Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Preparation of Samples

2.2. Experimental Equipment and Methods

3. Results and Discussion

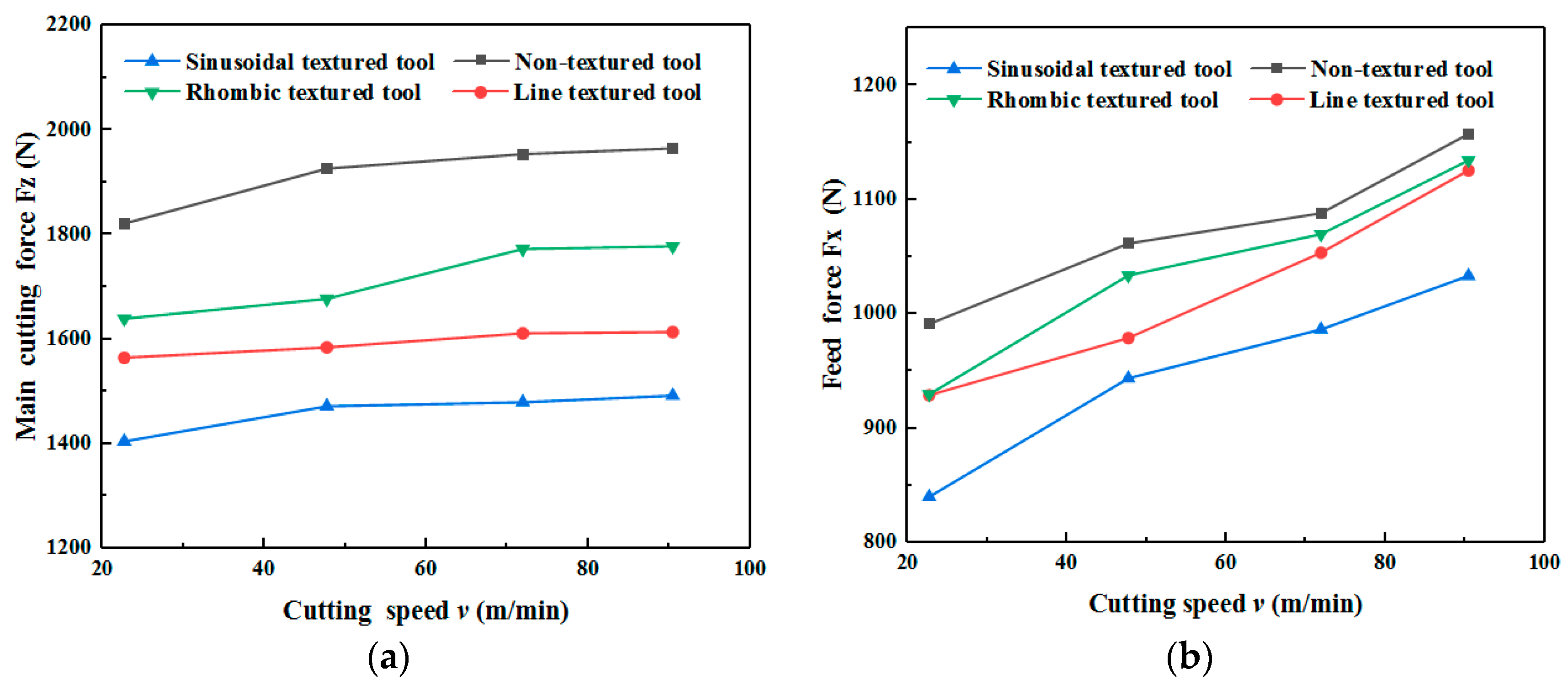

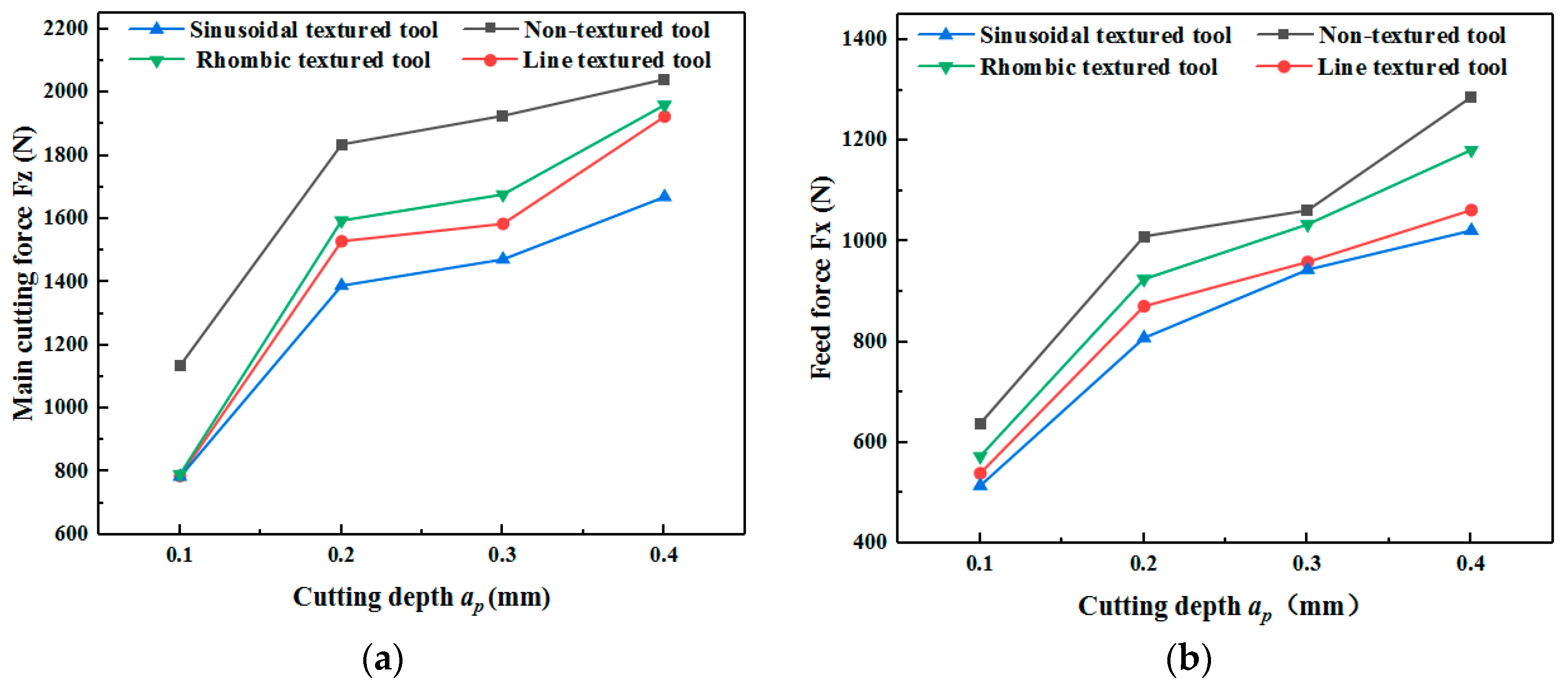

3.1. Effect of Cutting Parameters on Cutting Forces

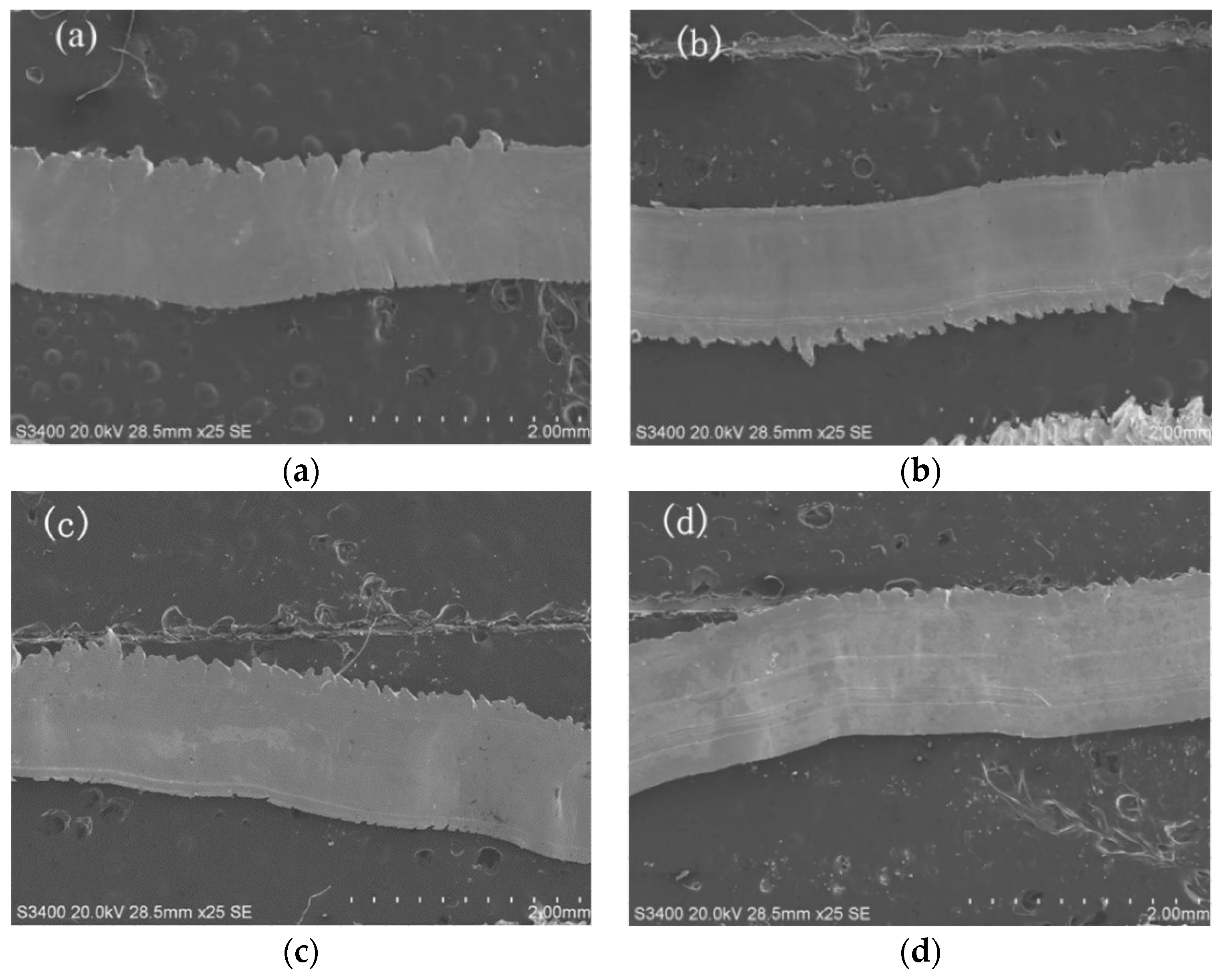

