Assessment of the Optimum Linker Tethering Site of Alternariol Haptens for Antibody Generation and Immunoassay Development

Abstract

1. Introduction

2. Results and Discussion

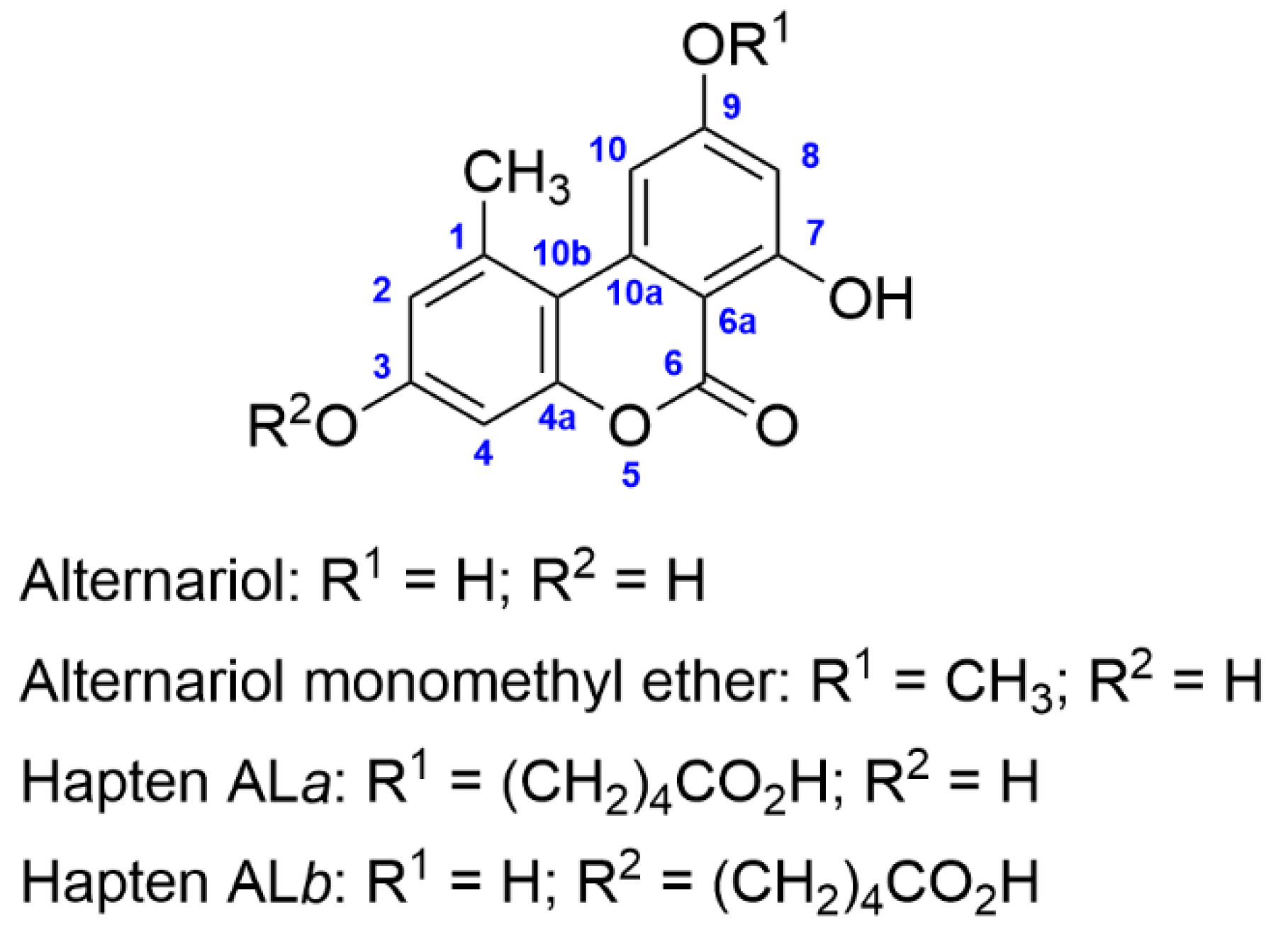

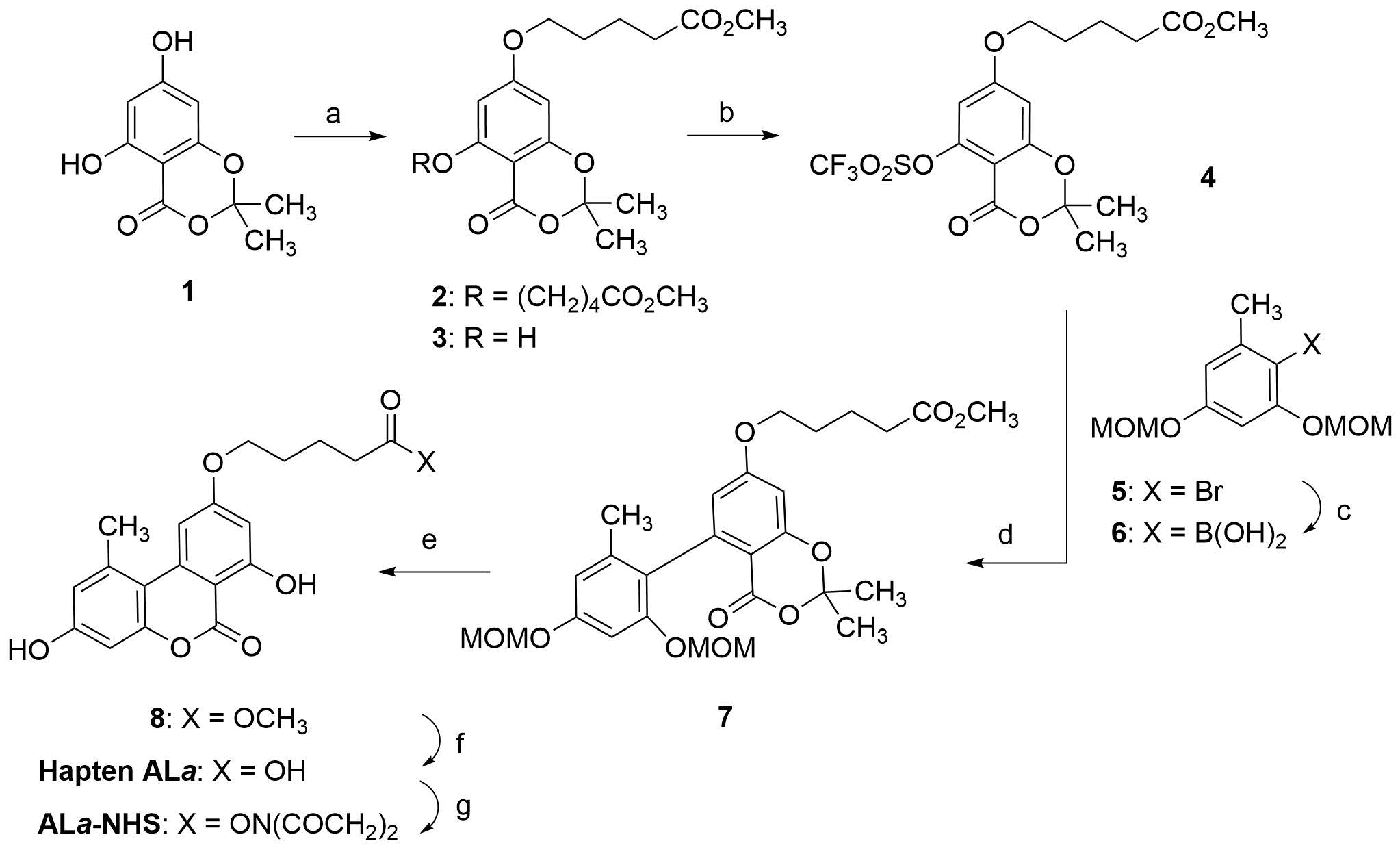

