Deep Reactive Ion Etching of Z-Cut Alpha Quartz for MEMS Resonant Devices Fabrication

Abstract

:1. Introduction

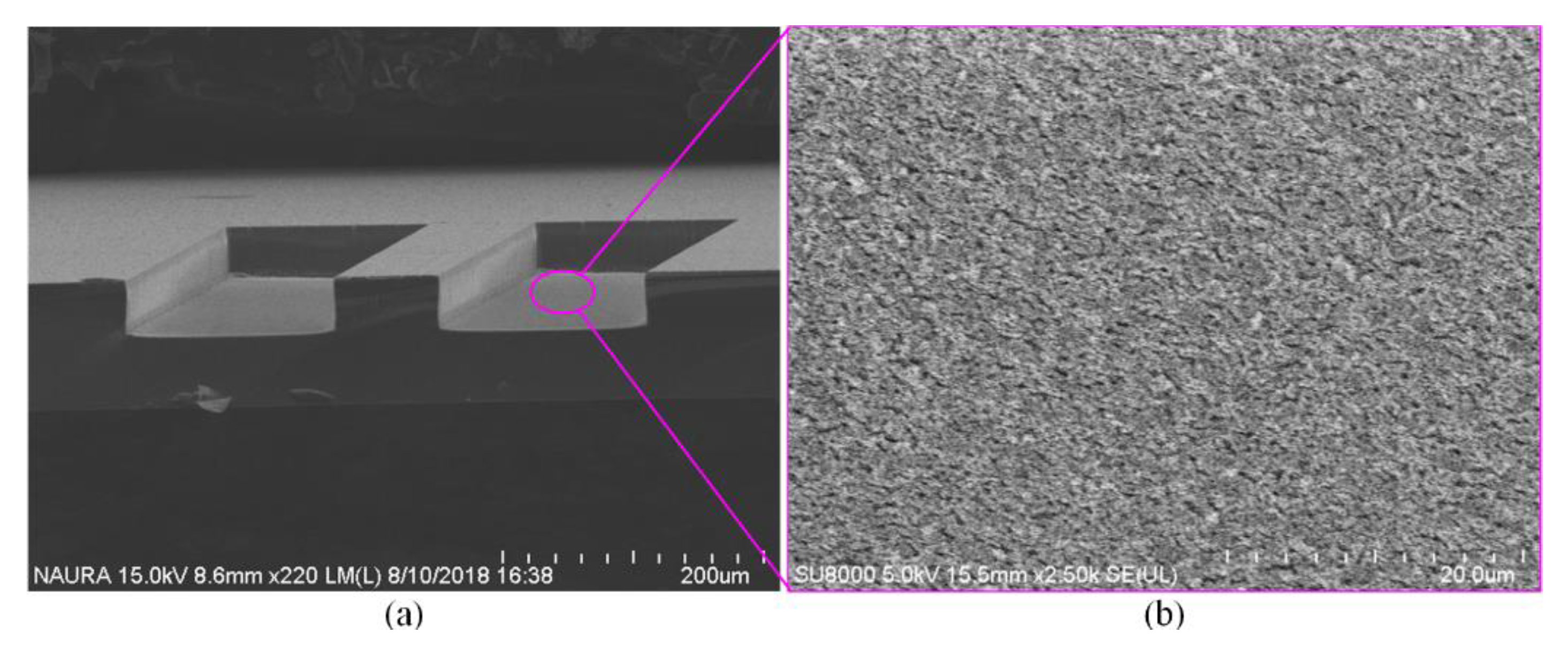

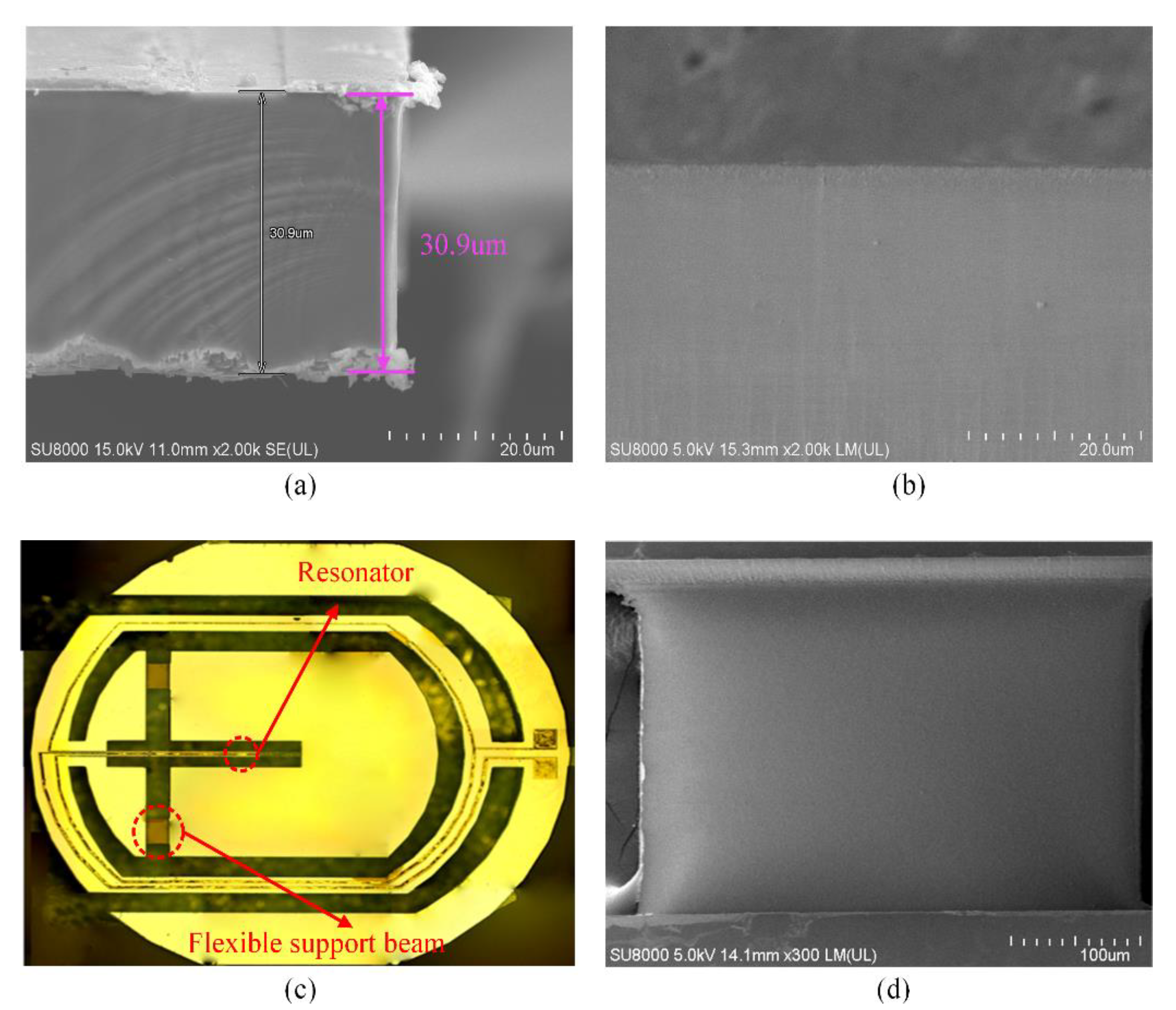

2. Experiment

3. Results

3.1. Effect of Etching Gas

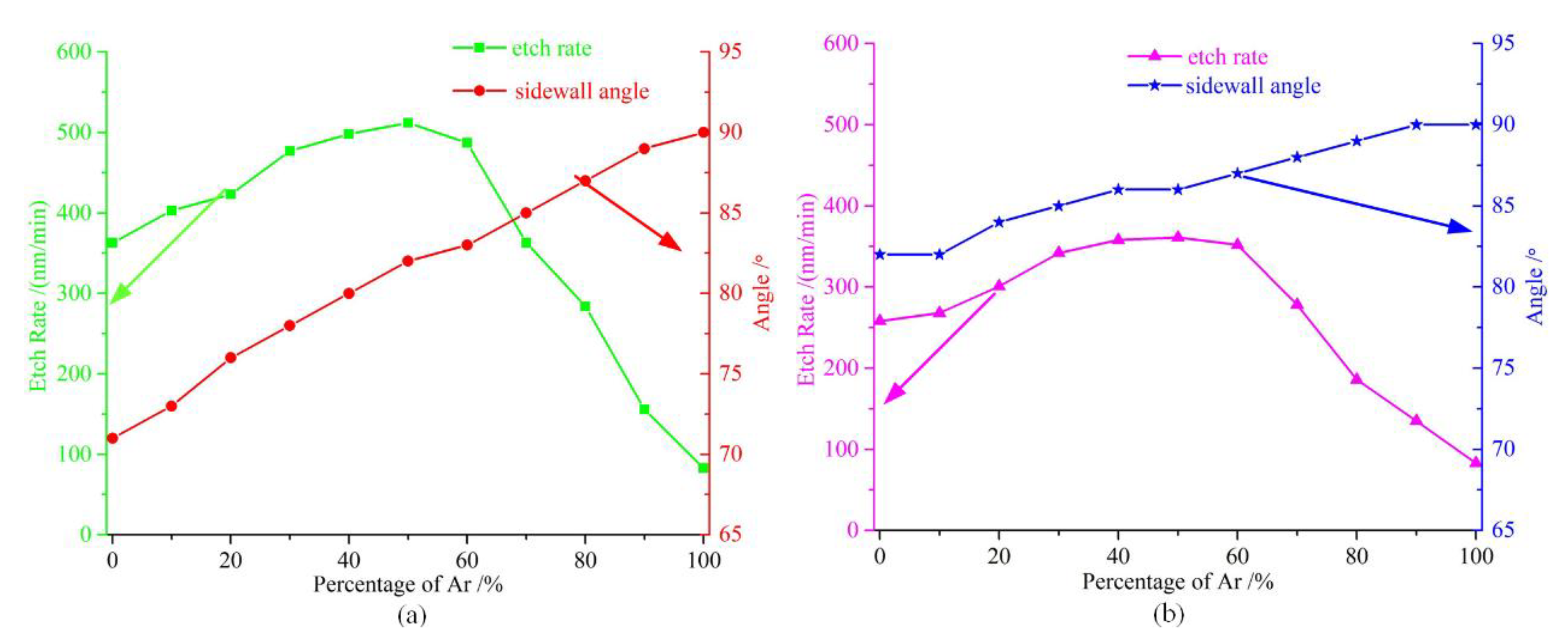