3.2. Effect of Tool Type on Chip Morphology

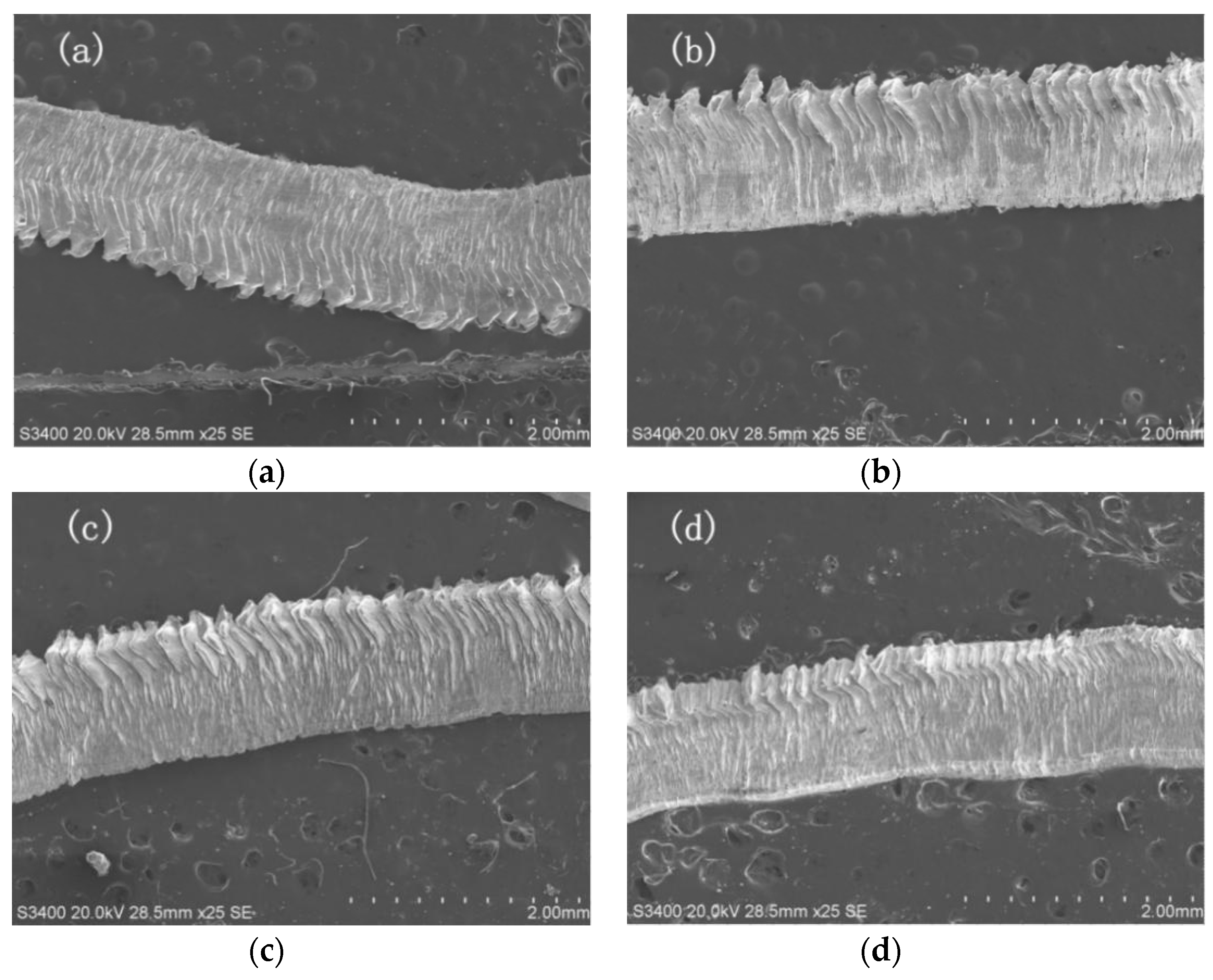

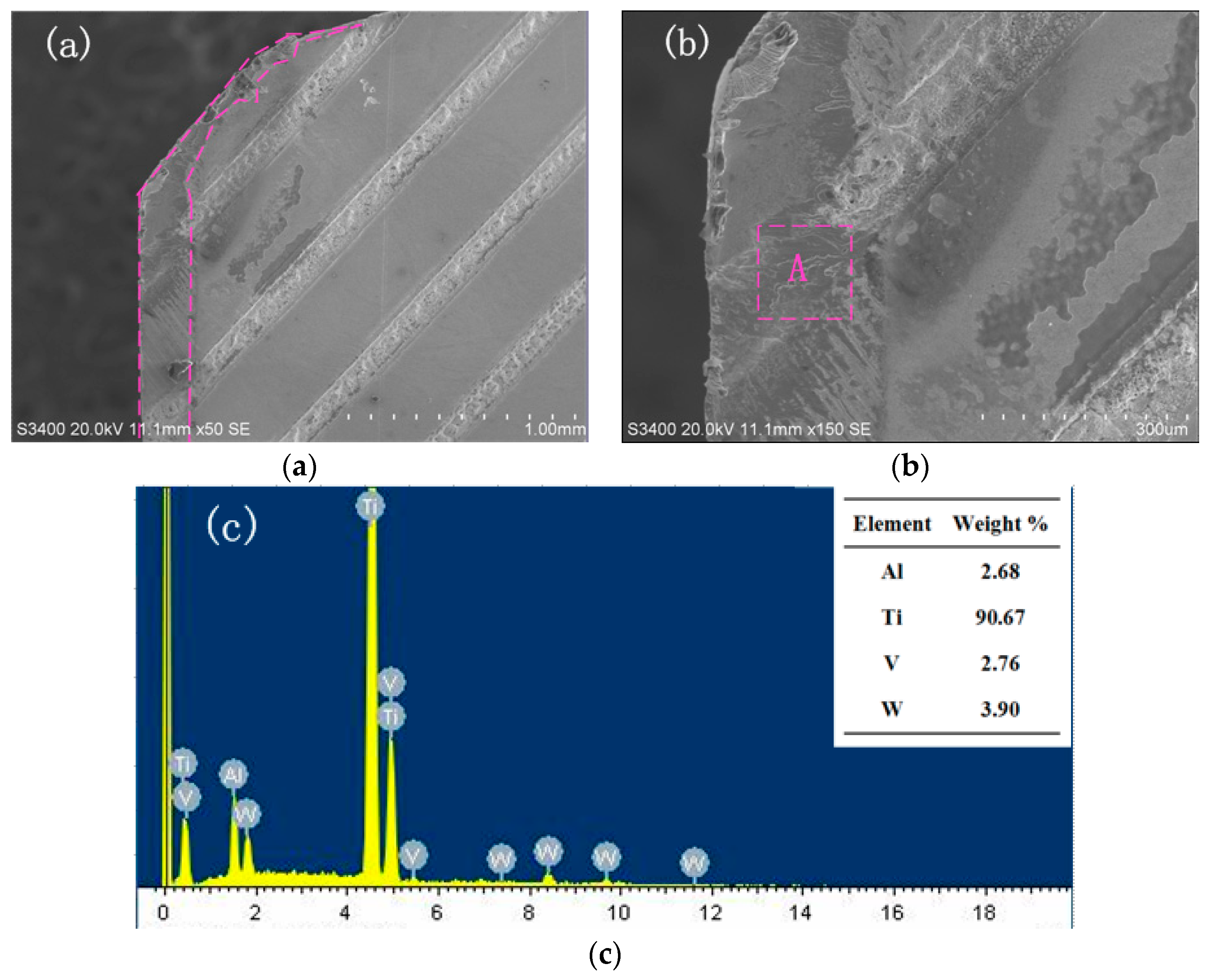

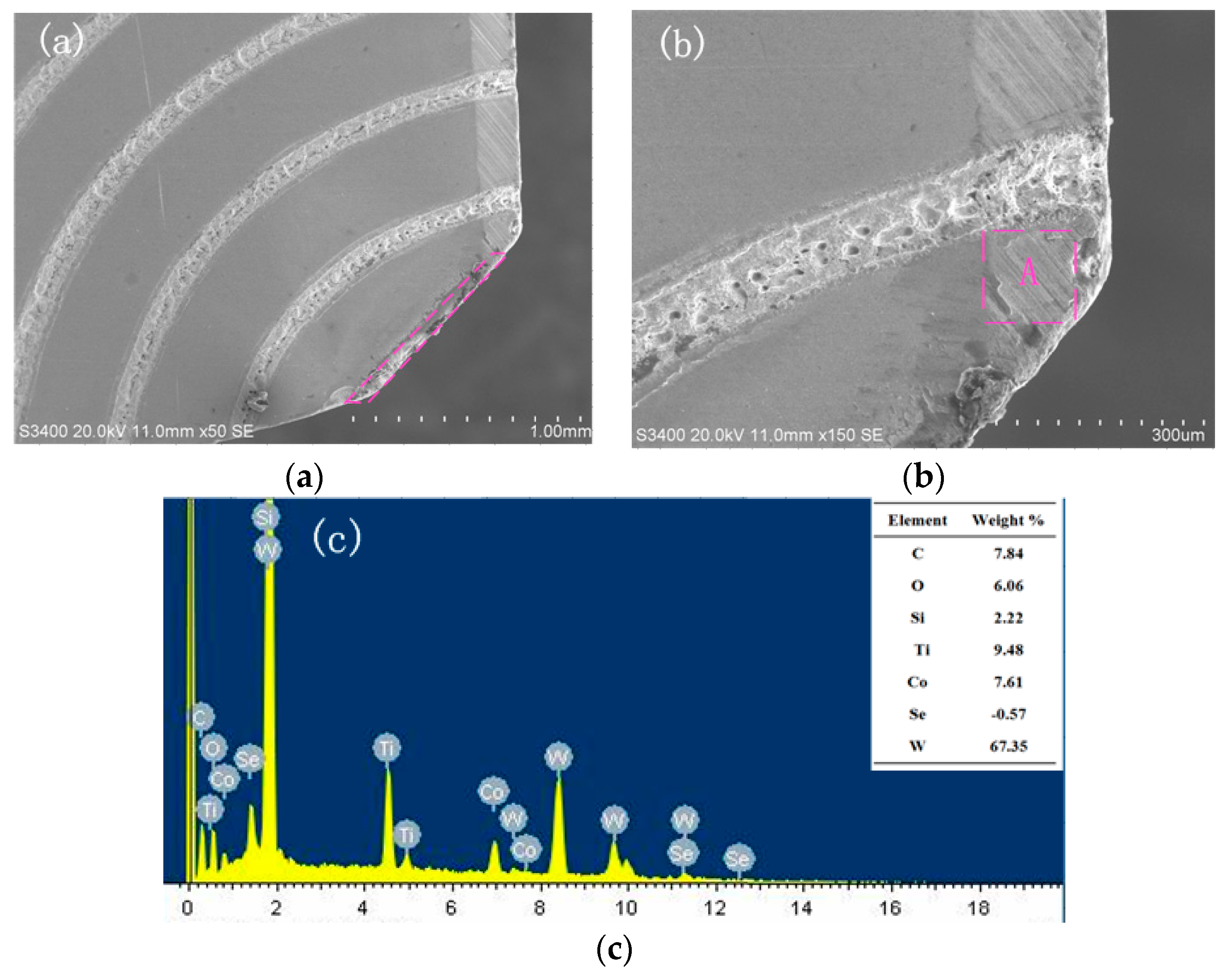

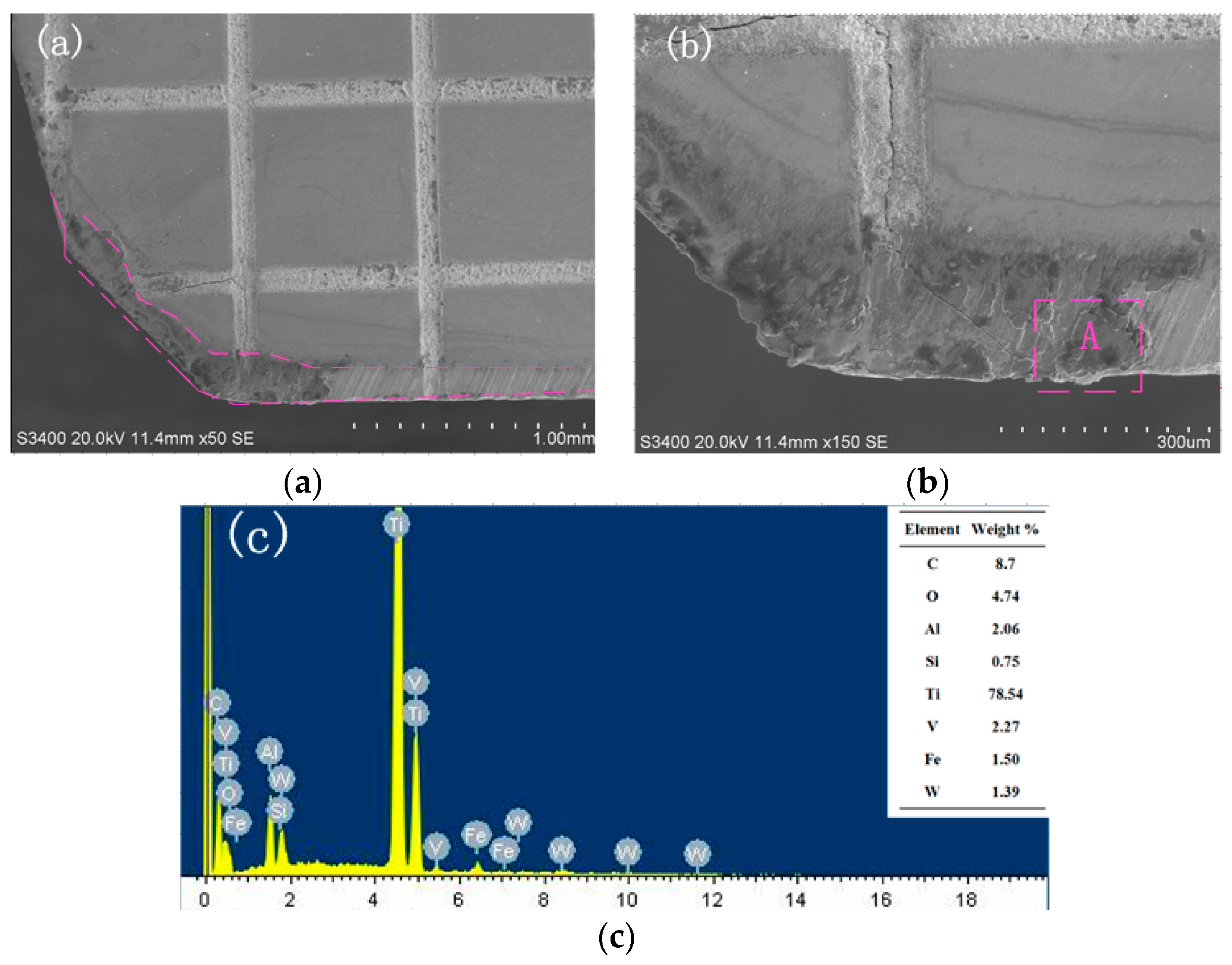

3.3. Effect of Tool Type on the Wear Morphology of the Rake Face