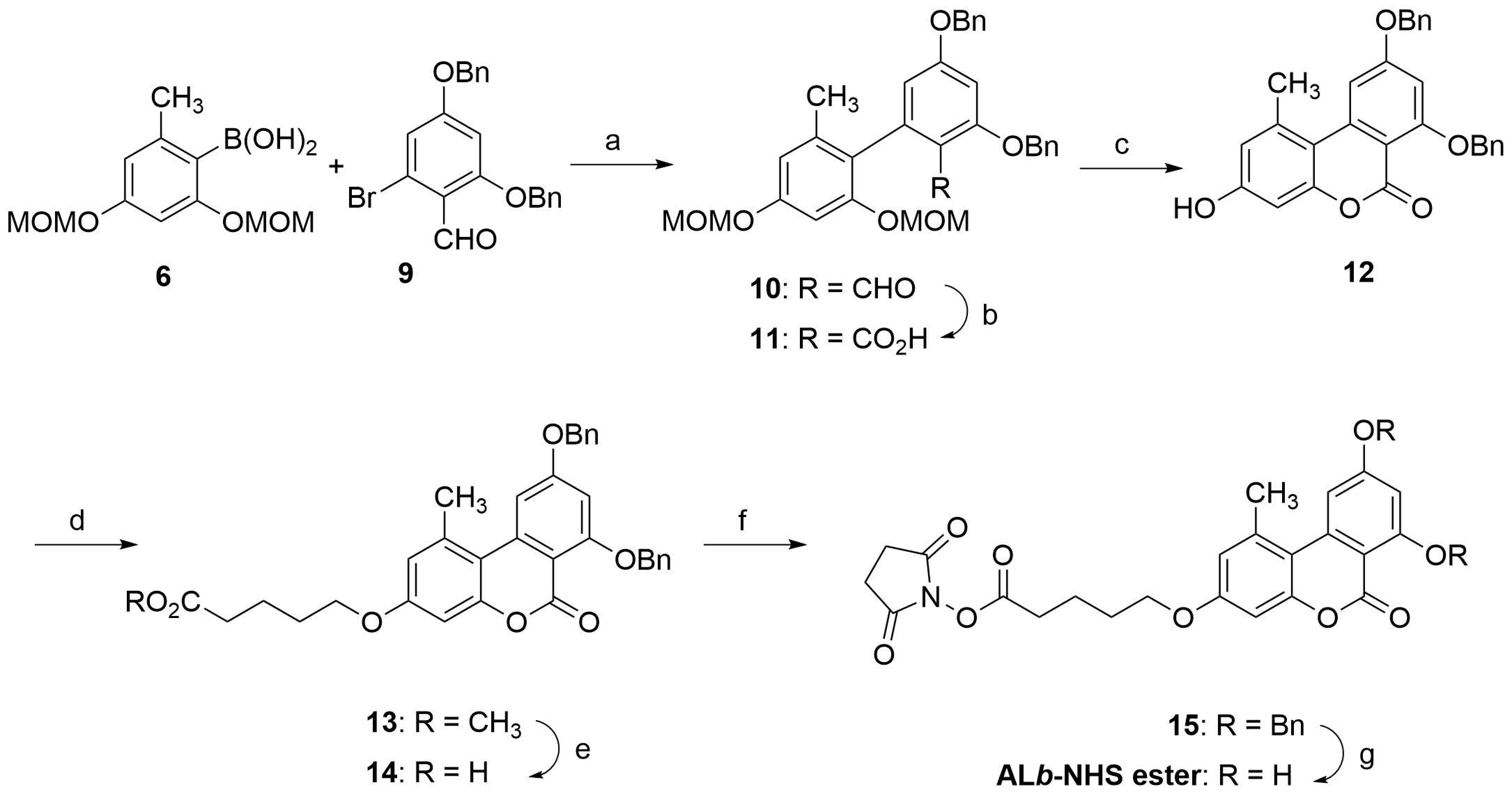

2.1. Hapten Design and Synthesis

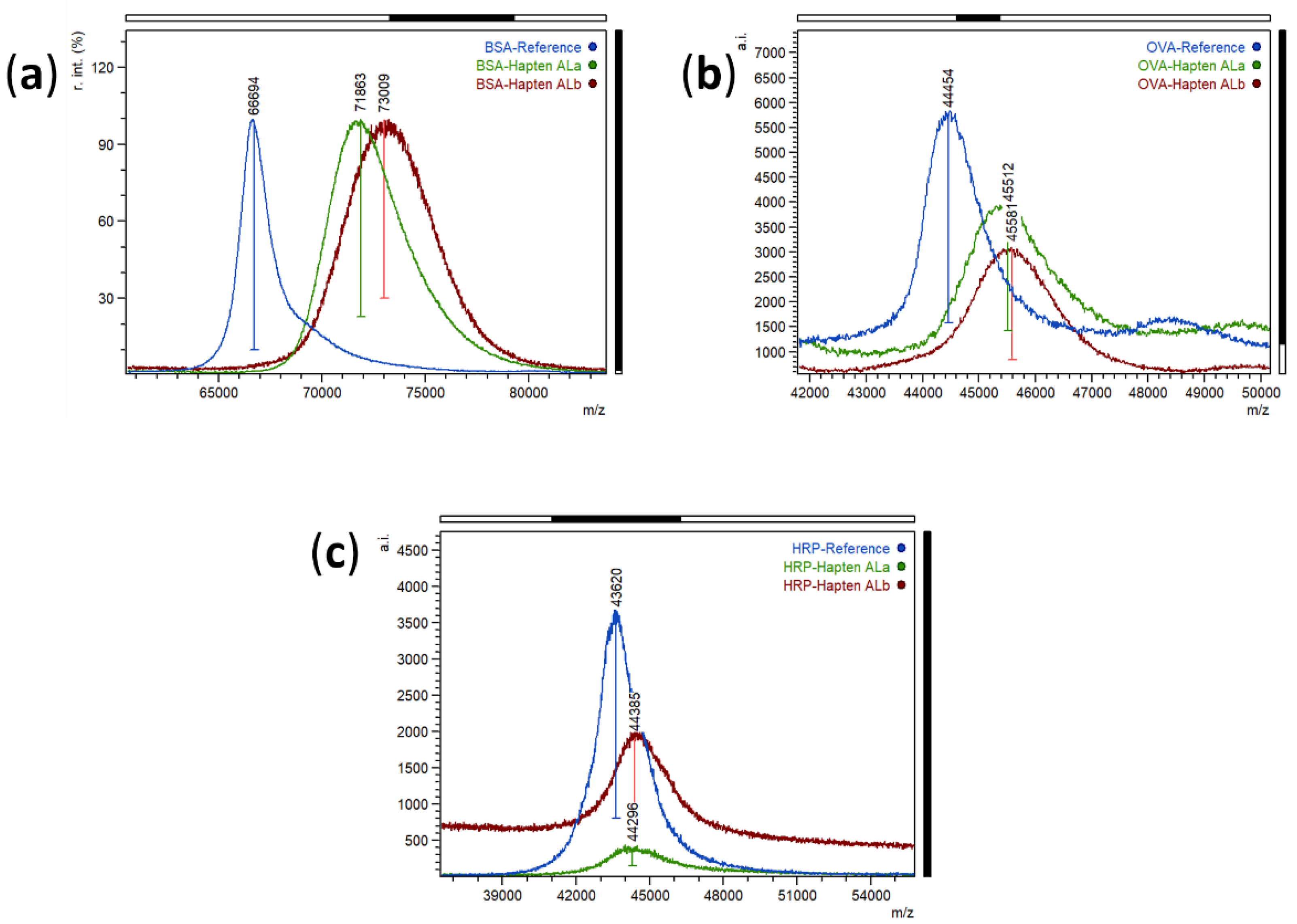

2.2. Bioconjugate Preparation

2.3. Assessment of the Immune Response

2.4. Assessment of Heterologous Conjugates

3. Conclusions

4. Materials and Methods

4.1. Reagents and Instruments

4.2. Synthesis of the N-hydroxysuccinimidyl Ester of Hapten ALa

4.2.1. Preparation of methyl 5-((5-hydroxy-2,2-dimethyl-4-oxo-4H-benzo[d][1,3]dioxin-7-yl)oxy)pentanoate (3)

4.2.2. Preparation of methyl 5-((2,2-dimethyl-4-oxo-5-(((trifluoromethyl)sulfonyl)oxy)-4H-benzo[d][1,3]dioxin-7-yl)oxy)pentanoate (4)

4.2.3. Preparation of methyl 5-((5-(2,4-bis(methoxymethoxy)-6-methylphenyl)-2,2-dimethyl-4-oxo-4H-benzo[d][1,3]dioxin-7-yl)oxy)pentanoate (7)

