A Review of MEMS Capacitive Microphones

Abstract

:1. Introduction

2. Summary of Academic Papers on MEMS Capacitive Microphones

3. Acoustic Diaphragm

3.1. Materials

3.2. Geometry and Surface Topology

3.3. Stress of the Diaphragm

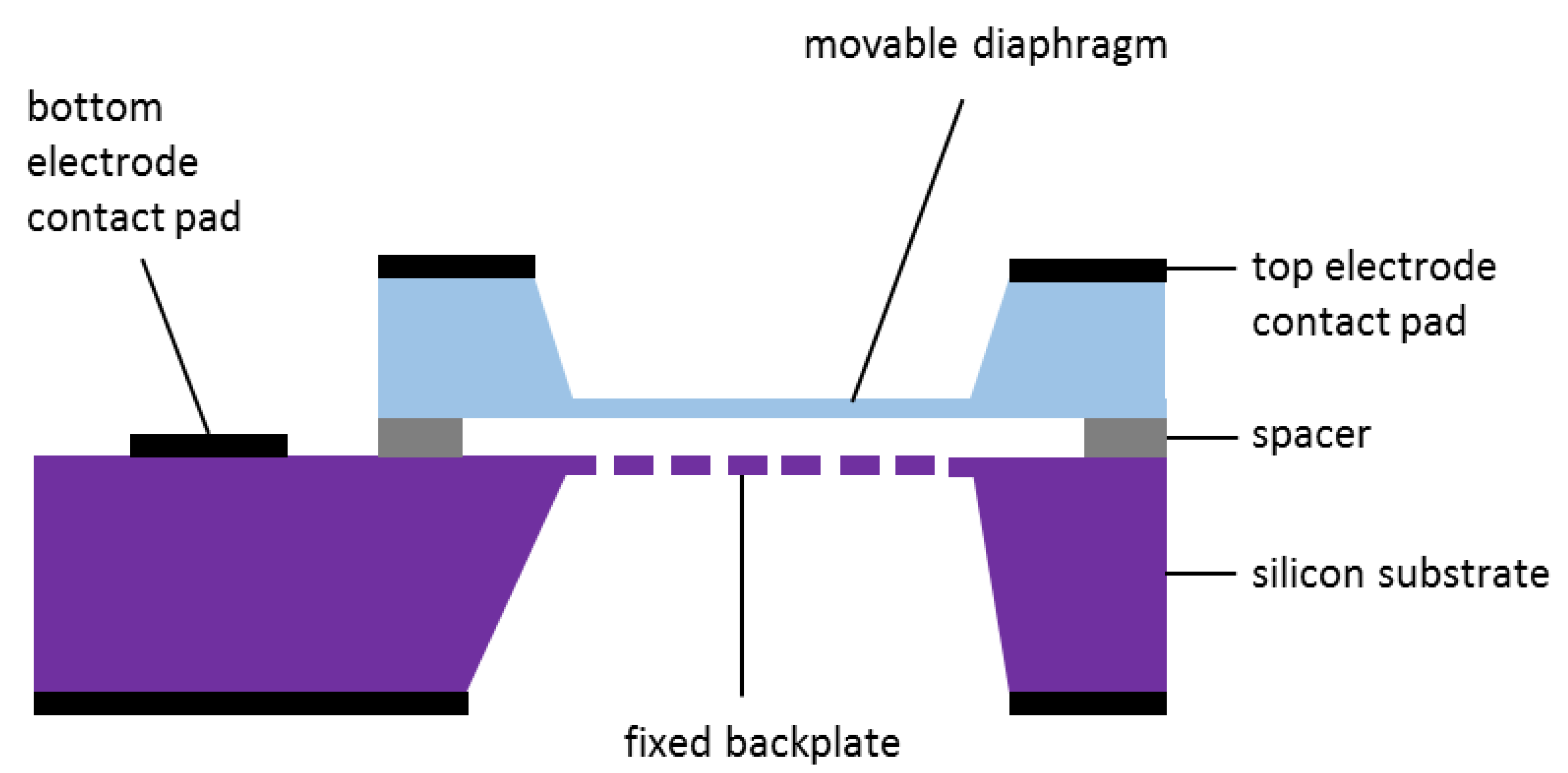

4. Backplate and Back Chamber

4.1. Backplate Materials

4.2. Acoustic Holes

4.3. Volume of Back Chamber

4.4. Air Gap

4.5. Electrodes

5. Parameters that Determine Performances of MEMS Capacitive Microphones

5.1. Bias Voltage

5.2. Stray Capacitance

5.3. Input SPL

5.4. Open Circuit Sensitivity

5.5. Resonant Frequency

5.6. Noise Floor

6. Future Research Direction for MEMS Capacitive Microphone

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arya, D.S.; Prasad, M.; Tripathi, C.C. Design and modeling of a ZnO-based MEMS acoustic sensor for aeroacoustic and audio applications. In Proceedings of the 2015 2nd International Symposium on Physics and Technology of Sensors (ISPTS), Pune, India, 7–10 March 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Loeppert, P.V.; Lee, S.B. A commercialized MEMS microphone for high-volume consumer electronics. J. Acoust. Soc. Am. 2004, 116, 2510. [Google Scholar] [CrossRef]

- Mallik, S.; Chowdhury, D.; Chattopadhyay, M. Development and performance analysis of a low-cost MEMS microphone-based hearing aid with three different audio amplifiers. Innov. Syst. Softw. Eng. 2019, 15, 17–25. [Google Scholar] [CrossRef]

- Zargarpour, N.; Zarifi, M.H. A piezoelectric micro-electromechanical microphone for implantable hearing aid applications. Microsyst. Technol. 2015, 21, 893–902. [Google Scholar] [CrossRef]

- Marek, J. MEMS for automotive and consumer electronics. In Proceedings of the 2010 IEEE International Solid-State Circuits Conference—(ISSCC), San Francisco, CA, USA, 7–11 February 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar]

- Zinserling, B. Silicon-based MEMS microphone for automotive applications. Micronano News. 2007. Available online: www.onboard-technology.com/pdf_febbraio2007/020705.pdf (accessed on 7 May 2020).

- MacLeod, E. Alexander Graham Bell: An Inventive Life; Kids Can Press: Toronto, ON, Canada, 1999. [Google Scholar]

- Huurdeman, A.A. The Worldwide History of Telecommunications; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Malcovati, P.; Grassi, M.; Baschirotto, A. Interface Circuits for MEMS Microphones. In Nyquist AD Converters, Sensor Interfaces, and Robustness: Advances in Analog Circuit Design, 2012; van Roermund, A.H.M., Baschirotto, A., Steyaert, M., Eds.; Springer: New York, NY, USA, 2013; pp. 149–174. [Google Scholar]

- Elko, G.W. Future Directions for Microphone Arrays. In Microphone Arrays: Signal Processing Techniques and Applications; Brandstein, M., Ward, D., Eds.; Springer: Berlin, Heidelberg, Germany, 2001; pp. 383–387. [Google Scholar]

- Eargle, J. The Microphone Book; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Horng, R.-H.; Chen, K.-F.; Tsai, Y.-C.; Suen, C.-Y.; Chang, C.-C. Fabrication of a dual-planar-coil dynamic microphone by MEMS techniques. J. Micromech. Microeng. 2010, 20, 065004. [Google Scholar] [CrossRef]

- Lee, C.-I.; Chien, H.-T.; Liu, P.-T.; Chen, J.M. High sensitivity silicon-based condenser microphone design. In Proceedings of the 2007 International Microsystems, Packaging, Assembly and Circuits Technolog, Taipei, Taiwan, 1–3 October 2007; IEEE: Piscataway, NJ, USA, 2007. [Google Scholar]

- Ried, R.; Kim, E.S.; Hong, D.; Muller, R. Piezoelectric microphone with on-chip CMOS circuits. J. Microelectromech. Syst. 1993, 2, 111–120. [Google Scholar] [CrossRef]

- Fuji, Y.; Higashi, Y.; Masunishi, K.; Yuzawa, A.; Nagata, T.; Kaji, S.; Okamoto, K.; Baba, S.; Ono, T.; Hara, M. Spin-MEMS microphone integrating a series of magnetic tunnel junctions on a rectangular diaphragm. J. Appl. Phys. 2018, 123, 163901. [Google Scholar] [CrossRef]

- Fuji, Y.; Hara, M.; Higashi, Y.; Kaji, S.; Masunishi, K.; Nagata, T.; Yuzawa, A.; Otsu, K.; Okamoto, K.; Baba, S.; et al. An ultra-sensitive spintronic strain-gauge sensor with gauge factor of 5000 and demonstration of a Spin-MEMS Microphone. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Higashi, Y.; Fuji, Y.; Kaji, S.; Masunishi, K.; Nagata, T.; Yuzawa, A.; Otsu, K.; Okamoto, K.; Baba, S.; Ono, T.; et al. SNR enhancement of a spin-MEMS microphone by optimum bias magnetic field and demonstration of operation sound monitoring of rotating equipment. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Fuji, Y.; Higashi, Y.; Kaji, S.; Masunishi, K.; Nagata, T.; Yuzawa, A.; Okamoto, K.; Baba, S.; Ono, T.; Hara, M. Highly sensitive spintronic strain-gauge sensor and Spin-MEMS microphone. Jpn. J. Appl. Phys. 2019, 58, SD0802. [Google Scholar] [CrossRef] [Green Version]

