Wireless E-Nose Sensors to Detect Volatile Organic Gases through Multivariate Analysis

Abstract

:1. Introduction

- To probe and differentiate commonly produced gases from mixtures (acetone, ethanol, and propane) in manufacturing industries using a high performance PCA-based multivariate analysis technique.

- To identify various clusters of these (acetone, ethanol, and propane) using a PCA numerical test.

Metal Oxide Semiconductors (MOS) Gas Sensors

2. The Methodology of Proposed MOS Sensor-Based E-Nose Detector

3. Theory of Principal Component Analysis

- (i)

- The matrix XM×N gives the information on row, which is represented by M, demonstrating that different redundancies happen amid the experiment. Column N delineates non-subordinate sensors.

- (ii)

- Normalization and arrangement of data is performed in matrix form Norm (XM × N) with a mean reduction. Subtraction and estimation of the average of each N column from the informational data is collected. This new information data quantity makes the mean equivalent to zero.

- (iii)

- Measurement of the covariance matrix is performed as Cov (XM×N), which helps discover eigenvectors and eigenvalues of the covariance matrix. The created eigenvectors ought to be unit eigenvectors.

- (iv)

- The eigenvalues and eigenvectors are arranged and adjusted. The eigenvalues are adjusted from eigenvectors from maximum to minimum (Cov (XM×N)) with max→min.

- (v)

- The output of PCA is restored by using the product of a matrix, transposed and given as ((Cov (XM×N))max→min*Norm (XM×N))T. Further to this, the accomplished informational data collection with orthogonal linear change presented in 2D/3D also includes free informational data collection.

