Magnetic Domain Transition of Adjacent Narrow Thin Film Strips with Inclined Uniaxial Magnetic Anisotropy

Abstract

:1. Introduction

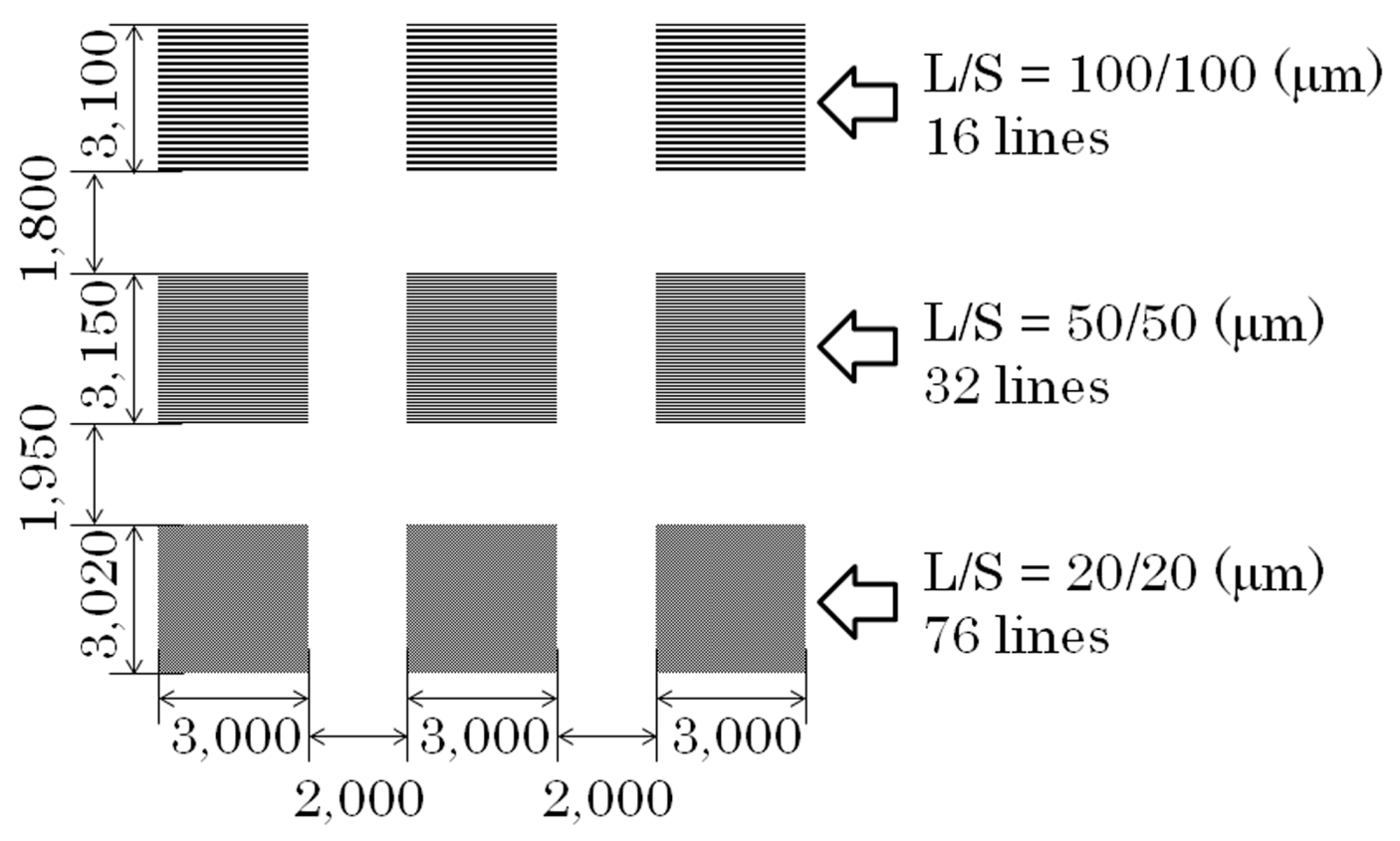

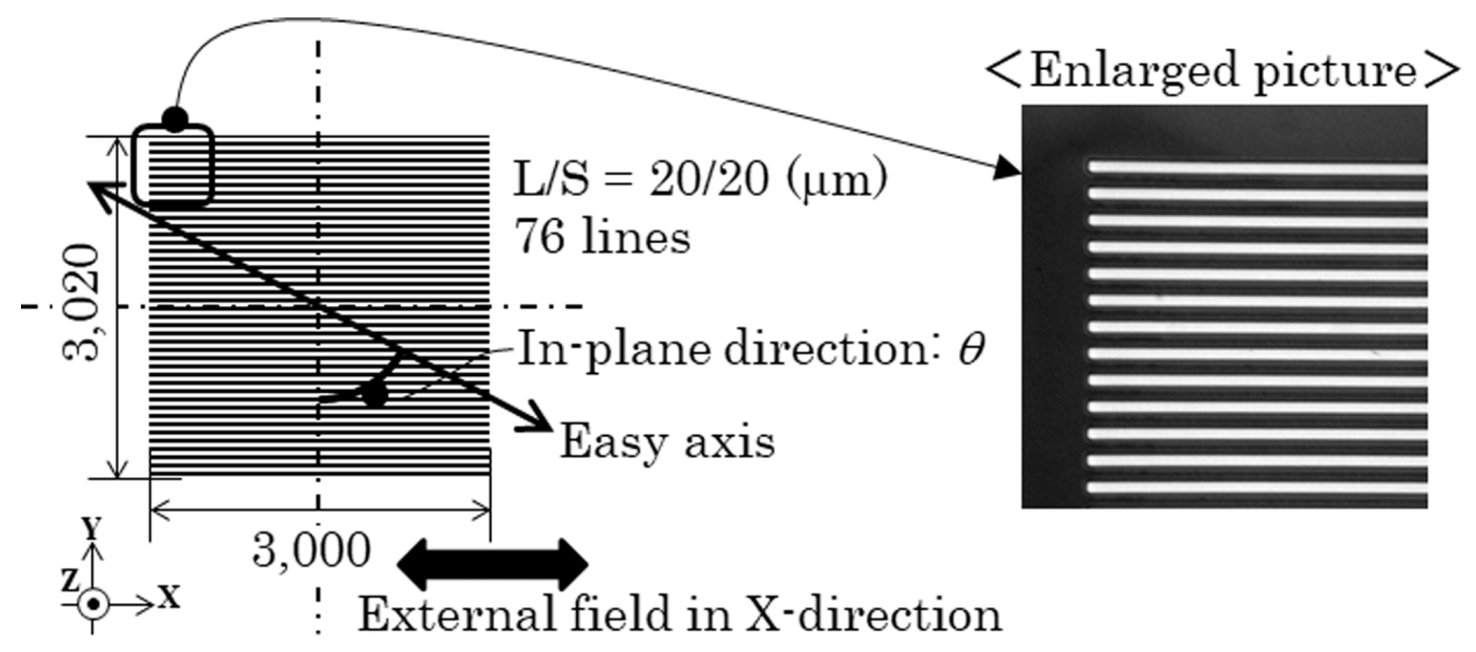

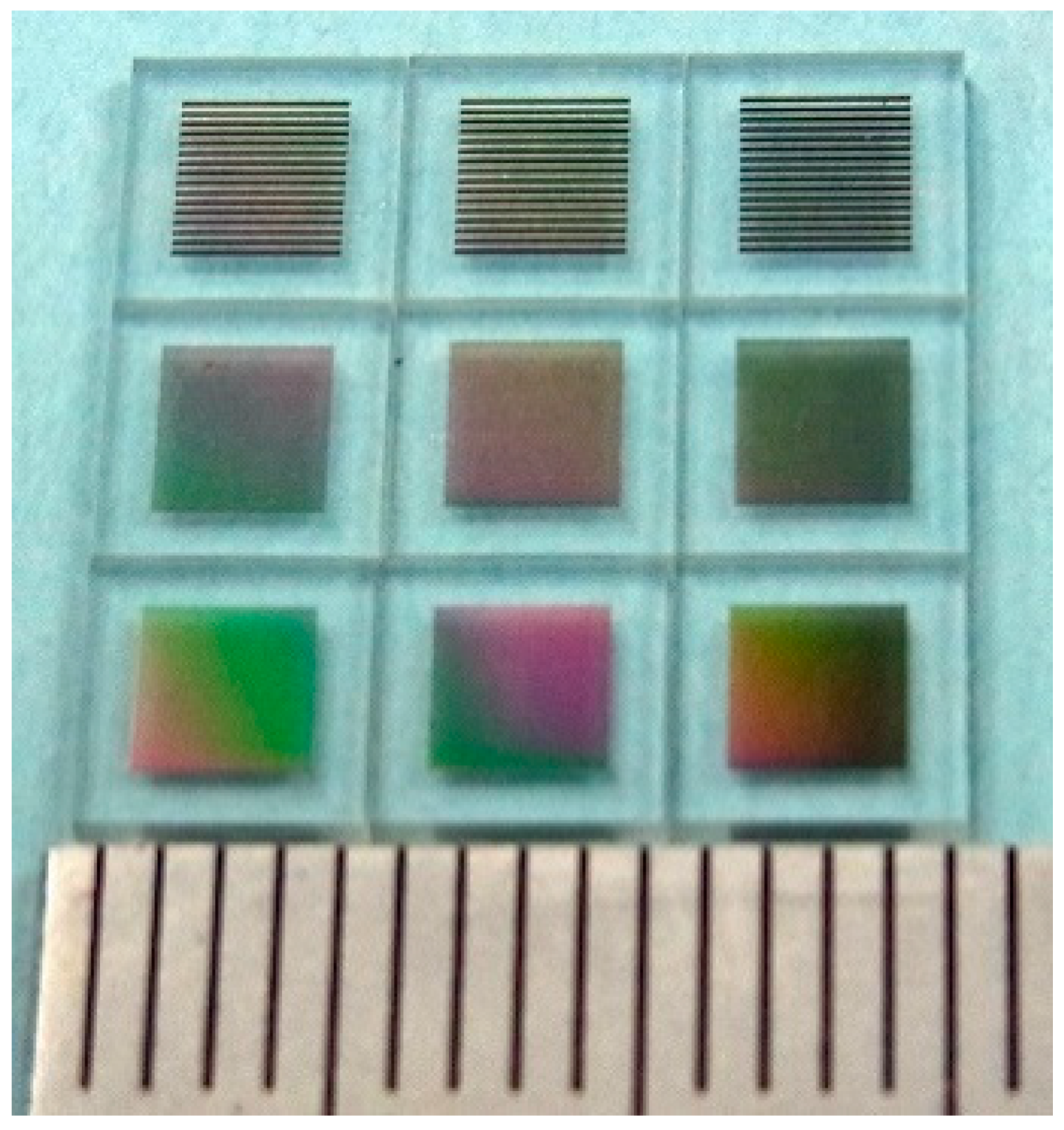

2. Experimental Procedure