- Van Rhijn, A. Integrated Circuits for High-Performance Electret Microphones; Penton Media, Inc.: New York, NY, USA, 2003; p. 38. [Google Scholar]

- Del Val, L.; Izquierdo, A.; Villacorta, J.J.; Suárez, L.; Suá Rez, L. Using a Planar Array of MEMS Microphones to Obtain Acoustic Images of a Fan Matrix. J. Sensors 2017, 2017, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Izquierdo, A.; Villacorta, J.J.; Del Val, L.; Suárez, L.; Suárez, D. Implementation of a Virtual Microphone Array to Obtain High Resolution Acoustic Images. Sensors 2017, 18, 25. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Huang, J.; Song, E.; Liu, H.; Li, B.; Yuan, X. Design of Small MEMS Microphone Array Systems for Direction Finding of Outdoors Moving Vehicles. Sensors 2014, 14, 4384–4398. [Google Scholar] [CrossRef] [Green Version]

- Johnson, R.C. MEMS Mics Taking Over. In EE Times; Aspencore: New York, NY, USA, 2014. [Google Scholar]

- Bouchaud, J.; Boustany, M. MEMS Market Tracker—Consumer and Mobile; IHS: London, UK, 2014. [Google Scholar]

- Dixon-Warren, S. Overview of MEMS Microphone Technologies for Consumer Applications; Mems Journal Inc.: Southfield, MI, USA, 2011. [Google Scholar]

- Gharaei, H.; Koohsorkhi, J. Design and characterization of high sensitive MEMS capacitive microphone with fungous coupled diaphragm structure. Microsyst. Technol. 2016, 22, 401–411. [Google Scholar] [CrossRef]

- Martin, D.T.; Liu, J.; Kadirvel, K.; Fox, R.M.; Sheplak, M.; Nishida, T. A Micromachined Dual-Backplate Capacitive Microphone for Aeroacoustic Measurements. J. Microelectromech. Syst. 2007, 16, 1289–1302. [Google Scholar] [CrossRef]

- Kim, B.-H.; Lee, H.-S. Acoustical-Thermal Noise in a Capacitive MEMS Microphone. IEEE Sens. J. 2015, 15, 6853–6860. [Google Scholar] [CrossRef]

- Scheeper, P.; Van Der Donk, A.; Olthuis, W.; Bergveld, P. A review of silicon microphones. Sens. Actuators A Phys. 1994, 44, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Ishfaque, A.; Kim, B. Fly Ormia Ochracea Inspired MEMS Directional Microphone: A Review. IEEE Sens. J. 2018, 18, 1778–1789. [Google Scholar] [CrossRef]

- Miles, R.N. Mechanically coupled ears for directional hearing in the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 1995, 98, 3059–3070. [Google Scholar] [CrossRef] [PubMed]

- Shah, M.A.; Shah, I.A.; Lee, D.-G.; Hur, S. Design Approaches of MEMS Microphones for Enhanced Performance. J. Sens. 2019, 2019, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Kühnel, W. Silicon condenser microphone with integrated field-effect transistor. Sens. Actuators A Phys. 1991, 26, 521–525. [Google Scholar] [CrossRef]

- Graf, E.; Kronast, W.; Dühring, S.; Muller, B.; Stoffel, A. Silicon membrane condenser microphone with integrated field-effect transistor. Sens. Actuators A Phys. 1993, 37, 708–711. [Google Scholar] [CrossRef]

- Mohd-Yasin, F.; Nagel, D.J.; E Korman, C. Noise in MEMS. Meas. Sci. Technol. 2009, 21, 12001. [Google Scholar] [CrossRef]

- Hohm, D. A subminiature condenser microphone with silicon nitride membrane and silicon back plate. J. Acoust. Soc. Am. 1989, 85, 476–480. [Google Scholar] [CrossRef]

- Bergqvist, J.; Rudolf, F. A new condenser microphone in silicon. Sens. Actuators A Phys. 1990, 21, 123–125. [Google Scholar] [CrossRef]

- Kühnel, W.; Hess, G. A silicon condenser microphone with structured back plate and silicon nitride membrane. Sens. Actuators A Phys. 1992, 30, 251–258. [Google Scholar] [CrossRef]

- Scheeper, P.; Van Der Donk, A.; Olthuis, W.; Bergveld, P. Fabrication of silicon condenser microphones using single wafer technology. J. Microelectromech. Syst. 1992, 1, 147–154. [Google Scholar] [CrossRef]

- Bourouina, T.; Spirkovitch, S.; Baillieu, F.; Vauge, C. A new condenser microphone with a p+ silicon membrane. Sens. Actuators A Phys. 1992, 31, 149–152. [Google Scholar] [CrossRef]

- Bergqvist, J.; Rudolf, F. A silicon condenser microphone using bond and etch-back technology. Sens. Actuators A Phys. 1994, 45, 115–124. [Google Scholar] [CrossRef]

- Bergqvist, J.; Gobet, J. Capacitive microphone with a surface micromachined backplate using electroplating technology. J. Microelectromech. Syst. 1994, 3, 69–75. [Google Scholar] [CrossRef]

- Scheeper, P.; Olthuis, W.; Bergveld, P. Improvement of the performance of microphones with a silicon nitride diaphragm and backplate. Sens. Actuators A Phys. 1994, 40, 179–186. [Google Scholar] [CrossRef] [Green Version]

- Schellin, R.; Hess, G.; Kühnel, W.; Thielemann, C.; Trost, D.; Wacker, J.; Steinmann, R. Measurements of the mechanical behaviour of micromachined silicon and silicon-nitride membranes for microphones, pressure sensors and gas flow meters. Sens. Actuators A Phys. 1994, 41, 287–292. [Google Scholar] [CrossRef]

- Van Der Donk, A.; Scheeper, P.; Olthuis, W.; Bergveld, P. Modelling of silicon condenser microphones. Sens. Actuators A Phys. 1994, 40, 203–216. [Google Scholar] [CrossRef] [Green Version]

- Bay, J.; Hansen, O.; Bouwstra, S. Design of a silicon microphone with differential read-out of a sealed double parallel-plate capacitor. Sens. Actuators A Phys. 1996, 53, 232–236. [Google Scholar] [CrossRef]

- Ning, Y.; Mitchell, A.; Tait, R. Fabrication of a silicon micromachined capacitive microphone using a dry-etch process. Sens. Actuators A Phys. 1996, 53, 237–242. [Google Scholar] [CrossRef]

- Zou, Q.; Li, Z.; Liu, L. Design and fabrication of silicon condenser microphone using corrugated diaphragm technique. J. Microelectromech. Syst. 1996, 5, 197–204. [Google Scholar]

- Thielemann, C.; Hess, G. Inorganic electret membrane for a silicon microphone. Sens. Actuators A Phys. 1997, 61, 352–355. [Google Scholar] [CrossRef]

- Hsu, P.-C.; Mastrangelo, C.H.; Wise, K.D. A high sensitivity polysilicon diaphragm condenser microphone. In Proceedings of the MEMS 98. IEEE. Eleventh Annual International Workshop on Micro Electro Mechanical Systems. An Investigation of Micro Structures, Sensors, Actuators, Machines and Systems (Cat. No.98CH36176), Heidelberg, Germany, 25–29 January 1998; IEEE: Piscataway, NJ, USA, 1998. [Google Scholar]

- Pederson, M.; Olthuis, W.; Bergveld, P. High-performance condenser microphone with fully integrated CMOS amplifier and DC-DC voltage converter. J. Microelectromech. Syst. 1998, 7, 387–394. [Google Scholar] [CrossRef]

- Pedersen, M.; Olthuis, W.; Bergveld, P. An integrated silicon capacitive microphone with frequency-modulated digital output. Sens. Actuators A Phys. 1998, 69, 267–275. [Google Scholar] [CrossRef]

- Bay, J.; Hansen, O.; Bouwstra, S. Micromachined double backplate differential capacitive microphone. J. Micromech. Microeng. 1999, 9, 30–33. [Google Scholar] [CrossRef]

- Kabir, A.; Bashir, R.; Bernstein, J.; De Santis, J.; Mathews, R.; O’Boyle, J.; Bracken, C. High sensitivity acoustic transducers with thin p+ membranes and gold back-plate. Sens. Actuators A Phys. 1999, 78, 138–142. [Google Scholar] [CrossRef]