3.1.1. Mixture of C4F8/Ar and SF6/Ar

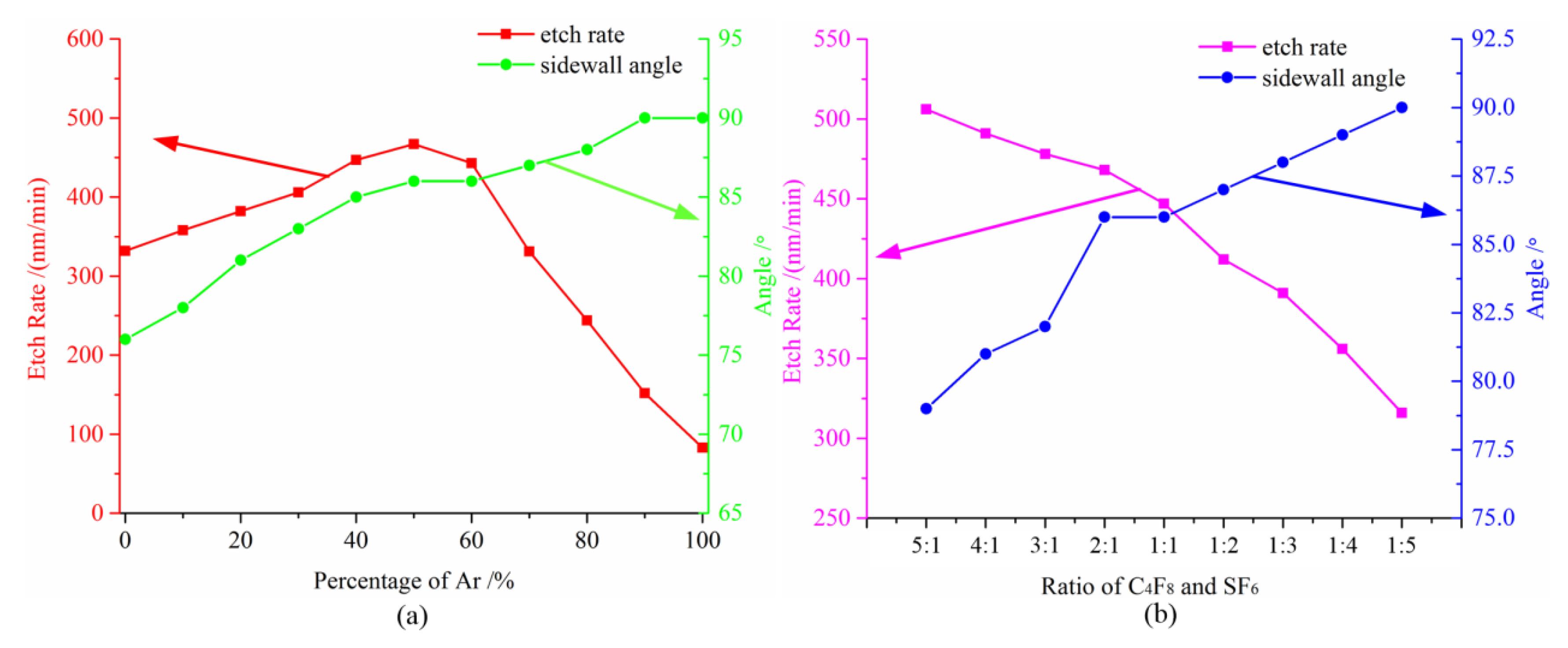

3.1.2. Mixture of C4F8/ SF6/Ar

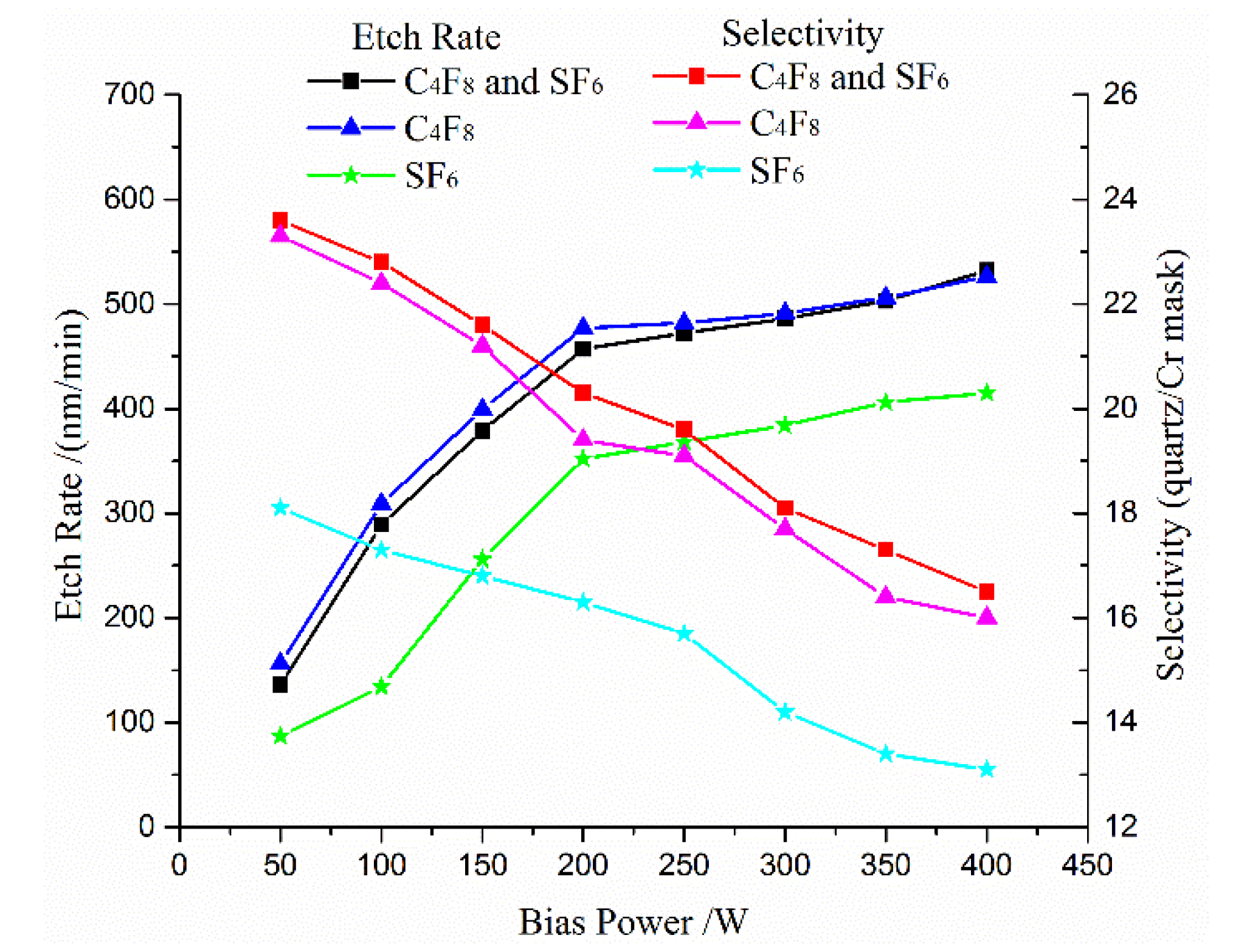

3.2. Effect of Bias Power

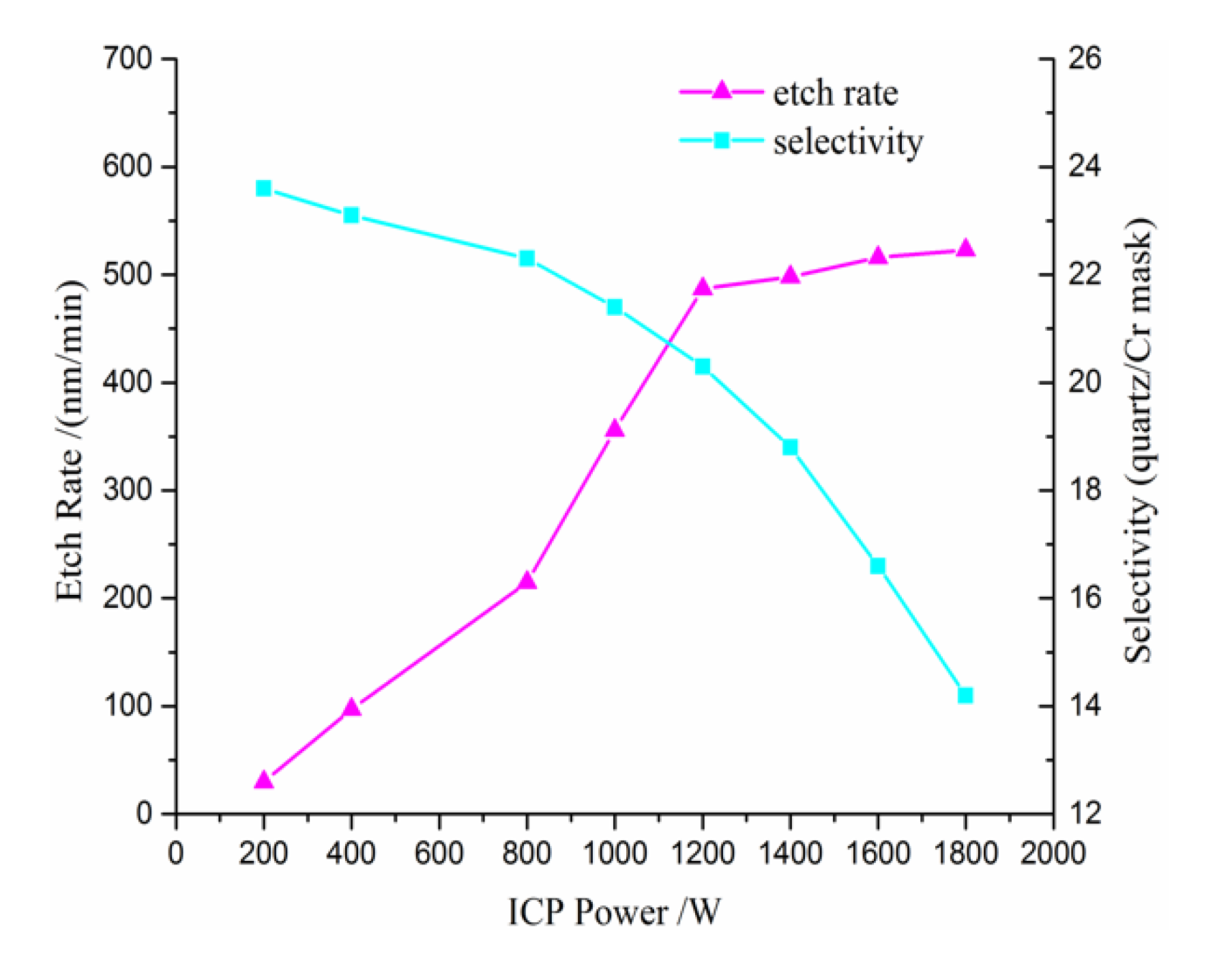

3.3. Effect of ICP Power