3. Results

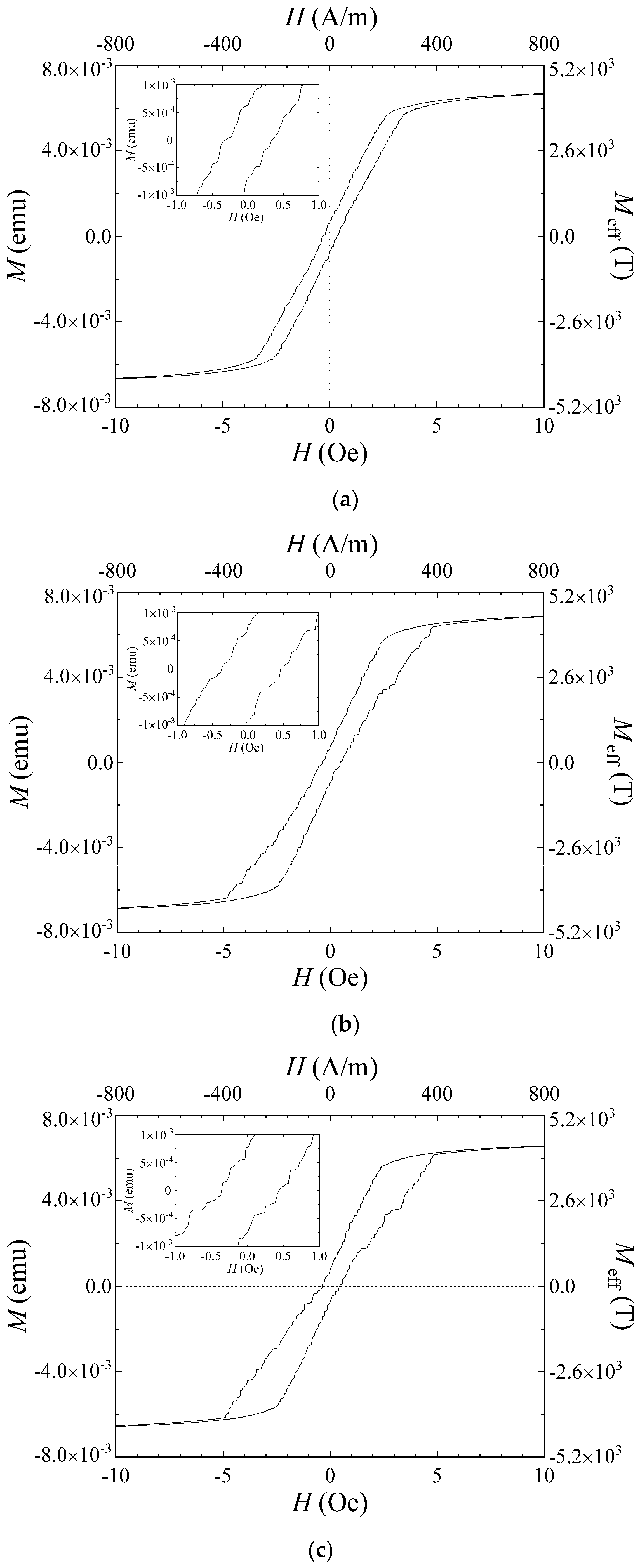

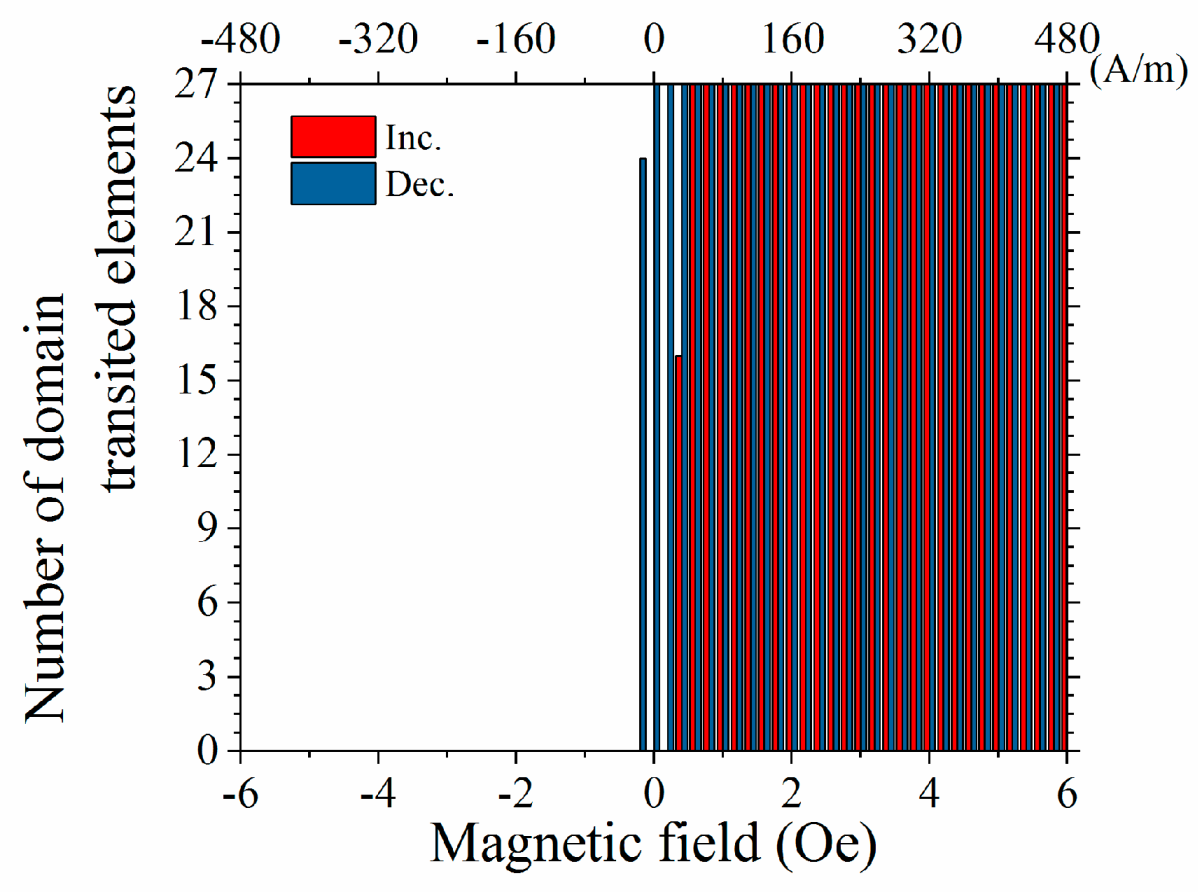

3.1. Magnetization Process of the Many-Body Elements

- (a)

- θ = 61°: The initial single domain in the − direction of whole elements as shown in the photo view change to the ILLD gradually and individually with the increase in the applied field. After the domain of all elements changes to the ILLD, then the width of the area of the striped domain gradually changes and, finally, the stripe of the ILLD is erased and all elements change to the single domain in the + direction. When the elements are all in the state of a single domain, +, the many-body element is getting magnetically saturated.

- (b)

- θ = 71°: The initial single domain in the − direction of whole elements as shown in the photo view change to the single domain in + gradually and individually with the increase in the applied field. When the elements are all in the state of single domain +, the many-body element is getting magnetically saturated.

- (c)

- θ = 90°: The domain transition was the same as the one with θ = 71°.