- Buhrdorf, A.; Tebje, L.; Ahrens, O.; Glitza, O.; Binder, J. Capacitive micromachined ultrasonic transducer (cMUT) array for the frequency range below 500 kHz In Proceedings of the 2000 IEEE Ultrasonics Symposium. In Proceedings of the An International Symposium (Cat. No.00CH37121), San Juan, PR, USA, 22–25 October 2000; IEEE: Piscataway, NJ, USA, 2000. [Google Scholar]

- Torkkeli, A.; Rusanen, O.; Saarilahti, J.; Seppä, H.; Sipola, H.; Hietanen, J. Capacitive microphone with low-stress polysilicon membrane and high-stress polysilicon backplate. Sens. Actuators A Phys. 2000, 85, 116–123. [Google Scholar] [CrossRef]

- Brauer, M.; Dehé, A.; Bever, T.; Barzen, S.; Schmitt, S.; Füldner, M.; Aigner, R. Silicon microphone based on surface and bulk micromachining. J. Micromech. Microeng. 2001, 11, 319–322. [Google Scholar] [CrossRef]

- Hansen, S.; Ergun, A.S.; Khuri-Yakub, B. Acoustic sensing using radio frequency detection and capacitive micromachined ultrasonic transducers. In Proceedings of the 2001 IEEE MTT-S International Microwave Sympsoium Digest (Cat. No.01CH37157), Phoenix, AZ, USA, 20–24 May 2001; IEEE: Piscataway, NJ, USA, 2001. [Google Scholar]

- Li, X.; Lin, R.; Kek, H.; Miao, J.; Zou, Q. Sensitivity-improved silicon condenser microphone with a novel single deeply corrugated diaphragm. Sens. Actuators A Phys. 2001, 92, 257–262. [Google Scholar] [CrossRef]

- Müllenborn, M.; Rombach, P.; Klein, U.; Rasmussen, K.; Kuhmann, J.; Heschel, M.; Gravad, M.; Janting, J.; Branebjerg, J.; Hoogerwerf, A.; et al. Chip-size-packaged silicon microphones. Sens. Actuators A Phys. 2001, 92, 23–29. [Google Scholar] [CrossRef]

- Noble, R.; Jones, A.; Robertson, T.; Hutchins, D.A.; Billson, D. Novel, wide bandwidth, micromachined ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2001, 48, 1495–1507. [Google Scholar] [CrossRef] [PubMed]

- Kronast, W.; Müller, B.; Siedel, W.; Stoffel, A. Single-chip condenser microphone using porous silicon as sacrificial layer for the air gap. Sens. Actuators A Phys. 2001, 87, 188–193. [Google Scholar] [CrossRef]

- Rombach, P.; Müllenborn, M.; Klein, U.; Rasmussen, K. The first low voltage, low noise differential silicon microphone, technology development and measurement results. Sens. Actuators A Phys. 2002, 95, 196–201. [Google Scholar] [CrossRef]

- Kressmann, R.; Klaiber, M.; Hess, G. Silicon condenser microphones with corrugated silicon oxide/nitride electret membranes. Sens. Actuators A Phys. 2002, 100, 301–309. [Google Scholar] [CrossRef]

- Sim, W.; Kim, B.; Choi, B.; Park, J.-O. Thermal and load-deflection FE analysis of Parylene Diaphragms. In Proceedings of the Modelling and Simulation of Microsystems Conference, San Juan, PR, USA, 22–25 April 2002. [Google Scholar]

- Chen, J.; Liu, L.; Li, Z.; Tan, Z.; Xu, Y.; Ma, J. Single-chip condenser miniature microphone with a high sensitive circular corrugated diaphragm. In Proceedings of the Technical Digest. MEMS 2002 IEEE International Conference. Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No.02CH37266), Las Vegas, NV, USA, 24 January 2002; IEEE: Piscataway, NJ, USA, 2002. [Google Scholar]

- Miao, J.; Lin, R.; Chen, L.; Zou, Q.; Lim, S.Y.; Seah, S.H. Design considerations in micromachined silicon microphones. Microelectron. J. 2002, 33, 21–28. [Google Scholar] [CrossRef]

- Chen, J.; Liu, L.; Li, Z.; Tan, Z.; Xu, Y.; Ma, J. On the single-chip condenser miniature microphone using DRIE and backside etching techniques. Sens. Actuators A Phys. 2003, 103, 42–47. [Google Scholar] [CrossRef]

- Scheeper, P.; Nordstrand, B.; Gullov, J.; Liu, B.; Clausen, T.; Midjord, L.; Storgaard-Larsen, T.; Gullv, J. A new measurement microphone based on MEMS technology. J. Microelectromech. Syst. 2003, 12, 880–891. [Google Scholar] [CrossRef]

- Tajima, T.; Nishiguchi, T.; Chiba, S.; Morita, A.; Abe, M.; Tanioka, K.; Saito, N.; Esashi, M. High-performance ultra-small single crystalline silicon microphone of an integrated structure. Microelectron. Eng. 2003, 67, 508–519. [Google Scholar] [CrossRef]

- Wang, W.J.; Lin, R.M.; Li, X.; Guo, D.G. Study of single deeply corrugated diaphragms for high-sensitivity microphones. J. Micromech. Microeng. 2002, 13, 184–189. [Google Scholar] [CrossRef]

- Hansen, S.T.; Ergün, A.S.; Liou, W.; Auld, B.A.; Khuri-Yakub, B.T. Wideband micromachined capacitive microphones with radio frequency detection. J. Acoust. Soc. Am. 2004, 116, 828–842. [Google Scholar] [CrossRef]

- Ning, J.; Liu, Z.; Liu, H.; Ge, Y. A silicon capacitive microphone based on oxidized porous silicon sacrificial technology. In Proceedings of the 7th International Conference on Solid-State and Integrated Circuits Technology, Beijing, China, 18–21 October 2004. [Google Scholar]

- Wang, W.J.; Lin, R.M.; Zou, Q.B.; Li, X.X. Modeling and characterization of a silicon condenser microphone. J. Micromech. Microeng. 2003, 14, 403–409. [Google Scholar] [CrossRef]

- Wang, W.J.; Lin, R.M.; Ren, Y. Design and fabrication of high sensitive microphone diaphragm using deep corrugation technique. Microsyst. Technol. 2004, 10, 142–146. [Google Scholar] [CrossRef]

- Sezen, A.S.; Sivaramakrishnan, S.; Hur, S.; Rajamani, R.; Robbins, W.; Nelson, B.J. Passive Wireless MEMS Microphones for Biomedical Applications. J. Biomech. Eng. 2005, 127, 1030–1034. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ko, S.C.; Jun, C.; Jang, W.I.; Choi, C.-A. Micromachined air-gap structure MEMS acoustic sensor using reproducible high-speed lateral etching and CMP process. J. Micromech. Microeng. 2006, 16, 2071–2076. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, S.Q.; Park, K.H. A novel capacitive type miniature microphone with a flexure hinge diaphragm. Optics East 2006, 6374, 63740. [Google Scholar]

- Weigold, J.; Brosnihan, T.; Bergeron, J.; Zhang, X. A MEMS Condenser Microphone for Consumer Applications. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006; pp. 86–89. [Google Scholar]

- Dehé, A. Silicon microphone development and application. Sens. Actuators A Phys. 2007, 133, 283–287. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, J.W.; Lee, S.Q.; Lee, S.K.; Park, K.H. A Miniature Condenser Microphone for Portable Terminals Applications. Sensors 2007. [CrossRef]

- Goto, M.; Iguchi, Y.; Ono, K.; Ando, A.; Takeshi, F.; Matsunaga, S.; Yasuno, Y.; Tanioka, K.; Tajima, T. High-Performance Condenser Microphone With Single-Crystalline Silicon Diaphragm and Backplate. IEEE Sens. J. 2006, 7, 4–10. [Google Scholar] [CrossRef]

- Iguchi, Y.; Goto, M.; Iwaki, M.; Ando, A.; Tanioka, K.; Tajima, T.; Takeshi, F.; Matsunaga, S.; Yasuno, Y. Silicon microphone with wide frequency range and high linearity. Sens. Actuators A Phys. 2007, 135, 420–425. [Google Scholar] [CrossRef]

- Kwon, H.-S.; Lee, K.-C. Double-chip condenser microphone for rigid backplate using DRIE and wafer bonding technology. Sens. Actuators A Phys. 2007, 138, 81–86. [Google Scholar] [CrossRef]

- Kasai, T.; Tsurukame, Y.; Takahashi, T.; Sato, F.; Horiike, S. Small Silicon Condenser Microphone Improved with a Backchamber with Concave Lateral Sides. In Proceedings of the TRANSDUCERS 2007-2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 2613–2616. [Google Scholar]

- Chen, J.-Y.; Hsu, Y.-C.; Lee, S.-S.; Mukherjee, T.; Fedder, G.K. Modeling and simulation of a condenser microphone. Sens. Actuators A Phys. 2008, 145, 224–230. [Google Scholar] [CrossRef]