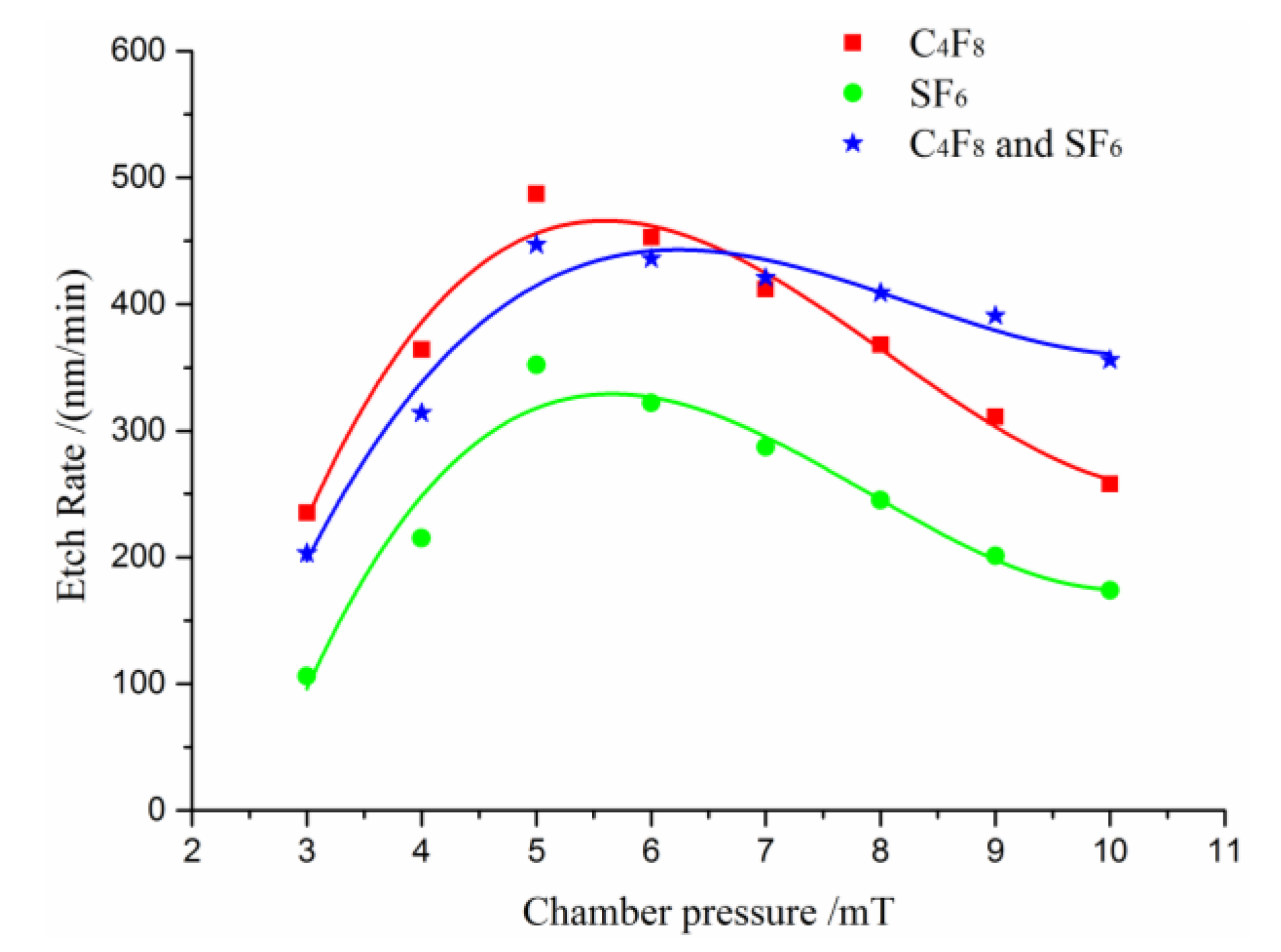

3.4. Effect of Chamber Pressure

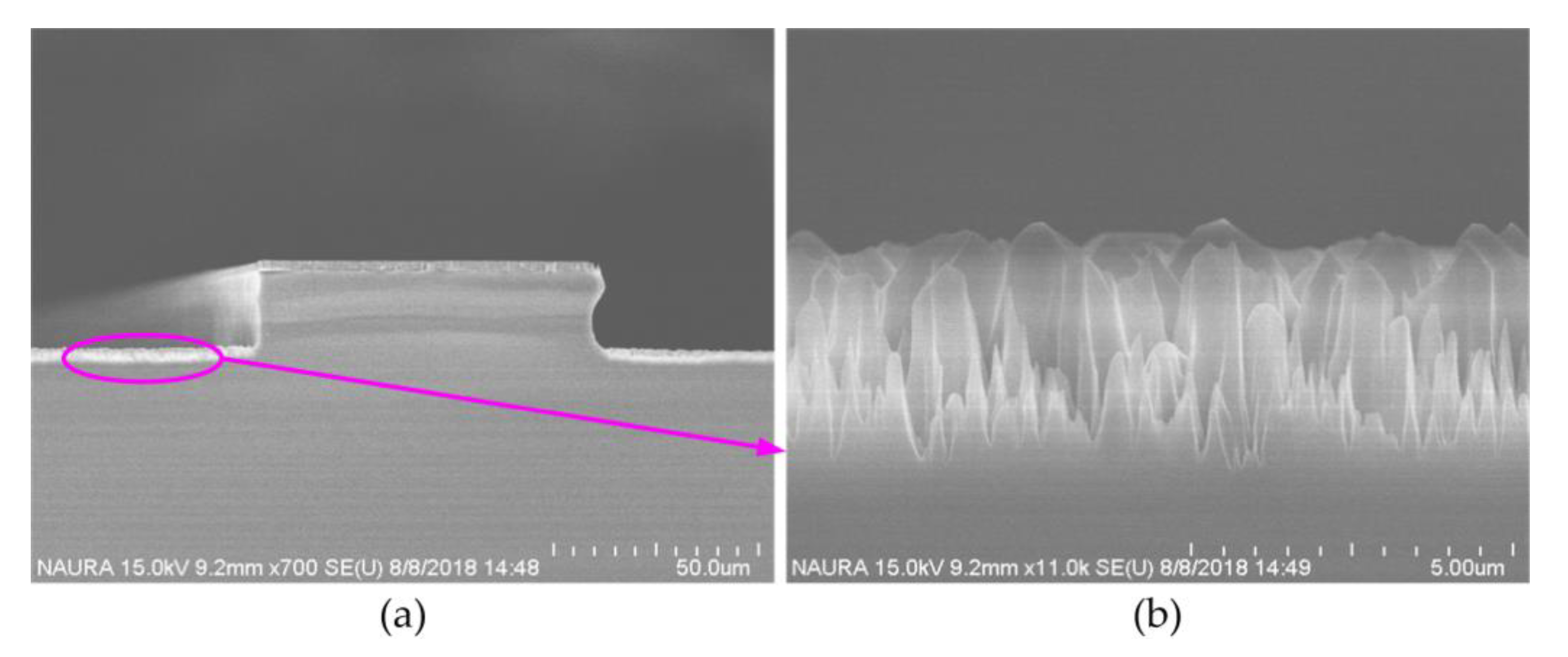

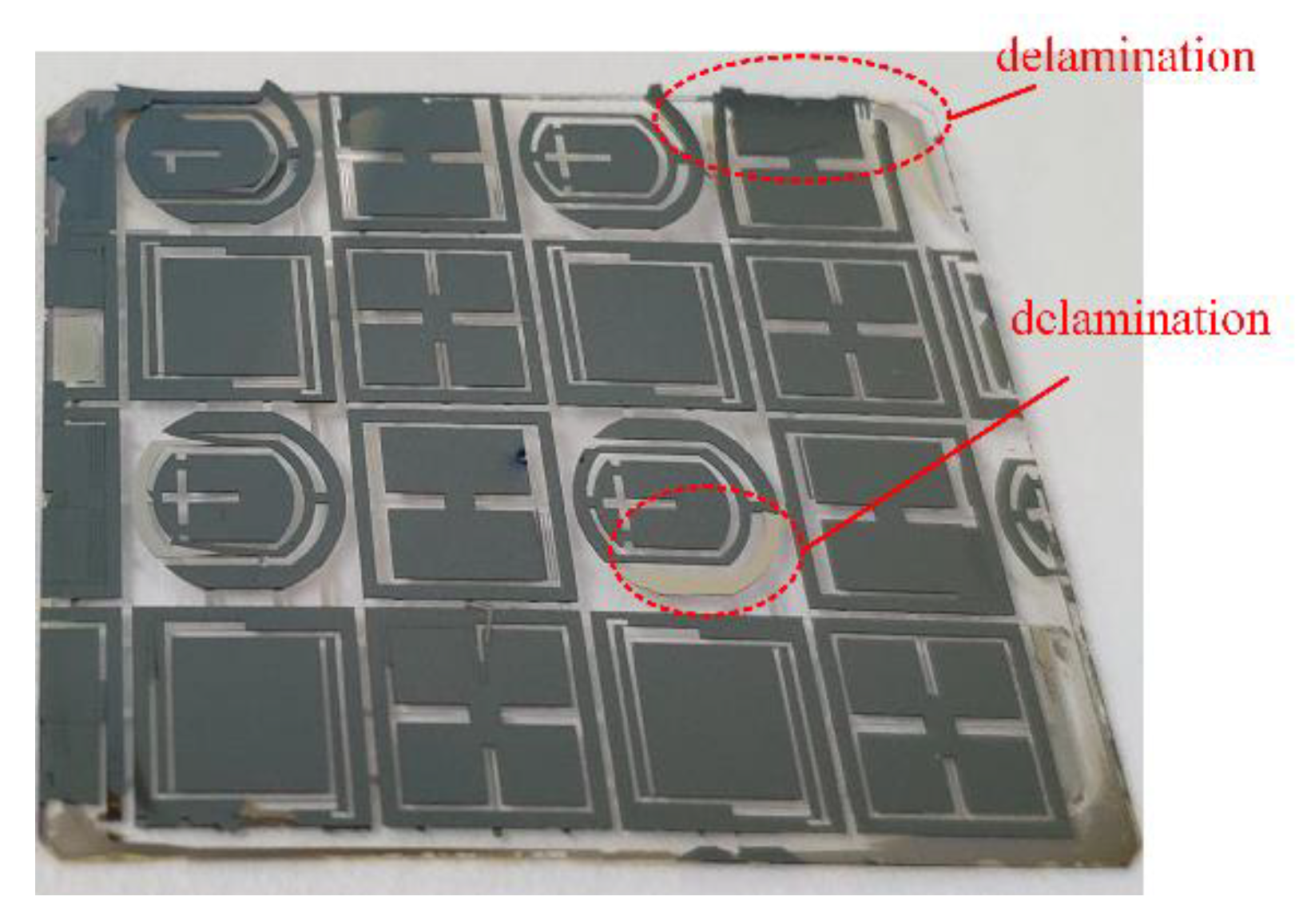

3.5. Effect of Mask

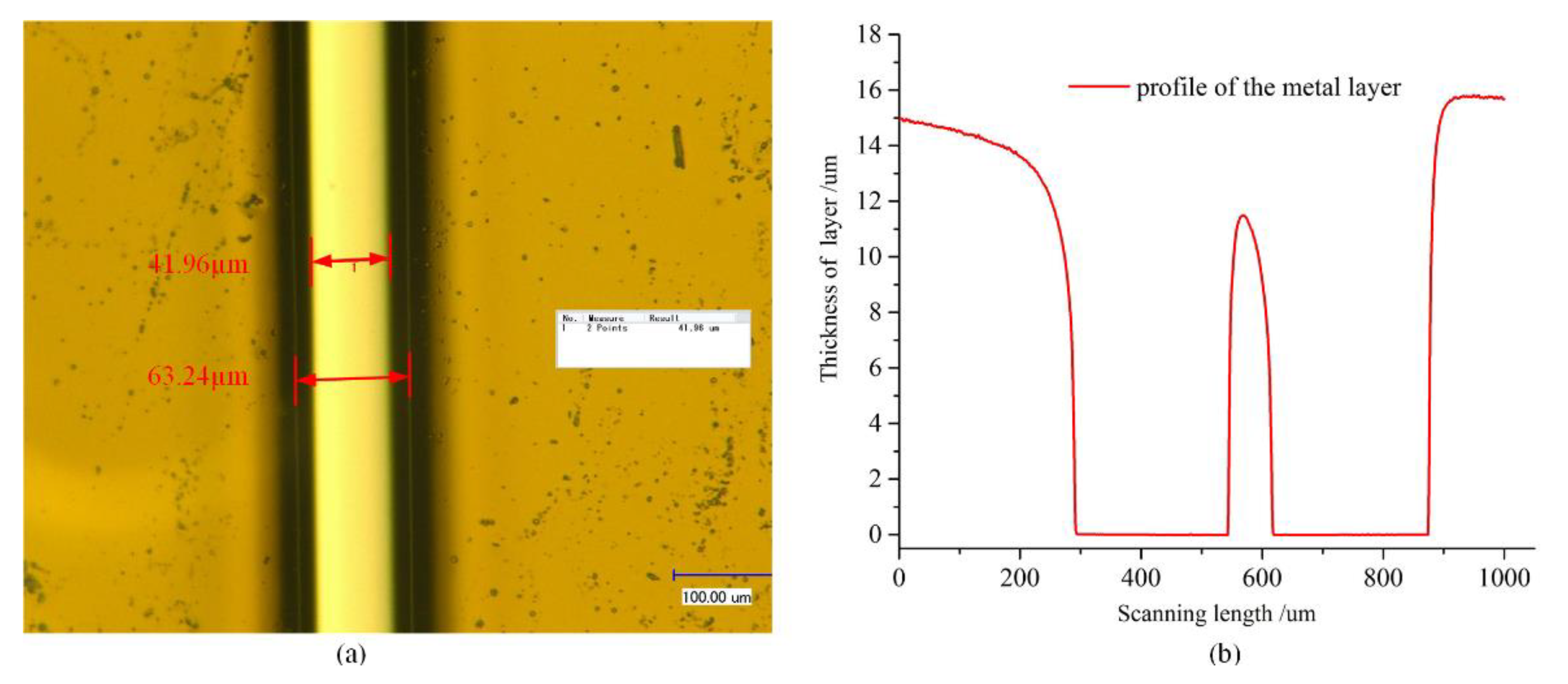

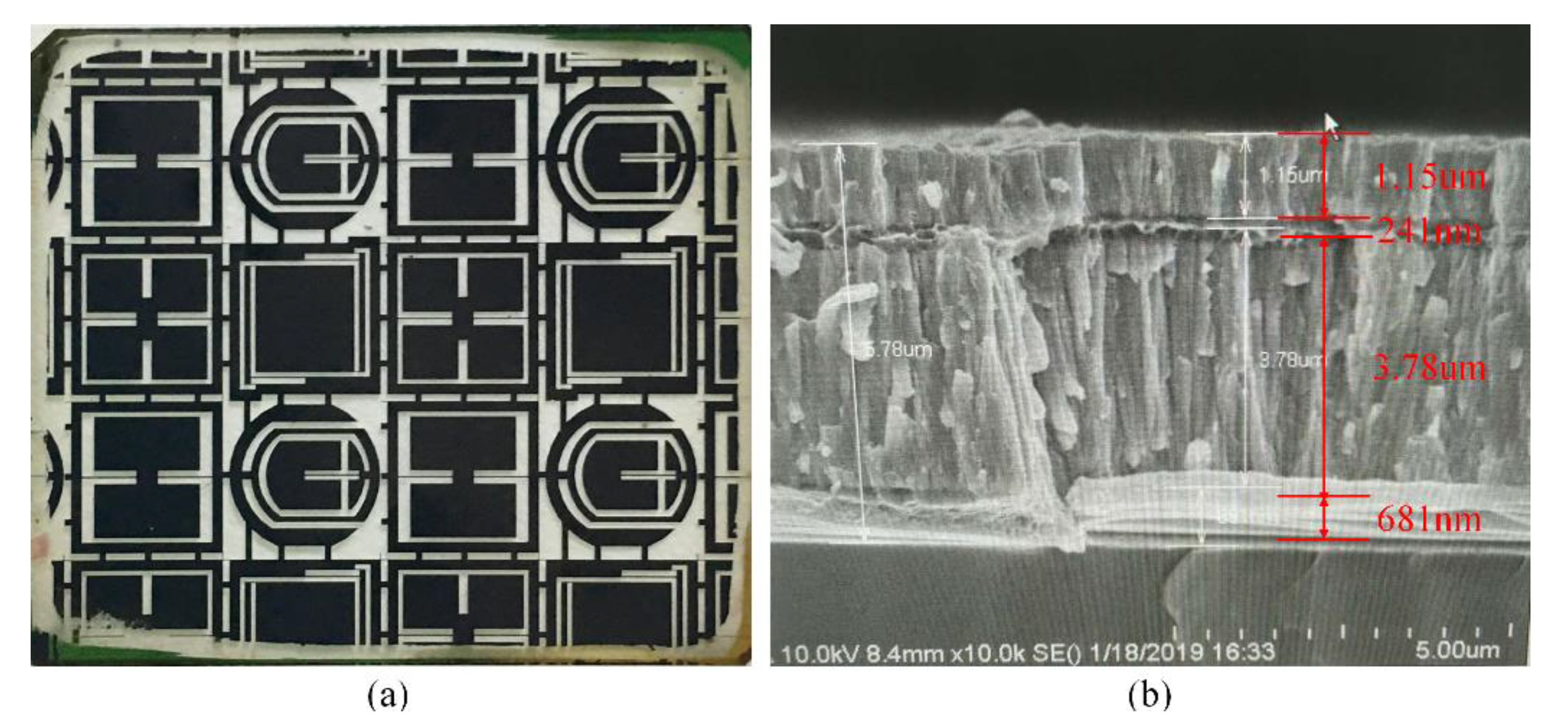

3.6. Preparation of the Thick Cr Mask

