Effect of Au Film Thickness and Surface Roughness on Room-Temperature Wafer Bonding and Wafer-Scale Vacuum Sealing by Au-Au Surface Activated Bonding

Abstract

:1. Introduction

2. Experimental Methods

2.1. Room-Temperature Pressureless Wafer Bonding in Ambient Air

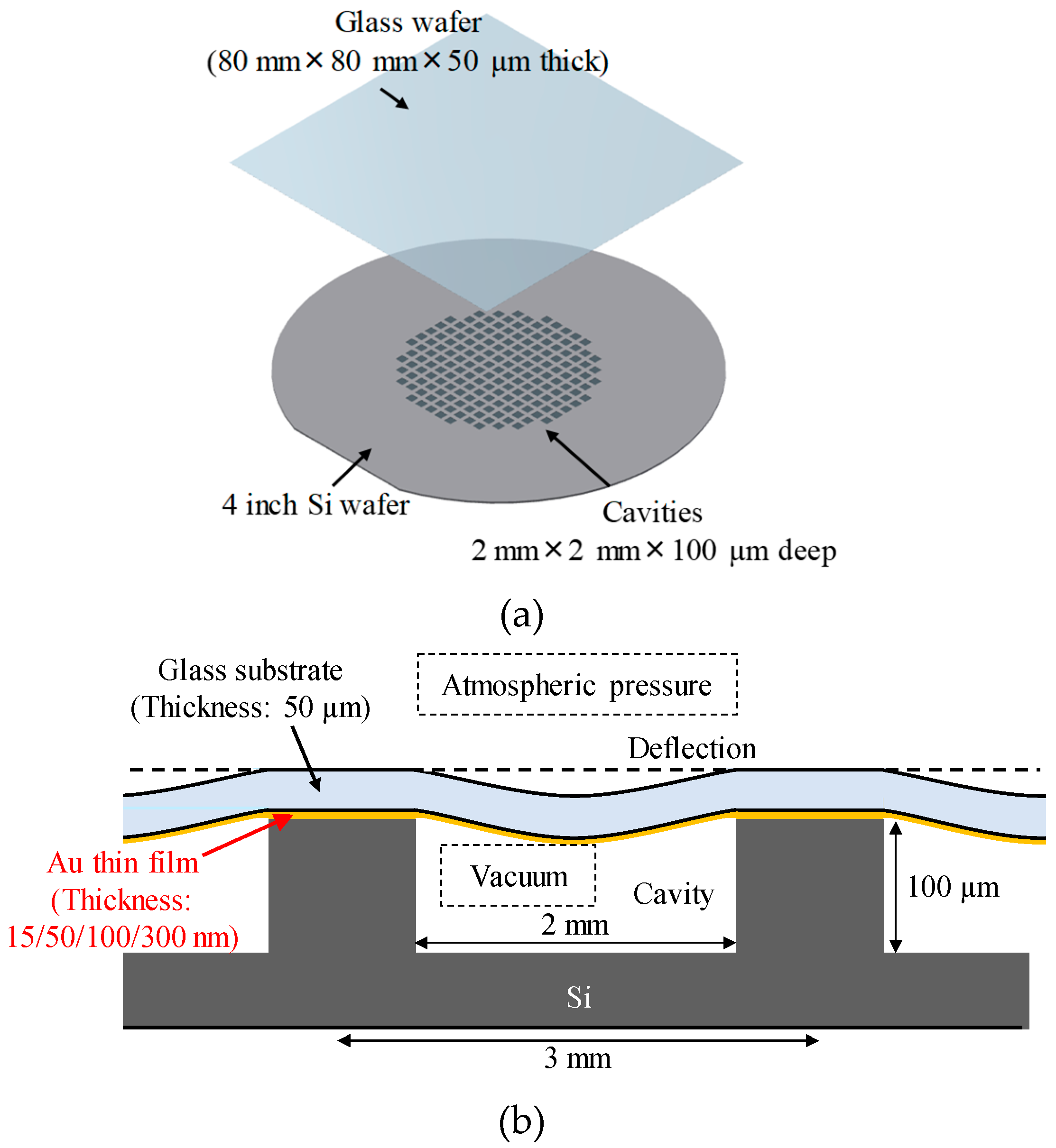

2.2. Room-Temperature Wafer Sealing in Vacuum

