Additive Manufacturing for Soft Robotics: Design and Fabrication of Airtight, Monolithic Bending PneuNets with Embedded Air Connectors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

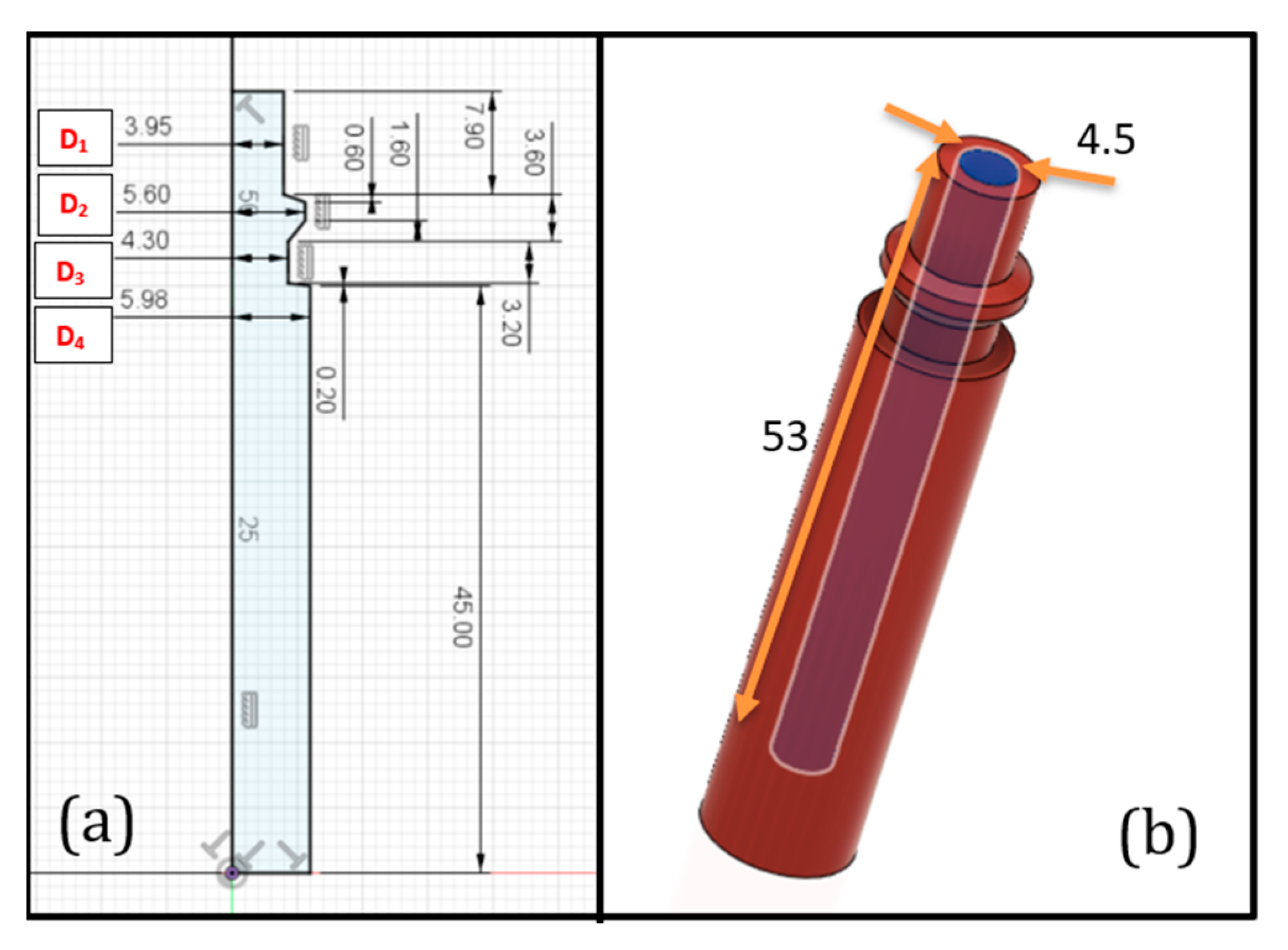

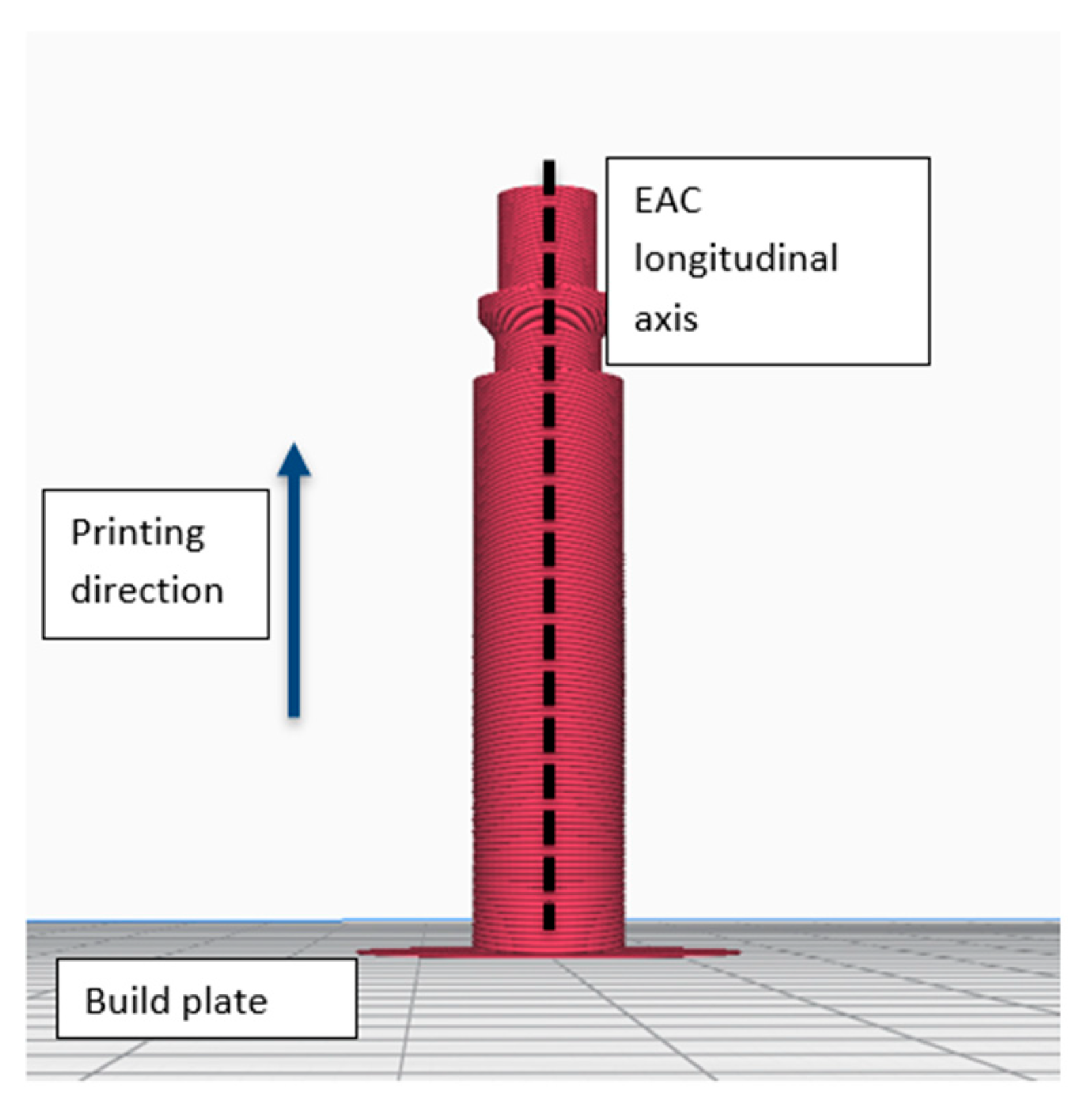

2.2. Leakage-Free 3D-Printed Embedded Air Connector—First Printing Orientation

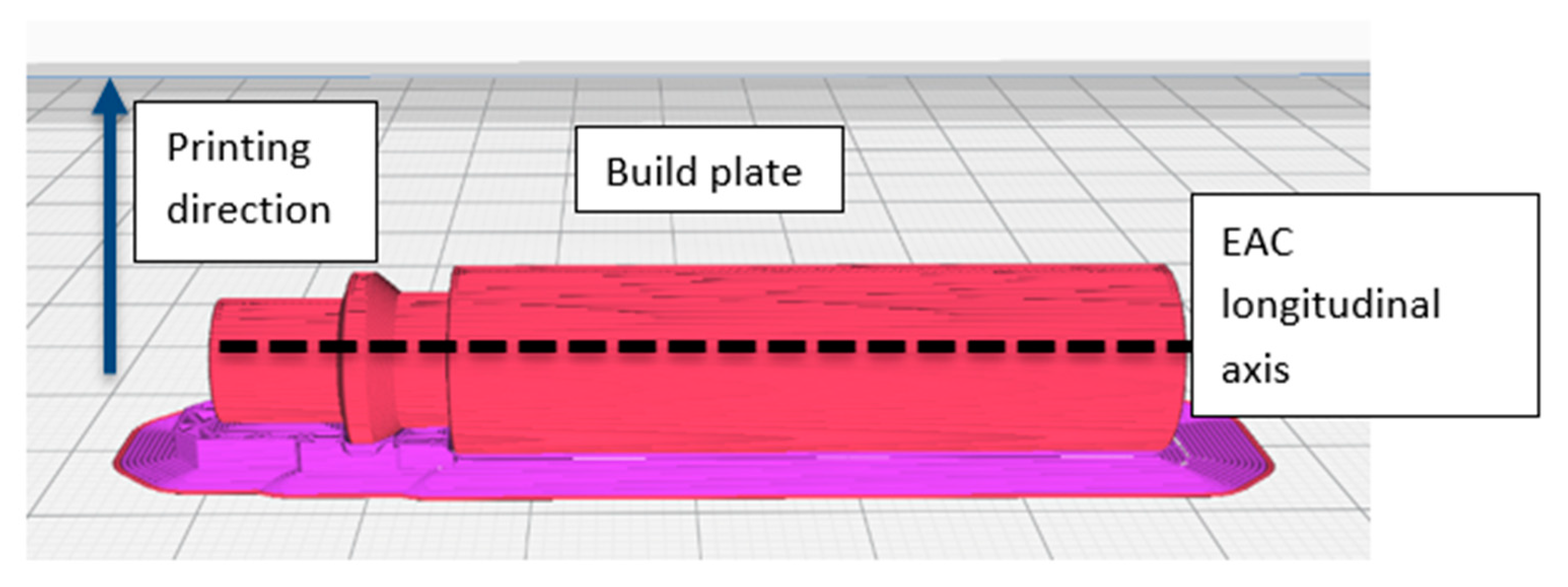

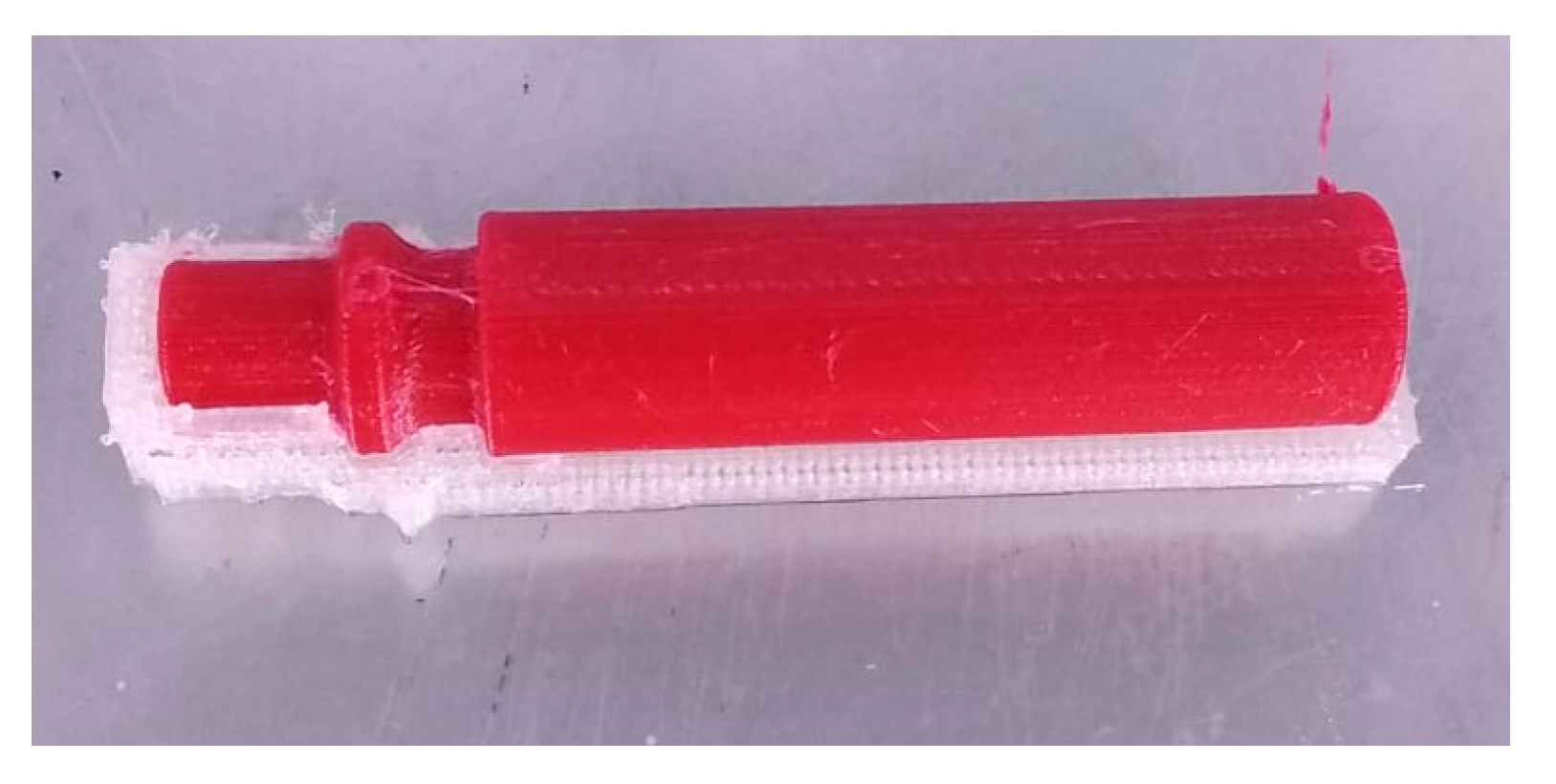

2.3. Leakage-Free 3D-Printed Embedded Air Connector—Second Printing Orientation

- The EAC is connected to the pneumatic pipe of the compressor and a pressure of 3 bar has been reached.

- The air supply is stopped and the amount of pressure reduction (indicative of an air leak) is measured, resulting in the time until a new pressure of 2 bar is reached.

