Batch Manufacturing of Split-Actuator Micro Air Vehicle Based on Monolithic Processing Technology

Abstract

:1. Introduction

2. Materials and Methods

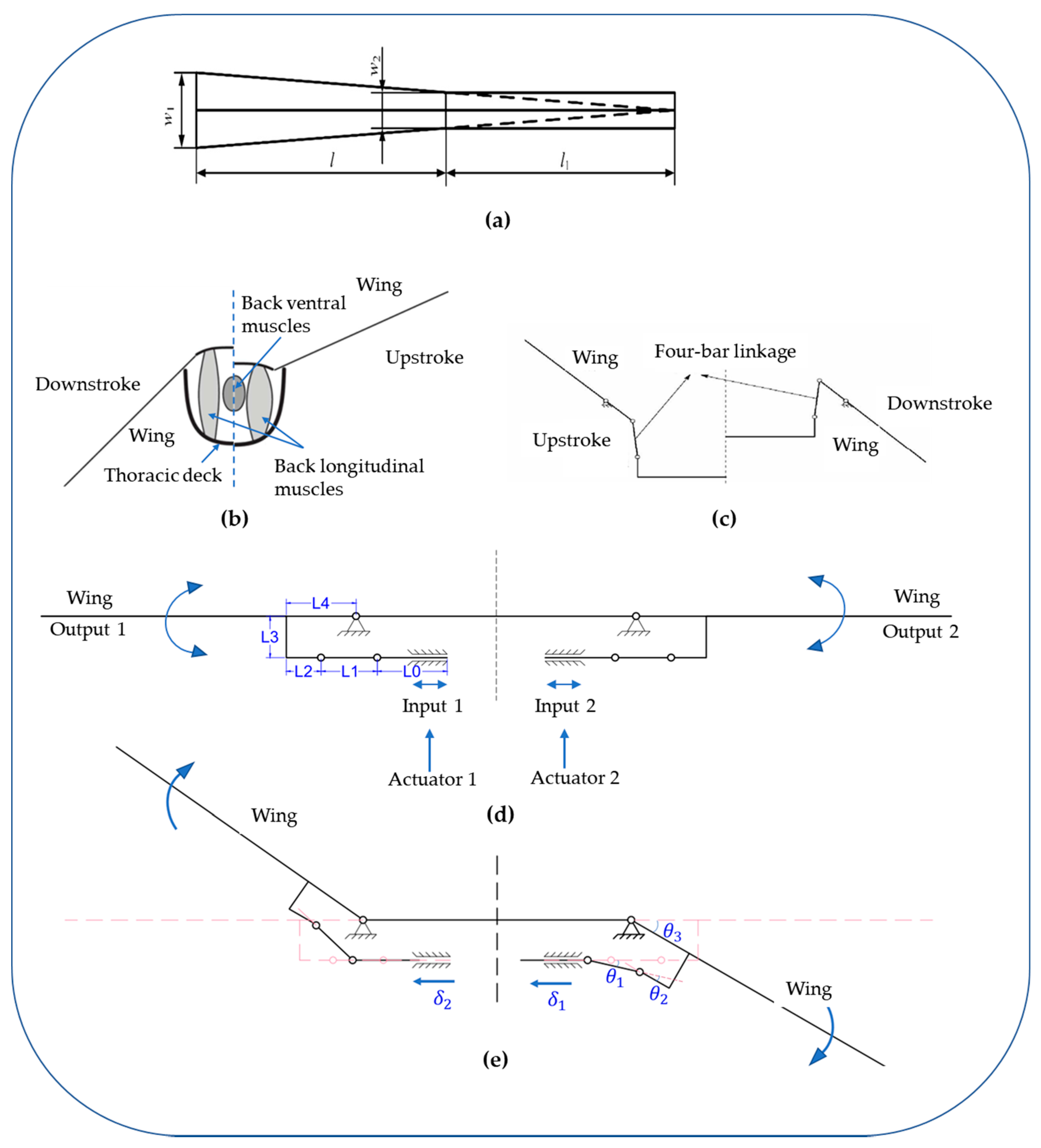

2.1. Design of Separate-Driven Micro Air Vehicle

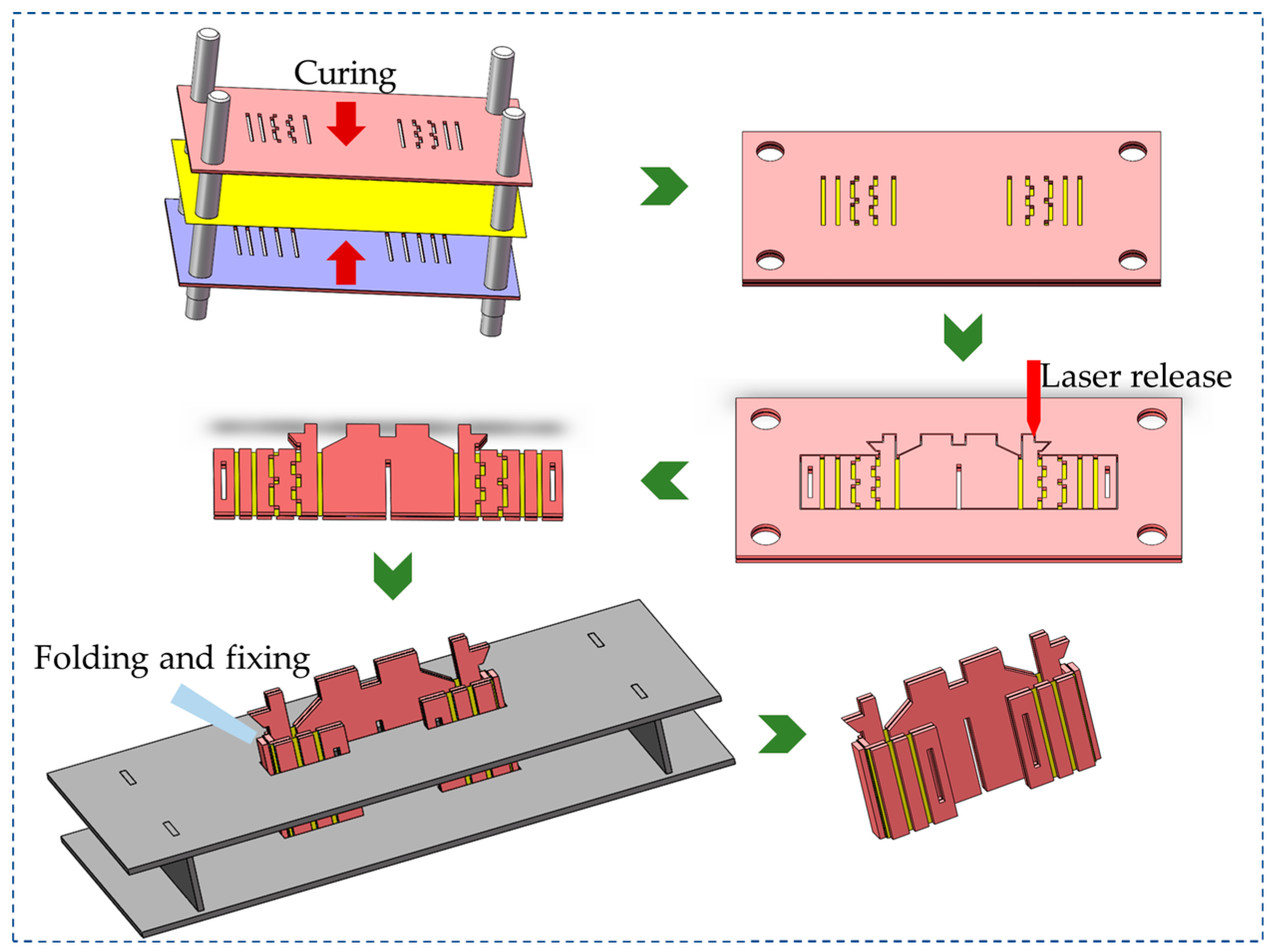