3.2. Comparison with Individual Element

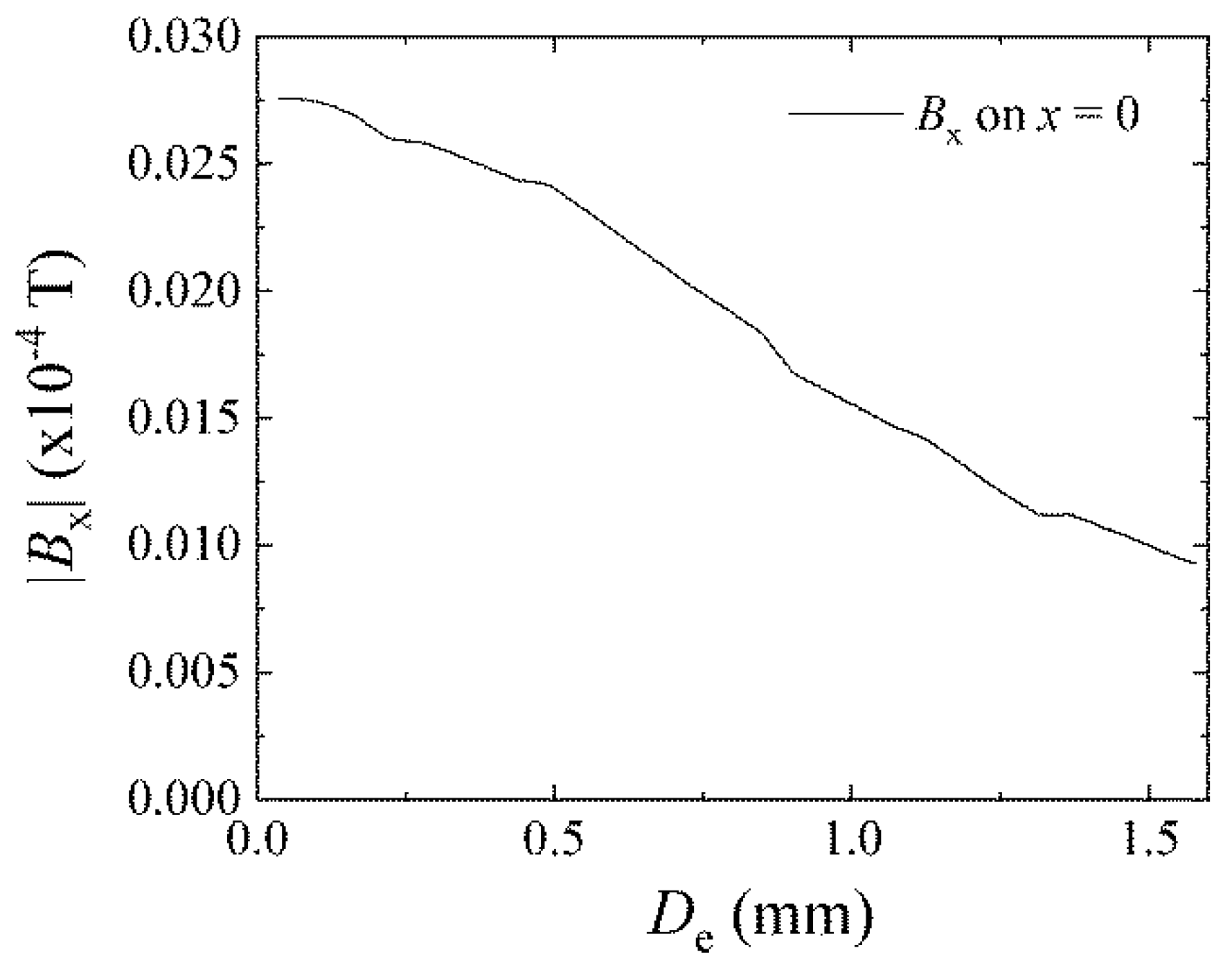

3.3. Effect of Distributed Normal Field

4. Discussion

5. Summary

Funding

Acknowledgments

Conflicts of Interest

References

- Hale, M.E.; Fuller, H.W.; Rubinstein, H. Magnetic Domain Observations by Electron Microscopy. J. Appl. Phys. 1959, 30, 789. [Google Scholar] [CrossRef]

- Fowler, C.A., Jr.; Fryer, E.M.; Stevens, J.R. Magnetic Domains in Evaporated Thin Films of Nickel-Iron. Phys. Rev. 1956, 104, 645. [Google Scholar] [CrossRef]

- Soares, M.M.; de Biasi, E.; Coelho, L.N.; Santos, M.C.d.; de Menezes, F.S.; Knobel, M.; Sampaio, L.C.; Garcia, F. Magnetic vortices in tridimensional nanomagnetic caps observed using transmission electron microscopy and magnetic force microscopy. Phys. Rev. B 2008, 77, 224405. [Google Scholar] [CrossRef] [Green Version]

- Park, D.G.; Song, H.; Park, C.Y.; Angani, C.S.; Kim, C.G.; Cheong, Y.M. Analysis of the Domain Wall Motion in the Ion Irradiated Amorphous Ribbon. IEEE Trans. Magn. 2009, 10, 4475–4477. [Google Scholar] [CrossRef]