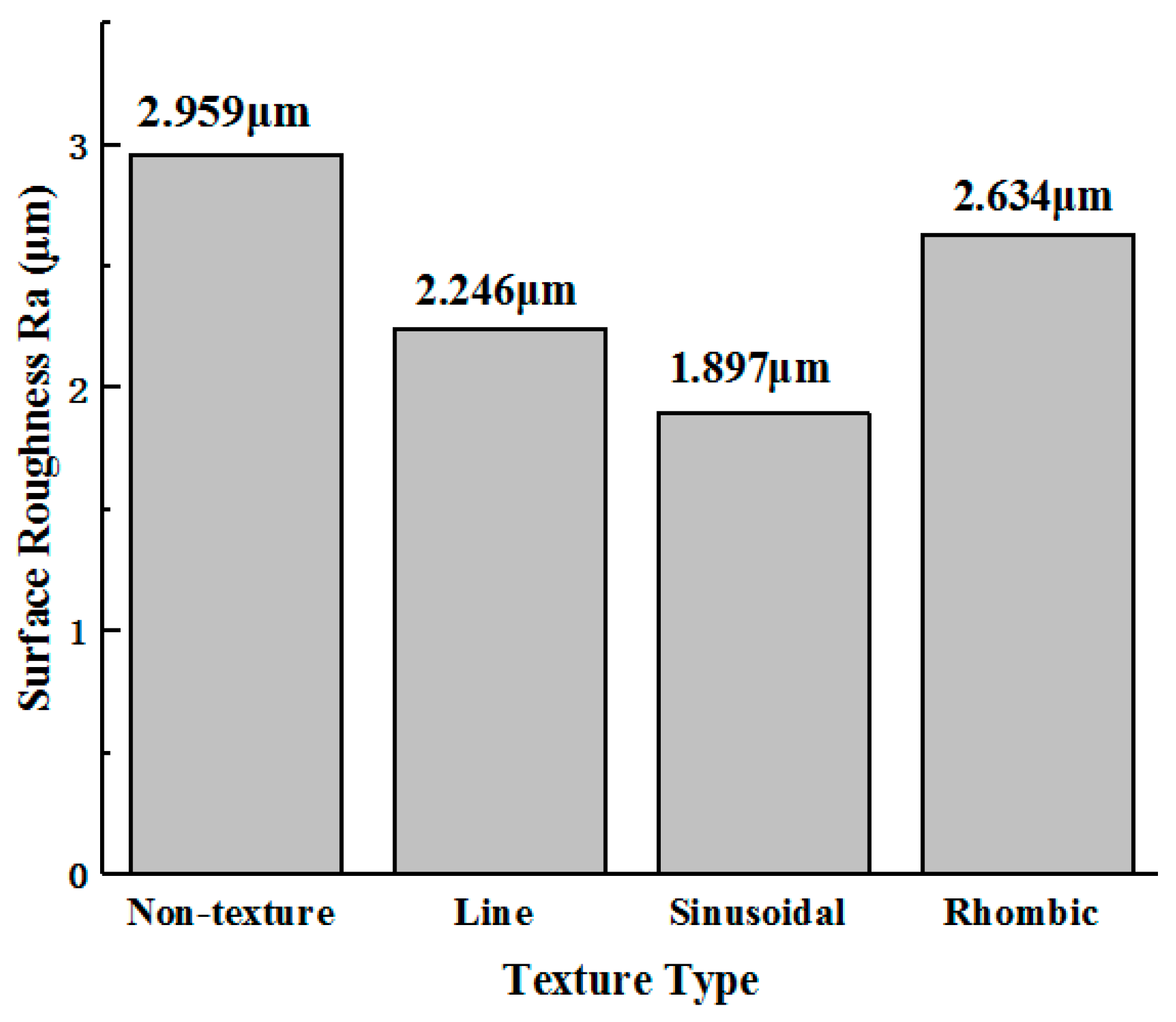

3.4. Effect of Tool Type on the Machined Surface Roughness

4. Conclusions

- (1)

- Under the same lubrication condition, three types of texture on the tool rake face were all effective in reducing cutting force and tool wear. Among the three types of textured tools, the sinusoidal textured tool caused the best cutting performance, followed by the line textured tool and rhombic textured tools.

- (2)

- The decrease of main cutting force can reach up to 30.97% by using textured tools. The morphology of chips produced by textured tools is better than that produced by non-textured tools. The existence of the textures on the tool surface is beneficial for chip breaking.

- (3)

- On the rake face of the non-textured tool appears violent adhesive wear, while adhesive wear of the textured tool is weaker. The sinusoidal textured tool shows the best anti-adhesion effect among the four kinds of tools.

- (4)

- The roughness of the machined surface produced by textured tools is significantly lower than that of the non-textured tool. Titanium alloy machined by the sinusoidal textured tool has the lowest surface roughness, which reduced by 35.8% compared with that of the non-texture tool.