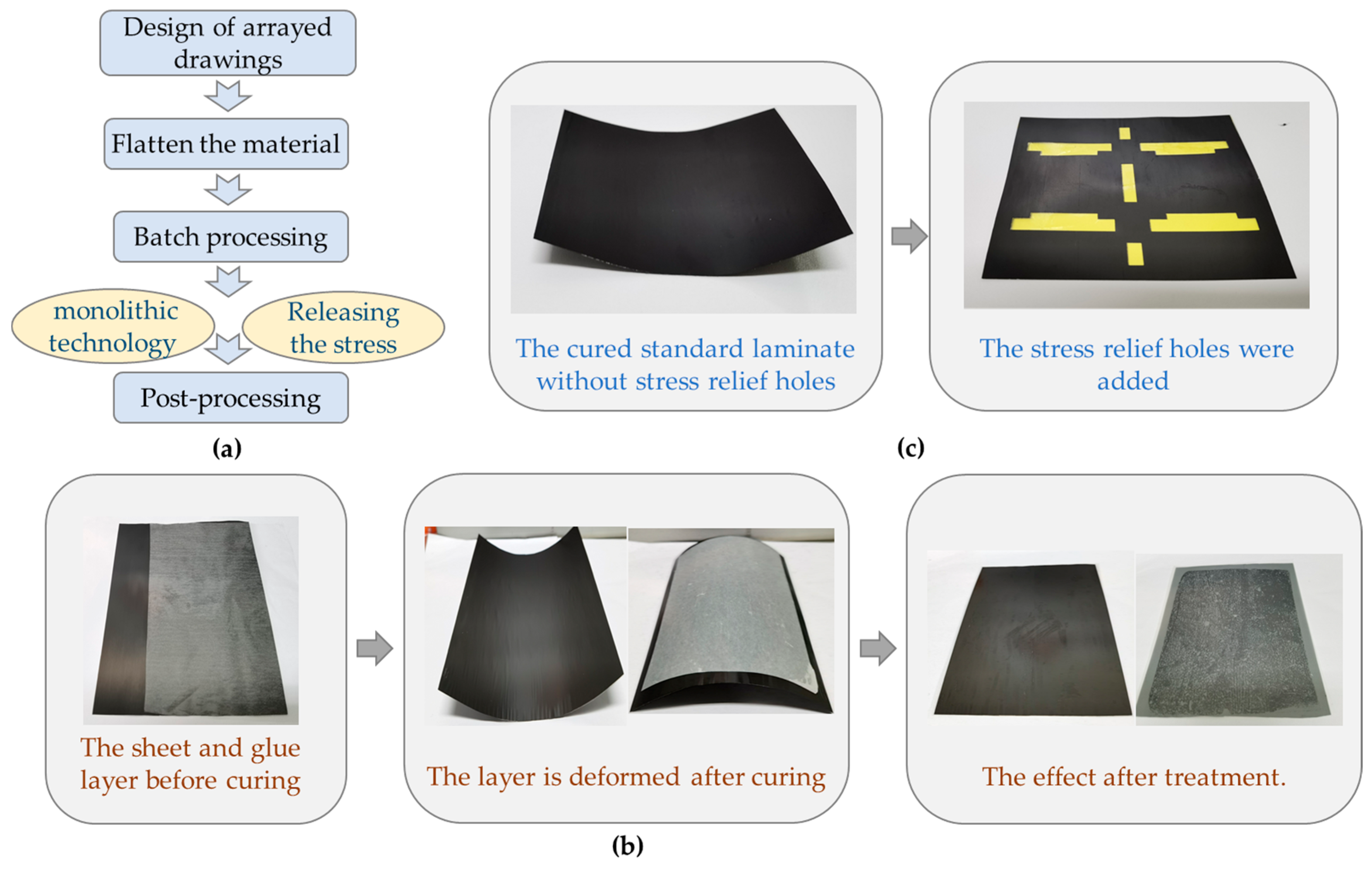

2.2. Monolithic Manufacturing Technology of Flapping-Wing Micro Air Vehicle

- The carbon fiberboard and resin glue were cured; laser etching was used to etch the designed hinge groove on the carbon fiberboard and the cured resin glue layer;

- The etched plates are aligned and stacked in order and then cured;

- The outer contour of the cured rigid–flexible composite material layer was released;

- The released flat rigid–flexible composite material layer was folded according to the designed structure’s fixed-body deformation mechanics.

