Towards Long-Term Stable Polyimide-Based Flexible Electrical Insulation for Chronically Implanted Neural Electrodes

Abstract

1. Introduction

2. Materials and Methods

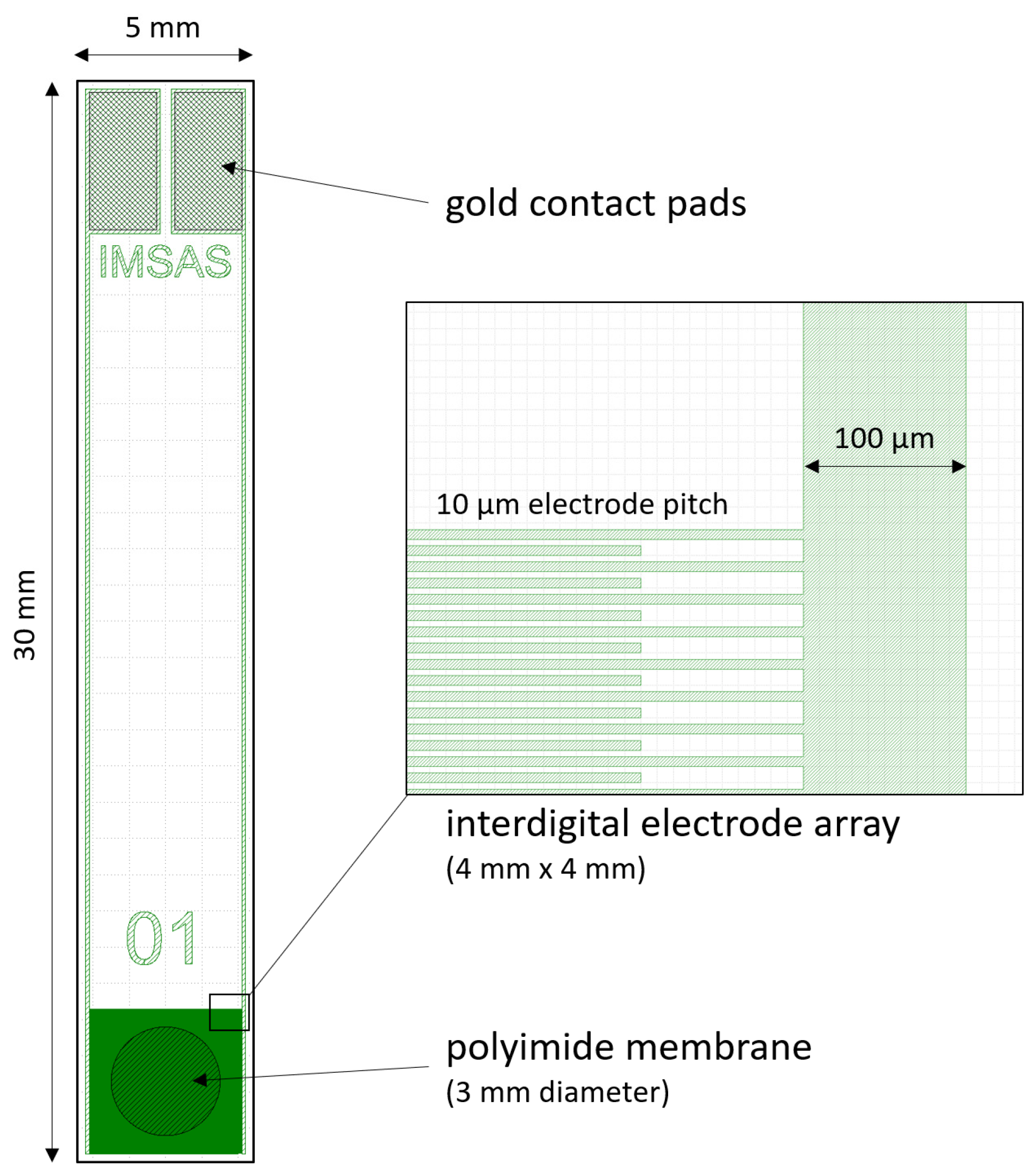

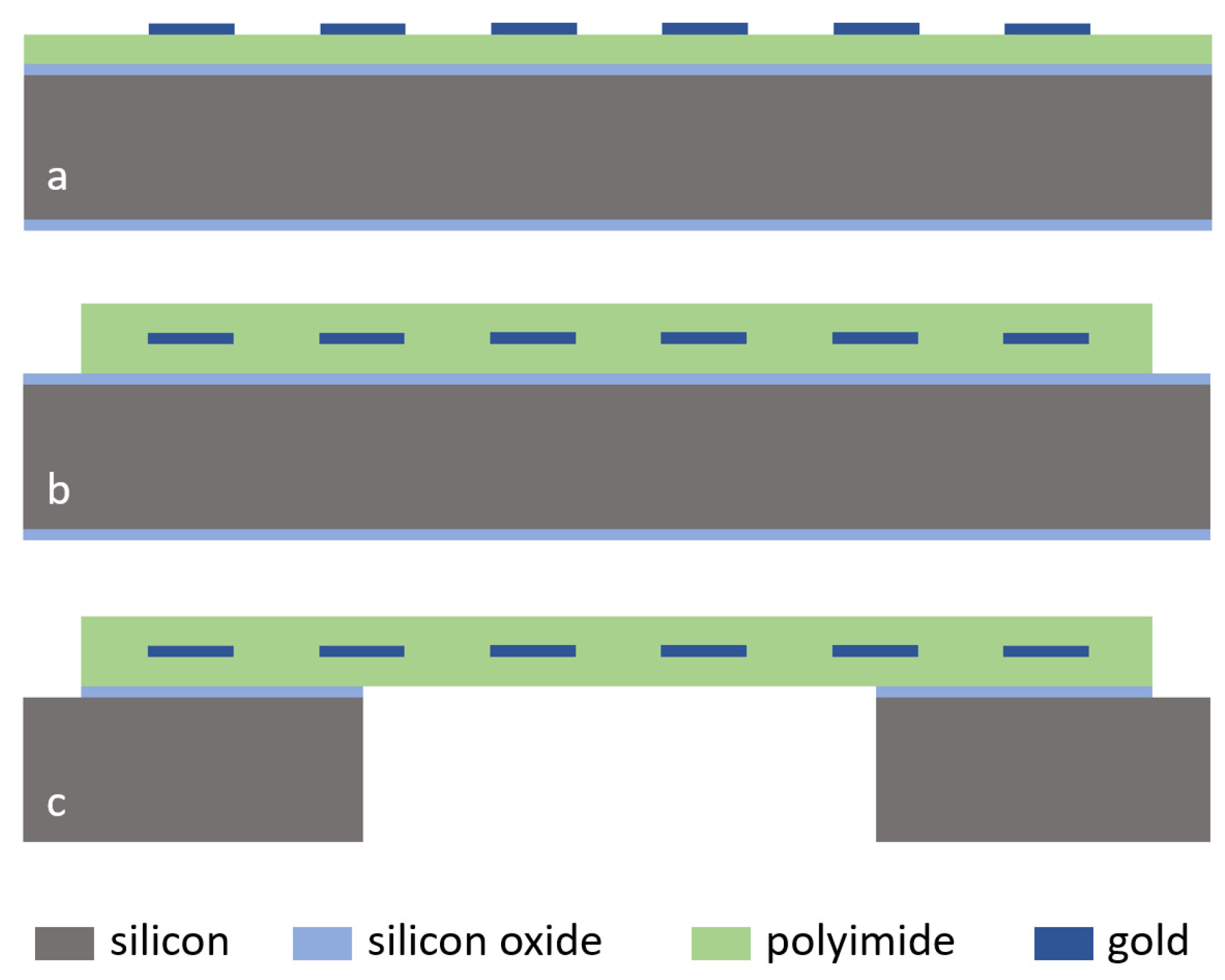

2.1. Design and Microfabrication Process of the Test Samples

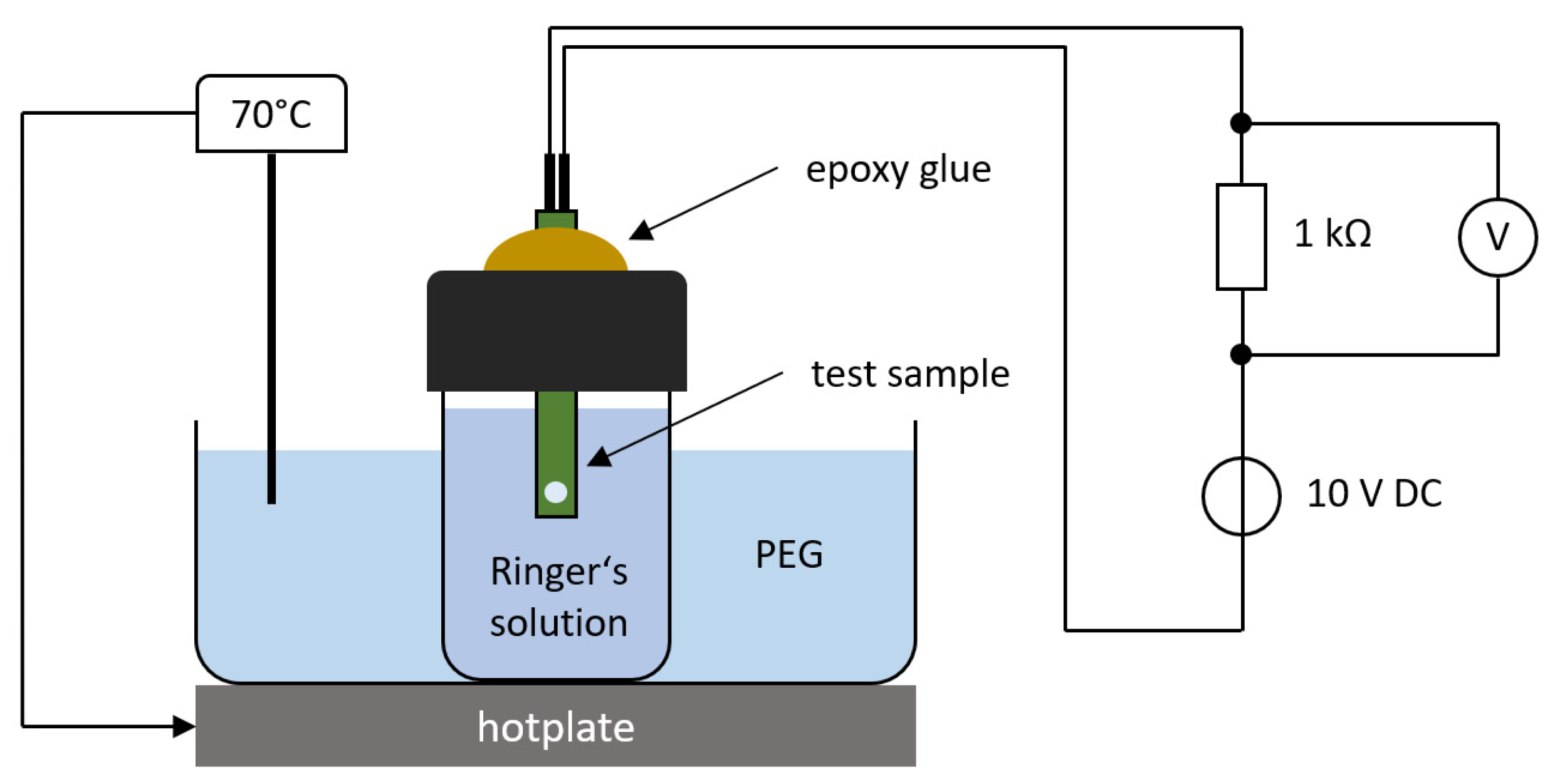

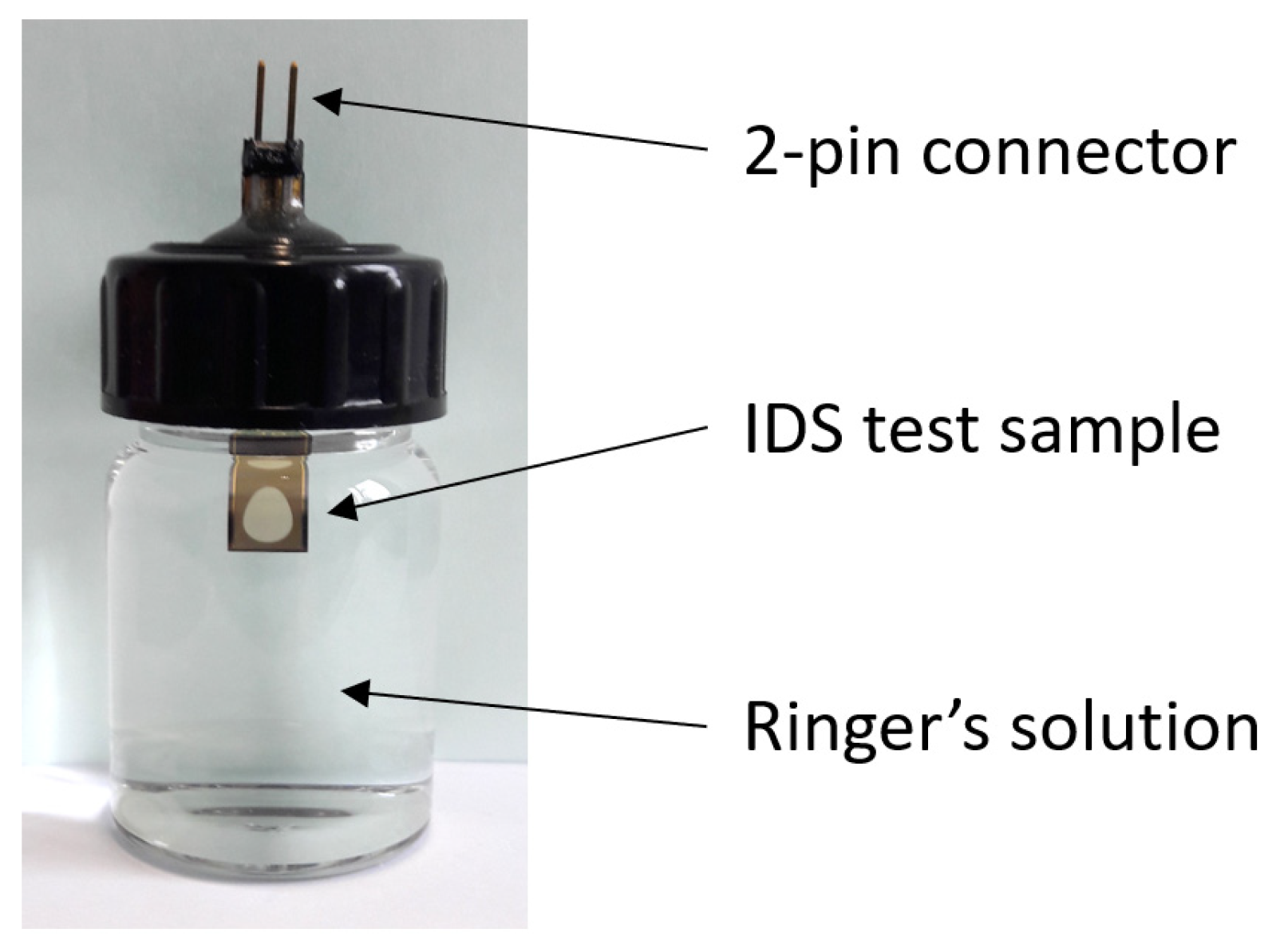