- Ganji, B.A.; Majlis, B.Y. Deposition and etching of diaphragm and sacrificial layer in novel MEMS capacitive microphone structure. In Proceedings of the 2008 IEEE International Conference on Semiconductor Electronics, Johor Bahru, Malaysia, 25–27 November 2008. [Google Scholar]

- Her, H.-C.; Wu, T.-L.; Huang, J.H. Acoustic analysis and fabrication of microelectromechanical system capacitive microphones. J. Appl. Phys. 2008, 104, 84509. [Google Scholar] [CrossRef]

- Hall, N.A.; Okandan, M.; Littrell, R.; Bicen, B.; Degertekin, F.L. Simulation of Thin-Film Damping and Thermal Mechanical Noise Spectra for Advanced Micromachined Microphone Structures. J. Microelectromech. Syst. 2008, 17, 688–697. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaur, M.C.; Pratap, R.; Bhat, N. Design of a high sensitivity FET integrated MEMS microphone. Procedia Chem. 2009, 1, 875–878. [Google Scholar] [CrossRef] [Green Version]

- Ganji, B.A.; Majlis, B.Y. Design and fabrication of a new MEMS capacitive microphone using a perforated aluminum diaphragm. Sens. Actuators A Phys. 2009, 149, 29–37. [Google Scholar] [CrossRef]

- Ganji, B.A.; Majlis, B.Y. High sensitivity and small size MEMS capacitive microphone using a novel slotted diaphragm. Microsyst. Technol. 2009, 15, 1401–1406. [Google Scholar] [CrossRef]

- Lee, J.; Ko, S.; Je, C.; Lee, M.; Choi, C.-A.; Yang, Y.; Heo, S.; Kim, J. A surface-micromachined MEMS acoustic sensor with X-shape bottom electrode anchor. Sensors 2009. [Google Scholar] [CrossRef]

- Leinenbach, C.; Van Teeffelen, K.; Laermer, F.; Seidel, H. A new capacitive type MEMS microphone. In Proceedings of the 2010 IEEE 23rd International Conference on Micro Electro Mechanical Systems (MEMS), Wanchai, Hong Kong, China, 24–28 January 2010. [Google Scholar]

- Ganji, B.A.; Majlis, B.Y. Slotted capacitive microphone with sputtered aluminum diaphragm and photoresist sacrificial layer. Microsyst. Technol. 2010, 16, 1803–1809. [Google Scholar] [CrossRef]

- Yang, C.-T. The sensitivity analysis of a MEMS microphone with different membrane diameters. J. Mar. Sci. Technol. 2010, 18, 790–796. [Google Scholar]

- Mohamad, N. Design of Spring-Supported Diaphragm Capacitive MEMS Microphone. Ph.D. Thesis, Swinburne University of Technology, Victoria, Australia, November 2016. [Google Scholar]

- Chan, C.K.; Lai, W.C.; Wu, M.; Wang, M.Y.; Fang, W. Design and Implementation of a Capacitive-type Microphone with Rigid Diaphragm and Flexible Spring Using the Two Poly Silicon Micromachining Processes. IEEE Sens. J. 2011, 11, 2365–2371. [Google Scholar] [CrossRef]

- Chiang, C.-T.; Wu, C.-Y. A CMOS Digitized Silicon Condenser Microphone for Acoustic Applications. IEEE Sens. J. 2011, 11, 296–304. [Google Scholar] [CrossRef]

- Huang, C.-H.; Lee, C.-H.; Hsieh, T.-M.; Tsao, L.-C.; Wu, S.; Liou, J.-C.; Wang, M.-Y.; Chen, L.-C.; Yip, M.-C.; Fang, W. Implementation of the CMOS MEMS Condenser Microphone with Corrugated Metal Diaphragm and Silicon Back-Plate. Sensors 2011, 11, 6257–6269. [Google Scholar] [CrossRef] [PubMed]

- Jawed, S.A.; Cattin, D.; Gottardi, M.; Massari, N.; Baschirotto, A.; Simoni, A. A 828μW 1.8V 80dB dynamic-range readout interface for a MEMS capacitive microphone. In Proceedings of the ESSCIRC 2008—34th European Solid-State Circuits Conference, Edinburgh, UK, 15–19 September 2008. [Google Scholar]

- Je, C.H.; Lee, J.; Yang, W.S.; Kim, J. The Novel Sensitivity Improved Surface Micromachined MEMS Microphone with the Center-Hole Membrane. Procedia Eng. 2011, 25, 583–586. [Google Scholar] [CrossRef] [Green Version]

- Kasai, T.; Sato, S.; Conti, S.; Padovani, I.; David, F.; Uchida, Y.; Takahashi, T.; Nishio, H. Novel concept for a MEMS microphone with dual channels for an ultrawide dynamic range. In Proceedings of the 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011. [Google Scholar]

- Lee, J.; Je, C.; Yang, W.; Kim, J. Structure-based equivalent circuit modeling of a capacitive-type MEMS microphone. In Proceedings of the 2012 International Symposium on Communications and Information Technologies (ISCIT), Gold Coast, QLD, Australia, 2–5 October 2012. [Google Scholar]

- Ahmadnejad, J.; Ganji, B.A.; Nemati, A.; Nemati, A. Design, analysis, and modelling of a MEMS capacitive microphone for integration into CMOS circuits. In Proceedings of the 2013 IEEE Asia Pacific Conference on Postgraduate Research in Microelectronics and Electronics (PrimeAsia), Visakhapatnam, India, 19–21 December 2013. [Google Scholar]

- Chao, P.C.-P.; Tsai, C.-Y.; Chiu, C.-W.; Tsai, C.-H.; Tu, T.-Y. A new hybrid fabrication process for a high sensitivity MEMS microphone. Microsyst. Technol. 2013, 19, 1425–1431. [Google Scholar] [CrossRef]

- Je, C.H.; Lee, J.; Yang, W.S.; Kwon, J.-K. A surface micromachined MEMS capacitive microphone with back-plate supporting pillars. In SENSORS, 2013 IEEE; IEEE: Piscataway, NJ, USA, 2013. [Google Scholar]

- Kuntzman, M.L.; Hall, N.A. A broadband, capacitive, surface-micromachined, omnidirectional microphone with more than 200 kHz bandwidth. J. Acoust. Soc. Am. 2014, 135, 3416–3424. [Google Scholar] [CrossRef]

- Lee, Y.H.; Jung, Y.D.; Kwak, J.-H.; Hur, S. Design and Fabrication of One-Chip MEMS Microphone for the Hearing Impaired. Appl. Mech. Mater. 2014, 461, 577–580. [Google Scholar] [CrossRef]

- Lee, Y.H.; Jung, Y.; Kwak, J.-H.; Hur, S. Development of capacitive-type MEMS microphone with CMOS amplifying chip. Int. J. Precis. Eng. Manuf. 2014, 15, 1423–1427. [Google Scholar] [CrossRef]

- Grixti, R.; Grech, I.; Casha, O.; Darmanin, J.M.; Gatt, E.; Micallef, J. Analysis and design of an electrostatic MEMS microphone using the PolyMUMPs process. Analog. Integr. Circuits Signal Process. 2015, 82, 599–610. [Google Scholar] [CrossRef]

- Kuntzman, M.L.; Kim, D.; Hall, N.A. Microfabrication and Experimental Evaluation of a Rotational Capacitive Micromachined Ultrasonic Transducer. J. Microelectromech. Syst. 2014, 24, 404–413. [Google Scholar] [CrossRef]

- Lo, S.-C.; Lai, W.-C.; Chang, C.-I.; Lo, Y.-Y.; Wang, C.; Bai, M.R.; Fang, W. Development of a no-back-plate SOI MEMS condenser microphone. In Proceedings of the 2015 Transducers-2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015. [Google Scholar]

- Shin, K.; Jeon, J.; West, J.E.; Moon, W. A Micro-Machined Microphone Based on a Combination of Electret and Field-Effect Transistor. Sensors 2015, 15, 20232–20249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Todorović, D.; Matković, A.; Milićević, M.; Jovanović, D.; Gajic, R.; Salom, I.; Spasenović, M. Multilayer graphene condenser microphone. 2D Mater. 2015, 2, 45013. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Jeon, J.H.; Kim, Y.-G.; Lee, S.Q.; Yang, W.S.; Lee, J.S.; Lee, S.-G. TiN/PECVD-Si3N4/TiN diaphragm-based capacitive-type MEMS acoustic sensor. Electron. Lett. 2016, 52, 468–470. [Google Scholar] [CrossRef]

- Manz, J.; Dehe, A.; Schrag, G. Modeling high signal-to-noise ratio in a novel silicon MEMS microphone with comb readout. In Proceedings of the Smart Sensors, Actuators, and MEMS VIII, Barcelona, Spain, 8–11 May 2017. [Google Scholar]

- Mao, W.-J.; Cheng, C.-L.; Lo, S.-C.; Chen, Y.-S.; Fang, W. Design and implementation of a CMOS-MEMS microphone without the back-plate. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017. [Google Scholar]