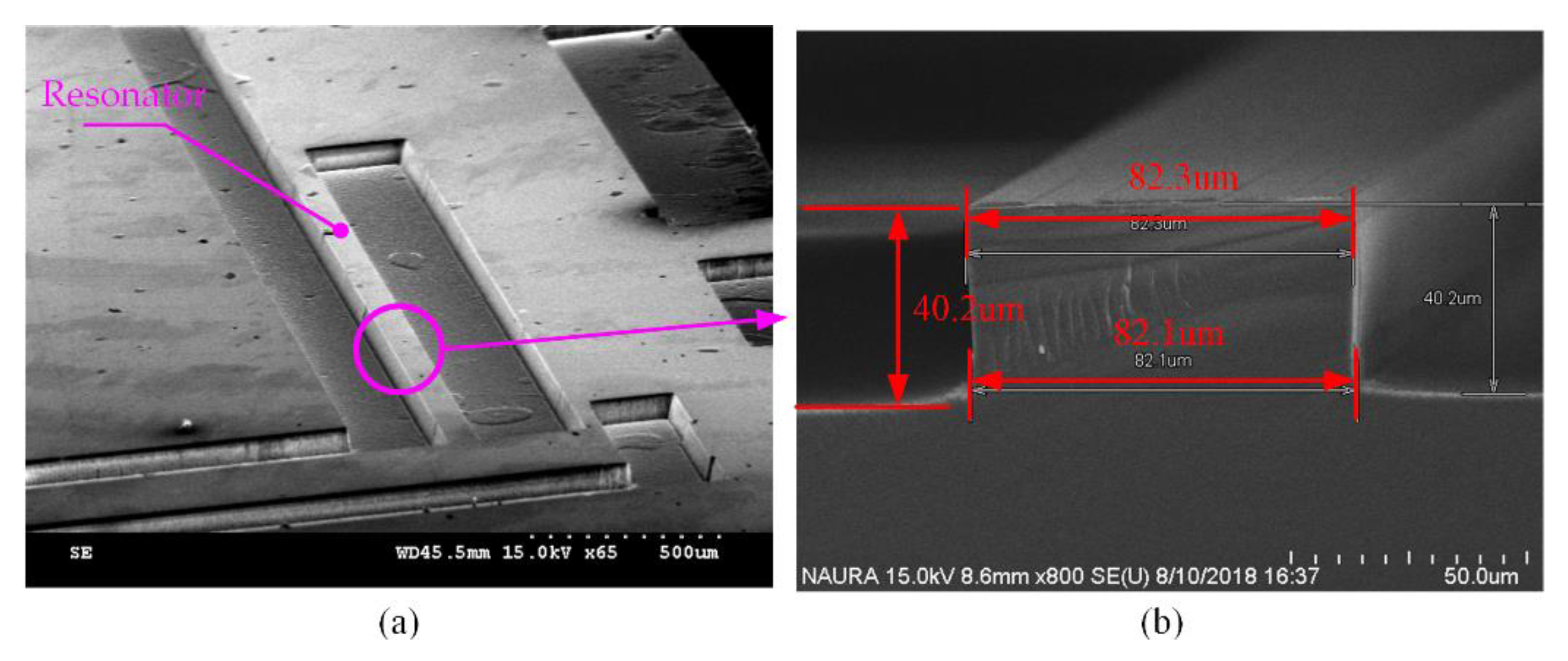

3.7. Statistic of the Experiments

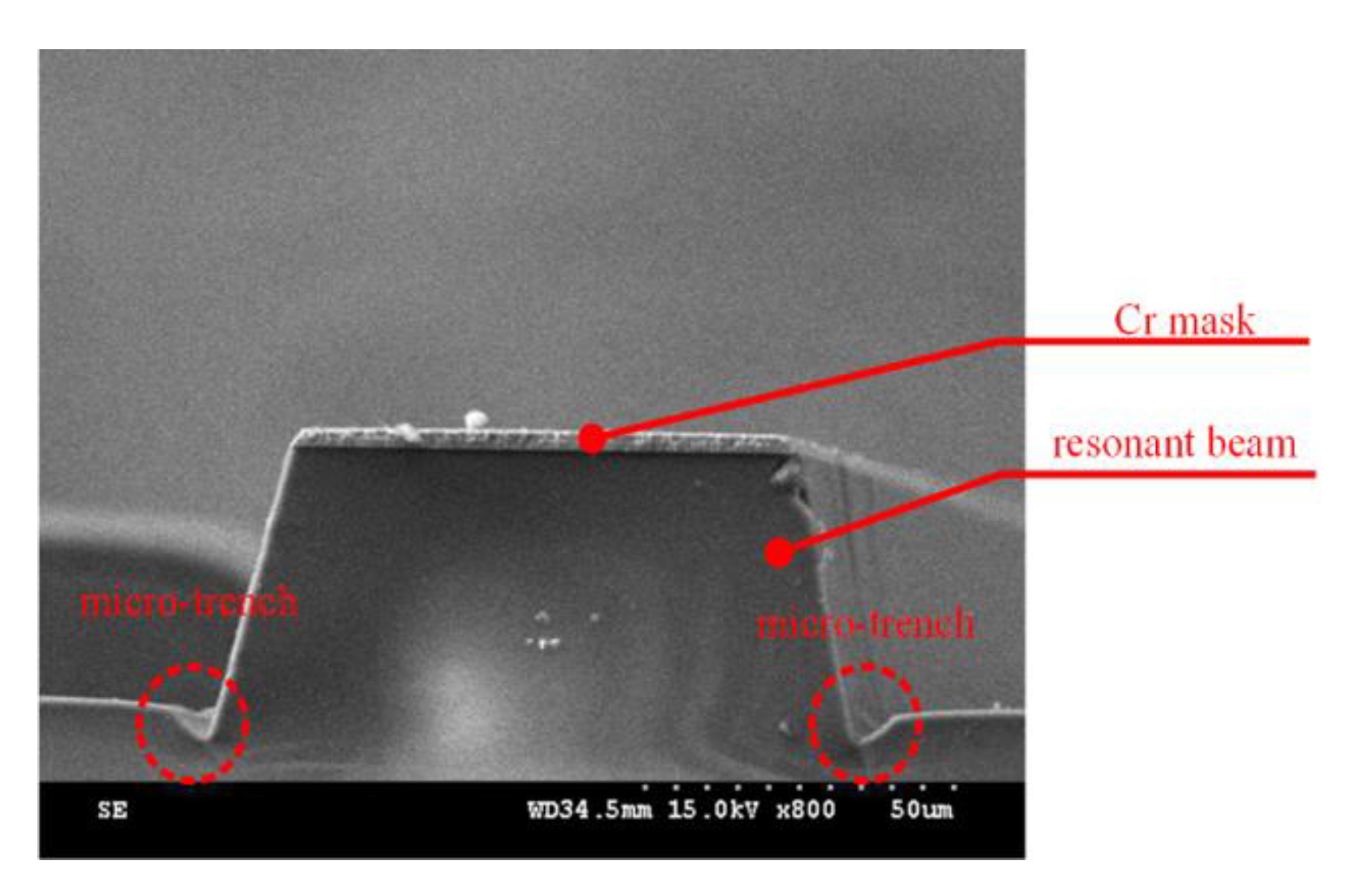

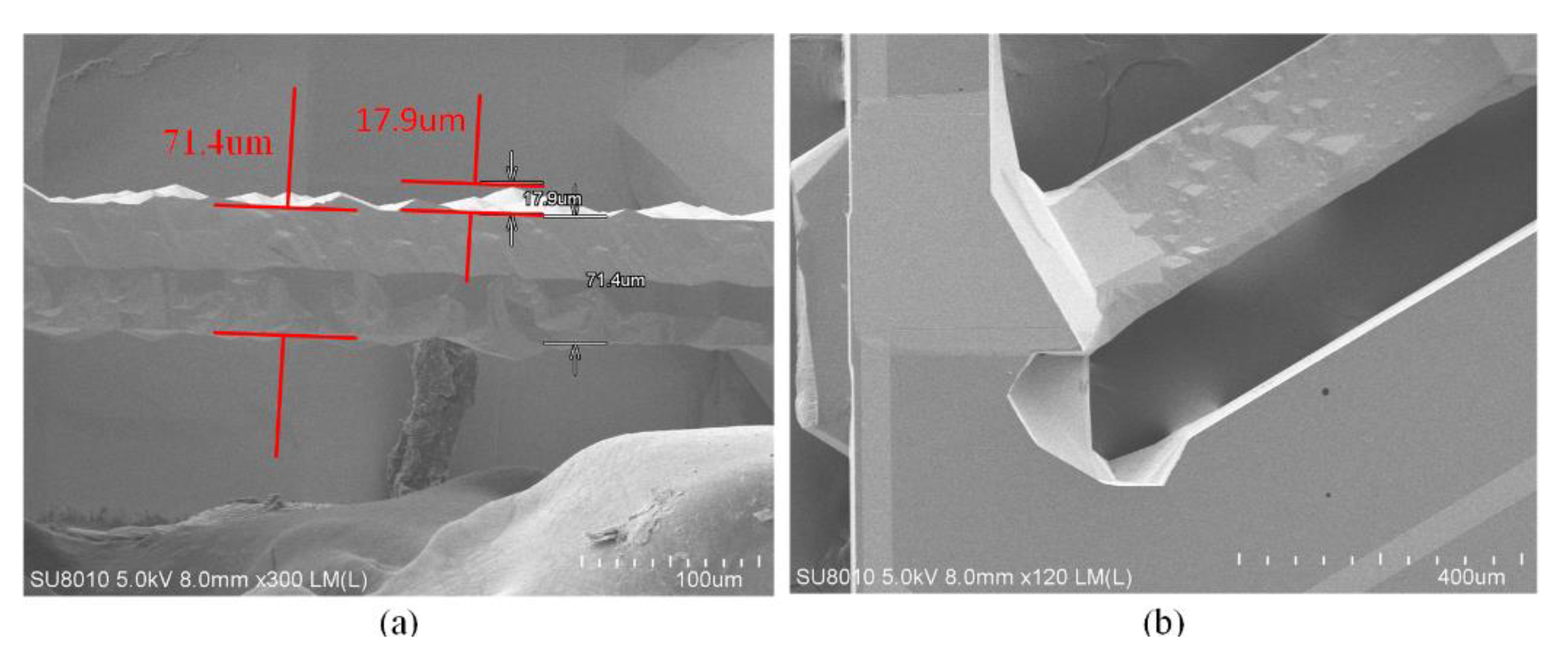

4. Discussion

4.1. Summary of the Quartz Deep Etching Technology

4.2. Compared with Other Quartz Etching Technology

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hung, C.-H.; Wang, W.-S.; Lin, Y.-C.; Liu, T.-W.; Sun, J.-H.; Chen, Y.-Y.; Esashi, M.; Wu, T.-T. Design and fabrication of an AT-cut quartz phononic Lamb wave resonator. J. Micromech. Microeng. 2013, 23, 065025. [Google Scholar] [CrossRef]

- Hussain, D.; Wen, Y.; Hui, X. Sidewall Imaging of Microstructures with a Tilted Quartz Tuning Fork (QTF) Force Sensor. In Proceedings of the 2018 International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Nagoya, Japan, 4–8 July 2018. [Google Scholar]