3. Results

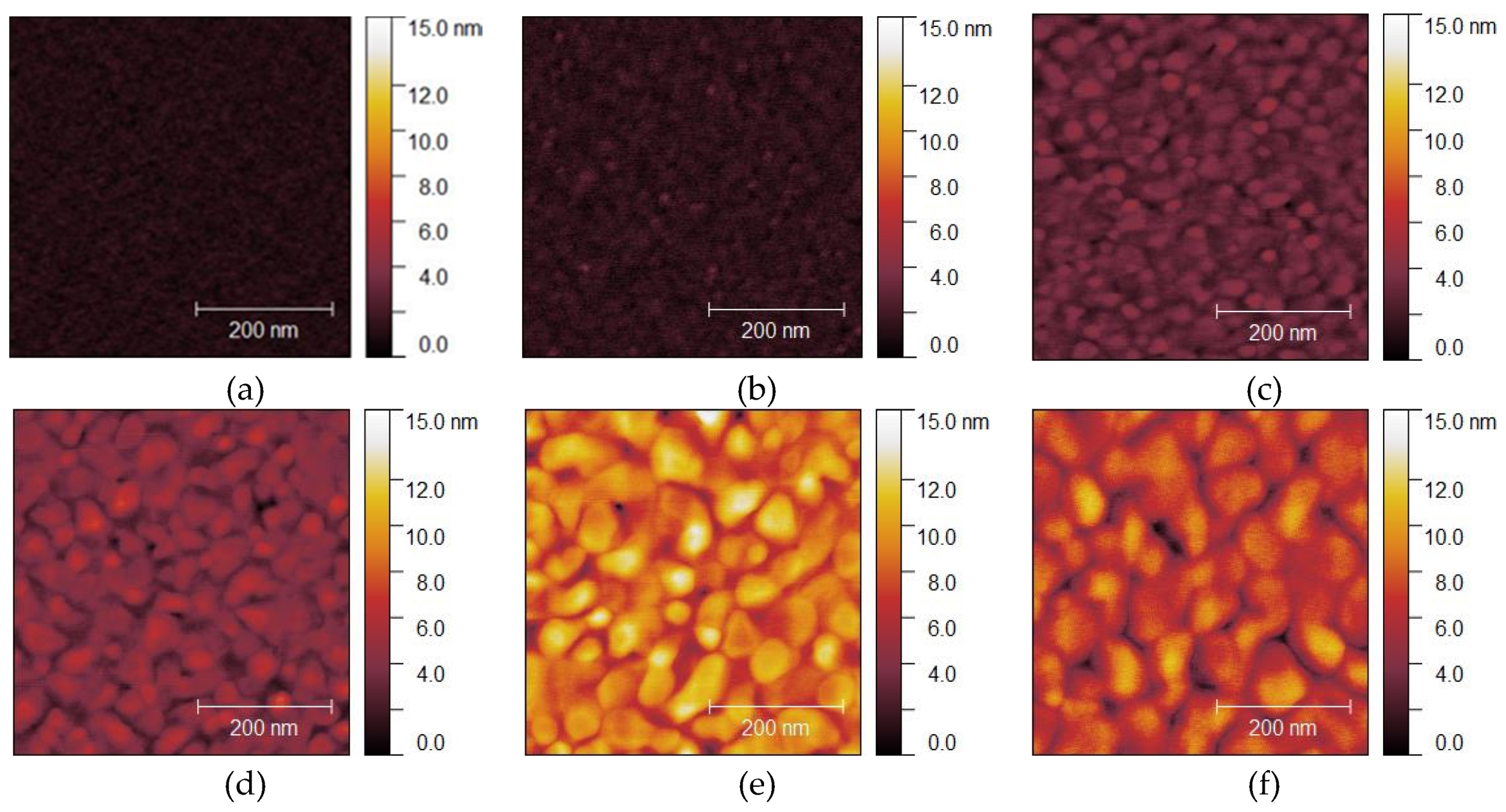

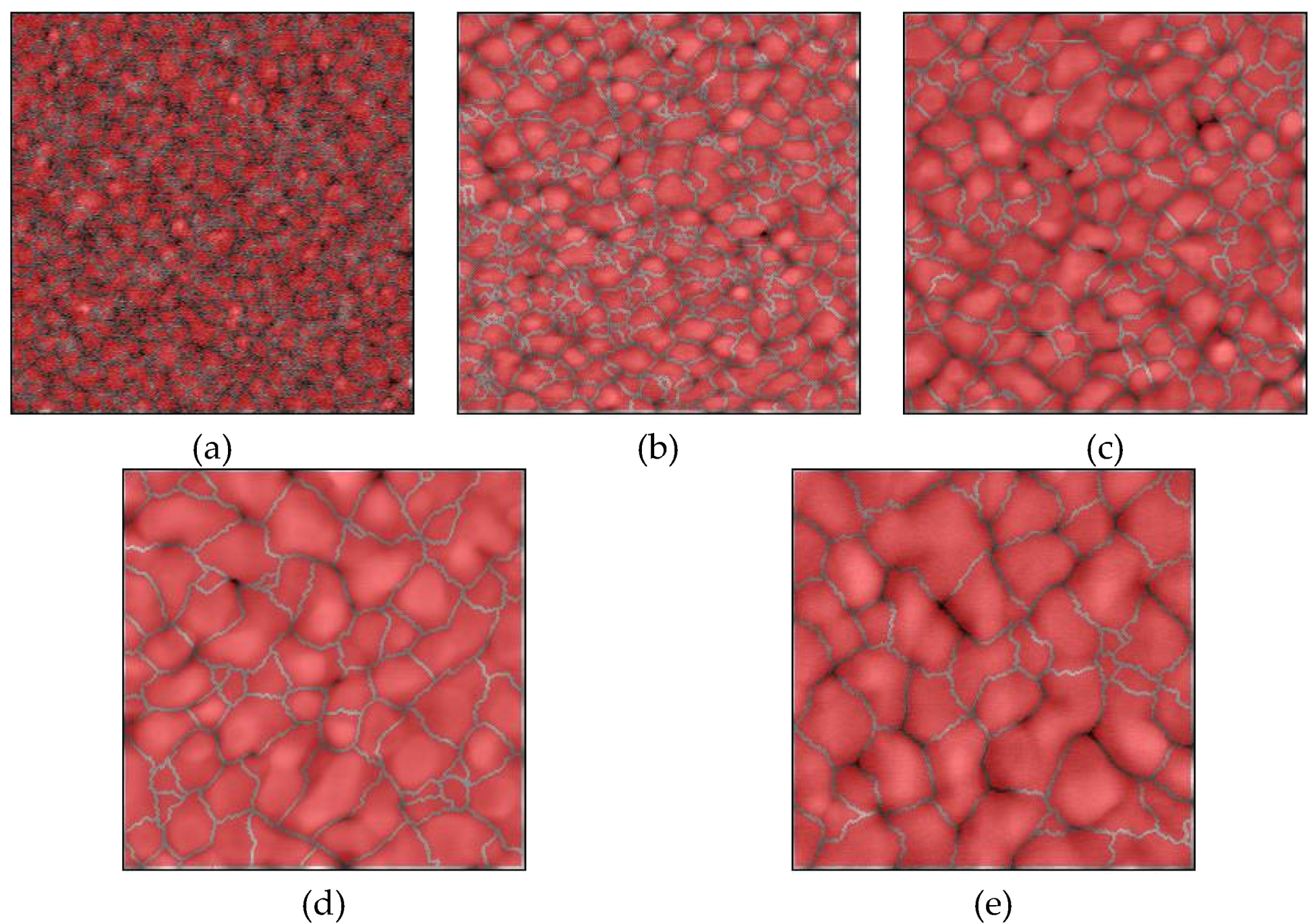

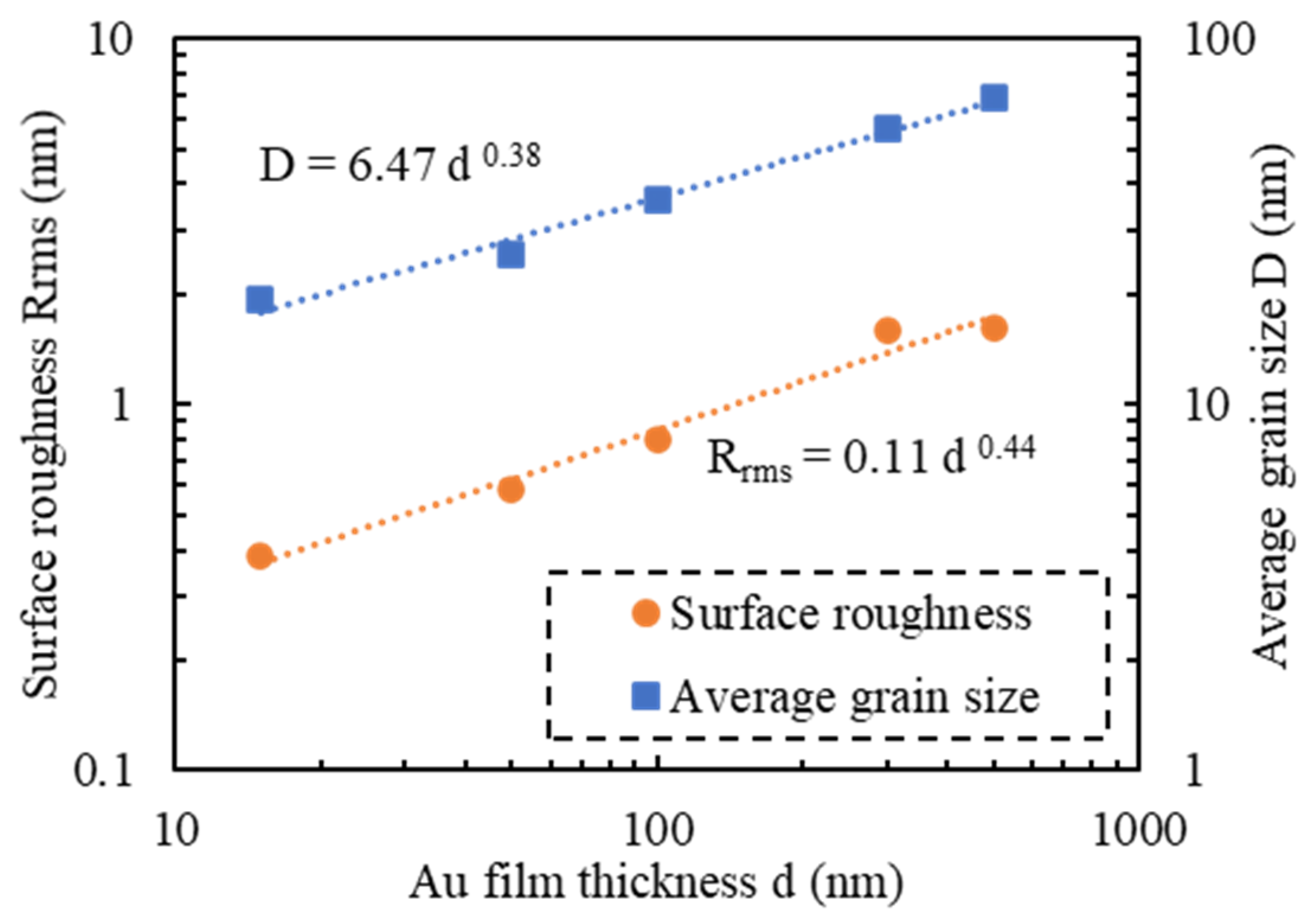

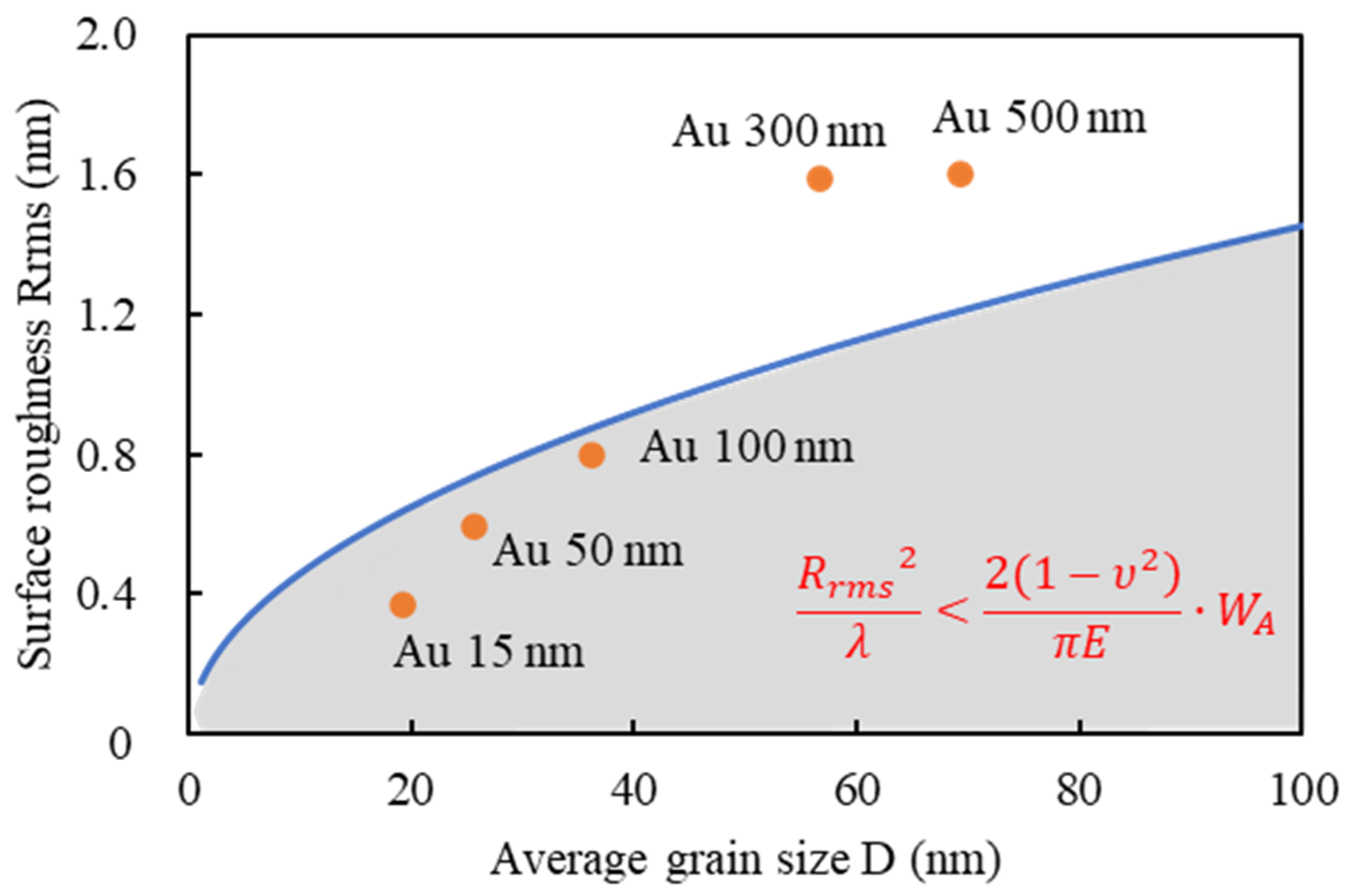

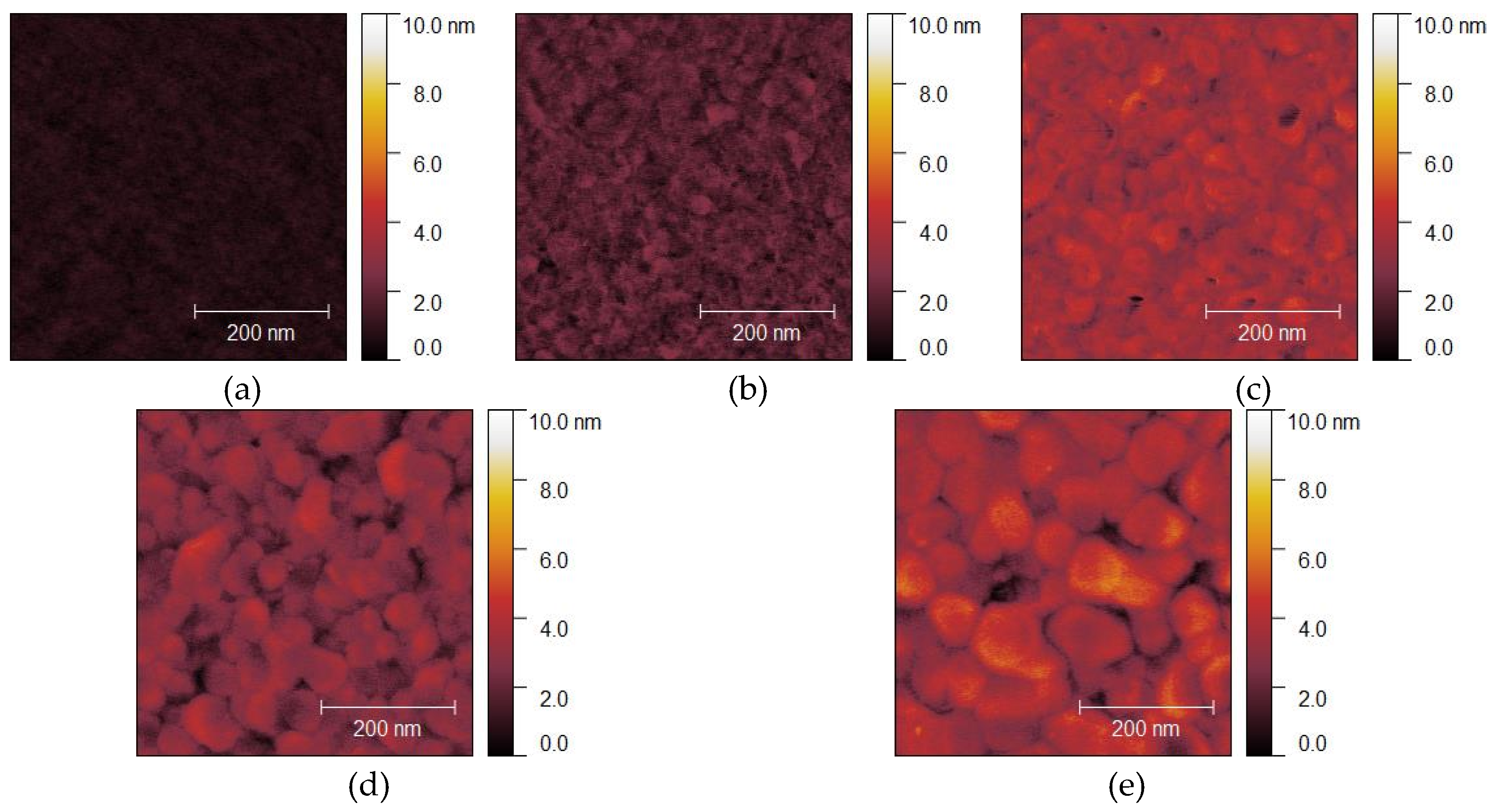

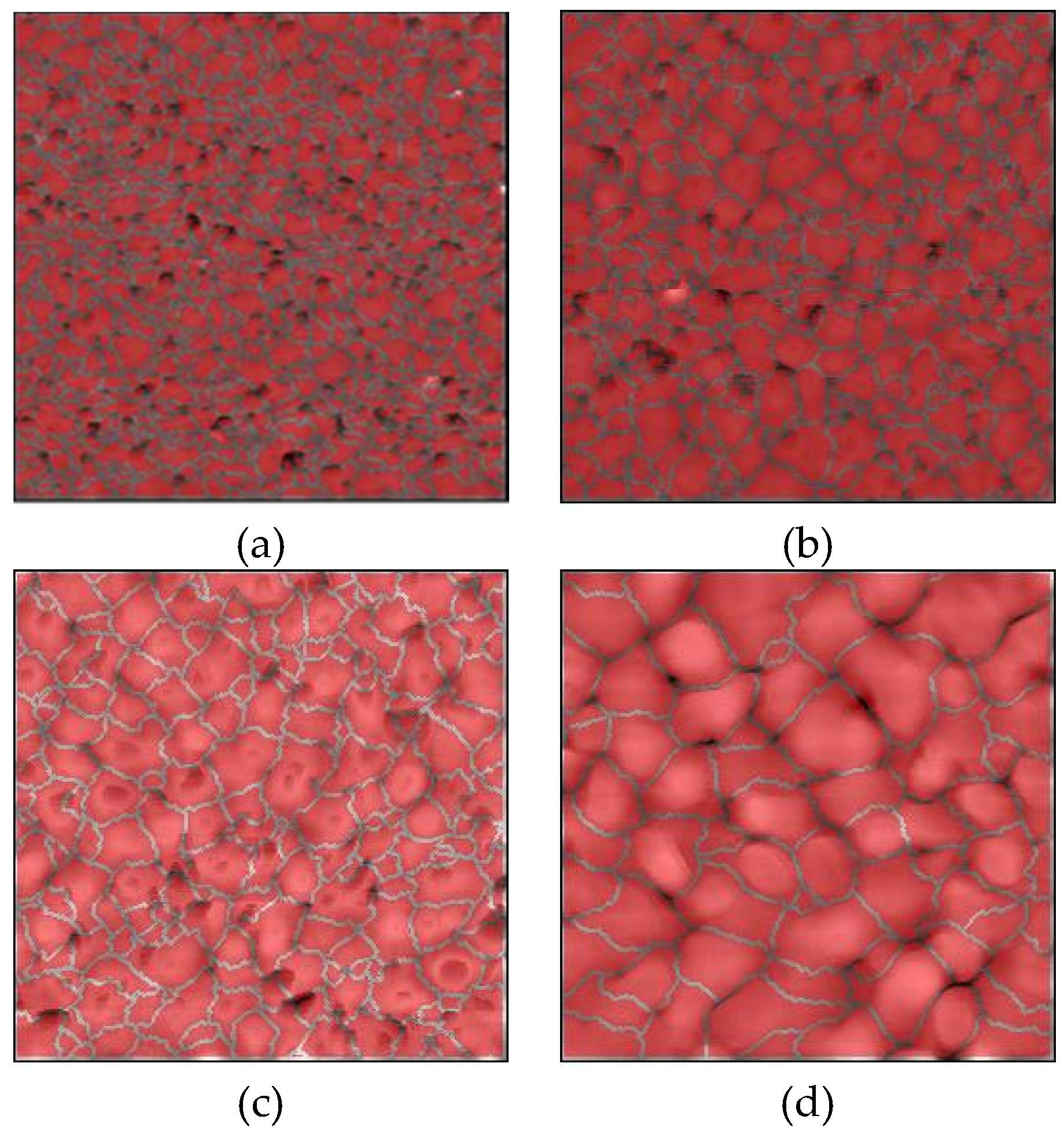

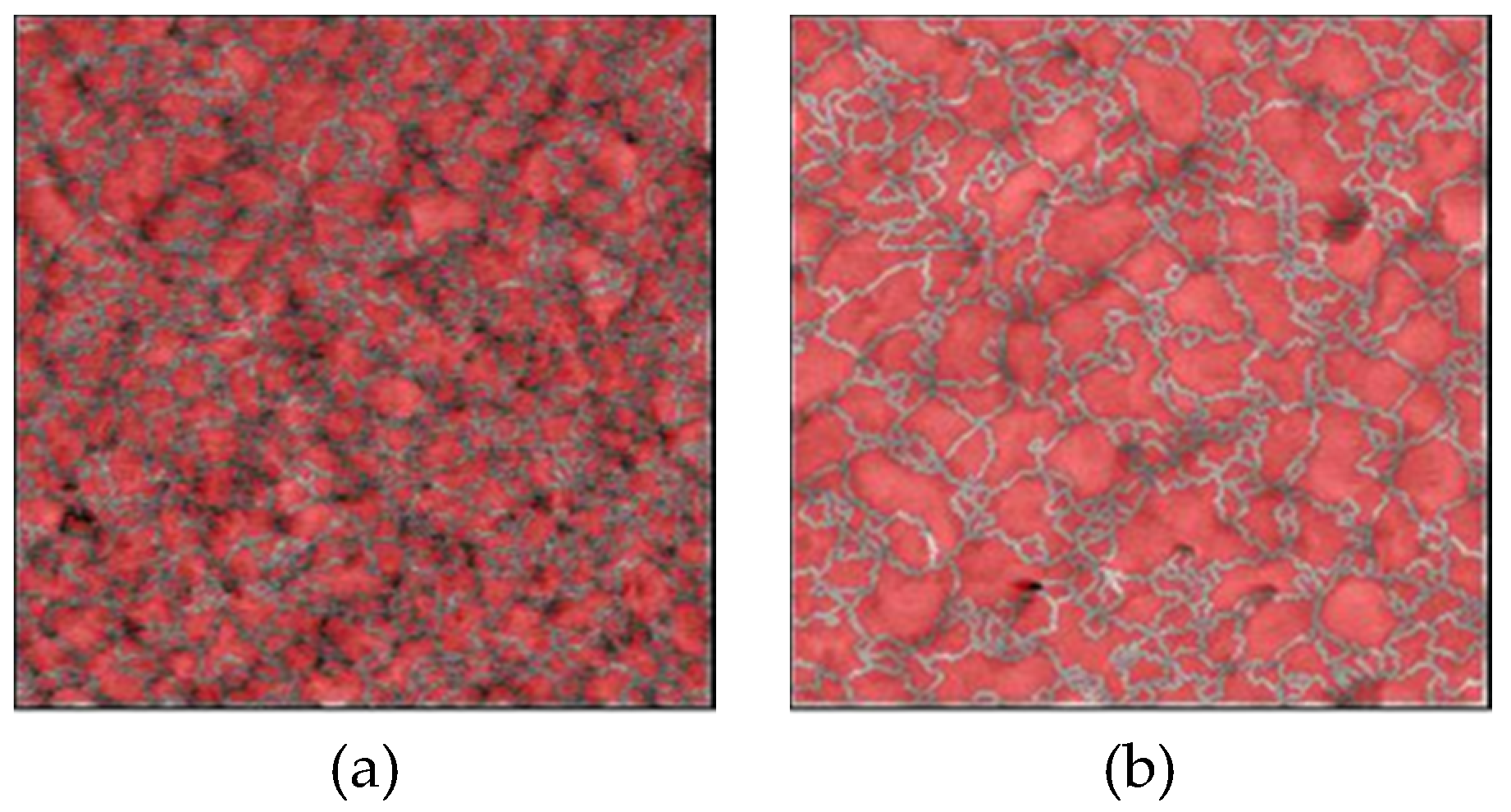