2.2. Connector Assembly and Sample Setup

2.3. Long-Term Test Method

3. Results

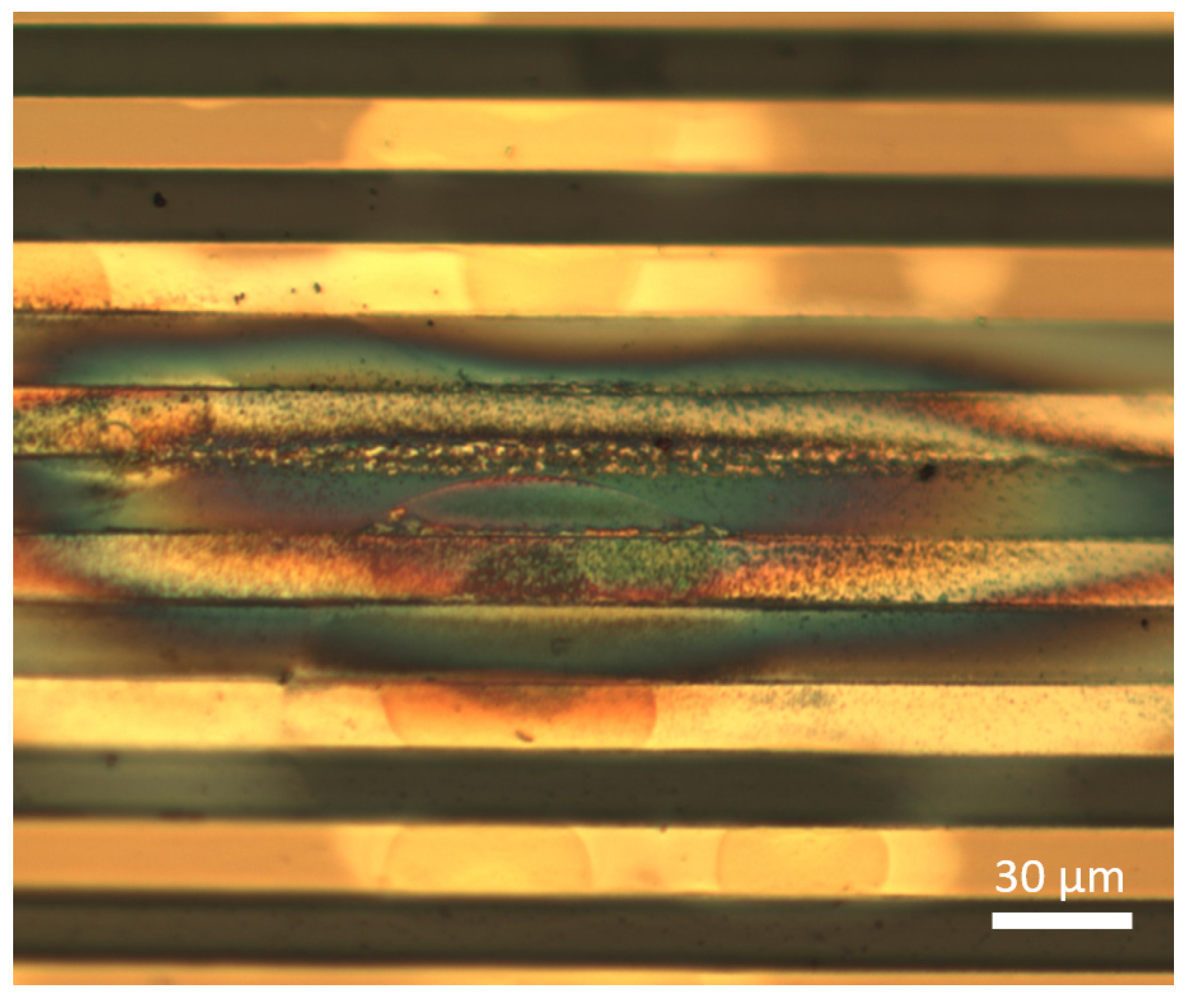

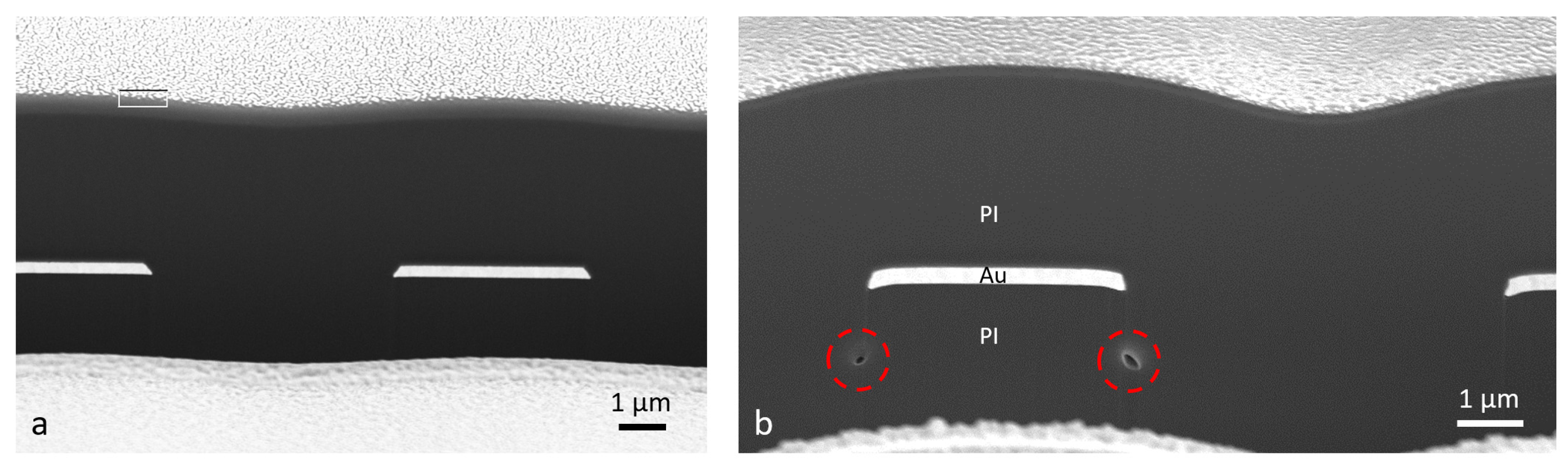

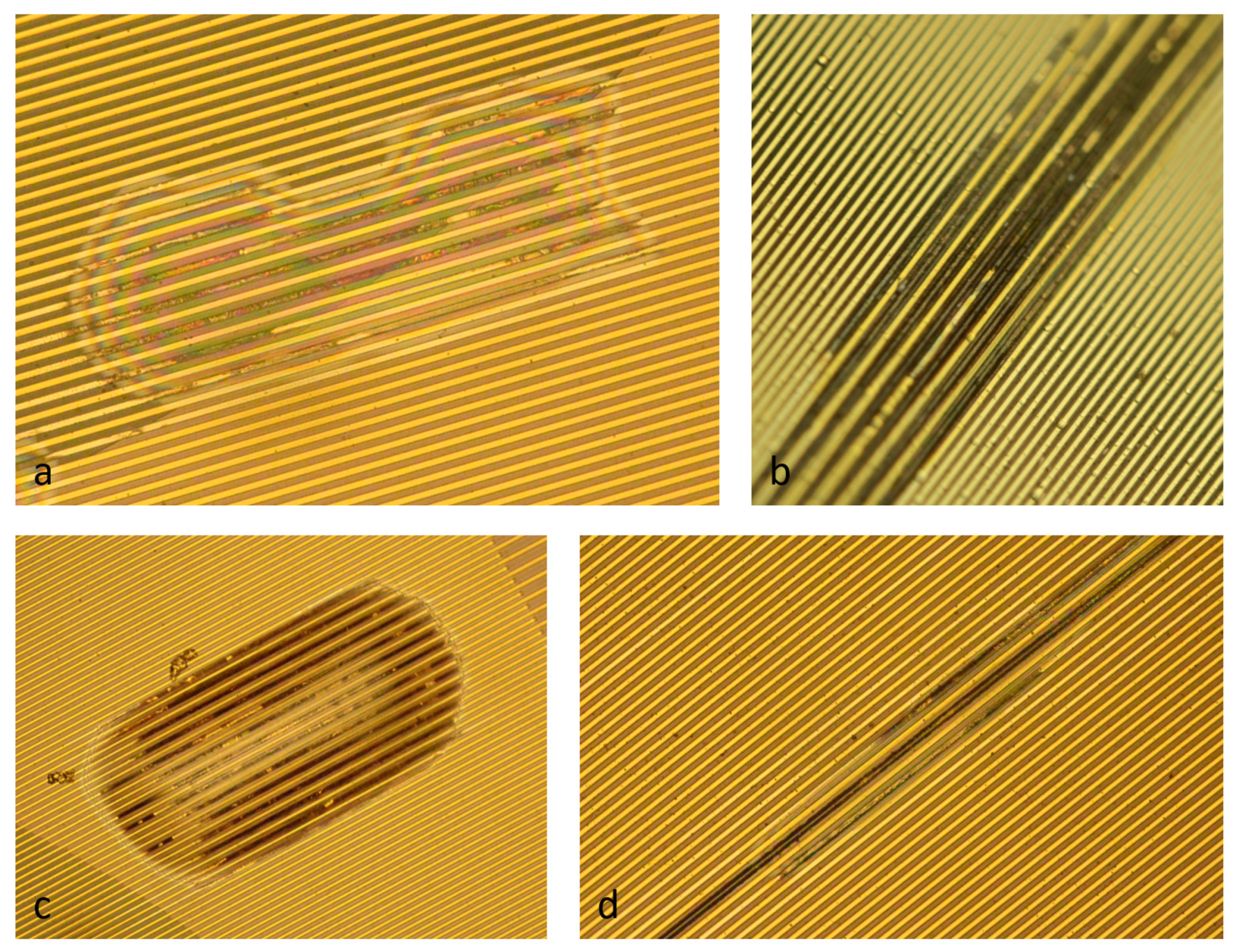

3.1. Microfabrication Results of the Test Samples

3.2. Connector Assembly and Sample Setup

3.3. Long-Term Test Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, J.H.; Kim, H.; Kim, J.H.; Lee, S.H. Soft implantable microelectrodes