- Compressed air is resupplied and the time to reach , , is measured.

- No combination resulted in complete air tightness when the EAC was printed with its longitudinal axis parallel to build plate.

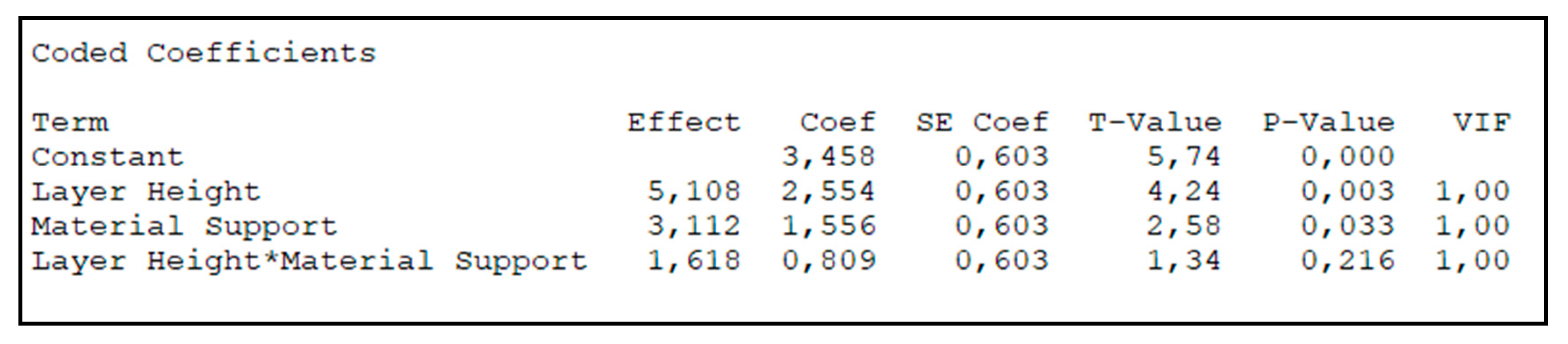

- The main parameter affecting air leakage is layer height which indicates that switching from a layer height of 0.05 to 0.15 mm resulted in a greater increase in air leakage than changing the support material.

- The type of support material only has a minor effect on air leakage. Keeping the layer height constant, the variance increases by moving from PVA to TPU 95 A which is due the latter material requiring the manual removal of the support.

- The interaction between both parameters is small in comparison to the effect of individual parameters. Additionally, in accordance with p-values, it is possible to assert that the main effects of A and B are statistically significant and that there is no interaction among them.

- The best solution in terms of minimizing air leakage is also the most expensive one because it requires the use of two different materials and the amount of extruded filament is larger than with other combinations (the quantity of extruded filament increases when the layer height decreases). The cost, as estimated by the slicing software, for the four combinations , , , and is 0.74, 0.61, 0.58, and 0.89 €, respectively.

