A Luminous Efficiency-Enhanced Laser Lighting Device with a Micro-Angle Tunable Filter to Recycle Unconverted Blue Laser Rays

Abstract

:1. Introduction

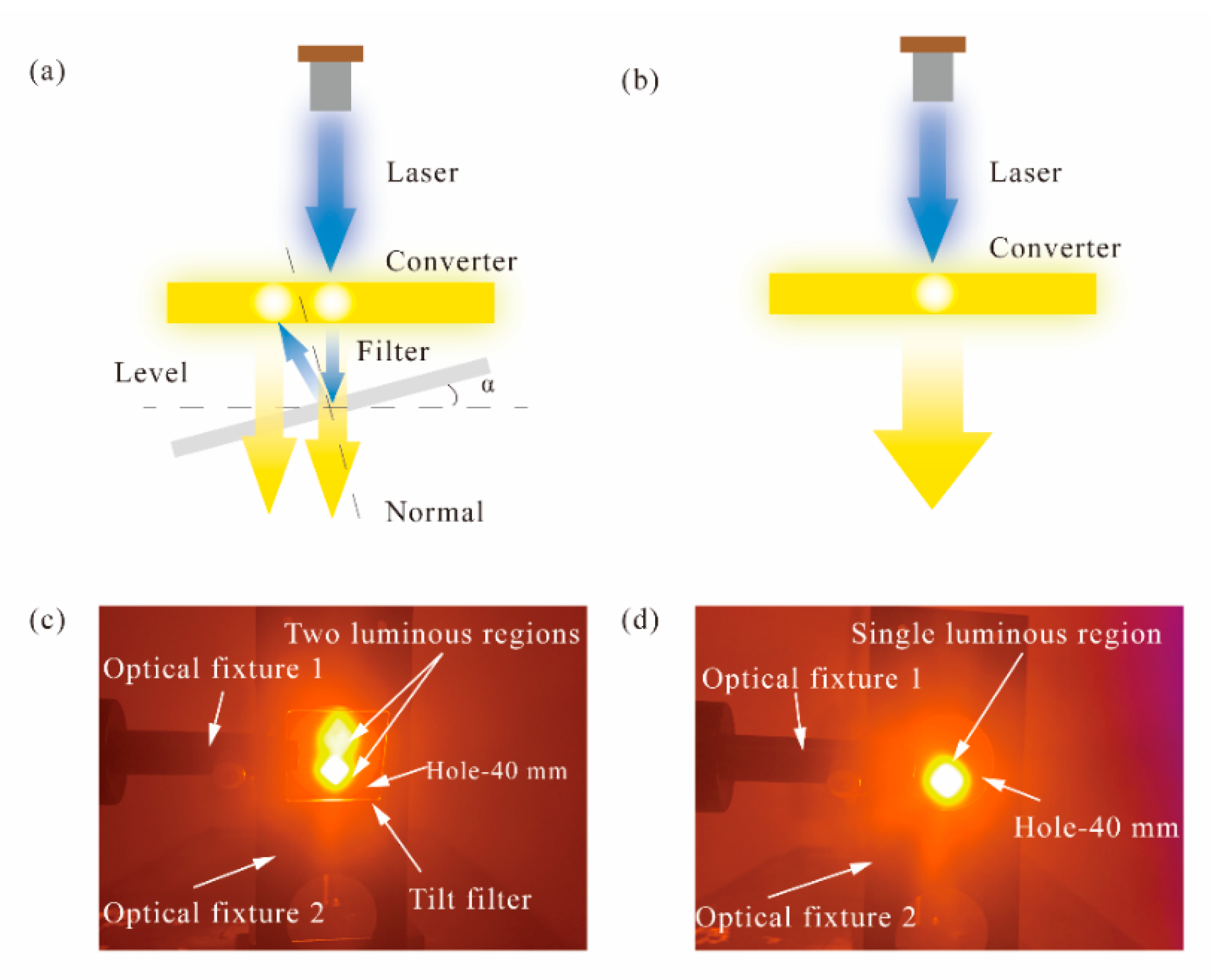

2. Materials and Methods

2.1. Characteristics of the Optical Filters

2.2. Fabrication of YAG Yellow Phosphor Converters

2.3. Experiment Setups

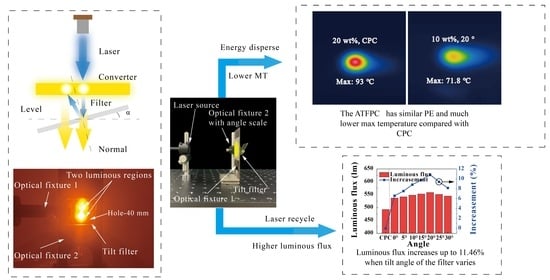

3. Results and Discussion

3.1. Scatter Characteristics of Phosphor Converters

3.2. Effects of Tilt Angles on Optical Performance

3.3. Effects of Concentration on Optical Performance

3.4. Thermal Performance of ATFPCs

3.5. Intensity Regulation of Uneven Lumination

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chang, Y.P.; Chang, J.K.; Chen, H.A.; Chang, S.H.; Liu, C.N.; Han, P.; Cheng, W.H. An advanced laser headlight module employing highly reliable glass phosphor. Opt. Express 2019, 27, 1808–1815. [Google Scholar] [CrossRef] [PubMed]

- Barnum, P.C.; Narasimhan, S.G.; Kanade, T. A multi-layered display with water drops. ACM Trans. Graph. 2010, 29, 1–7. [Google Scholar] [CrossRef]

- Chang, Y.P.; Liu, C.N.; Pei, Z.; Lee, S.M.; Lai, Y.K.; Han, P.; Shih, H.K.; Cheng, W.H. New scheme of LiDAR-Embedded smart laser headlight for autonomous vehicles. Opt. Express 2019, 27, A1481–A1489. [Google Scholar] [CrossRef]