for future medicine: Prosthetics, neural signal recording and neuromodulation. Lab Chip 2016, 16, 959–976. [Google Scholar] [CrossRef] [PubMed]

- Hong, G.; Lieber, C.M. Novel electrode technologies for neural recordings. Nat. Rev. Neurosci. 2019, 20, 330–345. [Google Scholar] [CrossRef] [PubMed]

- Ware, T.; Simon, D.; Rennaker, R.L.; Voit, W. Smart polymers for neural interfaces. Polym. Rev. 2013, 53, 108–129. [Google Scholar] [CrossRef]

- Hassler, C.; Boretius, T.; Stieglitz, T. Polymers for neural implants. J. Polym. Sci. Part. B Polym. Phys. 2011, 49, 18–33. [Google Scholar] [CrossRef]

- Blume, G.; Mielke, G.; Kohnert, J.; Pörtner, R.; Trieu, K.H. Development of a process for the manufacturing of SU-8 100 for the use in cell culture. J. Bioact. Compat. Polym. 2018, 33, 349–360. [Google Scholar] [CrossRef]

- Schander, A.; Stemmann, H.; Tolstosheeva, E.; Roese, R.; Biefeld, V.; Kempen, L.; Kreiter, A.; Lang, W. Design and fabrication of novel multi-channel floating neural probes for intracortical chronic recording. Sens. Actuators A Phys. 2016, 247, 125–135. [Google Scholar] [CrossRef]

- Schander, A.; Stemmann, H.; Claussen, K.C.; Kreiter, A.K.; Lang, W. In-Vitro and In-Vivo Longevity Evaluation of Free-Floating Intracortical Silicon-Stiffened Neural Probes. In Proceedings of the 9th International IEEE/EMBS Conference on Neural Engineering (NER), San Francisco, CA, USA, 20–23 March 2019; pp. 799–802. [Google Scholar]

- Ceyssens, F.; Puers, R. Insulation lifetime improvement of polyimide thin film neural implants. J. Neural Eng. 2015, 12, 054001. [Google Scholar] [CrossRef] [PubMed]

- Cen-Puc, M.; Schander, A.; Vargas Gleason, M.G.; Lang, W. An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films. Polymers 2021, 13, 1955. [Google Scholar] [CrossRef] [PubMed]

- Vomero, M.; Cruz, M.F.P.; Zucchini, E.; Ciarpella, F.; Delfino, E.; Carli, S.; Boehler, C.; Asplund, M.; Ricci, D.; Fadiga, L.; et al. Conformable polyimide-based μECoGs: Bringing the electrodes closer to the signal source. Biomaterials 2020, 255, 120178. [Google Scholar] [CrossRef] [PubMed]