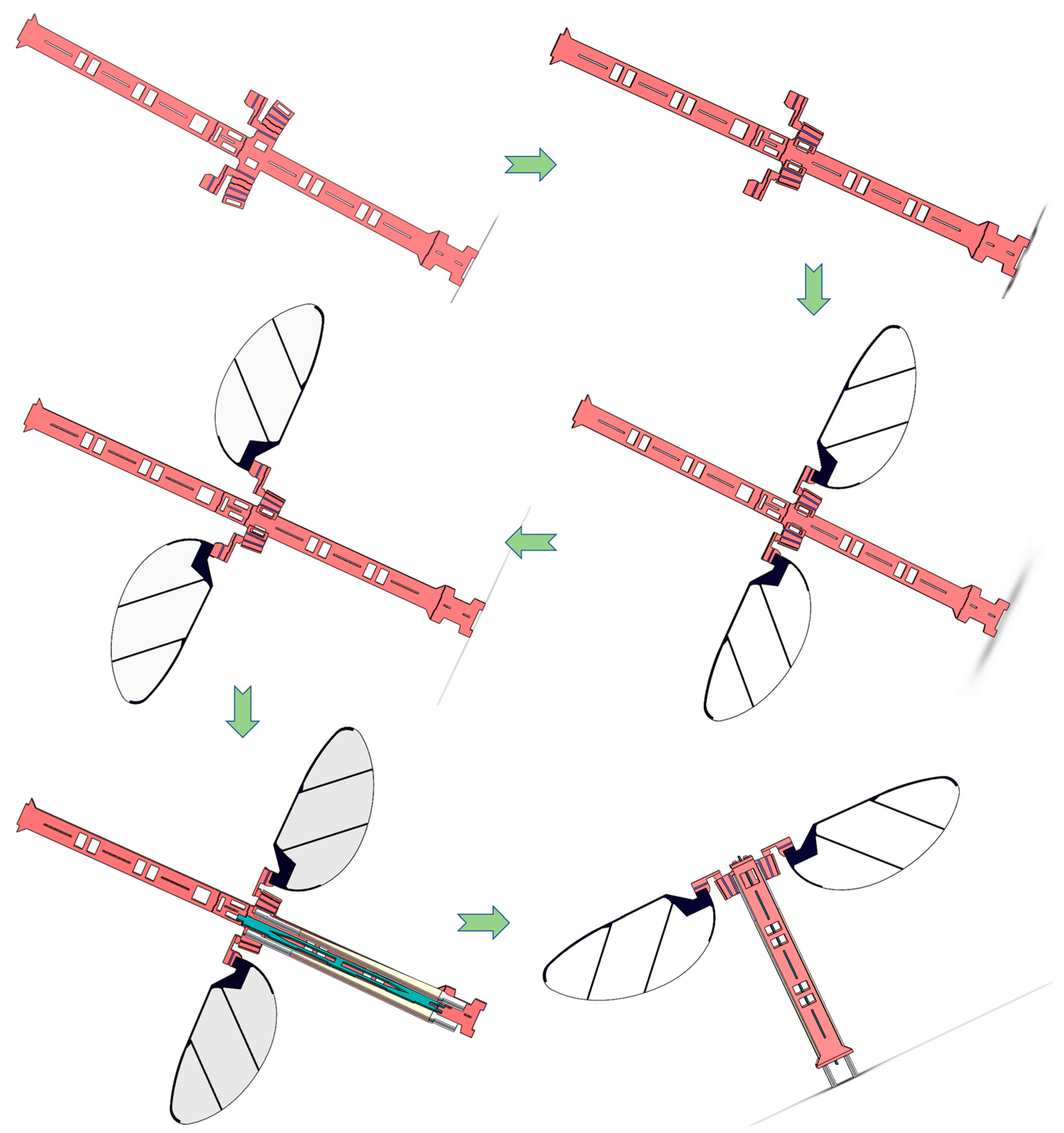

- Folding and fixing of the spherical four-bar linkage transmission mechanism;