- Woo, S.; Han, J.-H.; Lee, J.H.; Cho, S.; Seong, K.-W.; Choi, M.; Cho, J.-H. Realization of a High Sensitivity Microphone for a Hearing Aid Using a Graphene–PMMA Laminated Diaphragm. ACS Appl. Mater. Interfaces 2017, 9, 1237–1246. [Google Scholar] [CrossRef]

- Hamzah, A.; Zawawi, S.A.; Majlis, B.Y.; Mohd-Yasin, F. Mechanical performance of SiC based MEMS capacitive microphone for ultrasonic detection in harsh environment. In Proceedings of the Nanoengineering: Fabrication, Properties, Optics, and Devices XIV, San Diego, CA, USA, 9–10 August 2017. [Google Scholar]

- Sedaghat, S.B.; Ganji, B.A. A novel MEMS capacitive microphone using spring-type diaphragm. Microsyst. Technol. 2018, 25, 217–224. [Google Scholar] [CrossRef]

- Nicollini, G.; Devecchi, D. MEMS Capacitive Microphones: Acoustical, Electrical, and Hidden Thermal-Related Issues. IEEE Sens. J. 2018, 18, 5386–5394. [Google Scholar] [CrossRef]

- Ganji, B.A.; Sedaghat, S.B.; Roncaglia, A.; Belsito, L. Design and fabrication of very small MEMS microphone with silicon diaphragm supported by Z-shape arms using SOI wafer. Solid-State Electron. 2018, 148, 27–34. [Google Scholar] [CrossRef]

- Jantawong, J.; Atthi, N.; Leepattarapongpan, C.; Srisuwan, A.; Jeamsaksiri, W.; Sooriakumar, K.; Austin, A.; Niemcharoen, S. Fabrication of MEMS-based capacitive silicon microphone structure with staircase contour cavity using multi-film thickness mask. Microelectron. Eng. 2019, 206, 17–24. [Google Scholar] [CrossRef]

- Wittmann, S.; Glacer, C.; Wagner, S.; Pindl, S.; Lemme, M.C. Graphene Membranes for Hall Sensors and Microphones Integrated with CMOS-Compatible Processes. ACS Appl. Nano Mater. 2019, 2, 5079–5085. [Google Scholar] [CrossRef]

- Mustapha, H.M.; Wee, M.M.; Zain, A.R.; Mohamed, M.A. Characterization of Graphene based Capacitive Microphone. Sains Malays. 2019, 48, 1201–1207. [Google Scholar] [CrossRef]

- Auliya, R.Z.; Buyong, M.R.; Majlis, B.Y.; Wee, M.F.M.R.; Ooi, P.C. Characterization of embedded membrane in corrugated silicon microphones for high-frequency resonance applications. Microelectron. Int. 2019, 36, 137–142. [Google Scholar] [CrossRef]

- Wood, G.S.; Torin, A.; Al-Mashaal, A.K.; Smith, L.; Mastropaolo, E.; Newton, M.J.; Cheung, R. Design and Characterization of a Micro-Fabricated Graphene-Based MEMS Microphone. IEEE Sens. J. 2019, 19, 7234–7242. [Google Scholar] [CrossRef] [Green Version]

- Hohm, D.; Gerhard, R. Silicon-dioxide electret transducer. J. Acoust. Soc. Am. 1984, 75, 1297–1298. [Google Scholar] [CrossRef]

- Scheeper, P.; Olthuis, W.; Bergveld, P. The design, fabrication, and testing of corrugated silicon nitride diaphragms. J. Microelectromech. Syst. 1994, 3, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Ganji, B.A.; Majlis, B.Y. Fabrication and Characterization of a New MEMS Capacitive Microphone Using Perforated Diaphragm. IJE Trans. B 2009, 2, 153–160. [Google Scholar]

- Kälvesten, E.; Lofdahl, L.; Stemme, G. Small piezoresistive silicon microphones specially designed for the characterization of turbulent gas flows. Sens. Actuators A Phys. 1995, 46, 151–155. [Google Scholar] [CrossRef]

- Fu, M.; Dehe, A.; Lerch, R. Analytical analysis and finite element simulation of advanced membranes for silicon microphones. IEEE Sens. J. 2005, 5, 857–863. [Google Scholar] [CrossRef]

- Lu, C.-L.; Yeh, M.-K. Thermal stress analysis for a CMOS-MEMS microphone with various metallization and materials. Microelectron. Eng. 2019, 213, 47–54. [Google Scholar] [CrossRef]

- Kim, J.; Lee, H.; Kim, C.; Seo, D.; Shin, K.; Moon, W. MEMS microphone based on the membrane with bias voltage and FET (field effect transistor) mechano-electrical transduction. J. Acoust. Soc. Am. 2018, 144, 1701–1702. [Google Scholar] [CrossRef]

- Wang, Z.; Zou, Q.; Song, Q.; Tao, J.; Zhe, W. The era of silicon MEMS microphone and look beyond. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015. [Google Scholar]

| Diaphragm | Backplate | Performances | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Authors [Ref] Year | Niche Application | Fabrication Method(s) | Material | Geometry and Topology | Size | Thickness (µm) | Air Gap (µm) | Electrode Material | Backplate Materials | Air Damping Mechanism | Bias Voltage (V) | Stray Capacitance (pF) | Input SPL * (dB) | Open Circuit Sensitivity (mV/Pa) | Resonant Frequency (kHz) |

| Hohm et al. [36] (1989) | none | bulk, back etching, bonding | Si3N4 | Square flat | 0.8 × 0.8 mm2 | 0.15 | 2.0 | Al | SiO2 | none | 28 | 6.0 | 88 | 9 | N/A |

| Bergqvist et al. [37] (1990) | none | bulk, back etching, bonding | Si | Square flat | 2.0 × 2.0 mm2 | 5.0 | 4.0 | Al | Glass/ Si | 103 acoustic holes on back chamber | 16 | 3.5 | 94 | 13 | 24 |

| Kuhnel et al. [38] (1992) | none | bulk, back etching, bonding | Si3N4 | Square flat | 0.8 × 0.8 mm2 | 0.15 | 2.0 | Al | SiO2/ Si | perforated backplate | 28 | 3.0 | 94 | 1.8 | 30 |

| Scheeper et al. [39] (1992) | hearing aid | surface, Plasma-enhanced chemical vapor deposition (PECVD) | Si3N4 | Square flat | 0.6 × 0.6 mm2 | 1.0 | 2.2 | Ti/Au | SiO2 | acoustic holes (120–525 holes/mm2) | 16 | 7 | N/A | 2 | 14 |

| Bourouina et al. [40] (1992) | none | bulk, anodic bonding | p+ silicon. | Square flat | 1.0 × 1.0 mm2 | 1.0 | N/A | Al | Si/Al | 500 acoustic holes on backplate | 20 | N/A | N/A | 3.5 | 120 |

| Bergqvist et al. [41] (1994) | hearing aid | bonding, back-etching, surface micromachine | SiO2/Si | Square flat | 2.0 × 2.0 mm2 | 5.0 | 2.9 | Al | SiO2/ Si | 400 holes/mm2 on backplate, hole diameter is 30 µm | 10 | 4.3 | 94 | 15 | 17 |

| Bergqvist et al. [42] (1994) | none | surface micromachine | Si | Square flat | 1.8 × 1.8 mm2 | 4.0 | 3.0 | Copper | Ti-Au/Copper | 400 holes/mm2., where holes diameter is 30 µm | 28 | 2.9 | 43 | 1.4 | 47 |

| Scheeper et al. [43] (1994) | hearing aid | surface micromachining, no bonding | Si3N4 | Square flat | 2.0 × 2.0 mm2 | 1.0 | 1,2,3 | N/A | Si3N4 | 120–525 acoustic holes per mm2 | 5 | 6.6 | 30 | 10 | 14 |

| Schellin et al. [44] (1994) | none | bulk micromachining | Si | Square flat | 1.0 × 1.0 mm2 | 1.0 | N/A | Al | Si | N/A | N/A | N/A | N/A | N/A | N/A |

| Donk et al. [45] (1994) | none | N/A | Si3N4 | Square flat | 6.0 × 6.0 mm2 | 2.0 | 40 | N/A | Si3N4 | N/A | N/A | 5 | N/A | N/A | N/A |

| Bay et al. [46] (1996) | hearing aid | bulk, back etching, anodic bonding | Si3N4 | Square flat | 2.0 × 2.0 mm2 | 0.2 | 0.4 | N/A | Si | pillars at the center area of backplate electrode | N/A | N/A | N/A | N/A | N/A |

| Ning et al. [47] (1996) | none | bulk, surface, plasma dry etching | Si3N4 | Square flat | 20 × 20 µm2 | 0.5 - 1.0 | 3.1 | Al | Si3N4 | square perforated holes on backplate | 6 | 9.5 | N/A | 7 | 10 |