4. Result and Discussion

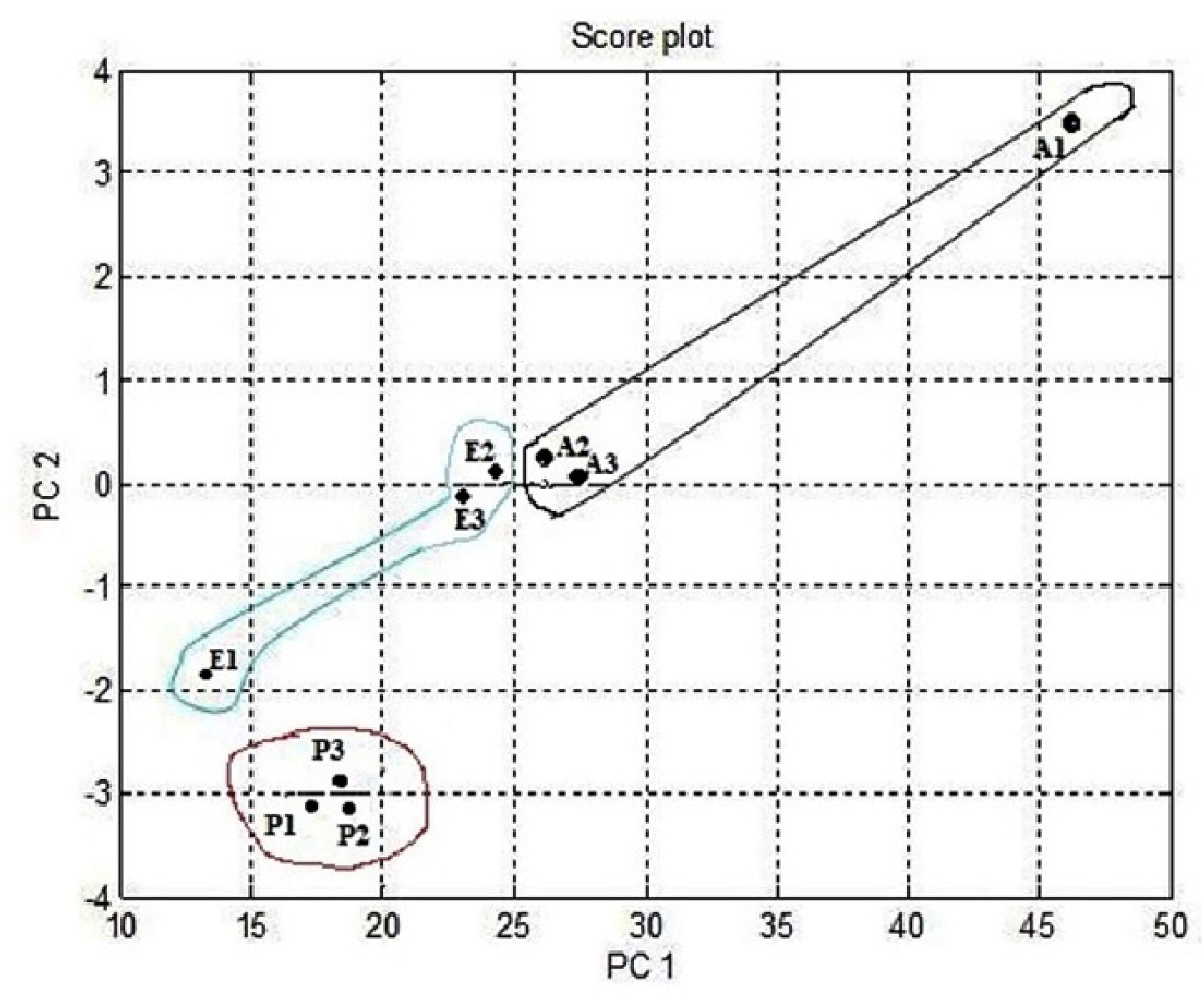

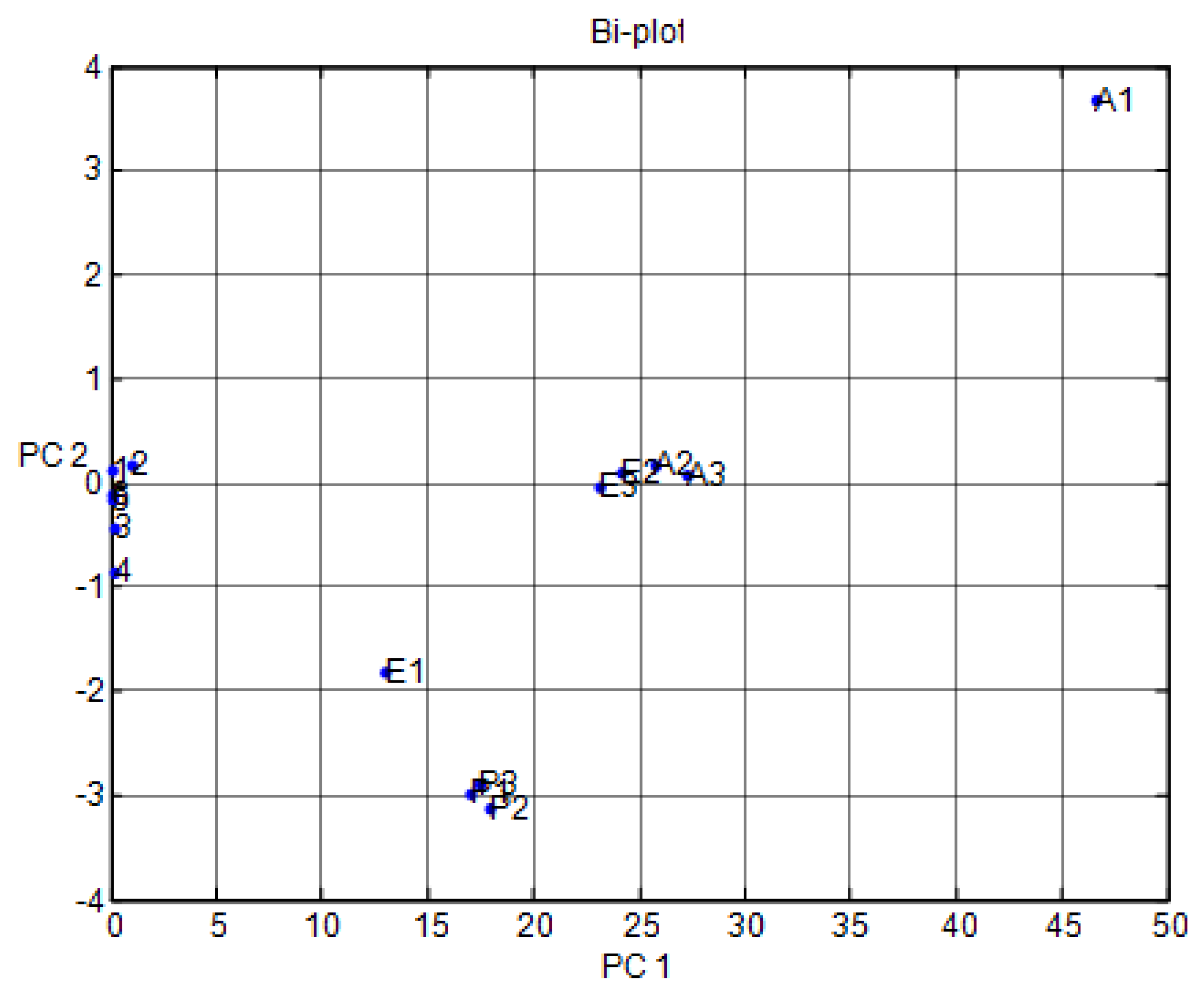

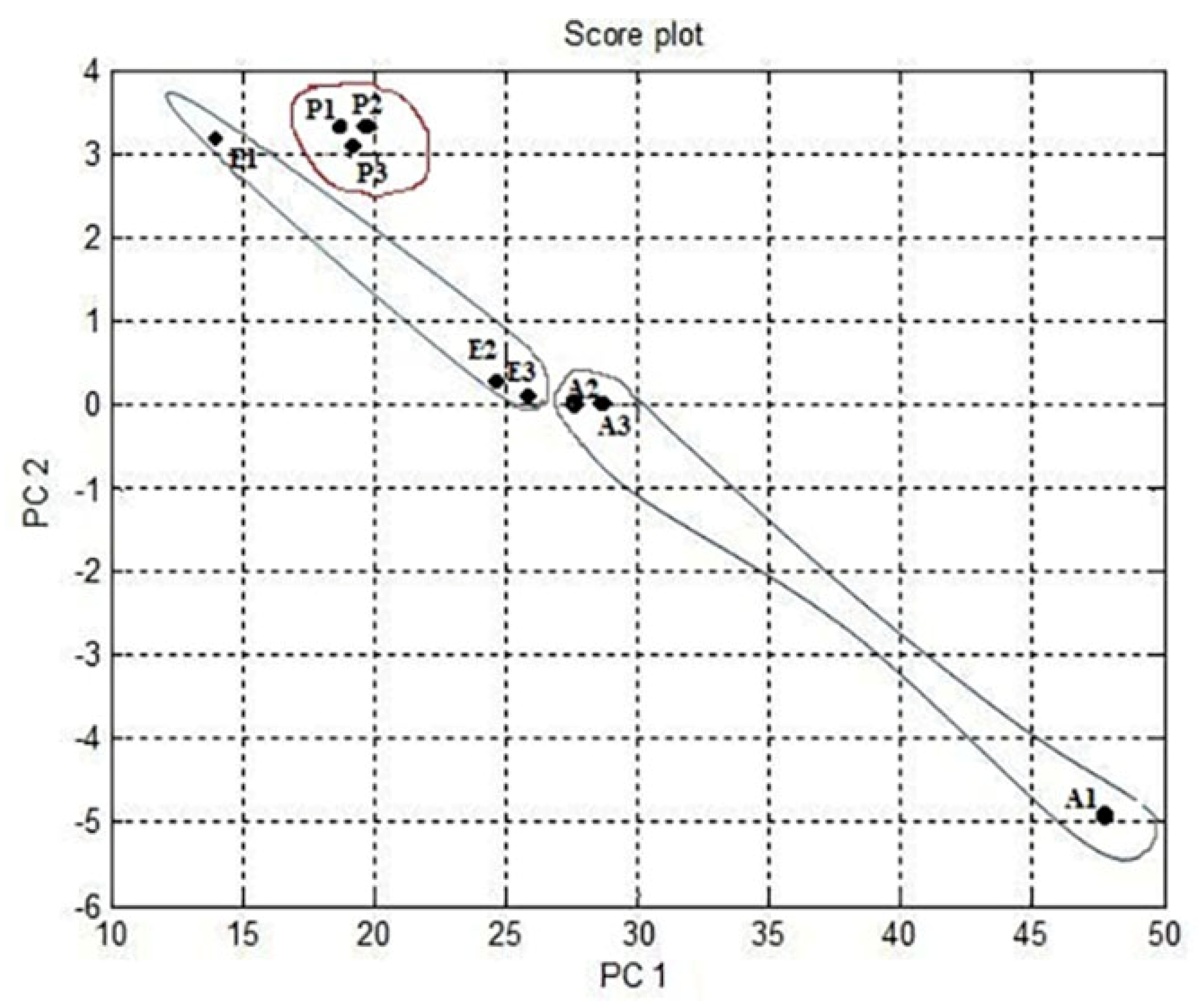

4.1. Data Difference Preprocessing Used for Principal Component Analysis of Volatile Organic Compounds and Gases Data

4.2. Data Fractional Preprocessing Used for Principal Component Analysis of Volatile Organic Compounds and Gas Database

4.3. Data Relative Preprocessing Used for Principal Component Analysis of Volatile Organic Compounds and Gas Database

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. PCA Variants

= Ys(t) − Ys(0))