- Schander, A.; Strokov, S.; Stemmann, H.; Teßmann, T.; Kreiter, A.K.; Lang, W. A flexible 202-channel epidural ECoG array with PEDOT: PSS coated electrodes for chronic recording of the visual cortex. IEEE Sens. J. 2018, 19, 820–825. [Google Scholar] [CrossRef]

- Takmakov, P.; Ruda, K.; Phillips, K.S.; Isayeva, I.S.; Krauthamer, V.; Welle, C.G. Rapid evaluation of the durability of cortical neural implants using accelerated aging with reactive oxygen species. J. Neural Eng. 2015, 12, 026003. [Google Scholar] [CrossRef] [PubMed]

- Rubehn, B.; Stieglitz, T. In vitro evaluation of the long-term stability of polyimide as a material for neural implants. Biomaterials 2010, 31, 3449–3458. [Google Scholar] [CrossRef] [PubMed]

- Tolstosheeva, E.; Biefeld, V.; Lang, W. Accelerated soak performance of BPDA-PPD polyimide for implantable MEAs. Procedia Eng. 2015, 120, 36–40. [Google Scholar] [CrossRef][Green Version]

- Schander, A.; Stemmann, H.; Kreiter, A.K.; Lang, W. Silicon-based microfabrication of free-floating neural probes and insertion tool for chronic applications. Micromachines 2018, 9, 131. [Google Scholar] [CrossRef] [PubMed]

- Hukins, D.W.L.; Mahomed, A.; Kukureka, S.N. Accelerated aging for testing polymeric biomaterials and medical devices. Med. Eng. Phys. 2008, 30, 1270–1274. [Google Scholar] [CrossRef] [PubMed]

- Frankenthal, R.P.; Siconolfi, D.J. The anodic corrosion of gold in concentrated chloride solutions. J. Electrochem. Soc. 1982, 129, 1192. [Google Scholar] [CrossRef]

- Chang, W.Y.; Fang, T.H.; Lin, Y.C. Physical characteristics of polyimide films for flexible sensors. Appl. Phys. A 2008, 92, 693–701. [Google Scholar] [CrossRef]

- Li, C.; Cauwe, M.; Mader, L.; Schaubroeck, D.; Op de Beeck, M. Accelerated hermeticity testing of biocompatible moisture barriers used for the encapsulation of implantable medical devices. Coatings 2020, 10, 19. [Google Scholar] [CrossRef]

| Polyimide Surface Treatment | Total Test Samples |

|---|---|

| No treatment | 19 |

| 0.5 min at 25 W bias power | 22 |

| 1 min at 25 W bias power | 18 |

| 2 min at 25 W bias power | 15 |

| 3 min at 25 W bias power | 17 |

| 5 min at 25 W bias power | 19 |

| 0.5 min at 50 W bias power | 20 |

| 1 min at 50 W bias power | 17 |

| 2 min at 50 W bias power | 22 |

| 3 min at 50 W bias power | 19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schander, A.; Gancz, J.M.; Tintelott, M.; Lang, W. Towards Long-Term Stable Polyimide-Based Flexible Electrical Insulation for Chronically Implanted Neural Electrodes. Micromachines 2021, 12, 1279. https://doi.org/10.3390/mi12111279

Schander A, Gancz JM, Tintelott M, Lang W. Towards Long-Term Stable Polyimide-Based Flexible Electrical Insulation for Chronically Implanted Neural Electrodes. Micromachines. 2021; 12(11):1279. https://doi.org/10.3390/mi12111279

Chicago/Turabian StyleSchander, Andreas, Julia Morais Gancz, Marcel Tintelott, and Walter Lang. 2021. "Towards Long-Term Stable Polyimide-Based Flexible Electrical Insulation for Chronically Implanted Neural Electrodes" Micromachines 12, no. 11: 1279. https://doi.org/10.3390/mi12111279

APA StyleSchander, A., Gancz, J. M., Tintelott, M., & Lang, W. (2021). Towards Long-Term Stable Polyimide-Based Flexible Electrical Insulation for Chronically Implanted Neural Electrodes. Micromachines, 12(11), 1279. https://doi.org/10.3390/mi12111279