Wireless Passive LC Temperature and Strain Dual-Parameter Sensor

Abstract

:1. Introduction

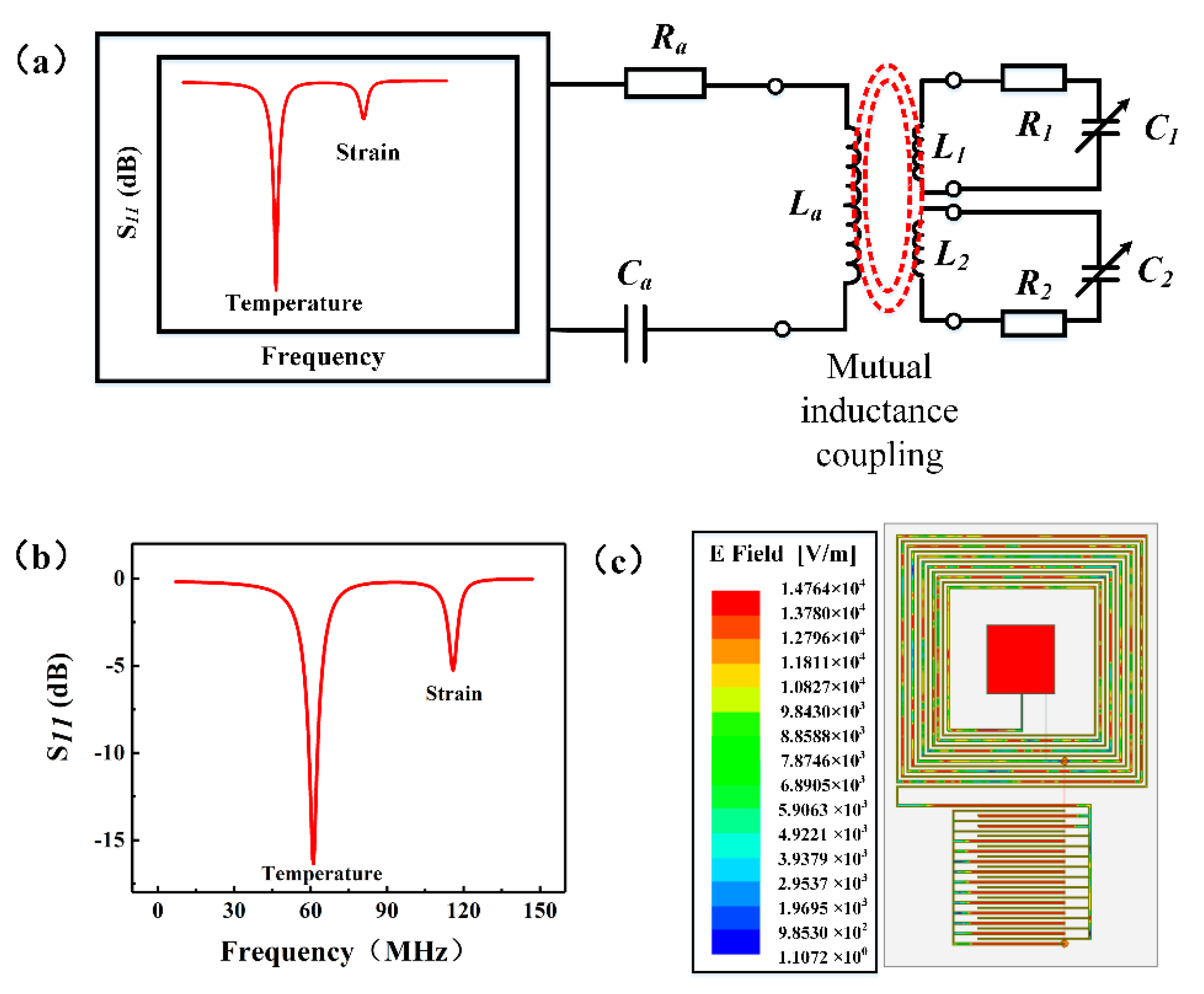

2. Design and Simulation

3. Results and Discussion