4.2.4. Preparation of methyl 5-((3,7-dihydroxy-1-methyl-6-oxo-6H-benzo[c]chromen-9-yl)oxy)pentanoate (8)

4.2.5. Preparation of 5-((3,7-dihydroxy-1-methyl-6-oxo-6H-benzo[c]chromen-9-yl)oxy)pentanoic acid (Hapten ALa)

4.2.6. Preparation of 2,5-dioxopyrrolidin-1-yl 5-((3,7-dihydroxy-1-methyl-6-oxo-6H-benzo[c]chromen-9-yl)oxy)pentanoate (ALa-NHS Ester)

4.3. Synthesis of the N-hydroxysuccinimidyl Ester of Hapten ALb

4.3.1. Preparation of 3,5-bis(benzyloxy)-2′,4′-bis(methoxymethoxy)-6′-methyl-[1,1′-biphenyl]-2-carbaldehyde (10)

4.3.2. Preparation of 3,5-bis(benzyloxy)-2′,4′-bis(methoxymethoxy)-6′-methyl-[1,1′-biphenyl]-2-carboxylic Acid (11)

4.3.3. Preparation of 7,9-bis(benzyloxy)-3-hydroxy-1-methyl-6H-benzo[c]chromen-6-one (12)

4.3.4. Preparation of methyl 5-((7,9-bis(benzyloxy)-1-methyl-6-oxo-6H-benzo[c]chromen-3-yl)oxy)pentanoate (13)

4.3.5. Preparation of 5-((7,9-bis(benzyloxy)-1-methyl-6-oxo-6H-benzo[c]chromen-3-yl)oxy)pentanoic Acid (14)

4.3.6. Preparation of 2,5-dioxopyrrolidin-1-yl 5-((7,9-dihydroxy-1-methyl-6-oxo-6H-benzo[c]chromen-3-yl)oxy)pentanoate (ALb-NHS Ester)

4.4. Immunoreagent Preparation

4.5. Competitive ELISA Procedures

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Escrivá, L.; Oueslati, S.; Font, G.; Manyes, L. Alternaria mycotoxins in food and feed: An overview. J. Food Qual. 2017, 2017, 1569748. [Google Scholar] [CrossRef]

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Scientific Opinion on the risks for animal and public health related to the presence of Alternaria toxins in feed and food. EFSA J. 2011, 9, 2407. [Google Scholar] [CrossRef]

- Arcella, D.; Eskola, M.; Gómez-Ruiz, J.A. EFSA Scientific Report. Dietary exposure assessment to Alternaria toxins in the European population. EFSA J. 2016, 14, 4654. [Google Scholar] [CrossRef]

- Ostry, V. Alternaria mycotoxins: An overview of chemical characterization, producers, toxicity, analysis and occurrence in foodstuffs. World Mycotoxin J. 2008, 1, 175–188. [Google Scholar] [CrossRef]

- Saha, D.; Fetzner, R.; Burkhardt, B.; Podlech, J.; Metzler, M.; Dang, H.; Lawrence, C.; Fischer, R. Identification of a polyketide synthase required for alternariol (AOH) and alternariol-9-methyl ether (AME) formation in Alternaria alternata. PLoS ONE 2012, 7, e40564. [Google Scholar] [CrossRef] [PubMed]

- Solfrizzo, M. Recent advances on Alternaria mycotoxins. Curr. Opin. Food Sci. 2017, 17, 57–61. [Google Scholar] [CrossRef]

- Hickert, S.; Bergmann, M.; Ersen, S.; Cramer, B.; Humpf, H.-U. Survey of Alternaria toxin contamination in food from the German market, using a rapid HPLC-MS/MS approach. Mycotoxin Res. 2016, 32, 7–18. [Google Scholar] [CrossRef] [PubMed]

- Man, Y.; Liang, G.; Li, A.; Pan, L. Analytical methods for the determination of Alternaria mycotoxins. Chromatographia 2017, 80, 9–22. [Google Scholar] [CrossRef]

- Chen, A.; Mao, X.; Sun, Q.; Wei, Z.; Li, J.; You, Y.; Zhao, J.; Jiang, G.; Wu, Y.; Wang, L.; et al. Alternaria mycotoxins: An overview of toxicity, metabolism, and analysis in food. J. Agric. Food Chem. 2021, 69, 7817–7830. [Google Scholar] [CrossRef]