- Barnum, P.; Narasimhan, S.; Kanade, T. A projector-camera system for creating a display with water drops. In Proceedings of the 2009 IEEE Computer Society Conference on Computer Vision and Pattern Recognition Workshops (IEEE2009), Miami, FL, USA, 20–25 June 2009; pp. 17–23. [Google Scholar]

- Wolf, A.; Kloppenburg, G.; Danov, R.; Lachmayer, R.J.D.P. DMD based automotive lighting unit. In DGaO Proceedings 2016; Deutschen Gesellschaft für angewandte Optik: Erlangen, Germany, 2016. [Google Scholar]

- Lee, B.L.; Douglass, M.R.; Lachmayer, R.; Kloppenburg, G.; Knöchelmann, M. Headlamp innovations: Optical concepts for fully adaptive light distributions. In Emerging Digital Micromirror Device Based Systems and Applications X; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10546, p. 105460K. [Google Scholar]

- Denault, K.A.; Cantore, M.; Nakamura, S.; DenBaars, S.P.; Seshadri, R. Efficient and stable laser-driven white lighting. AIP Adv. 2013, 3, 072107. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, D.; Zhou, B.; Feng, S.; Sun, M.; Zhang, S.; Gao, W.; Bi, Y.; Qin, H. High luminous fluorescence generation using Ce: YAG transparent ceramic excited by blue laser diode. Opt. Mater. Express 2018, 8, 2760–2767. [Google Scholar] [CrossRef]

- Gu, C.; Wang, X.-J.; Xia, C.; Li, S.; Liu, P.; Li, D.; Li, H.; Zhou, G.; Zhang, J.; Xie, R.-J. A new CaF2-YAG: Ce composite phosphor ceramic for high-power and high-color-rendering WLEDs. J. Mater. Chem. C 2019, 7, 8569–8574. [Google Scholar] [CrossRef]