| Zou et al. [48] (1997) | none | bulk, back etching | Si3N4 | Square corrugated | 1.0 × 1.0 mm2 | 1.2 | 2.6 | Al | Si3N4 | hole volume is 3 mm3 | 10 | N/A | N/A | 14.2 | 16 |

| Thielemann et al. [49] (1997) | none | bulk, back etching | SiO2/Si3N4 | Square flat | 1.2 × 1.2 mm2 | 0.4 | 3.0 | Al/Au | Si | 324 perforated holes on backplate | 40 | N/A | N/A | N/A | N/A |

| Hsu et al. [50] (1998) | none | N/A | Si | Square flat | 2.0 × 2.0 mm2 | N/A | N/A | N/A | Si | 60 × 60 µm 2 acoustic holes on backplate | 13 | 16.2 | N/A | 20 | 25 |

| Pedersen et al. [51] (1998) | none | CMOS, surface (dry etching) | Polyimide | Square flat | 2.2 × 2.2 mm2 | 1.1 | 3.6 | Cr/Au/Cr | Polyimide | 30 × 30 µm2 acoustic holes on backplate | 2 | N/A | 120 | 10 | 15 |

| Pedersen et al. [52] (1998) | none | CMOS, surface (dry etching) | Polyimide | Square flat | 2.2 × 2.2 mm2 | 1.1 | 3.6 | Cr/Au/Cr | Polyimide | 30 × 30 µm 2 acoustic holes on backplate | 4 | 10.1 | 120 | 10 | 15 |

| Bay et al. [53] (1999) | hearing aid | surface, bulk micromachining | Si3N4 | Square flat | 2.2 × 2.2 mm2 | 0.2 | 0.4 | N/A | Si | perforated backplate | N/A | N/A | N/A | 27 | N/A |

| Kabir et al. [54] (1999) | none | bulk and surface micromachining, electroplating technique | p+ silicon | Square flat | 850 × 850 µm2 | 3.0 | 2.2 | Au | Au | perforated backplate | 9 | 2.4 | N/A | 9.77 | N/A |

| Buhrdorf et al. [55] (2000) | ultrasonic | bulk, electroplating | poly-Si | Square flat | 0.8 × 0.8 mm2 | 1.0 | 2.0 | N/A | Nickel | perforated backplate | 8 | N/A | N/A | N/A | 110 |

| Torkkeli et al. [56] (2000) | none | bulk, surface micromachining | poly-Si | Square flat | 1.0 × 1.0 mm2 | 0.8 | 1.3 | Al | Si | acoustic hole size = 2 × 2 µm 2, perforated hole pitch = 10 µm | 3 | 11 | N/A | 4 | 12 |

| Brauer et al. [57] (2001) | none | bulk, surface micromachining, bonding | poly-Si | Circular flat | d = 800 − 1200 µm | 0.4 | N/A | N/A | Si | N/A | 4.5 | N/A | 120 | 3.2 | 100 Hz |

| Hansen et al. [58] (2000) | ultrasound in air and water | N/A | Si3N4 | Rectangular flat | 0.1 × 0.8 mm2 | 1.3 | 1.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | 300 |

| Li et al. [59] (2001) | none | bulk, surface micromachining, bonding | Si | Square corrugated | 1.0 × 1.0 mm2 | 1.2 | 2.6 | Al | Si | 40 × 40 holes on backplate, the dimension of each hole is 10 × 10 µm | 5 | 1.64 | N/A | 10 | 20 |

| Mullenborn et al. [60] (2001) | hearing aid | N/A | Si | Square flat | 2.0 × 2.0 mm2 | 0.4 | 1.0 | N/A | Si | N/A | 1.5 | N/A | 24 | 5 | N/A |

| Noble et al. [61] (2001) | ultrasound | surface micromachining | Si3N4 | Square flat | 5.0 × 5.0 mm2 | 0.5 | 2.0 | AlSi | AlSi | N/A | 20 | N/A | N/A | 1.4 | N/A |

| Kronast et al. [62] (2001) | none | bulk, surface micromachining, bonding | Si3N4 | Square flat | 2.0 × 2.0 mm2 | 0.3 | 1.3 | Al | Si | acoustic hole density = 123 holes/mm2, holes size = 60 × 60 µm2 | 6 | N/A | 37.7 | 11 | 25 |

| Rombach et al. [63] (2002) | hearing aid | bulk, surface micromachining | SiN & B++ poly Si | Square flat | 2 × 2 mm2, 1 × 1 mm2 | 0.5 | 0.9 | Cr/Pt | Si | perforated double backplate | 1.5 | N/A | 100 | 13 | 20Hz |

| Kressmann et al. [64] (2002) | none | bulk, back etching, bonding | SiO2/Si3N4 | Square corrugated | 1.0 × 1.0 mm2 | 0.6 | 2.0 | Al | Si | 144 holes, each has area of 35 × 35 µm2, 80 µm distance between each hole | N/A | 25 | 39 | 2.9 | 10 |

| Sim et al. [65] (2002) | none | patterning | parylene-C | Circular corrugated | d = 4.3 mm | 3.0 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | NA | N/A |

| Jing et al. [66] (2002) | none | N/A | Si / Si3N4 | Circular corrugated | N/A | N/A | N/A | Al | Si | N/A | 14 | N/A | N/A | 40 | 15 |

| Miao et al. [67] (2002) | none | bulk micromachining | poly-Si | Square flat | 1.0 × 1.0 mm2 | 3.0 | N/A | Al | slotted Al/nitride | acoustic holes on backplate | N/A | N/A | N/A | 10 | 15 |

| Chen et al. [68] (2003) | none | bulk micromachining, deep reactive ion etching (DRIE) | Si / Si3N4 | Circular corrugated | d = 1.0 mm | 0.6 | 2.5 | Al | Si | N/A | 14 | N/A | N/A | 40 | N/A |

| Scheeper et al. [69] (2003) | none | bulk micromachining, bonding | SiN | Square flat | 2.0 × 2.0 mm2 | 0.5 | 20 | Cr/Au | Si | 4 acoustic holes on backplate | N/A | N/A | N/A | 22 | N/A |

| Tajima et al. [70] (2003) | none | bulk, bonding | single crystalline Si | Square flat | 2.0 × 2.0 mm2 | 5.0 | 15 | N/A | Si | acoustic holes on backplate | 48 | N/A | N/A | 4.4 | 24 |

| Wang et al. [71] (2003) | none | bulk, surface micromachining | poly-Si | Square corrugated | 1.0 × 1.0 mm2 | 1.3 | 2.6 | Al | Si | 80 × 80 µm 2 acoustic holes on backplate | 6 | N/A | N/A | 20.8 | N/A |

| Hansen et al. [72] (2004) | wide-band operation | bulk, surface micromachining | Si3N4 | Rectangular flat | 70 × 190 µm 2 | 0.4 | N/A | Al | Si | N/A | 5.8 | N/A | 63.6 | N/A | 100 |

| Ning et al. [73] (2004) | none | bulk, surface micromachining | Si3N4 | Square flat | 1.5 × 1.5 mm2 | 0.5 | 1.5 | Al | Si | 40 × 40 µm 2 acoustic holes | 8.3 | N/A | N/A | 5.6 | 20 |

| Wang et al. [74] (2004) | none | bulk, surface micromachining | poly-Si | Square corrugated | 1.0 × 1.0 mm2 | 1.3 | 2.6 | Al | Si | N/A | 6 | N/A | N/A | 9.8 | N/A |

| Wang et al. [75] (2004) | none | bulk, surface micromachining | poly-Si | Square corrugated | 1.0 × 1.0 mm2 | 1.2 | 2.6 | Al | Si | N/A | 5 | N/A | 50 | 16.4 | 20 |

| Sezen et al. [76] (2005) | bio-medical | N/A | Si3N4 | Circular flat | d = 400 µm | 1.5 | 0.8 | Al | Si | N/A | N/A | N/A | N/A | N/A | N/A |