- Burkin, A.A.; Kononenko, G.P. Enzyme immunassay of alternariol for the assessment of risk of agricultural products contamination. Appl. Biochem. Microbiol. 2011, 47, 72–76. [Google Scholar] [CrossRef]

- Ackermann, Y.; Curtui, V.; Dietrich, R.; Gross, M.; Latif, H.; Märtlbauer, E.; Usleber, E. Widespread occurrence of low levels of alternariol in apple and tomato products, as determined by comparative immunochemical assessment using monoclonal and polyclonal antibodies. J. Agric. Food Chem. 2011, 59, 6360–6368. [Google Scholar] [CrossRef]

- Kong, D.; Xie, Z.; Liu, L.; Song, S.; Zheng, Q.; Kuang, H. Development of an immunochromatographic assay for the detection of alternariol in cereal and fruit juice samples. Food Agric. Immunol. 2017, 28, 1082–1093. [Google Scholar] [CrossRef][Green Version]

- Singh, G.; Velasquez, L.; Brady, B.; Koerner, T.; Huet, A.-C.; Delahaut, P. Development of an indirect competitive ELISA for analysis of alternariol in bread and bran samples. Food Anal. Methods 2018, 11, 1444–1450. [Google Scholar] [CrossRef]

- Man, Y.; Liang, G.; Jia, F.; Li, A.; Fu, H.; Wang, M.; Pan, L. Development of an immunochromatographic strip test for the rapid detection of alternariol monomethyl ether in fruit. Toxins 2017, 9, 152. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Peng, T.; Zhang, X.; Yao, K.; Ke, Y.; Shao, B.; Wang, Z.; Shen, J.; Jiang, H. A novel hapten and monoclonal antibody-based indirect competitive ELISA for simultaneous analysis of alternariol and alternariol monomethyl ether in wheat. Food Control 2018, 94, 65–70. [Google Scholar] [CrossRef]

- Yao, C.-Y.; Xu, Z.-L.; Wang, H.; Zhu, F.; Luo, L.; Yang, J.-Y.; Sun, Y.-M.; Lei, H.-T.; Tian, Y.-X.; Shen, Y.-D. High affinity antibody based on a rationally designed hapten and development of a chemiluminescence enzyme immunoassay for quantification of alternariol in fruit juice, maize and flour. Food Chem. 2019, 283, 359–366. [Google Scholar] [CrossRef]

- Bräse, S.; Gläser, F.; Kramer, C.; Lindner, S.; Linsenmeier, A.M.; Masters, K.-S.; Meister, A.C.; Ruff, B.M.; Zhong, S. The Chemistry of Mycotoxins; Springer: Berlin/Heidelberg, Germany, 2013; Chapter 11; Volume 97, pp. 127–137. [Google Scholar]

- Koch, K.; Podlech, J.; Pfeiffer, E.; Metzler, M. Total synthesis of alternariol. J. Org. Chem. 2005, 70, 3275–3276. [Google Scholar] [CrossRef]

- Liang, D.; Luo, H.; Liu, Y.-F.; Hao, Z.-Y.; Wang, Y.; Zhang, C.-L.; Zhang, Q.J.; Chen, R.-Y.; Yu, D.-Q. Lysilactones A-C, three 6H-dibenzo[b,d]pyran-6-one glycosides from Lysimachia clethroides, total synthesis of lysilactone A. Tetrahedron 2013, 69, 2093–2097. [Google Scholar] [CrossRef]

- Won, M.; Kwon, S.; Kim, T.-H. An efficient synthesis of alternariol. J. Korean Chem. Soc. 2015, 59, 471–474. [Google Scholar] [CrossRef][Green Version]

- Martinez-Solorio, D.; Belmore, K.A.; Jennings, M.P. Synthesis of the purported ent-pochonin J structure featuring a stereoselective oxocarbenium allylation. J. Org. Chem. 2011, 76, 3898–3908. [Google Scholar] [CrossRef]

- Mallampudi, N.A.; Choudhury, U.M.; Mohapatra, D.K. Total synthesis of (−)-citreoisocoumarin, (−)-citreoisocoumarinol, (−)-12-epi-citreoisocoumarinol, and (−)-mucorisocoumarins A and B using a gold(I)-catalyzed cyclization strategy. J. Org. Chem. 2020, 85, 4122–4129. [Google Scholar] [CrossRef] [PubMed]

