of the camera coordinate system in space. The static interior parameters, by adopting the classic viewing angle model [

20,

21,

22,

23,

24] as shown in

Figure 2, are used to accurately describe the viewing directions of every pixel in the satellite’s body-fixed system and then improve the internal geometric accuracy of images by correcting the camera distortion.

According to the above analysis, the geometric calibration model can be constructed for the TLC of ZY3-02 as expressed in Equation (2):

is defined as follows:

where

, and

are rotation angles about the

, and

axes, respectively.

and

are defined by the following model:

where

denotes the number of the image row and

are the parameters to be solved.

High-precision digital orthophoto map (DOM)/digital elevation model (DEM) reference data are used in the acquisition of GCPs by matching processes from which the and the coefficients of the viewing directions model correction can be deduced.

2.2. Geometric Model of Sensor Corrected (SC) Products

As shown in

Figure 1, ZY3-02 adopts a multi-chip CCD design with an enlarged swath. However, this brings about much inconvenience to users when providing separated CCD images. Sensor corrected (SC) products successfully solve the problem of CCD mosaicking. Assume that a perfect sensor with only one CCD array is observing Earth in a nearly identical state of the ephemeris and attitude compared with the real, and its platform has no high attitude perturbations. Then, attitudes and ephemeris data transmitted by real sensors can be processed with polynomial fitting at ground level and then used as perfect in a camera orbit and attitude model. The focal plane of the perfect sensor is described in

Figure 3, and its interior orientation can be modeled as shown in Equation (5), where

and

are determined by the calibrated parameters for the TLC:

After establishing the geometric model of a perfect sensor, the SC product can be generated by the following steps:

- (1)

Calculate the coordinates in the object space of any pixel in the SC image with the rigorous geometric model of the perfect sensor;

- (2)

The image coordinates in the original image that corresponds to in step (1) are calculated by using the rigorous geometric model of the original multi-CCDs image;

- (3)

The gray value of pixel in the original image is obtained by resampling using a raised cosine function, and it is assigned to pixel in the SC image;

- (4)

The SC product is generated by repeating steps (1)–(3) for all pixels in the SC image;

- (5)

The rational polynomial coefficients (RPCs) are then generated by adopting the terrain independent solution [

25,

26,

27]. First, divide the image space into a regular space and generate the virtual control points (VCPs) by using the rigorous imaging model of the SC image at each grid point defined by

to calculate the corresponding object space point

on different elevation datum from

to

by space intersection. In this case, the image point

and the object space point

constitute a set of VCPs, as shown in

Figure 4. Second, calculate the coefficients of RPCs by the iterative algorithm principle of the spectrum correction [

28]; the RPC is finally taken as the basic geometric model for ZY3-02 SC images and provided to users.

The flow chart for the generation of an SC product is presented in

Figure 5:

As is shown in

Figure 6,

and

denote the imaging angles of the conjugate points between the origin multi-chip CCDs and the perfect CCD defined in the orbit coordinate system, respectively;

represents the height error, and

is the parallax induced by

. Obviously,

can be calculated by the following equation:

Since the TLC of ZY3-02 adopts an optical butting system, the perfect sensor and origin sensors scan the same object with a small difference in the imaging angles, i.e., . The loss of the SC product’s internal accuracy induced by height error can be neglected.

In this paper, SC products are mainly used in the full investigation of the geometric potential of ZY3-02 instead of raw data, which are composed of multi-CCD arrays and metadata.