= (Ys(t))/(Ys(0))

Appendix B. Literature Review

| Reference Number | Year | Compounds Analyzed | Technique | Limitations |

|---|---|---|---|---|

| [6] | 2018 | Ethanol, propanol, acetone | KMP algorithm | If the extracted features yield poor separability between different classes, the performance of feature extraction is not good. |

| [7] | 2017 | Ethanol and acetone | 9 different classifiers: K Nearest Neighbors, Linear SVM, radial basis function (RBF) SVM, Decision Tree, Random Forest, AdaBoost, Naive Bayes, linear discriminant analysis (LDA), and quadratic discriminant analysis (QDA). | Results have shown deterioration by up to 30% when the movement speed of the data used for training highly differs from that of the testing. |

| [11] | 2018 | Acetone | Gas chromatography- mass spectrometry | Not done on the mixture of gases. |

| [12] | 2007 | Ethanol and acetone | Detection device | Cannot separate the mixture of three gases |

| [14] | 2018 | Medical field | PCA | Detect chronic diseases and not a mixture of gases. |

| [15] | 2018 | Food | Biosensors and electronic tongue | Detect food spoilage. |

| [18] | 2019 | CO, CH4, and their mixture | Convolutional neural network | Does not consider the mixture of A, E and P. |

Appendix C. Sensor Array

C.1. SPECIFICATION OF TGS 2600 SENSOR

C.1.1. Features

C.1.2. Applications

C.2. SPECIFICATION OF TGS 2602 SENSOR

C.2.1. Features

C.2.2. Applications

C.3. SPECIFICATION OF TGS 2611 SENSOR

C.3.1. Features

C.3.2. Applications

C.4. SPECIFICATION OF TGS 2620 SENSOR

C.4.1. Features

C.4.2. Applications

C.5. SPECIFICATION OF MICS 5135 SENSOR

Features

C.6. SPECIFICATION OF MICS 5521 SENSOR

Features

References

- Deshmukh, S.; Bandyopadhyay, R.; Bhattacharyya, N. Application of an electronic nose for industrial odors and gaseous emissions measurement and monitoring-An overview. Talanta 2015, 144, 329–340. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D.; Baietto, M. Applications and Advances in Electronic-Nose Technologies. Sensors 2009, 9, 5099–5148. [Google Scholar] [CrossRef]

- Rahman, S.; Saeed, S.H.; Siddiqui, M.J.; Rahman, S. Polymeric Chemoresistor Model Use in Design and Simulation of Sensor. In Proceedings of the IMPACT-2013, Aligarh, India, 23–25 November 2013. [Google Scholar]

- Rahman, S.; Usmani, T.; Saeed, S.H. Review of Electronic Nose and application. Int. J. Comput. Corp. Res. (IJCCR) 2013, 3, 1–9. [Google Scholar]

- Chandran, U.D.; Halim, Z.A.; Sidek, O.; Darah, I.; Mohamad-Salleh, J.; Mohamad, N.; Rashidah, A.R. Electronic Nose to Detect Sulphate Reducing Bacteria Which is an Agent of Corrosion. In Proceedings of the International Conference on Computer and Communication Engineering (ICCCE), Kuala Lumpur, Malaysia, 11–12 May 2010; pp. 1–4. [Google Scholar]

- Fan, H.; Bennetts, V.H.; Schaffernicht, E.; Lilienthal, A.J. A cluster analysis approach based on exploiting density peaks for gas discrimination with electronic noses in open environments. Sens. Actuators B Chem. 2018, 259, 183–203. [Google Scholar] [CrossRef] [Green Version]

- Monroy, J.G.; Gonzalez-Jimenez, J. Gas classification in motion: An experimental analysis. Sens. Actuators B Chem. 2017, 240, 1205–1215. [Google Scholar] [CrossRef]

- Dentoni, L.; Capelli, L.; Sironi, S.; del Rosso, R.; Zanetti, S.; Della Torre, M. Development of an Electronic Nose for Environmental Odour Monitoring. Sensors 2012, 12, 14363–14381. [Google Scholar] [CrossRef] [Green Version]