3.1. Sensor Preparation

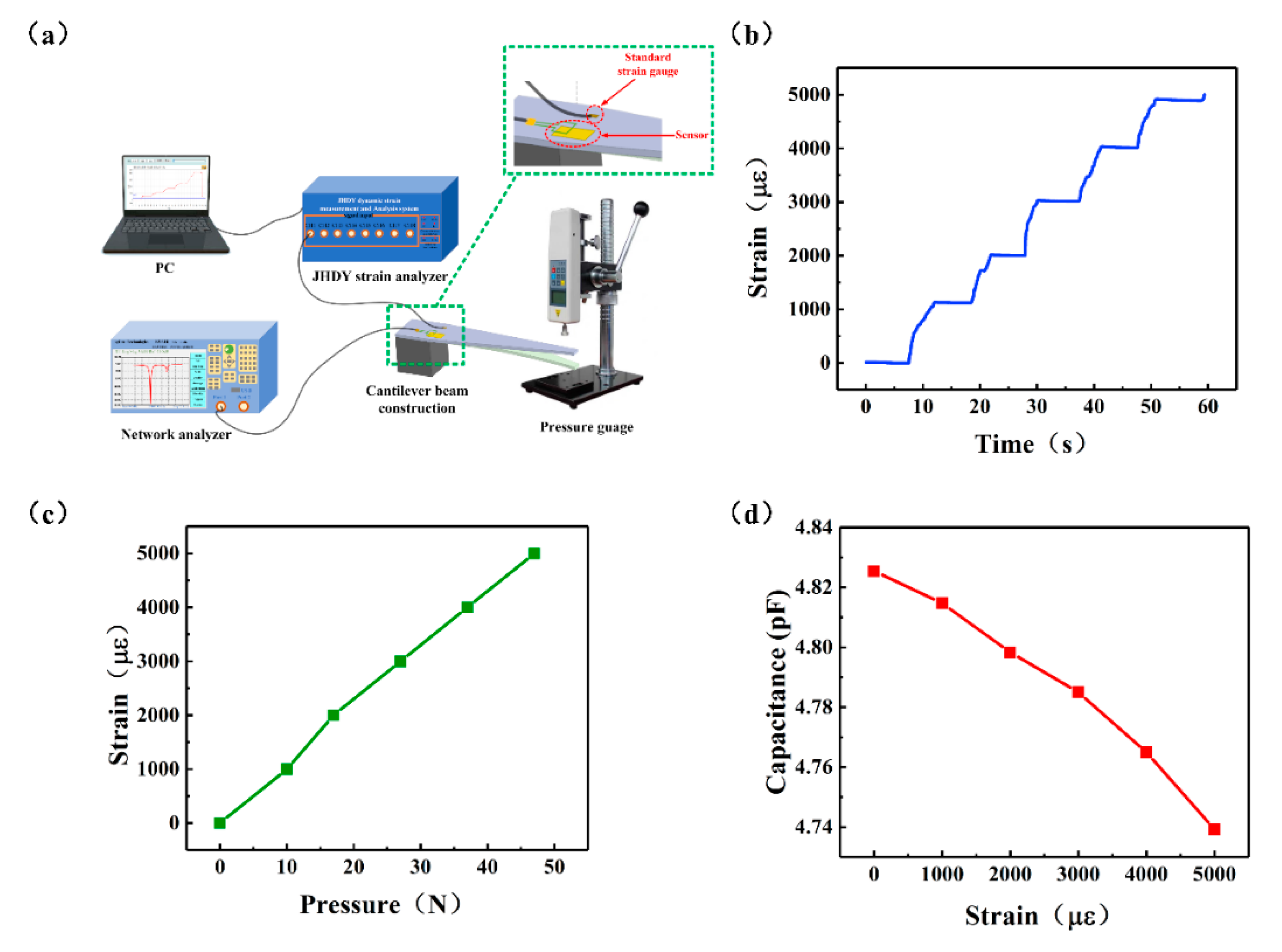

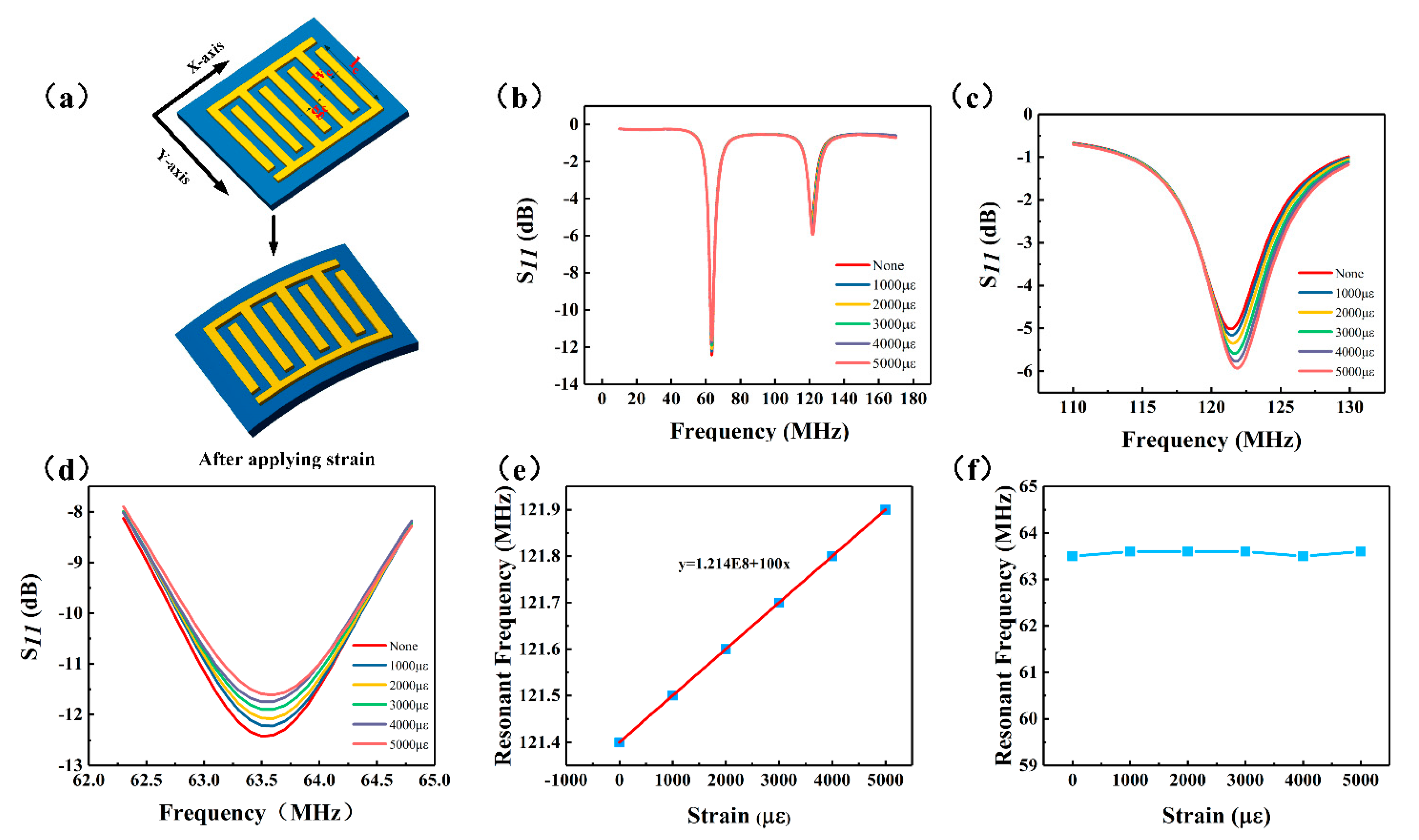

3.2. Strain Test

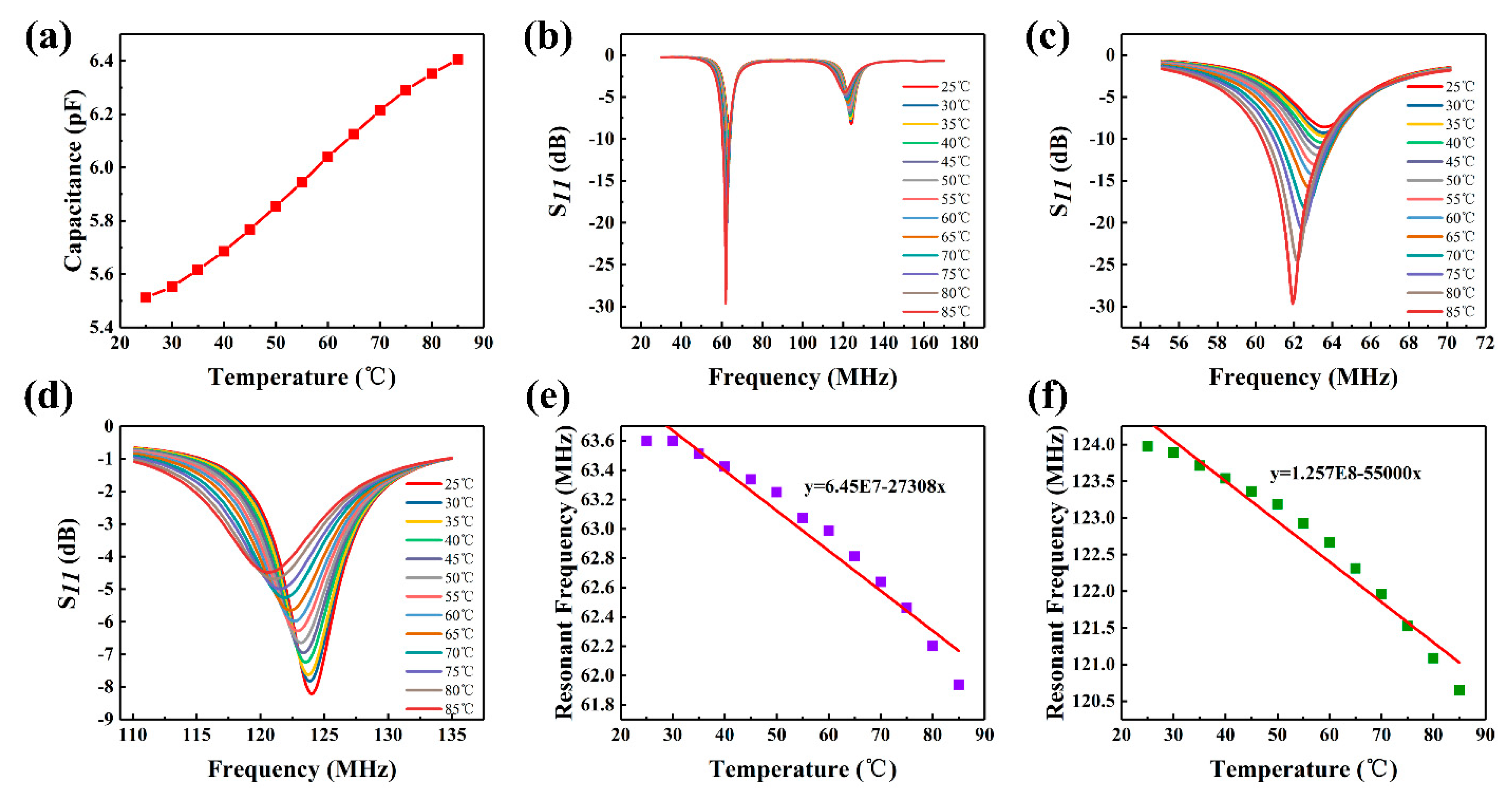

3.3. Temperature Test

- The strain range is sufficiently large to monitor a relatively larger range of strain changes.

- Integrated measurement of the sensor is realized, the sensor area is reduced, and the temperature and strain can be monitored simultaneously.

- The sensor comprises a flexible substrate and has the advantage of conformal attachment on curved surfaces.