3. Results and Discussion

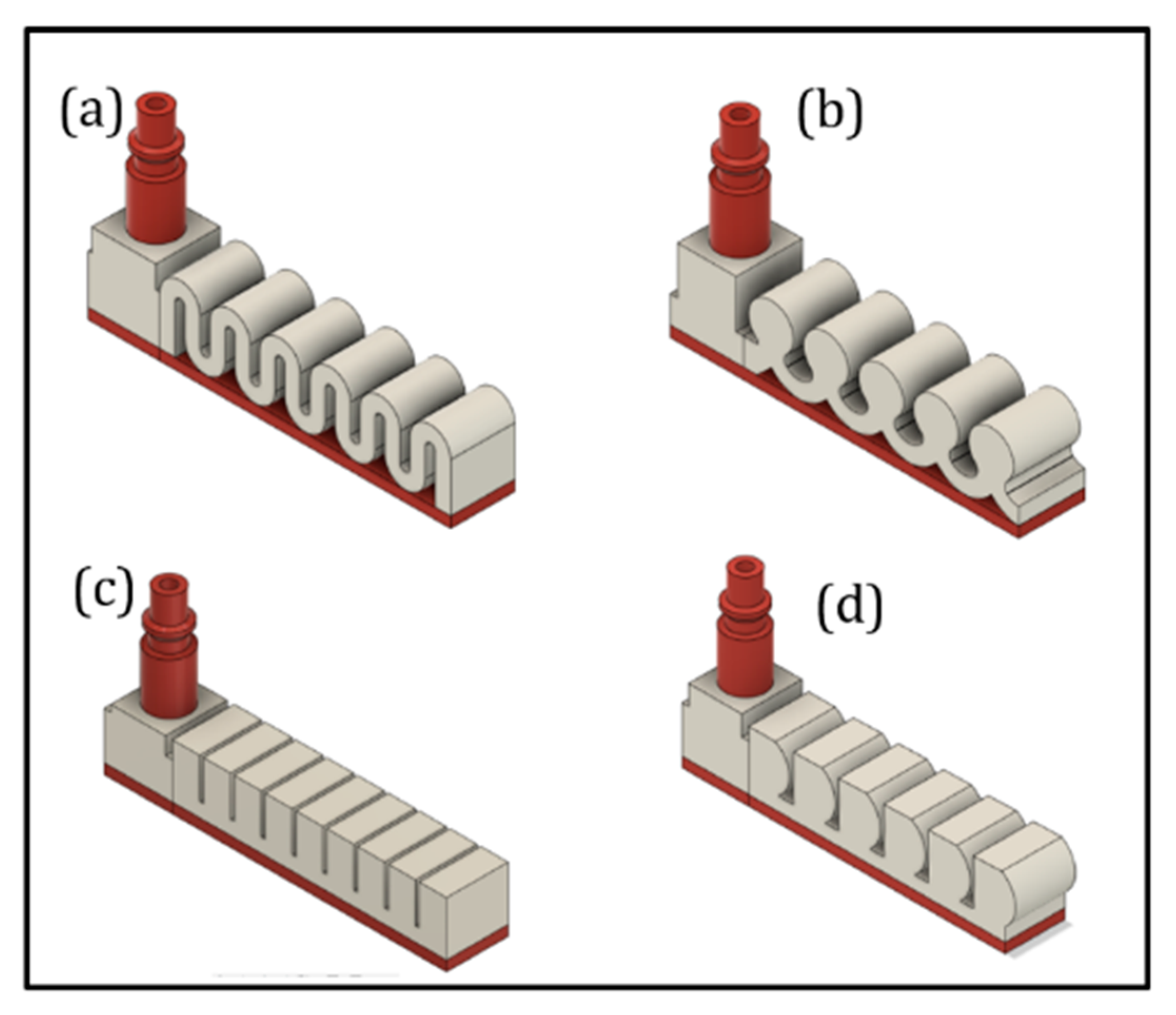

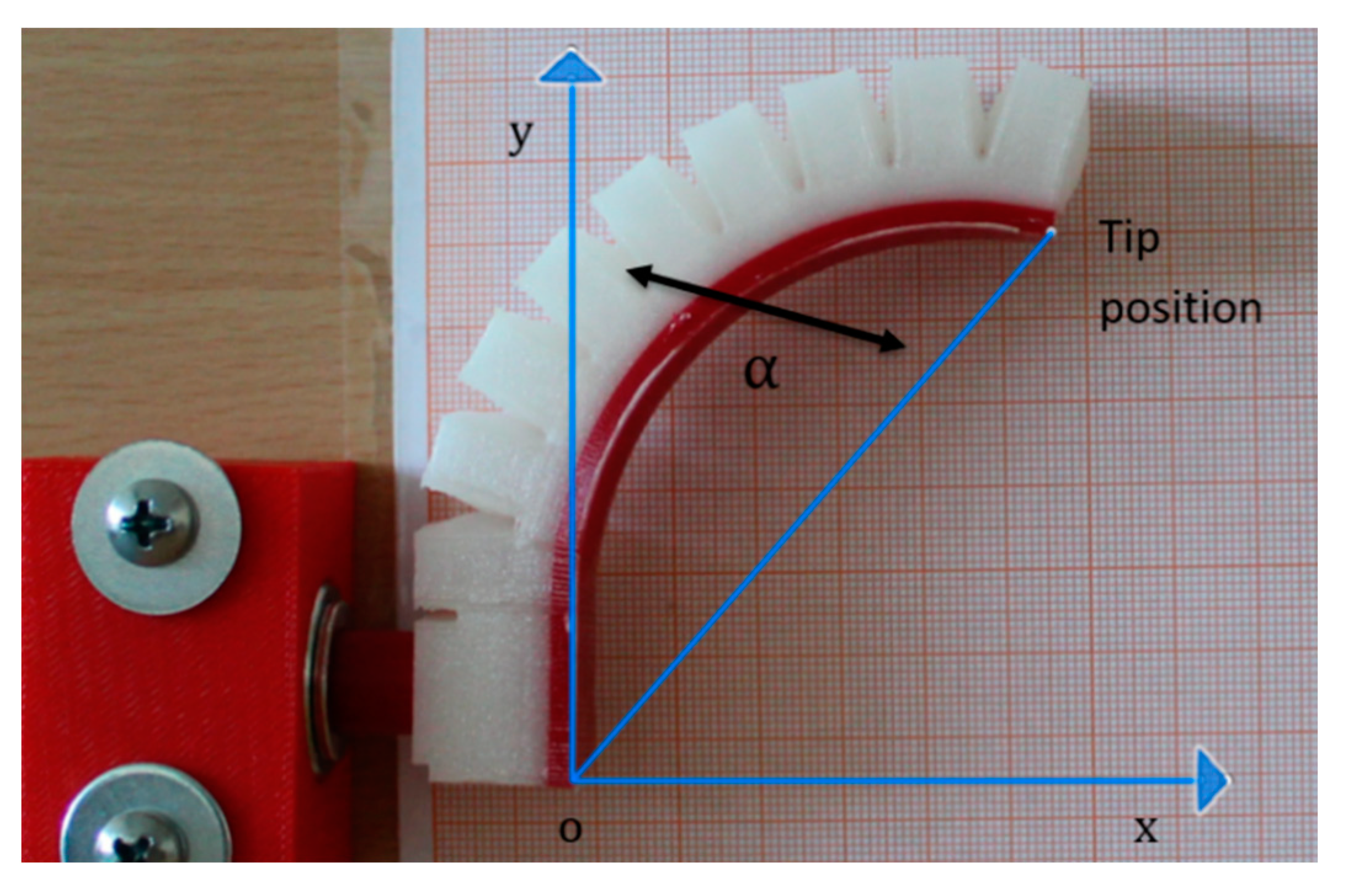

3.1. Monolithic Bending PneuNet (MBP)—Shape Investigation

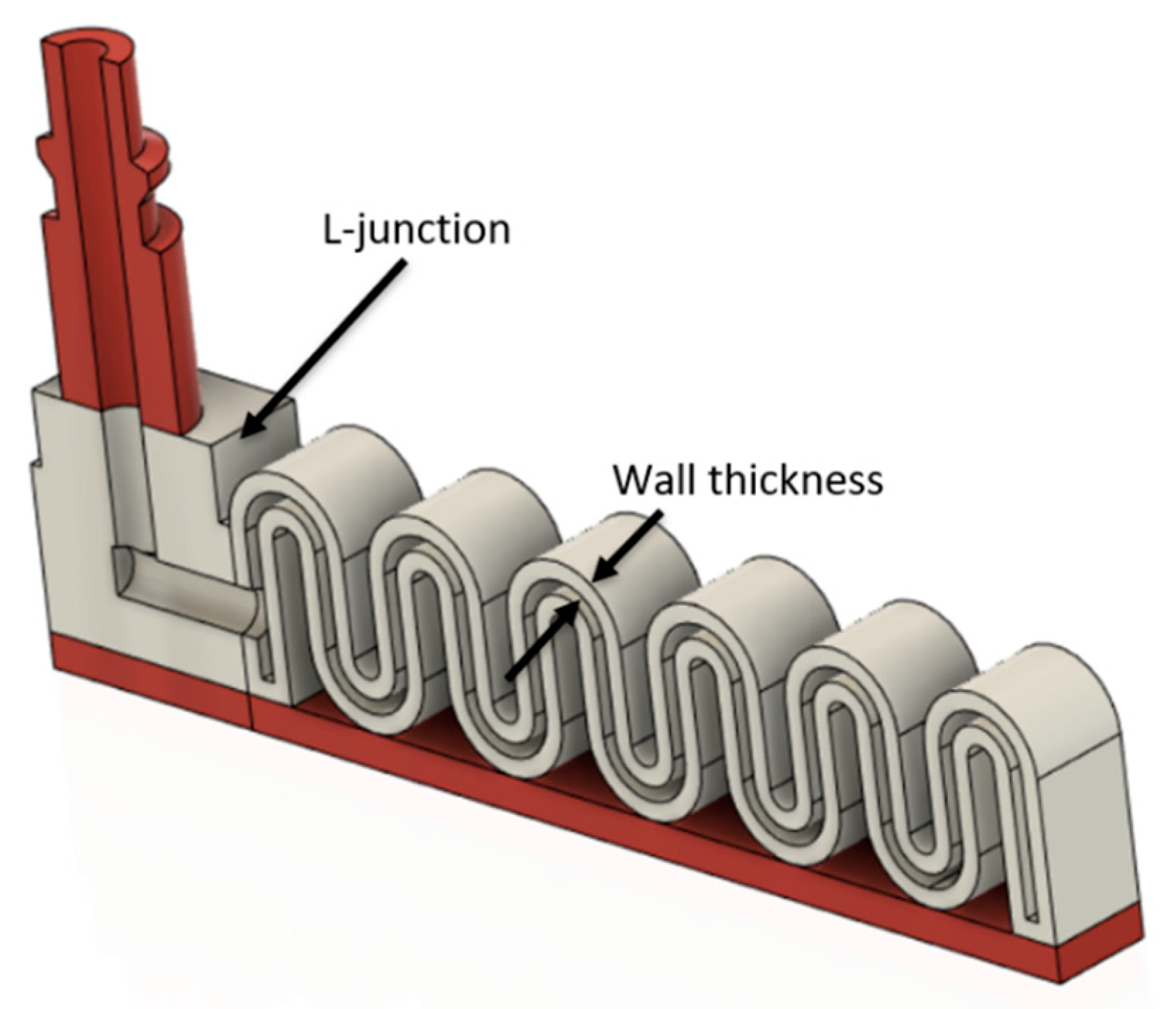

- The EAC embedded in the soft actuator structure has been designed for printing with its longitudinal axis perpendicular to the build plate to ensure air tightness at the pneumatic pipe interface. With this design choice, it is necessary to direct the air flow toward the extensible portion which is achieved through an embedded L-junction that can switch the air flow from the EAC to the pneumatic chambers (Figure 9).