- Assemble and fix the wings on the slot under the passive hinge;

- Folding fixed wings and passive hinges;

- Assemble the drive mechanism in the slot of the drive mechanism;

- Fold the body and fix the drive mechanism to complete the assembly of the prototype.

3. Results and Discussion

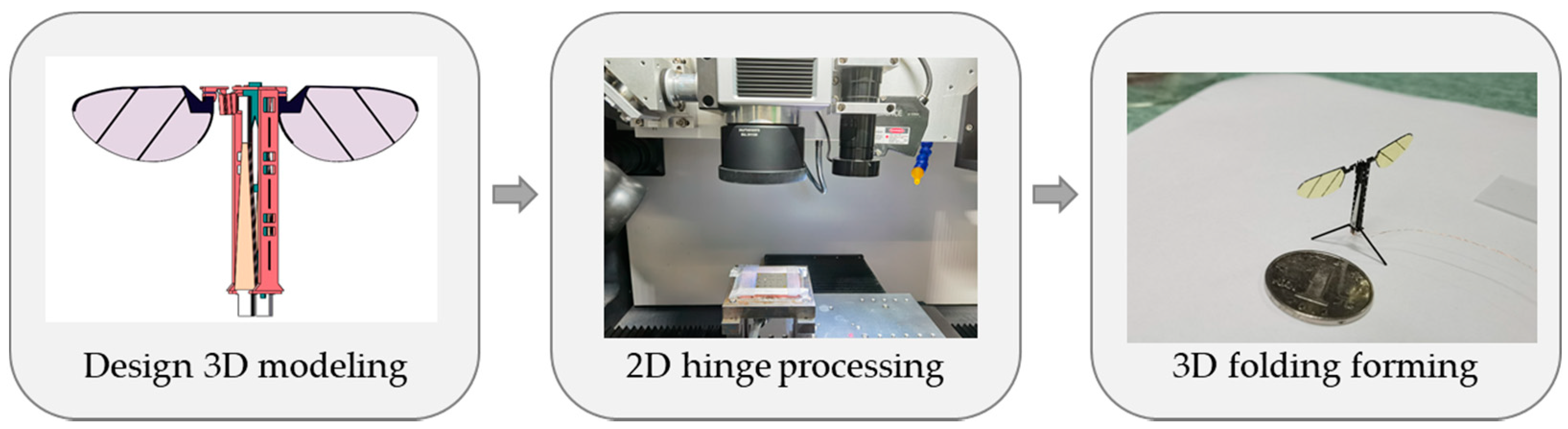

3.1. Batch Production of Micro Air Vehicle Prototypes Based on Monolithic Manufacturing

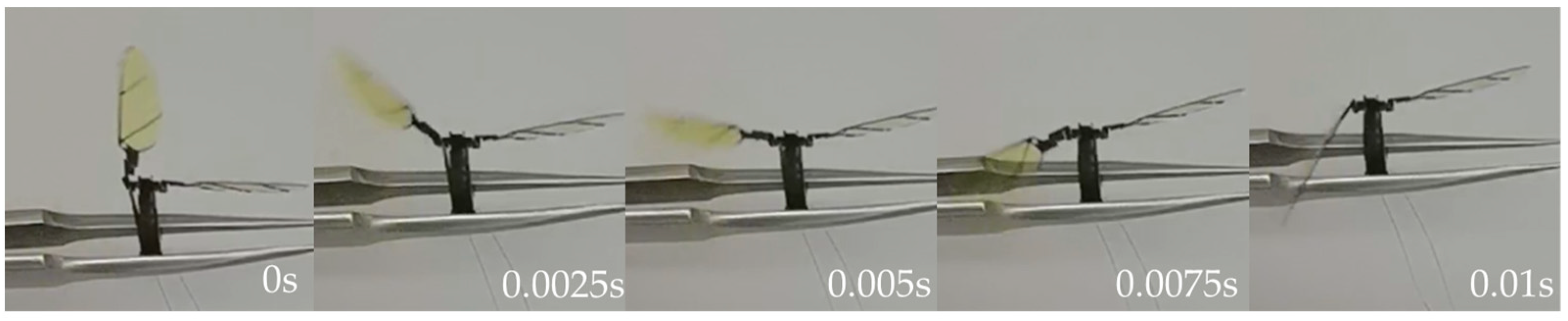

3.2. Actuate Test of Flapping-Wing Micro Air Vehicle

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, F. The Future’s Pupils: Micro Robots. Newton Cover. Story 1996, 9, 12–13. (In Chinese) [Google Scholar]

- Yang, J.; Zhang, C.; Wang, X.D.; Wang, W.; Xi, N.; Liu, L. Development of micro- and nanorobotics: A review. Sci. China Tech. Sci. 2019, 62, 1–20. (In Chinese) [Google Scholar] [CrossRef]

- Hou, Y.; Fang, Z.D.; Kong, J.Y.; Li, G.F. Current research status and key technology of bionic flapping wing flying mini-robots. J. Mach. Design. 2008, 25, 1–4. (In Chinese) [Google Scholar]

- Wood, R.J.; Finio, B.; Karpelson, M.; Ma, K.; Pérez-Arancibia, N.O.; Sreetharan, P.S.; Tanaka, H.; Whitney, J.P. Progress on ‘pico’ air vehicles. Int. J. Robot. Research. 2012, 31, 1292–1302. [Google Scholar] [CrossRef]

- Marc, Z.M.; Alejandro, J.C.; Kyle, D.; Esposito, E.P.; Reynolds, M.F.; Liu, Q.; Cao, M.; Muller, D.A.; McEuen, P.L.; Cohen, I. Electronically integrated, mass-manufactured, microscopic robots. Nature 2020, 584, 557–561. [Google Scholar]