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- De Bernardis, P.; Columbro, F.; Masi, S.; Paiella, A.; Romeo, G. A simple method to measure the temperature and levitation height of devices rotating at cryogenic temperatures. Rev. Sci. Instrum. 2020, 91, 045118. [Google Scholar] [CrossRef] [PubMed]

- Tan, Q.; Ji, Y.; Lv, W.; Wu, F.; Dong, H.; Zhang, W.; Xiong, J. Signal Readout of LC Pressure Sensor Operated in Multi-dimensional rotating Environment with Dual-inductance Resonator. Sens. Actuators A Phys. 2019, 296, 178–185. [Google Scholar] [CrossRef]

- Hembree, W.; Bochtler, B.; Busch, R. High-temperature rotating cylinder rheometer for studying metallic glass forming liquids. Rev. Sci. Instrum. 2018, 89, 113904. [Google Scholar] [CrossRef] [PubMed]

- Lopata, R.G.P.; Hansen, H.H.G.; Nillesen, M.M.; Thijssen, J.M.; Kapusta, L.; De Korte, C.L. Methodical study on the estimation of strain in shearing and rotating structures using radio frequency ultrasound based on 1-D and 2-D strain estimation techniques. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2010, 57, 855–865. [Google Scholar] [CrossRef] [PubMed]

- Hua, L.; Deng, S.; Han, X.; Huang, S. Effect of material defects on crack initiation under rolling contact fatigue in a bearing ring. Tribol. Int. 2013, 66, 315–323. [Google Scholar] [CrossRef]

- Deng, S.; Qin, X.; Huang, S. A study on the effect of subsurface crack propagation on rolling contact fatigue in a bearing ring. J. Mech. Sci. Technol. 2015, 29, 1029–1038. [Google Scholar] [CrossRef]

- Karim, H.; Delfin, D.; Chavez, L.A.; Delfin, L.; Martinez, R.; Avila, J.; Rodriguez, C.; Rumpf, R.C.; Love, N.; Lin, Y. Metamaterial Based Passive Wireless Temperature Sensor. Adv. Eng. Mater. 2017, 19, 1600741. [Google Scholar] [CrossRef]

- Childs, P.R.N.; Greenwood, J.R.; Long, C. Review of temperature measurement. Rev. Sci. Instrum. 2000, 71, 2959–2978. [Google Scholar] [CrossRef] [Green Version]

- Pertijs, M.A.P.; Huijsing, J.H. Precision Temperature Sensors in CMOS Technology; Springer Netherlands: Berlin, The Germany, 2006. [Google Scholar]

- Kim, G.-D.; Lee, H.-S.; Park, C.-H.; Lee, S.-S.; Lim, B.T.; Bae, H.K.; Lee, W.-G. Silicon photonic temperature sensor employing a ring resonator manufactured using a standard CMOS process. Opt. Express 2010, 18, 22215–22221. [Google Scholar] [CrossRef]

- Lin, R.; Kim, H.-J.; Achavananthadith, S.; Kurt, S.A.; Tan, S.C.C.; Yao, H.; Tee, B.C.K.; Lee, J.K.W.; Ho, J.S. Wireless battery-free body sensor networks using near-field-enabled clothing. Nat. Commun. 2020, 11, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Qin, Y.; Peng, Q.; Ding, Y.; Lin, Z.; Wang, C.; Li, Y.; Xu, F.; Li, J.; Yuan, Y.; He, X.; et al. Lightweight, Superelastic, and Mechanically Flexible Graphene/Polyimide Nanocomposite Foam for Strain Sensor Application. ACS Nano 2015, 9, 8933. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Li, Z.; Sha, X.; Xu, Y. Strain Sensor-Based Wireless Measurement System for Bridge. J. Tongji Univ. (Nat. Sci.) 2007, 10, 7. [Google Scholar]

- Santana, J.; Hoven, R.V.D.; Van Liempd, C.; Colin, M.E.G.D.; Saillen, N.; Zonta, D.; Trapani, D.; Torfs, T.; Van Hoof, C. A 3-axis accelerometer and strain sensor system for building integrity monitoring. Sens. Actuators A Phys. 2012, 188, 141–147. [Google Scholar] [CrossRef]