- Hu, S.; Liu, Y.; Zhang, Y.; Xue, Z.; Wang, Z.; Zhou, G.; Lu, C.; Li, H.; Wang, S. 3D printed ceramic phosphor and the photoluminescence property under blue laser excitation. J. Eur. Ceram. Soc. 2019, 39, 2731–2738. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Huang, Y.; Wang, L.; Zhang, H.; Jiang, R.; Huang, F.; Yao, X.; Liu, X.; Huang, Z. The effect of the porosity on the Al2O3-YAG: Ce phosphor ceramic: Microstructure; luminescent efficiency; and luminous stability in laser-driven lighting. J. Alloys Compd. 2019, 785, 125–130. [Google Scholar] [CrossRef]

- Wang, H.; Mou, Y.; Peng, Y.; Zhang, Y.; Wang, A.; Xu, L.; Long, H.; Chen, M.; Dai, J.; Chen, C. Fabrication of phosphor glass film on aluminum plate by using lead-free tellurite glass for laser-driven white lighting. J. Alloys Compd. 2020, 814, 152331. [Google Scholar] [CrossRef]

- Xu, J.; Yang, Y.; Wang, J.; Du, B.; Santamaría, A.A.; Hu, B.; Liu, B.; Ji, H.; Dam-Hansen, C.; Jensen, O.B. Industry-friendly synthesis and high saturation threshold of a LuAG: Ce/glass composite film realizing high- brightness laser lighting. J. Eur. Ceram. Soc. 2020, 40, 6031–6036. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Tian, Z.; Liu, X.; Takeda, T.; Hirosaki, N.; Xu, F.; Huang, Z.; Xie, R.-J. New insights into the microstructure of translucent CaAlSiN3:Eu2+ phosphor ceramics for solid-state laser lighting. J. Mater. Chem. C 2017, 5, 1042–1051. [Google Scholar] [CrossRef]

- Wang, H.; Dai, J.; Sun, H.; Mou, Y.; Cai, Y.; Liang, R.; Xu, L.; Gao, Y.; Peng, Y.; Li, J.; et al. Phosphor Glass- Coated Sapphire with Moth-Eye Microstructures for Ultraviolet-Excited White Light-Emitting Diodes. IEEE Trans. Electron Devices 2019, 66, 3007–3011. [Google Scholar] [CrossRef]

- Li, Z.-T.; Wang, Q.-H.; Tang, Y.; Li, C.; Ding, X.-R.; He, Z.-H. Light Extraction Improvement for LED COB Devices by Introducing a Patterned Lead frame Substrate Configuration. IEEE Trans. Electron Devices 2013, 60, 1397–1403. [Google Scholar] [CrossRef]

- Ding, X.; Tang, Y.; Li, Z.; Li, J.; Xie, Y.; Lin, L. Multichip LED Modules with V-Groove Surfaces for Light Extraction Efficiency Enhancements Considering Roughness Scattering. IEEE Trans. Electron Devices 2017, 64, 182–188. [Google Scholar] [CrossRef]

- Pan, J.-W.; Wang, C.-S.J.O.e. Light extraction efficiency of GaN-based LED with pyramid texture by using ray path analysis. Opt. Express 2012, 20, 630–640. [Google Scholar] [CrossRef]

- Fujii, T.; Gao, Y.; Sharma, R.; Hu, E.L.; DenBaars, S.P.; Nakamura, S. Increase in the extraction efficiency of GaN-based light-emitting diodes via surface roughening. Appl. Phys. Lett. 2004, 84, 855–857. [Google Scholar] [CrossRef]

- Sun, B.; Zhao, L.; Wei, T.; Yi, X.; Liu, Z.; Wang, G.; Li, J.; Yi, F. Light extraction enhancement of bulk GaN light-emitting diode with hemisphere-cones-hybrid surface. Opt. Express 2012, 20, 18537–18544. [Google Scholar] [CrossRef]

- Tang, Y.; Liang, Y.; Ding, X.; Wu, Q.; Yu, B. A laser-driven phosphor converted system with enhanced optical efficiency by using light-recycling dichroic filters. J. Lumin. 2020, 223, 117180. [Google Scholar] [CrossRef]