- Cui, J.; Huang, T.Y.; Luo, Z.; Testa, P.; Gu, H.; Chen, X.; Nelson, B.J.; Heyderman, L.J. Nanomagnetic encoding of shape-morphing micromachines. Nat. Int. Wkly. J. Sci. 2019, 575, 164–168. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Feng, X.M.; Pei, A.; Kane, C.R.; Tam, R.; Hennessy, C.; Wang, J. Bioinspired helical microswimmers based on vascular plants. Nano Lett. 2014, 14, 305–310. [Google Scholar] [CrossRef] [Green Version]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nat. Int. Wkly. J. Sci. 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, J.; Salehizadeh, M.; Onaizah, O.; Diller, E. Millimeter-scale flexible robots with programmable three-dimensional magnetization and motions. Sci. Robot. 2019, 4, eaav4494. [Google Scholar] [CrossRef]

- Ranzani, T.; Russo, S.; Bartlett, N.W.; Wehner, M.; Wood, R.J. Increasing the Dimensionality of Soft Microstructures through Injection-Induced Self-Folding. Adv. Mater. 2018, 30, e1802739. [Google Scholar] [CrossRef] [Green Version]

- Felton, S.M.; Becker, K.P.; Aukes, D.M.; Wood, R.J. Self-Folding with Shape Memory Composites at the Millimeter Scale. J. Micromech. Microeng. 2015, 25, 85004. [Google Scholar] [CrossRef] [Green Version]

- Onal, C.D.; Wood, R.J.; Rus, D. Towards printable robotics: Origami-inspired planar fabrication of three-dimensional mechanisms. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011. [Google Scholar]