- Li, B.; Zhao, Y.; Li, C.; Cheng, R.; Sun, D.; Wang, S. A Differential Resonant Accelerometer with Low Cross-Interference and Temperature Drift. Sensors 2017, 17, 178. [Google Scholar] [CrossRef] [Green Version]

- Abe, T.; Esashi, M. One-chip multichannel quartz crystal microbalance (QCM) fabricated by Deep RIE. Sensors Actuators A-Phys. 2000, 82, 139–143. [Google Scholar] [CrossRef]

- Abe, T.; Itasaka, Y. A fabrication method of high-Q quartz crystal resonator using double-layered etching mask for DRIE. Sensors Actuators A-Phys. 2012, 188, 503–506. [Google Scholar] [CrossRef]

- Girault, P.; Lorrain, N.; Lemaitre, J.; Poffo, L.; Guendouz, M.; Hardy, I.; Gadonna, M.; Gutierrez, A.; Bodiou, L.; Charrier, J. Racetrack micro-resonators based on ridge waveguides made of porous silica. Opt. Mater. 2015, 50, 167–174. [Google Scholar] [CrossRef] [Green Version]

- Nanto, H.; Yokoi, Y.; Mukai, T.; Fujioka, J.; Kusano, E.; Kinbara, A.; Douguchi, Y. Novel gas sensor using polymer-film-coated quartz resonator for environmental monitoring. Mater. Sci. Eng. C-Biomim. Supramol. Syst. 2000, 12, 43–48. [Google Scholar] [CrossRef]

- Papp, S.B.; Diddams, S.A. Spectral and temporal characterization of a fused-quartz microresonator optical frequency comb. Phys. Rev. A 2011, 84, 6302–6312. [Google Scholar] [CrossRef] [Green Version]

- Song, E.-S.; Kang, S.; Kim, H.; Kim, Y.-K.; An, J.-E.; Baek, C.-W. Wafer-Level Fabrication of a Fused-Quartz Double-Ended Tuning Fork Resonator Oscillator Using Quartz-on-Quartz Direct Bonding. IEEE Electron Device Lett. 2013, 34, 692–694. [Google Scholar] [CrossRef]

- Zhou, L.; Zhong, Q.; Li, J.; Xing, H.; Wang, X.; Zhou, Z.; Wang, X. Design and Fabrication of a Novel 5 times 5 Beam Dammann Grating. Micronanoelectron. Technol. 2018, 55, 677–682. [Google Scholar]

- Lazorina, E.I.; Soroka, V.V. Etching of quartz and some features of the surface layer. Sov. Phys. Crystallogr. 1974, 18, 651–653. [Google Scholar]

- Tellier, C.R. some results on chemical etching of at-cut quartz wafers in ammonium bifluoride solutions. J. Mater. Sci. 1982, 17, 1348–1354. [Google Scholar] [CrossRef]

- Xing, Y.; Gosalvez, M.A.; Zhang, H.; Li, Y.; Qiu, X. Transient and Stable Profiles during Anisotropic Wet Etching of Quartz. J. Microelectromechanical Syst. 2017, 26, 1063–1072. [Google Scholar] [CrossRef]

- Varel, H.; Ashkenasi, D.; Rosenfeld, A.; Wahmer, M.; Campbell, E.E.B. Micromachining of quartz with ultrashort laser pulses. Appl. Phys. A-Mater. Sci. Process. 1997, 65, 367–373. [Google Scholar] [CrossRef]

- Moridi, A.; Wang, J.; Ali, Y.M.; Mathew, P.; Li, X. A Study of Abrasive Jet Micro-Grooving of Quartz Crystals. In Advances in Materials Processing Ix; Wang, J., Mathew, P., Li, X.P., Huang, C.Z., Zhu, H.T., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2010; p. 645. [Google Scholar]

- Wang, J.; Moridi, A.; Mathew, P. Micro-grooving on quartz crystals by an abrasive air jet. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 2161–2173. [Google Scholar] [CrossRef]

- Chen, X.; Tian, C.; Huang, Y.; Li, D.; Wang, H.; Zhang, W. Surface quality for rotary ultrasonic milling of quartz glass employing diamond ball end tool with tool inclination angle. In Proceedings of the 13th Global Congress on Manufacturing and Management, Zhengzhou, China, 28–30 November 2016; pp. 360–369. [Google Scholar]

- Kamaraj, A.B.; Jui, S.K.; Cai, Z.; Sundaram, M.M. A mathematical model to predict overcut during electrochemical discharge machining. Int. J. Adv. Manuf. Technol. 2015, 81, 685–691. [Google Scholar] [CrossRef]

- Khac-Ha, N.; Lee, P.A.; Kim, B.H. Experimental Investigation of ECDM for Fabricating Micro Structures of Quartz. Int. J. Precis. Eng. Manuf. 2015, 16, 5–12. [Google Scholar]

- Saranya, S.; Sankar, A.R. Fabrication of precise micro-holes on quartz substrates with improved aspect ratio using a constant velocity-feed drilling technique of an ECDM process. J. Micromech. Microeng. 2018, 28, 125009. [Google Scholar] [CrossRef]

- Saranya, S.; Sankar, A.R.; IEEE. Effect of Tool Shape and Tool Feed Rate on the Machined Profile of a Quartz Substrate Using an Electrochemical Discharge Machining Process. In Proceedings of the 2015 2nd International Symposium on Physics and Technology of Sensors (ISPTS), Pune, India, 7–10 March 2015. [Google Scholar]

- Bliznetsov, V.; Lin, H.M.; Zhang, Y.J.; Johnson, D. Deep SiO2 etching with Al and AlN masks for MEMS devices. J. Micromech. Microeng. 2015, 25, 87002. [Google Scholar] [CrossRef] [Green Version]

- Chapellier, P.; Verlhac, B.; Lavenus, P.; Dulmet, B.; IEEE. DRIE of high Q-factor length-extensional mode quartz micro-resonator. In Proceedings of the 2017 Joint Conference of the European Frequency and Time Forum and Ieee International Frequency Control Symposium, Besançon, France, 9–13 July 2017; pp. 218–221. [Google Scholar]

- Ichiki, T.; Sugiyama, Y.; Ujiie, T.; Horiike, Y. Deep dry etching of borosilicate glass using fluorine-based high-density plasmas for micrbelectromechanical system fabrication. J. Vac. Sci. Technol. B 2003, 21, 2188–2192. [Google Scholar] [CrossRef]

- Kamijo, A.; Monoe, S.; Murayama, N.; Saito, T.; Kimura, N.; IEEE. Wafer-Level Quartz Dry Etching Technolog. In Proceedings of the 2014 IEEE International Frequency Control Symposium, Taipei, Taiwan, 19–22 May 2014; pp. 80–83. [Google Scholar]

- Kim, J.S.; Jeong, H.W.; Lee, W.; Park, B.G.; Kim, B.M.; Lee, K.B. A simple and fast fabrication of a both self-cleanable and deep-UV antireflective quartz nanostructured surface. Nanoscale Res. Lett. 2012, 7, 430. [Google Scholar] [CrossRef] [Green Version]

- Kimura, S.; Imai, Y. Parabolic refractive X-ray lenses made of quartz glass for high-energy X-ray focusing. Jpn. J. Appl. Phys. 2016, 55, 38001. [Google Scholar] [CrossRef]

- Kolari, K. High etch selectivity for plasma etching SiO2 with AlN and Al2O3 masks. Microelectron. Eng. 2008, 85, 985–987. [Google Scholar] [CrossRef]

- Li, W.T.; Bulla, D.A.P.; Love, J.; Luther-Davies, B.; Charles, C.; Boswell, R. Deep dry-etch of silica in a helicon plasma etcher for optical waveguide fabricatlon. J. Vac. Sci. Technol. A 2005, 23, 146–150. [Google Scholar] [CrossRef]

- Minnick, M.D.; Devenyi, G.A.; Kleiman, R.N. Optimum reactive ion etching of x-cut quartz using SF6 and Ar. J. Micromech. Microeng. 2013, 23, 117002. [Google Scholar] [CrossRef]

- Odinokov, S.B.; Sagatelyan, G.R.; Kovalev, M.S.; Bugorkov, K.N. Features of the plasma-chemical etching of quartz glass during the formation of deep surface relief on high-precision components of devices. J. Opt. Technol. 2019, 86, 317–322. [Google Scholar] [CrossRef]

- Osipov, A.A.; Aleksandrov, S.E.; Osipov, A.A.; Berezenko, V.I. Development of Process for Fast Plasma-Chemical Through Etching of Single-Crystal Quartz in SF6/O-2 Gas Mixture. Russ. J. Appl. Chem. 2018, 91, 1255–1261. [Google Scholar] [CrossRef]