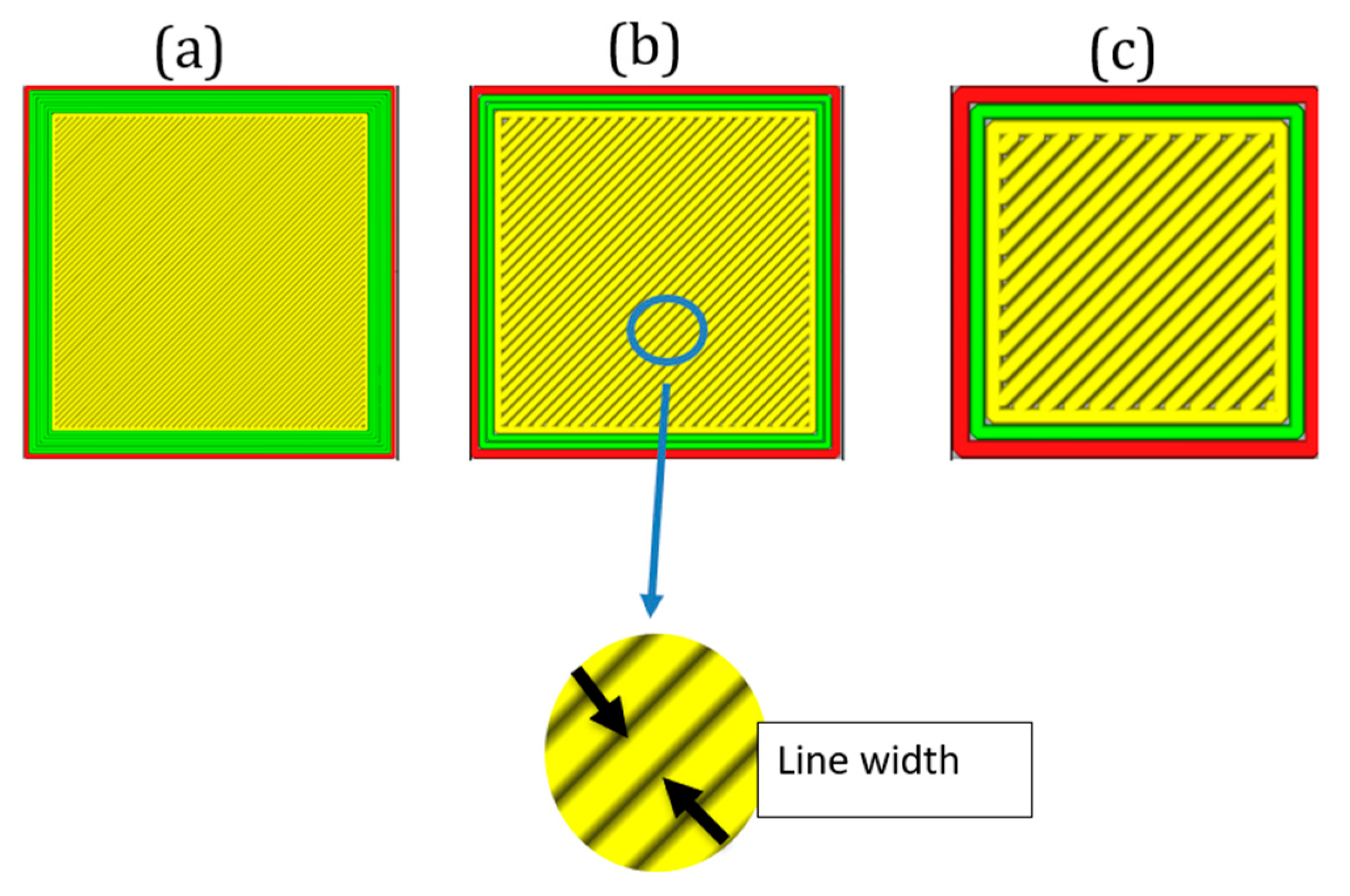

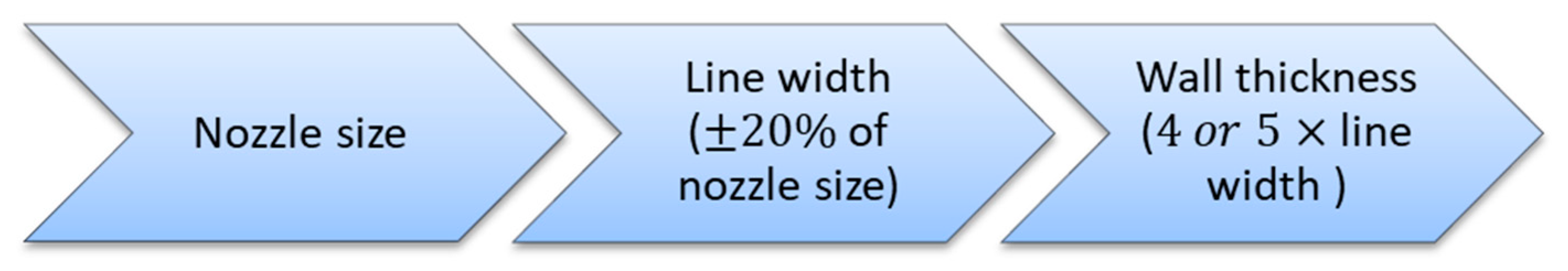

- Apart from ensuring the absence of air leakage at the interface between EAC and pneumatic pipe, the authors also made sure that there is no leakage into the extensible portion. This is crucial for finding a suitable thickness of the pneumatic chamber walls (Figure 8). Both portions were fabricated using a nozzle diameter of 0.4 mm; for this reason, in the slicing software Ultimaker Cura 4.4, the line width parameter was set to 0.4 mm. For this reason, the thickness of the pneumatic chamber walls will be a multiple of 0.4 mm. Through trial-and-error method, it has been found that the minimum chamber wall thickness to ensure air tightness is 1.6 mm. Hence, the minimum number of adjacent lines of extruded filament needed to avoid air leakage is 4 (Figure 10).

3.2. Monolithic Bending PneuNet (MBP)—Improving Bending Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alici, G. Softer is harder: What differentiates soft robotics from hard robotics? MRS Adv. 2018, 3, 1557–1568. [Google Scholar] [CrossRef] [Green Version]

- Majidi, C. Soft-Matter Engineering for Soft Robotics. Adv. Mater. Technol. 2019, 4, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [Green Version]

- Coyle, S.; Majidi, C.; LeDuc, P.; Hsia, K.J. Bio-inspired soft robotics: Material selection, actuation, and design. Extrem. Mech. Lett. 2018, 22, 51–59. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Laschi, C.; Cianchetti, M.; Mazzolai, B.; Margheri, L.; Follador, M.; Dario, P. Soft robot arm inspired by the octopus. Adv. Robot. 2012, 26, 709–727. [Google Scholar] [CrossRef]

- Lin, H.T.; Leisk, G.G.; Trimmer, B. GoQBot: A caterpillar-inspired soft-bodied rolling robot. Bioinspir. Biomim. 2011, 6, 026007. [Google Scholar] [CrossRef]