Author Contributions

Funding

Conflicts of Interest

References

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, C.J. State of the Art in Beta Titanium Alloys for Airframe Applications. JOM 2015, 67, 1281–1303. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Liu, S.F.; Wang, L.Q. Surface Modification of Biomedical Titanium Alloy: Micromorphology, Microstructure Evolution and Biomedical pplications. Coatings 2019, 9, 249. [Google Scholar] [CrossRef] [Green Version]

- Wirwicki, M.; Pejkowski, L.; Topolinski, T. Fatigue Testing of Titanium Alloy Ti6Al4V Used in Medical Devices. Solid State Phenom. 2016, 250, 250–254. [Google Scholar] [CrossRef]

- Sui, H.; Zhang, X.Y.; Jiang, D.Y.; Jiang, X.G.; Wu, R.B. Feasibility study of high-speed ultrasonic vibration cutting titanium alloy. J. Mater. Process. Technol. 2017, 247, 111–120. [Google Scholar] [CrossRef]

- Trabelsi, S.; Morel, A.; Germain, G.; Bouaziz, Z. Tool wear and cutting forces under cryogenic machining of titanium alloy (Ti17). Int. J. Adv. Manuf. Technol. 2017, 91, 1493–1505. [Google Scholar] [CrossRef] [Green Version]

- Waqar, S.; Asad, S.; Ahmad, S.; Abbas, C.A.; Elahi1, H. Effect of Drilling Parameters on Hole Quality of Ti-6Al-4V Titanium Alloy in Dry Drilling. Mater. Sci. Forum 2016, 880, 33–36. [Google Scholar] [CrossRef]

- Ramskogler, C.; Warchomicka, F.; Mostofi, S.; Weinbergb, A.; Sommitscha, C. Innovative surface modification of Ti6Al4V alloy by electron beam technique for biomedical application. Mater. Sci. Eng. C Mater. 2017, 78, 105–113. [Google Scholar] [CrossRef]

- Patil, S.; Jadhav, S.; Kekade, S.; Supare, A.; Powar, A.; SinghDr, R.K.P. The Influence of Cutting Heat on the Surface Integrity during Machining of Titanium Alloy Ti6Al4V. Procedia Manuf. 2016, 5, 857–869. [Google Scholar] [CrossRef] [Green Version]

- Pervaiz, S.; Rashid, A.; Deiab, I.; Nicolescu, C.M. An experimental investigation on effect of minimum quantity cooling lubrication (MQCL) in machining titanium alloy (Ti6Al4V). Int. J. Adv. Manuf. Techol. 2016, 87, 1371–1386. [Google Scholar] [CrossRef]

- Yang, S.C.; He, C.S.; Zheng, M.L.; Wan, Q.; Zhang, Y.H. Temperature Field of Tool Engaged Cutting Zone for Milling of Titanium Alloy with Ball-End Milling. Micromachines 2018, 9, 672. [Google Scholar] [CrossRef] [Green Version]

- Ulas, H.B.; Ozkan, M.T.; Bilgin, M.; Sezer, H.K. Performance of coated and uncoated carbide/cermet cutting tools during turning. Mater. Test. 2018, 60, 893–901. [Google Scholar] [CrossRef]

- Li, B.X.; Zhang, T.; Zhang, S. Deep cryogenic treatment of carbide tool and its cutting performances in hard milling of AISI H13 steel. Procedia CIRP 2018, 71, 35–40. [Google Scholar] [CrossRef]

- Matsuoka, H.; Ryu, T.; Ono, H.; Nakae, T.; Kubo, A.; Qiu, H. Influence of Water-Miscible Cutting Fluids on Tool Wear Behavior of Different Coated HSS Tools in Hobbing. Mech. Eng. Res. 2018, 8, 10–24. [Google Scholar] [CrossRef]

- Singh, A.; Patel, D.S.; RamkumarJ Balani, K. Single step laser surface texturing for enhancing contact angle and tribological properties. Int. J. Adv. Manuf. Techol. 2019, 100, 1253–1267. [Google Scholar] [CrossRef]

- Jiang, S.Q.; Xu, H.G.; Jiang, Z.F.; Li, R.X.; Li, B.K.; Xu, P.; Xu, Z.M. Study on Surface Micro-texture of Characterization and Laser Processing on 45 Steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 490, 052035. [Google Scholar] [CrossRef]

- Zhang, J.J.; Yang, D.H.; Rosenkranz, A.; Zhang, J.G.; Zhao, L.; Song, C.W.; Yan, Y.D.; Sun, T. Laser Surface Texturing of Stainless Steel−Effect of Pulse Duration on Texture’s Morphology and Frictional Response. Adv. Eng. Mater. 2019, 21, 1801016. [Google Scholar] [CrossRef]

- Bai, J.X.; Bai, Q.S.; Tong, Z. Dislocation Dynamics-Based Modeling and Simulations of Subsurface Damages Microstructure of Orthogonal Cutting of Titanium Alloy. Micromachines 2017, 8, 309. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Sasi, R.; Kanmani Subbu, S.; Muralidharan, B. Electric discharge texturing of HSS cutting tool and its performance in dry machining of aerospace alloy. J. Braz. Soc. Mech. Sci. 2019, 41, 152. [Google Scholar] [CrossRef]

- Pang, M.H.; Liu, X.J.; Liu, K. Effect of surface texture on the friction of WC-TiC/Co cemented carbide under a water-miscible cutting fluid environment. Ind. Lubr. Tribol. 2018, 70, 1350–1359. [Google Scholar] [CrossRef]

- Olleak, A.; Ozel, T. 3D Finite Element Modeling Based Investigations of Micro-textured Tool Designs in Machining Titanium Alloy Ti-6Al-4V. Procedia Manuf. 2017, 10, 536–545. [Google Scholar] [CrossRef]