- Hodgkinson, J.; Tatam, R.P. Optical gas sensing: A review. Meas. Sci. Technol. 2012, 24, 012004. [Google Scholar] [CrossRef] [Green Version]

- Gardner, J.W.; Wei, G.; Vincent, T.; Volans, K.; Tremlett, P.; Wotherspoon, T.; Dyer, D.C. A Gas Sensor System for Harsh Environment Applications. Procedia Eng. 2015, 120, 275–278. [Google Scholar] [CrossRef] [Green Version]

- Rydosz, A. Sensors for Enhanced Detection of Acetone as a Potential Tool for Noninvasive Diabetes Monitoring. Sensors 2018, 18, 2298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reungchaiwat, A.; Wongchanapiboon, T.; Liawruangrath, S.; Phanichphant, S. Home-made Detection Device for a Mixture of Ethanol and Acetone. Sensors 2007, 7, 202–213. [Google Scholar] [CrossRef] [Green Version]

- Saeed, S.H.; Abbas, Z.; Gopal, B. Experimental Use of Electronic Nose for Analysis of Volatile Organic Compound (VOC). In Proceedings of the IEEE digital library organized by International Conference on Multimedia, Signal Processing and Communication Technologies (IMPACT 2009), Aligarh, India, 14–16 March 2009. [Google Scholar]

- Maniscalco, M.; Motta, A. Clinical and Inflammatory Phenotyping: Can Electronic Nose and NMR-based Metabolomics Work at the Bedside? Arch. Med. Res. 2018, 1, 74–76. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi-Varnamkhasti, M.; Apetrei, C.; Lozano, J. Potential. Use of Electronic Noses, Electronic Tongues and Biosensors as Multisensor Systems for Spoilage Examination in Foods. Tends Food Sci. Technol. 2018, 10, 71–92. [Google Scholar] [CrossRef]

- Neaves, P.I.; Hatfield, J.V. A new generation of integrated electronic noses. Sens. Actuators B 1995, 27, 223–231. [Google Scholar] [CrossRef]

- VanGeloven, P.; Honore, M.; Roggen, J.; Leppavuori, S.; Rantala, T. The influence of relative humidity on the response of tin oxide gas sensors to carbon monoxide. Sens. Actuators B 1991, 4, 185. [Google Scholar] [CrossRef]

- Wei, G.; Li, G.; Zhao, J.; He, A. Development of a LeNet-5 Gas Identification CNN Structure for Electronic Noses. Sensors 2019, 19, 217. [Google Scholar] [CrossRef] [Green Version]

- Peng, P.; Xiaojin, Z.; Xiaofang, P. Gas Classification Using Deep Convolutional Neural Networks. Sensors 2018, 18, 157. [Google Scholar] [CrossRef] [Green Version]

- Jolliffe, I.T. Principal Component Analysis; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Debebe, A.; Redi-Abshiro, M.; Chandravanshi, B.S. Non-destructive determination of ethanol levels in fermented alcoholic beverages using Fourier transform mid-infrared spectroscopy. Chem. Cent. J. 2017, 11, 27. [Google Scholar] [CrossRef] [Green Version]

- Saasa, V.; Malwela, T.; Beukes, M.; Mokgotho, M.; Liu, C.-P.; Mwakikunga, B. Sensing Technologies for Detection of Acetone in Human Breath for Diabetes Diagnosis and Monitoring. Diagnostics 2018, 8, 12. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wei, Y.; Liu, T.; Sun, T.; Grattan, K.T.V. TDLAS Detection of Propane/Butane Gas Mixture by Using Reference Gas Absorption Cells and Partial Least Square Approach. IEEE Sens. J. 2018, 18, 8587–8596. [Google Scholar] [CrossRef]

- Awais, M.; Badruddin, N.; Drieberg, M. A hybrid approach to detect driver drowsiness utilizing physiological signals to improve system performance and wearability. Sensors 2017, 17, 1991. [Google Scholar] [CrossRef] [Green Version]

- Awais, M.; Badruddin, N.; Drieberg, M. Driver drowsiness detection using EEG power spectrum analysis. In Proceedings of the IEEE Region 10 Symposium, Kuala Lumpur, Malaysia, 14–16 April 2014; pp. 244–247. [Google Scholar]