- Nishikubo, A.; Ito, S.; Mifune, T.; Matsuo, T.; Kaido, C.; Takahashi, Y.; Fujiwara, K. Efficient multiscale magnetic-domain analysis of iron-core material under mechanical stress. AIP Adv. 2018, 8, 056617. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E. On the Theory of the Dispersion of Magnetic Permeability in Ferromagnetic Bodies. Phys. Z. Sowjetunion 1935, 8, 153. [Google Scholar]

- Hubert, A.; Schäfer, R. Magnetic Domains; Springer: New York, NY, USA, 1998. [Google Scholar]

- Takezawa, M.; Yamasaki, J. Dynamic domain observation in narrow thin films. IEEE Trans. Magn. 2001, 37, 2034–2037. [Google Scholar] [CrossRef]

- Sun, Z.G.; Kuramochi, H.; Mizuguchi, M.; Takano, F.; Semba, Y.; Akinaga, H. Magnetic properties and domain structures of FeSiB thin films. Surf. Sci. 2004, 556, 33–38. [Google Scholar] [CrossRef]

- Shin, J.; Kim, S.H.; Hashi, S.; Ishiyama, K. Analysis of thin-film magneto-impedance sensor using the variations in impedance and the magnetic domain structure. J. Appl. Phys. 2014, 115, E507. [Google Scholar] [CrossRef]

- Morikawa, T.; Nishibe, Y.; Yamadera, H.; Nonomura, Y.; Takeuchi, M.; Taga, Y. Giant magneto-impedance effect in layered thin films. IEEE Trans. Magn. 1997, 33, 4367–4372. [Google Scholar] [CrossRef]

- Takezawa, M.; Kikuchi, H.; Yamaguchi, M.; Arai, K.I. Miniaturization of high-frequency carrier-type thin-film magnetic field sensor using laminated film. IEEE Trans. Magn. 2000, 36, 3664–3666. [Google Scholar] [CrossRef]

- Zhong, Z.; Zhang, H.; Jing, Y.; Tang, X.; Liu, S. Magnetic microstructure and magnetoimpedance effect in NiFe/FeAlN multilayer films. Sens. Actuators A Phys. 2008, 141, 29–33. [Google Scholar] [CrossRef]

- Kikuchi, H.; Ajiro, N.; Yamaguchi, M.; Arai, K.I.; Takezawa, M. Miniaturized high-frequency carrier-type thin-film magnetic field sensor with high sensitivity. IEEE Trans. Magn. 2001, 37, 2042–2044. [Google Scholar] [CrossRef]

- Shin, J.; Miwa, Y.; Kim, S.H.; Hashi, S.; Ishiyama, K. Observation of the Magnetic Properties According to Changes in the Shape of Thin-Film Giant Magnetoimpedance Sensor. IEEE Trans. Magn. 2014, 50, 4005603. [Google Scholar] [CrossRef]

- Wang, M.; Cao, Q.P.; Liu, S.Y.; Wang, X.D.; Zhang, D.X.; Fang, Y.Z.; He, X.W.; Chang, C.T.; Tao, Q.; Jiang, J.Z. The effect of thickness and annealing treatment on microstructure and magnetic properties of amorphous Fe-Si-B-P-C thin films. J. Non-Cryst. Solids 2019, 505, 52–61. [Google Scholar] [CrossRef]

- Svalov, A.V.; Aseguinolaza, I.R.; Garcia-Arribas, A.; Orue, I.; Barandiaran, J.M.; Alonso, J.; FernÁndez-Gubieda, M.L.; Kurlyandskaya, G.V. Structure and Magnetic Properties of Thin Permalloy Films Near the Transcritical State. IEEE Trans. Magn. 2010, 46, 333–336. [Google Scholar] [CrossRef]

- Kikuchi, H.; Sumida, C. Observation of Static Domain Structures of Thin-Film Magnetoimpedance Elements with DC Bias Current. IEEE Trans. Magn. 2019, 55, 4001405. [Google Scholar] [CrossRef]