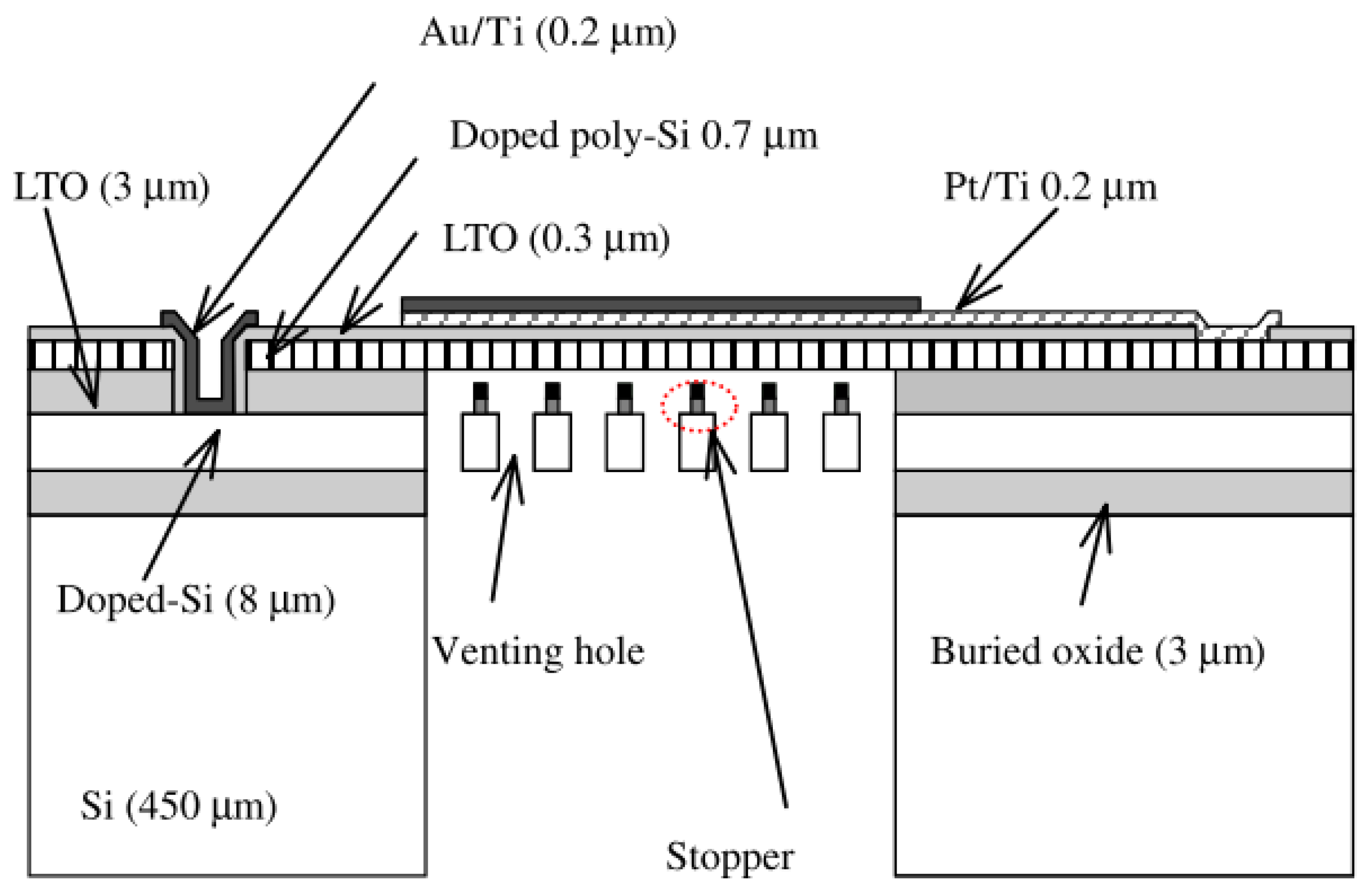

| Ko et al. [77] (2006) | none | bulk, surface micromachining | doped-polySi | Square flat | 1.5 × 1.5 mm2 | 0.7 | 2.4 | Au/Ti and Pt/Ti | Si | acoustic holes on backplate with stopper | 5 | N/A | N/A | 5.17 | 15 |

| Kim et al. [78] (2006) | none | N/A | Al | Square hinge | 1.5 × 1.5 mm2 | N/A | N/A | Al | SiN/Al/SOI | N/A | 25 | N/A | N/A | N/A | 20 |

| Weigold et al. [79] (2006) | none | bulk | Si | Circular flat | N/A | N/A | 3.0 | N/A | Si | N/A | N/A | N/A | N/A | 4.4 | N/A |

| Dehe et al. [80] (2007) | hand free & hearing aid | bulk, surface micromachining | Si | Circular corrugation edge | d = 1 mm | 0.4 | 2.0 | N/A | Si | perforated backplate | 2 | N/A | N/A | 11.2 | 4 |

| Kim et al. [81] (2007) | portable terminals | N/A | Au | Square hinge | 1.5 × 1.5 mm2 | 0.6 | 1.0 | N/A | Si | N/A | 1 | N/A | N/A | 0.01 | 13 |

| Goto et al. [82] (2007) | none | bulk micromachining, bonding | Si | Square flat | 2.0 × 2.0 mm2 | 8.0 | varied up to 100 µm | Al | Si | N/A | 48 | N/A | 122 | 6.6 | 20 |

| Iguchi et al. [83] (2007) | none | bulk micromachining, bonding | Si | Square flat | 2.1 × 2.1 mm2 | 8.0 | 10 | Al | Si | 10 × 10 µm2 acoustic holes on backplate | 39 | N/A | 134 | 2.5 | 20 |

| Kwon et al. [84] (2007) | none | bulk micromachining and Si DRIE | Si3N4 | Square flat | 2.5 × 2.5 mm2 | 0.5 | 9.0 | Au/Ni/Cr | Si | 50–60 µm radius circular acoustic holes on backplate | 28 | N/A | 120 | 0.0089 | 5 |

| Martin et al. [27] (2007) | aeroacoustic measurement | bulk, surface micromachining | Si | Circular flat | d = 0.46 mm | 2.25 | 2.0 | N/A | Si | hole radius: 5 µm | 9.3 | N/A | 164 | 0.39 | 20 |

| Kasai et al. [85] (2007) | none | 4 corner supported diaphragm | poly Si | Square flat | 1.2 × 1.2 mm2 | N/A | N/A | N/A | Si | N/A | 12 | N/A | N/A | 8.8 | 10 |

| Chen et al. [86] (2008) | none | modeling and simulation | Si | Circular flat | d =560 µm | N/A | 4.0 | N/A | N/A | acoustic holes with diameter of 4 µm | 11 | N/A | 100 | 17.7 | 20 |

| Ganji et al. [87] (2008) | none | surface micromachining | Al | Square perforated | 0.5 × 0.5 mm2 | 3.0 | 1.0 | n+ backplate electrode | Si | 20 × 20 µm2 acoustic holes | 105 | N/A | N/A | 0.2 | 20 |

| Her et al. [88] (2008) | none | bulk, surface micromachining | Si | Circular flat | d = 670 µm | 1.0 | 3.0 | Cr/Au | Si | perforated backplate | 6 | N/A | 94 | 7.9 | 10 |

| Hall et al. [89] (2008) | none | N/A | Si | Circular flat | d = 1.5 mm | 2.3 | 3.0 | N/A | Si | perforated backplate | N/A | N/A | N/A | N/A | 20 |

| Kaur et al. [90] (2009) | none | SOI | Si | Square flat | 0.5 × 0.5 mm2 | 10 - 20 nm | 0.1 to 1.95 | N/A | N/A | N/A | 0.04 | N/A | N/A | N/A | 20 |

| Ganji et al. [91] (2009) | none | surface micromachining | Al | Square perforated | 0.5 × 0.5 mm2 | 3 | 1.0 | n+ backplate electrode | Si | holes size of 20 × 20 µm 2, distance between holes is 80 µm | 105 | 2.12 | N/A | 0.2 | 20 |

| Ganji et al. [92] (2009) | none | simulation | Al | Square slotted | 2.43 × 2.43 mm2 | 3.0 | 1.0 | n+ backplate electrode | Si | N/A | 105 | N/A | N/A | N/A | 528 |

| Lee et al. [93] (2009) | none | surface micromachining | Au | Circular flat | d = 300 µm | N/A | 2.0 | Ti/Al/TiN | Si | N/A | 5 | 1.87 | N/A | 0.57 | N/A |

| Leinenbach et al. [94] (2010) | none | bulk | Si | Circular flat | d = 0.6 mm | N/A | N/A | N/A | Si | perforated backplate | N/A | N/A | N/A | N/A | 12 |

| Ganji et al. [95] (2010) | none | surface micromachining | Al | Square slotted | N/A | 3.0 | 1.3 | Al | Si | perforated diaphragm | N/A | 17.5 | N/A | N/A | N/A |

| Yang et al. [96] (2010) | none | N/A | Si3N4 | Circular flat | d = 450 µm | 1.5 | 2.75 | Al/ Au | Si3N4 | N/A | 12 | N/A | N/A | 14 | N/A |

| Mohamad et al. [97] (2010) | none | Poly Multi-Users MEMS Process (MUMPS) | Poly-Si | Square flat spring | 4.0 × 4.0 mm2 | 4 | 4 | Au | Poly-Si | 50 holes on backplate | 3 | N/A | N/A | 4.67 | 10.2 |

| Chan et al. [98] (2011) | none | surface micromachining | poly Si | Circular spring | d = 1 mm | 3.0 | 2.0 | N/A | Si | perforated rigid backplate | N/A | 1.81 | 94 | 12.63 | 24.9 |

| Chiang et al. [99] (2011) | mobile phones, laptops, hearing aids | N/A | Si | Rectangular flat | 1444 × 1383 µm 2 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | 94 | N/A | 20 |

| Huang et al. [100] (2011) | none | bulk, surface micromachining | Corrugated Al | Circular corrugated | d = 800 µm | 1.1 | 4.2 | N/A | Si | air holes diameter: 20 µm | 6 | 0.7 | N/A | 7.9 | 10 |