- Pedersen, M.; Huff, M. Plasma Etching of Deep High-Aspect Ratio Features Into Fused Silica. J. Microelectronmech. Syst. 2017, 26, 448–455. [Google Scholar] [CrossRef]

- Perros, A.; Bosund, M.; Sajavaara, T.; Laitinen, M.; Sainiemi, L.; Huhtio, T.; Lipsanen, H. Plasma etch characteristics of aluminum nitride mask layers grown by low-temperature plasma enhanced atomic layer deposition in SF6 based plasmas. J. Vac. Science Technol. A 2012, 30, 11504. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.-H.; Lin, Y.-H.; Chen, P.-L.; Shiao, M.-H.; Hsiao, C.-N. Comparison of optimised conditions for inductively coupled plasma-reactive ion etching of quartz substrates and its optical applications. Micro Nano Lett. 2014, 9, 395–398. [Google Scholar] [CrossRef]

- Tang, Y.-H.; Lin, Y.-H.; Huang, T.-T.; Wang, J.-S.; Shiao, M.-H.; Yu, C.-S.; IEEE. Investigation of Fabricated Through Glass Via (TGV) Process by Inductively Coupled Plasma Reactive Ion Etching of Quartz Glass. In Proceedings of the 2015 IEEE 10th International Conference on Nano/Micro Engineered and Molecular Systems, Xi’an, China, 7–11 April 2015; pp. 401–404. [Google Scholar]

- Chen, H.; Fu, C. An investigation into the characteristics of deep reactive ion etching of quartz using SU-8 as a mask. J. Micromech. Microeng. 2008, 18, 105001. [Google Scholar] [CrossRef]

- Kolari, K.; Saarela, V.; Franssila, S. Deep plasma etching of glass for fluidic devices with different mask materials. J. Micromech. Microeng. 2008, 18, 064010. [Google Scholar] [CrossRef]

- Li, L.; Abe, T.; Esashi, M. Smooth surface glass etching by deep reactive ion etching with SF6 and Xe gases. J. Vac. Sci. Technol. B 2003, 21, 2545–2549. [Google Scholar] [CrossRef]

- Mohamed, K.; Alkaisi, M.M. Investigation of a nanofabrication process to achieve high aspect-ratio nanostructures on a quartz substrate. Nanotechnology 2013, 24, 015302. [Google Scholar] [CrossRef]

- Ray, T.; Zhu, H.; Meldrum, D.R. Deep reactive ion etching of fused silica using a single-coated soft mask layer for bio-analytical applications. J. Micromech. Microeng. 2010, 20, 97002. [Google Scholar] [CrossRef]

- Tang, Y.-H.; Huang, M.-J.; Su, J.-Y.; Shiao, M.-H. Fabrication of Nanocone Subwavelength Antireflection Structures on Quartz Substrates. Jpn. J. Appl. Phys. 2012, 51, 06FF06. [Google Scholar] [CrossRef]

- Zeze, D.A.; Forrest, R.D.; Carey, J.D.; Cox, D.C.; Robertson, I.D.; Weiss, B.L.; Silva, S.R.P. Reactive ion etching of quartz and Pyrex for microelectronic applications. J. Appl. Phys. 2002, 92, 3624–3629. [Google Scholar] [CrossRef] [Green Version]

- Li, W.-T.; Bulla, D.A.P.; Boswell, R. Surface oxidation of Al masks for deep dry-etch of silica optical waveguides. Surface Coat. Technol. 2007, 201, 4979–4983. [Google Scholar] [CrossRef]

- Hedlund, C.; Lindberg, U.; Bucht, U.; Soderkvist, J. Anisotropic etching of Z-cut quartz. J. Micromech. Microeng. 1993, 3, 65–73. [Google Scholar] [CrossRef]

- Zhang, H.; Xing, Y.; Li, Y.; Gosalvez, M.A.; Qiu, X. Kinetic Monte Carlo method for the simulation of anisotropic wet etching of quartz. Sensors Actuators A-Phys. 2017, 256, 24–34. [Google Scholar] [CrossRef]

- Zhang, H.; Xing, Y.; Zhang, J.; Gosalvez, M.A.; Li, Y.; Zhang, Y.; IEEE. Evolutionary Kinetic Monte Carlo Method for The Simulation of Anisotropic Etching of Z-Cut, At-Cut And Bt-Cut Quartz. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017. [Google Scholar]

| Parameter | Al Mask | Ti Mask | Cr Mask |

|---|---|---|---|

| ICP power (W) | 1200 | 1200 | 1200 |

| Bias power (W) | 200 | 200 | 200 |

| Chamber pressure (mT) | 5 | 5 | 5 |

| C4F8 (sccm) | 30 | 30 | 30 |

| SF6 (sccm) | 30 | 30 | 30 |

| Ar (sccm) | 60 | 60 | 60 |

| Etch rate of quartz (nm min−1) | 0.2 | 0.23 | 0.42 |

| Selectivity (quartz/mask) | 6 | 10.92 | 21.06 |

| Profile (°) | 76 | 84 | 89 |

| Parameters | ICP Power (W) | Bias Power (W) | Chamber Pressure (mT) | Temperature (°C) | Ar (sccm) | C4F8 (sccm) | SF6 (sccm) | Etching Time (min) |

|---|---|---|---|---|---|---|---|---|

| Value | 1200 | 230 | 6 | 90 | 60 | 30 | 30 | 155 |

| Experiment | Run 1 | Run 2 | Run 3 | |

|---|---|---|---|---|

| Sample | ||||

| 1 | 70.1 μm | 69.7 μm | 70.1 μm | |

| 2 | 70.4 μm | 69.3 μm | 70.2 μm | |

| 3 | 70.3 μm | 69.1 μm | 69.8 μm | |

| 4 | 69.9 μm | 70 μm | 69.6 μm | |

| 5 | 70.5 μm | 69.5 μm | 70 μm | |

| Average value | 74.24 μm | 69.52 μm | 69.94 μm | |

| Standard deviation | 0.24083 | 0.34928 | 0.24083 | |

| Etching rate (μm/min) | 0.453 | 0.449 | 0.451 | |

| Etch Gas | Etch Rate of Quartz (μm/min) | Profile (°) |

|---|---|---|

| C4F8/Ar | 0.48 | 82 |

| SF6/Ar | 0.31 | 86 |

| C4F8/SF6/Ar | 0.43 | 90 |

| Parameters | ICP Power (W) | Bias Power (W) | Chamber Pressure (mT) | Temperature (°C) | Ar (sccm) | O2 (sccm) |

|---|---|---|---|---|---|---|

| Value | 1200 | 200 | 5 | 90 | 40 | 15 |

| Parameters | Target | Mask | Etch Rate (μm/min) | Selectivity | Profile (Degree) | Depth (μm) |

|---|---|---|---|---|---|---|

| H. Chen [37] | quartz | SU-8 | 0.22 | 0.34 | 86 | 55 |

| V. Bliznetsov [22] | USG | AlN | 0.32 | 49 | 88 | 21 |

| Tathagata Ray [41] | Fused silica | KMPR®1025 | 0.0933 | 1.13 | 85 | 30 |

| M. Esashi [4] | quartz | Ni | 0.5 | 30 | 87 | 20 |

| K. Kolari [38] | PyrexTM | Ni | 0.7 | 23.3 | 78 | 100 |

| This work | quartz | Cr | 0.45 | 21.06 | 90 | 75.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Li, C.; Zhao, Y.; Han, C.; Zhang, Q. Deep Reactive Ion Etching of Z-Cut Alpha Quartz for MEMS Resonant Devices Fabrication. Micromachines 2020, 11, 724. https://doi.org/10.3390/mi11080724

Li B, Li C, Zhao Y, Han C, Zhang Q. Deep Reactive Ion Etching of Z-Cut Alpha Quartz for MEMS Resonant Devices Fabrication. Micromachines. 2020; 11(8):724. https://doi.org/10.3390/mi11080724

Chicago/Turabian StyleLi, Bo, Cun Li, Yulong Zhao, Chao Han, and Quanwei Zhang. 2020. "Deep Reactive Ion Etching of Z-Cut Alpha Quartz for MEMS Resonant Devices Fabrication" Micromachines 11, no. 8: 724. https://doi.org/10.3390/mi11080724

APA StyleLi, B., Li, C., Zhao, Y., Han, C., & Zhang, Q. (2020). Deep Reactive Ion Etching of Z-Cut Alpha Quartz for MEMS Resonant Devices Fabrication. Micromachines, 11(8), 724. https://doi.org/10.3390/mi11080724