- Kilic, U.; Garcia, C.; Ross, C.A. Tailoring the Asymmetric Magnetoimpedance Response in Exchange-Biased. Phys. Rev. Appl. 2018, 10, 034043. [Google Scholar] [CrossRef] [Green Version]

- Dong, C.; Chen, S.; Hsu, T.Y. A simple model of giant magneto-impedance effect in amorphous thin films. J. Magn. Magn. Mater. 2002, 250, 288–294. [Google Scholar] [CrossRef]

- Matsuo, T. Magnetization process analysis using a simplified domain structure model. J. Appl. Phys. 2011, 109, 07D332. [Google Scholar] [CrossRef] [Green Version]

- Nakai, T.; Abe, H.; Yabukami, S.; Arai, K.I. Impedance property of thin film GMI sensor with controlled inclined angle of stripe magnetic domain. J. Magn. Magn. Mater. 2005, 290–291, 1355–1358. [Google Scholar] [CrossRef]

- Nakai, T.; Ishiyama, K.; Yamasaki, J. Analysis of steplike change of impedance for thin-film giant magnetoimpedance element with inclined stripe magnetic domain based on magnetic energy. J. Appl. Phys. 2007, 101, 09N106. [Google Scholar] [CrossRef] [Green Version]

- Nakai, T.; Takada, K.; Ishiyama, K. Existence of Three Stable States of Magnetic Domain for the Stepped Giant Magneto-impedance Element and Proposal for Sensor with Memory Function. IEEE Trans. Magn. 2009, 45, 3499–3502. [Google Scholar] [CrossRef]

- Nakai, T.; Arai, K.I.; Yamasaki, J.; Yamaguchi, M.; Ishiyama, K.; Yabukami, S.; Takada, K.; Abe, H. Correlation of Domain Structure with Magneto-Impedance Effect, in Magnetic Thin Films; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2011; pp. 175–232. [Google Scholar]

- Nakai, T.; Ishiyama, K.; Yamasaki, J. Study of hysteresis for steplike giant magnetoimpedance sensor based on magnetic energy. J. Magn. Magn. Mater. 2008, 320, e958–e962. [Google Scholar] [CrossRef]

- Tejima, S.; Ito, S.; Mifune, T.; Matsuo, T.; Nakai, T. Magnetization analysis of stepped giant magneto impedance sensor using assembled domain structure model. Int. J. Appl. Electromagn. Mech. 2016, 52, 541–546. [Google Scholar] [CrossRef]

- Nakai, T.; Ishiyama, K. Impedance Variation with Subjecting to Normal Field for the Stepped Giant Magnetoimpedance Element. IEEE Trans. Magn. 2014, 50, 4000904. [Google Scholar] [CrossRef]

- Nakai, T. Magnetic Domain Observation of Stepped Giant Magneto-Impedance Sensor with Subjecting to Normal Magnetic Field. Proc. IEEE Sens. 2015, 2015, 1461–1464. [Google Scholar]

- Nakai, T. Magnetic domain transition controlled by distributed normal magnetic field for stepped magneto-impedance sensor. Int. J. Appl. Electromagn. Mech. 2019, 59, 105–114. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakai, T. Magnetic Domain Transition of Adjacent Narrow Thin Film Strips with Inclined Uniaxial Magnetic Anisotropy. Micromachines 2020, 11, 279. https://doi.org/10.3390/mi11030279

Nakai T. Magnetic Domain Transition of Adjacent Narrow Thin Film Strips with Inclined Uniaxial Magnetic Anisotropy. Micromachines. 2020; 11(3):279. https://doi.org/10.3390/mi11030279

Chicago/Turabian StyleNakai, Tomoo. 2020. "Magnetic Domain Transition of Adjacent Narrow Thin Film Strips with Inclined Uniaxial Magnetic Anisotropy" Micromachines 11, no. 3: 279. https://doi.org/10.3390/mi11030279