- Oh, J.H.; Yang, S.J.; Do, Y.R. Polarized white light from LEDs using remote-phosphor layer sandwiched between reflective polarizer and light-recycling dichroic filter. Opt. Express 2013, 21, A765–A773. [Google Scholar] [CrossRef] [PubMed]

- Fujita, S.; Umayahara, Y.; Tanabe, S.J. Influence of light scattering on luminous efficacy in Ce: YAG glass-ceramic phosphor. J. Ceram. Soc. Jpn. 2010, 118, 128–131. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Kim, H. Optical properties of phosphor-in-glass through modification of pore properties for LED packaging. Opt. Mater. 2018, 75, 814–820. [Google Scholar] [CrossRef]

- Li, J.-S.; Chen, J.-X.; Lin, L.-W.; Li, Z.-T.; Tang, Y.; Yu, B.-H.; Ding, X.-R. A Detailed Study on Phosphor- Converted Light-Emitting Diodes with Multi-Phosphor Configuration Using the Finite-Difference Time-Domain and Ray-Tracing Methods. IEEE J. Quantum Electron. 2015, 51, 1–10. [Google Scholar] [CrossRef]

- Yang, Y.; Long, T.; Zhuang, S.; Wang, L.; Luo, Y. High-Particle-Density YAG: Ce Phosphor Coating for High Power Laser Lighting. J. Electron. Packag. 2020, 142, 031101. [Google Scholar] [CrossRef]

- Zhuo, N.; Zhang, N.; Jiang, T.; Chen, P.; Wang, H. Effect of particle sizes and mass ratios of a phosphor on light color performance of a green phosphor thin film and a laminated white light-emitting diode. RSC Adv. 2019, 9, 27424–27431. [Google Scholar] [CrossRef] [Green Version]

- Murshed, S.M.S.; de Castro, C.A.N. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sustain. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- Beni, S.B.; Bahrami, A.; Salimpour, M.R. Design of novel geometries for microchannel heat sinks used for cooling diode lasers. Int. J. Heat Mass Transf. 2017, 112, 689–698. [Google Scholar] [CrossRef]

- Kozłowska, A.; Łapka, P.; Seredyński, M.; Teodorczyk, M.; Dąbrowska-Tumańska, E. Experimental study and numerical modeling of micro-channel cooler with micro-pipes for high-power diode laser arrays. Appl. Therm. Eng. 2015, 91, 279–287. [Google Scholar] [CrossRef]

- Nozaki, S.; Yoshida, S.; Yamanaka, K.; Imafuji, O.; Takigawa, S.; Katayama, T.; Tanaka, T. High-power and high-temperature operation of an InGaN laser over 3 W at 85 °C using a novel double-heat-flow packaging technology. Jpn. J. Appl. Phys. 2016, 55, 04EH05. [Google Scholar] [CrossRef]

- Zhu, H.; Hao, M.; Zhang, J.; Ji, W.; Lin, X.; Zhang, J.; Ning, Y. Development and thermal management of 10 kW CW; direct diode laser source. Opt. Laser Technol. 2016, 76, 101–105. [Google Scholar] [CrossRef]

- Trivellin, N.; Yushchenko, M.; Buffolo, M.; de Santi, C.; Meneghini, M.; Meneghesso, G.; Zanoni, E. Laser-Based Lighting: Experimental Analysis and Perspectives. Materials 2017, 10, 1166. [Google Scholar] [CrossRef] [Green Version]

- Ding, X.; Li, M.; Li, Z.; Tang, Y.; Xie, Y.; Tang, X.; Fu, T. Thermal and optical investigations of a laser-driven phosphor converter coated on a heat pipe. Appl. Therm. Eng. 2019, 148, 1099–1106. [Google Scholar] [CrossRef]

- Perera, I.U.; Narendran, N. Analysis of a remote phosphor layer heat sink to reduce phosphor operating temperature. Int. J. Heat Mass Transf. 2018, 117, 211–222. [Google Scholar] [CrossRef]