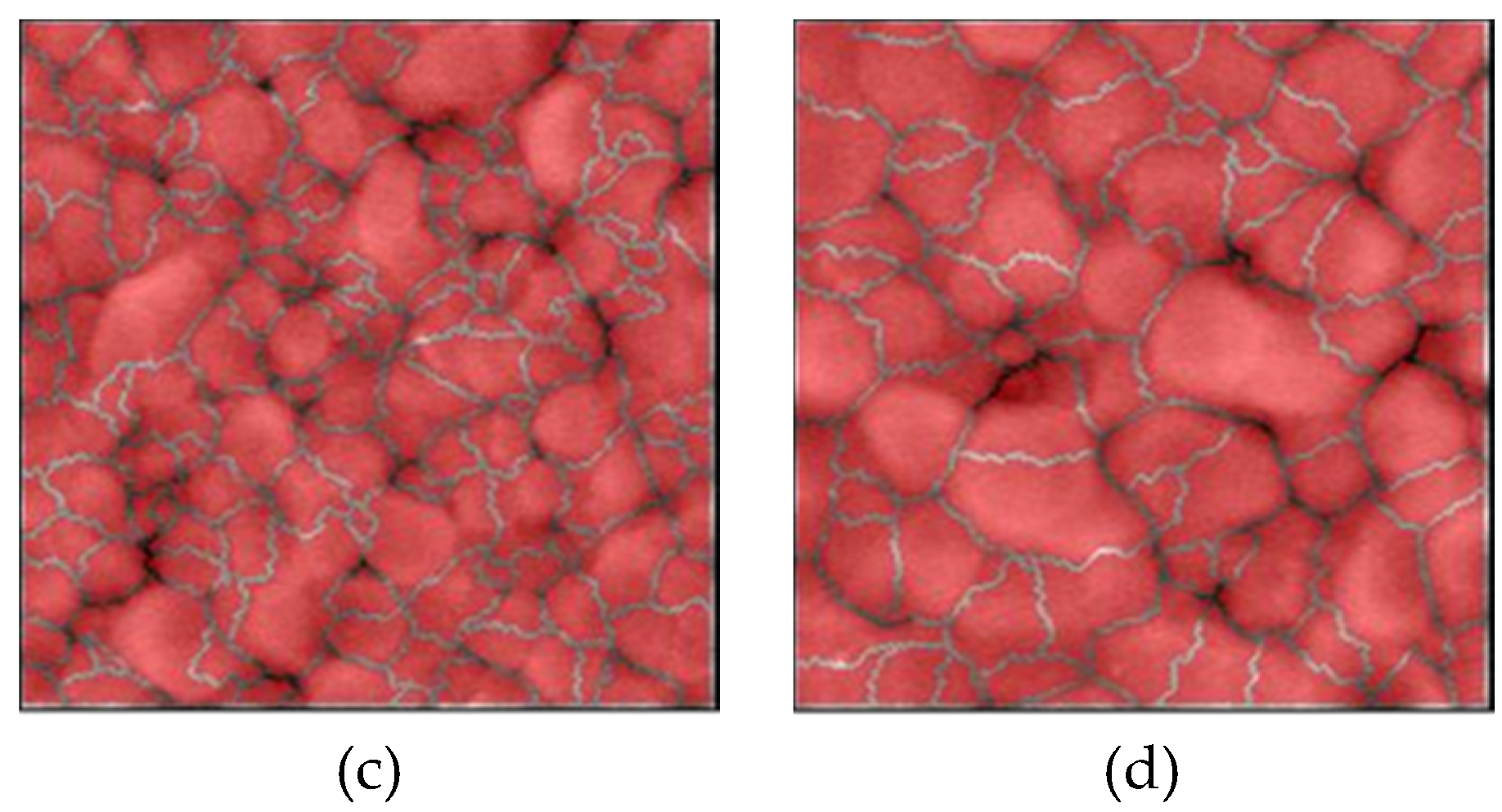

3.1. Room-Temperature Pressureless Wafer Bonding in Ambient Air

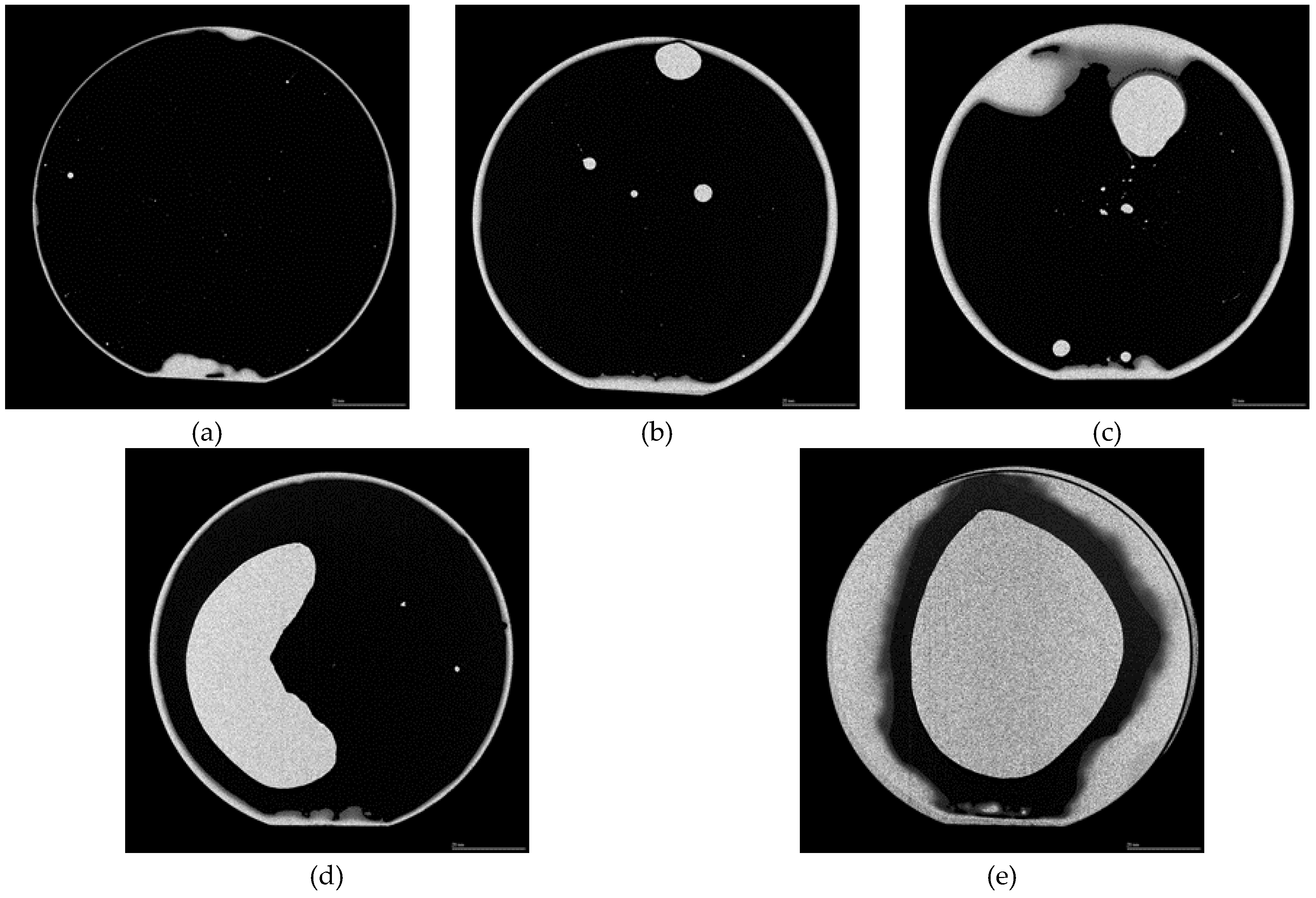

3.2. Room-Temperature Wafer Sealing in Vacuum

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Higurashi, E. Heterogeneous integration based on low-temperature bonding for advanced optoelectronic