| Jawed et al. [101] (2011) | none | bulk, surface micromachining | Si | Square flat | N/A | N/A | N/A | N/A | Au | N/A | N/A | 1.64 | 55 | 10 | 9 |

| Je et al. [102] (2011) | none | surface micromachining | Al | Circular flat center-hole | d = 500 µm | 1.0 | 2.0 | Ti/Al | SiO2/Al/SiN | 5 holes at the center of diaphragm, where diameter of each hole is 12 µm | 6 | N/A | N/A | N/A | 20 |

| Kasai et al. [103] (2011) | none | bulk, surface micromachining | Si | Square flat dual channel | N/A | N/A | N/A | N/A | Si3N4 / Si | N/A | N/A | N/A | N/A | 5.6 | 20 |

| Lee et al. [104] (2012) | none | bulk, surface micromachining | Si3N4 | Circular flat | d = 600 µm | 0.9 | 2.45 | Al | SiO2 / Si3N4 | 1668 acoustic holes on backplate, where hole radius = 4 µm. | 10.4 | 1.02 | N/A | 3.75 | 18 |

| Ahmadnejad et al. [105] (2013) | none | simulation | Al | Square perforated | 2.43 × 2.43 mm2 | 1.0 | 1.0 | n+ backplate electrode | Si | 16 holes on diaphragm, side length = 20 µm | 2.3 | N/A | N/A | 6.916 | N/A |

| Chao et al. [106] (2013) | mobile device | bulk, surface | poly Si | Square flat | 2.0 × 2.0 mm2 | 1.1 | 3.75 | N/A | Si | perforated backplate | 4.5 | 2.4 | N/A | 1.7 | 10 |

| Je et al. [107] (2013) | none | surface micromachining, CMOS | Al/Si3N4/Al | Circular flat | d = 500 µm | 1.0 | 2.5 | Al | Al/Si3N4/Al | perforated backplate | 6 | N/A | N/A | 10.37 | 20 |

| Kuntzman et al. [108] (2014) | none | surface micromachining | poly Si | Circular flat | d = 630 µm | 2.25 | 11 | N/A | Si | air volume in the cavity with radius of 315–504 µm | 100 | 0.25 | N/A | 0.167 | 230 |

| Lee et al. [109] (2014) | none | simulation | Si | Square flat | 900 × 900 µm 2 | 1.0 | 3 | Ti/Au | Si | Acoustic holes with diameter of 24 µm. | 12 | N/A | N/A | 9 | 79.4 |

| Lee et al. [110] (2014) | none | bulk, eutectic bonding | Si3N4 | Circular flat | d = 2 mm | 1.0 | 3.0 | Ti/Au | Si | acoustic holes cover 18% of backplate | 12 | N/A | N/A | 13 | 10 |

| Grixti et al. [111] (2015) | none | N/A | Si | Square flat | 675 × 675 µm2 | 0.5 | 2.0 | Au | Si | holes-to-backplate ratio = 0.33 | 6 | 1.53 | 139 | 8.4 | 1 |

| Kuntzman et al. [112] (2015) | ultrasonic | N/A | Si | Circular flat | d = 630 µm | 2.3 | 0.3 | N/A | Si | square holes on backplate | 50 | N/A | N/A | 10 | 18.8 |

| Lo et al. [113] (2015) | none | bulk, surface micromachining | Si | Circular flat | d = 600 µm | 1.6 | 1.6 | N/A | No backplate | N/A | N/A | N/A | N/A | N/A | 1 |

| Shin et al. [114] (2015) | none | electret substrate: bulk, surface | Si | Circular flat | d = 1.2 mm | 5.0 | 5.0 | Cr/Au | Si | 110 µm diameter acoustic holes | N/A | N/A | 107 | N/A | 20 |

| Todorovic et al. [115] (2015) | none | bulk, surface micromachining | Multilayer graphene | Circular flat | d = 12 mm | 0.025 | 18.6 | N/A | N/A | N/A | 200 | N/A | 90 | 50 | 6.5 |

| Gharaei et al. [26] (2016) | aerospace application | simulation | Si | Circular flat | d = 660 µm | 230 | 2.0 | N/A | Si | 367 acoustic holes on backplate | 11 | 1.15 | N/A | 0.478 | 100 |

| Lee et al. [116] (2016) | none | bulk, surface micromachining | TiN/Si3N4/TiN | Circular flat | d= 0.65 mm | 0.6 | 1.6 | Al | Si3N4 | acoustic holes on backplate, radius: 4 µm | 11.1 | 0.23 | N/A | 5.3 | 10 |

| Manz et al. [117] (2017) | none | N/A | Si | Rectangular flat | 500 × 800 µm 2 | N/A | 0.5 | N/A | N/A | N/A | N/A | N/A | 73 | 12.5 | 35 |

| Mao et al. [118] (2017) | none | CMOS | Pure dielectric-film | Circular flat | d = 300 µm | N/A | N/A | N/A | No backplate | N/A | 13.5 | N/A | N/A | 0.6 | 22 |

| Woo et al. [119] (2017) | hearing aid | Bulk micromachining | Graphene / Polymethylmethacrylate (Acrylic) or PMMA | Circular flat | d = 4.0 mm | N/A | 10 | Au | Ti | N/A | N/A | N/A | 90 | 100 | 7.0 |

| Zawawi et al. [120] (2017) | detect poisonous gas | Finite element analysis (FEA) simulation | 3C-SiC | Square flat | 1.0 × 1.0 mm2 | 1.0 | 3.0 | N/A | N/A | perforated backplate | N/A | N/A | N/A | N/A | 36 |

| Sedaghat et al. [121] (2018) | none | FEA (simulation) | Al | Square perforated | 0.5 × 0.5 mm2 | 3.0 | 1.0 | N/A | Si | perforated diaphragm area is 0.0144 mm2 | 1.35 | N/A | N/A | 6.677 | 21.504 |

| Nicollini et al. [122] (2018) | none | CMOS | Poly-Si | Rectangular flat | 0.5 × 1.0 mm | N/A | 5.6 | N/A | N/A | acoustic holes on the backplate | N/A | N/A | 120 | 12.58 | 20 |

| Ganji et al. [123] (2018) | none | bulk micromachining using SOI wafer | Si | Square perforated | 0.3 × 0.3 mm2 | 5.0 | 1.0 | N/A | Si | 5 × 5 µm holes size on perforated diaphragm | 5 | N/A | N/A | 2.46 | 60 |

| Jantawong et al. [124] (2019) | none | bulk micromachining | Poly-Si | Circular flat | d = 930 µm | 0.8 | 3.5 | Al | Si | perforated backplate | N/A | N/A | 123 | N/A | N/A |

| Wittmann et al. [125] (2019) | none | CMOS | Graphene | Circular flat | d = 40 µm | N/A | N/A | Au | Si | N/A | 1.5 | N/A | N/A | 1.051 | 100 |

| Mustapha et al. [126] (2019) | none | bulk micromachining | Graphene | Circular flat | d = 40 µm | 0.5 | 0.2 | Cr/Au | Si | N/A | 3.0 | N/A | N/A | 0.035 | 20 |

| Auliya et al. [127] (2019) | none | FEA simulation | Si/SiC/tungsten | Circular corrugated | d = 2.0 mm | 18 | 18 | N/A | N/A | N/A | 41 | N/A | N/A | 0.15 | 70 |

| Malik et al. [3] (2019) | hearing aid | N/A | Si3N4 | Circular flat | area = 7850 µm 2 | 2.0 | N/A | N/A | Si | perforated backplate | 4.0 | N/A | N/A | 0.086 | 10 |

| Wood et al. [128] (2019) | none | bulk micromachining | Graphene/PMMA | Circular flat | d = 3.5 mm | 0.2 | 8.0 | Al | SiO2/Si | N/A | 1.0 | N/A | 80 | 10 | 20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zawawi, S.A.; Hamzah, A.A.; Majlis, B.Y.; Mohd-Yasin, F. A Review of MEMS Capacitive Microphones. Micromachines 2020, 11, 484. https://doi.org/10.3390/mi11050484

Zawawi SA, Hamzah AA, Majlis BY, Mohd-Yasin F. A Review of MEMS Capacitive Microphones. Micromachines. 2020; 11(5):484. https://doi.org/10.3390/mi11050484

Chicago/Turabian StyleZawawi, Siti Aisyah, Azrul Azlan Hamzah, Burhanuddin Yeop Majlis, and Faisal Mohd-Yasin. 2020. "A Review of MEMS Capacitive Microphones" Micromachines 11, no. 5: 484. https://doi.org/10.3390/mi11050484

APA StyleZawawi, S. A., Hamzah, A. A., Majlis, B. Y., & Mohd-Yasin, F. (2020). A Review of MEMS Capacitive Microphones. Micromachines, 11(5), 484. https://doi.org/10.3390/mi11050484