- Ma, Y.; Lan, W.; Xie, B.; Hu, R.; Luo, X. An optical-thermal model for laser-excited remote phosphor with thermal quenching. Int. J. Heat Mass Transf. 2018, 116, 694–702. [Google Scholar] [CrossRef]

- Peng, Y.; Sun, Q.; Liu, J.; Mou, Y.; Wang, X.; Chen, M.; Luo, X. Reflective Phosphor-in-Glass Color Converter for Laser-Driven White Lighting. IEEE Photonics Technol. Lett. 2020, 32, 983–986. [Google Scholar] [CrossRef]

- Zheng, P.; Li, S.; Wang, L.; Zhou, T.L.; You, S.; Takeda, T.; Hirosaki, N.; Xie, R.J. Unique Color Converter Architecture Enabling Phosphor-in-Glass (PiG) Films Suitable for High-Power and High-Luminance Laser- Driven White Lighting. ACS Appl. Mater. Interfaces 2018, 10, 14930–14940. [Google Scholar] [CrossRef]

| CIE Coordinates | 0° | 5° | 10° | 15° | 20° | 25° | 30° | WTO |

|---|---|---|---|---|---|---|---|---|

| x | 0.3176 | 0.3154 | 0.3154 | 0.3138 | 0.3114 | 0.3083 | 0.3024 | 0.2419 |

| y | 0.3465 | 0.3428 | 0.3424 | 0.3413 | 0.3374 | 0.3334 | 0.3242 | 0.1973 |

| z | 0.3359 | 0.3418 | 0.3422 | 0.3449 | 0.3512 | 0.3582 | 0.3734 | 0.5609 |

| CIE Coordinates | 10 wt% | 17.5 wt% | 20 wt% | 22.5 wt% | 25 wt% | 27.5 wt% | 30 wt% |

|---|---|---|---|---|---|---|---|

| x | 0.3071 | 0.3185 | 0.3401 | 0.335 | 0.3433 | 0.3533 | 0.3486 |

| y | 0.3279 | 0.3522 | 0.3907 | 0.3821 | 0.3961 | 0.4083 | 0.4044 |

| z | 0.365 | 0.3294 | 0.2692 | 0.2829 | 0.2606 | 0.2383 | 0.2471 |

| CIE Coordinates | 10 wt% | 17.5 wt% | 20 wt% | 22.5 wt% | 25 wt% | 27.5 wt% | 30 wt% |

|---|---|---|---|---|---|---|---|

| x | 0.2381 | 0.2537 | 0.2979 | 0.2806 | 0.3074 | 0.3456 | 0.3123 |

| y | 0.1891 | 0.2213 | 0.3145 | 0.2787 | 0.3315 | 0.4075 | 0.3415 |

| z | 0.5728 | 0.525 | 0.3876 | 0.4408 | 0.3611 | 0.2469 | 0.3462 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Qian, R.; Xu, L.; Li, Z.; Li, J.; Yan, C.; Yu, B. A Luminous Efficiency-Enhanced Laser Lighting Device with a Micro-Angle Tunable Filter to Recycle Unconverted Blue Laser Rays. Micromachines 2021, 12, 1144. https://doi.org/10.3390/mi12101144

Ding X, Qian R, Xu L, Li Z, Li J, Yan C, Yu B. A Luminous Efficiency-Enhanced Laser Lighting Device with a Micro-Angle Tunable Filter to Recycle Unconverted Blue Laser Rays. Micromachines. 2021; 12(10):1144. https://doi.org/10.3390/mi12101144

Chicago/Turabian StyleDing, Xinrui, Ruixiang Qian, Liang Xu, Zongtao Li, Jiasheng Li, Caiman Yan, and Binhai Yu. 2021. "A Luminous Efficiency-Enhanced Laser Lighting Device with a Micro-Angle Tunable Filter to Recycle Unconverted Blue Laser Rays" Micromachines 12, no. 10: 1144. https://doi.org/10.3390/mi12101144