devices. Jpn. J. Appl. Phys. 2018, 57, 04FA02. [Google Scholar] [CrossRef] [Green Version]

- Higurashi, E.; Suga, T. Review of Low-Temperature Bonding Technologies and Their Application in Optoelectronic Devices. Electron. Commun. Jpn. 2016, 99, 63–71. [Google Scholar] [CrossRef]

- Higurashi, E.; Sawada, R.; Suga, T. Optical Microsensors Integration Technologies for Biomedical Applications. IEICE Trans. Electron. 2009, 231–238. [Google Scholar] [CrossRef]

- Tanaka, S. Wafer-level hermetic MEMS packaging by anodic bonding and its reliability issues. Microelectron. Reliab. 2014, 54, 875–881. [Google Scholar] [CrossRef]

- Tan, C.S.; Fan, J.; Lim, D.F.; Chong, G.Y.; Li, H. Low temperature wafer-level bonding for hermetic packaging of 3D microsystems. J. Micromech. Microeng. 2011, 21, 75006. [Google Scholar] [CrossRef]

- Henmi, H.; Shoji, S.; Shoji, Y.; Yoshimi, K.; Esashi, M. Vacuum packaging for microsensors by glass-silicon anodic bonding. Sens. Actuators A Phys. 1994, 43, 243–248. [Google Scholar] [CrossRef]