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft manipulators and grippers: A review. Front. Robot. AI 2016, 3, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 2018, 3, 143–153. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [Green Version]

- Andria, G.; Attivissimo, F.; Di Nisio, A.; Lanzolla, A.M.L.; Larizza, P.; Selicato, S. Development and performance evaluation of an electromagnetic tracking system for surgery navigation. Meas. J. Int. Meas. Confed. 2019, 148, 106916. [Google Scholar] [CrossRef]

- Andria, G.; Attivissimo, F.; Di Nisio, A.; Maria, A.; Lanzolla, L. Assessment of Position Repeatability Error in an Surgical Navigation. Sensors 2020, 20, 961. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft robot review. Int. J. Control. Autom. Syst. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Martinez, R.V.; Fish, C.R.; Chen, X.; Whitesides, G.M. Whitesides Elastomeric Origami: Programmable Paper-Elastomer Composites as Pneumatics Actuators. Adv. Funct. Mater. 2012, 22, 1376–1384. [Google Scholar] [CrossRef]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A Resilient, Untethered Soft Robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Moqadam, A.D.; Bodaghi, M.; Liao, W.-H. Contact/impact modeling and analysis of 4D printed shape memory polymer beams. Smart Mater. Struct. 2020. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Kouzani, A. Closed-loop 4D-printed soft robots. Mater. Des. 2020, 188, 108411. [Google Scholar] [CrossRef]

- Byrne, O.; Coulter, F.; Glynn, M.; Jones, J.F.X.; Ní Annaidh, A.; O’Cearbhaill, E.D.; Holland, D.P. Additive Manufacture of Composite Soft Pneumatic Actuators. Soft Robot. 2018, 5, 726–736. [Google Scholar] [CrossRef] [PubMed]

- Souhail, A.; Vessakosol, P. PneuNets Bending Actuator Design and Fabrication Using low Cost Silicones. Available online: https://www.researchgate.net/profile/Amir_Souhail2/publication/329736390_PneuNets_bending_actuator_design_and_fabrication_using_low_cost_silicones/links/5c18a3cca6fdcc494ffca1d2/PneuNets-bending-actuator-design-and-fabrication-using-low-cost-silicones.pdf (accessed on 23 August 2019).

- Hu, W.; Mutlu, R.; Li, W.; Alici, G. A structural optimisation method for a soft pneumatic actuator. Robotics 2018, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.B.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of Soft Fiber-Reinforced Bending Actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef] [Green Version]

- Elgeneidy, K.; Lohse, N.; Jackson, M. Bending angle prediction and control of soft pneumatic actuators with embedded flex sensors—A data-driven approach. Mechatronics 2018, 50, 234–247. [Google Scholar] [CrossRef] [Green Version]

- Manti, M.; Hassan, T.; Passetti, G.; D’Elia, N.; Laschi, C.; Cianchetti, M. A Bioinspired Soft Robotic Gripper for Adaptable and Effective Grasping. Soft Robot. 2015, 2, 107–116. [Google Scholar] [CrossRef]

- Yirmibeşoğlu, O.D.; Oshiro, T.; Olson, G.; Palmer, C.; Mengüç, Y. Evaluation of 3D printed soft robots in radiation environments and comparison with molded counterparts. Front. Robot. AI 2019, 6, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Manns, M.; Morales, J.; Frohn, P. Additive manufacturing of silicon based PneuNets as soft robotic actuators. Procedia CIRP 2018, 72, 328–333. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 29, 1–9. [Google Scholar] [CrossRef]

- Joyee, E.B.; Pan, Y. Multi-material Additive Manufacturing of Functional Soft Robot. Procedia Manuf. 2019, 34, 566–573. [Google Scholar] [CrossRef]

- Lopes, L.R.; Silva, A.F.; Carneiro, O.S. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Elgeneidy, K.; Neumann, G.; Jackson, M.; Lohse, N. Directly printable flexible strain sensors for bending and contact feedback of soft actuators. Front. Robot. AI 2018, 5, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann.-Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Pradel, P.; Zhu, Z.; Bibb, R.; Moultrie, J. A framework for mapping design for additive manufacturing knowledge for industrial and product design. J. Eng. Des. 2018, 29, 291–326. [Google Scholar] [CrossRef] [Green Version]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef] [Green Version]

- Terryn, S.; Brancart, J.; Lefeber, D.; Van Assche, G.; Vanderborght, B. Self-healing soft pneumatic robots. Sci. Robot. 2017, 2, 1–12. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Nozzle diameter | 0.4 mm |