- Feng, Y.H.; Zhang, J.Y.; Wang, L.; Zhang, W.Q.; Tian, Y.; Kong, X. Fabrication techniques and cutting performance of micro-textured self-lubricating ceramic cutting tools by in-situ forming of Al2O3-TiC. Int. J. Refract. Met. Hard Mater. 2017, 68, 121–129. [Google Scholar] [CrossRef]

- Hu, Y.T.; He, Y.Y.; Wang, W. The Influence of Surface Texture on Abrasive Wear. Key Eng. Mater. 2019, 4812, 33–40. [Google Scholar] [CrossRef]

- Lian, Y.S.; Mu, C.L.; Wang, L.; Yao, B.; Deng, J.X.; Lei, S.T. Numerical simulation and experimental investigation on friction and wear behaviour of micro-textured cemented carbide in dry sliding against TC4 titanium alloy balls. Int. J. Refract. Met. Hard Mater. 2018, 73, 121–131. [Google Scholar] [CrossRef]

- Ren, J.; Liu, X.B.; Lu, X.L.; Yu, P.C.; Zhu, G.X.; Chen, Y.; Xu, D. Microstructure and tribolo-gical properties of self-lubricating antiwear composite coating on Ti6Al4 V alloy. Surf. Eng. 2017, 33, 20–26. [Google Scholar] [CrossRef]

- Ranjan, P.; Hiremath, S.S. Role of textured tool in improving machining performance: A review. J. Manuf. Process. 2019, 43, 47–73. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Deng, J.X.; Li, S.P.; Yue, H.Z.; Meng, R.; Gao, P. Cutting performance and wear characteristics of Al2O3/TiC ceramic cutting tools with WS2/Zr soft-coatings and nano-textures in dry cutting. Wear 2014, 318, 12–26. [Google Scholar] [CrossRef]

- Behera, B.C.; Ghosh, S.; Rao, P.V. Modeling of cutting force in MQL machining environment considering chip tool contact friction. Tribol. Int. 2018, 117, 283–295. [Google Scholar] [CrossRef]

- Dinesh, S.; Senthilkumar, V.; Asokan, P. Experimental studies on the cryogenic machining of biodegradable ZK60 Mg alloy using micro-textured tools. Mater. Manuf. Process. 2017, 32, 979–987. [Google Scholar] [CrossRef]

- Kishor, K.G.; Mamilla, R.S.; Rokkham, P.K.R. Tribo-mechanical and surface morphological comparison of untextured, mechanical micro-textured (M mu T), and coated-M mu T cutting tools during machining. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 95–111. [Google Scholar]

- Vasumathy, D.; Meena, A. Influence of micro scale textured tools on tribological properties at tool-chip interface in turning AISI 316 austenitic stainless steel. Wear 2017, 376, 1747–1758. [Google Scholar] [CrossRef]

- Bahi, S.; Nouari, M.; Moufki, A.; ElMansori, M.; Molinari, A. Hybrid modelling of sliding–sticking zones at the tool–chip interface under dry machining and tool wear analysis. Wear 2012, 286, 45–54. [Google Scholar] [CrossRef]

- Bahi, S.; List, G.; Sutter, G. Analysis of adhered contacts and boundary conditions of the secondary shear zone. Wear 2015, 330, 608–617. [Google Scholar] [CrossRef]

| Material | Hardness (HRA) | Density (g/cm3) | Elastic Modulus (GPa) | Bending Strength (MPa) | Thermal Conductivity (W/mk) |

|---|---|---|---|---|---|

| YG8 | 89 | 14.6 | 630 | 1840 | 79.6 |

| Rake Angle γo | Inclination Angle λs | Clearance Angle αo | Side Cutting Edge Angle kr |

|---|---|---|---|

| 6° | −6° | 11° | 75° |

| Wave Length (nm) | Frequency (KHz) | Power (W) | Pulse Width (ns) | Scanning Speed (mm/s) | Repetitions |

|---|---|---|---|---|---|

| 1064 | 20 | 40 | 20 | 100 | 200 |

| Number | Cutting Speed v (m/min) | Cutting Depth ap (mm) | Feed f (mm/r) | Cutting Time (s) |

|---|---|---|---|---|

| 1 | 22.7 | 0.3 | 0.2 | 160 |

| 2 | 47.7 | 0.3 | 0.2 | 160 |

| 3 | 71.9 | 0.3 | 0.2 | 160 |

| 4 | 90.4 | 0.3 | 0.2 | 160 |

| 5 | 47.7 | 0.1 | 0.2 | 160 |

| 6 | 47.7 | 0.2 | 0.2 | 160 |

| 7 | 47.7 | 0.3 | 0.2 | 160 |

| 8 | 47.7 | 0.4 | 0.2 | 160 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, K.; Yang, F.; Zhang, N.; Liu, Q.; Jiang, F. Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy. Micromachines 2020, 11, 137. https://doi.org/10.3390/mi11020137

Zheng K, Yang F, Zhang N, Liu Q, Jiang F. Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy. Micromachines. 2020; 11(2):137. https://doi.org/10.3390/mi11020137

Chicago/Turabian StyleZheng, Kairui, Fazhan Yang, Na Zhang, Qingyu Liu, and Fulin Jiang. 2020. "Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy" Micromachines 11, no. 2: 137. https://doi.org/10.3390/mi11020137

APA StyleZheng, K., Yang, F., Zhang, N., Liu, Q., & Jiang, F. (2020). Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy. Micromachines, 11(2), 137. https://doi.org/10.3390/mi11020137