- Tanaka, K.; Hirano, H.; Kumano, M.; Froemel, J.; Tanaka, S. Bonding-Based Wafer-Level Vacuum Packaging Using Atomic Hydrogen Pre-Treated Cu Bonding Frames. Micromachines 2018, 9, 181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Higurashi, E.; Kawai, H.; Suga, T.; Okada, S.; Hagihara, T. Low-Temperature Solid-State Bonding Using Hydrogen Radical Treated Solder for Optoelectronic and MEMS Packaging. ECS Trans. 2014, 64, 267–274. [Google Scholar] [CrossRef]

- Goyal, A.; Cheong, J.; Tadigadapa, S. Tin-based solder bonding for MEMS fabrication and packaging applications. J. Micromech. Microeng. 2004, 14, 819–825. [Google Scholar] [CrossRef]

- Wang, Q.; Choa, S.-H.; Kim, W.; Hwang, J.; Ham, S.; Moon, C. Application of Au-Sn eutectic bonding in hermetic radio-frequency microelectromechanical system wafer level packaging. J. Electron. Mater. 2006, 35, 425–432. [Google Scholar] [CrossRef]

- Tsau, C.; Spearing, S.; Schmidt, M.A. Characterization of Wafer-Level Thermocompression Bonds. J. Microelectromech. Syst. 2004, 13, 963–971. [Google Scholar] [CrossRef]

- Taklo, M.M.V.; Storås, P.; Schjølberg-Henriksen, K.; Hasting, H.K.; Jakobsen, H. Strong, high-yield and low-temperature thermocompression silicon wafer-level bonding with gold. J. Micromech. Microeng. 2004, 14, 884–890. [Google Scholar] [CrossRef]

- Park, G.-S.; Kim, Y.-K.; Paek, K.-K.; Kim, J.-S.; Lee, J.-H.; Ju, B.-K. Low-Temperature Silicon Wafer-Scale Thermocompression Bonding Using Electroplated Gold Layers in Hermetic Packaging. Electrochem. Solid State Lett. 2005, 8, G330. [Google Scholar] [CrossRef]

- Shimatsu, T.; Uomoto, M.; Oba, K.; Furukata, Y. Atomic diffusion bonding of wafers in air with thin Au films and its application to optical devices fabrication. In Proceedings of the 2012 3rd IEEE International Workshop on Low Temperature Bonding for 3D Integration, Tokyo, Japan, 22–23 May 2012; p. 103. [Google Scholar] [CrossRef]

- Goorsky, M.; Schjølberg-Henriksen, K.; Beekley, B.; Bai, T.; Mani, K.; Ambhore, P.; Bajwa, A.; Malik, N.; Iyer, S.S. Characterization of interfacial morphology of low temperature, low pressure Au–Au thermocompression bonding. Jpn. J. Appl. Phys. 2017, 57, 02BC03. [Google Scholar] [CrossRef]

- Matsumae, T.; Kurashima, Y.; Umezawa, H.; Mokuno, Y.; Takagi, H. Room-temperature bonding of single-crystal diamond and Si using Au/Au atomic diffusion bonding in atmospheric air. Microelectron. Eng. 2018, 195, 68–73. [Google Scholar] [CrossRef]

- Okada, H.; Itoh, T.; Frömel, J.; Gessner, T.; Suga, T. Room temperature vacuum sealing using surfaced activated bonding with Au thin films. In Proceedings of the 13th International Conference on Solid-State Sensors, Actuators and Microsystems, 2005. Digest of Technical Papers. TRANSDUCERS ’05, Seoul, Korea, 5–9 June 2005; Volume 1, pp. 932–935. [Google Scholar] [CrossRef]

- Higurashi, E.; Imamura, T.; Suga, T.; Sawada, R. Low-Temperature Bonding of Laser Diode Chips on Silicon Substrates Using Plasma Activation of Au Films. IEEE Photonics Technol. Lett. 2007, 19, 1994–1996. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Shinada, S.; Kawanishi, T. Low-temperature Au-to-Au Bonding for LiNbO3/Si Structure Achieved in Ambient Air. IEICE Trans. Electron. 2007, E90-C, 145–146. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Sawada, R. Room-Temperature Bonding of Vertical-Cavity Surface-Emitting Laser Chips on Si Substrates Using Au Microbumps in Ambient Air. Appl. Phys. Express 2008, 1, 112201. [Google Scholar] [CrossRef]

- Higurashi, E.; Chino, D.; Suga, T.; Sawada, R. Au–Au Surface-Activated Bonding and Its Application to Optical Microsensors With 3-D Structure. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 1500–1505. [Google Scholar] [CrossRef]

- Takigawa, R.; Higurashi, E.; Suga, T.; Kawanishi, T. Passive Alignment and Mounting of LiNbO3 Waveguide Chips on Si Substrates by Low-Temperature Solid-State Bonding of Au. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 652–658. [Google Scholar] [CrossRef]

- Higurashi, E.; Fukunaga, T.; Suga, T. Low-Temperature Bonding of GaN on Si Using a Nonalloyed Metal Ohmic Contact Layer for GaN-Based Heterogeneous Devices. IEEE J. Quantum Electron. 2011, 48, 182–186. [Google Scholar] [CrossRef]

- Yamamoto, S.-I.; Higurashi, E.; Suga, T.; Sawada, R. Low-temperature hermetic packaging for microsystems using Au–Au surface-activated bonding at atmospheric pressure. J. Micromech. Microeng. 2012, 22, 55026. [Google Scholar] [CrossRef]

- Kurashima, Y.; Maeda, A.; Takigawa, R.; Takagi, H. Room temperature wafer bonding of metal films using flattening by thermal imprint process. Microelectron. Eng. 2013, 112, 52–56. [Google Scholar] [CrossRef]

- Kurashima, Y.; Maeda, A.; Takagi, H. Replication of atomically smooth surface shape onto electroplated Au patterns by lift-off process and room-temperature Au–Au bonding in atmospheric air. Microelectron. Eng. 2014, 129, 1–4. [Google Scholar] [CrossRef]

- Goto, M.; Hagiwara, K.; Iguchi, Y.; Ohtake, H.; Saraya, T.; Higurashi, E.; Toshiyoshi, H.; Hiramoto, T. 3-D Silicon-on-Insulator Integrated Circuits With NFET and PFET on Separate Layers Using Au/SiO2 Hybrid Bonding. IEEE Trans. Electron Devices 2014, 61, 2886–2892. [Google Scholar] [CrossRef]

- Kurashima, Y.; Maeda, A.; Takagi, H. Room-temperature wafer scale bonding using smoothed Au seal ring surfaces for hermetic sealing. Jpn. J. Appl. Phys. 2015, 55, 16701. [Google Scholar] [CrossRef]

- Higurashi, E.; Yamamoto, M.; Sato, T.; Suga, T.; Sawada, R. Room-Temperature Gold-Gold Bonding Method Based on Argon and Hydrogen Gas Mixture Atmospheric-Pressure Plasma Treatment for Optoelectronic Device Integration. IEICE Trans. Electron. 2016, 339–345. [Google Scholar] [CrossRef] [Green Version]