- Whitney, J.P.; Sreetharan, P.S.; Ma, K.Y.; Wood, R.J. Pop-up book MEMS. J. Micromech. Microeng. 2011, 21, 11502. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.F.; Chang, L.L.; Pérez-Arancibia, N.O. An 88-milligram insect-scale autonomous crawling robot driven by a catalytic artificial muscle. Sci. Robot. 2020, 5, 2470–9476. [Google Scholar] [CrossRef]

- Vikram, I.; Ali, N.; Johannes, J.; Sawyer, F.; Shyamnath, G. Wireless steerable vision for live insects and insect-scale robots. Sci. Robot. 2020, 5, 2470–9476. [Google Scholar]

- Zou, Y.; Zhang, W.; Zhang, Z. Liftoff of an electromagnetically driven insect-inspired flapping-wing robot. IEEE Trans. Robot. 2016, 32, 1285–1289. [Google Scholar] [CrossRef]

- Hiroyuki, S.; Robert, J.W. Origami-inspired miniature manipulator for teleoperated microsurgery. Nat. Mach. Intell. 2020, 2, 437–446. [Google Scholar]

- Cui, R.Q.; Wu, F.J.; Li, Z.; Fu, Y.L. Development of MAV Configurations and Key Techniques. Mech. Eng. Automation. 2012, 1, 1672–6413. [Google Scholar]

- He, W.; Sun, C.Y. Design of flapping-wing flying robot system. Chem. Ind. Press. 2019. [Google Scholar]

- Wood, R.J.; Steltz, E.; Fearing, R.S. Optimal energy density piezoelectric bending actuators. Sens. Actuators A Phys. 2005, 119, 476–488. [Google Scholar] [CrossRef]

- Karpelson, M.; Wei, G.Y.; Wood, R.J. A review of actuation and power electronics options for flapping-wing robotic insects. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008. [Google Scholar]

- Noah, T.J.; Mario, L.; Nastasia, W.; Gu, Y.W.; Robert, J.W. Multilayer laminated piezoelectric bending actuators: Design and manufacturing for optimum power density and efficiency. Smart Mater. Struct. 2016, 25, 055033. [Google Scholar]

- Lu, X.; Xi, X.; Lu, K.; Wang, C.X.; Xiao, D.B.; Chen, X.; Wu, Y.; Wu, X. Miniature Ultralight Deformable Squama Mechanics and Skin Based on Piezoelectric Actuation. Micromachines 2021, 12, 969. [Google Scholar] [CrossRef] [PubMed]

| Structural Part | L1 | L2 | L3 | L4 | ||||

|---|---|---|---|---|---|---|---|---|

| Size (mm) | 9 | 1.75 | 0.5 | 3.6 | 0.45 | 0.25 | 0.3 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Wang, C.; Lu, K.; Xi, X.; Wu, Y.; Wu, X.; Xiao, D. Batch Manufacturing of Split-Actuator Micro Air Vehicle Based on Monolithic Processing Technology. Micromachines 2021, 12, 1270. https://doi.org/10.3390/mi12101270

Lu X, Wang C, Lu K, Xi X, Wu Y, Wu X, Xiao D. Batch Manufacturing of Split-Actuator Micro Air Vehicle Based on Monolithic Processing Technology. Micromachines. 2021; 12(10):1270. https://doi.org/10.3390/mi12101270

Chicago/Turabian StyleLu, Xiang, Chengxiang Wang, Kun Lu, Xiang Xi, Yulie Wu, Xuezhong Wu, and Dingbang Xiao. 2021. "Batch Manufacturing of Split-Actuator Micro Air Vehicle Based on Monolithic Processing Technology" Micromachines 12, no. 10: 1270. https://doi.org/10.3390/mi12101270

APA StyleLu, X., Wang, C., Lu, K., Xi, X., Wu, Y., Wu, X., & Xiao, D. (2021). Batch Manufacturing of Split-Actuator Micro Air Vehicle Based on Monolithic Processing Technology. Micromachines, 12(10), 1270. https://doi.org/10.3390/mi12101270