- Hinman, A.W.; Davis, D.; Kheifets, V. Preparation of Resorcinol Compounds for Dermatological Use. U.S. Patent 20140256830 A1, 6 March 2014. [Google Scholar]

- Marcyk, P.; Brown, L.E.; Huang, D.; Cowen, L.E.; Whitesell, L. Preparation of Resorcylate Aminopyrazole Compounds as Hsp90 Inhibitors and Uses. Thereof. Patent WO 2020/227368 A1, 6 May 2020. [Google Scholar]

- Roedel, T.; Gerlach, H. Enantioselective synthesis of the polyketide antibiotic (3R,4S)-(−)-citrinin. Liebigs Ann. 1995, 5, 885–888. [Google Scholar] [CrossRef]

- Lozada, J.; Liu, Z.; Perrin, D.M. Base-promoted protodeboronation of 2,6-disubstituted arylboronic acids. J. Org. Chem. 2014, 79, 5365–5368. [Google Scholar] [CrossRef] [PubMed]

- López-Puertollano, D.; Mercader, J.V.; Agulló, C.; Abad-Somovilla, A.; Abad-Fuentes, A. Novel haptens and monoclonal antibodies with subnanomolar affinity for a classical analytical target, ochratoxin A. Sci. Rep. 2018, 8, 9761. [Google Scholar] [CrossRef] [PubMed]

| Assay Conjugate | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Direct Assay | Indirect Assay | |||||||||

| pAb | [pAb] b | [HRP] c | IC50 d AOH | IC50 AME | CR e (%) | [pAb] | [OVA] | IC50 AOH | IC50 AME | CR (%) |

| ALa#1 | 10 | 10 | 2.20 | 2.20 | 100 | 100 | 100 | 6.28 | 3.08 | 204 |

| ALa#2 | 10 | 10 | 7.61 | 3.83 | 199 | 10 | 10 | 36.2 | 8.18 | 442 |

| ALb#1 | 10 | 10 | 1.19 | 170 | 0.70 | 100 | 100 | 6.23 | 402 | 1.55 |

| ALb#2 | 10 | 10 | 1.19 | 218 | 0.55 | 300 | 100 | 27.5 | 403 | 6.82 |

| pAb | [pAb] b | [OVA] c | IC50 d AOH | IC50 AME | CR (%) |

|---|---|---|---|---|---|

| ALa#1 | 20 | 100 | 3.83 | 6.06 | 63.2 |

| ALa#2 | 10 | 100 | 11.2 | 2.80 | 400 |

| ALb#1 | 20 | 1000 | 3.32 | 230 | 1.44 |

| ALb#2 | 30 | 1000 | 13.4 | 168 | 7.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Addante-Moya, L.G.; Abad-Somovilla, A.; Abad-Fuentes, A.; Agulló, C.; Mercader, J.V. Assessment of the Optimum Linker Tethering Site of Alternariol Haptens for Antibody Generation and Immunoassay Development. Toxins 2021, 13, 883. https://doi.org/10.3390/toxins13120883

Addante-Moya LG, Abad-Somovilla A, Abad-Fuentes A, Agulló C, Mercader JV. Assessment of the Optimum Linker Tethering Site of Alternariol Haptens for Antibody Generation and Immunoassay Development. Toxins. 2021; 13(12):883. https://doi.org/10.3390/toxins13120883

Chicago/Turabian StyleAddante-Moya, Luis G., Antonio Abad-Somovilla, Antonio Abad-Fuentes, Consuelo Agulló, and Josep V. Mercader. 2021. "Assessment of the Optimum Linker Tethering Site of Alternariol Haptens for Antibody Generation and Immunoassay Development" Toxins 13, no. 12: 883. https://doi.org/10.3390/toxins13120883

APA StyleAddante-Moya, L. G., Abad-Somovilla, A., Abad-Fuentes, A., Agulló, C., & Mercader, J. V. (2021). Assessment of the Optimum Linker Tethering Site of Alternariol Haptens for Antibody Generation and Immunoassay Development. Toxins, 13(12), 883. https://doi.org/10.3390/toxins13120883