| Printing temperature | 225 °C |

| Printing speed | 25 mm/s |

| Infill density | 100% |

| Infill pattern | Circular |

| Retraction distance | 7.5 mm |

| Adhesion type | Brim |

| Layer height | 0.15 mm |

| Line width | 0.4 |

| Bed temperature | 60 °C |

| A (Layer height) | B (Support material) | |

|---|---|---|

| −1 | 0.05 mm | PVA |

| +1 | 0.15 mm | TPU95A |

| Combination Name | A | B | Replicates () | ||||

|---|---|---|---|---|---|---|---|

| −1 | −1 | 0.17 | 0.11 | 0.19 | 0.157 | 0.001 | |

| +1 | +1 | 12.78 | 4.62 | 7.73 | 8.38 | 11.30 | |

| +1 | −1 | 3.61 | 3.84 | 3.49 | 3.65 | 0.021 | |

| −1 | +1 | 1.66 | 2.31 | 0.98 | 1.65 | 0.29 | |

| Parameter | EAC | Inextensible Portion | Extensible Portion | L-Junction |

|---|---|---|---|---|

| Material | TPU 95 A | TPU 95 A | TPU 80 A LF | TPU 80 A LF |

| Flow | 106% | 106% | 120% | 120% |

| Infill percentage | 100% | 100% | 100% | 100% |

| Infill pattern | Circular | Zigzag | Lines | Lines |

| Temperature | 225 °C | 225 °C | 240 °C | 240 °C |

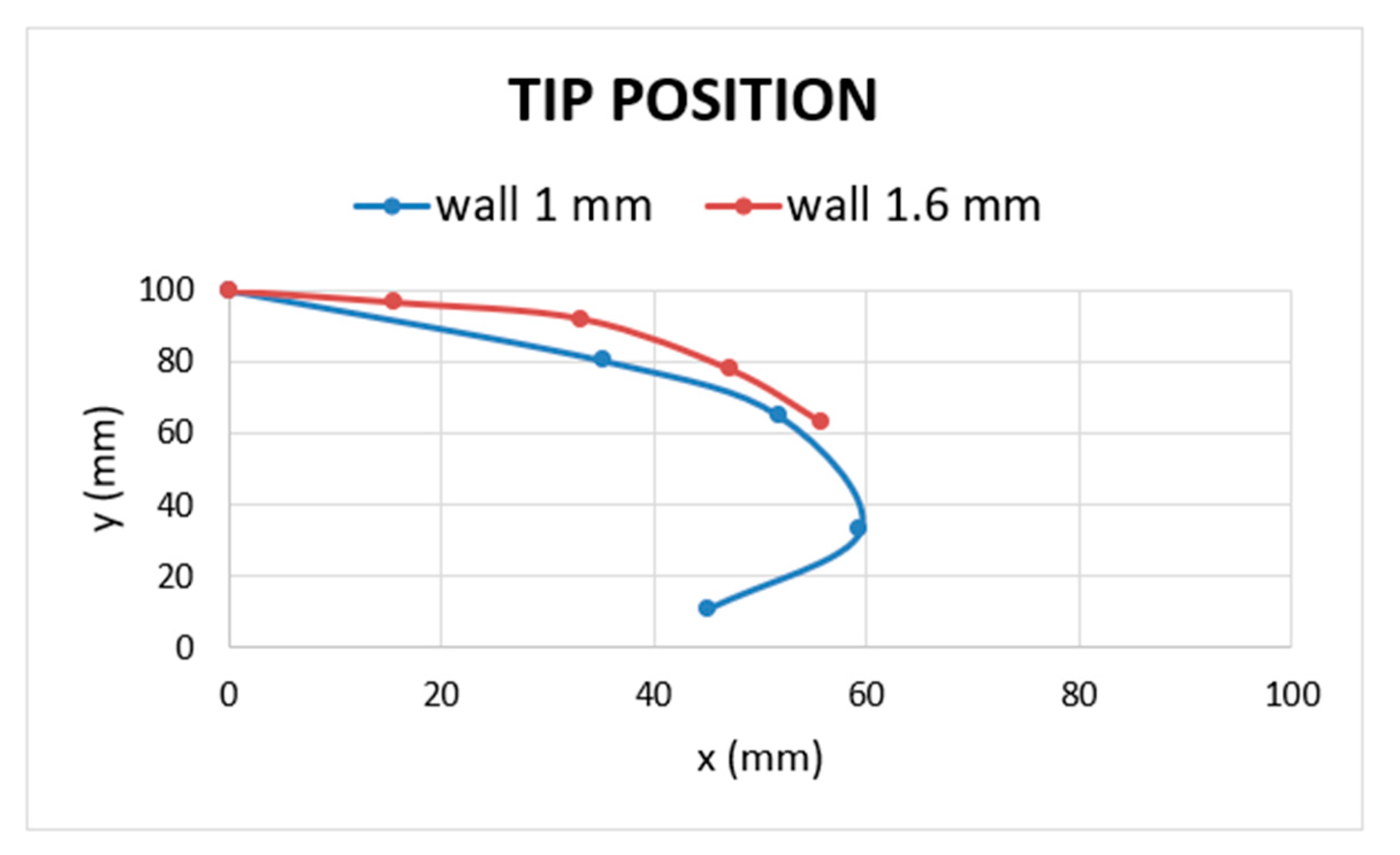

| R Type | S Type | B Type | D Type | ||||

|---|---|---|---|---|---|---|---|

| Tip Rest Position (mm) (x = 0; y = 100) | Tip Rest Position (mm) (x = 0; y = 101.4) | Tip Rest Position (mm) (x = 0; y = 95) | Tip Rest Position (mm) (x = 0; y = 96.9) | ||||

| Pressure input (bar) | Tip displacement (x;y) (mm) | Pressure input (bar) | Tip displacement (x;y) (mm) | Pressure input (bar) | Tip displacement (x;y) (mm) | Pressure input (bar) | Tip Displacement (x;y) (mm) |

| 0 | (0;0) | 0 | (0;0) | 0 | (0;0) | 0 | (0;0) |

| 1 | (15.6;3.3) | 1 | (15.6;3.2) | 1 | (7.4;1.2) | 1 | (8.2;1) |

| 2 | (33.2;8) | 2 | (27.2;8) | 2 | (15.6;3.1) | 2 | (17;3.3) |

| 3 | (47.1;22.1) | 3 | (39.9;18) | 3 | (29.8;10.7) | 3 | (27.7;8.4) |

| 4 | (55.6;37) | 4 | (54.6;39.3) | 4 | (36.7;17.4) | 4 | (41.9;23.4) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stano, G.; Arleo, L.; Percoco, G. Additive Manufacturing for Soft Robotics: Design and Fabrication of Airtight, Monolithic Bending PneuNets with Embedded Air Connectors. Micromachines 2020, 11, 485. https://doi.org/10.3390/mi11050485

Stano G, Arleo L, Percoco G. Additive Manufacturing for Soft Robotics: Design and Fabrication of Airtight, Monolithic Bending PneuNets with Embedded Air Connectors. Micromachines. 2020; 11(5):485. https://doi.org/10.3390/mi11050485

Chicago/Turabian StyleStano, Gianni, Luca Arleo, and Gianluca Percoco. 2020. "Additive Manufacturing for Soft Robotics: Design and Fabrication of Airtight, Monolithic Bending PneuNets with Embedded Air Connectors" Micromachines 11, no. 5: 485. https://doi.org/10.3390/mi11050485

APA StyleStano, G., Arleo, L., & Percoco, G. (2020). Additive Manufacturing for Soft Robotics: Design and Fabrication of Airtight, Monolithic Bending PneuNets with Embedded Air Connectors. Micromachines, 11(5), 485. https://doi.org/10.3390/mi11050485