- Rodriguez, R.I.; Jia, Y. A wireless inductive-capacitive (L-C) sensor for rotating component temperature monitoring. Int. J. Smart Sens. Intell. Syst. 2011, 4, 325–337. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Wei, D.; Tang, L.; Song, X.; Luo, W.; Chu, J.; Gao, T.; Shi, H.; Du, C. Wearable temperature sensor based on graphene nanowalls. RSC Adv. 2015, 5, 25609–25615. [Google Scholar] [CrossRef]

- Jia, Y.; Sun, K.; Agosto, F.J.; Quiñones, M.T. Design and characterization of a passive wireless strain sensor. Meas. Sci. Technol. 2006, 17, 2869–2876. [Google Scholar] [CrossRef]

- Fassler, A.; Majidi, C. Soft-matter capacitors and inductors for hyperelastic strain sensing and stretchable electronics. Smart Mater. Struct. 2013, 22, 055023. [Google Scholar] [CrossRef]

- Mattmann, C.; Clemens, F.; Tröster, G. Sensor for Measuring Strain in Textile. Sensors 2008, 8, 3719–3732. [Google Scholar] [CrossRef]

- Tan, Q.; Luo, T.; Wei, T.; Liu, J.; Lin, L.; Xiong, J. A Wireless Passive Pressure and Temperature Sensor via a Dual LC Resonant Circuit in Harsh Environments. J. Microelectromech. Syst. 2017, 26, 351–356. [Google Scholar] [CrossRef]

- Ren, Q.-Y.; Wang, L.-F.; Huang, J.-Q.; Zhang, C.; Huang, Q.-A. Simultaneous Remote Sensing of Temperature and Humidity by LC-Type Passive Wireless Sensors. J. Microelectromech. Syst. 2015, 24, 1. [Google Scholar] [CrossRef]

- Tan, Q.; Lv, W.; Ji, Y.; Song, R.; Lu, F.; Dong, H.; Zhang, W.; Xiong, J. A LC wireless passive temperature-pressure-humidity (TPH) sensor integrated on LTCC ceramic for harsh monitoring. Sens. Actuators B Chem. 2018, 270, 433–442. [Google Scholar] [CrossRef]

- Maskay, A.; Da Cunha, M.P. High-temperature static strain langasite SAWR sensor: Temperature compensation and numerical calibration for direct strain reading. Sens. Actuators A Phys. 2017, 259, 34–43. [Google Scholar] [CrossRef] [Green Version]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.; Yu, K.J.; Cheng, H.; Shi, M.; Bian, Z.; Liu, Z.; Kim, Y.; et al. Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nat. Mater. 2013, 12, 938–944. [Google Scholar] [CrossRef] [PubMed]

- Kou, H.; Tan, Q.; Wang, Y.; Zhang, G.; Xiong, J. A wireless slot-antenna integrated temperature-pressure-humidity sensor loaded with CSRR for harsh-environment applications. Sens. Actuators B Chem. 2020, 311, 127907. [Google Scholar] [CrossRef]

- Deng, W.-J.; Wang, L.-F.; Dong, L.; Huang, Q.-A. Symmetric LC Circuit Configurations for Passive Wireless Multifunctional Sensors. J. Microelectromech. Syst. 2019, 28, 344–350. [Google Scholar] [CrossRef]

- Dong, L.; Wang, L.-F.; Huang, Q.-A. Implementation of Multiparameter Monitoring by an LC-Type Passive Wireless Sensor Through Specific Winding Stacked Inductors. IEEE Internet Things J. 2015, 2, 168–174. [Google Scholar] [CrossRef]

- Chen, C.-M.; Xu, J.; Yao, Y. Fabrication of miniaturized CSRR-loaded HMSIW humidity sensors with high sensitivity and ultra-low humidity hysteresis. Sens. Actuators B Chem. 2018, 256, 1100–1106. [Google Scholar] [CrossRef]

- Ong, K.; Grimes, C.; Robbins, C.; Singh, R. Design and application of a wireless, passive, resonant-circuit environmental monitoring sensor. Sens. Actuators A Phys. 2001, 93, 33–43. [Google Scholar] [CrossRef]