- Higurashi, E.; Okumura, K.; Kunimune, Y.; Suga, T.; Hagiwara, K. Room-Temperature Bonding of Wafers with Smooth Au Thin Films in Ambient Air Using a Surface-Activated Bonding Method. IEICE Trans. Electron. 2017, 156–160. [Google Scholar] [CrossRef] [Green Version]

- Kurashima, Y.; Matsumae, T.; Takagi, H. Room-temperature Au–Au bonding in atmospheric air using direct transferred atomically smooth Au film on electroplated patterns. Microelectron. Eng. 2018, 189, 1–5. [Google Scholar] [CrossRef]

- Shiratori, Y.; Hoshi, T.; Ida, M.; Higurashi, E.; Matsuzaki, H. High-Speed InP/InGaAsSb DHBT on High-Thermal-Conductivity SiC Substrate. IEEE Electron Device Lett. 2018, 39, 807–810. [Google Scholar] [CrossRef]

- Yamamoto, M.; Higurashi, E.; Suga, T.; Sawada, R.; Itoh, T. Properties of various plasma surface treatments for low-temperature Au–Au bonding. Jpn. J. Appl. Phys. 2018, 57, 04FC12. [Google Scholar] [CrossRef]

- Yamamoto, M.; Matsumae, T.; Kurashima, Y.; Takagi, H.; Suga, T.; Itoh, T.; Higurashi, E. Comparison of Argon and Oxygen Plasma Treatments for Ambient Room-Temperature Wafer-Scale Au–Au Bonding Using Ultrathin Au Films. Micromachines 2019, 10, 119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamamoto, M.; Kunimune, Y.; Matsumae, T.; Kurashima, Y.; Takagi, H.; Iguchi, Y.; Honda, Y.; Suga, T.; Itoh, T.; Higurashi, E. Room-temperature pressureless wafer-scale hermetic sealing in air and vacuum using surface activated bonding with ultrathin Au films. Jpn. J. Appl. Phys. 2019, 59, SBBB01. [Google Scholar] [CrossRef]

- Klapetek, P.; Ohlídal, I.; Montaigne-Ramil, A.; Bonanni, A.; Stifter, D.; Sitter, H. Atomic Force Microscopy Characterization of ZnTe Epitaxial Thin Films. Jpn. J. Appl. Phys. 2003, 42, 4706–4709. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1909, 82, 172–175. [Google Scholar] [CrossRef] [Green Version]

- Fournel, F.; Continni, L.; Morales, C.; Da Fonseca, J.; Moriceau, H.; Rieutord, F.; Barthélémy, A.; Radu, I. Measurement of bonding energy in an anhydrous nitrogen atmosphere and its application to silicon direct bonding technology. J. Appl. Phys. 2012, 111, 104907. [Google Scholar] [CrossRef]

- Brantley, W.A. Calculated elastic constants for stress problems associated with semiconductor devices. J. Appl. Phys. 1973, 44, 534. [Google Scholar] [CrossRef]

- Available online: http://imagej.nih.gov/ij/ (accessed on 25 April 2020).

- Maszara, W.P.; Goetz, G.; Caviglia, A.; McKitterick, J.B. Bonding of Silicon Wafers for Silicon-on-Insulator. J. Appl. Phys. 1988, 64, 4943–4950. [Google Scholar] [CrossRef]

- Zhang, X.; Song, X.H.; Zhang, D.L. Thickness Dependence of Grain Size and Surface Roughness for DC Magnetron Sputtered Au Films. Chin. Phys. B 2010, 19, 086802. [Google Scholar] [CrossRef]

- Takagi, H.; Maeda, R.; Chung, T.R.; Hosoda, N.; Suga, T. Effect of Surface Roughness on Room-Temperature Wafer Bonding by Ar Beam Surface Activation. Jpn. J. Appl. Phys. 1998, 37, 4197–4203. [Google Scholar] [CrossRef]

- Tan, C.W.; Miao, J. Optimization of Sputtered Cr/Au Thin Film for Diaphragm-Based MEMS Applications. Thin Solid Films 2009, 517, 4921–4925. [Google Scholar] [CrossRef]

- Abadias, G.; Chason, E.; Keckes, J.; Sebastiani, M.; Thompson, G.B.; Barthel, E.; Doll, G.L.; Murray, C.E.; Stoessel, C.H.; Martinu, L. Review Article: Stress in Thin Films and Coatings: Current Status, Challenges, and Prospects. J. Vac. Sci. Technol. A Vac. Surf. Film 2018, 36, 020801. [Google Scholar] [CrossRef] [Green Version]

- Hoffman, D.W.; Thornton, J.A. Internal Stresses in Cr, Mo, Ta, and Pt Films Deposited by Sputtering from a Planar Magnetron Source. J. Vac. Sci. Technol. 1982, 20, 355–358. [Google Scholar] [CrossRef]

- Tong, Q.-Y.; Kim, W.J.; Lee, T.; Gösele, U. Low Vacuum Wafer Bonding. Electrochem. Solid-State Lett. 1999, 1, 52–53. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamamoto, M.; Matsumae, T.; Kurashima, Y.; Takagi, H.; Suga, T.; Takamatsu, S.; Itoh, T.; Higurashi, E. Effect of Au Film Thickness and Surface Roughness on Room-Temperature Wafer Bonding and Wafer-Scale Vacuum Sealing by Au-Au Surface Activated Bonding. Micromachines 2020, 11, 454. https://doi.org/10.3390/mi11050454

Yamamoto M, Matsumae T, Kurashima Y, Takagi H, Suga T, Takamatsu S, Itoh T, Higurashi E. Effect of Au Film Thickness and Surface Roughness on Room-Temperature Wafer Bonding and Wafer-Scale Vacuum Sealing by Au-Au Surface Activated Bonding. Micromachines. 2020; 11(5):454. https://doi.org/10.3390/mi11050454

Chicago/Turabian StyleYamamoto, Michitaka, Takashi Matsumae, Yuichi Kurashima, Hideki Takagi, Tadatomo Suga, Seiichi Takamatsu, Toshihiro Itoh, and Eiji Higurashi. 2020. "Effect of Au Film Thickness and Surface Roughness on Room-Temperature Wafer Bonding and Wafer-Scale Vacuum Sealing by Au-Au Surface Activated Bonding" Micromachines 11, no. 5: 454. https://doi.org/10.3390/mi11050454

APA StyleYamamoto, M., Matsumae, T., Kurashima, Y., Takagi, H., Suga, T., Takamatsu, S., Itoh, T., & Higurashi, E. (2020). Effect of Au Film Thickness and Surface Roughness on Room-Temperature Wafer Bonding and Wafer-Scale Vacuum Sealing by Au-Au Surface Activated Bonding. Micromachines, 11(5), 454. https://doi.org/10.3390/mi11050454