- Muhammad, A.; Badruddin, N.; Drieberg, M. A non-invasive approach to detect drowsiness in a monotonous driving environment. In Proceedings of the IEEE Region 10 Conference (TENCON), Bangkok, Thailand, 22–25 October 2014; pp. 1–4. [Google Scholar]

- Raza, M.; Awais, M.; Ellahi, W.; Aslam, N.; Nguyen, H.X.; Le-Minh, H. Diagnosis and monitoring of Alzheimer’s patients using classical and deep learning techniques. Expert Syst. Appl. 2019, 136, 353–364. [Google Scholar] [CrossRef]

- Awais, M.; Chiari, L.; Ihlen, E.A.F.; Helbostad, J.L.; Palmerini, L. Physical activity classification for elderly people in free-living conditions. IEEE J. Biomed. Health Inform. 2018, 23, 197–207. [Google Scholar] [CrossRef] [PubMed]

- Rahman, S.; Irfan, M.; Raza, M.; Moyeezullah Ghori, K.; Yaqoob, S.; Awais, M. Performance analysis of boosting classifiers in recognizing activities of daily living. Int. J. Environ. Res. Public Health 2020, 17, 1082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghori, K.M.; Abbasi, R.A.; Awais, M.; Imran, M.; Ullah, A.; Szathmary, L. Performance analysis of different types of machine learning classifiers for non-technical loss detection. IEEE Access 2019, 8, 16033–16048. [Google Scholar] [CrossRef]

- Awais, M.; Palmerini, L.; Chiari, L. Physical activity classification using body-worn inertial sensors in a multi-sensor setup. In Proceedings of the IEEE 2nd International Forum on Research and Technologies for Society and Industry Leveraging a better tomorrow (RTSI), Bologna, Italy, 7–9 September 2016; pp. 1–4. [Google Scholar]

| Preprocessing Technique | MOS Sensor Set Interaction | MOS Sensor Set Un Interacted | Contrary | Important |

|---|---|---|---|---|

| Difference | None | {1}, {2}, {3}, {4}, {5}, {6} | {3}, {4} | {3}, {2}, {4} |

| Fraction | {5,6} | {1}, {2}, {3}, {4} | {3}, {4}, {5}, {6} | {2}, {3}, {4} |

| Relative | {5,6} | {1}, {2}, {3}, {4} | {1}, {3}, {4}, {5}, {6} | {2}, {3}, {4} |

| Volatile Organic Compounds | Model | Sample/MOS Sensors | Preprocessing Method | References |

|---|---|---|---|---|

| Ethanol | Exp. Model | 25 Samples of beverages | mid infrared spectroscopy with partial least squares regression (MIR-PLS) | [21] |

| Acetone | Exp. Model | Samples were taken from diabetic patients | Gas Chromatography Mass Spectrometry (GC-MS) | [22] |

| Propane | Exp. Model | Samples taken from petrochemical storage tanks | PLS | [23] |

| Preprocessing Technique | Classifying | Overlapping of Gases | ||

|---|---|---|---|---|

| Acetone + Ethanol | Ethanol + Propane | Acetone + Propane | ||

| Difference | Yes | Yes | Yes | No |

| Fraction | Yes | Yes | Yes | No |

| Relative | Yes | Yes | Yes | No |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, S.; Alwadie, A.S.; Irfan, M.; Nawaz, R.; Raza, M.; Javed, E.; Awais, M. Wireless E-Nose Sensors to Detect Volatile Organic Gases through Multivariate Analysis. Micromachines 2020, 11, 597. https://doi.org/10.3390/mi11060597

Rahman S, Alwadie AS, Irfan M, Nawaz R, Raza M, Javed E, Awais M. Wireless E-Nose Sensors to Detect Volatile Organic Gases through Multivariate Analysis. Micromachines. 2020; 11(6):597. https://doi.org/10.3390/mi11060597

Chicago/Turabian StyleRahman, Saifur, Abdullah S. Alwadie, Muhammed Irfan, Rabia Nawaz, Mohsin Raza, Ehtasham Javed, and Muhammad Awais. 2020. "Wireless E-Nose Sensors to Detect Volatile Organic Gases through Multivariate Analysis" Micromachines 11, no. 6: 597. https://doi.org/10.3390/mi11060597

APA StyleRahman, S., Alwadie, A. S., Irfan, M., Nawaz, R., Raza, M., Javed, E., & Awais, M. (2020). Wireless E-Nose Sensors to Detect Volatile Organic Gases through Multivariate Analysis. Micromachines, 11(6), 597. https://doi.org/10.3390/mi11060597