- Ozbey, B.; Altintas, A.; Demir, H.V.; Erturk, V.B. An Equivalent Circuit Model for Nested Split-Ring Resonators. IEEE Trans. Microw. Theory Tech. 2017, 65, 3733–3743. [Google Scholar] [CrossRef]

- Stone, D.C.; Thompson, M. Interdigital capacitance and surface acoustic wave sensors. Anal. Chem. 1993, 65, 352–362. [Google Scholar] [CrossRef]

- Zhang, L.; Kou, H.; Tan, Q.; Liu, G.; Xiong, J. High-performance strain sensor based on a three-dimensional conductive structure for wearable electronics. J. Phys. D Appl. Phys. 2019, 52, 395401. [Google Scholar] [CrossRef]

- Xiefu, W.; Jing, Z.; Bingbing, X.; Wenning, D.; Li, L.; Fei, H.; Haosu, L.; Haoshuang, G. Theoretical Model and Experiments of Resonance Frequency Shift by LC Tuning in Magnetoelectric Sensor. Phys. Status Solidi 2019, 216, 1800966. [Google Scholar]

- Cheng, Z.; Wei, L.; An-Lin, L.; Zhan, Z.; Ling-Yun, W.; Dao-Heng, S. Design and Manufacturing of a Passive Pressure Sensor Based on LC Resonance. Micromachines 2016, 7, 87. [Google Scholar]

- Zhang, L.; Tan, Q.; Kou, H.; Wu, D.; Zhang, W.; Xiong, J. Highly Sensitive NH3 Wireless Sensor Based on Ag-RGO Composite Operated at Room-temperature. Sci. Rep. 2019, 9, 1–10. [Google Scholar] [CrossRef]

- Ren, S.; Jiang, S.W.; Liu, H.; Zhang, W.; Li, Y. Investigation of strain gauges based on interdigitated Ba0.5Sr0.5TiO3 thin film capacitors. Sens. Actuators A Phys. 2015, 236, 159–163. [Google Scholar] [CrossRef]

- Qin, L.; Shen, D.; Wei, T.; Tan, Q.; Luo, T.; Zhou, Z.; Xiong, J. A Wireless Passive LC Resonant Sensor Based on LTCC under High-Temperature/Pressure Environments. Sensors 2015, 15, 16729–16739. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.-Y.; Huang, Q.-A.; Qin, M.; Lu, T. A micromachined silicon capacitive temperature sensor for wide temperature range applications. J. Micromech. Microeng. 2010, 20, 055036. [Google Scholar] [CrossRef]

- Dou, S.; Qi, M.; Chen, C.; Zhou, H.; Mu, X. High-temperature high-sensitivity AlN-on-SOI Lamb wave resonant strain sensor. AIP Adv. 2018, 8, 065315. [Google Scholar] [CrossRef]

| Sensor Type | Range | Integration | Basal | References |

|---|---|---|---|---|

| Temperature sensor | 0–200 °C | No | rigid | [15] |

| Temperature sensor | −70–100 °C | No | rigid | [38] |

| Strain sensor | 0–2500 με | No | rigid | [36] |

| Strain sensor | 0–400 με | No | rigid | [39] |

| Sensor in this study | 25–85 °C/0–5000 με | Yes | flexible |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Tan, Q.; Zhang, L.; Lin, B.; Li, M.; Fan, Z. Wireless Passive LC Temperature and Strain Dual-Parameter Sensor. Micromachines 2021, 12, 34. https://doi.org/10.3390/mi12010034

Wang Y, Tan Q, Zhang L, Lin B, Li M, Fan Z. Wireless Passive LC Temperature and Strain Dual-Parameter Sensor. Micromachines. 2021; 12(1):34. https://doi.org/10.3390/mi12010034

Chicago/Turabian StyleWang, Ya, Qiulin Tan, Lei Zhang, Baimao Lin, Meipu Li, and Zhihong Fan. 2021. "Wireless Passive LC Temperature and Strain Dual-Parameter Sensor" Micromachines 12, no. 1: 34. https://doi.org/10.3390/mi12010034